Strain Transfer for Optimal Performance of Sensing Sheet

Abstract

:1. Introduction

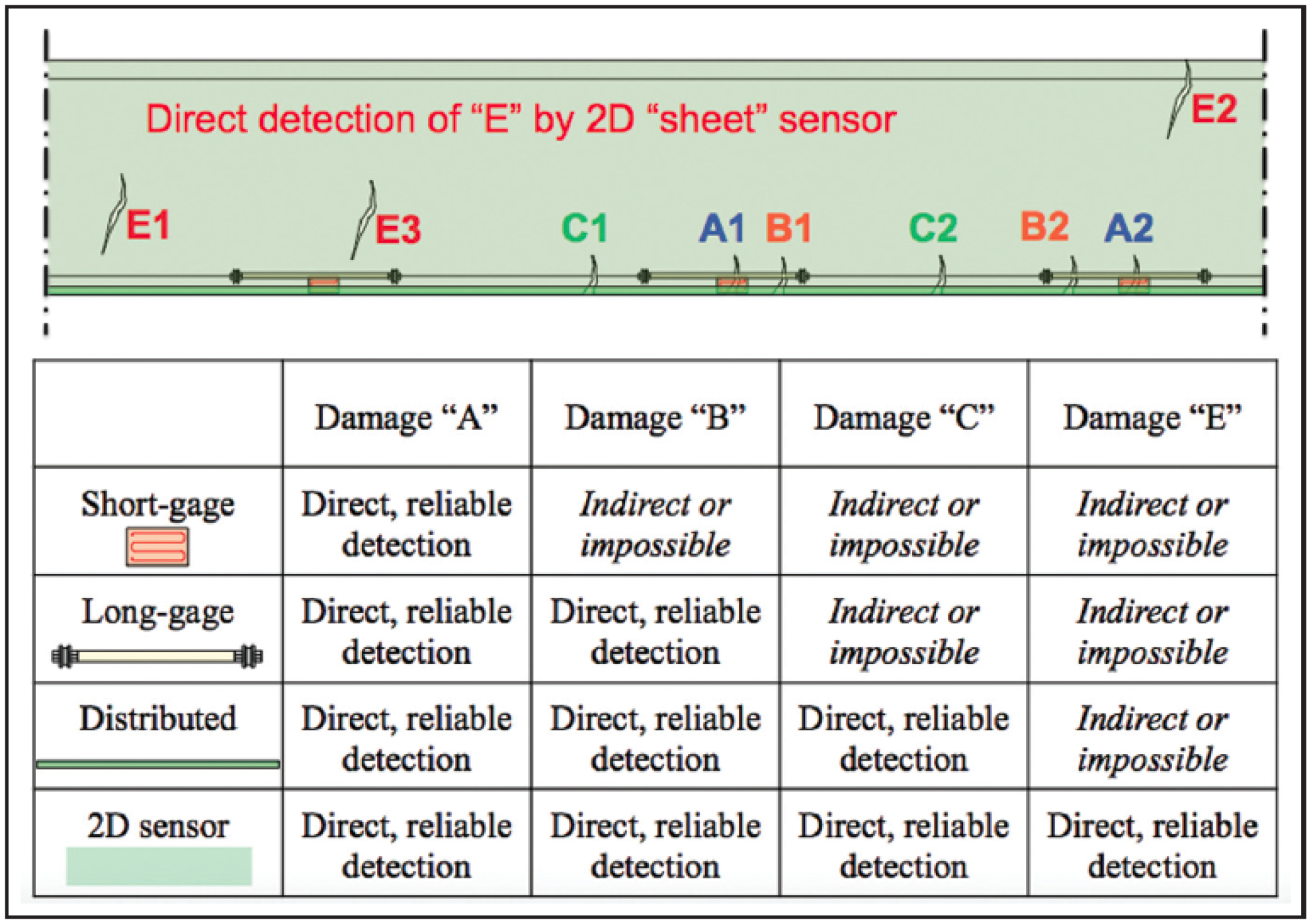

1.1. Strain-Based Monitoring

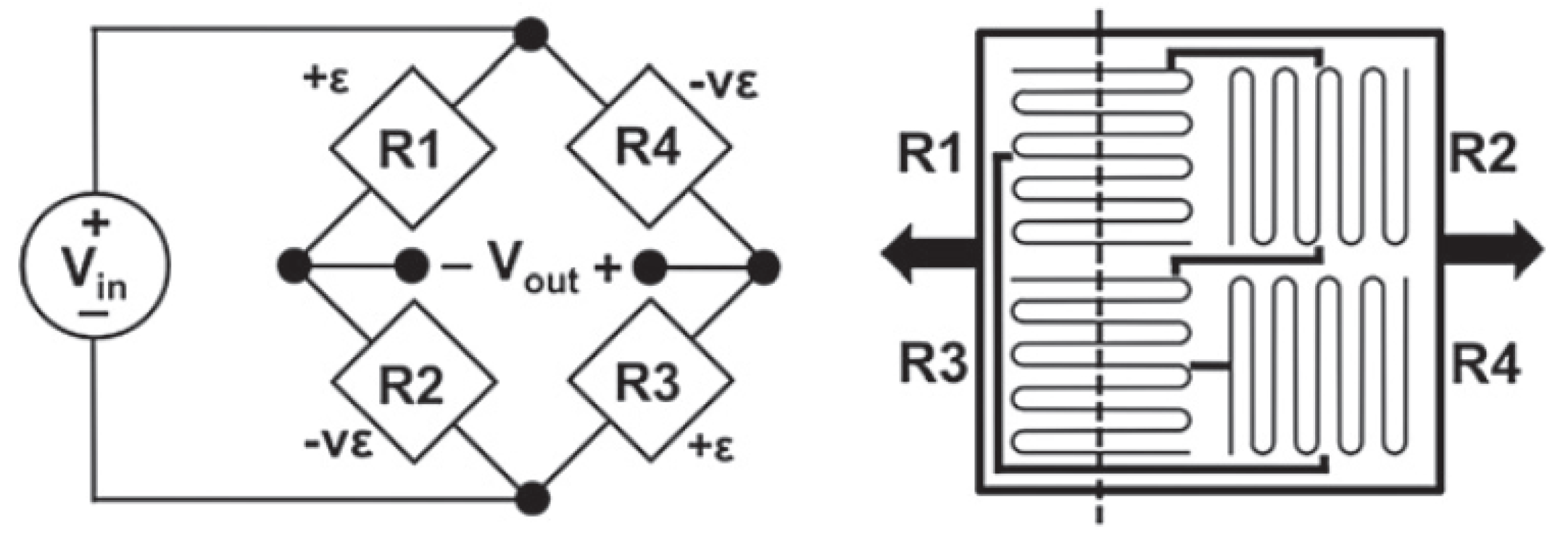

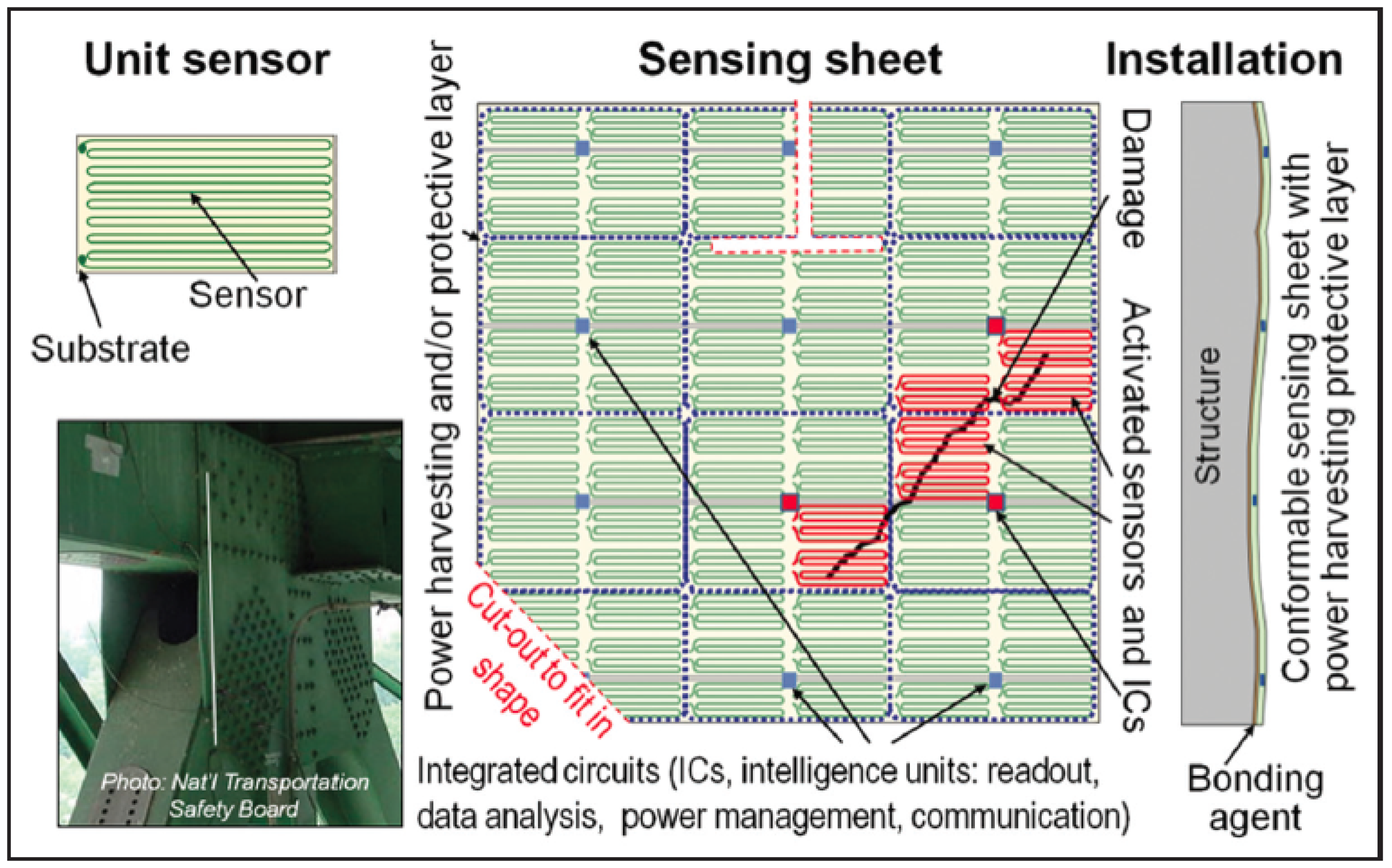

1.2. 2D Strain Monitoring

1.3. 2D Strain Sensing Research and Testing

2. Selecting a Suitable Adhesive

2.1. Objective

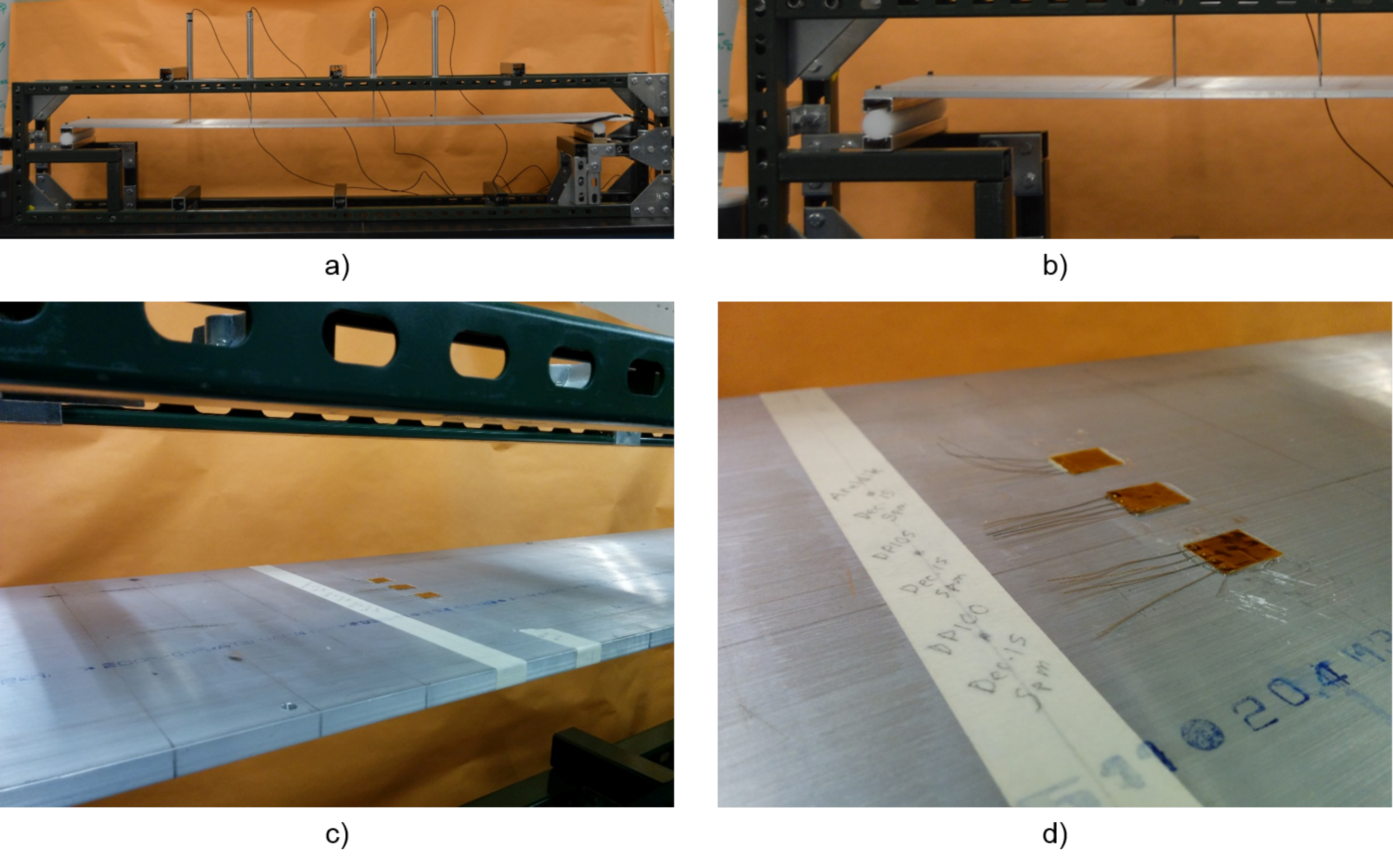

2.2. Qualitative Tests

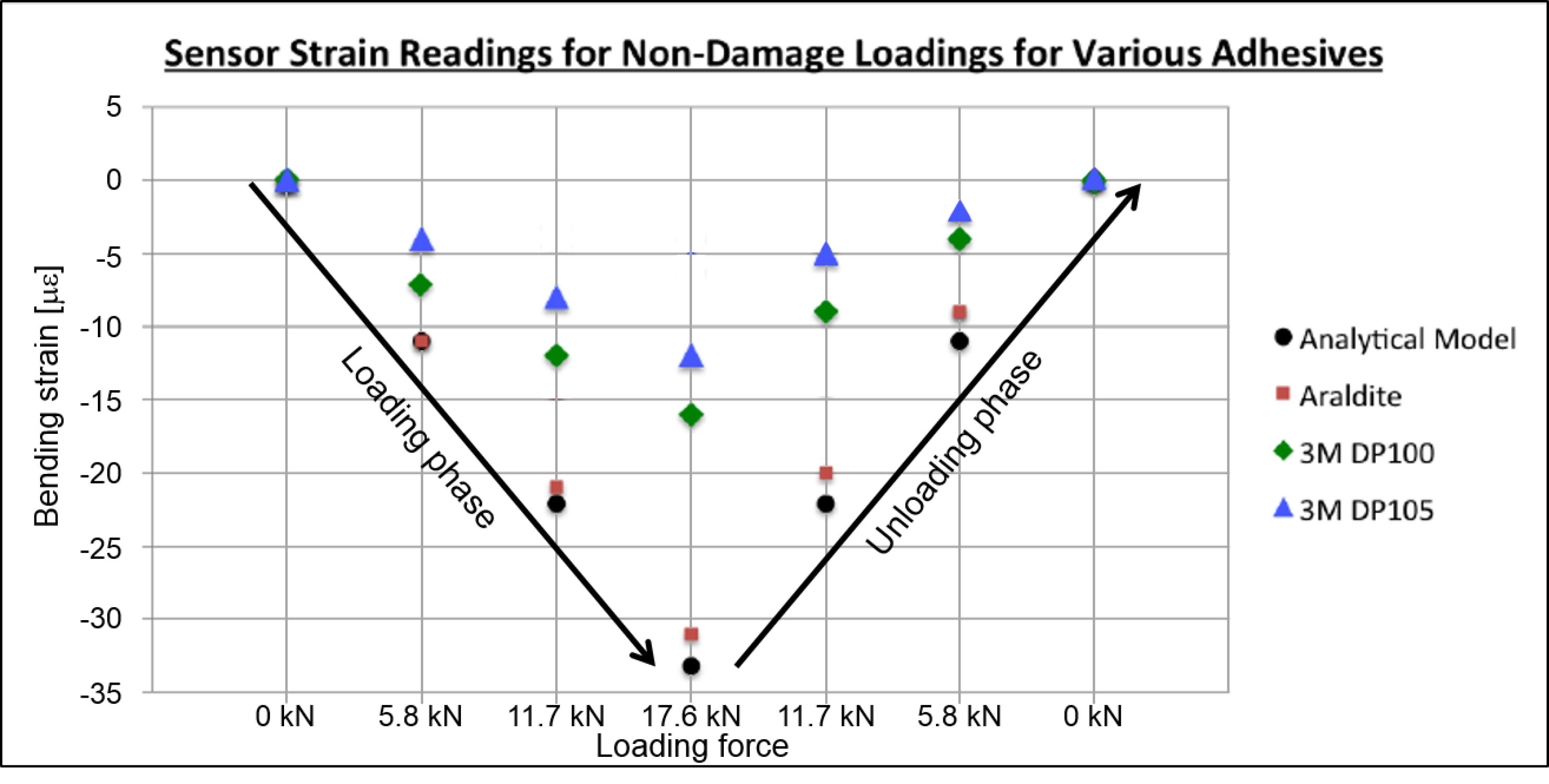

2.3. Quantitative Tests: Loading and Unloading

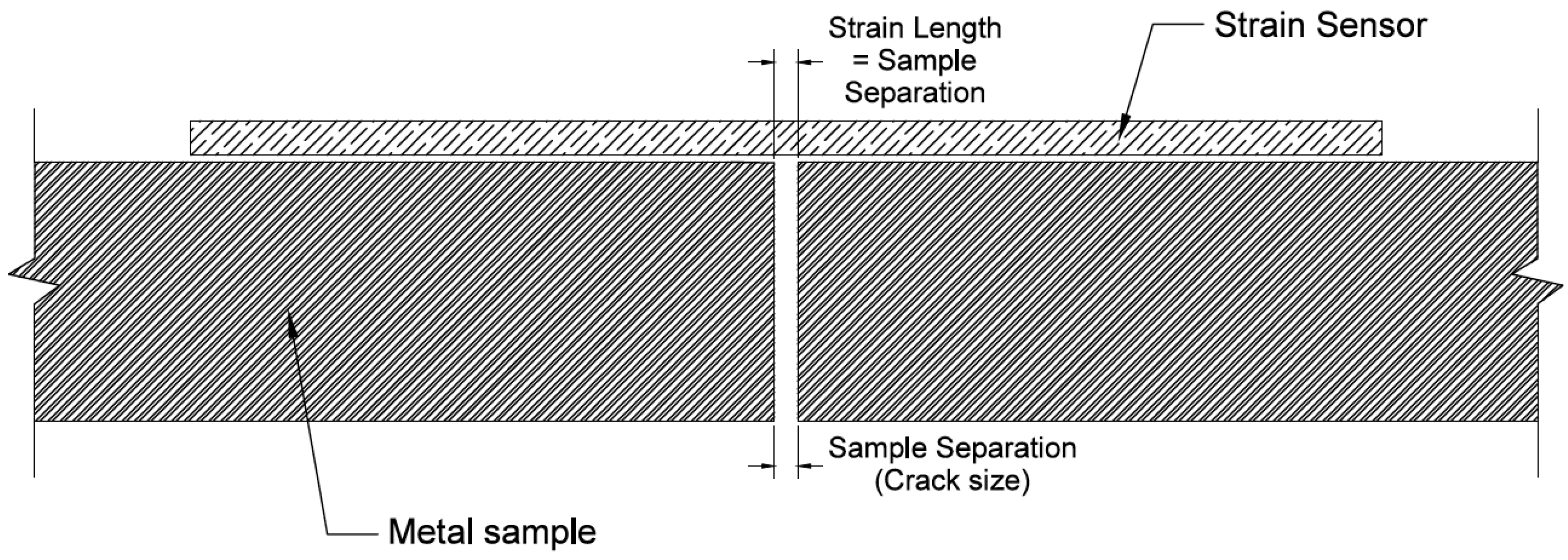

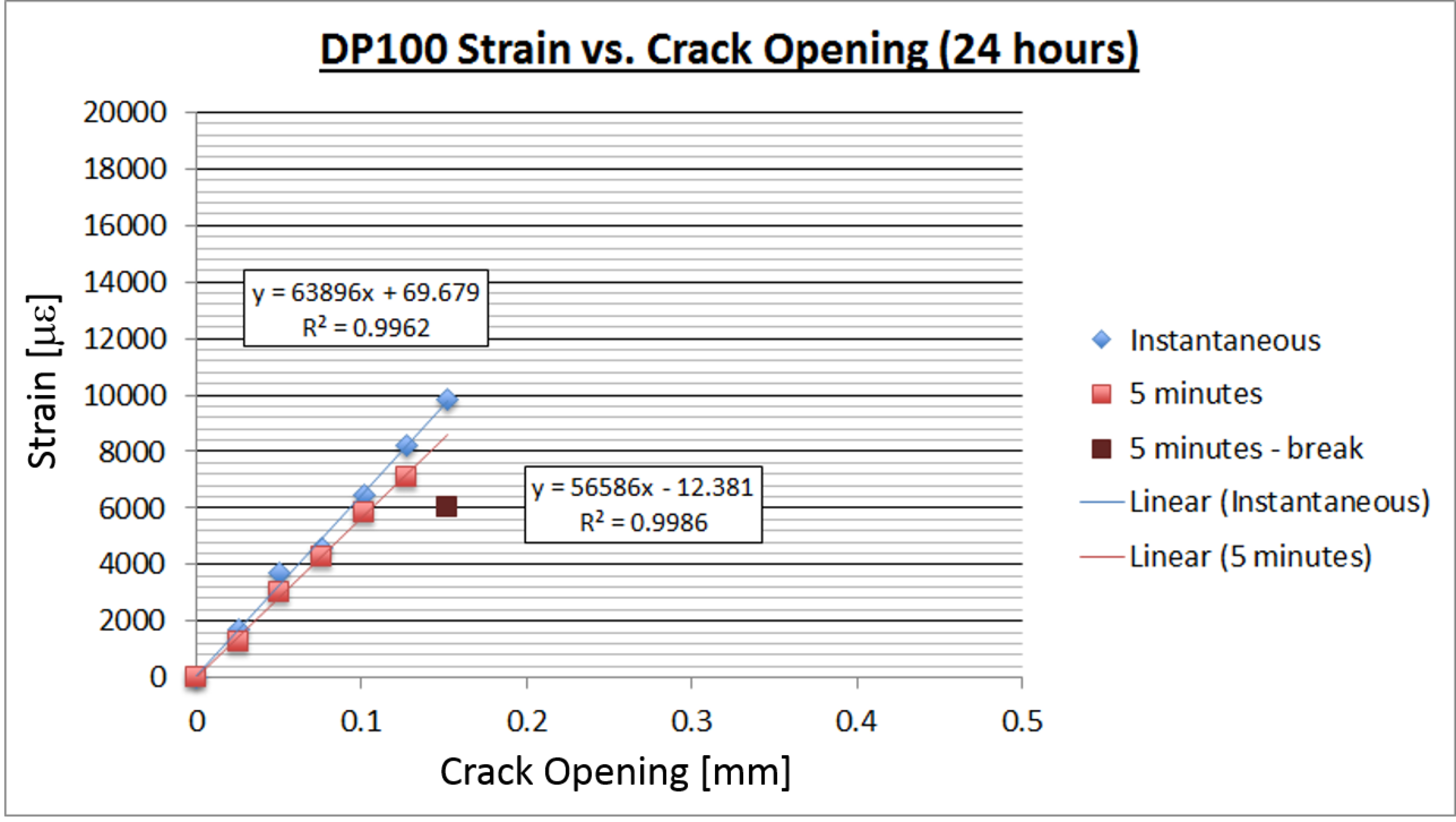

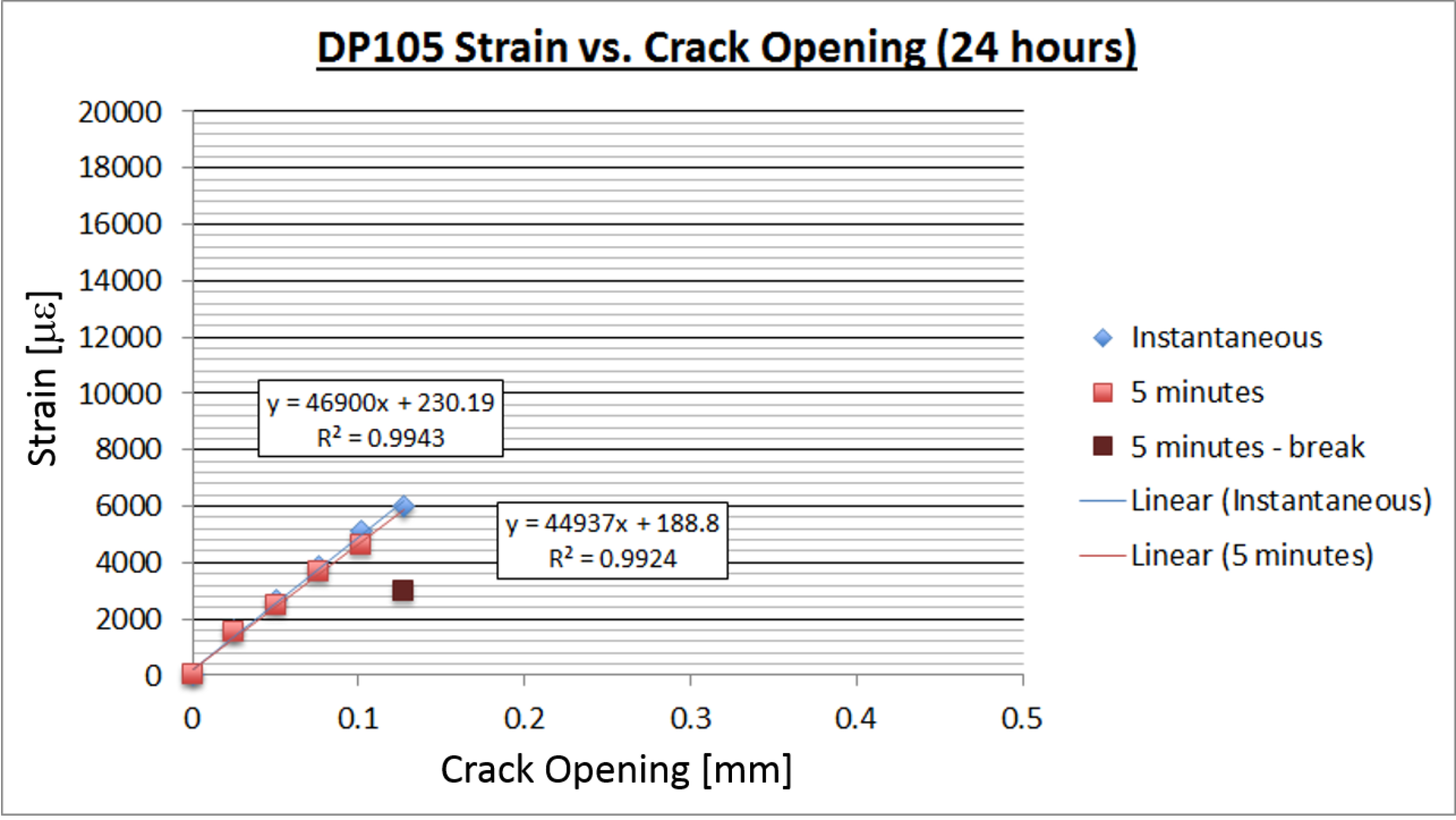

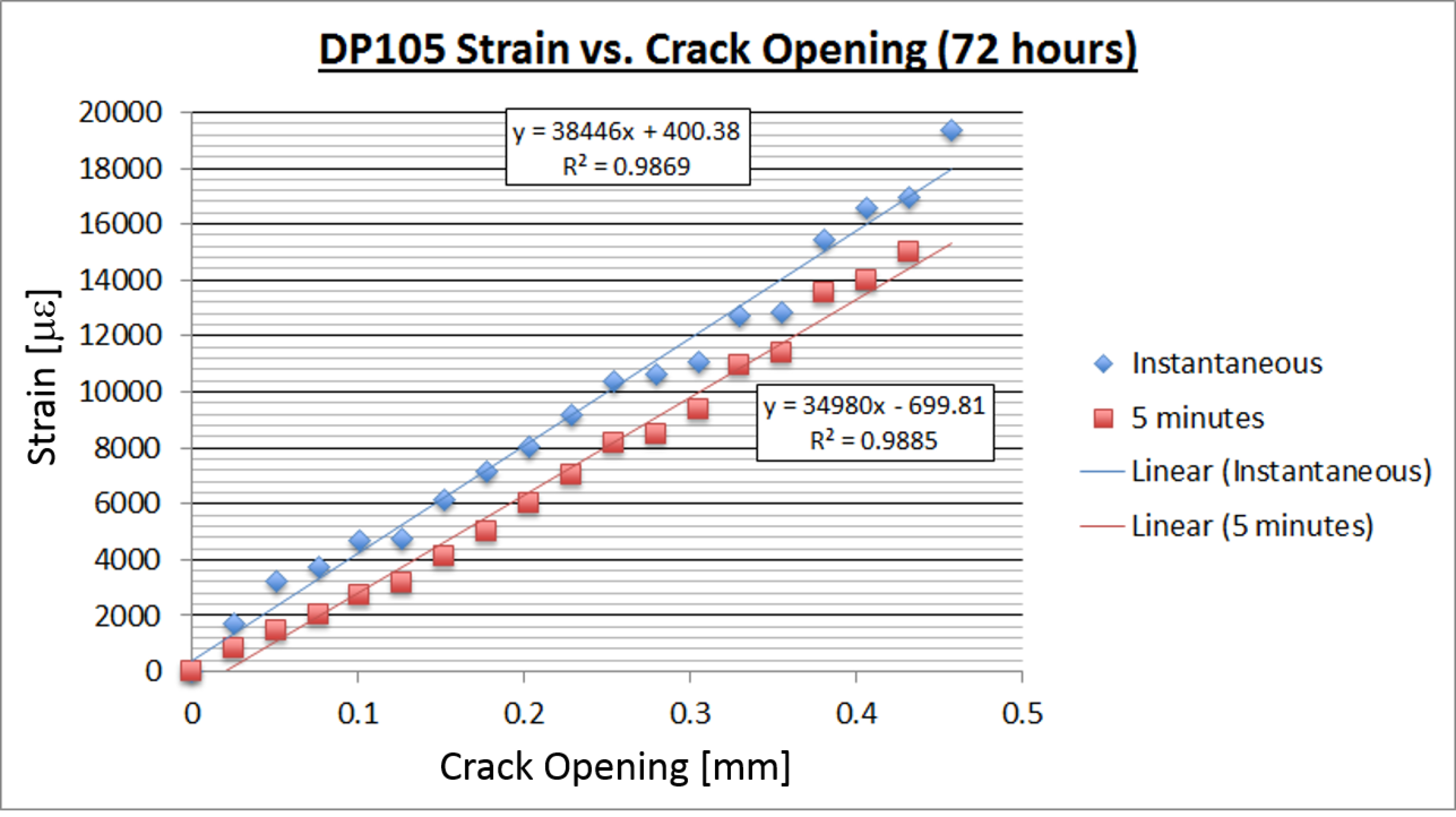

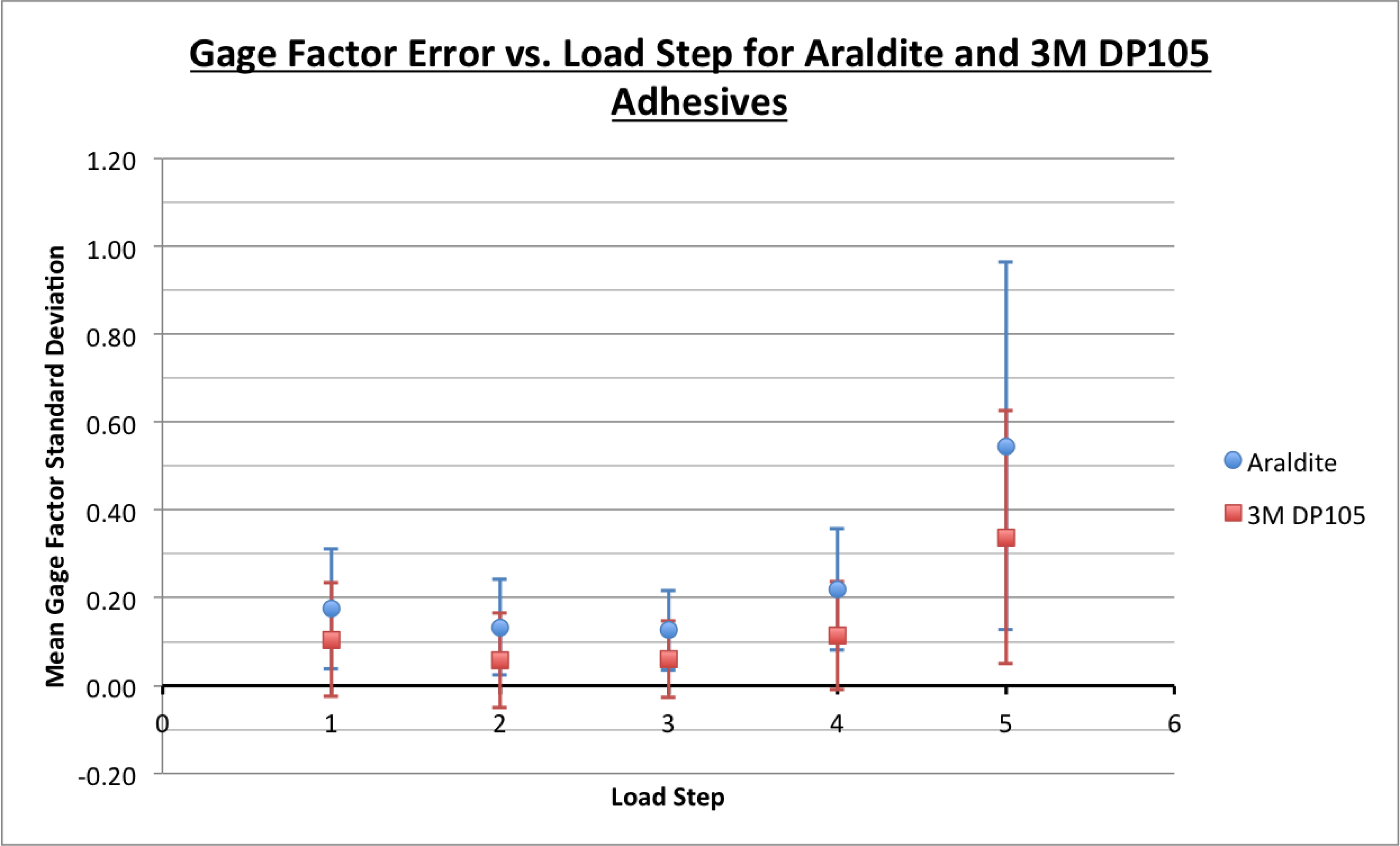

2.4. Damage Tests: Crack Opening vs. Strain Test

3. Application to a Sensing Sheet Prototype

3.1. Objective

3.2. Results

3.3. Discussion

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Yao, Y.; Glišić, B. Reliable damage detection and localization using direct strain sensing. In Proceedings of the Sixth International IAMBAS Conference on Bridge Maintenance, Safety and Management, Stresa, Italy, 8–12 July 2012; pp. 714–721. [Google Scholar]

- Yao, Y.; Tung, S.-T.E.; Glišić, B. Crack detection and characterization techniques—An overview. Struct. Control Health Monit. 2014, 21, 1387–1413. [Google Scholar] [CrossRef]

- Tung, S.-T.; Yao, Y.; Glišić, B. Sensing Sheet: The Sensitivity of Thin-Film Full- Bridge Strain Sensors for Crack Detection and Characterization. Meas. Sci. Technol. 2014, 25, 14. [Google Scholar] [CrossRef]

- Glišić, B.; Chen, J.; Hubbell, D. Streicker Bridge: A comparison between Bragg-gratings long-gauge strain and temperature sensors and Brillouin scattering-based distributed strain and temperature sensors. In Proceedings of the SPIE Smart Structures/NDE and Materials + Nondestructive Evaluation and Health Monitoring, San Diego, CA, USA, 6–10 March 2011. [Google Scholar]

- Loh, K.J.; Hou, T.C.; Lynch, J.P.; Kotov, N.A. Carbon Nanotube Sensing Skins for Spatial Strain and Impact Damage Identification. J. Nondestruct. Eval. 2009, 28, 9–25. [Google Scholar] [CrossRef] [Green Version]

- Pyo, S.; Loh, K.J.; Hou, T.C.; Jarva, E.; Lynch, J.P. A wireless impedance analyzer for automated tomographic mapping of a nanoengineered sensing skin. Smart Struct. Syst. 2011, 8, 139–155. [Google Scholar] [CrossRef]

- Pour-Ghaz, M.; Weiss, J. Application of Frequency Selective Circuits for Crack Detection in Concrete Elements. J. ASTM Int. 2011, 8, 1–11. [Google Scholar]

- Schumacher, T.; Thostenson, E.T. Development of structural carbon nanotube-based sensing composites for concrete structures. J. Intell. Mater. Syst. Struct. 2014, 25, 1331–1339. [Google Scholar] [CrossRef]

- Laflamme, S.; Saleem, H.; Song, C.H.; Vasan, B.; Geiger, R.; Chen, D.; Kessler, M.; Bowler, N.; Rajan, K. Sensing Skin for Condition Assessment of Civil Infrastructure. In Structural Health Monitoring 2013: A Roadmap to Intelligent Structures, Proceedings of the 9th International Workshop on Structural Health Monitoring, September 10–12, 2013; DEStech Publications, Inc.: Lancaster, PA, USA, 2013; Volume 2, pp. 2795–2802. [Google Scholar]

- Salowitz, N.; Guo, Z.; Kim, S.-J.; Li, Y.-H.; Lanzara, G.; Chang, F.-K. Screen Printed Piezoceramic Actuators/Sensors Microfabricated on Organic Films and Stretchable Networks. In Proceedings of the 9th International Workshop on Structural Health Monitoring, Palo Alto, CA, USA, 10–12 September 2013. [Google Scholar]

- Withey, P.A.; Vemuru, V.S.M.; Bachilo, S.M.; Nagarajaiah, S.; Weisman, R.B. Strain paint: Noncontact strain measurement using single-walled carbon nanotube composite coatings. Nano Lett. 2012, 12, 3497–3500. [Google Scholar] [CrossRef] [PubMed]

- Ladani, R.B.; Wu, S.; Kinloch, A.J.; Ghorbani, K.; Mouritz, A.P.; Wang, C.H. Enhancing fatigue resistance and damage characterisation in adhesively-bonded composite joints by carbon nanofibres. Compos. Sci. Technol. 2017, 149, 116–126. [Google Scholar] [CrossRef]

- Lim, A.S.; Melrose, Z.R.; Thostenson, E.T.; Chou, T.W. Damage sensing of adhesively-bonded hybrid composite/steel joints using carbon nanotubes. Compos. Sci. Technol. 2011, 71, 1183–1189. [Google Scholar] [CrossRef]

- Wu, S.; Ladani, R.B.; Ravindran, A.R.; Zhang, J.; Mouritz, A.P.; Kinloch, A.J.; Wang, C.H. Aligning carbon nanofibres in glass-fibre/epoxy composites to improve interlaminar toughness and crack-detection capability. Compos. Sci. Technol. 2017, 152, 46–56. [Google Scholar] [CrossRef]

- Zonta, D.; Chiappini, A.; Chiasera, A.; Ferrari, M.; Pozzi, M.; Battisti, L.; Benedetti, M. Photonic crystals for monitoring fatigue phenomena in steel structures. In Proceedings of the SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring, San Diego, CA, USA, 8–12 March 2009; Volume 7292. [Google Scholar]

- Yao, Y.; Glišić, B. Detection of steel fatigue cracks with strain sensing sheets based on large area electronics. Sensors 2015, 15, 8088–8108. [Google Scholar] [CrossRef] [PubMed]

- Glišić, B.; Verma, N. Very dense arrays of sensors for SHM based on large area electronics. In Structural Health Monitoring 2011: Condition-Based Maintenance and Intelligent Structures, Proceedings of the 8th International Workshop on Structural Health Monitoring, Stanford University, Stanford, CA, September 13–15, 2011; DEStech Publications, Inc.: Lancaster, PA, USA, 2011; Volume 2, pp. 1409–1416. [Google Scholar]

- Hu, Y.; Rieutort-Louis, W.S.A.; Sanz-Robinson, J.; Huang, L.; Glišić, B.; Sturm, J.C.; Wagner, S.; Verma, N. Large-Scale Sensing System Combining Large-Area Electronics and CMOS ICs for Structural-Health Monitoring. IEEE J. Solid-State Circuits 2014, 49, 1–12. [Google Scholar] [CrossRef]

- Verma, N.; Hu, Y.; Huang, L.; Rieutort-Louis, W.; Sanz-Robinson, J.; Moy, T.; Glišić, B.; Wagner, S.; Sturm, J.C. Enabling Scalable Hybrid Systems: Architectures for exploiting large-area electronics in applications. Proc. IEEE 2015, 103, 690–712. [Google Scholar] [CrossRef]

- Glišić, B.; Yao, Y.; Tung, S.-T.; Wagner, S.; Sturm, J.C.; Verma, N. Strain Sensing Sheets for Structural Health Monitoring based on Large-area Electronics and Integrated Circuits. Proc. IEEE 2016, 104, 1513–1528. [Google Scholar] [CrossRef]

- Arias, A.C.; MacKenzie, J.D.; McCulloch, I.; Rivnay, J.; Salleo, A. Materials and applications for large area electronics: Solution-based approaches. Chem. Rev. 2010, 110, 3–24. [Google Scholar] [CrossRef] [PubMed]

- Someya, T.; Pal, B.; Huang, J.; Katz, H.E. Organic semiconductor devices with enhanced field and environmental responses for novel applications. MRS Bull. 2008, 33, 690–696. [Google Scholar] [CrossRef]

- Someya, T.; Sakurai, T. Integration of organic field-effect transistors and rubbery pressure sensors for artificial skin applications. In Proceedings of the International Electron Devices Meeting, Washington, DC, USA, 8–10 December 2003; pp. 203–206. [Google Scholar]

- Subramanian, V.; Lee, J.B.; Liu, V.H.; Molesam, S. Printed electronic nose vapor sensors for consumer product monitoring. In Proceedings of the International Solid-State Circuits Conference, San Francisco, CA, USA, 6–9 February 2006; pp. 274–275. [Google Scholar]

- Wyrsch, N.; Dunand, S.; Miazza, C.; Shah, A.; Anelli, G.; Despeisse, M.; Garrigos, A.; Jarron, P.; Kaplon, J.; Moraes, D.; et al. Thin-film silicon detectors for particle detection. Phys. Status Solidi 2004, 1, 1284–1291. [Google Scholar] [CrossRef] [Green Version]

| Araldite GF | 3M DP105 GF | |

|---|---|---|

| 1.35 | 0.54 | |

| 0.240 | 0.128 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gerber, M.; Weaver, C.; Aygun, L.E.; Verma, N.; Sturm, J.C.; Glišić, B. Strain Transfer for Optimal Performance of Sensing Sheet. Sensors 2018, 18, 1907. https://doi.org/10.3390/s18061907

Gerber M, Weaver C, Aygun LE, Verma N, Sturm JC, Glišić B. Strain Transfer for Optimal Performance of Sensing Sheet. Sensors. 2018; 18(6):1907. https://doi.org/10.3390/s18061907

Chicago/Turabian StyleGerber, Matthew, Campbell Weaver, Levent E. Aygun, Naveen Verma, James C. Sturm, and Branko Glišić. 2018. "Strain Transfer for Optimal Performance of Sensing Sheet" Sensors 18, no. 6: 1907. https://doi.org/10.3390/s18061907