3.1. Fabrication of Nanostructures

Although many of the fabrication steps have been described in previous work [

11,

14,

15,

16], we still provide a complete description here for the convenience of readers who wish to reproduce the process using a single complete protocol. We also try to include several tips and tricks that increase the chance of success.

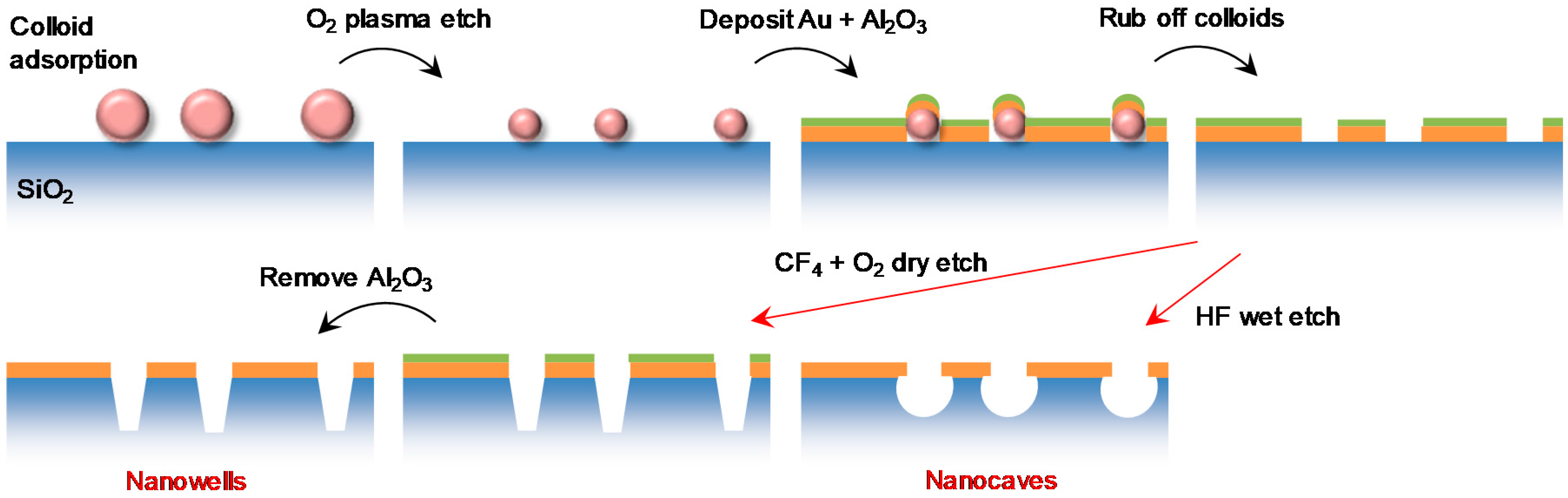

The fabrication process for preparing nanowells and nanocaves is outlined in

Figure 1, starting with a clean fused silica (amorphous SiO

2) support. For nanocaves, almost any type of ordinary glass may be used instead, while for nanowells we could only get the process to work well on fused silica. We denote the solid support as SiO

2 throughout this paper. Colloidal self-assembly is first used to prepare a short-range ordered monolayer of monodisperse polystyrene particles [

14]. When performing colloidal lithography, in order to avoid defects, it is important to keep the surface wet until the colloids can be fixed to the SiO

2 support by heating [

17], normally by pouring ~150 °C ethylene glycol onto the surface. Oxygen plasma was used to modify the diameter of the adsorbed particles, thereby defining the diameter of the final pores [

16]. We observed that a relatively high pressure (250 mTorr) and low power (50 W) in the O

2 plasma was beneficial for preserving the colloidal particle shape during shrinking, which may not always be straightforward [

18]. Note that by small modifications in the colloidal lithography step it is also possible to prepare hexagonally long-range ordered arrays [

19]. However, it is important to note that the pattern from the colloidal lithography process used here does not give a fully random pattern since there is a characteristic distance between neighboring particles [

15,

16,

20] (here ~300 nm). No pores are connected to each other when the lithography is performed correctly.

After creating the colloidal pattern gold and alumina was deposited by physical vapor deposition using electron gun heating. A 1 nm Cr layer is necessary to provide adhesion between Au and SiO

2. Ti also provides adhesion, but makes the samples sensitive to cleaning by H

2O

2. The role of the Al

2O

3 is to protect the gold when removing the colloids by rubbing the surface in liquid [

16] and during RIE [

11]. For all structures investigated in this work, we deposited 30 nm Au, but this thickness can naturally be changed. We found that in order to protect Au, at least ~15 nm Al

2O

3 is needed (we typically used 20 nm). Note that the thickness of the Au and Al

2O

3 layers limits the diameter of the final apertures since it must be possible to remove the colloids after depositing these layers. As a rule of thumb, if the sum of the Au and Al

2O

3 thickness is equal to the diameter, it is not possible to remove the colloids, but they can still be removed even if it is higher than the radius. To remove colloids, the surface needs to be kept in liquid (water works fine) and rubbed by something soft (such as a finger covered by a glove). Note that removal by tape stripping [

14] tends not to work after O

2 plasma treatment because the colloids become stuck very hard to the surface. The tape also leaves residues on the surface.

For preparing nanowells, the underlying material is anisotropically etched using RIE with CF

4 (or NF

3, CHF

3, etc.) mixed with O

2. The ratio of O

2 to CF

4 was 1:4 and the pressure was kept to a minimum (15 mTorr). For SiO

2 this process requires only a low power (50 W) to achieve a relatively high etch rate (~20 nm/min depending on machine). After RIE the Al

2O

3 needs to be removed to expose the planar top Au film, which can be done by any weakly basic solution [

11].

For preparing nanocaves, isotropic wet etching with HF was used to make a void, shaped roughly as a half sphere, in the underlying support. This transforms each aperture into a pore in a free-standing Au film. The samples were dipped in the etchant bath and rinsed thoroughly with water afterwards. We recommend caution since HF etchants are extremely toxic and exposure to skin can be fatal. The etch rate was found to be fast (~160 nm/min for 6% HF concentration). This process also removes the Al

2O

3 but does not influence Au [

21]. Prolonged etching made the entire Au film peel off from the surface since the caves start to connect underneath the metal, i.e., the whole SiO

2 support is lost evetually. Both the dry and wet etch rates were estimated based on measuring the depth for three different etch times, indicating a linear relationship.

An optional last step in the fabrication is to do thermal annealing to increase the stability of the samples, which will otherwise undergo recrystallization and faceting in Au with time. The temperature needs to be kept around 250 °C for recrystallization to occur reasonably fast (<1 h). Higher temperatures may alter the nanostructure due to mobility of Au atoms and the intrinsic stress at high curvature regions [

22]. However, we noted that the standard cleaning procedure we used for the samples (H

2O

2 and NH

3 in water at 80 °C) gives a similar recrystallization effect (and removes Al

2O

3), hence the cleaning may replace the annealing.

3.2. Electron Microscopy Imaging

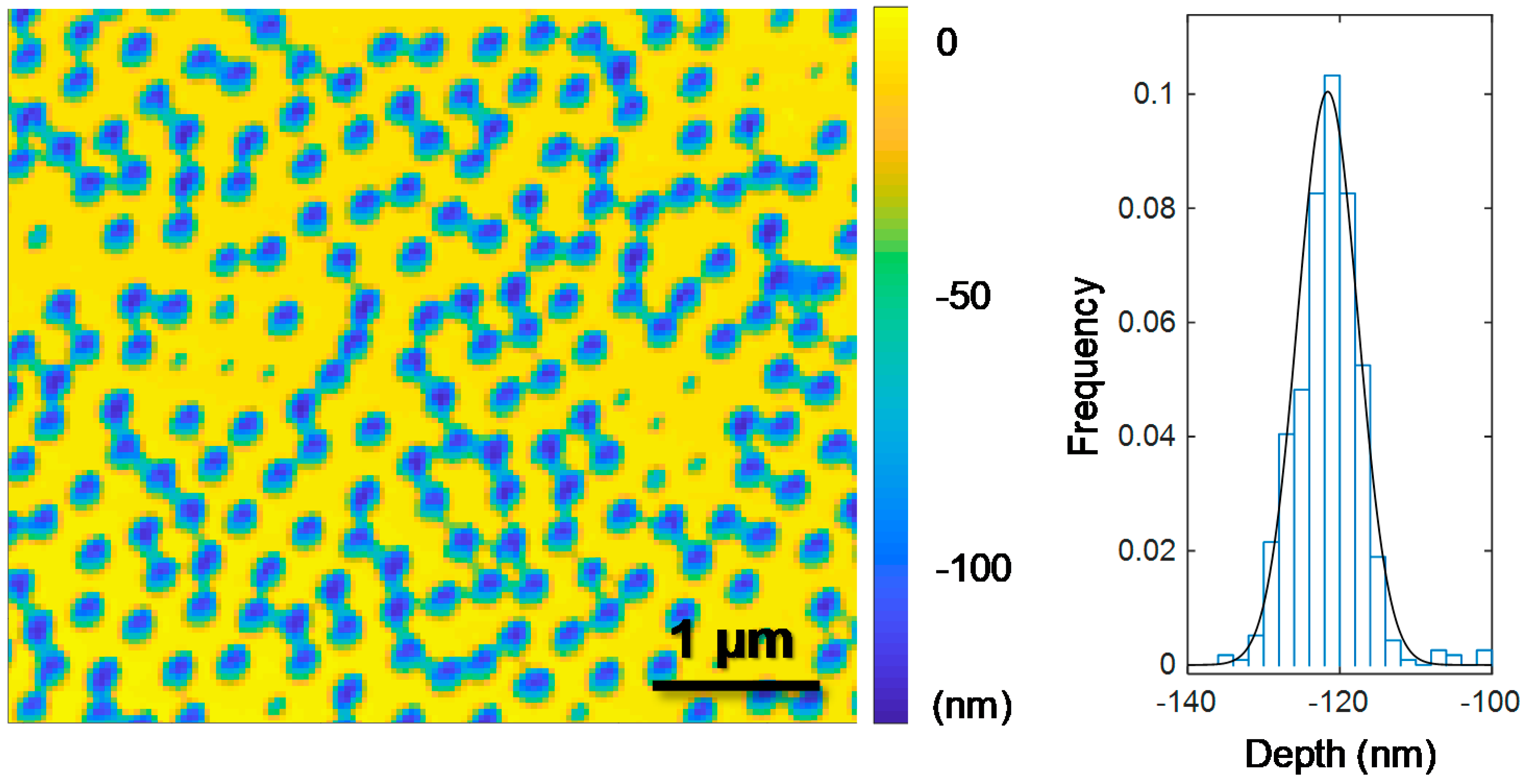

Representative SEM images of nanowells and nanocaves are shown in

Figure 2. The structures appeared identical when imaged from above except that for nanowells it was possible to see parts of the walls in the underlying cavities. Also, the RIE causes a small increase in the average diameter, typically 10 nm after 5 min etching. This is expected since the RIE process cannot entirely avoid reactions with the exposed gold sidewalls, i.e., it is not completely anisotropic with respect to the vertical direction.

Since these nanostructures should be particularly useful for studying phenomena associated with nanoscale geometry [

9] it is important to visualize the shape of the cavities in SiO

2 underneath Au. A combined focused ion beam (FIB) and SEM was used to perform cross-sections (

Figure 2b) and thus reveal the structure of the cavities (

Figure 2c). For nanowells, the walls in SiO

2 are clearly almost vertical but with a small inclination on the wall. It appears to be widely believed that the RIE process used can result in an undercut for an appropriate amount of O

2 in the reactant gases. However, we always observed walls with a slight inclination towards the pore center even when making changes in the RIE recipe. In other words, the bottom of the wells were slightly smaller in diameter than the top aperture regardless of gas ratio, pressure, power, and machine used. The maximum depth of the nanowells prepared in this work was 200 nm but deeper wells up to at least 1 µm can most likely be achieved [

18].

For nanocaves, the cross-section images can be used to analyze whether the wet etch is fully isotropic. Since the exposed SiO

2 surface is a circle at the start of the etch and not a point source, the cavity is not expected to be a perfect half sphere. A fully isotropic etch would give a depth that is equal to the etch undercut along the Au film. This is not the case as shown in

Figure 2d (the depth is ~100 nm and the undercut is ~50 nm). This is important to take into account since it influences how large cavities that can be prepared for the case of nanowells. When the caves start to connect laterally underneath the Au film the structure collapses. For the same reason, the maximum possible depth also depends on the diameter in Au. If the aperture is smaller, there is more SiO

2 available to be etched laterally before the caves connect. The ‘not fully isotropic’ etch provides cavities that are actually very close to half spherical voids (

Figure 2d) because of the size of the exposed initial SiO

2 area.

3.4. Extinction Spectra

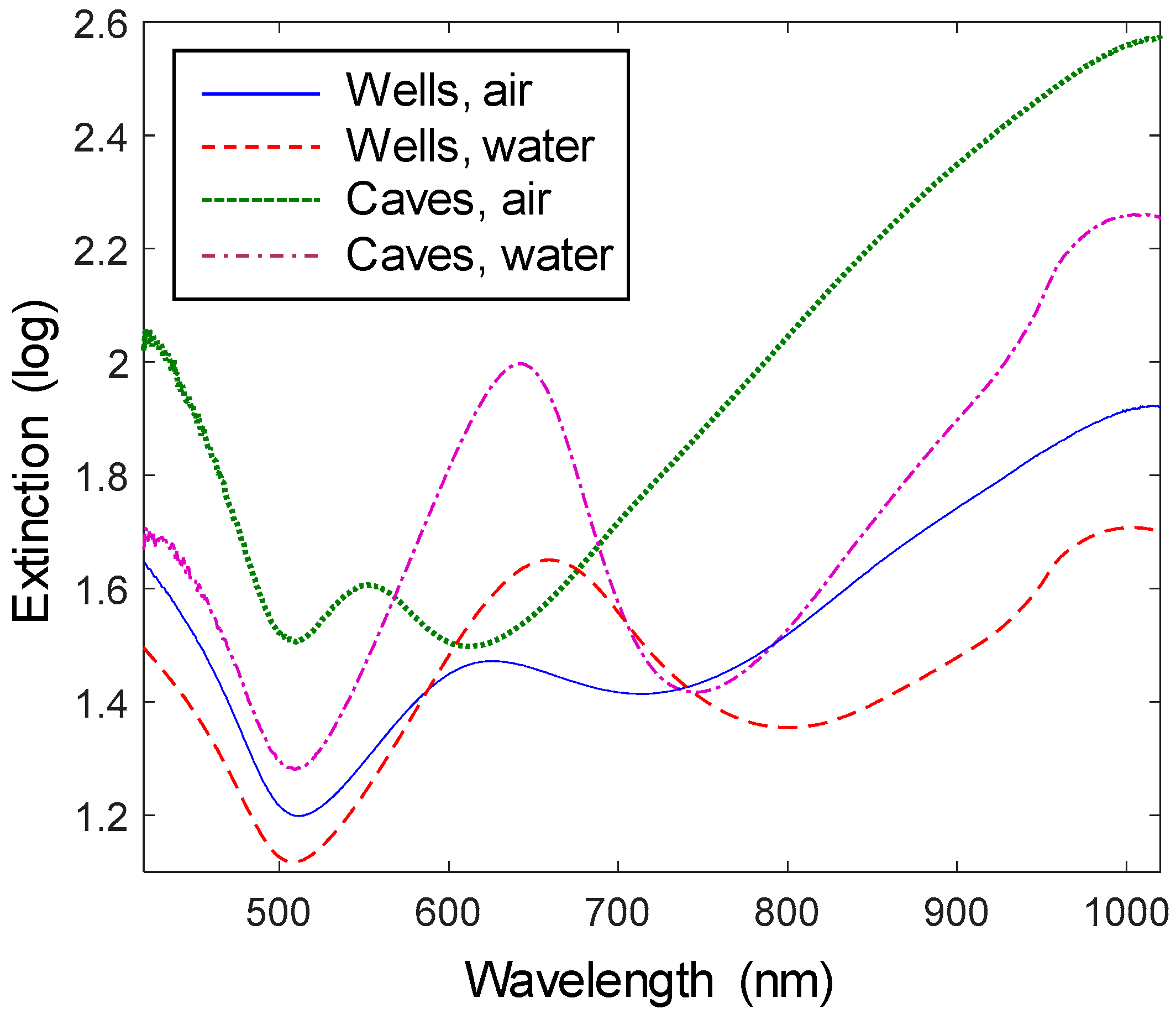

The extinction spectra (absorption + scattering) of the nanopores showed the characteristic asymmetric resonance (a ‘peak‘ and a ‘dip‘) associated with this kind of arrays of apertures in thin Au films [

8] (

Figure 4). Since we have characterized the plasmon modes extensively in previous work [

11,

15,

20], no detailed description will be presented here. In brief, the short-range ordering of the apertures gives them similar properties to long-range ordered arrays and the peak represents Bloch wave coupling to surface plasmon modes with symmetric charge distribution across the finite Au film [

20]. Because of this excitation, the resonance peak wavelength depends on the characteristic distance between the apertures (~300 nm for the colloids used in this work) and the thickness of the Au film. It does not, however, depend on the aperture diameter since that parameter is irrelevant for a grating-type coupling mechanism of light to plasmons [

16]. For all spectra the peak is accompanied with an extinction minimum (transmission maximum) at nearby longer wavelengths, i.e., the dip. This dip behaves like a localized resonance in the sense that its field is more focused to the interior of the pore and its spectral position is sensitive to the shape of the apertures [

16,

20]. Here, we will focus on the effect on the optical properties when etching out the cavities in the solid support, i.e., how they compare with ‘regular nanohole arrays’ where the SiO

2 support is not etched [

14,

16].

As the solid support is partly removed the effective refractive index (RI) of the environment decreases (as long as the cavities contain air). Indeed, in air the resonance peaks are quite blue shifted compared to ordinary nanohole arrays [

16] and weak due to the interband transitions in Au which contribute to damping below ~600 nm. The nanocaves are more blue shifted than the nanowells, in agreement with more of the solid support being etched away. It should be kept in mind that the characteristic spacing between the apertures and the metal film thickness are kept constant. This means that the plasmon resonance condition only depends on the weighted average RI of the environment. The resonance peaks become much stronger in water and the red shift when going from air to water is higher for caves, again because of the higher cavity volume which makes the change in effective RI higher.

The sharpness of the resonances is also important for sensing applications. The nanocaves exhibit a significantly sharper resonance dip than the nanowells. This can be attributed to the differences in the etching processes. While the HF etch is essentially fully chemically selective to SiO2, the RIE with CF4 will attack the exposed Au walls to some extent, possibly by physical ‘milling’ rather than chemical etching. This is in agreement with the slight increase in diameter observed for nanowells (but not nanocaves) after etching. Such sidewall etching will make the shape of the apertures less controlled and as a result the extinction dip is red shifted and broadened.

3.5. Refractive Index Sensitivities

One motivation for etching the underlying support is to increase the refractometric sensitivity of nanoplasmonic sensors [

10]. As more of the solid support is removed, a larger volume of liquid is present close to the metal where changes in RI due to molecular binding can occur, i.e., more of the probing volume is utilized. Therefore, increasing the cavity volume will increase the sensitivity defined as resonance spectral shift per RI change in the liquid. For nanowells, the increase will continue up to a certain point when the cavity bottom lies outside of the plasmonic field extension, which is typically on the order of ~50 nm for this thickness of Au [

23]. However, for nanocaves the lateral etching under the Au film will still continue to liberate liquid volume that does have a strong plasmonic field. Note that the sensitivity is not expected to be influenced by the aperture diameter, although the degree of field confinement to the pores may be higher for smaller apertures [

16].

We measured the sensitivity of the plasmon resonances using glycerol/water mixtures (

Figure 5) for nanocaves that were 100 nm deep and nanowells that were also 100 nm deep. For nanowells, the peak sensitivity was 147 nm per RI unit, which is much higher than for our previous nanowell structures based on Nb

2O

5. The reason is that the plasmonic field is always focused to the side of the finite Au film where the RI is higher [

15,

20,

24]. SiO

2 does not differ too much in RI (1.48) from water (1.33) as compared to Nb

2O

5 (2.24) and, as a consequence, the field is strong on the metal-liquid interface, rather than the metal-support interface. This enhances the sensitivity and shows that these new nanowells are generally better for sensing applications. In addition, SiO

2 is a material which is easier to chemically modify (or at least more studied) than Nb

2O

5. The variation in the sensitivity between samples was typically ±5 nm/RI unit. Increasing the depth did not lead to a noticeable increase in sensitivity beyond ~100 nm.

For nanocaves, the peak sensitivity was 294 nm per RI unit, which is more than twice as high as for structures where the support is not etched [

16]. As mentioned, this is in part because the more isotropic etch liberates volume underneath the Au film. However, since the sensitivity increases by more than a factor of two, it is clear that the increment does not scale linearly with the volume liberated. The liquid probing volume is definitely not twice as high after etching the support. We attribute this effect as well to the asymmetric field distribution across the metal for the bonding surface plasmon mode [

15]. In this interpretation, etching the SiO

2 does not only liberate liquid volume. As mentioned, it also makes the field strength higher on the top side of the metal film. In conclusion, the wet etch process presented in this work leads to quite a substantial sensitivity enhancement.

The extinction dip is known to have a near field distribution more focused to the interior of the holes [

16,

20]. Indeed, a high sensitivity of 278 nm per RI unit is observed for the dip of nanowells upon etching away the SiO

2. As expected, the etch undercut for nanocaves gives an even higher dip sensitivity or 388 nm per RI unit. Recall again that the metal thickness and aperture arrangement is the same. Although these values are higher than the peak sensitivities one must also take into account other factors when deciding which parameter to use in refractometric sensing. For one thing, the dip is a more broadened spectral feature and as a result it has a higher noise level. The uncertainty when tracking the resonance wavelength of the peak is below 0.01 nm, but around 0.02 nm for the dip (temporal resolution of 200 ms). In addition, the field extension in relation to the thickness of any molecular layer on the surface strongly influences the magnitude of the signal induced [

23]. For these structures, the field extension at the peak wavelength is mainly determined by the thickness of the Au film, which influences the bonding surface plasmon mode (a thinner film makes the field more focused to the metal). At the dip wavelength, the field is mainly localized to the pores [

16], so for this parameter to give a high signal it is important that molecules do bind to the cavities or the Au walls.

3.6. Molecular Binding and Location-Specific Detection

We characterized the sensor response to molecular adsorption by first binding thiolated short (2 kDa) poly(ethylene glycol) chains to Au, followed by adsorption of the protein avidin inside the cavities. All binding was performed in PBS buffer and the data, i.e., centroid shift for both peak and dip [

9], is presented in

Figure 6. All binding was irreversible, i.e., the molecules remained on the surface (the signal did not decrease) upon rinsing. These material-specific reactions offer a way to not only evaluate the ability of the sensor to detect molecular binding events but also to provide information about the sensitivity distribution in the nanostructure. In the first step, molecules bind only to Au and in the latter only to SiO

2 inside the cavities since the poly(ethylene glycol) prevents adsorption to Au. Further, by full spectral analysis it is possible to track both the peak and the dip shifts, thereby obtaining information about how the refractometric sensitivity is distributed in the nanostructures for the different resonance features.

It is clear from

Figure 6a that the nanocaves provide higher signals for binding to Au, which makes them preferable from a performance point of view. This is expected when more of the Au surface is available for binding and when the field is higher on the top surface away from the solid support as explained above. For binding to SiO

2, the nanocaves clearly give more moderate signals, even though they have a higher SiO

2 surface area available. This can be explained by the fact that the SiO

2 walls are not close to the pore where the sensitivity is highest. One should also keep in mind that most of the exposed area is Au and not SiO

2 in both these structures. The nanowells give a reasonably high dip shift (~1.4 nm) upon protein adsorption inside the cavities. This illustrates that the ideal structure can depend on which material is chemically modified for binding a target. Note that, based on the size of the protein (~5 nm) and the cavities, the signal to noise is sufficient to detect one protein per cavity as long as it binds close to the metal [

16].

Looking at the ratio of the signals in dip and peak for binding to Au and SiO

2 it is clear that it is always higher than one and a higher value for this ratio indicates binding inside the cavities [

9]. The ratio does not change so much for nanocaves when looking at the material specific binding (1.3 for Au vs. 1.2 for SiO

2), while for nanowells the ratio is 1.8 for Au and 3.7 for SiO

2. Although these ratios will vary somewhat depending on e.g., the depth of the cavities, it is clear that the nanowells give a higher change in the ratio when comparing binding to Au and the interior of the cavities. In other words, the considerable change in dip/peak signal ratio constitutes a built-in sensor signature for binding inside the cavities for the nanowells. This illustrates how full spectral analysis with multiple parameters can provide location-specific detection, at least in a qualitative manner.