Near-Field Chipless Radio-Frequency Identification (RFID) Sensing and Identification System with Switching Reading

Abstract

:1. Introduction

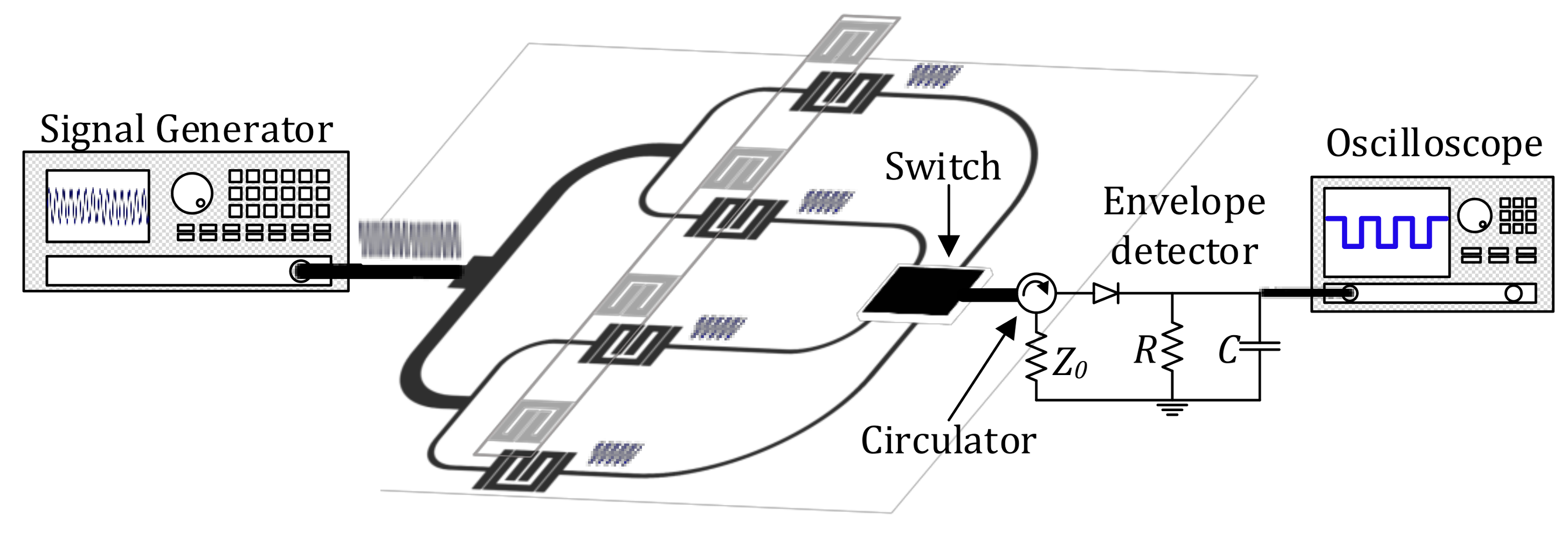

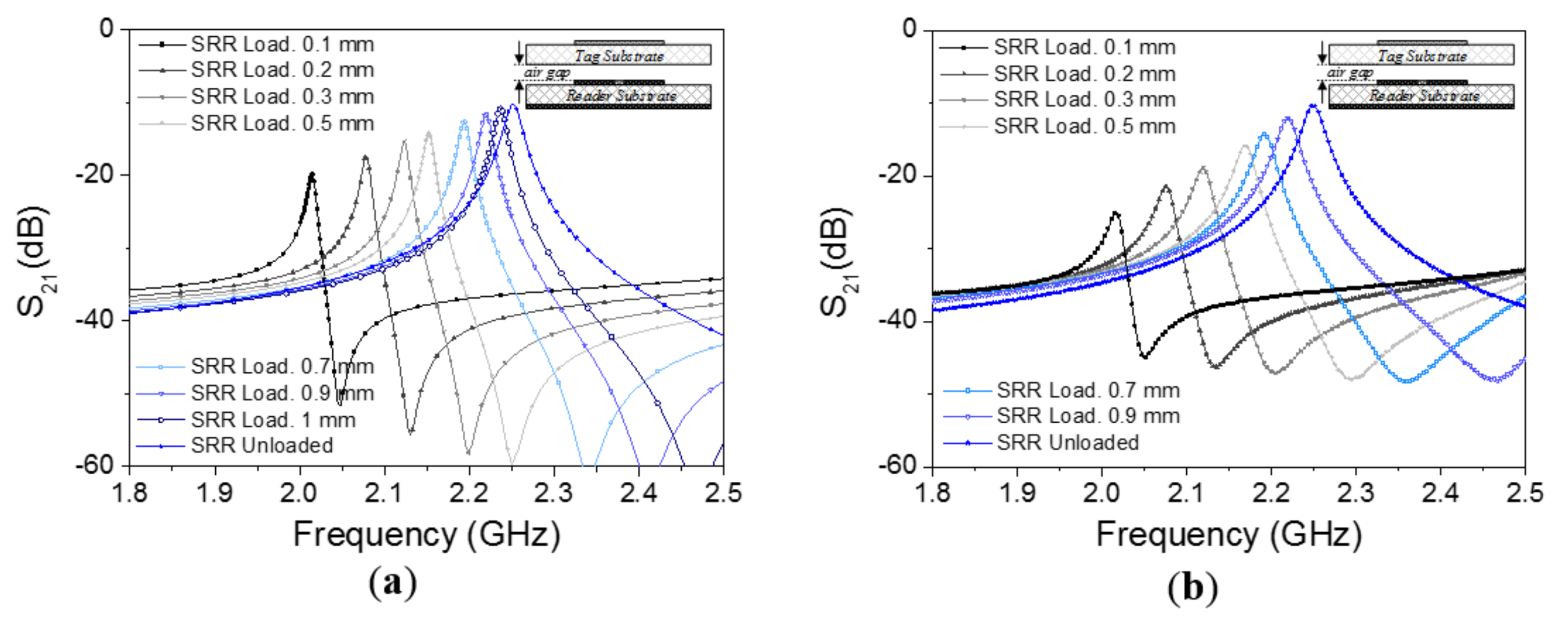

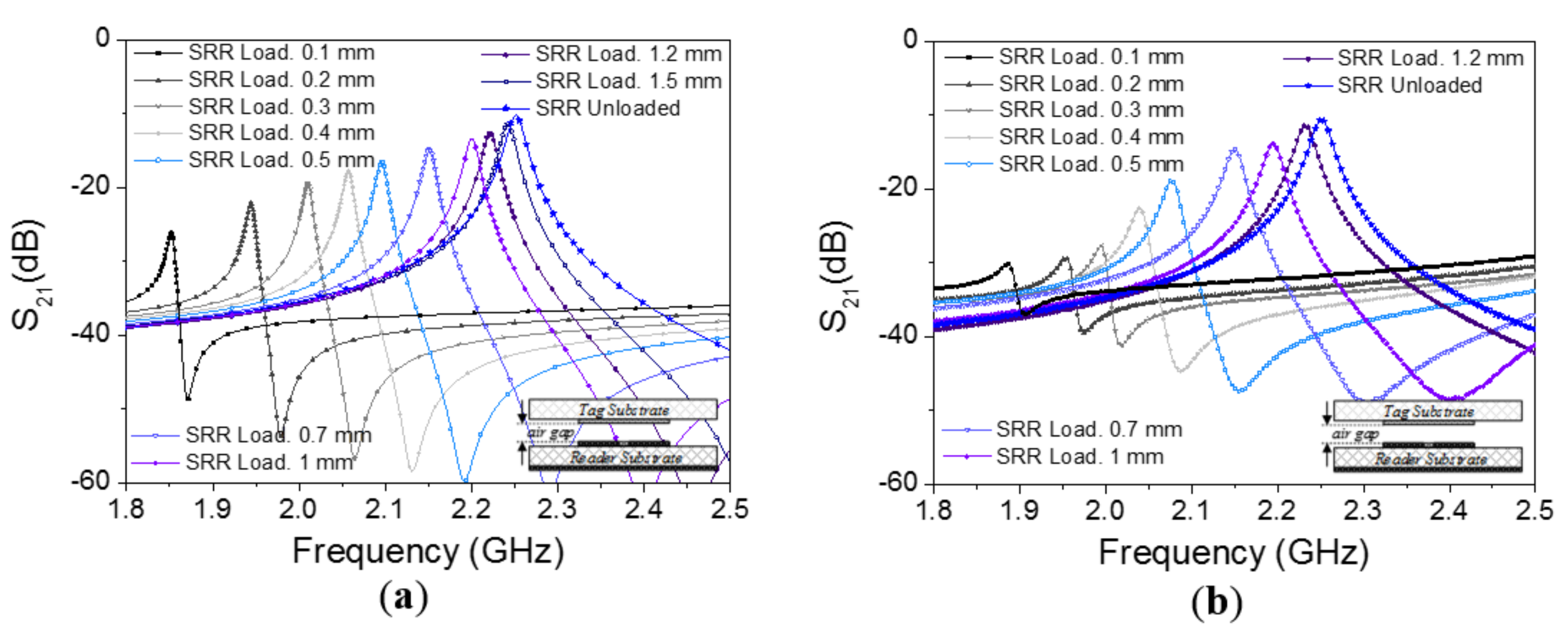

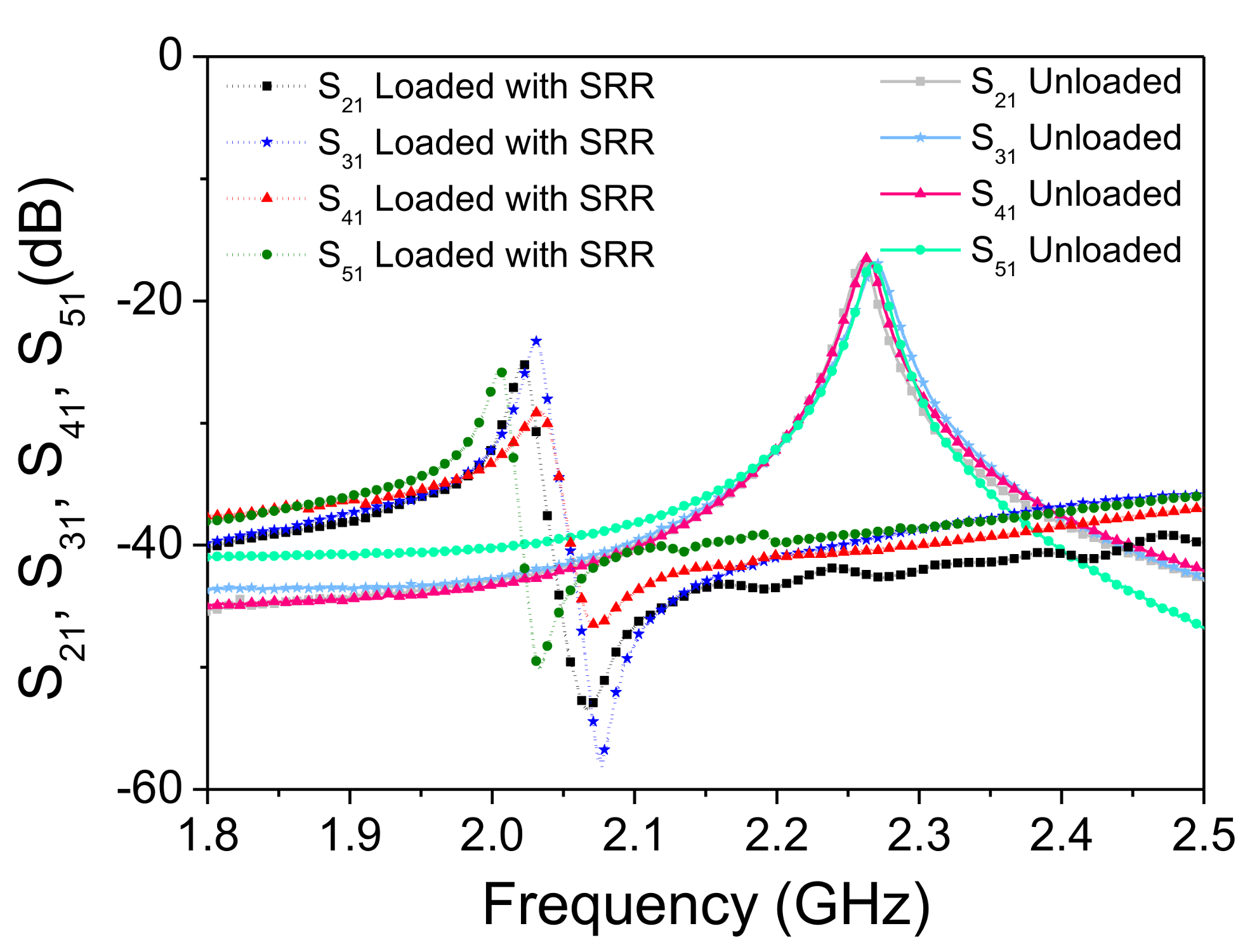

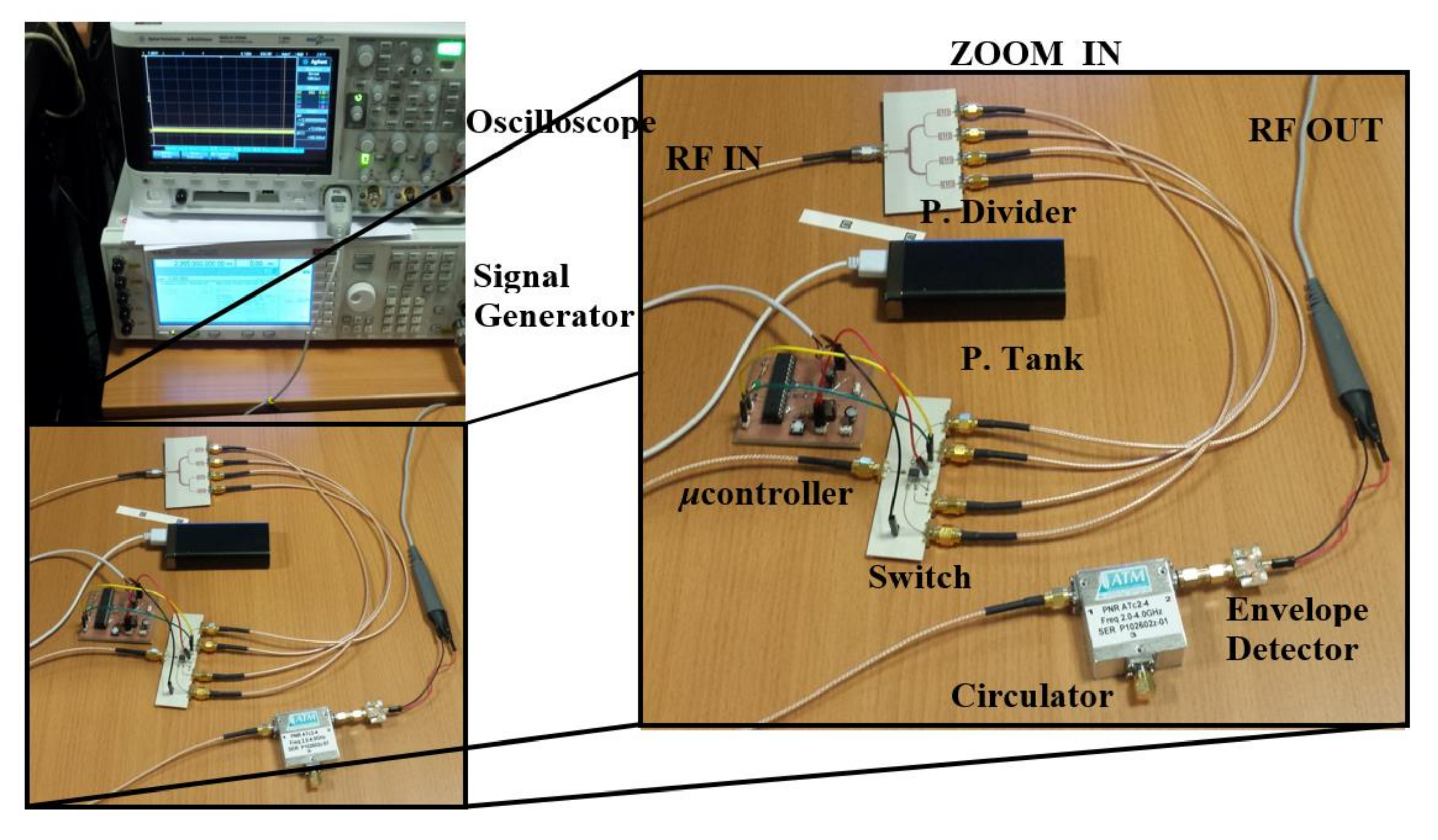

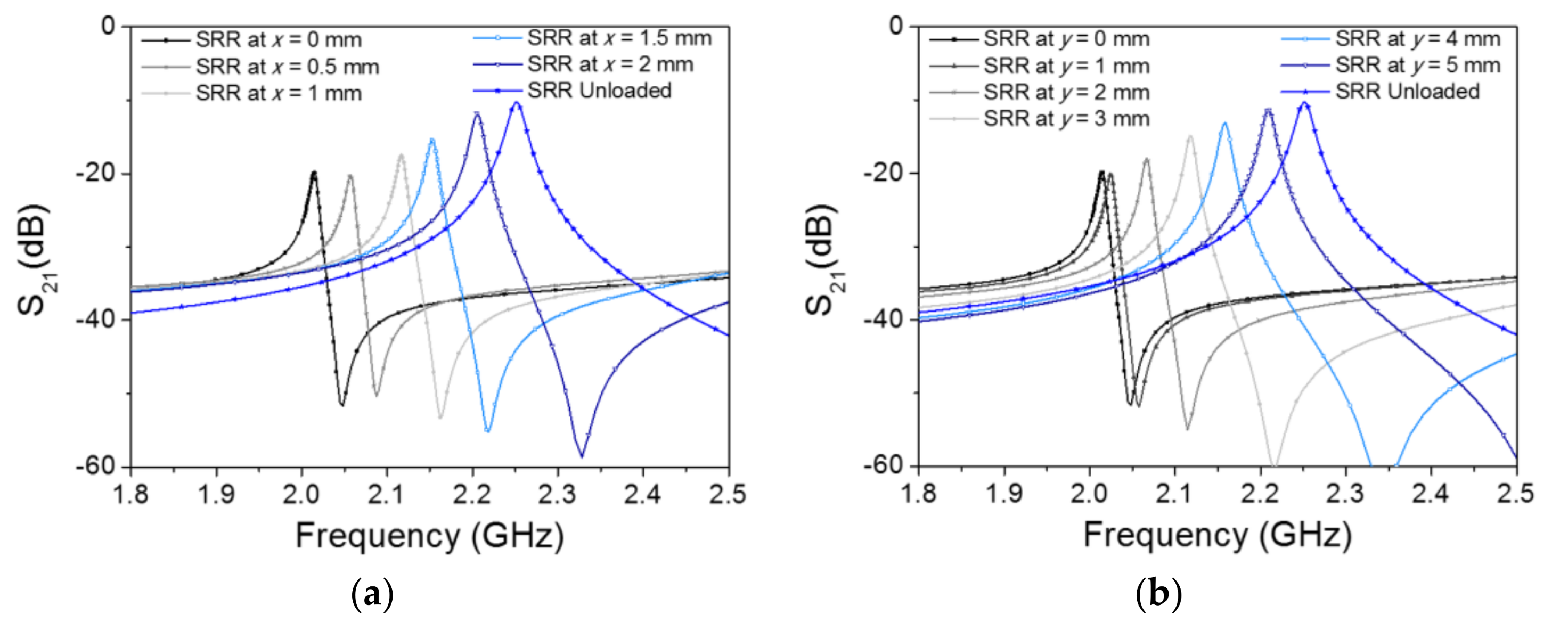

2. The Proposed Chipless-RFID Sensing and Identification System

3. System Validation

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Finkenzeller, K. RFID Handbook: Fundamentals and Applications in Contactless Smart Cards, Radio-Frequency Identification and Near-Field Communication, 3rd ed.; John Wiley: New York, NY, USA, 2010; ISBN 9780470665121. [Google Scholar]

- Hunt, V.D.; Puglia, A.; Puglia, M. RFID: A Guide to Radiofrequency Identification, 1st ed.; John Wiley: New York, NY, USA, 2007; ISBN 9780470107645. [Google Scholar]

- Preradovic, S.; Karmakar, N.C. Chipless RFID: Bar code of the future. IEEE Microw. Mag. 2010, 11, 87–97. [Google Scholar] [CrossRef]

- Preradovic, S.; Karmakar, N.C. Multiresonator-Based Chipless RFID: Barcode of the Future, 1st ed.; Springer: London, UK, 2011; ISBN 9781461420958. [Google Scholar]

- Karmakar, N.C.; Koswatta, R.; Kalansuriya, P.; Azim, R.E. Chipless RFID Reader Architecture, 1st ed.; Artech House: Boston, MA, USA, 2013; ISBN 9781608075614. [Google Scholar]

- Perret, E. Radio Frequency Identification and Sensors: From RFID to Chipless RFID, 1st ed.; John Wiley: New York, NY, USA, 2014; ISBN 9781848217669. [Google Scholar]

- Rezaiesarlak, R.; Manteghi, M. Chipless RFID: Design Procedure and Detection Techniques; Springer: London, UK, 2015; ISBN 9783319101699. [Google Scholar]

- Karmakar, N.C.; Zomorrodi, M.; Divarathne, C. Advanced Chipless RFID; John Wiley: New York, NY, USA, 2016; ISBN 9781119227311. [Google Scholar]

- Hartmann, C.S. A global SAW ID tag with large data capacity. In Proceedings of the IEEE Ultrasonics Symposium, Munich, Germany, 8–11 October 2002; pp. 65–69. [Google Scholar]

- Chamarti, A.; Varahramyan, K. Transmission delay line based ID generation circuit for RFID applications. IEEE Microw. Wirel. Compon. Lett. 2006, 16, 588–590. [Google Scholar] [CrossRef]

- Schüßler, M.; Damm, C.; Jakoby, R. Periodically LC loaded lines for RFID backscatter applications. In Proceedings of the Metamaterials, Rome, Italy, 22–26 October 2007; pp. 103–106. [Google Scholar]

- Saldanha, N.; Malocha, D.C. Design Parameters for SAW multi-tone frequency coded reflectors. In Proceedings of the IEEE Ultrasonics Symposium, New York, NY, USA, 28–31 October 2007; pp. 2087–2090. [Google Scholar]

- Schüßler, M.; Damm, C.; Maasch, M.; Jakoby, R. Performance evaluation of left-handed delay lines for RFID backscatter applications. In Proceedings of the IEEE MTT-S International Microwave Symposium, Atlanta, GA, USA, 15–20 June 2008; pp. 177–180. [Google Scholar]

- Harma, S.; Plessky, V.P.; Hartmann, C.S.; Steichen, W. Z-path SAW RFID tag. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2008, 55, 208–213. [Google Scholar] [CrossRef] [PubMed]

- Tao, H.; Weibiao, W.; Haodong, W.; Yongan, S. Reflection and scattering characteristics of reflectors in SAW tags. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2008, 55, 1387–1390. [Google Scholar] [CrossRef]

- Harma, S.; Plessky, V.P.; Li, X.; Hartogh, P. Feasibility of ultra-wideband SAW RFID tags meeting FCC rules. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2012, 56, 812–820. [Google Scholar] [CrossRef] [PubMed]

- Herraiz-Martínez, F.J.; Paredes, F.; Zamora, G.; Martín, F.; Bonache, J. Printed magnetoinductive-wave (MIW) delay lines for chipless RFID applications. IEEE Trans. Antennas Propag. 2012, 60, 5075–5082. [Google Scholar] [CrossRef]

- Tedjini, S.; Perret, E.; Vena, A.; Kaddout, D. Mastering the electromagnetic signature of chipless RFID tags. In Chipless and Conventional Radiofrequency Identification, 1st ed.; IGI Global: Hershey, PA, USA, 2012; ISBN 9781466616165. [Google Scholar]

- Preradovic, S.; Balbin, I.; Karmakar, N.C.; Swiegers, G.F. Multiresonator-based chipless RFID system for low-cost item tracking. IEEE Trans. Microw. Theory Tech. 2009, 57, 1411–1419. [Google Scholar] [CrossRef]

- Preradovic, S.; Karmakar, N.C. Design of chipless RFID tag for operation on flexible laminates. IEEE Antennas Wirel. Propag. Lett. 2010, 9, 207–210. [Google Scholar] [CrossRef]

- Rance, O.; Siragusa, R.; Lemaître-Auger, P.; Perret, E. Toward RCS magnitude level coding for chipless RFID. IEEE Trans. Microw. Theory Tech. 2016, 64, 2315–2325. [Google Scholar] [CrossRef]

- McVay, J.; Hoorfar, A.; Engheta, N. Space-filling curve RFID tags. In Proceedings of the 2006 IEEE Radio Wireless Symposium, San Diego, CA, USA, 17–19 January 2006; pp. 199–202. [Google Scholar]

- Jalaly, I.; Robertson, D. Capacitively-tuned split microstrip resonators for RFID barcodes. In Proceedings of the European Microwave Conferences, Paris, France, 3–7 October 2005; pp. 4–7. [Google Scholar]

- Jang, H.S.; Lim, W.G.; Oh, K.S.; Moon, S.M.; Yu, J.W. Design of low-cost chipless system using printable chipless tag with electromagnetic code. IEEE Microw. Wirel. Compon. Lett. 2010, 20, 640–642. [Google Scholar] [CrossRef]

- Vena, A.; Perret, E.; Tedjini, S. A fully printable chipless RFID tag with detuning correction technique. IEEE Microw. Wirel. Compon. Lett. 2012, 22, 209–211. [Google Scholar] [CrossRef]

- Vena, A.; Perret, E.; Tedjini, S. Design of compact and auto-compensated single-layer chipless RFID tag. IEEE Trans. Microw. Theory Tech. 2012, 60, 2913–2924. [Google Scholar] [CrossRef]

- Vena, A.; Perret, E.; Tedjini, S. High-capacity chipless RFID tag insensitive to the polarization. IEEE Trans. Antennas Propag. 2012, 60, 4509–4515. [Google Scholar] [CrossRef]

- Khan, M.M.; Tahir, F.A.; Farooqui, M.F.; Shamim, A.; Cheema, H.M. 3.56-bits/cm2 compact inkjet printed and application specific chipless RFID tag. IEEE Antennas Wirel. Propag. Lett. 2016, 15, 1109–1112. [Google Scholar] [CrossRef]

- Islam, M.A.; Karmakar, N.C. A novel compact printable dual-polarized chipless RFID system. IEEE Trans. Microw. Theory Tech. 2012, 60, 2142–2151. [Google Scholar] [CrossRef]

- Rezaiesarlak, R.; Manteghi, M. Complex-natural-resonance-based design of chipless RFID tag for high-density data. IEEE Trans. Antennas Propag. 2014, 62, 898–904. [Google Scholar] [CrossRef]

- Svanda, M.; Machac, J.; Polivka, M.; Havlicek, J. A comparison of two ways to reducing the mutual coupling of chipless RFID tag scatterers. In Proceedings of the 21st International Conference Microwave Radar & Wireless Communication (MIKON), Krakow, Poland, 9–11 May 2016; pp. 1–4. [Google Scholar]

- Vena, A.; Perret, E.; Tedjini, S. Chipless RFID tag using hybrid coding technique. IEEE Trans. Microw. Theory Tech. 2011, 59, 3356–3364. [Google Scholar] [CrossRef]

- Vena, A.; Perret, E.; Tedjini, S. A compact chipless RFID tag using polarization diversity for encoding and sensing. In Proceedings of the IEEE International Conference on RFID, Orlando, FL, USA, 3–5 April 2012; pp. 191–197. [Google Scholar]

- Balbin, I.; Karmakar, N.C. Phase-encoded chipless RFID transponder for large scale low cost applications. IEEE Microw. Wirel. Compon. Lett. 2009, 19, 509–511. [Google Scholar] [CrossRef]

- Genovesi, S.; Costa, F.; Monorchio, A.; Manara, G. Chipless RFID tag exploiting multifrequency delta-phase quantization encoding. IEEE Antennas Wirel. Propag. Lett. 2015, 15, 738–741. [Google Scholar] [CrossRef]

- Herrojo, C.; Naqui, J.; Paredes, F.; Martín, F. Spectral Signature Barcodes based on S-shaped Split Ring Resonators (S-SRR). EPJ Appl. Metamat. 2016, 3, 1–6. [Google Scholar] [CrossRef]

- Herrojo, C.; Naqui, J.; Paredes, F.; Martín, F. Spectral signature barcodes implemented by multi-state multi-resonator circuits for chipless RFID tags. In Proceedings of the IEEE MTT-S International Microwave Symposium, San Francisco, CA, USA, 22–27 May 2016. [Google Scholar]

- Herrojo, C.; Paredes, F.; Mata-Contreras, J.; Zuffanelli, S.; Martín, F. Multi-state multi-resonator spectral signature barcodes implemented by means of S-shaped Split Ring Resonators (S-SRR). IEEE Trans. Microw. Theory Tech. 2017, 65, 2341–2352. [Google Scholar] [CrossRef]

- El-Awamry, A.; Khaliel, M.; Fawky, A.; El-Hadidy, M.; Kaiser, T. Novel notch modulation algorithm for enhancing the chipless RFID tags coding capacity. In Proceedings of the IEEE International Conference on RFID, San Diego, CA, USA, 15–17 April 2015; pp. 25–31. [Google Scholar]

- Herrojo, C.; Mata-Contreras, J.; Paredes, F.; Martín, F. Near-Field chipless RFID encoders with sequential bit reading and high data capacity. In Proceedings of the IEEE MTT-S International Microwave Symposium, Honolulu, HI, USA, 4–9 June 2017. [Google Scholar]

- Herrojo, C.; Mata-Contreras, J.; Paredes, F.; Núñez, A.; Ramón, E.; Martín, F. Near-field chipless-RFID tags with sequential bit reading implemented in plastic substrates. J. Magn. Magn. Mater. 2017. [Google Scholar] [CrossRef]

- Herrojo, C.; Mata-Contreras, J.; Paredes, F.; Martín, F. Microwave encoders for chipless RFID and angular velocity sensors based on S-shaped split ring resonators (S-SRRs). IEEE Sens. J. 2017, 17, 4805–4813. [Google Scholar] [CrossRef]

- Herrojo, C.; Mata-Contreras, J.; Paredes, F.; Martín, F. High data density and capacity in chipless radiofrequency identification (chipless-RFID) tags based on double-chains of S-shaped split ring resonators (S-SRRs). EPJ Appl. Metamat. 2017, 4, 1–6. [Google Scholar] [CrossRef]

- Herrojo, C.; Mata-Contreras, J.; Paredes, F.; Martín, F. Near-field chipless RFID system with high data capacity for security and authentication applications. IEEE Trans. Microw. Theory Tech. 2017, 65, 5298–5308. [Google Scholar] [CrossRef]

- Herrojo, C.; Mata-Contreras, J.; Paredes, F.; Núñez, A.; Ramon, E.; Martín, F. Near-field chipless-RFID system with erasable/programable 40-bit tags inkjet printed on paper substrates. IEEE Microw. Wirel. Compon. Lett. 2018, 28, 272–274. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paredes, F.; Herrojo, C.; Mata-Contreras, J.; Moras, M.; Núñez, A.; Ramon, E.; Martín, F. Near-Field Chipless Radio-Frequency Identification (RFID) Sensing and Identification System with Switching Reading. Sensors 2018, 18, 1148. https://doi.org/10.3390/s18041148

Paredes F, Herrojo C, Mata-Contreras J, Moras M, Núñez A, Ramon E, Martín F. Near-Field Chipless Radio-Frequency Identification (RFID) Sensing and Identification System with Switching Reading. Sensors. 2018; 18(4):1148. https://doi.org/10.3390/s18041148

Chicago/Turabian StyleParedes, Ferran, Cristian Herrojo, Javier Mata-Contreras, Miquel Moras, Alba Núñez, Eloi Ramon, and Ferran Martín. 2018. "Near-Field Chipless Radio-Frequency Identification (RFID) Sensing and Identification System with Switching Reading" Sensors 18, no. 4: 1148. https://doi.org/10.3390/s18041148