Ontology-Based Method for Fault Diagnosis of Loaders

Abstract

:1. Introduction

- (1)

- It is difficult for computers to understand and integrate fault diagnosis knowledge of loaders, especially when there are heterogeneous knowledge types, wide knowledge sources and different storage types of knowledge.

- (2)

- It is difficult to reuse the existing loaders fault diagnosis model. Numerous scholars have to reestablish models and methods during the study of loaders fault diagnosis, resulting in the waste of research energy.

2. Background and Related Works

2.1. Ontology

2.2. CBR/RBR Method

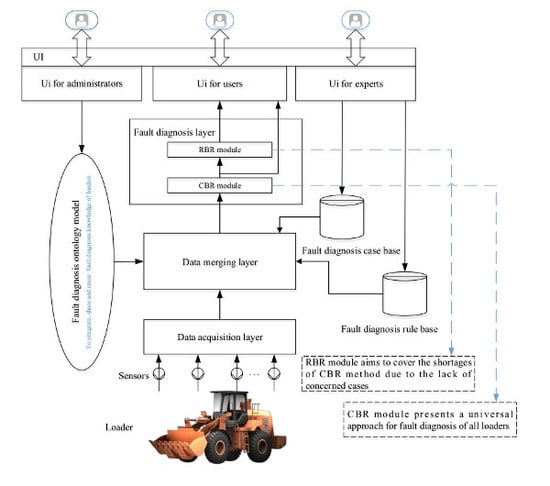

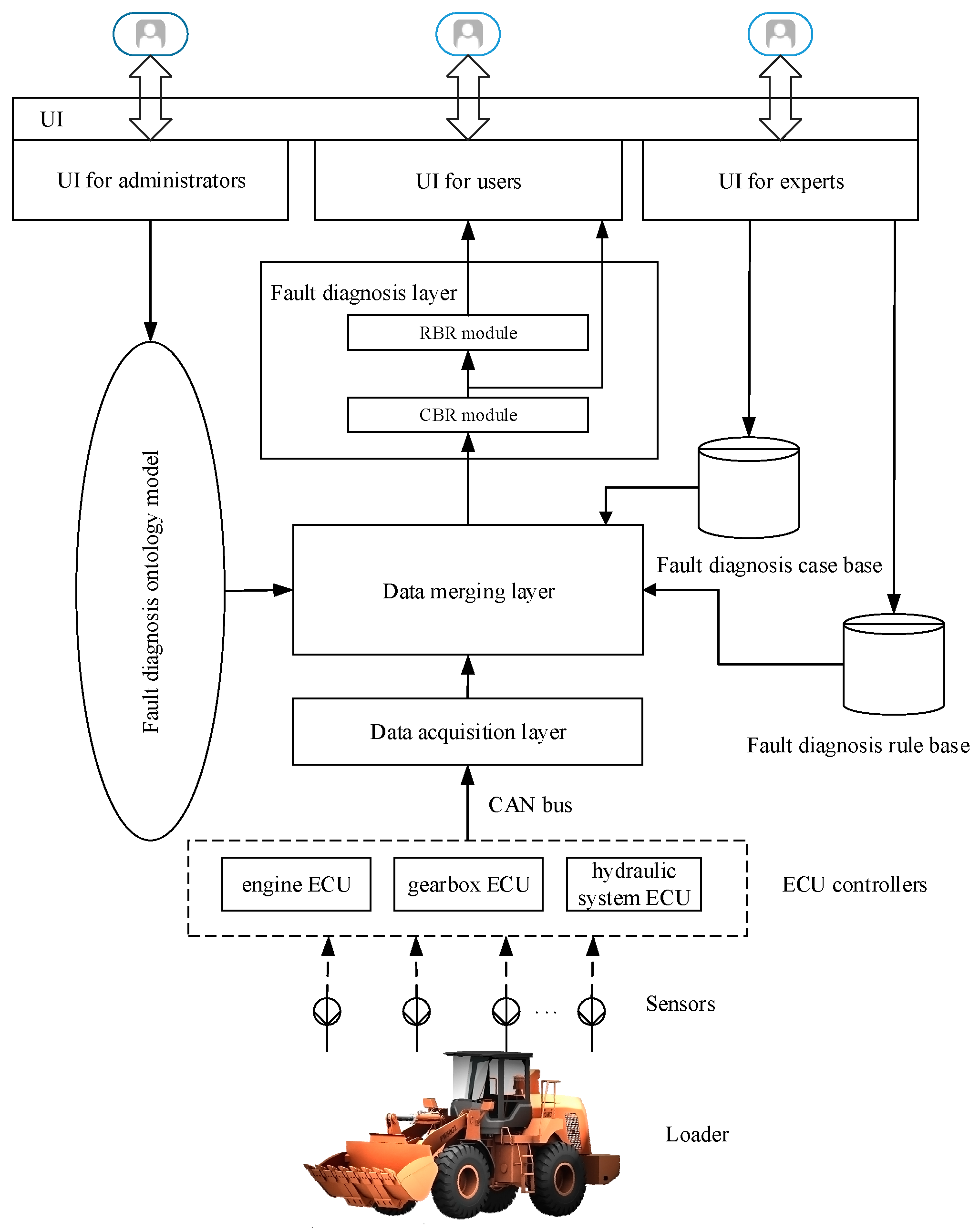

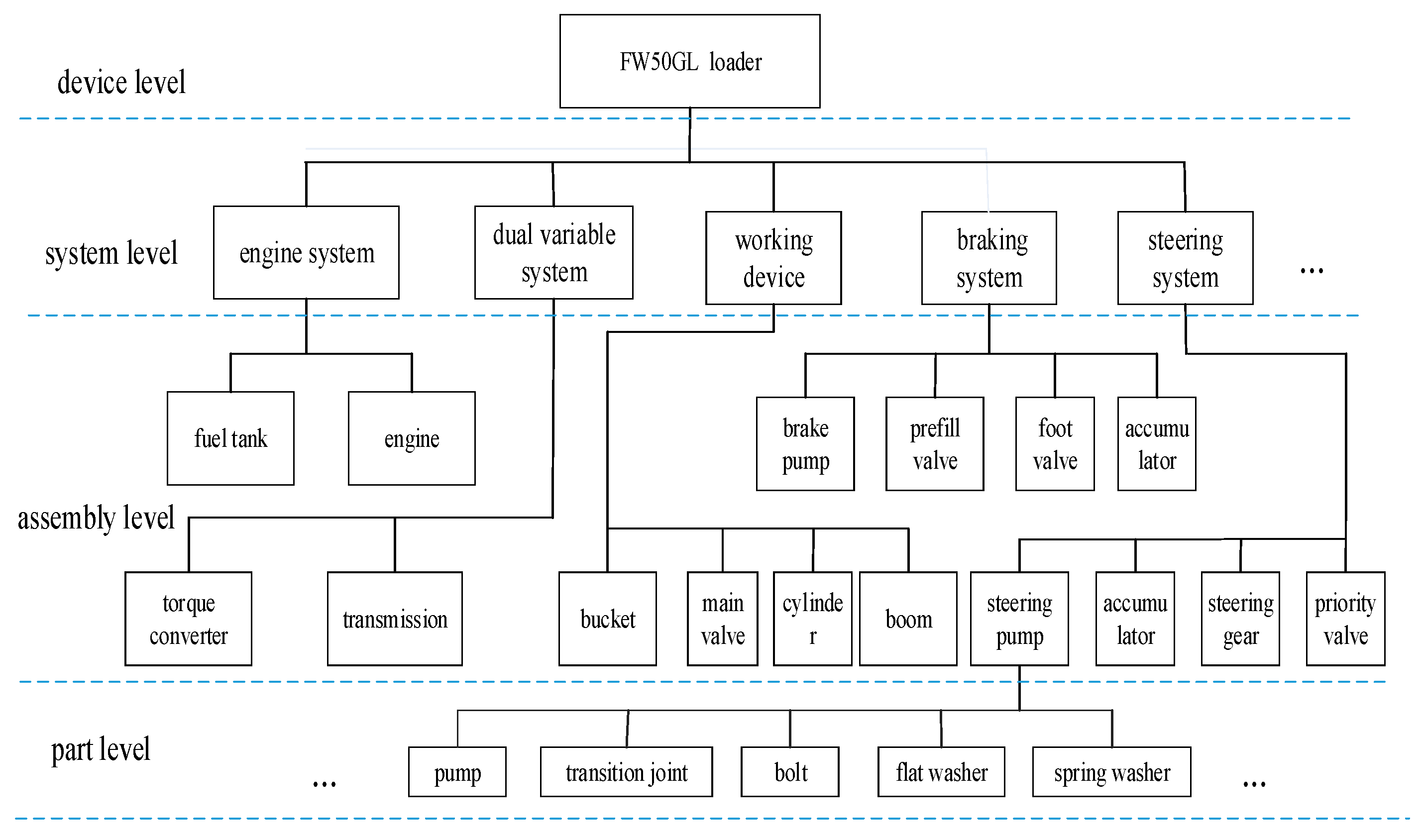

3. The Overall Structure of Fault Diagnosis System

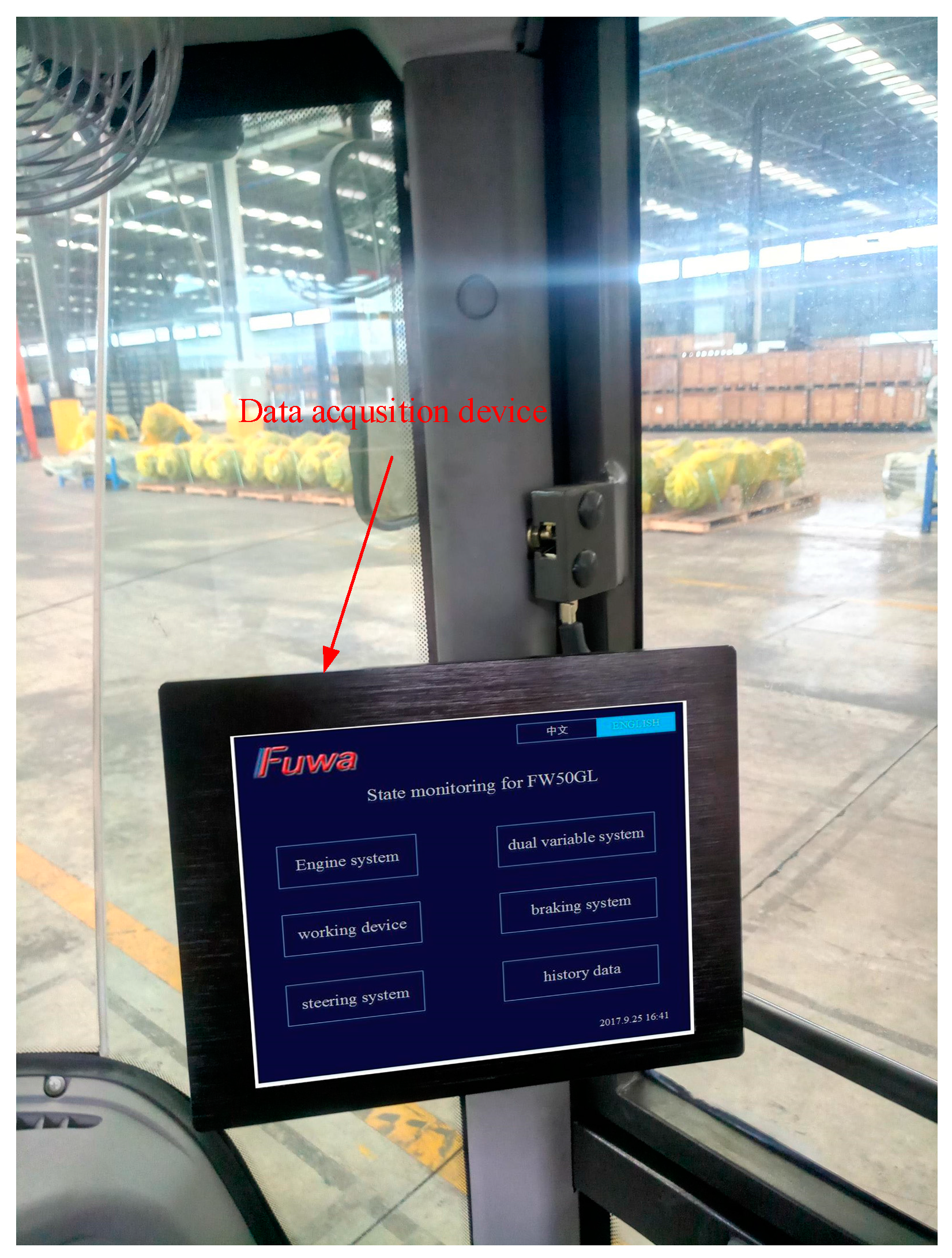

- Data acquisition layer. Firstly, the sensors collect data (such as engine speed, oil pressure of engine, hydraulic oil temperature etc.) every 2 s. Secondly, the collected data is encapsulated by three ECU controllers, including engine ECU, gearbox ECU and hydraulic system ECU. Thirdly, the data acquisition device gathers and processes all data from the three ECU controllers according to the Controller Area Network (CAN) protocol every five minutes. On one hand, within 5 min, the data acquisition device processes 150 data from each parameter to obtain an average value for each parameter. In this way, the average values of running parameters for fault diagnosis are more useful and effective. On the other hand, data is transferred to the data merging layer every 5 min, with the aim of reducing the frequency of data transmission so as to decrease the data processing pressure on the data acquisition device and data merging layer. This data acquisition device is developed by embedded technology, and it is composed of an Microcontroller Unit (MCU), a power module, an Liquid Crystal Display (LCD) module, a CAN module and a 3G module. MCU selects the stm32f103 microprocessor as the main control unit, which is responsible for receiving data, analyzing data and sending data. The power module mainly provides the power supply for the data acquisition device to ensure normal operation. The LCD module is used to display the operating data. The CAN module is used to receive data from three ECU controllers. The 3G module is responsible for sending data to the data merging layer. At last, the processed data is transferred to the data merging layer via the Internet in the form of Transmission Control Protocol/Internet Protocol (TCP/IP). The collected data lays the data foundation for the fault diagnosis layer to diagnose loaders’ faults. The data package from each ECU controller has 29 bytes, and then the data merging layer transferred from the data acquisition device has 29 × 3 = 87 bytes. Given that the loader works 8 h per day, and the historical data can be saved for three months, the memory size for collected data is 87 × 8 × 60/5 × 30 = 250,560 bytes = 245 MB. Currently, there is one diagnosed loader; the memory size for collected data is 245 MB. Supposing that the ontology-based fault diagnosis system will diagnose 1000 loaders in the future, then the memory size for collected data is 245 MB × 1000/1024 = 239 GB.

- Data merging layer. The data merging layer is used to integrate collected data, the ontology model, the fault diagnosis case base, and the fault diagnosis rule base. The data collected by sensors is transferred to the data merging layer through the data acquisition device. The fault diagnosis ontology model semantically handles the relevant information of loaders fault diagnoses, so that the information can be stored and expressed. The case base summarizes previous diagnosis experience and provides case support for CBR. The rule base, which is defined by experts and expressed in the form of SWRL, provides rule support for RBR. The data merging layer is responsible for laying the foundation for the fault diagnosis layer, which is of great significance. Moreover, the ontology model, rule base and case base can be updated and improved continually. With the increase in data in the data merging layer, it will be able to diagnose more faults and can diagnose more accurately.

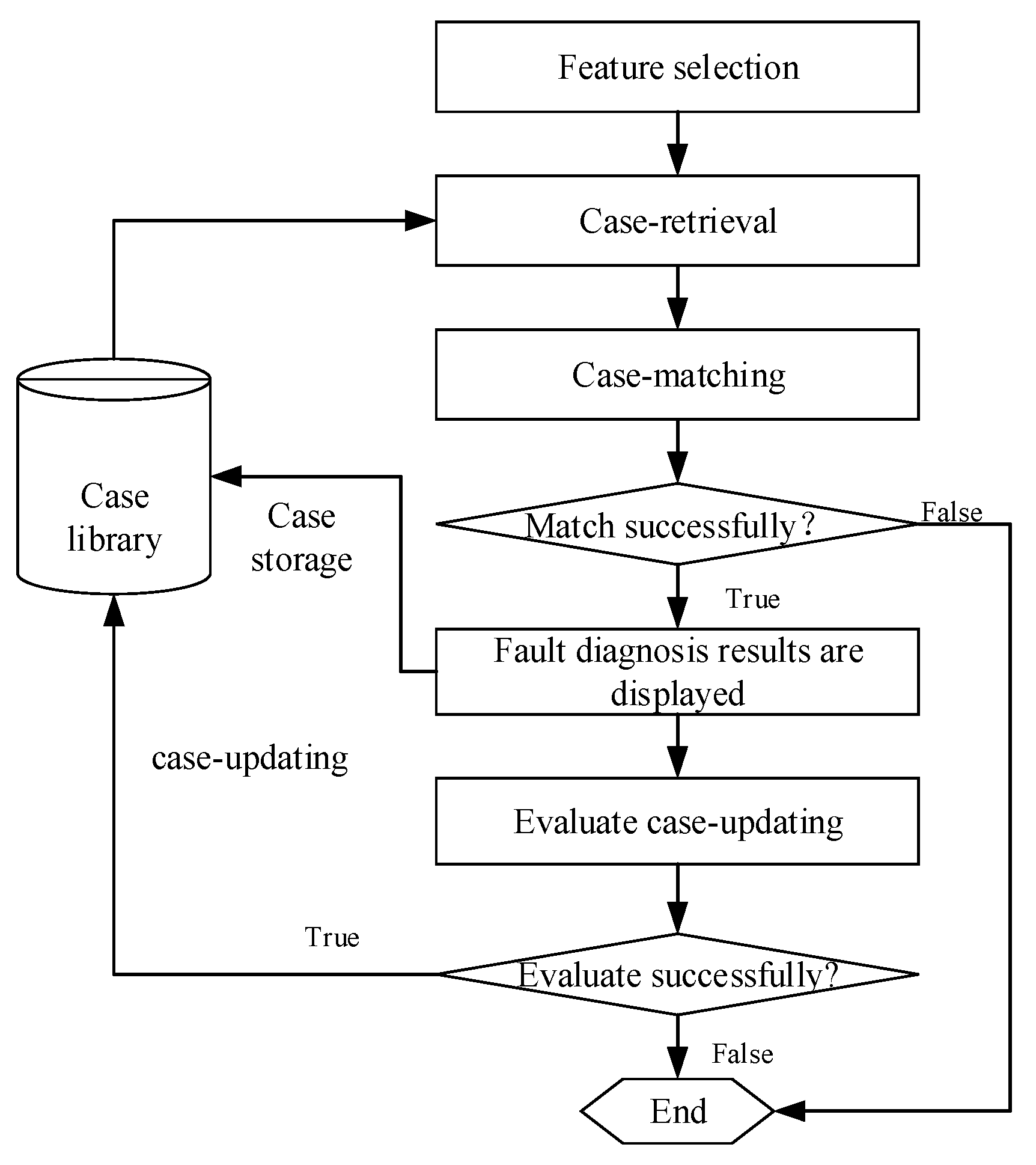

- Fault diagnosis layer. This layer is the core part for diagnosing loaders’ faults. Based on the fault diagnosis ontology model, the CBR module is used for fault diagnosis following four steps: feature selection, case-retrieval, case-matching and case-updating. The CBR module is able to obtain accurate fault diagnoses because it exploits historical cases which have actually happened. Once the CBR module fails, due to the lack of corresponding cases, the RBR module will be executed. The RBR module is used to deduce fault causes, fault locations and maintenance measures based on defined SWRL rules which make up the fault diagnosis rule base. By making full use of the advantages of the ontology model in knowledge management, CBR and RBR can obtain accurate and effective fault diagnoses of loaders.

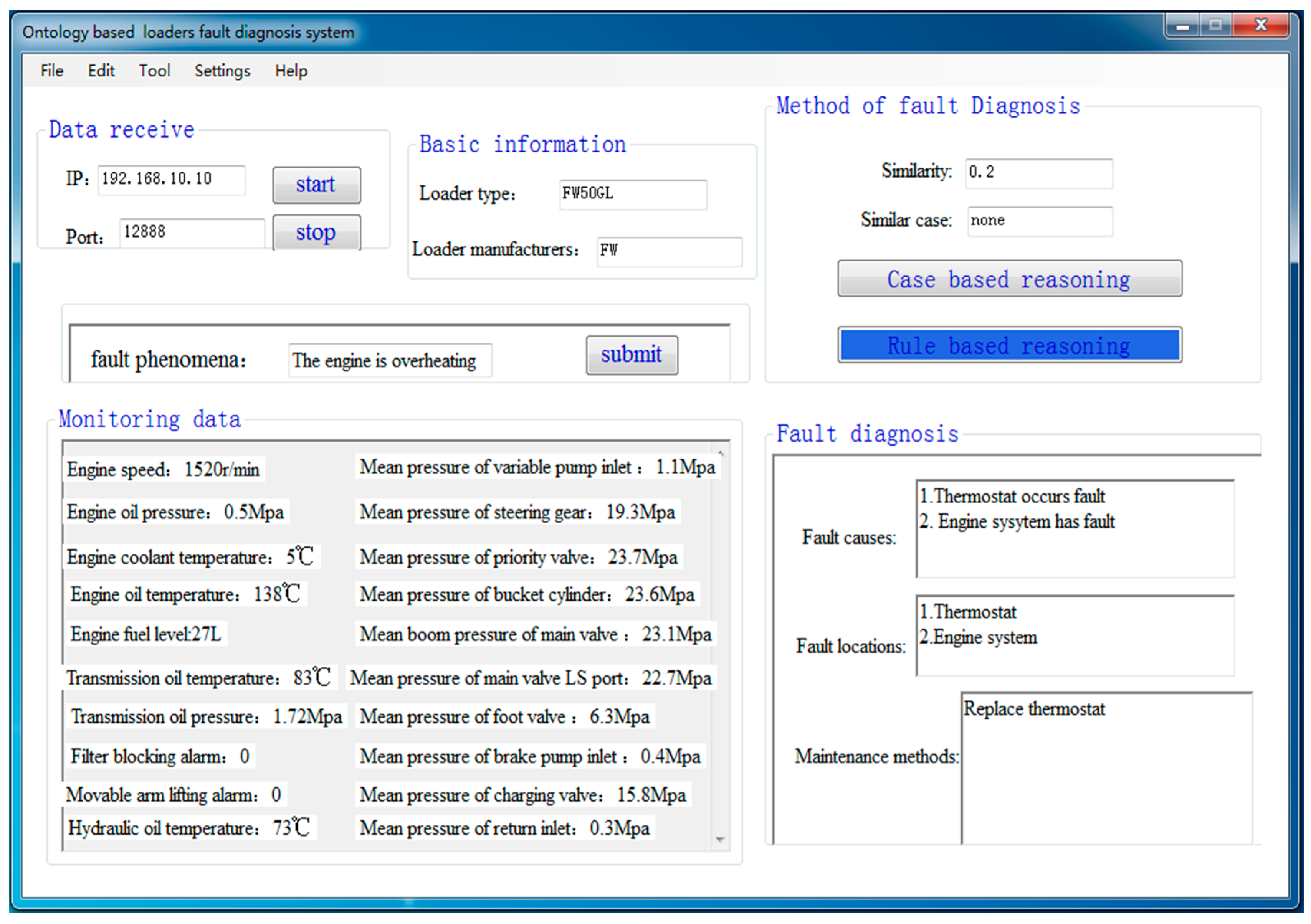

- UI (user interface). The UI was mainly developed for users, experts and administrators. Users (including drivers, operators and manufacturers) can obtain fault diagnosis results of loaders through UI. Experts are responsible for constructing and managing the case library and the rule library. Administrators mainly design and supervise the fault diagnosis ontology model. The results, including fault causes, fault locations and maintenance measures, can be obtained through UI. The UI application program was developed with the Visual Studio2017 software platform and C# language under the Windows 7 system.

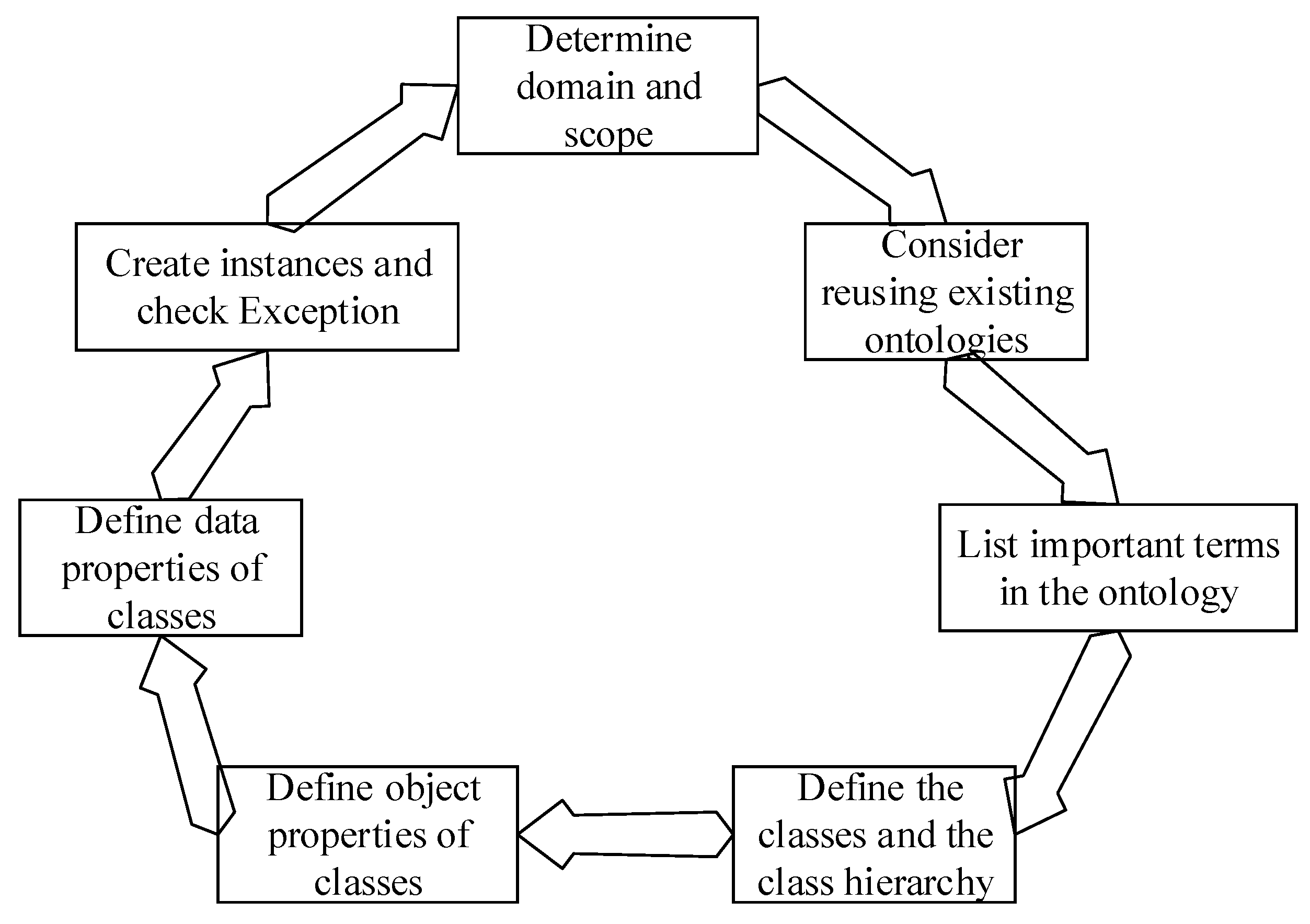

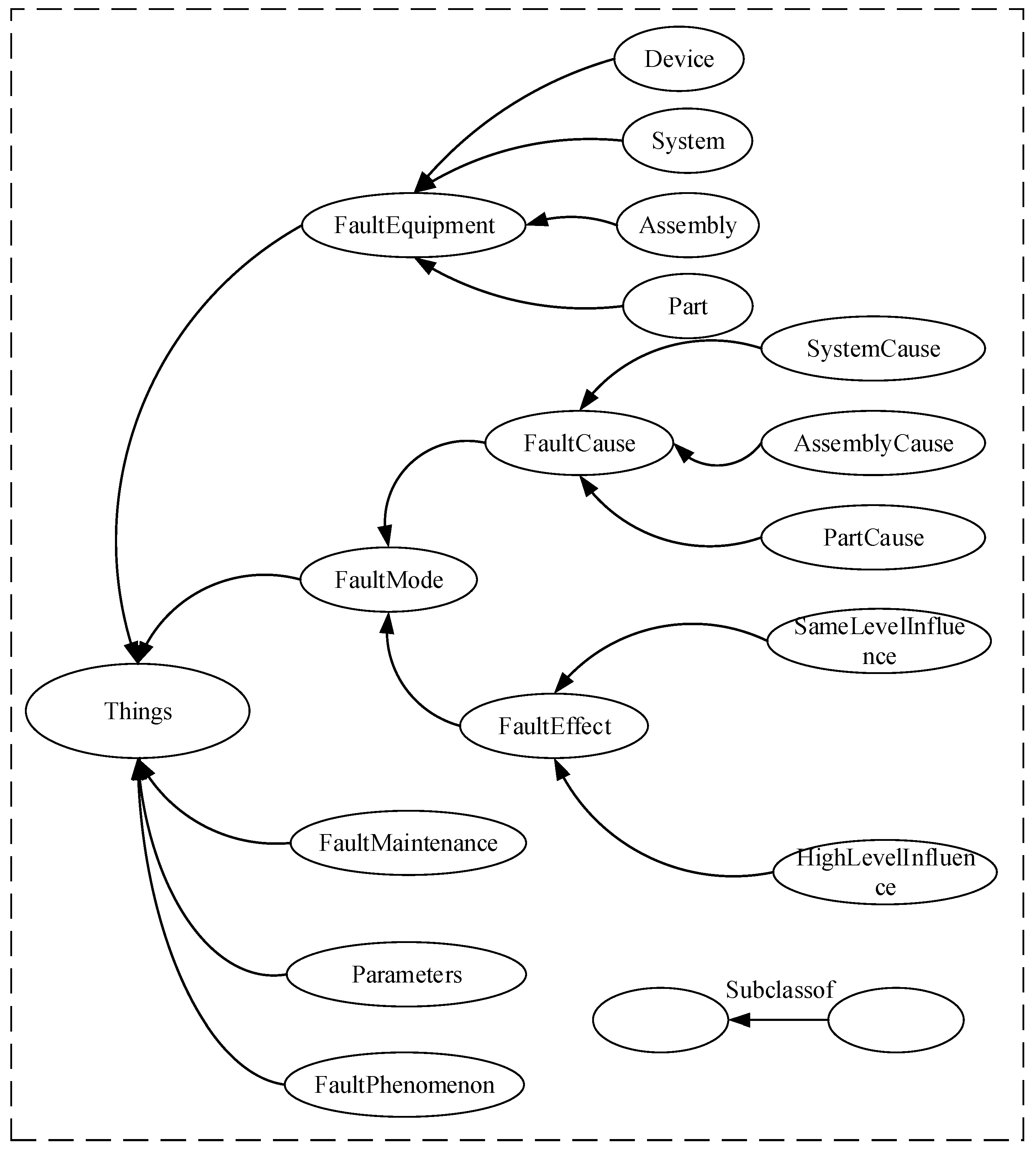

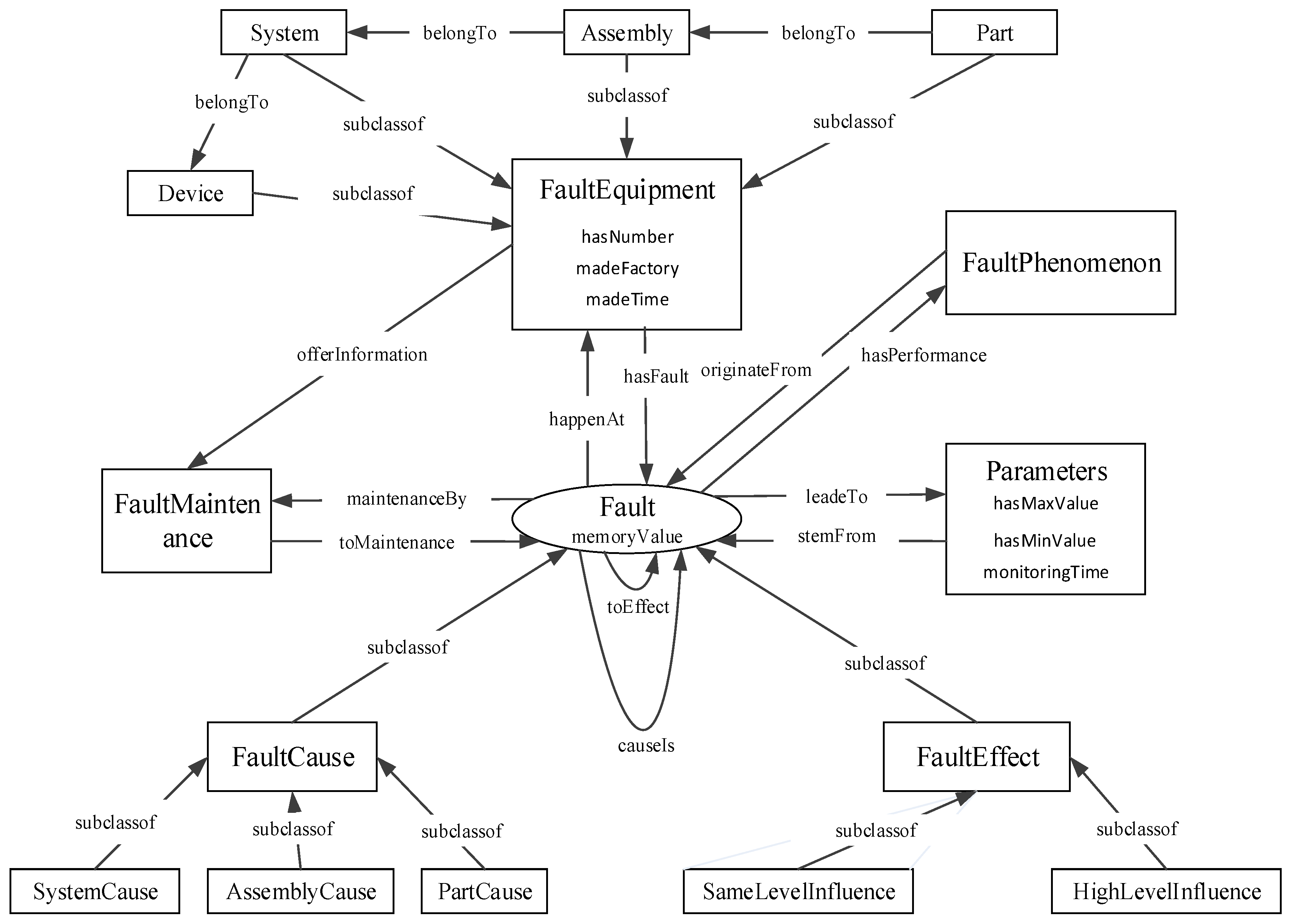

4. Construction of the Fault Diagnosis Ontology Model

4.1. Construction of the Ontology Model

- (1)

- Property 1 indicates the change in operating parameters caused by the fault mode.

- (2)

- Property 2 shows the relationship between the fault mode and the fault causes.

- (3)

- Property 3 indicates the relationship between the fault components and their sub-components.

- (4)

- Property 4 shows the relationship between the fault mode and fault effects. Property 5 and 6 are sub-properties of property 4, and property 5 indicates the relationship fault mode and its same level effects, and property 6 indicates the relationship fault mode and its higher level effects.

- (5)

- Property 7 indicates that fault locations provide information support for maintenance methods.

- (6)

- Property 8 indicates that the fault mode is able to be repaired through using maintenance methods.

- (7)

- Property 9 shows that the fault mode happens in components of loaders.

- (8)

- Property 10 indicates that the fault mode is accompanied by phenomena.

4.2. Parsing and Querying of the Ontology Model

5. CBR for Loaders Fault Diagnosis

5.1. Feature Selection and Case-Retrieval

5.2. Case-Matching

- (1)

- If the loader type is the same as the case in the case library, then equals 1, or else equals 0.

- (2)

- If fault phenomena are identical to a case in the case base, then equals 1, or else equals 0.

- (3)

- Operating parameters collected by sensors are calculated with Equation (2).where represents the weight of the jth operating parameter, which is determined directly by system experts, N stands for the number of operating parameter, is calculated by Equation (3), which represents the jth operating parameter similarity value between to-be-diagnosed faults and the case, denotes the kth operating parameter value of to-be-diagnosed faults, and represents the kth operating parameter value of the case.

5.3. Case-Updating

6. RBR for Loaders Fault Diagnosis

6.1. Fault Diagnosis Rules

- (1)

- C (?x): If x is an instance of the class C or the value of its data property, then C (?x) is established;

- (2)

- P (?x, y): If x and y are associated with the property, P, then P (?x, y) is valid.

- Rule 1: If fault mode x occurs with the occurrence of fault phenomena y, then the direct fault locations of fault mode x are z.

- Rule 2: If fault mode x’s change derives from parameter y, and x happens at device component a, and fault mode z affects x at the same level, then the cause of x is fault mode z, and x has fault causes at the system level.

- Rule 5: If fault mode x’s change derives from parameter y, and x happens at system component a, and fault mode z affects x at a higher level, then the cause of x is fault mode z, and x has fault causes at the system level.

- Rule 8: If fault mode x happens at equipment y, and the reasons for the components’ faults are x, then the fault locations are y.

- Rule 11: If the fault mode x happens at equipment y, and the fault locations provide the method for troubleshooting z, then failure maintenance z can repair fault mode x.

6.2. RBR for the Loaders Fault Diagnosis Process

7. System Implementation and Validation

7.1. System Implementation

7.2. System Validation

8. Conclusions and Future Work

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhang, Z.; Shao, X.; Yu, D. Fault Diagnosis of a Wheel Loader by Artificial Neural Networks and Fuzzy Logic. In Proceedings of the IEEE International Conference on Robotics, Automation and Mechatronics, Bangkok, Thailand, 1–3 June 2006; pp. 1–5. [Google Scholar]

- Li, Y.; Feng, X.; Yang, L. Intelligent Fault Diagnosis Methodology of Hydraulic Traveling System for Construction Machinery. In Proceedings of the IEEE International Conference on Industrial Informatics, Beijing, China, 25–27 July 2012; pp. 139–144. [Google Scholar]

- Chadli, M.; Abdo, A.; Ding, S.X. H_/H∞ Fault Detection Filter Design for Discrete-time Takagi-Sugeno Fuzzy System. Automatica 2013, 49, 1996–2005. [Google Scholar] [CrossRef]

- Gao, Z.; Cecati, C.; Ding, S.X. A Survey of Fault Diagnosis and Fault-Tolerant Techniques—Part I: Fault Diagnosis with Model-Based and Signal-Based Approaches. IEEE Trans. Ind. Electron. 2015, 62, 3757–3767. [Google Scholar] [CrossRef]

- Ding, S.X.; Yang, Y.; Zhang, Y.; Li, L. Data-driven realizations of kernel and image representations and their application to fault detection and control system design. Automatica 2014, 50, 2615–2623. [Google Scholar] [CrossRef]

- Youssef, T.; Chadli, M.; Karimi, H.R.; Wang, R. Actuator and sensor faults estimation based on proportional integral observer for TS fuzzy model. J. Frankl. Inst. 2017, 354, 2524–2542. [Google Scholar] [CrossRef]

- Shi, P.; Zhang, Y.; Chadli, M.; Agarwal, R.K. Mixed H-infinity and passive filtering for discrete fuzzy neural networks with stochastic jumps and time delays. IEEE Trans. Neural Netw. Learn. Syst. 2016, 27, 903–909. [Google Scholar] [CrossRef] [PubMed]

- Chibani, A.; Chadli, M.; Shi, P.; Braiek, N.B. Fuzzy Fault Detection Filter Design for T-S Fuzzy Systems in Finite Frequency Domain. IEEE Trans. Fuzzy Syst. 2017, 25, 1051–1061. [Google Scholar] [CrossRef]

- Gao, Z.; Cecati, C.; Ding, S.X. A Survey of Fault Diagnosis and Fault-Tolerant Techniques—Part II: Fault Diagnosis with Knowledge-Based and Hybrid/Active Approaches. IEEE Trans. Ind. Electron. 2015, 62, 3768–3774. [Google Scholar] [CrossRef]

- Yang, B.; Zheng, W.; Ke, X. Forecasting of Industrial Water Demand Using Case-Based Reasoning—A Case Study in Zhangye City, China. Water 2017, 9, 626. [Google Scholar]

- Ketler, K. Case-Based Reasoning: An Introduction. Expert Syst. Appl. 1993, 6, 3–8. [Google Scholar] [CrossRef]

- Bryant, S.M. A Case-Based Reasoning Approach to Bankruptcy Prediction Modeling. Intell. Syst. Account. Financ. Manag. 2015, 6, 195–214. [Google Scholar] [CrossRef]

- Elhdad, R.; Chilamkurti, N.; Torabi, T. An Ontology-based Framework for Process Monitoring and Maintenance in Petroleum Plant. J. Loss Prev. Process Ind. 2013, 26, 104–116. [Google Scholar] [CrossRef]

- Verstichel, S.; Ongenae, F.; Loeve, L.; Vermeulen, F.; Dings, P.; Dhoedt, B.; Dhaene, T.; Turck, F.D. Efficient Data Integration in the Railway Domain through an Ontology-based Methodology. Transp. Res. Part C 2011, 19, 617–643. [Google Scholar] [CrossRef] [Green Version]

- Chira, O.; Chira, C.; Roche, T.; Tormey, D.; Brennan, A. An Agent-based Approach to Knowledge Management in Distributed Design. J. Intell. Manuf. 2006, 17, 737–750. [Google Scholar] [CrossRef]

- Panetto, H; Dassisti, M; Tursi, A. ONTO-PDM: Product-driven Ontology for Product Data Management Interoperability within Manufacturing Process Environment. Adv. Eng. Inform. 2012, 26, 334–348. [Google Scholar] [CrossRef]

- Yang, D.; Miao, R.; Wu, H.; Zhou, Y. Product Configuration Knowledge Modeling Using Ontology Web Language. Expert Syst. Appl. 2009, 36, 4399–4411. [Google Scholar] [CrossRef]

- Yang, D.; Dong, M.; Miao, R. Development of a Product Configuration System with an Ontology-based Approach. Comput.-Aided Des. 2008, 40, 863–878. [Google Scholar] [CrossRef]

- McGuinness, D.L.; Van Harmelen, F. OWL Web Ontology Language Overview; W3C Recommendation. Available online: http://www.w3.org/TR/owl-features/ (accessed on 2 August 2014).

- Shekarpour, S.; Auer, S.; Ngonga Ngomo, A.C.; Gerber, D.; Hellmann, S.; Stadler, C. Generating SPARQL Queries Using Templates. Web Intell. Agent Syst. 2013, 11, 283–295. [Google Scholar]

- Huang, X.; Yi, J.; Zhu, X.; Chen, S. A Semantic Approach with Decision Support for Safety Service in Smart Home Management. Sensors 2016, 16, 1224. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Yi, J.; Zhu, X.; Luo, J.; Ji, B. Developing an Ontology-Based Cold Chain Logistics Monitoring and Decision System. J. Sens. 2015, 2015, 1–8. [Google Scholar] [CrossRef]

- Huang, X.; Yi, J.; Chen, S.; Zhu, X. A Wireless Sensor Network-based Approach with Decision Support for Monitoring Lake Water Quality. Sensors 2015, 15, 29273–29296. [Google Scholar] [CrossRef] [PubMed]

- Zhu, X.; Yi, J.; Huang, X.; Chen, S. An Ontology-based Knowledge Modelling Approach for River Water Quality Monitoring and Assessment. In Proceedings of the 20th International Conference on Knowledge Based and Intelligent Information and Engineering Systems, York, UK, 5–7 September 2016; pp. 335–344. [Google Scholar]

- Chen, R.; Zhou, Z.; Liu, Q.; Pham, D.T.; Zhao, Y.; Yan, J.; Wei, Q. Knowledge modeling of fault diagnosis for rotating machinery based on ontology, Industrial Informatics (INDIN). In Proceedings of the 2015 IEEE 13th International Conference on Industrial Informatics, Cambridge, UK, 22–24 July 2015. [Google Scholar]

- Peng, H.; Chang, D.; Wang, Y. Fault Diagnosis of Conveyor Based on Ontology. Sens. Transducers 2013, 157, 338–345. [Google Scholar]

- Medina-Oliva, G.; Voisin, A.; Monnin, M.; Leger, J.B. Predictive diagnosis based on a fleet-wide ontology approach. Knowl.-Based Syst. 2014, 68, 40–57. [Google Scholar] [CrossRef]

- Castro, A.; Sedano, A.A.; García, F.J.; Villoslada, E.; Villagrá, V.A. Application of a Multimedia Service and Resource Management Architecture for Fault Diagnosis. Sensors 2018, 18, 68. [Google Scholar] [CrossRef] [PubMed]

- Samirmi, F.D.; Tang, W.; Wu, Q. Fuzzy Ontology Reasoning for Power Transformer Fault Diagnosis. Adv. Electr. Comput. Eng. 2015, 15, 107–114. [Google Scholar] [CrossRef]

- Ma, G.; Jiang, L.; Xu, G.; Zheng, J. A Model of Intelligent Fault Diagnosis of Power Equipment Based on CBR. Math. Probl. Eng. 2015, 2015, 1–9. [Google Scholar] [CrossRef]

- Olsson, T.; Gillblad, D.; Funk, P.; Xiong, N. Explaining Probabilistic Fault Diagnosis and Classification Using Case-based Reasoning. In Proceedings of the International Conference on Case-Based Reasoning, Cork, Ireland, 29 September–1 October 2014; pp. 360–374. [Google Scholar]

- Dou, D.; Yang, J.; Liu, J.; Zhao, Y. A Rule-based Intelligent Method for Fault Diagnosis of Rotating Machinery. Knowl.-Based Syst. 2012, 36, 1–8. [Google Scholar] [CrossRef]

- Deng, X.-W.; Gao, Q.-S.; Zhang, C.; Hu, D.; Yang, T. Rule-based Fault Diagnosis Expert System for Wind Turbine. In Proceedings of the ITM Web of Conferences, 26 May 2017; pp. 1–9. [Google Scholar]

- Olsson, E.; Funk, P.; Bengtsson, M. Fault Diagnosis of Industrial Robots Using Acoustic Signals and Case-Based Reasoning. In Proceedings of the European Conference on Case-Based Reasoning, Madrid, Spain, 30 August–2 September 2004; pp. 686–701. [Google Scholar]

- Vo, D.P.; Macchion, D. A Use of Case-based Reasoning Technique in Building Expert Systems. Future Gener. Comput. Syst. 1993, 9, 311–319. [Google Scholar] [CrossRef]

- Guo, R.; Peng, Y.; Hu, J. Research on high creative application of case-based reasoning system on engineering design. Comput. Ind. 2013, 64, 90–103. [Google Scholar] [CrossRef]

- Chen, S.; Yi, J.; Jiang, H.; Zhu, X. Ontology and CBR Based Automated Decision-making Method for the Disassembly of Electromechanical Products. Adv. Eng. Inform. 2016, 30, 564–584. [Google Scholar] [CrossRef]

- Dendani-Hadiby, N.; Khadir, M.T. A Case based Reasoning System Based on Domain Ontology for Fault Diagnosis of Steam Turbines. Int. J. Hybrid Inf. Technol. 2012, 3, 89–103. [Google Scholar]

- Dendani-Hadiby, N.; Khadir, M.T. A Fault Diagnosis Application Based on a Combination Case-based Reasoning and Ontology Approach. Int. J. Knowl.-Based Intell. Eng. Syst. 2013, 17, 305–317. [Google Scholar] [CrossRef]

- Zhou, A.; Yu, D.; Zhang, W. A Research on Intelligent Fault Diagnosis of Wind Turbines Based on Ontology and FMECA. Adv. Eng. Inform. 2015, 29, 115–225. [Google Scholar] [CrossRef]

- Huang, X.; Yin, L. An Ontology Based Approach with Intelligent Decision for Off-Line Diagnosis of ECU. Int. J. Simul. Syst. Sci. Technol. 2016, 17, 1–8. [Google Scholar]

- Tung, Y.H.; Tseng, S.S.; Weng, J.F.; Lee, T.P.; Liao, A.Y.; Tsai, W.N. A Rule-based CBR Approach for Expert Finding and Problem Diagnosis. Expert Syst. Appl. 2010, 37, 2427–2438. [Google Scholar] [CrossRef]

- Zhou, Q.; Yan, P.; Xin, Y. Research on a Knowledge Modeling Methodology for Fault Diagnosis of Machine Tools Based on Formal Semantics. Adv. Eng. Inform. 2017, 32, 92–112. [Google Scholar] [CrossRef]

- Wang, D.; Tang, W.H.; Wu, Q.H. Ontology-based Fault Diagnosis for Power Transformers. Power Energy Soc. Gen. Meet. 2011, 45, 1–8. [Google Scholar]

- Wu, C.-Y. Expert System for Tractor Fault Diagnosis System Based on Ontology; South China Agricultural University: Guangzhou, China, 2012. [Google Scholar]

- Ion, S.; Bogdan, I. Source Code Plagiarism Detection Method Using Protégé Built Ontologies. Inform. Econ. J. 2013, 17, 75–86. [Google Scholar]

- Alderfer, C.P. Clarfing the Meaning of Mentor-Protégé Relationships. Consult. Psychol. J. Pract. Res. 2014, 66, 6–19. [Google Scholar] [CrossRef]

- Uchibayashi, T.; Apduhan, B.O.; Shiratori, N. A domain specific sub-ontology derivation end-user tool for the Semantic Grid. Telecommun. Syst. 2014, 55, 125–135. [Google Scholar] [CrossRef]

- Hu, Q.; Wang, H.; Xu, G.; Wu, D.; Yao, Y.; Lu, Q. The IDEF5-based Modeling of Process Ontology for Rapid Production Enterprise. Mach. Des. Manuf. Eng. 2008, 37, 6–10. [Google Scholar]

- Zhou, Y. Research on Machine Learning Based on Ontology; Shenyang University of Technology: Shenyang, China, 2007. [Google Scholar]

- Chaware, S.; Rao, S. Integrated Approach to Ontology Development Methodology with Case Study. Int. J. Database Manag. Syst. 2010, 2, 486. [Google Scholar]

- Scheuermann, A.; Leukel, J. Supply Chain Management Ontology from an Ontology Engineering Perspective. Comput. Ind. 2014, 65, 913–923. [Google Scholar] [CrossRef]

- Schank, R.C. Dynamic Memory: A Theory of Reminding and Learning in Computers and People; Cambridge University Press: Cambridge, UK, 1983. [Google Scholar]

- Wang, S.L.; Hsu, S.H. A Web-based CBR Knowledge Management System for PC Troubleshooting. Int. J. Adv. Manuf. Technol. 2004, 23, 523–540. [Google Scholar] [CrossRef]

- Relich, M.; Pawlewski, P. A case-based reasoning approach to cost estimation of new product development. Neurocomputing 2018, 272, 40–45. [Google Scholar] [CrossRef]

- Derbinsky, N.; Laird, J.E. Effective and Efficient Forgetting of Learned Knowledge in Soar’s Working and Procedural Memories. Cogn. Syst. Res. 2013, 24, 104–113. [Google Scholar] [CrossRef]

- Wang, X.; Wong, T.N.; Fan, Z.-P. Ontology-based supply chain decision support for steel manufacturers in China. Expert Syst. Appl. 2013, 40, 7519–7533. [Google Scholar] [CrossRef]

| No | Object Property | Domains | Ranges | Inverse Property |

|---|---|---|---|---|

| 1 | stemFrom | FaultMode | Parameters | leadTo |

| 2 | causeIs | FaultMode | FaultMode | N/A |

| 3 | belongTo | FaultEquipment | FaultEquipment | N/A |

| 4 | toEffect | FaultMode | FaultMode | N/A |

| 5 | toSameLevelEffect | FaultMode | FaultMode | N/A |

| 6 | toHighLevelEffect | FaultMode | FaultMode | N/A |

| 7 | offerInformation | FaultEquipment | FaultMaintenance | N/A |

| 8 | toMaintenance | FaultMaintenance | FaultMode | maintenanceBy |

| 9 | happenAt | FaultMode | FaultEquipment | hasFault |

| 10 | hasPhenomenon | FaultMode | FaultPhenomenon | originateFrom |

| No | Data Property | Domains | Ranges | Description |

|---|---|---|---|---|

| 1 | hasNumber | FaultEquipment | string | To record types of components |

| 2 | madeFactory | FaultEquipment | string | To indicate the manufacturer that produces the components |

| 3 | madeTime | FaultEquipment | datetime | To indicate the production time of components |

| 4 | hasMaxValue | Parameters | float | To indicate the maximum value in the normal range of parameters |

| 5 | hasMinValue | Parameters | float | To indicate the minimum value in the normal range of parameters |

| 6 | monitoringTime | Parameters | datetime | To record the monitoring time of parameters |

| 7 | memoryValue | FaultMode | float | To record the memory value of a fault in case library, also used for case-updating |

| No | Rules |

|---|---|

| Rule 1 | FaultMode(?x) ^FaultPhenomenon(?y) ^ hasPhenomenon(?x, ?y) → FaultEquipment(?z) ^ happenAt(?x,?z) |

| Rule 2 | FaultMode(?x) ^ Parameters(?y) ^ stemFrom(?x, ?y) ^ Device(?a) ^ happenAt(?x, ?a) ^ FaultMode(?z) ^ toHighLevelEffect(?z, ?x) → causeIs(?x, ?z) ^ SystemCause(?x) |

| Rule 3 | FaultMode(?x) ^ Parameters(?y) ^ stemFrom(?x, ?y) ^ System(?a) ^ happenAt(?x, ?a) ^ FaultMode(?z) ^ toHighLevelEffect(?z, ?x) → causeIs(?x,?z) ^ AsseamblyCause(?x) |

| Rule 4 | FaultMode(?x) ^ Parameters(?y) ^ stemFrom(?x, ?y) ^Asseambly(?a) ^ happenAt(?x, ?a) ^ FaultMode(?z) ^ toHighLevelEffect(?z, ?x) → causeIs(?x, ?z) ^ PartCause(?x) |

| Rule 5 | FaultMode(?x) ^ Parameters(?y) ^ stemFrom(?x, ?y) ^ System(?a) ^ happenAt(?x, ?a) ^ FaultMode(?z) ^ toSameLevelEffect(?z, ?x) → causeIs(?x, ?z) ^ SystemCause(?x) |

| Rule 6 | FaultMode(?x) ^ Parameters(?y) ^ stemFrom(?x, ?y) ^ Asseambly (?a) ^ happenAt(?x, ?a) ^ FaultMode(?z) ^ toSameLevelEffect(?z, ?x) → causeIs(?x, ?z) ^ Asseambly Cause(?x) |

| Rule 7 | FaultMode(?x) ^ Parameters(?y) ^ stemFrom(?x, ?y) ^Part(?a) ^ happenAt(?x, ?a) ^ FaultMode(?z) ^ toSameLevelEffect(?z, ?x) → causeIs(?x, ?z) ^ PartCause(?x) |

| Rule 8 | FaultMode(?x) ^ FaultEquipment(?y) ^ happenAt(?x,?y) ^ PartCause(?x) → Part(?y) |

| Rule 9 | FaultMode(?x) ^ FaultEquipment(?y) happenAt (?x,?y) ^ AsseamblyCause(?x) → Asseambly(?y) |

| Rule 10 | FaultMode(?x) ^ FaultEquipment(?y) ^ happenAt(?x,?y) ^ SystemCause(?x) → System(?y) |

| Rule 11 | FaultMode(?x) ^ FaultEquipment(?y) ^ happenAt(?x,?y) ^ FaultMaintenance(?z) ^ offInformation(?y,?z) → toMaintenance(?z, ?x) |

| No | Parameters | Abnormal State 1 below Normal Value | Normal State | Abnormal State 2 above Normal Value |

|---|---|---|---|---|

| 1 | Engine speed | ≤680 r/min | 680–2400 r/min | ≥2400 r/min |

| 2 | Engine oil pressure | ≤0.07 Mpa | 0.07–0.4 Mpa | ≥0.4 Mpa |

| 3 | Engine coolant temperature | ≤0 °C | 0–110 °C | ≥110 °C |

| 4 | Engine oil temperature | ≤40 °C | 40–120 °C | ≥120 °C |

| 5 | Engine fuel level | ≤6.25 L | 6.25–50 L | ≥50 L |

| 6 | Transmission oil temperature | ≤0 °C | 0–127 °C | ≥127 °C |

| 7 | Transmission oil pressure | ≤0.36 Mpa | 0.36–2.24 Mpa | ≥2.24 Mpa |

| 8 | Filter blocking alarm | >0 | ≤0 (0:normal 1:alarming) | >0 |

| 9 | Movable arm lifting alarm | >0 | ≤0 (0:normal 1:alarming) | >0 |

| 10 | Hydraulic oil temperature | ≤0 °C | 0–95 °C | ≥95 °C |

| 11 | Mean pressure of variable pump inlet | ≤0 Mpa | 0–3 Mpa | ≥3 Mpa |

| 12 | Mean pressure of steering gear | ≤18 Mpa | 18–21 Mpa | ≥21 Mpa |

| 13 | Mean pressure of priority valve | ≤22 Mpa | 22–24 Mpa | ≥24 Mpa |

| 14 | Mean pressure of bucket cylinder | ≤22 Mpa | 22–24 Mpa | ≥24 Mpa |

| 15 | Mean boom pressure of main valve | ≤22 Mpa | 22–24 Mpa | ≥24 Mpa |

| 16 | Mean pressure of main valve LS port | ≤22 Mpa | 22–24 Mpa | ≥24 Mpa |

| 17 | Mean pressure of foot valve | ≤6 Mpa | 6–7 Mpa | ≥7 Mpa |

| 18 | Mean pressure of brake pump inlet | ≤0 Mpa | 0–1 Mpa | ≥1 Mpa |

| 19 | Mean pressure of charging valve | ≤15 Mpa | 15–18 Mpa | ≥18 Mpa |

| 20 | Mean pressure of return inlet | ≤0 Mpa | 0–1 Mpa | ≥1 Mpa |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, F.; Liu, X.; Chen, W.; Zhou, C.; Cao, B. Ontology-Based Method for Fault Diagnosis of Loaders. Sensors 2018, 18, 729. https://doi.org/10.3390/s18030729

Xu F, Liu X, Chen W, Zhou C, Cao B. Ontology-Based Method for Fault Diagnosis of Loaders. Sensors. 2018; 18(3):729. https://doi.org/10.3390/s18030729

Chicago/Turabian StyleXu, Feixiang, Xinhui Liu, Wei Chen, Chen Zhou, and Bingwei Cao. 2018. "Ontology-Based Method for Fault Diagnosis of Loaders" Sensors 18, no. 3: 729. https://doi.org/10.3390/s18030729