Robust Segmentation of Planar and Linear Features of Terrestrial Laser Scanner Point Clouds Acquired from Construction Sites

Abstract

:1. Introduction

- Outliers exist in construction site point clouds due to data artefacts, occlusions and dust.

- Many object-based recognition models depend on the 3D/4D planned building information model (BIM), which is neither readily available nor accurate, and the as-built is not necessarily constructed to plan. The compliance of the as-built to the planned specifications, must in fact be checked through the monitoring and control process; hence, a monitoring and control process solely reliant on the details of the planned is not desirable.

- Most planar and linear classification and segmentation algorithms use inconsistent and subjectively-defined thresholds (see Section 2.2.2), which change from one dataset to another, and hence, are not generalizable for every environment.

2. Literature Review

2.1. TLS in Construction Management

2.1.1. Application of TLS to Measure Key Performance Indicators

2.1.2. State-of-the-Art in Automated TLS Object Extraction

2.2. Automated Classification and Segmentation of Planar and Linear Features from TLS Point Clouds

- Planar (linear) classification: The process of extracting points that locally follow a planar (linear) pattern within a point cloud dataset. In other words, points that locally follow a planar (linear) pattern are classified as planar (linear) regardless of their specific parametric equation.

- Planar (linear) segmentation: The process of grouping the classified planar (linear) points that follow a similar planar (linear) parametric equation. In other words, points that are globally on the same plane (line).

2.2.1. Robust PCA-Based Point Cloud Classification

2.2.2. Planar and Linear Segmentation

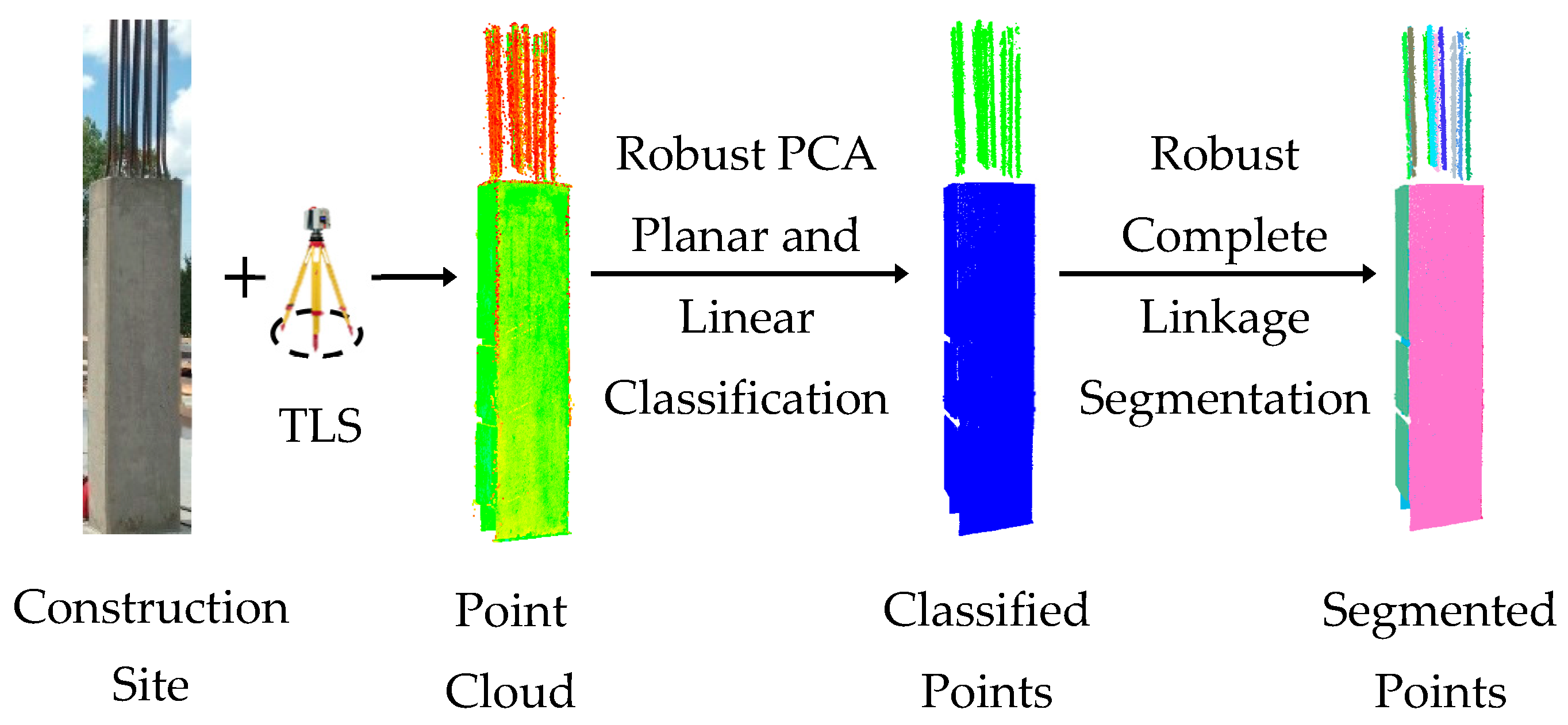

3. Methodology

3.1. Robust Planar and Linear Classification

3.1.1. Neighbourhood Definition

3.1.2. Robust PCA

3.2. Robust Planar and Linear Segmentation

3.2.1. Attribute Definition

3.2.2. New Iterative Complete Linkage for Point Cloud Clustering

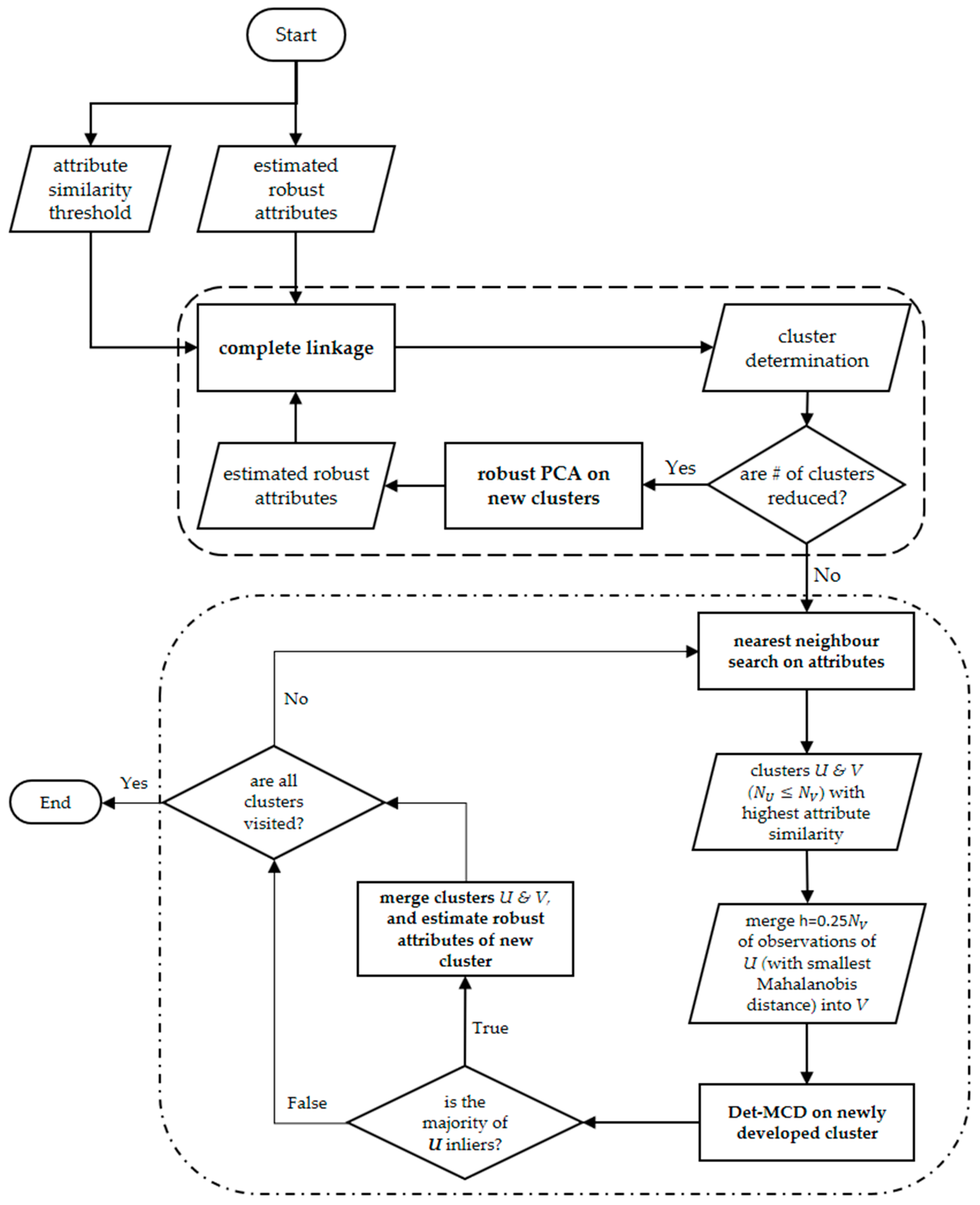

3.2.3. Systematic Choice of Initial Similarity Threshold

3.2.4. Robust Complete Linkage

3.2.5. Spatial Continuity of Clusters

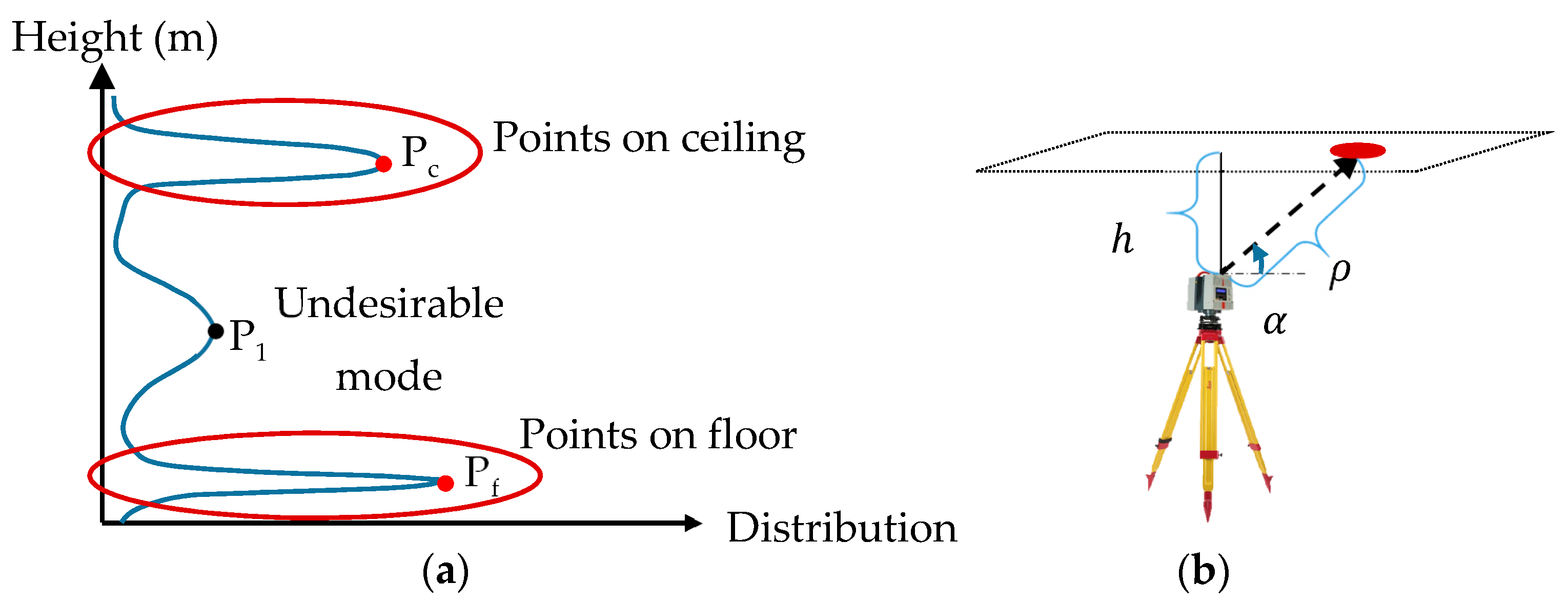

3.3. Robust Extraction of Flat Slab Floors

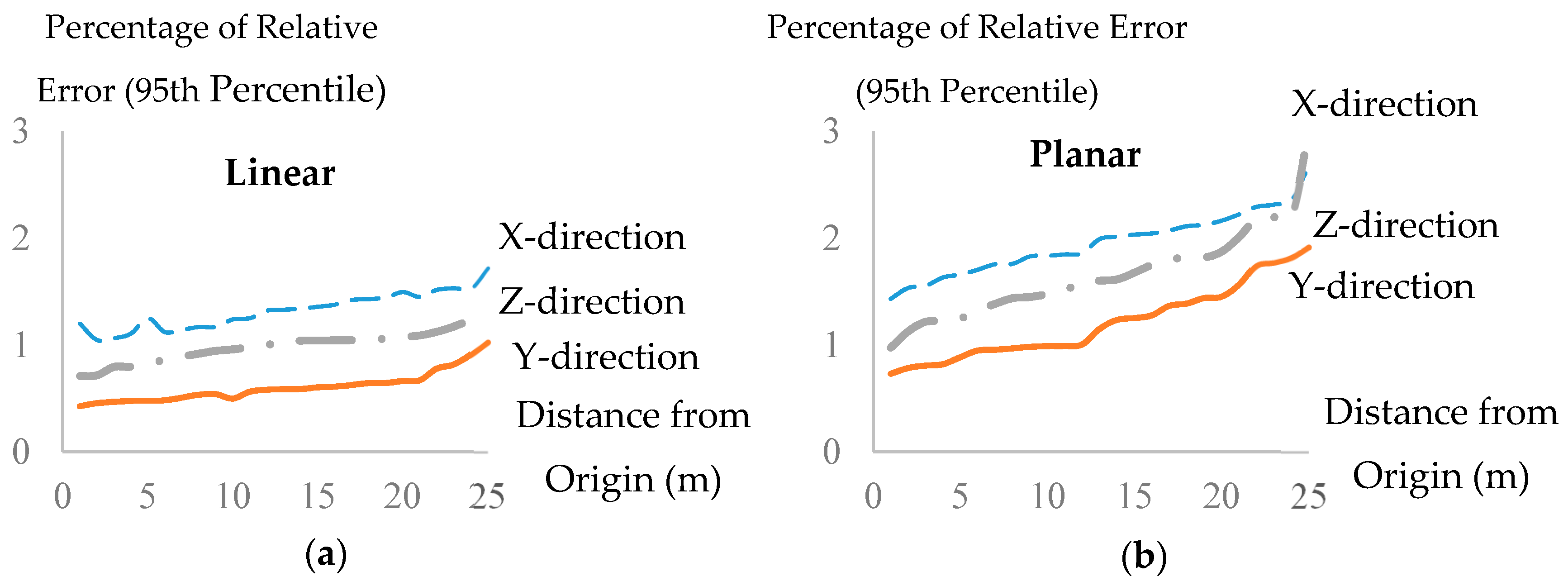

3.4. Method of Validation of Results

4. Experiment Description

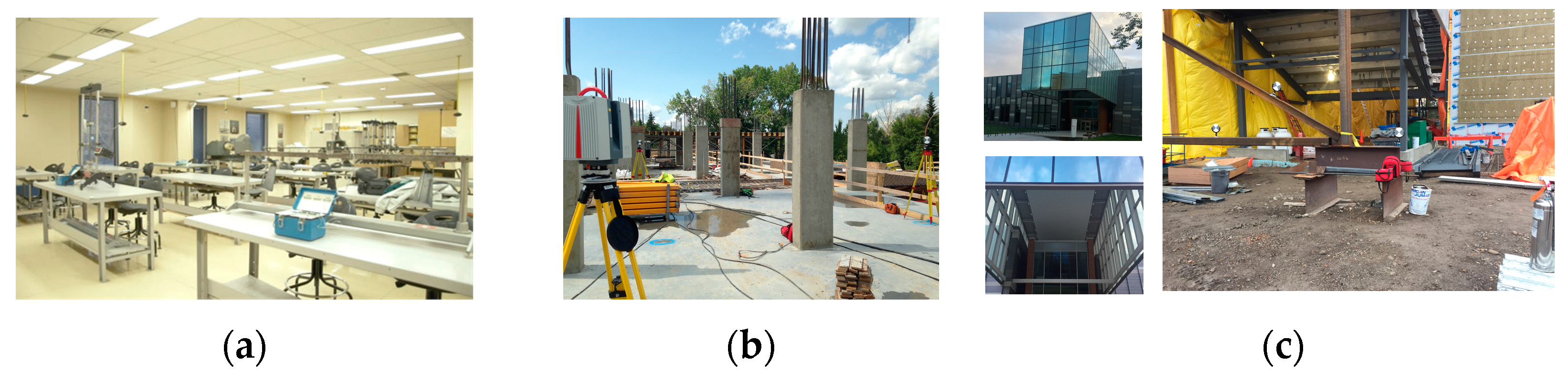

4.1. Experiment 1: Mechanics of Material Laboratory

4.2. Experiment 2: Graduate Student Hall of Residence Construction Site

4.3. Experiment 3: Taylor Institute of Teaching and Learning Construction Site

5. Experimental Results

5.1. Experiment 1: Mechanics of Materials Laboratory

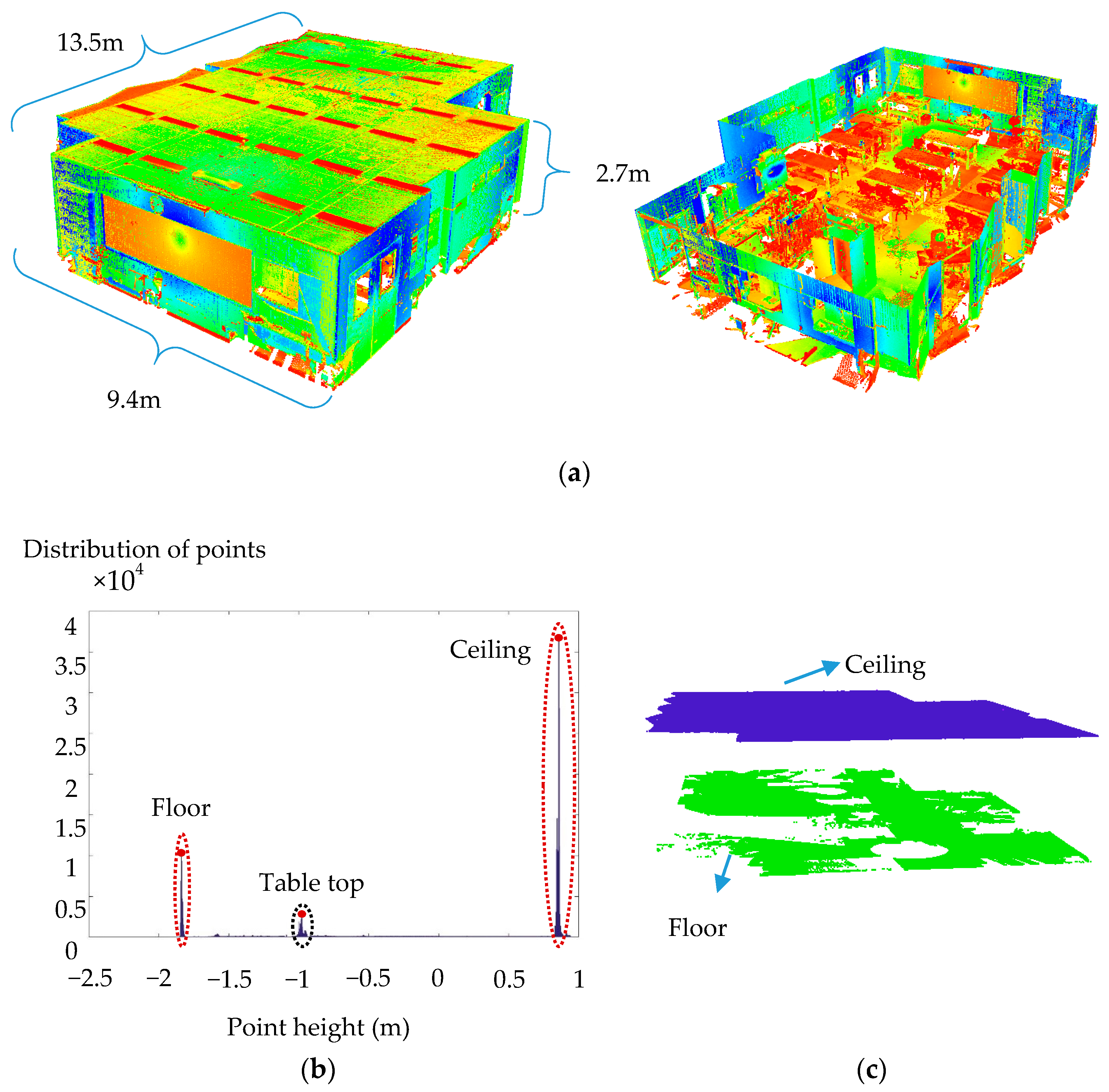

5.1.1. Robust Floor and Ceiling Extraction

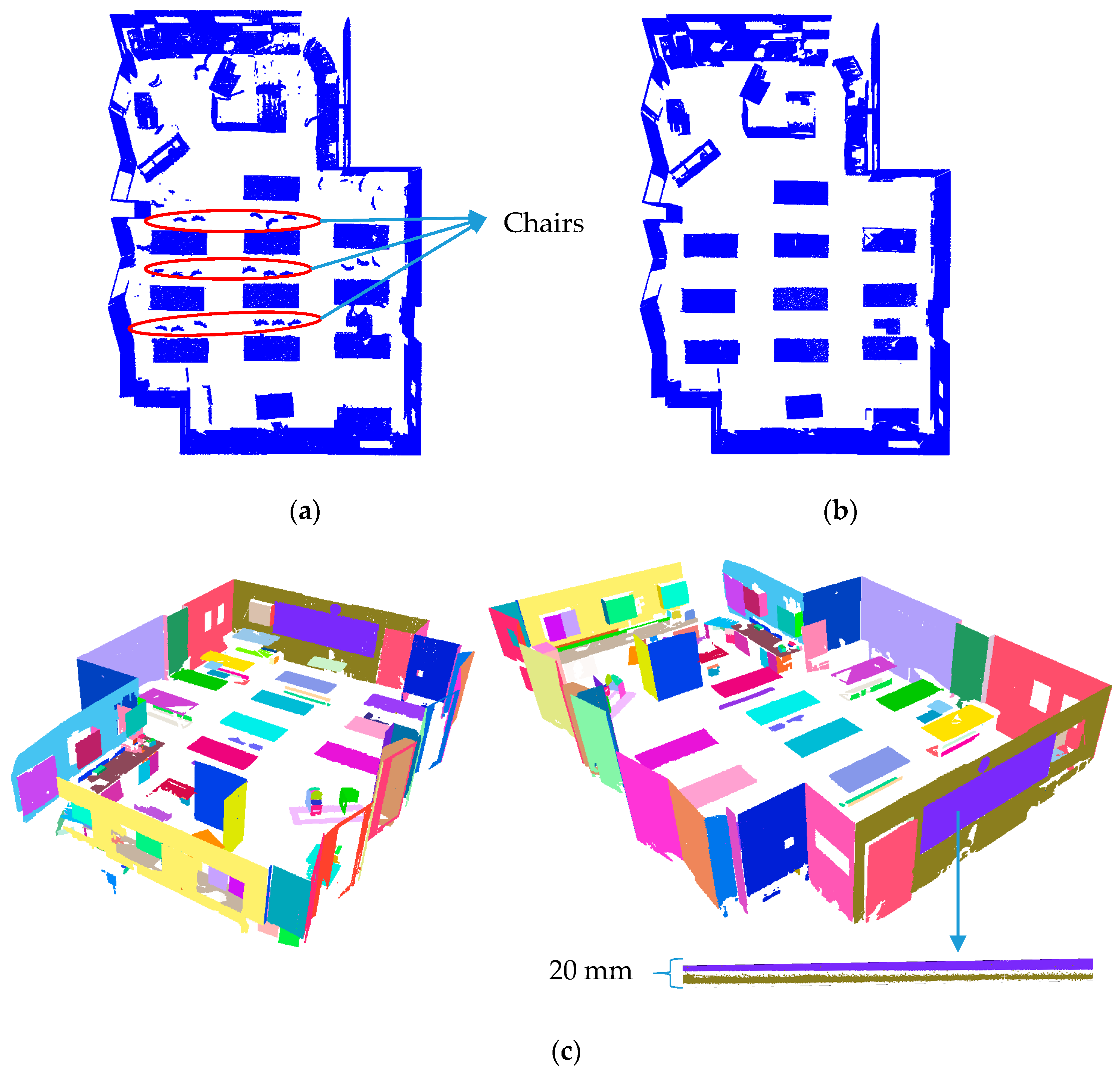

5.1.2. Robust Planar Classification and Segmentation

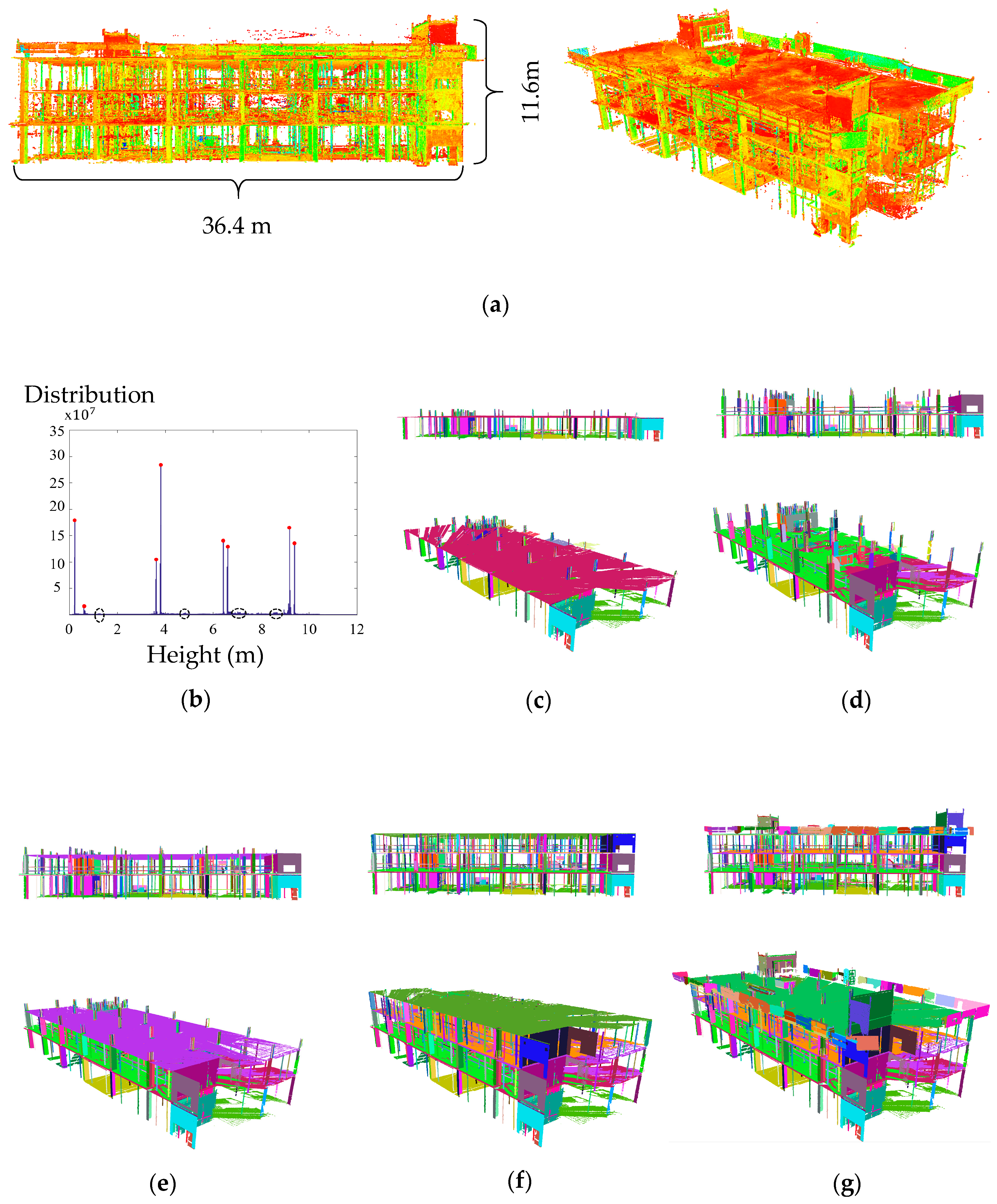

5.2. Experiment 2: Graduate Student Hall of Residence

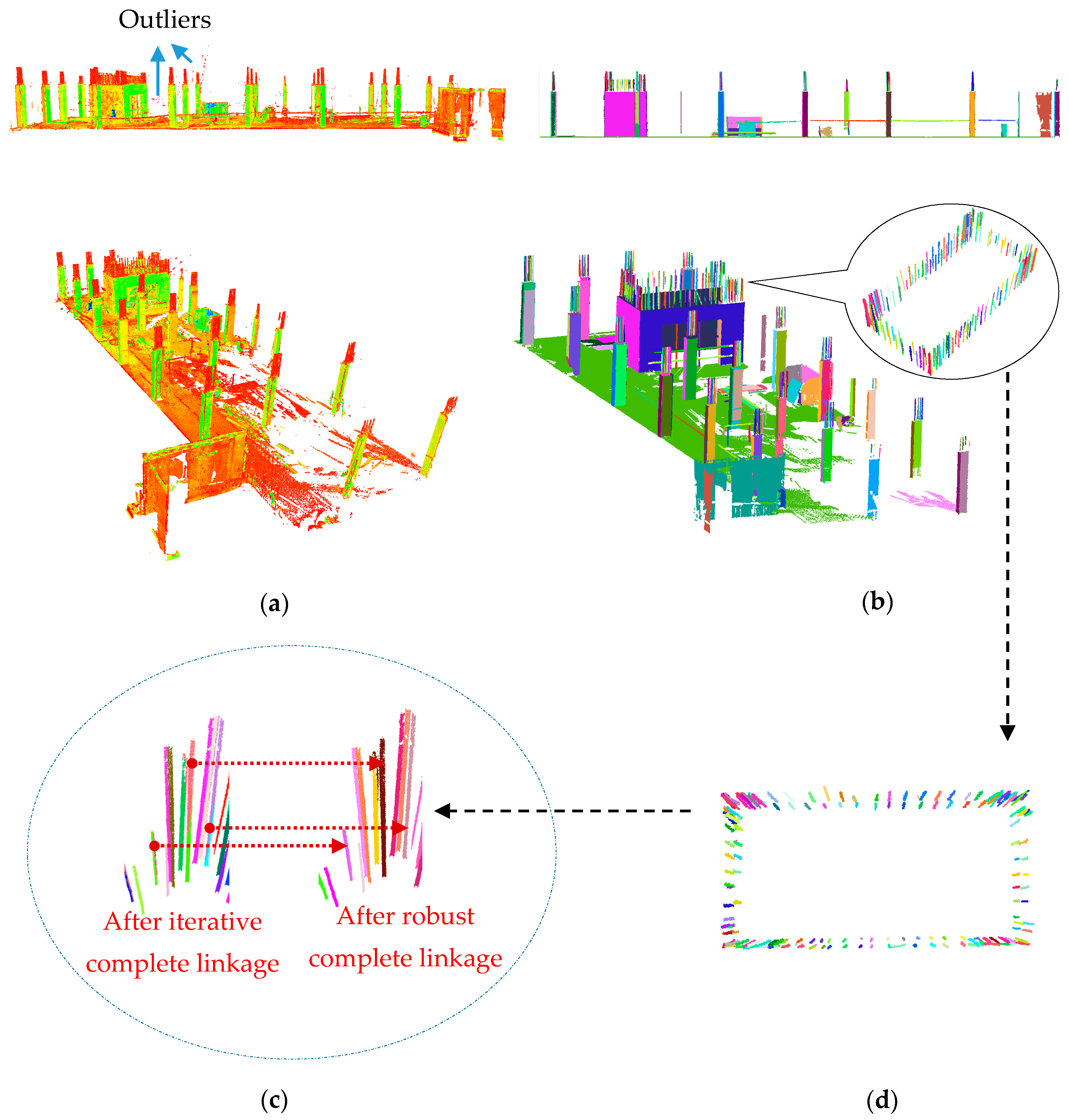

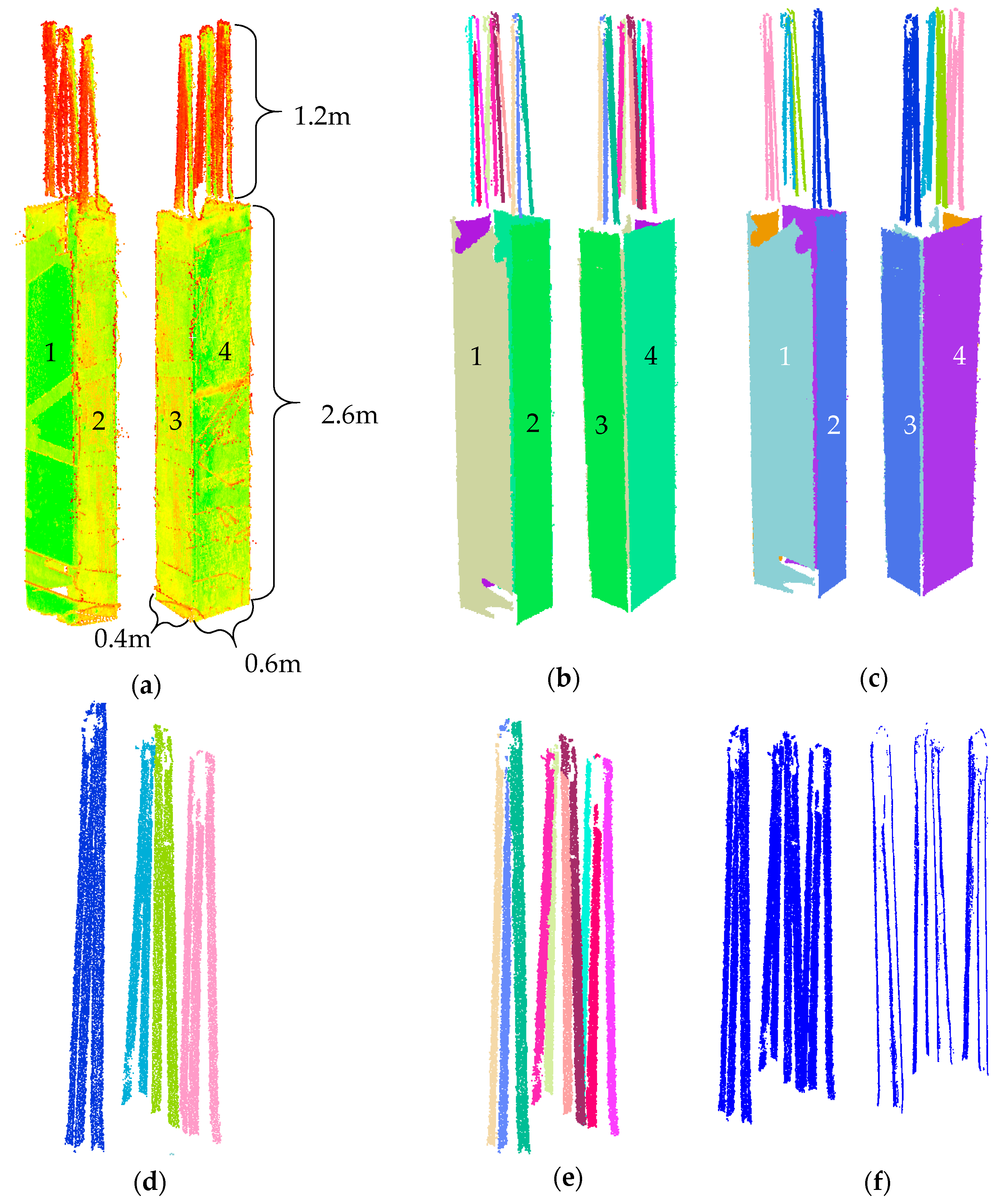

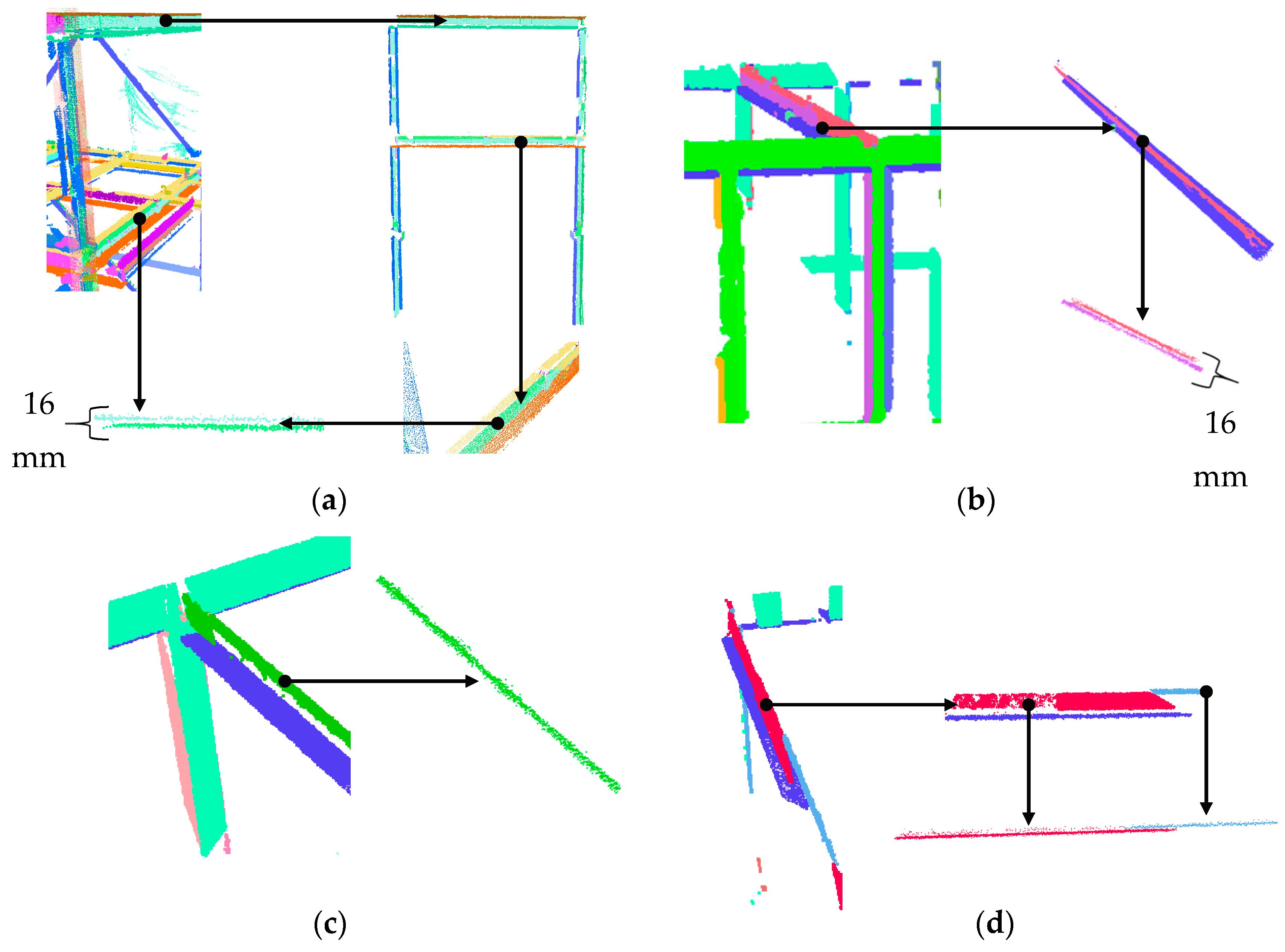

5.2.1. Epoch 1: Linear Segmentation Results

5.2.2. Epoch 1: Comparative Evaluation of Rebar Segmentation Using Robust Complete Linkage

5.2.3. Epochs 1–6: Robust Floor Extraction

5.2.4. Epochs 2–6: Robust Planar and Linear Segmentation

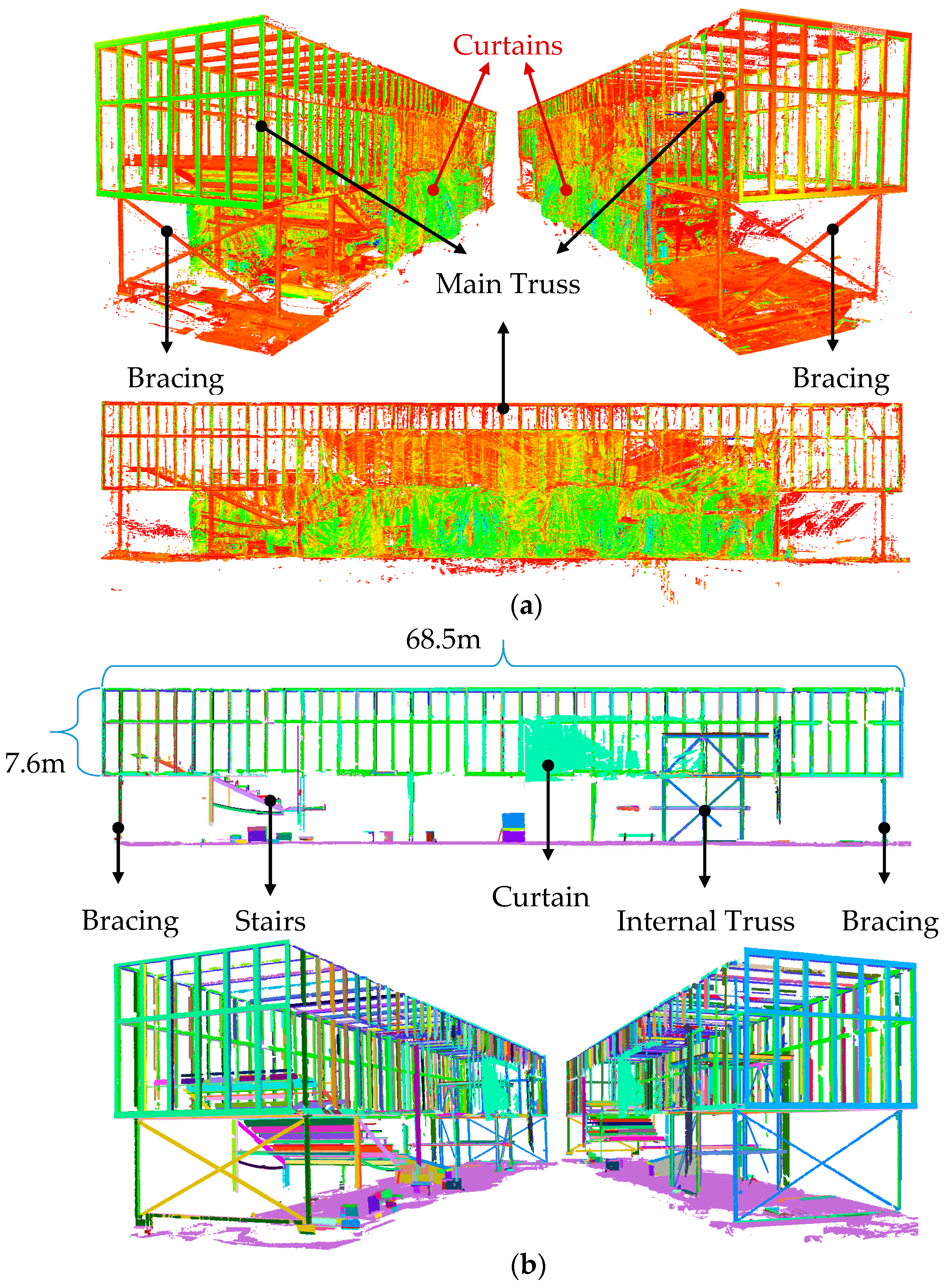

5.3. Experiment 3: Taylor Institute of Teaching and Learning

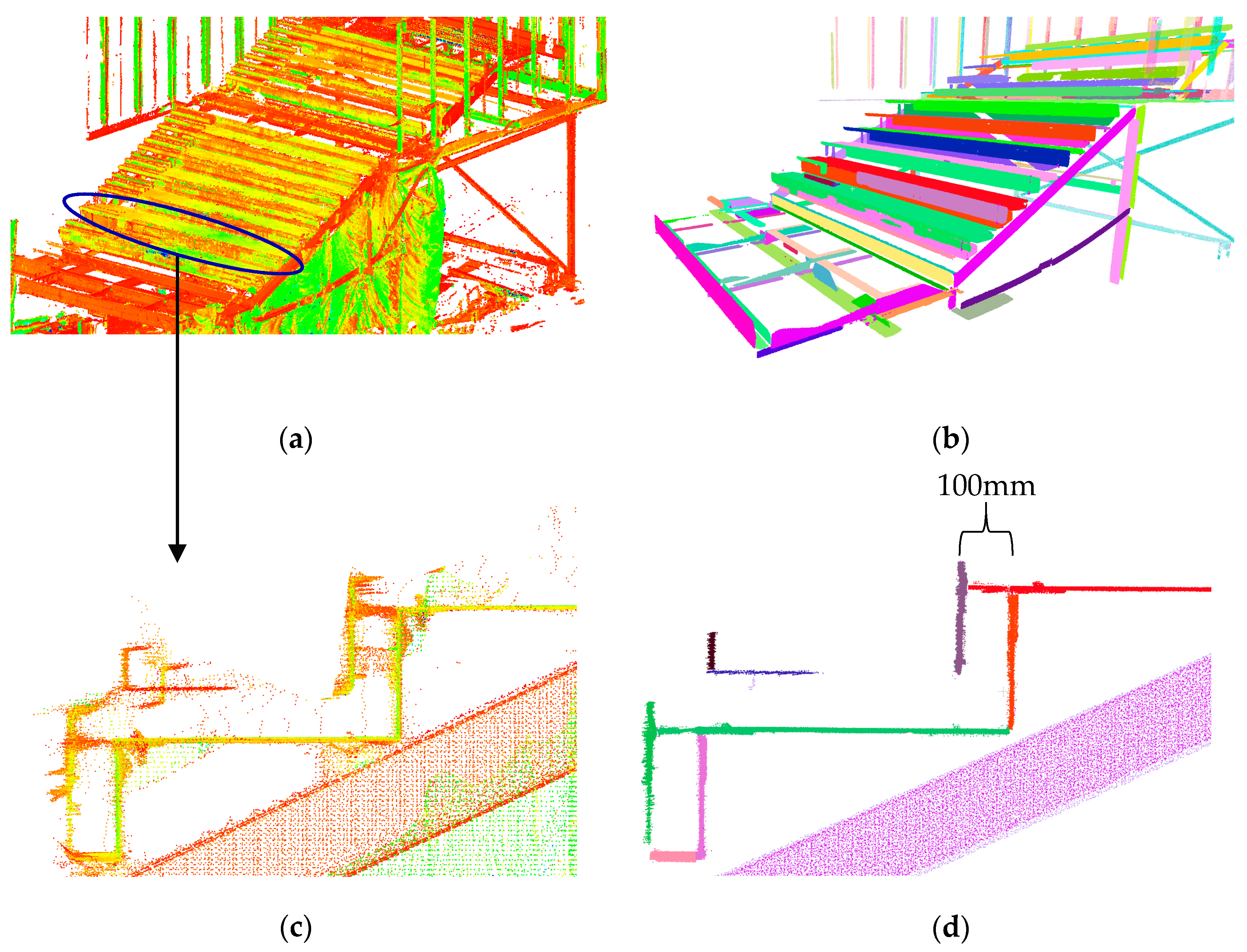

5.3.1. Stairs: Robust Planar Segmentation

5.3.2. Internal Truss: Robust Planar Segmentation

5.3.3. Evaluation of H-Section Web Segmentation Using Robust Complete Linkage

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Maalek, R.; Sadeghpour, F. Accuracy assessment of Ultra-Wide Band technology in tracking static resources in indoor construction scenarios. Autom. Constr. 2013, 30, 170–183. [Google Scholar] [CrossRef]

- Golparvar-Fard, M.; Peña-Mora, F.; Savarese, S. Automated progress monitoring using unordered daily construction photographs and IFC-based building information models. J. Comput. Civ. Eng. 2012, 29, 04014025. [Google Scholar] [CrossRef]

- Maalek, R.; Sadeghpour, F. Accuracy assessment of ultra-wide band technology in locating dynamic resources in indoor scenarios. Autom. Constr. 2016, 63, 12–26. [Google Scholar] [CrossRef]

- Choy, E.; Ruwanpura, J.Y. Predicting construction productivity using situation-based simulation models. Can. J. Civ. Eng. 2006, 33, 1585–1600. [Google Scholar] [CrossRef]

- Nunnally, S.W. Construction Methods and Management, 8th ed.; Pearson Education: London, UK, 2010; pp. 517–518. [Google Scholar]

- Maalek, R.; Ruwanpura, J.; Ranaweera, K. Evaluation of the state-of-the-art automated construction progress monitoring and control systems. In Proceedings of the Construction Research Congress: Construction in a Global Network, Atlanta, GA, USA, 19–21 May 2014; pp. 1023–1032. [Google Scholar]

- Ballast, D.K. Handbook of Construction Tolerances; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Bosché, F.; Biotteau, B. Terrestrial laser scanning and continuous wavelet transform for controlling surface flatness in construction—A first investigation. Adv. Eng. Inform. 2015, 29, 591–601. [Google Scholar] [CrossRef]

- Mill, T.; Alt, A.; Liias, R. Combined 3D building surveying techniques–terrestrial laser scanning (TLS) and total station surveying for BIM data management purposes. J. Civ. Eng. Manag. 2013, 19 (Suppl. 1), S23–S32. [Google Scholar] [CrossRef]

- Hullo, J.F.; Thibault, G.; Boucheny, C. Advances in multi-sensor scanning and visualization of complex plants: The utmost case of a reactor building. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2015, 40, 163. [Google Scholar] [CrossRef]

- Bosché, F.; Ahmed, M.; Turkan, Y.; Haas, C.T.; Haas, R. The value of integrating Scan-to-BIM and Scan-vs-BIM techniques for construction monitoring using laser scanning and BIM: The case of cylindrical MEP components. Autom. Constr. 2015, 49, 201–213. [Google Scholar] [CrossRef]

- Pătrăucean, V.; Armeni, I.; Nahangi, M.; Yeung, J.; Brilakis, I.; Haas, C. State of research in automatic as-built modelling. Adv. Eng. Inform. 2015, 29, 162–171. [Google Scholar] [CrossRef]

- Shahi, A.; West, J.S.; Haas, C.T. On site 3D marking for construction activity tracking. Autom. Constr. 2013, 30, 136–143. [Google Scholar] [CrossRef]

- Son, H.; Bosché, F.; Kim, C. As-built data acquisition and its use in production monitoring and automated layout of civil infrastructure: A survey. Adv. Eng. Inform. 2015, 29, 172–183. [Google Scholar] [CrossRef]

- Vosselman, G.; Gorte, B.; Sithole, G.; Rabbani, T. Recognizing structure in laser scanner point clouds. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2004, 46, 33–38. [Google Scholar]

- Lari, Z.; Habib, A. An adaptive approach for the segmentation and extraction of planar and linear/cylindrical features from laser scanning data. ISPRS J. Photogramm. Remote Sens. 2014, 93, 192–212. [Google Scholar] [CrossRef]

- Vo, A.V.; Truong-Hong, L.; Laefer, D.F.; Bertolotto, M. Octree-based region growing for point cloud segmentation. ISPRS J. Photogramm. Remote Sens. 2015, 104, 88–100. [Google Scholar] [CrossRef]

- Illingworth, J.; Kittler, J. A survey of the Hough transform. Comput. Vis. Graph. Image Process. 1988, 44, 87–116. [Google Scholar] [CrossRef]

- Tarsha-Kurdi, F.; Landes, T.; Grussenmeyer, P. Hough-transform and extended ransac algorithms for automatic detection of 3d building roof planes from lidar data. In Proceedings of the ISPRS Workshop on Laser Scanning–Silvilaser, Espoo, Finland, 12–14 September 2007; pp. 407–412. [Google Scholar]

- Serneels, S.; Verdonck, T. Principal component analysis for data containing outliers and missing elements. Comput. Stat. Data Anal. 2008, 52, 1712–1727. [Google Scholar] [CrossRef]

- Hubert, M.; Rousseeuw, P.J.; Verdonck, T. A deterministic algorithm for robust location and scatter. J. Comput. Graph. Stat. 2012, 21, 618–637. [Google Scholar] [CrossRef]

- Schnabel, R.; Wahl, R.; Klein, R. Efficient RANSAC for point-cloud shape detection. Comput. Graph. Forum 2007, 26, 214–226. [Google Scholar] [CrossRef]

- Liu, Y.J.; Zhang, J.B.; Hou, J.C.; Ren, J.C.; Tang, W.Q. Cylinder detection in large-scale point cloud of pipeline plant. IEEE Trans. Visual. Comput. Graph. 2013, 19, 1700–1707. [Google Scholar] [CrossRef] [PubMed]

- Chen, D.; Zhang, Z.; Mathiopoulos, P.T. A methodology for automated segmentation and reconstruction of urban 3-D buildings from ALS point clouds. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2014, 7, 1–19. [Google Scholar] [CrossRef]

- Poux, F.; Neuville, R.; Van Wersch, L.; Nys, G.A.; Billen, R. 3D point clouds in archaeology: Advances in acquisition, processing and knowledge integration applied to quasi-planar objects. Geosciences 2017, 7, 96. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, L.; Mathiopoulos, P.T.; Liu, F.; Zhang, L.; Li, S.; Liu, H. A hierarchical methodology for urban facade parsing from TLS point clouds. ISPRS J. Photogramm. Remote Sens. 2017, 123, 75–93. [Google Scholar] [CrossRef]

- Nurunnabi, A.; Belton, D.; West, G. Robust statistical approaches for local planar surface fitting in 3D laser scanning data. ISPRS J. Photogramm. Remote Sens. 2014, 96, 106–122. [Google Scholar] [CrossRef]

- Tóvári, D.; Pfeifer, N. Segmentation based robust interpolation—A new approach to laser filtering. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2005, 36, 79–84. [Google Scholar]

- Rottensteiner, F.; Trinder, J.; Clode, S.; Kubik, K. Using the Dempster Shafer method for the fusion of TLS data and multispectral images for building detection. Inf. Fusion 2005, 6, 283–300. [Google Scholar] [CrossRef]

- Pu, S.; Vosselman, G. Automatic extraction of building features from terrestrial laser scanning. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2006, 36, 25–27. [Google Scholar]

- Belton, D.; Lichti, D. Classification and segmentation of terrestrial lasers canner point clouds using local variance information. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2006, 36, 44–49. [Google Scholar]

- Su, Y.T.; Bethel, J.; Hu, S. Octree-based segmentation for terrestrial TLS point cloud data in industrial applications. ISPRS J. Photogramm. Remote Sens. 2016, 113, 59–74. [Google Scholar] [CrossRef]

- Filin, S.; Pfeifer, N. Segmentation of airborne laser scanning data using a slope adaptive neighborhood. ISPRS J. Photogramm. Remote Sens. 2006, 60, 71–80. [Google Scholar] [CrossRef]

- Kim, C.; Habib, A.; Mrstik, P. New Approach for Planar Patch Segmentation using Airborne Laser Data. In Proceedings of the ASPRS, Tampa, FL, USA, 7–11 May 2007. [Google Scholar]

- Bremer, M.; Wichmann, V.; Rutzinger, M. Eigenvalue and graph-based object extraction from mobile laser scanning point clouds. ISPRS Ann. Photogramm. Remote Sens. Spat. Inf. Sci. 2013, II-5/W2, 55–60. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, L.; Fang, T.; Mathiopoulos, P.T.; Tong, X.; Qu, H.; Xiao, Z.; Li, F.; Chen, D. A multiscale and hierarchical feature extraction method for terrestrial laser scanning point cloud classification. IEEE Trans. Geosci. Remote Sens. 2015, 53, 2409–2425. [Google Scholar] [CrossRef]

- Kim, C.; Habib, A.; Pyeon, M.; Kwon, G.R.; Jung, J.; Heo, J. Segmentation of planar surfaces from laser scanning data using the magnitude of normal position vector for adaptive neighborhoods. Sensors 2016, 16, 140. [Google Scholar] [CrossRef] [PubMed]

- Maronna, R.A.; Martin, D.R.; Yohai, V.J. Robust Statistics: Theory and Methods; Wiley: London, UK, 2006. [Google Scholar]

- Butler, R.W.; Davies, P.L.; Jhun, M. Asymptotics for the Minimum Covariance Determinant Estimator. Ann. Stat. 1993, 21, 1385–1400. [Google Scholar] [CrossRef]

- Davies, P.L. The asymptotics of Rousseeuw’s minimum volume ellipsoid. Ann. Stat. 1992, 20, 1828–1843. [Google Scholar] [CrossRef]

- Jensen, W.A.; Birch, J.B.; Woodall, W.H. Monitoring correlation within linear profiles using mixed models. J. Qual. Technol. 2008, 40, 167–183. [Google Scholar] [CrossRef]

- Rousseeuw, P.J.; Van Driessen, K. A fast algorithm for the Minimum Covariance Determinant estimator. Technometrics 1999, 41, 212–223. [Google Scholar] [CrossRef]

- Maalek, R.; Lichti, D.D.; Ruwanpura, J. Robust classification and segmentation of planar and linear features for construction site progress monitoring and structural dimensional compliance control. ISPRS Ann. Photogramm. Remote Sens. Spat. Inf. Sci. 2015, II-3/W5, 129–136. [Google Scholar] [CrossRef]

- Patil, A.K.; Holi, P.; Lee, S.K.; Chai, Y.H. An adaptive approach for the reconstruction and modelling of as-built 3D pipelines from point clouds. Autom. Constr. 2017, 75, 65–78. [Google Scholar] [CrossRef]

- Wang, J.; Shan, J. Segmentation of LiDAR point clouds for building extraction. In Proceedings of the ASPRS Annual Conference, Baltimore, MD, USA, 9–13 March 2009; pp. 9–13. [Google Scholar]

- Teboul, O.; Simon, L.; Koutsourakis, P.; Paragios, N. Segmentation of building facades using procedural shape priors. In Proceedings of the IEEE Computer Society Conference on Computer Vision and Pattern Recognition (CVPR), San Francisco, CA, USA, 13–18 June 2010; pp. 3105–3112. [Google Scholar]

- Rabbani, T.; van den Heuvel, F.; Vosselmann, G. Segmentation of point clouds using smoothness constraint. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2006, 36, 248–253. [Google Scholar]

- Deschaud, J.E.; Goulette, F. A fast and accurate plane detection algorithm for large noisy point clouds using filtered normals and voxel growing. In Proceedings of the 3D Processing, Visualization and Transmission Conference, Paris, France, 17–20 May 2010. [Google Scholar]

- Song, H.; Feng, H.Y. A global clustering approach to point cloud simplification with a specified data reduction ratio. Comput.-Aided Des. 2008, 40, 281–292. [Google Scholar] [CrossRef]

- Shi, B.Q.; Liang, J.; Liu, Q. Adaptive simplification of point cloud using k-means clustering. Comput.-Aided Des. 2011, 43, 910–922. [Google Scholar] [CrossRef]

- Haralick, R.M.; Shapiro, L.G. Computer and Robot Vision; Addison-Wesley: New York, NY, USA, 1992. [Google Scholar]

- Bayne, C.K.; Beauchamp, J.J.; Begovich, C.L.; Kane, V.E. Monte Carlo comparisons of selected clustering procedures. Pattern Recog. 1980, 12, 51–62. [Google Scholar] [CrossRef]

- Golden, R.R.; Meehl, P.E. Detection of biological sex: An empirical test of cluster methods. Multivariate Behav. Res. 1980, 15, 475–496. [Google Scholar] [CrossRef] [PubMed]

- Hartigan, P.M. Statistical algorithms: Algorithm AS 217. Computation of the dip statistic to test for unimodality. Appl. Stat. 1985, 34, 320–325. [Google Scholar] [CrossRef]

- Everitt, B.S.; Landau, S.; Leese, M.; Stahl, D. Cluster Analysis, 5th ed.; John Wiley & Sons: London, UK, 2011; pp. 43–110. [Google Scholar]

- Johnson, S.C. Hierarchical clustering schemes. Psychometrika 1967, 32, 241–254. [Google Scholar] [CrossRef] [PubMed]

- Steinbach, M.; Ertoz, L.; Kumar, V. The Challenges of Clustering in High Dimensional Data. In New Directions in Statistical Physics; Wille, L.T., Ed.; Springer: Berlin/Heidelberg, Germany, 2004. [Google Scholar]

- Nurunnabi, A.; Belton, D.; West, G. Diagnostics based principal component analysis for robust plane fitting in laser data. In Proceedings of the 2013 16th International Conference on Computer and Information Technology (ICCIT), Khulna, Bangladesh, 8–10 March 2014; pp. 484–489. [Google Scholar]

- Verboven, S.; Hubert, M. LIBRA: A MATLAB library for robust analysis. Chemometr. Intell. Lab. Syst. 2005, 75, 127–136. [Google Scholar] [CrossRef]

- Scagliarini, M. Multivariate process capability using principal component analysis in the presence of measurement errors. ASTA Adv. Stat. Anal. 2011, 95, 113–128. [Google Scholar] [CrossRef]

- Hellton, K.H.; Thoresen, M. The impact of measurement error on principal component analysis. Scand. J. Stat. 2014, 41, 1051–1063. [Google Scholar] [CrossRef]

- Mikhail, E.M.; Ackermann, F.E. Observations and Least Squares; Harper and Row: New York, NY, USA, 1976. [Google Scholar]

- Mahalanobis, P.C. On the Generalized Distance in Statistics. Available online: http://bayes.acs.unt.edu:8083/BayesContent/class/Jon/MiscDocs/1936_Mahalanobis.pdf (accessed on 6 March 2018).

- Edelsbrunner, H.; Kirkpatrick, D.; Seidel, R. On the shape of a set of points in the plane. IEEE Trans. Inf. Theory 1983, 29, 551–559. [Google Scholar] [CrossRef]

- Fayed, M.; Mouftah, H.T. Localised alpha-shape computations for boundary recognition in sensor networks. Ad Hoc Netw. 2009, 7, 1259–1269. [Google Scholar] [CrossRef]

- Shapira, L.; Avidan, S.; Shamir, A. Mode-detection via median-shift. In Proceedings of the 2009 IEEE 12th International Conference on Computer Vision, Kyoto, Japan, 29 September–2 October 2009; pp. 1909–1916. [Google Scholar]

- Macher, H.; Landes, T.; Grussenmeyer, P. From point clouds to building information models: 3D semi-automatic econstruction of indoors of existing buildings. Appl. Sci. 2017, 7, 1030. [Google Scholar] [CrossRef]

- Hampel, F.R. The influence curve and its role in robust estimation. J. Am. Stat. Assoc. 1974, 69, 383–393. [Google Scholar] [CrossRef]

- Leica HDS6100 TLS Datasheet and Key Performance Specifications. Available online: http://w3.leica-geosystems.com/downloads123/hds/hds/HDS6100/brochures/Leica_HDS6100_brochure_us.pdf (accessed on 6 March 2018).

- Soudarissanane, S.; Lindenbergh, R.; Menenti, M.; Teunissen, P. Scanning geometry: Influencing factor on the quality of terrestrial laser scanning points. ISPRS J. Photogramm. Remote Sens. 2011, 66, 389–399. [Google Scholar] [CrossRef]

- Rousseeuw, P.J.; Hubert, M. Robust statistics for outlier detection. Wiley Interdiscip. Rev.: Data Mining Knowl. Discov. 2011, 1, 73–79. [Google Scholar] [CrossRef]

- Sprent, P.; Smeeton, N.C. Applied Nonparametric Statistical Methods; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Olsen, D.L.; Denlen, D. Advanced Data Mining Techniques; Springer: New York, NY, USA, 2008; p. 138. [Google Scholar]

| Experiment | Epoch | # of Scan-Stations | Total # of Points (millions) | Average # of Targets per Scan Location | Registration Precision (mm) |

|---|---|---|---|---|---|

| Experiment 1: MML | 1 | 3 | 30 | 4 | 1.2 |

| Experiment 2: GSHR | 1 | 3 | 37 | 7 | 1.5 |

| 2 | 3 | 153 | 6 | 1.4 | |

| 3 | 4 | 201 | 8 | 2.2 | |

| 4 | 3 | 115 | 8 | 1.5 | |

| 5 | 5 | 358 | 6 | 1.8 | |

| 6 | 3 | 128 | 7 | 1.2 | |

| Experiment 3: TITL | 1 | 6 | 537 | 5 | 1.7 |

| Planar Classification Results | Linear Classification Results | Overall | |||||||

| Precision | Recall | Accuracy | Precision | Recall | Accuracy | Precision | Recall | Accuracy | |

| Epoch 1 | 95.0 | 94.6 | 91.1 | 92.6 | 91.6 | 98.4 | 94.7 | 94.3 | 94.7 |

| Epoch 2 | 95.4 | 93.9 | 91.0 | 90.9 | 90.9 | 97.7 | 94.7 | 93.5 | 94.6 |

| Epoch 3 | 93.7 | 95.2 | 91.1 | 93.1 | 92.2 | 98.6 | 93.7 | 94.9 | 94.8 |

| Epoch 4 | 94.5 | 96.4 | 92.7 | 90.1 | 94.1 | 97.8 | 93.7 | 96.0 | 95.4 |

| Epoch 5 | 96.5 | 94.3 | 92.1 | 93.0 | 93.4 | 98.5 | 96.0 | 94.2 | 95.5 |

| Epoch 6 | 94.5 | 93.0 | 92.3 | 92.5 | 91.0 | 95.1 | 93.9 | 92.4 | 93.7 |

| Overall | 95.1 | 94.8 | 91.8 | 91.7 | 92.4 | 97.8 | 94.6 | 94.4 | 95.0 |

| Planar Segmentation Results | Linear Segmentation Results | Overall | |||||||

| Precision | Recall | Accuracy | Precision | Recall | Accuracy | Precision | Recall | Accuracy | |

| Epoch 1 | 97.6 | 98.1 | 96.0 | 95.7 | 97.3 | 93.7 | 97.4 | 98.1 | 95.8 |

| Epoch 2 | 98.3 | 99.7 | 98.1 | 96.1 | 99.3 | 95.7 | 98.0 | 99.6 | 97.7 |

| Epoch 3 | 97.2 | 98.1 | 95.6 | 95.4 | 95.6 | 92.0 | 97.0 | 97.9 | 95.2 |

| Epoch 4 | 96.4 | 97.1 | 93.9 | 97.1 | 98.9 | 96.2 | 96.5 | 97.4 | 94.3 |

| Epoch 5 | 98.1 | 99.8 | 98.0 | 95.8 | 99.7 | 95.7 | 97.8 | 99.8 | 97.7 |

| Epoch 6 | 96.9 | 97.2 | 94.7 | 94.9 | 98.5 | 93.9 | 96.2 | 97.6 | 94.4 |

| Overall | 97.5 | 98.5 | 96.2 | 96.0 | 98.7 | 95.0 | 97.2 | 98.6 | 96.1 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maalek, R.; Lichti, D.D.; Ruwanpura, J.Y. Robust Segmentation of Planar and Linear Features of Terrestrial Laser Scanner Point Clouds Acquired from Construction Sites. Sensors 2018, 18, 819. https://doi.org/10.3390/s18030819

Maalek R, Lichti DD, Ruwanpura JY. Robust Segmentation of Planar and Linear Features of Terrestrial Laser Scanner Point Clouds Acquired from Construction Sites. Sensors. 2018; 18(3):819. https://doi.org/10.3390/s18030819

Chicago/Turabian StyleMaalek, Reza, Derek D Lichti, and Janaka Y Ruwanpura. 2018. "Robust Segmentation of Planar and Linear Features of Terrestrial Laser Scanner Point Clouds Acquired from Construction Sites" Sensors 18, no. 3: 819. https://doi.org/10.3390/s18030819