Infrastructure for Integration of Legacy Electrical Equipment into a Smart-Grid Using Wireless Sensor Networks

Abstract

:1. Introduction

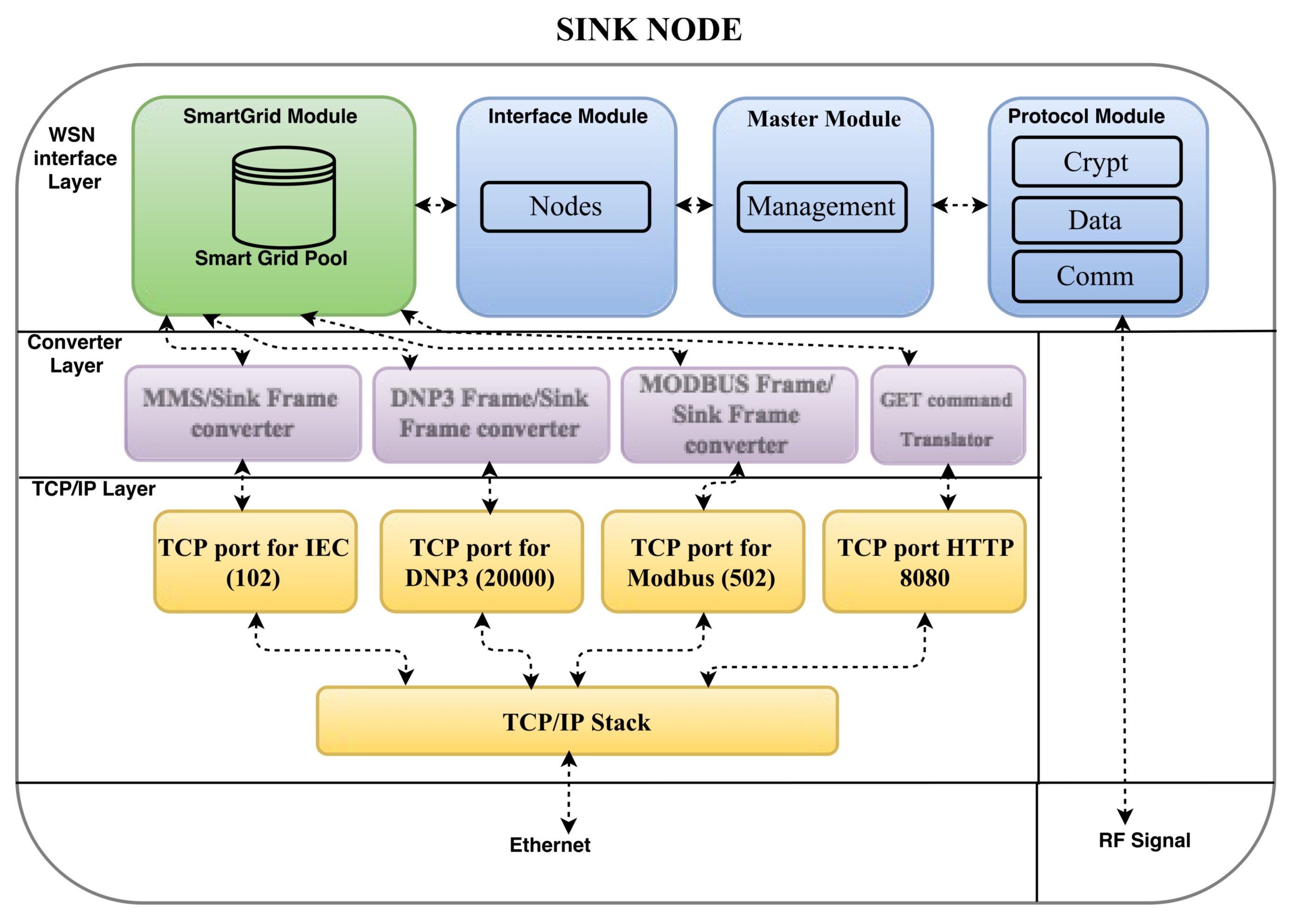

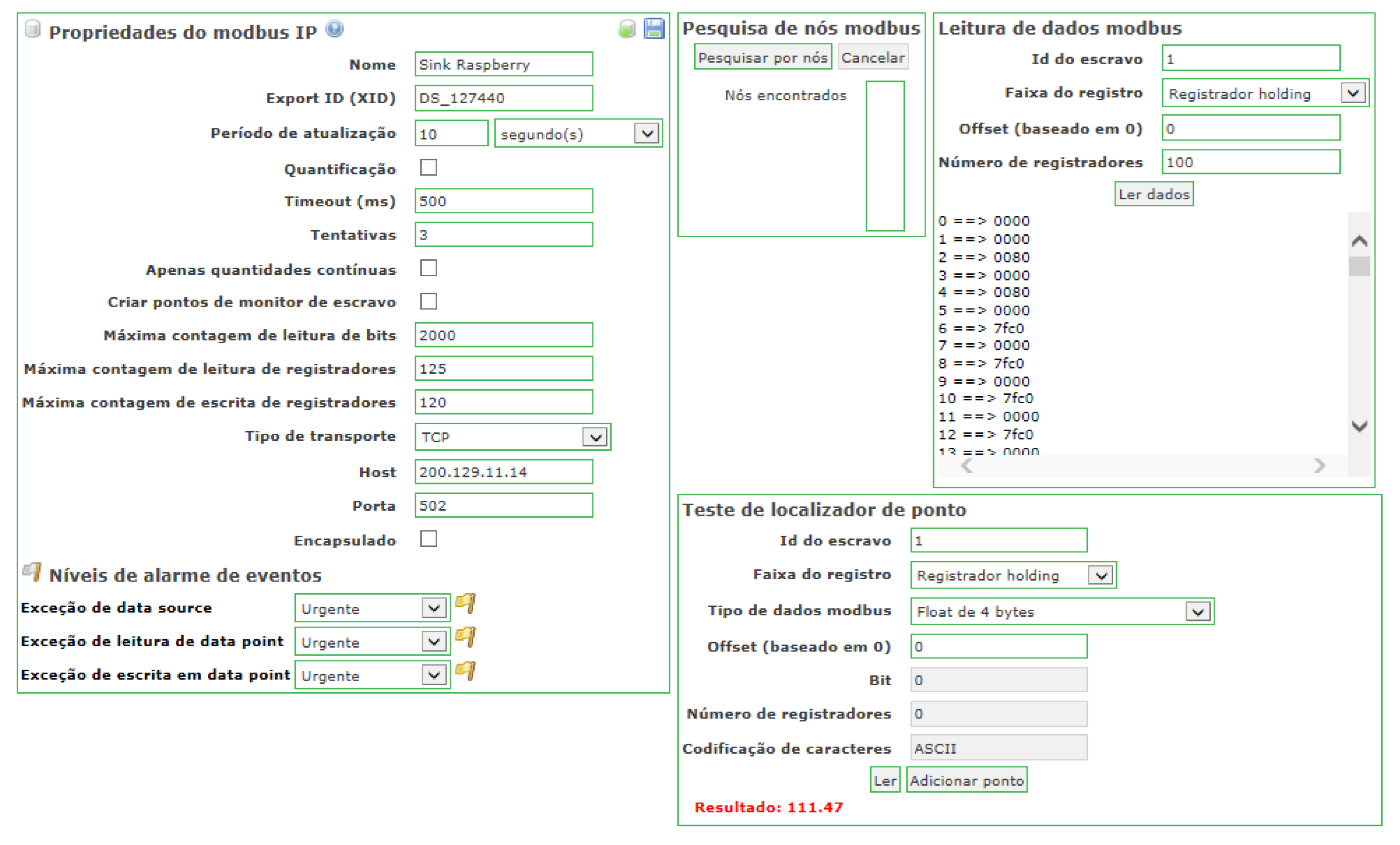

- This solution enables electrical companies to integrate their legacy equipment into smart-grid distribution networks using the following smart-grid protocols: IEC 61850, DNP3, and Modbus.

- The infrastructure proposed in this study provides the facilities to guarantee the important requirements for smart-grid applications, such as short response time, communications security, and even automatic configuration capabilities.

- The infrastructure presented in this paper allows both the interoperability of electrical equipment from different manufacturers and the reduction of costs related to the modernisation of power substations.

2. Related Work

3. Materials and Methods

3.1. Power Substation and Infrastructure Components

- There are real applications using ZigBee technology for smart metering infrastructures. For instance, the gridstream smart metering solution from Landis+Gyr for Helen Electricity Network uses ZigBee technology [50]. Southern California Edison installed millionth Itron OpenWay Smart Meter that uses ZigBee technology for its communication [52]. In France, a first lot of 300,000 smart meters installed by Enedis Operator (Paris, France) communicate to IHDs using ZigBee or KNX interface [53]. More than 70 million ZigBee power meters have being deployed by dozens of utility companies in USA [54].

- Many devices for energy metering and management use ZigBee technology, such as universal controller ENOCEAN ZigBee (Schneider Electric, Inc. Rueil-Malmaison, Paris, France) [55], smart plugs (Develco, Inc. Aarhus, Denmark) [56], EMU-2 (Rainforest Automation, Inc. Burnaby, Canada) [57], OpenWay CENTRON smart meters (Itron, Inc. Liberty Lake, WA, USA) [58], and Landis+Gyr G370 (Landis+Gyr, Inc. Alpharetta, GA, USA) [59].

- There are smart metering technical specifications that suggested ZigBee technology as standard for HAN applications. For instance, the smart metering implementation programme (Department of Energy and Climate Change—UK Government) presented the smart metering equipment technical specifications—Version 2 (SMETS 2), which suggested the ZigBee technology as the standard for the HAN application layer [60].

- Power utilities in most regions of Brazil do not offer infrastructure (concentrating units, repeater units, and communication transformers) for PLC-based communication in their power grid. They do not authorize the use or installation of any equipment in their power network. Thus, no PLC-based communication test is possible.

- ZigBee technology has lower cost than other technologies such as LoRaWAN and Sigfox. These technologies require base stations or access points (APs) to operate, which must be installed on RF transmission towers. In many cases, RF transmission towers must be built, which increase the financial cost. DLMS is considered a standard protocol for smart metering, and there is no study or related work that evaluates whether the LoRa or Sigfox technology has sufficient bandwidth to satisfy the amount of information exchanged in a DLMS communication.

3.2. Infrastructure to Integrate Legacy Electrical Equipment to Smart Grid Using WSNs

3.2.1. Integration Requirements

- Standardisation: Power substations are currently using standardised equipment for operation, monitoring, and communications. This facilitates the integration and interoperability among electrical devices, improving the power system maintenance and operation. In particular, communication protocols such as DNP3, IEC 61850, and Modbus are widely used in smart grids. Thus, a WSN-based integration of legacy electrical equipment and sensors into a smart grid requires the use of such standardised protocols. Moreover, a middleware must support the WSN sink node to enable the communication between different equipment and either the PSCC or another smart-grid system.

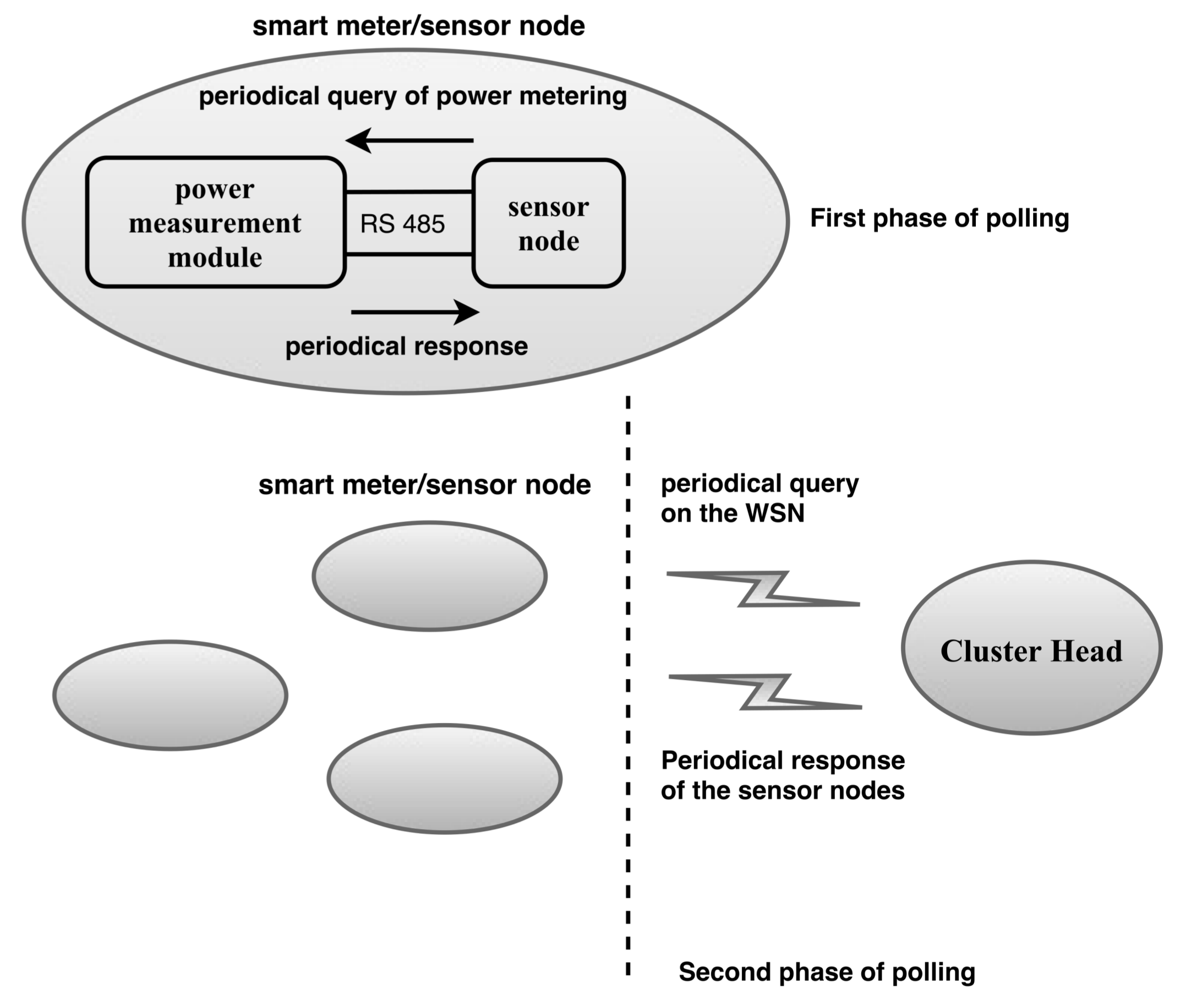

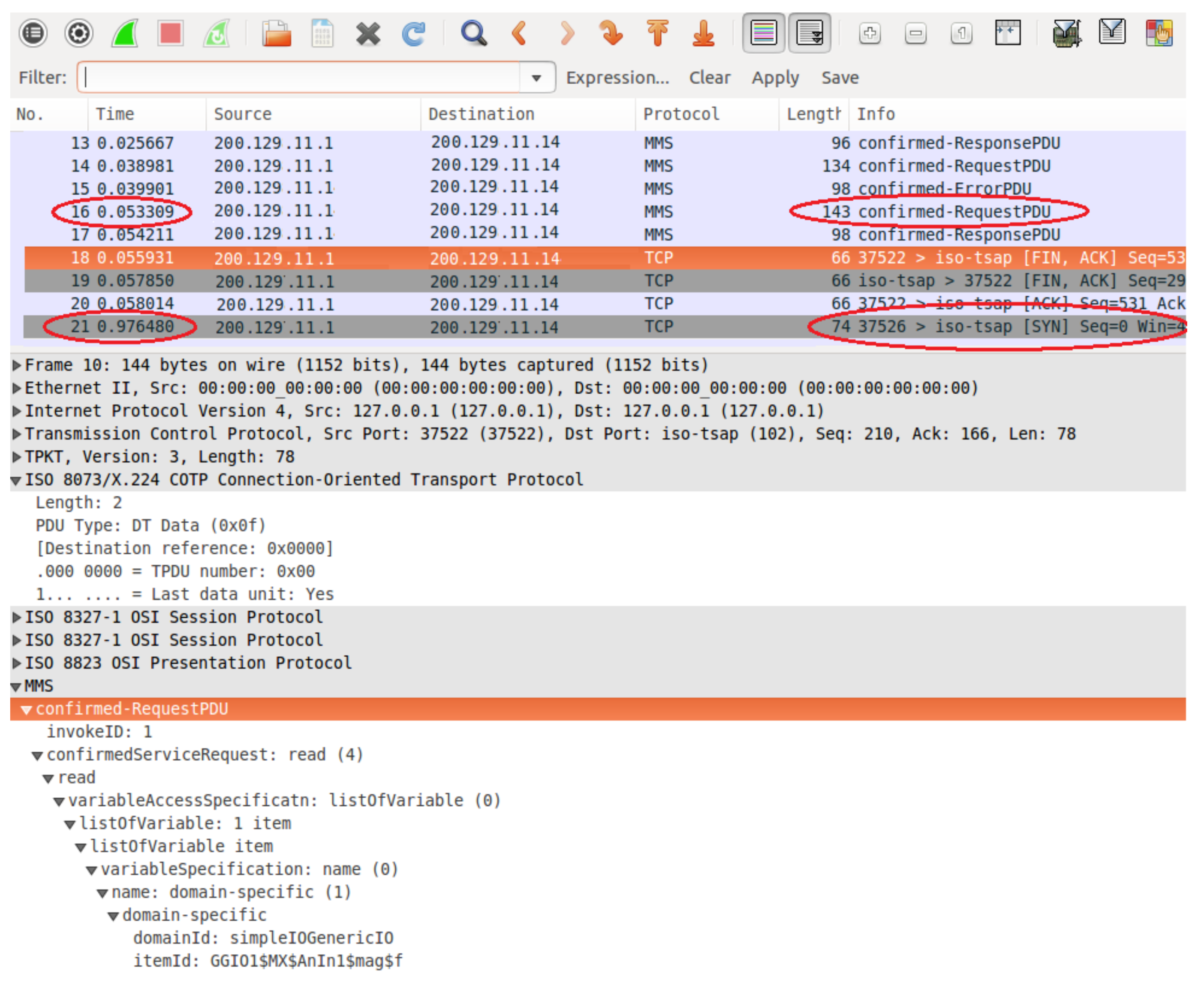

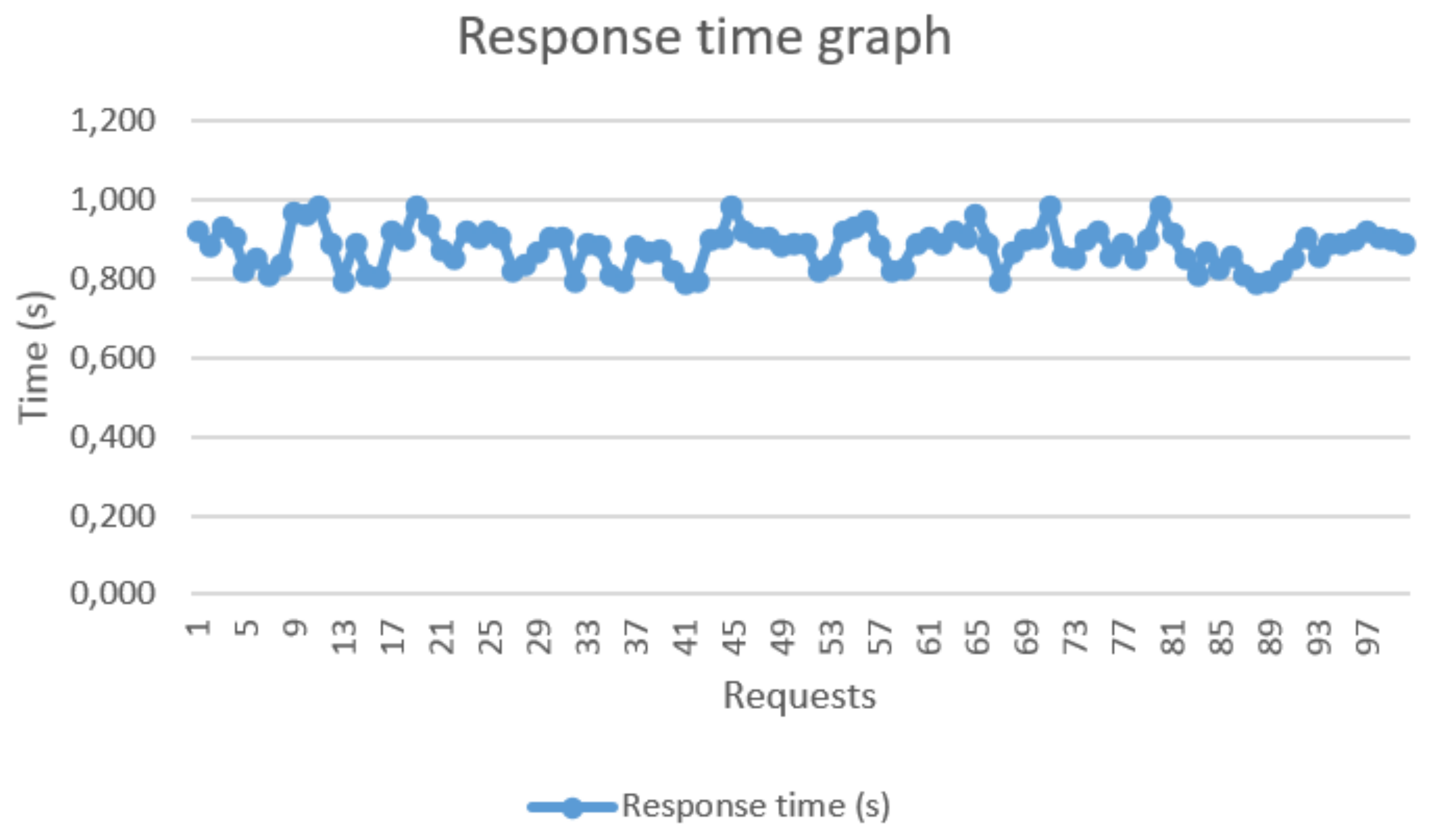

- Response Time: Smart-grid applications must comply with a suitable response time. In fact, the IEC 61850 protocol specifies a time constrain for message exchange. For instance, this protocol limits the transmission time of type 3 messages (i.e. low-speed messages) to 500 ms [61]. Likewise, we implemented a strategy to improve the response time for WSN communication, which has allowed to meet some time requirements of the IEC 61850 protocol. Specifically, the proposed strategy is based on two phases of the polling technique, which uses periodic requests at either the sink node or the device connected to the sensor node. We provide further details of this strategy in Section 3.3.2.

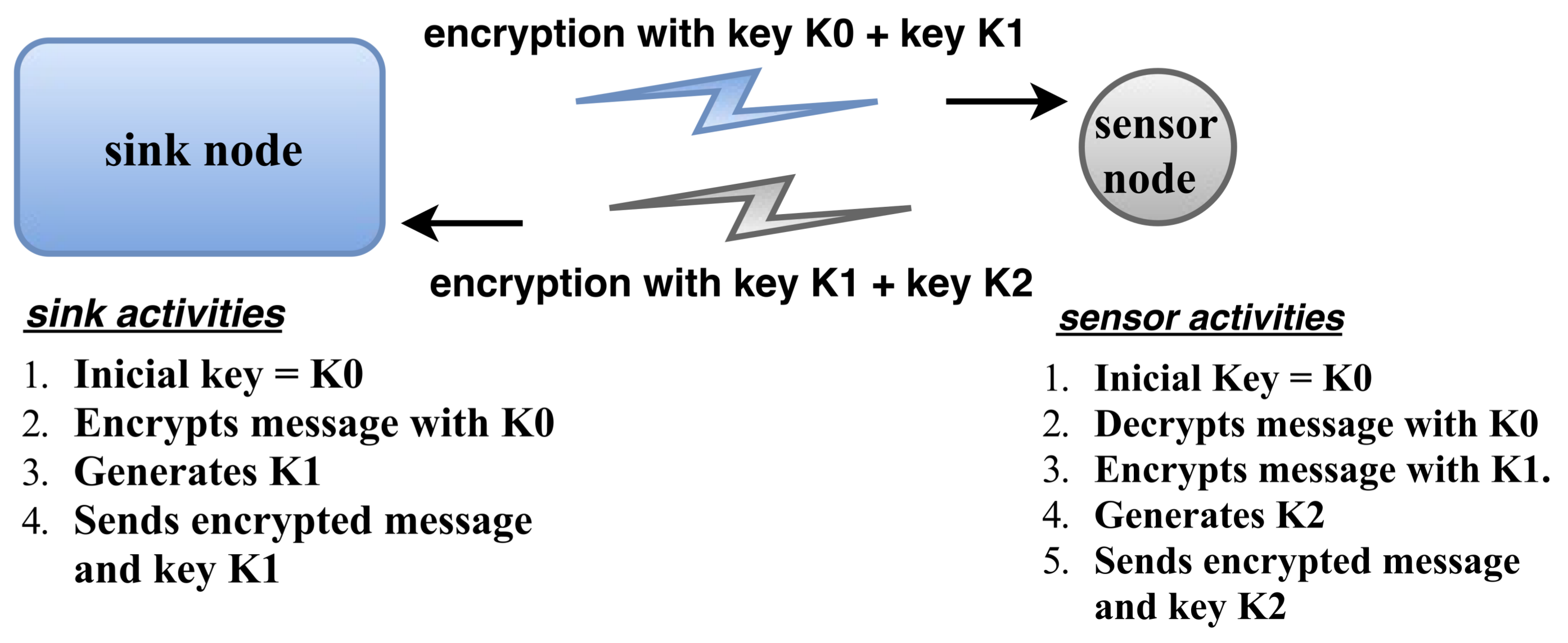

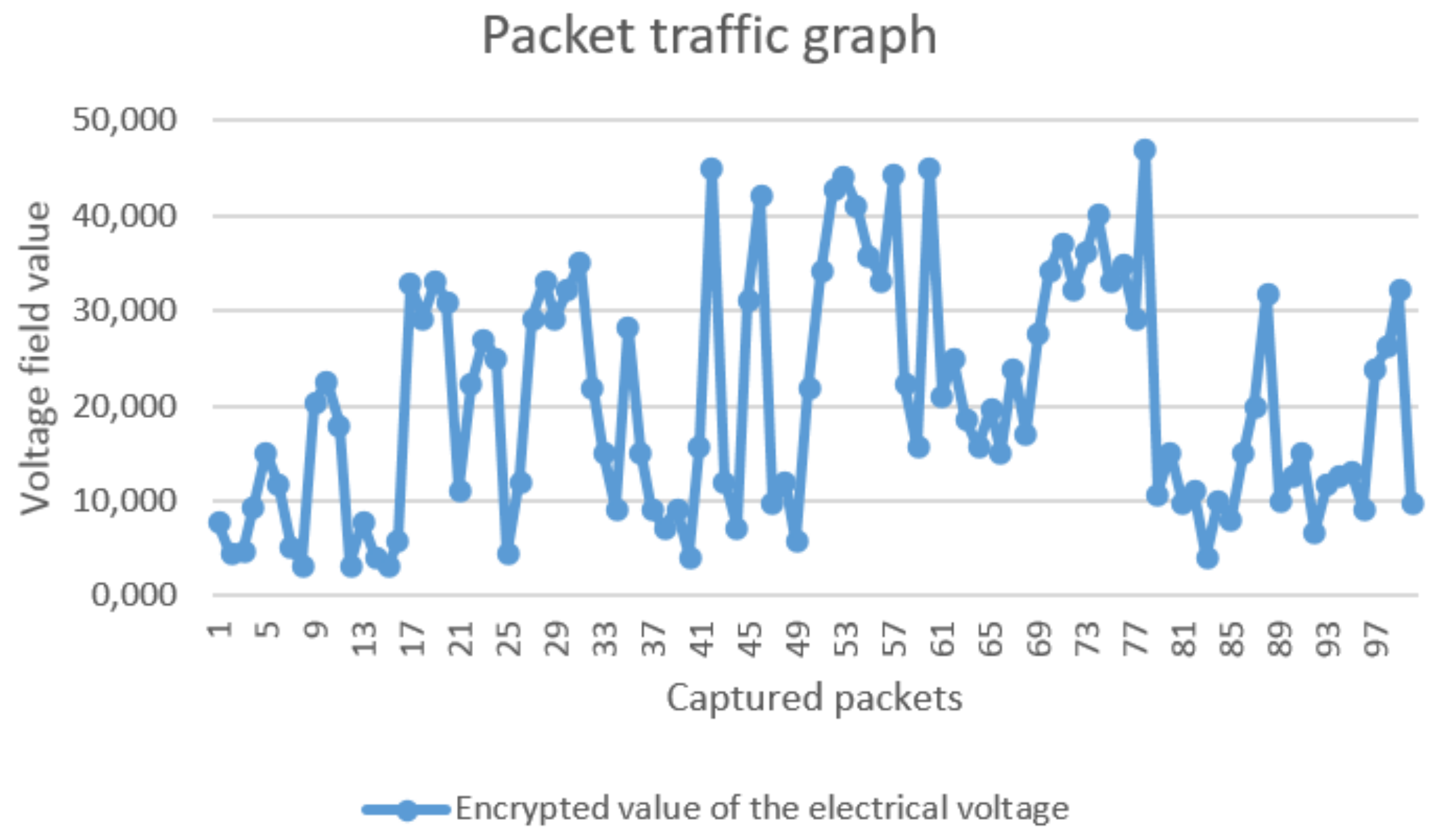

- Security: Security is a major concern in smart-grid applications. For instance, in a power metering application, the information of customer power consumption retrieved by the electricity utility must be treated with safety and reliability. Otherwise, a WSN transmitting information between the electricity utility and smart meters might be corrupted by a spy node, which could alter the consumption readings in the benefit of the customer. To avoid this type of problem, we propose the use of an encrypted channel with keys generated at the sink and sensor nodes to secure their communications. The keys are modified at runtime to hamper the inclusion of corrupted data, and we verified the effectivity of this encryption method, as shown in the corresponding results of Section 4.

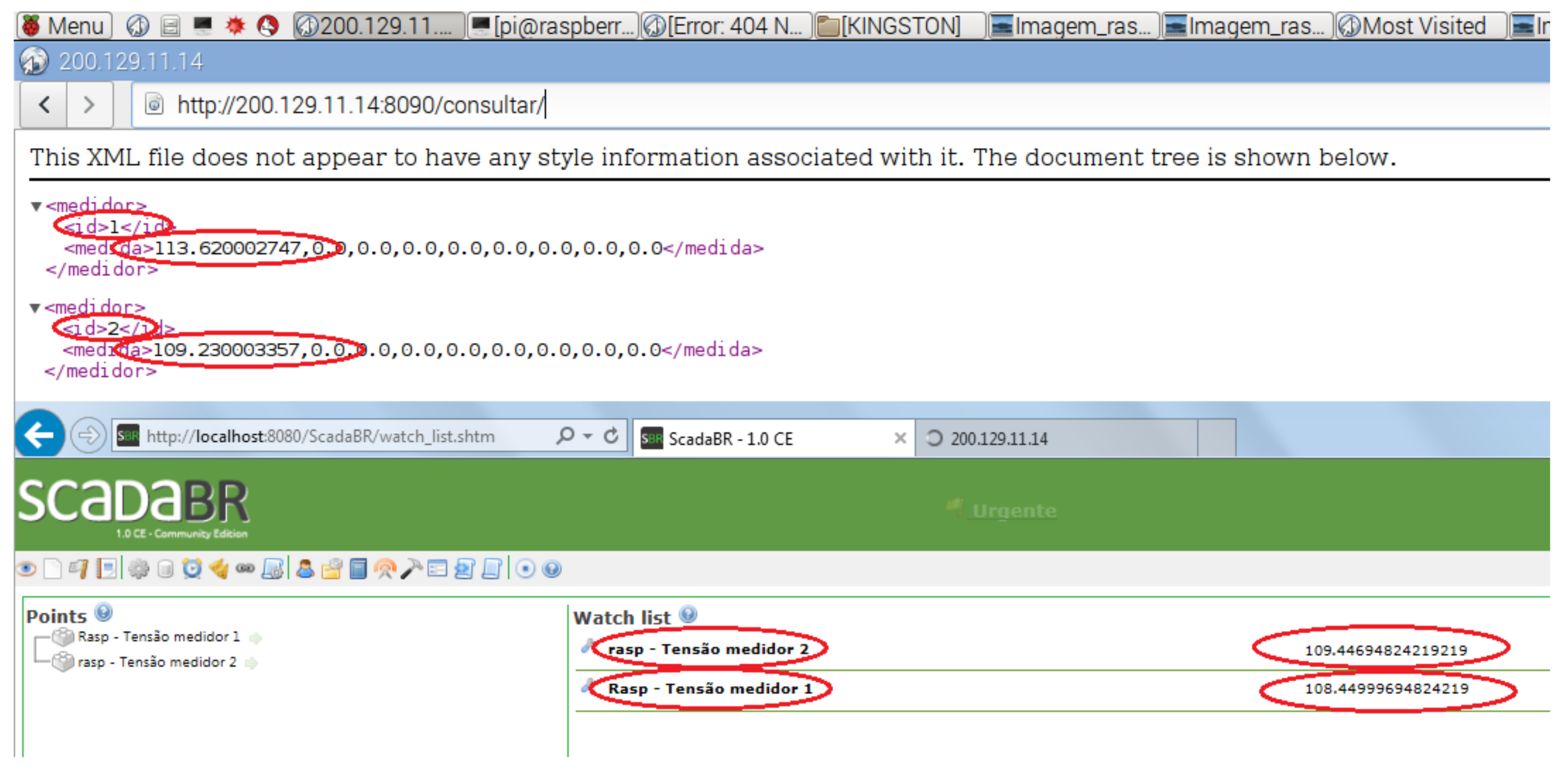

3.2.2. Integration Middleware

3.3. Requirement Compliance for Smart-Grid Applications

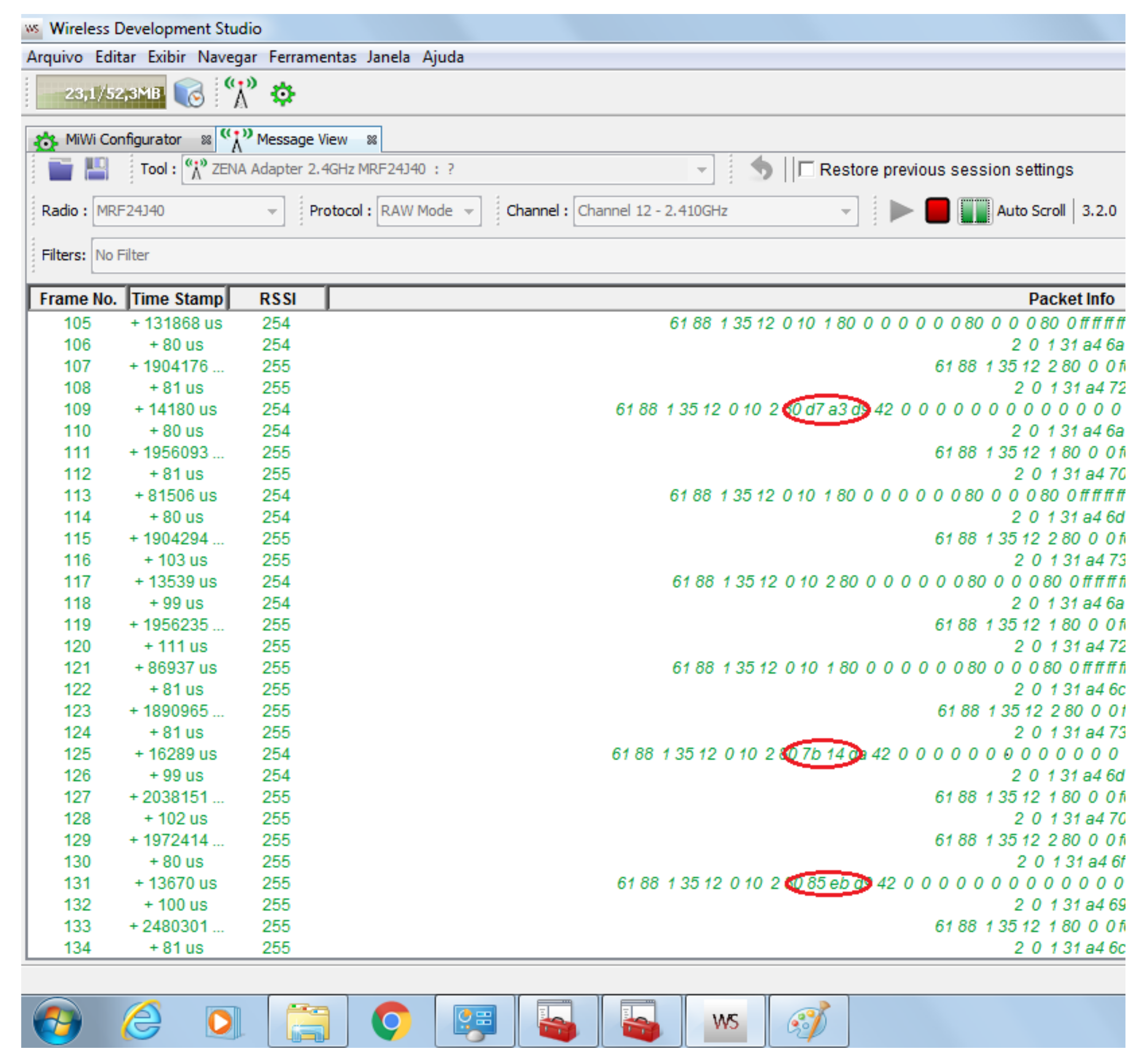

3.3.1. Communication Security in WSN

3.3.2. Response Time in WSN Communication

3.3.3. Automatic Configuration

4. Experiments and Results

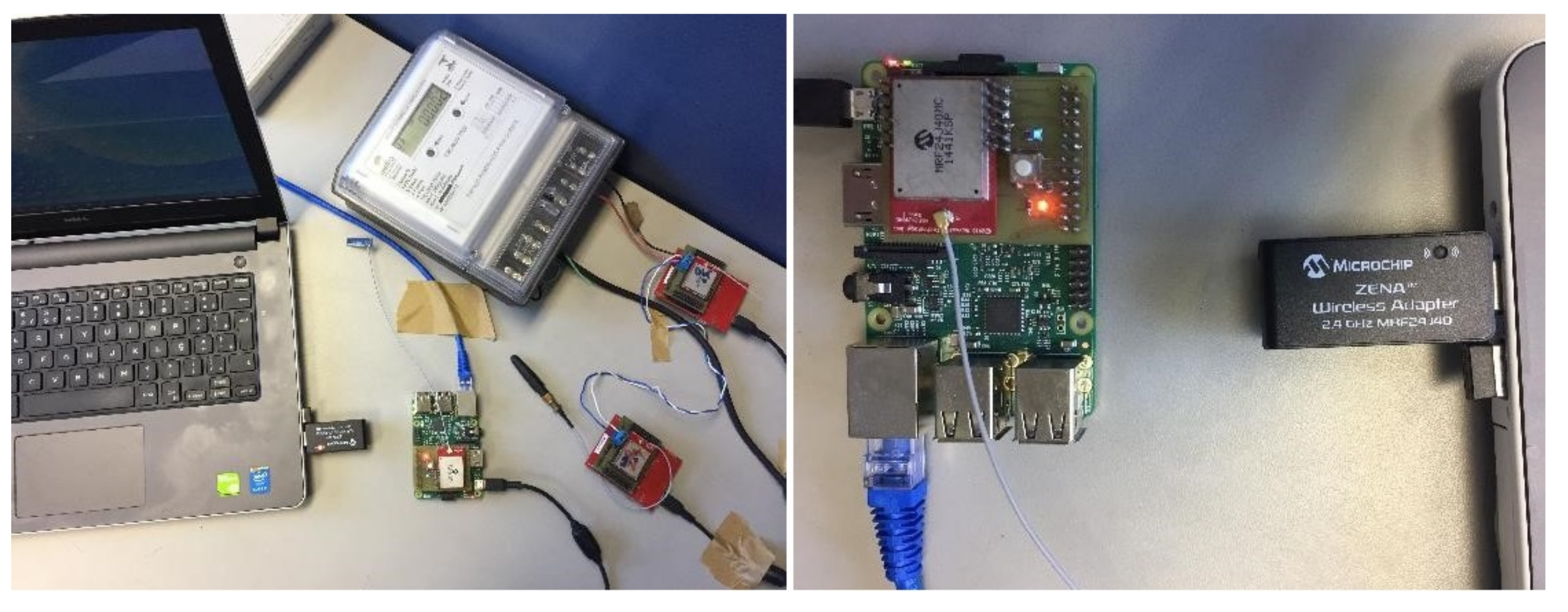

4.1. Experimental Setup

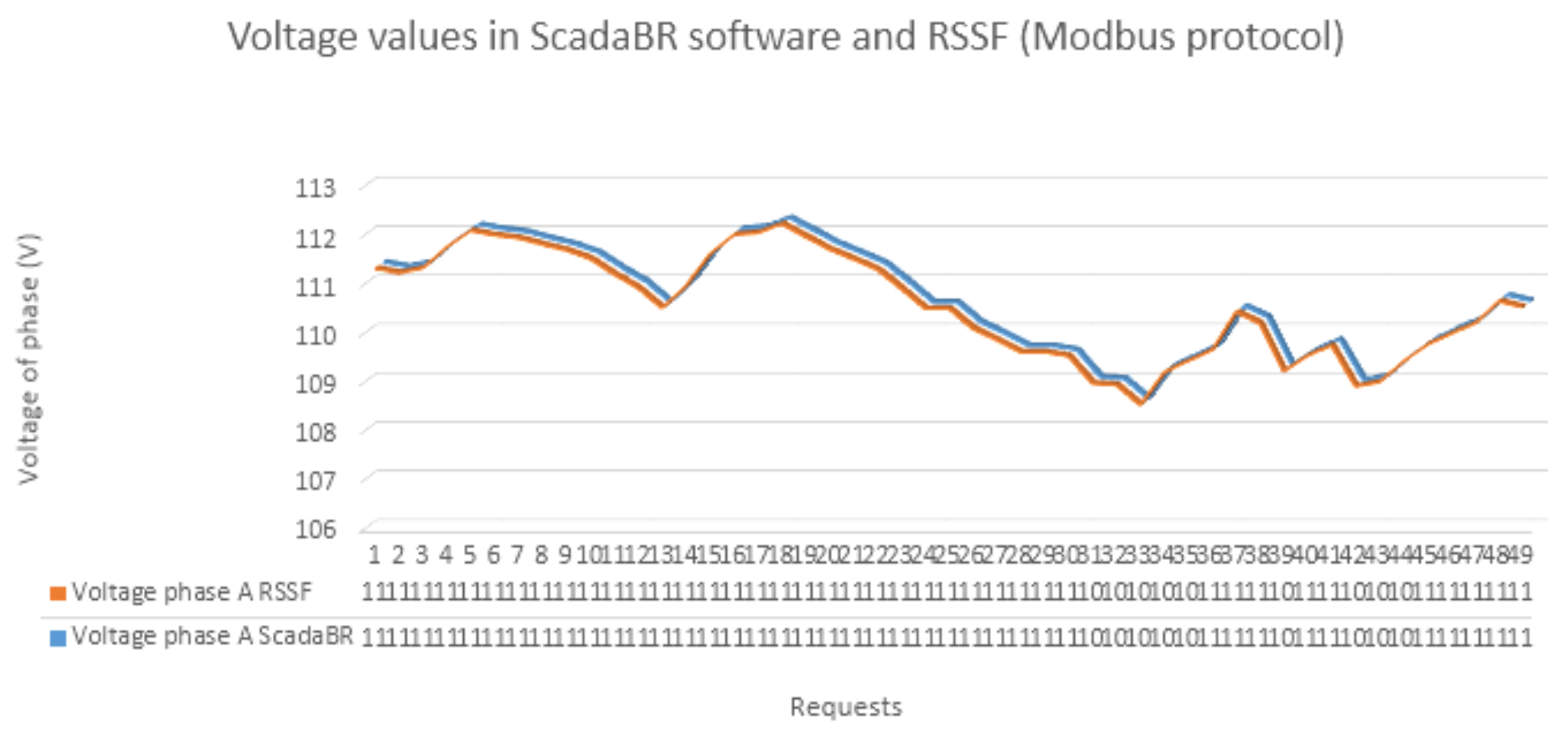

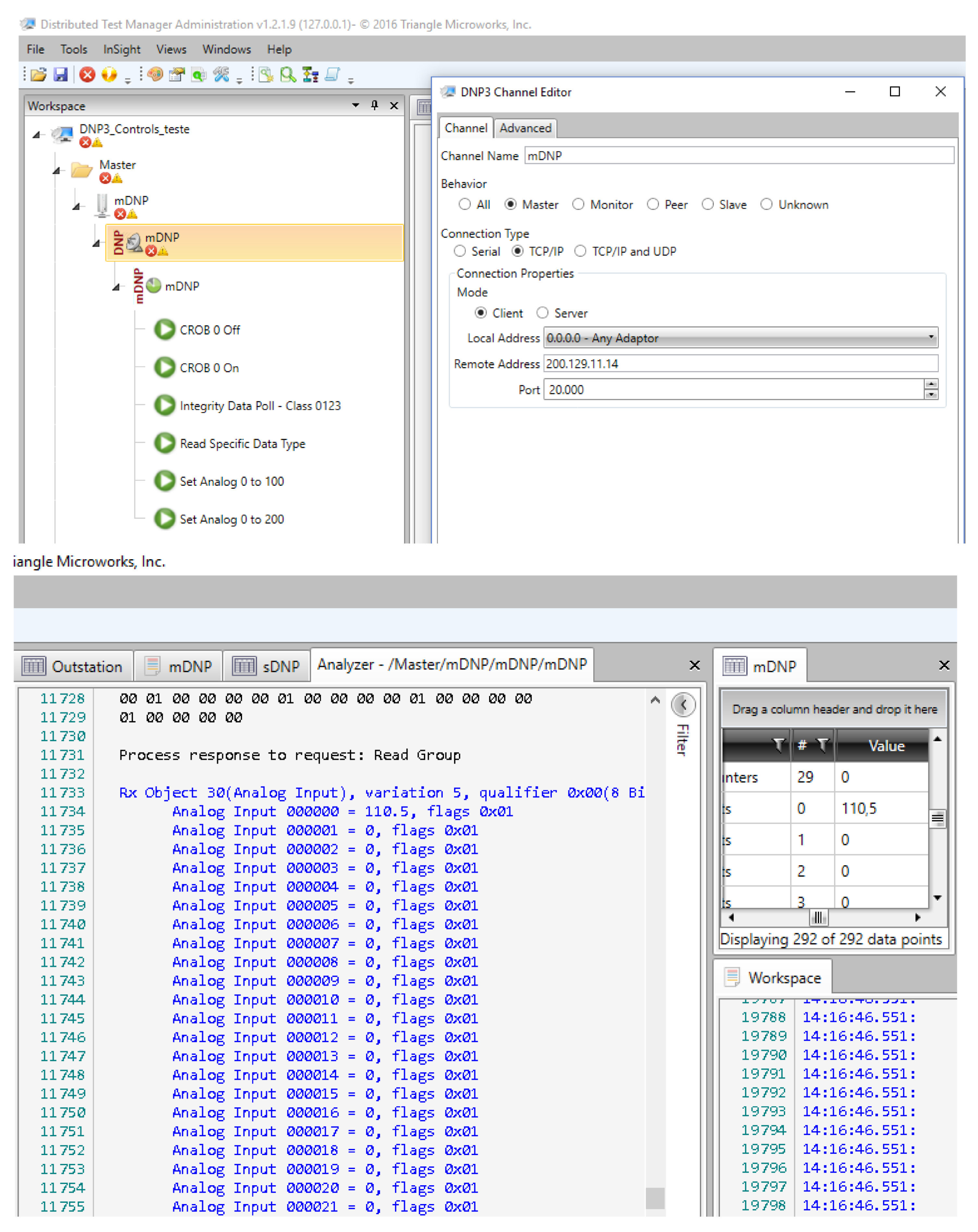

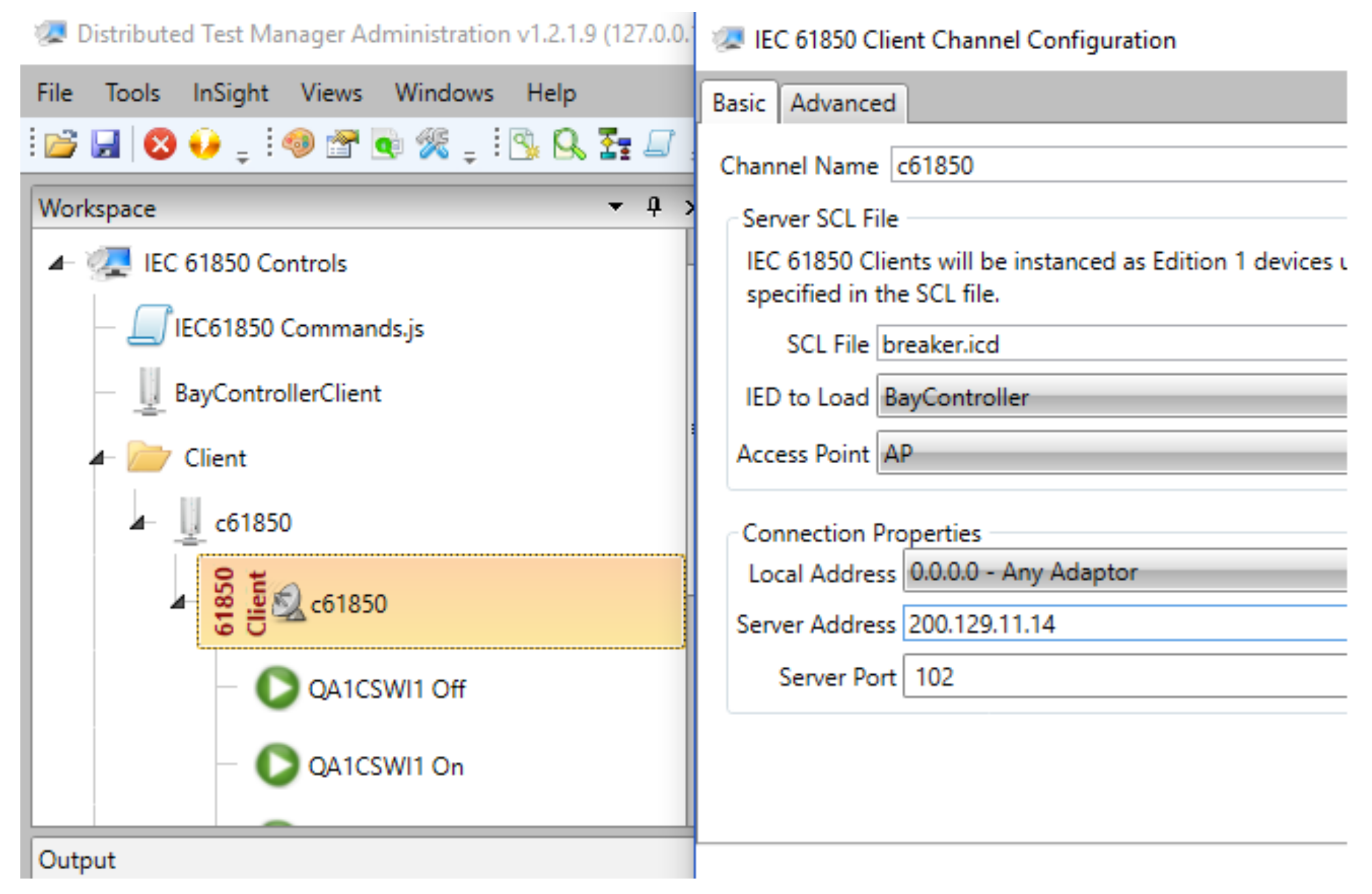

4.2. Results

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Qian, C.; Luo, Z.; Tian, X.; Wang, X.; Guizani, M. Cognitive transmission based on data priority classification in WSNs for Smart Grid. In Proceedings of the IEEE Global Communications Conference (GLOBECOM), Anaheim, CA, USA, 3–7 December2012; pp. 5166–5171. [Google Scholar]

- Zhang, P.; Li, F.; Bhatt, N. Next-generation monitoring, analysis, and control for the future smart control center. IEEE Trans. Smart Grid 2010, 1, 186–192. [Google Scholar] [CrossRef]

- El Brak, M.; Essaaidi, M. Wireless sensor network in home automation network and smart grid. In Proceedings of the International Conference on Complex Systems (ICCS), Agadir, Morocco, 5–6 November 2012; pp. 1–6. [Google Scholar]

- Abid, M.R.; Khallaayoun, A.; Harroud, H.; Lghoul, R.; Boulmalf, M.; Benhaddou, D. A wireless mesh architecture for the advanced metering infrastructure in residential smart grids. In Proceedings of the IEEE Green Technologies Conference, Denver, CO, USA, 4–5 April 2013; pp. 338–344. [Google Scholar]

- Castellani, A.P.; Ministeri, G.; Rotoloni, M.; Vangelista, L.; Zorzi, M. Interoperable and globally interconnected Smart Grid using IPv6 and 6LoWPAN. In Proceedings of the IEEE International Conference on Communications (ICC), Ottawa, ON, Canada, 10–15 June 2012. [Google Scholar]

- Distributed Network Protocol. Overview of the DNP3 Protocol. Available online: http://www.dnp.org/Pages/AboutDefault.aspx (accessed on 6 June 2016).

- National Instruments Inc. Introduction to MODBUS. Available online: http://www.ni.com/white-paper/7675/pt/ (accessed on 10 September 2014).

- Shi, K.; Bi, Y.; Jiang, L. Middleware-based implementation of smart micro-grid monitoring using data distribution service over IP networks. In Proceedings of the 49th International Universities Power Engineering Conference (UPEC), Cluj-Napoca, Romania, 2–5 September2014; pp. 1–5. [Google Scholar]

- Gungor, V.C.; Bin, L.; Hancke, G.P. Opportunities and challenges of wireless sensor networks in smart grid. IEEE Trans. Ind. Electron. 2010, 57, 3557–3564. [Google Scholar] [CrossRef]

- Tuna, G.; Gungor, V.C.; Gulez, K. Wireless sensor networks for smart grid applications: A case study on link reliability and node lifetime evaluations in power distribution systems. Int. J. Distrib. Sens. Netw. 2013, 9, 796248. [Google Scholar] [CrossRef]

- Erol-Kantarci, M.; Mouftah, H.T. Wireless multimedia sensor and actor networks for the next-generation power grid. Ad Hoc Netw. 2011, 9, 542–551. [Google Scholar] [CrossRef]

- Abid, M.R.; Khallaayoun, A.; Harroud, H.; Lghoul, R.; Boulmalf, M.; Benhaddou, D. A wireless mesh architecture for the advanced metering infrastructure in residential smart grids. In Proceedings of the IEEE Green Technologies Conference, Denver, CO, USA, 4–5April 2013; pp. 338–344. [Google Scholar]

- Zhou, L.; Joel, J.P.C. Service-oriented middleware for smart grid: Principle, infrastructure, and application. IEEE Commun. Mag. 2013, 51, 84–89. [Google Scholar] [CrossRef]

- Zhou, L.; Joel, J.P.C. QoE-driven power scheduling in smart grid: Architecture, strategy, and methodology. IEEE Commun. Mag. 2012, 50, 136–141. [Google Scholar] [CrossRef]

- Zaballos, A.; Vallejo, A.; Selga, J.M. Heterogeneous communication architecture for the smart grid. IEEE Netw. 2011, 25, 30–37. [Google Scholar] [CrossRef]

- Talei, H.; Zizi, B.; Abid, M.R.; Essaaidi, M.; Benhaddou, D.; Khalil, N. Smart campus microgrid: Advantages and the main architectural components. In Proceedings of the 3rd International Renewable and Sustainable Energy Conference (IRSEC), Marrakech, Morocco, 10–13 December2015; pp. 1–7. [Google Scholar]

- Wilcox, J.; Kaleshi, D.; Sooriyabandara, M. DIRECTOR: A distributed communication transport manager for the smart grid. In Proceedings of the IEEE International Conference on Communications (ICC), Sydney, Australia, 10–14 June 2014; pp. 4227–4232. [Google Scholar]

- Ibrahim, C.; Mougharbel, I.; Daher, N.A.; Kanaan, H.Y.; Saad, M.; Georges, S. A novel generic architecture for the implementation of demand response programs in a smart grid. In Proceedings of the IEEE International Conference on Industrial Technology (ICIT), Toronto, ON, Canada, 22–25 March 2017; pp. 558–563. [Google Scholar]

- Bacarreli, E.; Naranjo, P.G.V.; Scarpiniti, M.; Shojafar, M.; Abawajy, J.H. Fog of everything: Energy-efficient networked computing architectures, research challenges, and a case study. IEEE Access 2017, 5, 9882–9910. [Google Scholar] [CrossRef]

- Naranjo, P.G.V.; Pooranian, Z.; Shojafar, M.; Conti, M.; Buyya, R. FOCAN: A fog-supported smart city network architecture for management of applications in the internet of everything environments. arXiv Preprint, 2017; arXiv:1710.01801. [Google Scholar]

- Pooranian, Z.; Nikmehr, N.; Najafi-Ravadanegh, S.; Mahdin, H.; Abawajy, J. Economical and environmental operation of smart networked microgrids under uncertainties using NSGA-II. In Proceedings of the 24th International Conference on Software, Telecommunications and Computer Networks (SoftCOM), Split, Croatia, 22–24 September 2016. [Google Scholar]

- Schroder Filho, H.G.; Pissolato Filho, J.; Moreli, V.L. The adequacy of LoRaWAN on smart grids: A comparison with RF mesh technology. In Proceedings of the IEEE International Smart Cities Conference (ISC2), Trento, Italy, 12–15 September 2016. [Google Scholar]

- Rizzi, M.; Ferrari, P.; Flammini, A.; Sisinni, E. Evaluation of the IoT LoRaWAN solution for distributed measurement applications. IEEE Trans. Instrum. Low Meas. 2017, 66, 3340–3349. [Google Scholar] [CrossRef]

- Barriquello, C.H.; Bernardon, D.P.; Canha, L.N.; Silva, F.E.S.; Porto, D.S.; Ramos, M.J.S. Performance assessment of a low power wide area network in rural smart grids. In Proceedings of the 52nd International Universities Power Engineering Conference (UPEC), Heraklion, Greece, 28–31 August 2017. [Google Scholar]

- Wibisono, G.; Saktiaji, G.P.; Ibrahim, I. Techno economic analysis of smart meter reading implementation in PLN Bali using LoRa technology. In Proceedings of the International Conference on Broadband Communication, Wireless Sensors and Powering (BCWSP), Jakarta, Indonesia, 21–23 November 2017. [Google Scholar]

- Saravanan, M.; Das, A.; Iyer, V. Smart water grid management using LPWAN IoT technology. In Proceedings of the Global Internet of Things Summit (GIoTS), Geneva, Switzerland, 6–9 June 2017. [Google Scholar]

- Vigni, V.L.; Di Stefano, A.; Candela, R.; Sanseverino, E.R. A two-end traveling wave fault location system for MV cables based on LoRa technology. In Proceedings of the IEEE International Conference on Environment and Electrical Engineering and IEEE Industrial and Commercial Power Systems Europe (EEEIC/ICPS Europe), Milan, Italy, 6–9 June 2017. [Google Scholar]

- Lloret, J.; Tomas, J.; Canovas, A.; Parra, L. An integrated IoT architecture for smart metering. IEEE Commun. Mag. 2016, 54, 50–57. [Google Scholar] [CrossRef]

- Lloret, J.; Gilg, M.; Garcia, M.; Lorenz, P. A group-based protocol for improving energy distribution in smart grids. In Proceedings of the IEEE International Conference on Communications (ICC), Kyoto, Japan, 5–9 June 2011. [Google Scholar]

- Khameis, A.; Rashed, S.; Abou-Elnour, A.; Tarique, M. ZigBee based optimal scheduling system for home appliances in the United Arab Emirates. Netw. Protoc. Algorithms 2015, 7, 60–80. [Google Scholar]

- Salvadori, F.; Gehrke, C.; Oliveira, A.C.; Campos, M.; Sausen, P.S. Smart grid infrastructure using a hybrid network architecture. IEEE Trans. Smart Grid 2013, 4, 1630–1639. [Google Scholar] [CrossRef]

- Wu, Y.; He, Y.; Mendis, G.J.; Wei, J. A pivacy-preserving middleware mechanism for smart grids. In Proceedings of the 2nd IEEE International Conference on Cloud Computing and Big Data Analysis, Chengdu, China, 28–30 April 2017; pp. 394–399. [Google Scholar]

- Talei, H.; Zizi, B.; Abid, M.R.; Essaaidi, M.; Benhaddou, D.; Khalil, N. Smart campus microgrid: Advantages and the main architectural components. In Proceedings of the 3rd International Renewable and Sustainable Energy Conference (IRSEC), Marrakech, Morocco, 10–13 December 2015. [Google Scholar]

- Martin, S.; Hernandez, J.; Valmaseda, C. A novel middleware for smart grid data exchange towards the energy efficiency in buildings. In Proceedings of the International Conference and Workshops on Networked Systems (NetSys), Cottbus, Germany, 9–12 March 2015. [Google Scholar]

- Patti, E.; Syrri, A.L.A.; Jahn, M.; Mancarella, P.; Acquaviva, A.; Macii, E. Distributed software infrastructure for general purpose services in smart grid. IEEE Trans. Smart Grid 2016, 7, 1156–1163. [Google Scholar] [CrossRef]

- Tourani, R.; Misra, S.; Mick, T.; Brahma, S.; Biswal, M.; Ameme, D. iCenS: An information-centric smart grid network architecture. In Proceedings of the IEEE International Conference on Smart Grid Communications (SmartGridComm), Sydney, Australia, 6–9 November 2016. [Google Scholar]

- Cavalieri, S.; Regalbuto, A. Integration of IEC 61850 SCL and OPC UA to improve interoperability in Smart Grid environment. Comput. Stand. Interfaces 2016, 47, 77–99. [Google Scholar] [CrossRef]

- B-Scada Inc. Beyond SCADA. Available online: http://scada.com (accessed on 16 June 2016).

- Triangle MicroWorks. Distributed Test Manager (DTM). Available online: http://www.trianglemicroworks.com/products/testing-and-configurationtools/dtm-pages (accessed on 3 September 2017).

- Raspberry. Raspberry PI Model B. Available online: http://www.raspberrypi.org/products/model-b/ (accessed on 20 February 2016).

- Microchip. MRF24J40MC Data Sheet. Available online: http://ww1.microchip.com/downloads/en/DeviceDoc/75002A.pdf (accessed on 12 July 2016).

- Araujo, P.R.C.; Holanda, R.; Rodrigues, A.W.; Araujo, A.L.C.; Filho, J.A.M.; Oliveira, J.P.C.M. A middleware for the integration of smart grid elements with WSN based solutions. Int. J. Distrib. Sensor Netw. 2014, 10, 1–15. [Google Scholar] [CrossRef]

- Texas Instruments. ARM Cortex-M4F Based MCU TM4C123G. Available online: http://www.ti.com/tool/ek-tm4c123gxl (accessed on 13 June 2016).

- Batista, N.C.; Melicio, R.; Matias, J.C.O.; Catalao, J.P.S. Photovoltaic and wind energy systems monitoring and building/home energy management using ZigBee devices within a smart grid. Energy 2012, 49, 306–315. [Google Scholar] [CrossRef]

- Spano, E.; Niccolini, L.; Di Pascoli, S.; Iannaccone, G. Last-meter smart grid embedded in an Internet-of-things platform. IEEE Trans. Smart Grid 2015, 6, 468–476. [Google Scholar] [CrossRef]

- Arif, A.; Al-Hussain, M.; Al-Mutairi, N.; Al-Ammar, E.; Khan, Y.; Malik, N. Experimental study and design of smart energy meter for the smart grid. In Proceedings of the International Renewable and Sustainable Energy Conference (IRSEC), Ouarzazate, Morocco, 7–9 March 2015. [Google Scholar]

- Luan, S.-W.; Teng, J.-H.; Chan, S.-Y.; Hwang, L.-C. Development of a Smart Power Meter for AMI Based on ZigBee Communication. In Proceedings of the International Conference on Power Electronics and Drive Systems, Taipei, Taiwan, 2–5 November 2009; pp. 661–665. [Google Scholar]

- Bilgin, B.E.; Gungor, V.C. Performance evaluations of ZigBee in different smart grid environments. Comput. Netw. 2012, 56, 2196–2205. [Google Scholar] [CrossRef]

- Leccese, F.; Cagnetti, M.; Trina, D. A smart city application: A fully controlled street lighting isle based on Raspberry-Pi card, a ZigBee Sensor Network and WiMAX. Sensors 2014, 14, 24409–24424. [Google Scholar] [CrossRef] [PubMed]

- Landis+Gyr, Inc. Landis+Gyr Agreement in Helsinki is at the Forefront of Smart Meter Deployment in EU. Available online: http://www.landisgyr.com/landisgyr-agreement-in-helsinki-is-at-the-forefront-of-smart-meter-deployment-in-eu/ (accessed on 12 February 2018).

- Itron, Inc. Itron Expands Functionality of its OpenWay CENTRON Smart Meter to Enable Seamless Migration Path from AMR to Advanced Metering/Smart Grid. Available online: https://www.itron.com/br/newsroom/press-releases/2009/09/15/itron-expands-functionality-of-its-openway-centron-smart-meter-to-enable-seamless-migration-path (accessed on 20 February 2018).

- Itron, Inc. Southern California Edison Installs Millionth Itron OpenWay Smart Meter. Available online: https://www.itron.com/br/newsroom/press-releases/2010/07/12/southern-california-edison-installs-millionth-itron-openway-smart-meter (accessed on 3 February 2018).

- Bertoldo, R.; Poumadere, M.; Luis, C.R. When meters start to talk: The public’s encounter with smart meters in France. Energy Res. Soc. Sci. 2015, 9, 146–156. [Google Scholar] [CrossRef]

- ZigBee Alliance. Utility Industry. Available online: http://www.zigbee.org/what-is-zigbee/utility-industry/ (accessed on 17 February 2018).

- Schneider Electric, Inc. Universal Controller ENOCEAN ZIGBEE. Available online: https://www.schneider-electric.com.br/pt/product/MPM-UN-CI4-5045/controlador-univ-enocean-zigbee (accessed on 11 February 2018).

- Develco, Inc. Smart Plugs. Available online: https://www.develcoproducts.com/products/smart-plugs/ (accessed on 15 February 2018).

- Rainforest Automation, Inc. Energy Management Unit-2. Available online: https://rainforestautomation.com/buy/rfa-z105-2-emu-2/ (accessed on 15 February 2018).

- Itron, Inc. Itron expands functionality of its openway centron smart meter to enable seamless migration path. Available online: https://www.itron.com/br/newsroom/press-releases/2009/09/15/itron-expands-functionality-of-its-openway-centron-smart-meter-to-enable-seamless-migration-path (accessed on 15 February 2018).

- Landis+Gyr, Inc. G370 Series. Available online: https://www.landisgyr.eu/product/landisgyr-g370-series/ (accessed on 15 February 2018).

- Department of Energy and Climate Change—UK Government. Smart Metering Equipment Technical Specifications—Version 2 (SMETS 2). Available online: https://www.gov.uk/government/uploads/system/uploads/attachment_data/file/209841/smart_meters_equipment_technical_spec_2_consultation_response_part_1.pdf (accessed on 16 February 2018).

- International Electrotechnical Commission. Core IEC Standards. Available online: http://www.iec.ch/smartgrid/standards/ (accessed on 20 July 2016).

- Araujo, P.R.C.; Holanda, R.; Rodrigues, J.J.P.C.; Oliveira, J.P.C.M.; Braga, S.A. Middleware for integration of legacy electrical equipment into smart grid infrastructure using wireless sensor networks. Int. J. Commun. Syst. 2017, 31, e3380. [Google Scholar] [CrossRef]

- Hussain, I.; Pandey, N. Carrier Data Security using Public Key Steganography in ZigBee. In Proceedings of the International Conference on Innovation and Challenges in Cyber Security (ICICCS-INBUSH), Noida, India, 3–5 February 2016. [Google Scholar]

- Durech, J.; Franekova, M. Security attacks to ZigBee technology and their practical realization. In Proceedings of the IEEE 12th International Symposium on Applied Machine Intelligence and Informatics (SAMI), Herl’any, Slovakia, 23–25 January 2014. [Google Scholar]

- Dilli, R.; Reddy, P.C.S. Implementation of security features in MANETs using SHA-3 standard algorithm. In Proceedings of the International Conference on Computation System and Information Technology for Sustainable Solutions (CSITSS), Bangalore, India, 6–8 October 2016; pp. 455–458. [Google Scholar]

- Stinson, D.R. Cryptography Theory and Practice, 2nd ed.; CRC Press LLC: Boca Raton, FL, USA, 2002. [Google Scholar]

- Saito, M.; Matsumoto, M. SIMD-Oriented Fast Mersenne Twister: A 128-bit Pseudo Random Number Generator; Springer: Berlin, Germany, 2008. [Google Scholar]

- Stallings, W. The whirlpool secure hash function. J. Cryptol. 2006, 30, 55–67. [Google Scholar] [CrossRef]

- Eletra Energy Solutions. Cronos 7023. Available online: http://www.eletraenergy.com/index.php?q=node/27 (accessed on 20 June 2015).

- Feng, J.; Lian, B.; Zhao, H. Smart power management and delay reduction for target tracking in wireless sensor networks. J. Electr. Comput. Eng. 2014, 2014, 1–8. [Google Scholar] [CrossRef]

- Khanafer, M.; Al-Anbagi, I.; Mouftah, H.T. An optimized WSN design for latency-critical smart grid applications. J. Sens. 2017, 2017, 1–8. [Google Scholar] [CrossRef]

- Zel, L.V. Guidelines for Implementing Substation Automation Using IEC61850, the International Power System Information Modeling Standard; Electric Power Research Institute (EPRI): Palo Alto, CA, USA, 2004. [Google Scholar]

- Microchip Technology Inc. ZENA Wireless Adapter—2.4 GHz MRF24J40. Available online: http://www.microchip.com/DevelopmentTools/ProductDetails.aspx?PartNO=AC182015-1 (accessed on 10 February 2017).

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Araújo, P.R.C.; Filho, R.H.; Rodrigues, J.J.P.C.; Oliveira, J.P.C.M.; Braga, S.A. Infrastructure for Integration of Legacy Electrical Equipment into a Smart-Grid Using Wireless Sensor Networks. Sensors 2018, 18, 1312. https://doi.org/10.3390/s18051312

De Araújo PRC, Filho RH, Rodrigues JJPC, Oliveira JPCM, Braga SA. Infrastructure for Integration of Legacy Electrical Equipment into a Smart-Grid Using Wireless Sensor Networks. Sensors. 2018; 18(5):1312. https://doi.org/10.3390/s18051312

Chicago/Turabian StyleDe Araújo, Paulo Régis C., Raimir Holanda Filho, Joel J. P. C. Rodrigues, João P. C. M. Oliveira, and Stephanie A. Braga. 2018. "Infrastructure for Integration of Legacy Electrical Equipment into a Smart-Grid Using Wireless Sensor Networks" Sensors 18, no. 5: 1312. https://doi.org/10.3390/s18051312