Quality Control Procedure Based on Partitioning of NMR Time Series

Abstract

:1. Introduction

2. Materials and Methods

2.1. Phantom Data

2.2. Quantification of 1H-MRS Signals

2.3. Partitioning of Time Series

3. Results

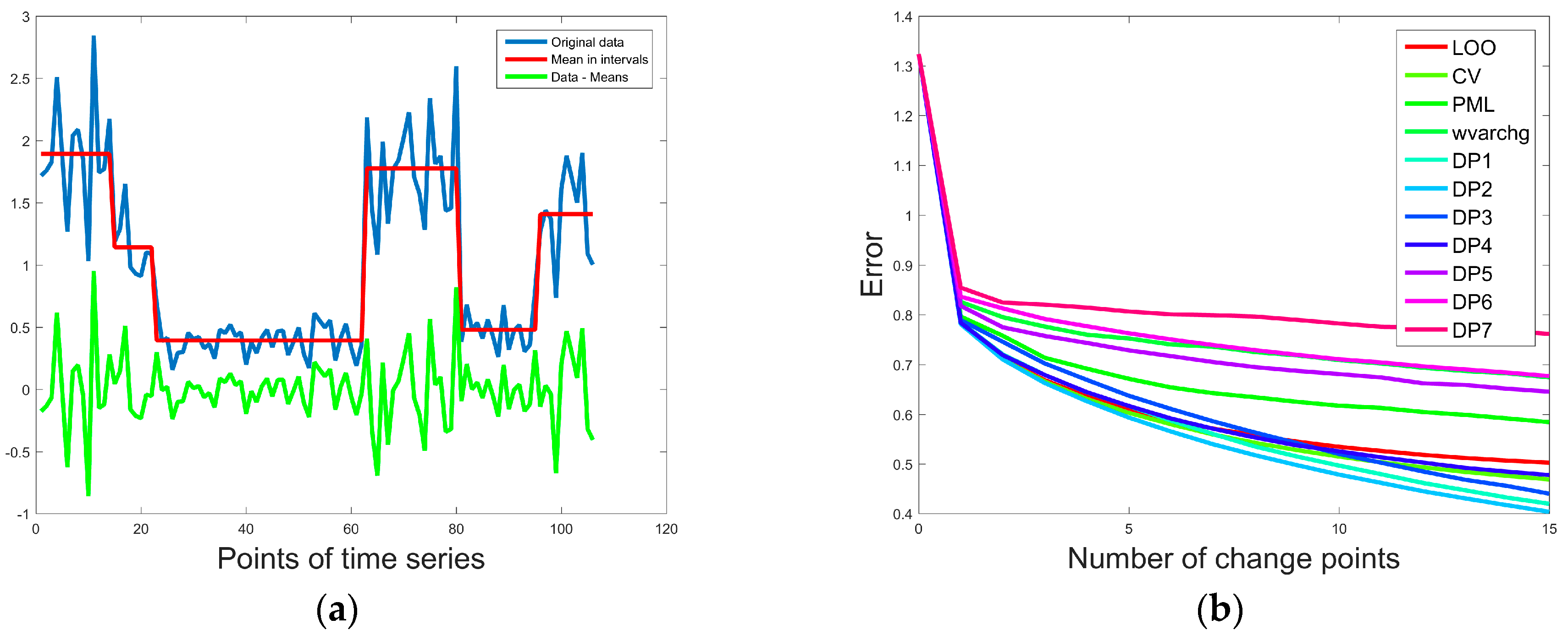

3.1. Simulated Data

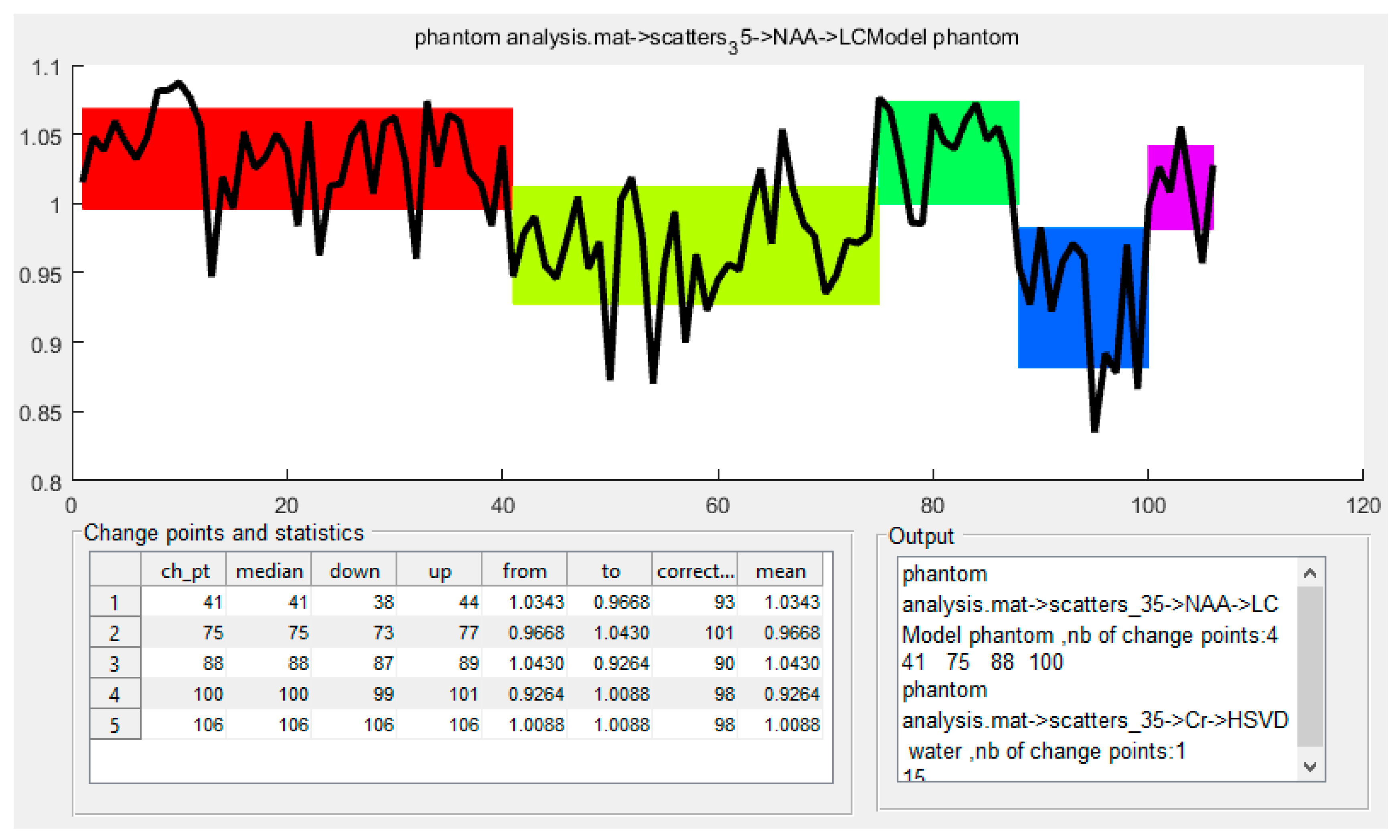

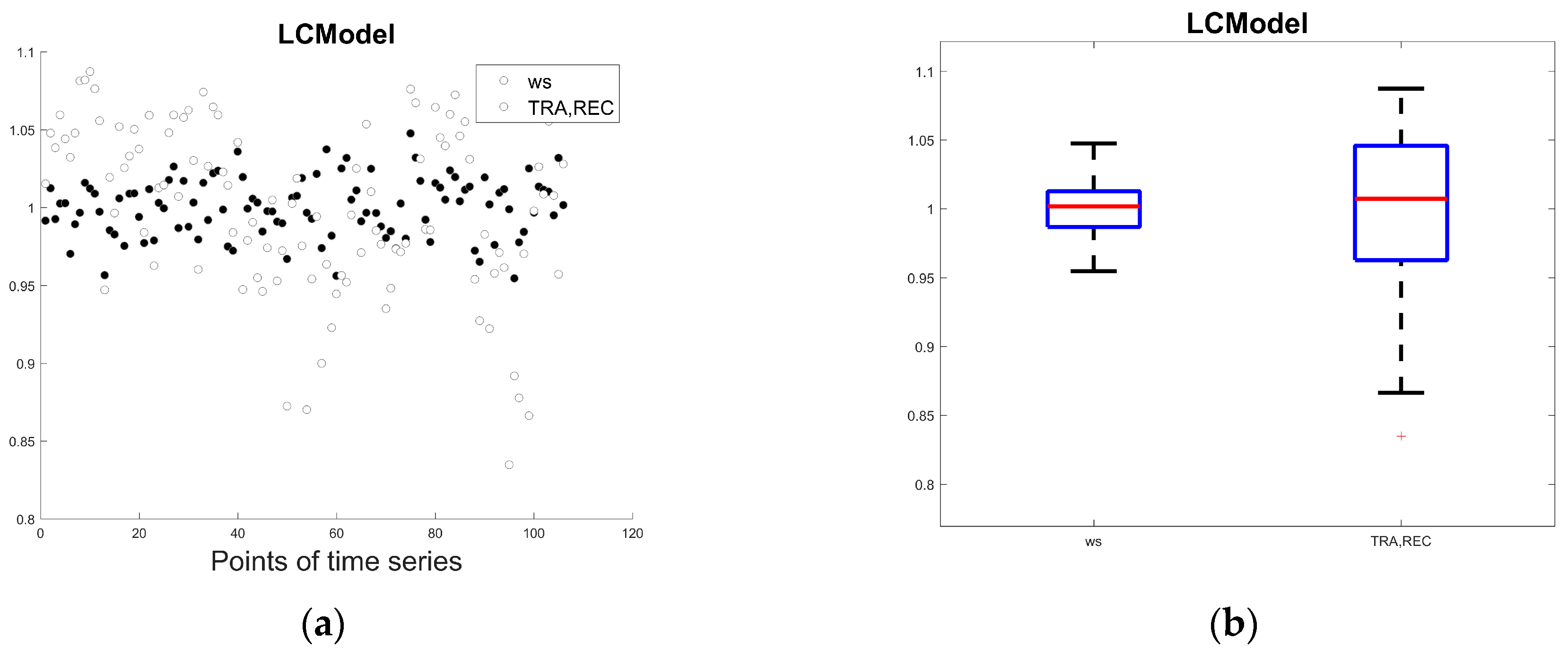

3.2. Analysis of Phantom Data

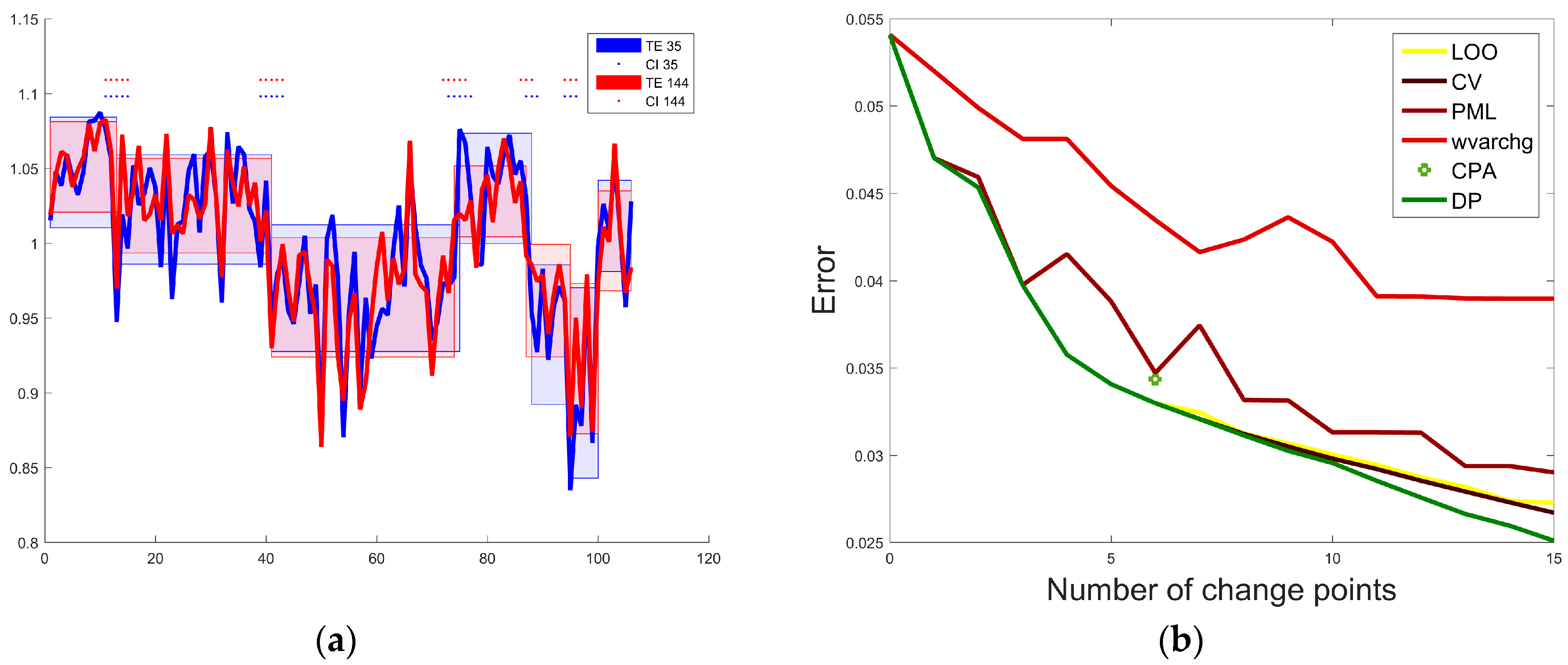

3.3. Analysis of 1H-MRS Time Series

4. Discussion

5. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Tosi, R. Nuclear Magnetic Resonance Spectroscopy in the Study of Neoplastic Tissue; Nova Publishers: New York, NY, USA, 2005; ISBN 978-1-59454-258-9. [Google Scholar]

- Schirmer, T.; Auer, D.P. On the reliability of quantitative clinical magnetic resonance spectroscopy of the human brain. NMR Biomed. 2000, 13, 28–36. [Google Scholar] [CrossRef]

- Hájek, M.; Burian, M.; Dezortová, M. Application of LCModel for quality control and quantitative in vivo 1H MR spectroscopy by short echo time STEAM sequence. Magn. Reson. Mater. Phys. Biol. Med. 2000, 10, 6–17. [Google Scholar] [CrossRef]

- Lin, A.; Tran, T.; Bluml, S.; Merugumala, S.; Liao, H.-J.; Ross, B.D. Guidelines for acquiring and reporting clinical neurospectroscopy. Semin. Neurol. 2012, 32, 432–453. [Google Scholar] [CrossRef] [PubMed]

- Skorupa, A.; Wicher, M.; Banasik, T.; Jamroz, E.; Paprocka, J.; Kiettyka, A.; Sokót, M.; Konopka, M. Four-and-one-half years’ experience in monitoring of reproducibility of an MR spectroscopy system—Application of in vitro results to interpretation of in vivo data. J. Appl. Clin. Med. Phys. 2014, 15, 323–334. [Google Scholar] [CrossRef] [PubMed]

- Change-Point Analysis: A Powerful New Tool for Detecting Changes. Available online: http://www.variation.com/cpa/tech/changepoint.html (accessed on 15 February 2018).

- Jandhyala, V.; Fotopoulos, S.; MacNeill, I.; Liu, P. Inference for single and multiple change-points in time series. J. Time Ser. Anal. 2013, 34, 423–446. [Google Scholar] [CrossRef]

- Amiri, A.; Allahyari, S. Change Point Estimation Methods for Control Chart Postsignal Diagnostics: A Literature Review. Qual. Reliab. Eng. Int. 2012, 28, 673–685. [Google Scholar] [CrossRef]

- Percival, D.B.; Walden, A.T. Wavelet Methods for Time Series Analysis, 1st ed.; Cambridge University Press: Cambridge, UK, 2006; ISBN 978-0-521-68508-5. [Google Scholar]

- Guo, H.; Liu, X.; Song, L. Dynamic programming approach for segmentation of multivariate time series. Stoch. Environ. Res. Risk Assess. 2015, 29, 265–273. [Google Scholar] [CrossRef]

- Brodsky, B. Change-Point Analysis in Nonstationary Stochastic Models, 1st ed.; Chapman and Hall/CRC: Boca Raton, FL, USA, 2017; ISBN 978-1-4987-5596-2. [Google Scholar]

- Arlot, S.; Celisse, A. Segmentation of the mean of heteroscedastic data via cross-validation. Stat. Comput. 2011, 21, 613–632. [Google Scholar] [CrossRef]

- Provencher, S.W. Estimation of metabolite concentrations from localized in vivo proton NMR spectra. Magn. Reson. Med. 1993, 30, 672–679. [Google Scholar] [CrossRef] [PubMed]

- Barreto, F.R.; Salmon, C.G. SU-E-I-64: 1H-MRS Quality Assurance in Short and Long Term Using a Phantom Object. Med. Phys. 2012, 39, 3639. [Google Scholar] [CrossRef] [PubMed]

- LCModel’s Home Page. Available online: http://s-provencher.com/lcmodel.shtml (accessed on 15 February 2018).

- Priestley, M.B. Spectral Analysis and Time Series, Two-Volume Set, Volume 1-2: Volumes I and II; Academic Press: London, UK, 1983; ISBN 978-0-12-564922-3. [Google Scholar]

- McGill, R.; Tukey, J.W.; Larsen, W.A. Variations of Box Plots. Am. Stat. 1978, 32, 12–16. [Google Scholar] [CrossRef]

- Picard, F.; Robin, S.; Lavielle, M.; Vaisse, C.; Daudin, J.-J. A statistical approach for array CGH data analysis. BMC Bioinform. 2005, 6, 27. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, N.R.; Siegmund, D.O. A Modified Bayes Information Criterion with Applications to the Analysis of Comparative Genomic Hybridization Data. Biometrics 2007, 63, 22–32. [Google Scholar] [CrossRef] [PubMed]

- Lavielle, M. Using penalized contrasts for the change-point problem. Signal Process. 2005, 85, 1501–1510. [Google Scholar] [CrossRef]

- Lachenbruch, P.A.; Mickey, M.R. Estimation of Error Rates in Discriminant Analysis. Technometrics 1968, 10, 1–11. [Google Scholar] [CrossRef]

- Geisser, S. A Predictive Approach to the Random Effect Model. Biometrika 1974, 61, 101–107. [Google Scholar] [CrossRef]

- Lavielle, M. Detection of multiple changes in a sequence of dependent variables. Stoch. Process. Their Appl. 1999, 83, 79–102. [Google Scholar] [CrossRef]

- LCModel User’s Manual. Available online: http://s-provencher.com/lcm-manual.shtml (accessed on 15 February 2018).

- Pedrosa de Barros, N.; Slotboom, J. Quality management in in vivo proton MRS. Anal. Biochem. 2017, 529, 98–116. [Google Scholar] [CrossRef] [PubMed]

- Rice, J.R.; Milbrandt, R.H.; Madsen, E.L.; Frank, G.R.; Boote, E.J.; Blechinger, J.C. Anthropomorphic 1H MRS head phantom. Med. Phys. 1998, 25, 1145–1156. [Google Scholar] [CrossRef] [PubMed]

- Song, K.-H.; Kim, S.-Y.; Lee, D.-W.; Jung, J.-Y.; Lee, J.-H.; Baek, H.-M.; Choe, B.-Y. Design of a fused phantom for quantitative evaluation of brain metabolites and enhanced quality assurance testing for magnetic resonance imaging and spectroscopy. J. Neurosci. Methods 2015, 255, 75–84. [Google Scholar] [CrossRef] [PubMed]

- Helms, G. The principles of quantification applied to in vivo proton MR spectroscopy. Eur. J. Radiol. 2008, 67, 218–229. [Google Scholar] [CrossRef] [PubMed]

- Skorupa, A.; Jamroz, E.; Paprocka, J.; Sokół, M.; Wicher, M.; Kiełtyka, A. Bridging the gap between metabolic profile determination and visualization in neurometabolic disorders: A multivariate analysis of proton magnetic resonance in vivo spectra. J. Chemom. 2013, 27, 76–90. [Google Scholar] [CrossRef]

| DP1 | DP2 (2) | DP3 | DP4 |

| DP5 | DP6 | DP7 | |

| From 3/4/2006 to 19/10/2006 | From 31/10/2006 to 30/10/2007 | From 5/12/2007 to 19/12/2008 | From 20/12/2008 to 10/12/2009 | From 22/12/2009 to 2/2/2010 | From 24/2/2010 to 22/6/2010 | From 6/7/2010 to 21/9/2010 | Whole Time Interval | |

|---|---|---|---|---|---|---|---|---|

| Change point position | 13 | 41 | 75 | 88 | 95 | 100 | ||

| FWHM [ppm] mean + std | 0.0207 0.0039 | 0.0208 0.0039 | 0.0216 0.0044 | 0.0213 0.0044 | 0.0233 0.0053 | 0.027 0.0045 | 0.0219 0.0049 | 0.0216 0.0044 |

| SNR mean + std | 33.8333 3.3799 | 32.9286 2.3716 | 31.5 3.0674 | 32.0769 2.3616 | 32.8571 2.2678 | 25 6.5955 | 34 2.1602 | 32.1604 3.4430 |

| TG [0.1 dB] mean + std | 144.25 1.2154 | 141.8214 1.7858 | 141.2058 2.2263 | 140.9231 1.6053 | 139.8571 1.7728 | 142.286 1.6036 | 142.2857 1.6036 | 141.604 2.1559 |

| DP | CV | LOO | PML | wvarchg | CPA |

|---|---|---|---|---|---|

| Error for NAA obtained from LCModel for 6 change points | |||||

| 0.0330 | 0.0330 | 0.0330 | 0.0347 | 0.0435 | 0.0344 |

| Position of detected change points | |||||

| 13; 41; 75; 88; 95; 100 | 13; 41; 75; 88; 95; 100 | 13; 41; 75; 88; 95; 100 | 41; 75; 78; 80; 88; 100 | 49; 50; 51; 94; 99; 100 | 12; 41; 60; 75; 88; 100 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Staniszewski, M.; Skorupa, A.; Boguszewicz, Ł.; Sokół, M.; Polański, A. Quality Control Procedure Based on Partitioning of NMR Time Series. Sensors 2018, 18, 792. https://doi.org/10.3390/s18030792

Staniszewski M, Skorupa A, Boguszewicz Ł, Sokół M, Polański A. Quality Control Procedure Based on Partitioning of NMR Time Series. Sensors. 2018; 18(3):792. https://doi.org/10.3390/s18030792

Chicago/Turabian StyleStaniszewski, Michał, Agnieszka Skorupa, Łukasz Boguszewicz, Maria Sokół, and Andrzej Polański. 2018. "Quality Control Procedure Based on Partitioning of NMR Time Series" Sensors 18, no. 3: 792. https://doi.org/10.3390/s18030792