Instrumented Compliant Wrist with Proximity and Contact Sensing for Close Robot Interaction Control

Abstract

:1. Introduction

2. Literature Review

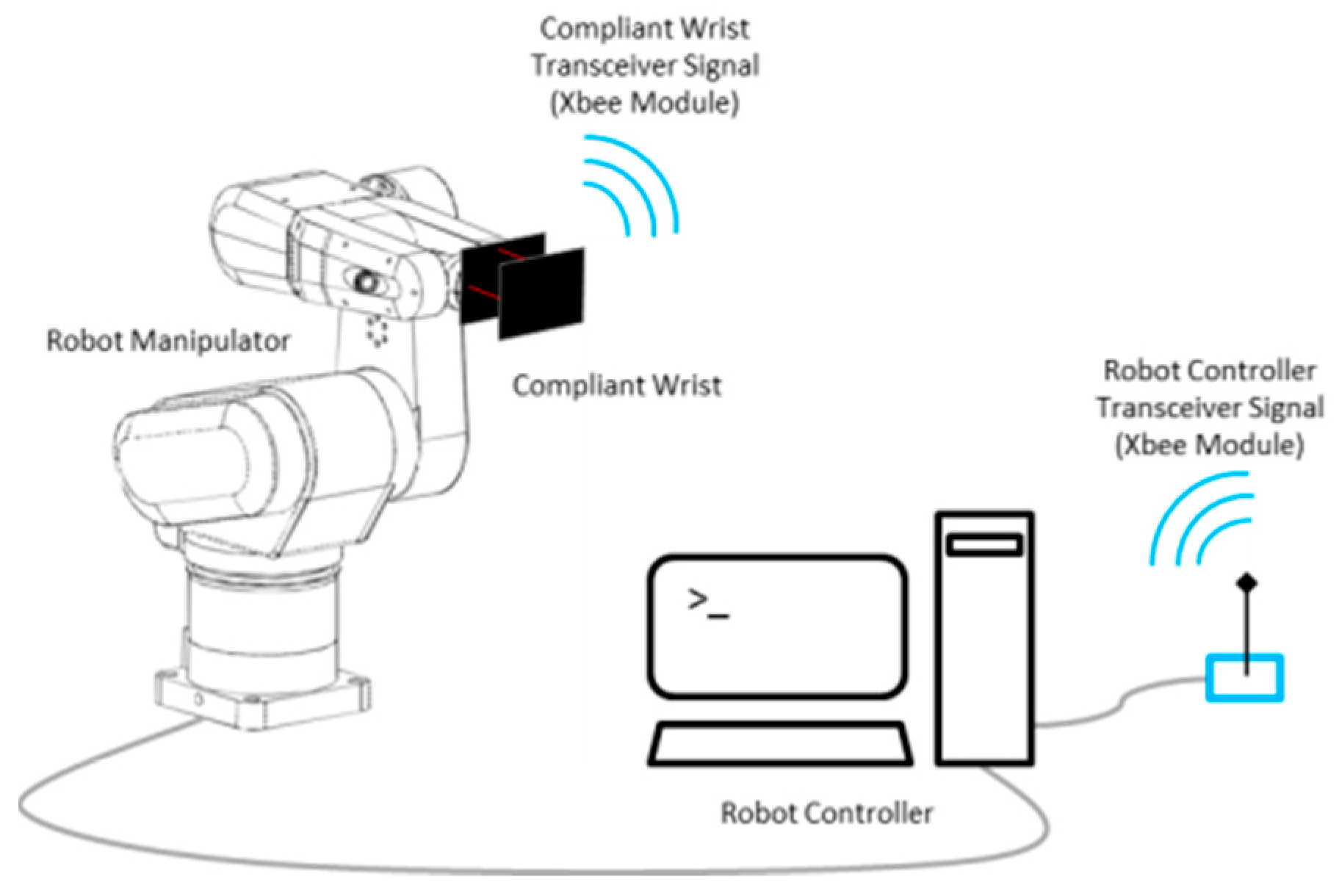

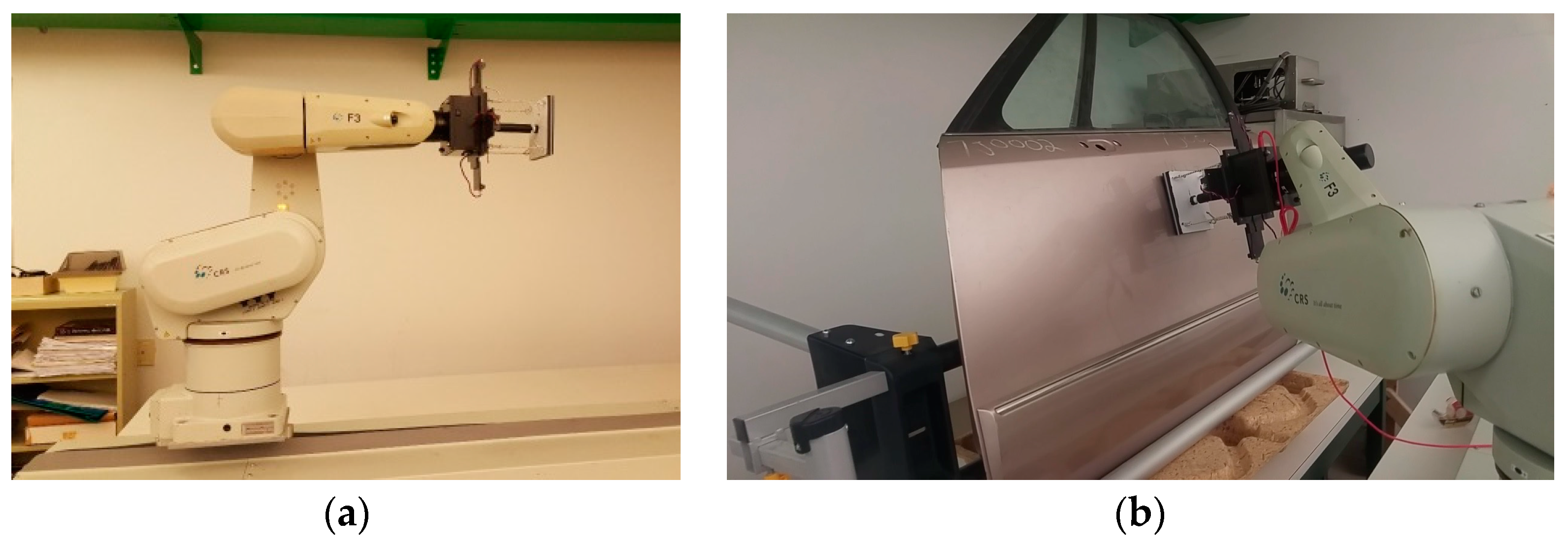

3. Context and Design Requirements

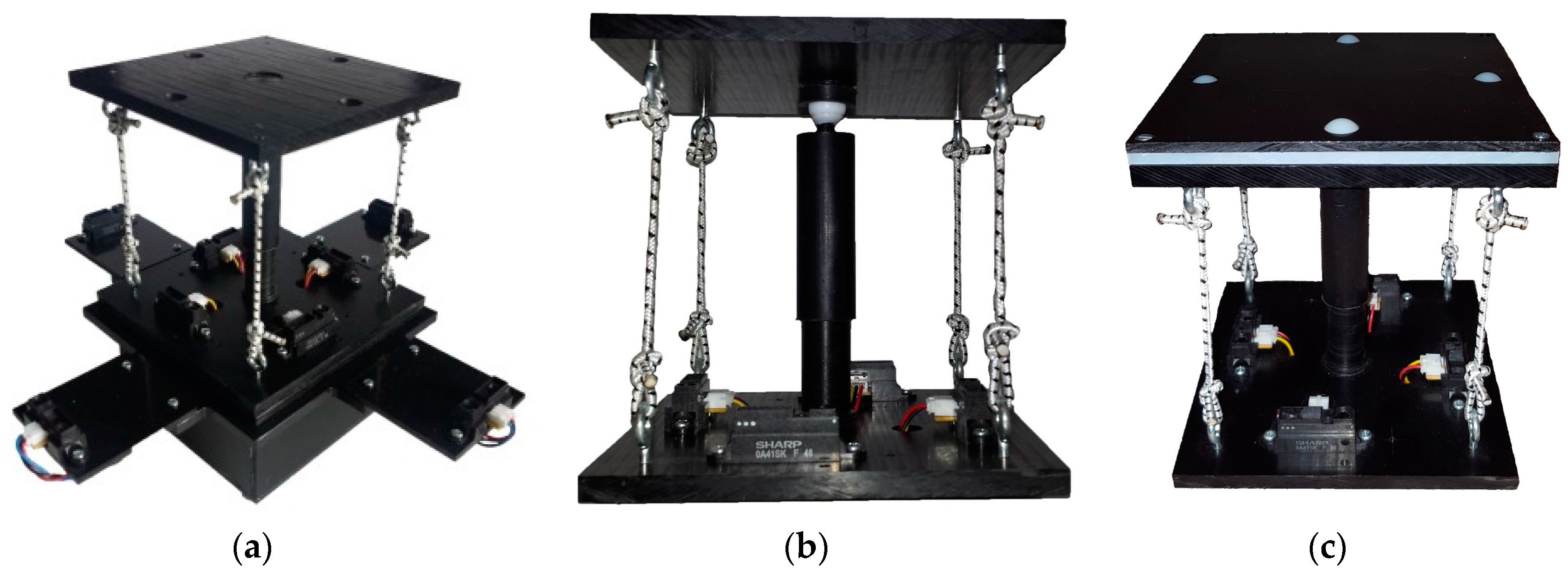

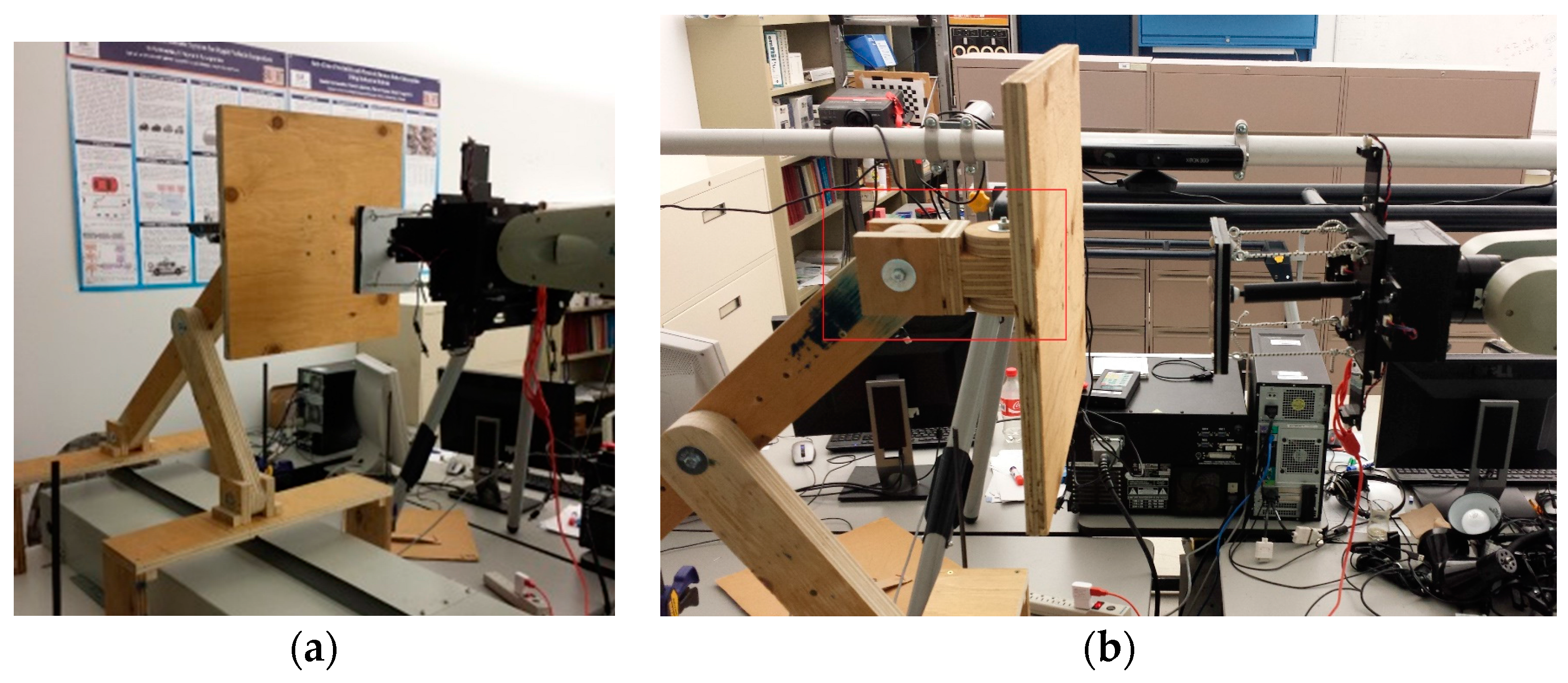

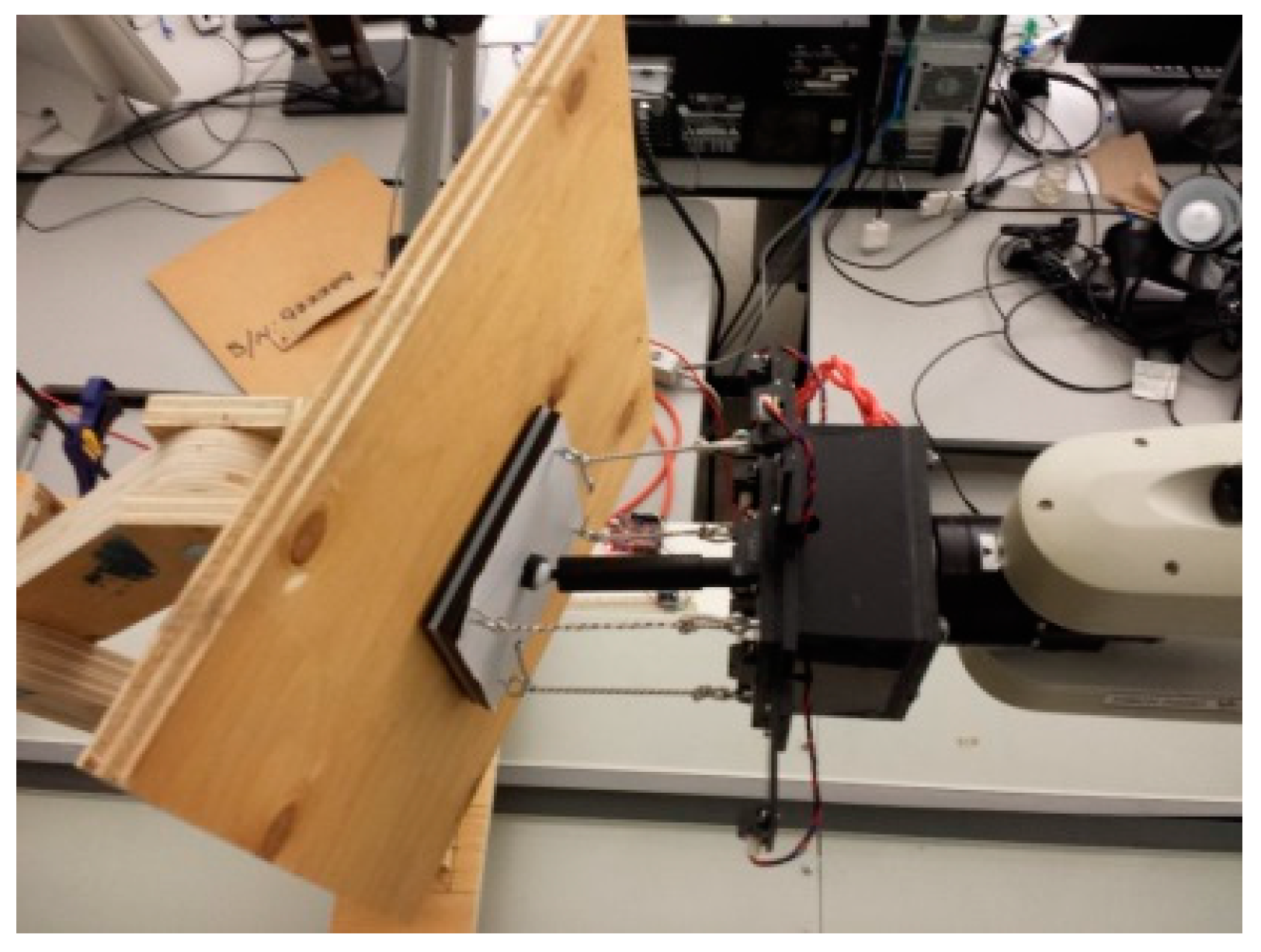

4. Instrumented Compliant Wrist Design

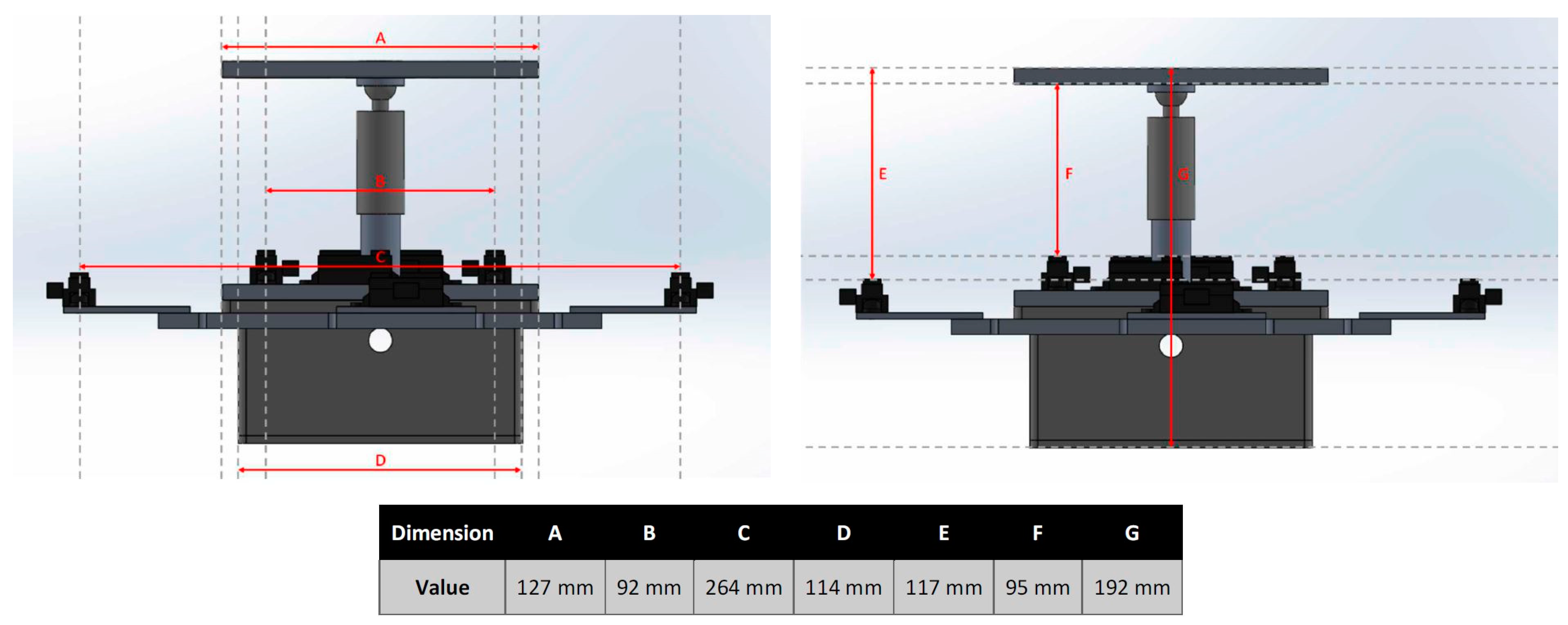

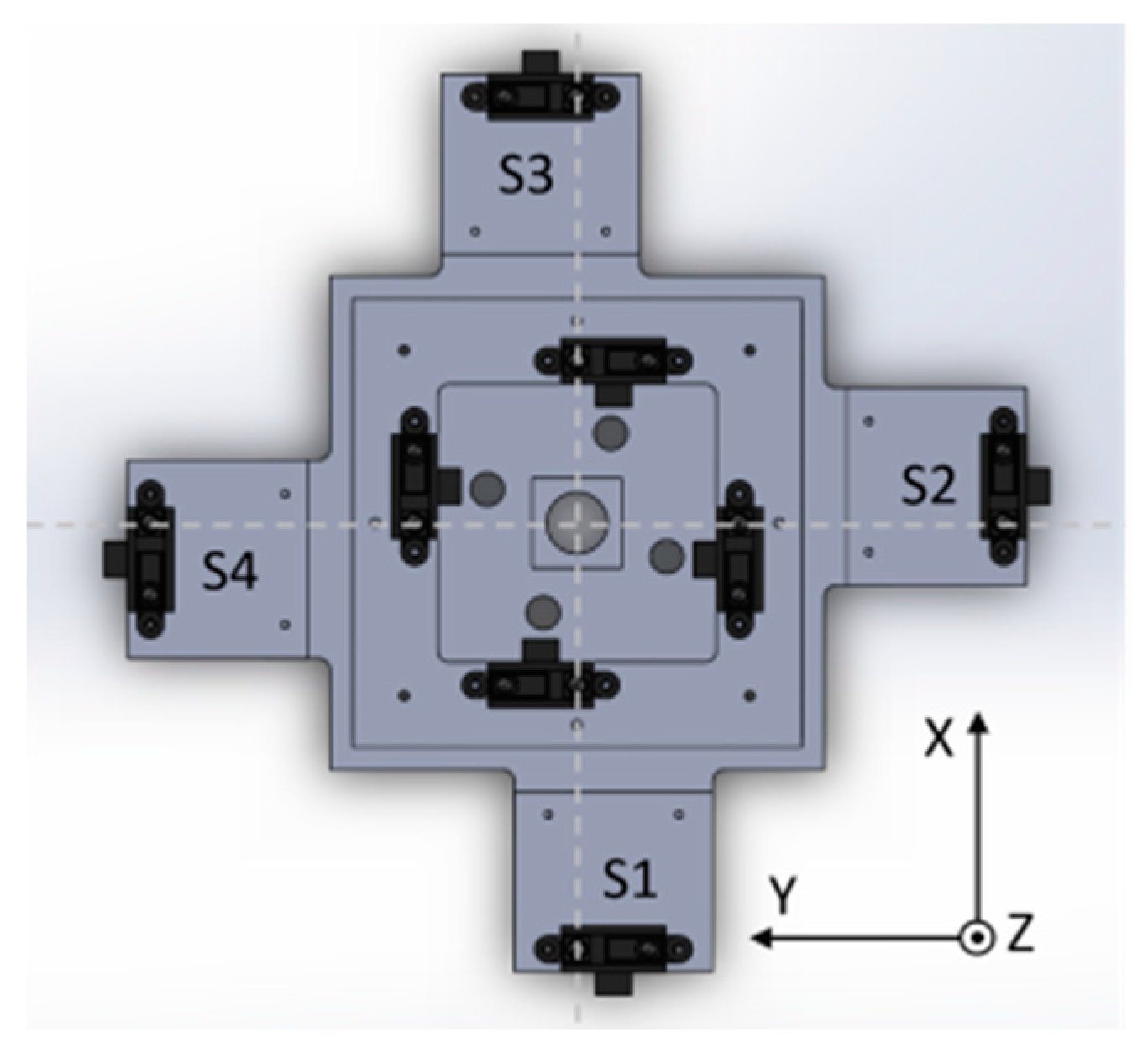

4.1. Mechanical System Design

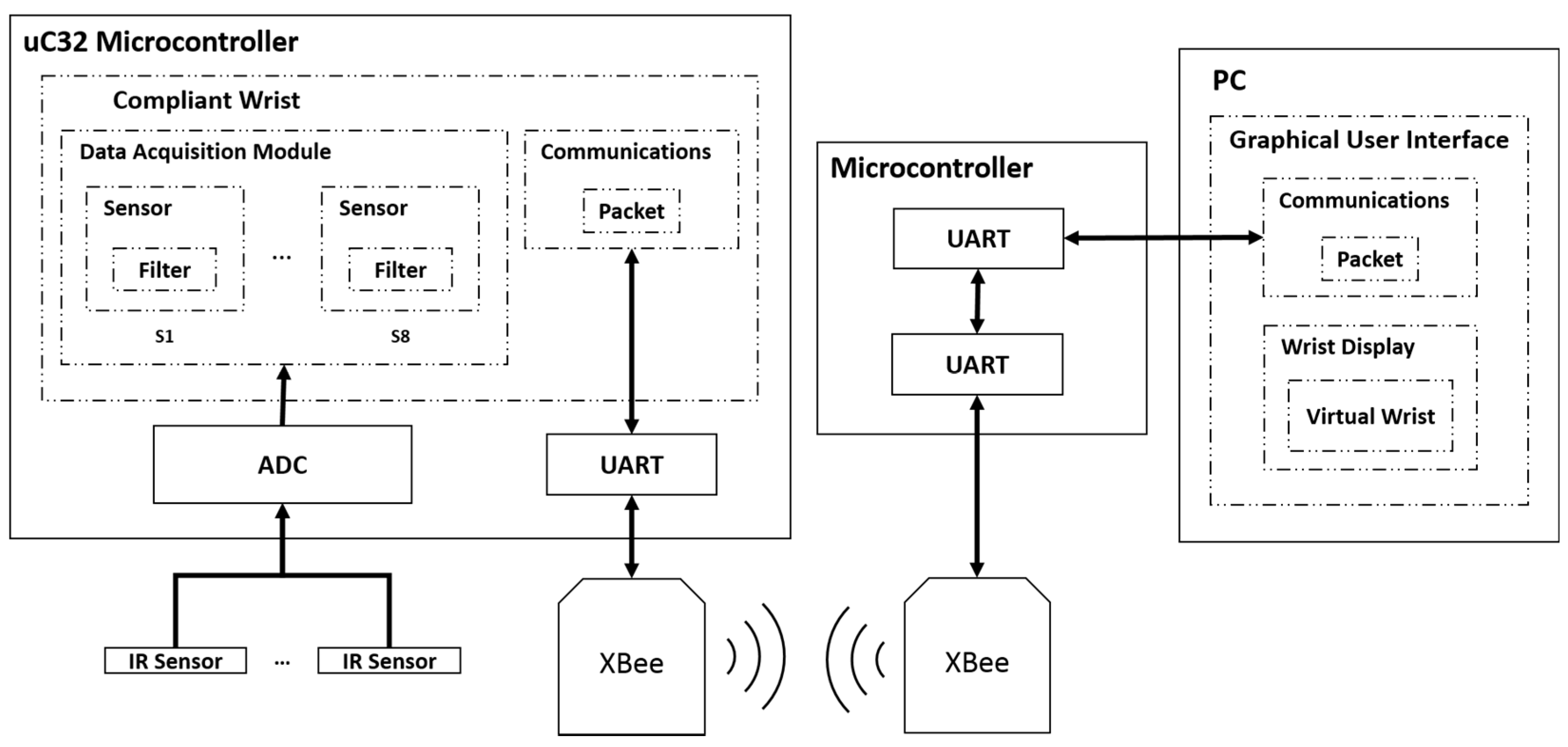

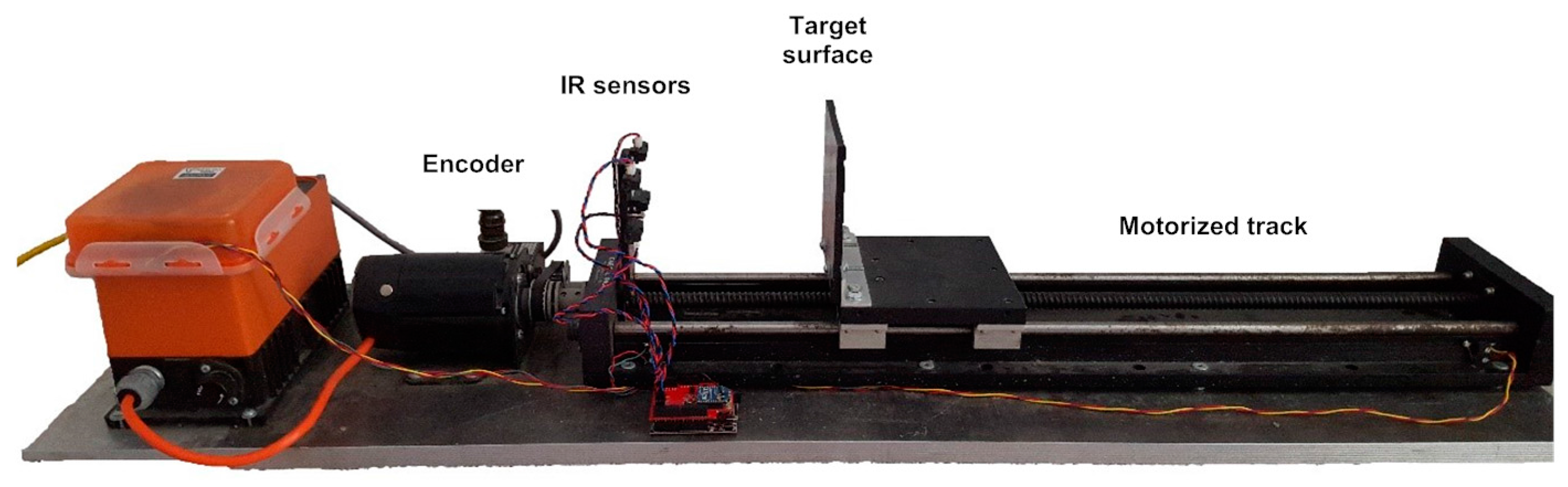

4.2. Embedded Instrumentation

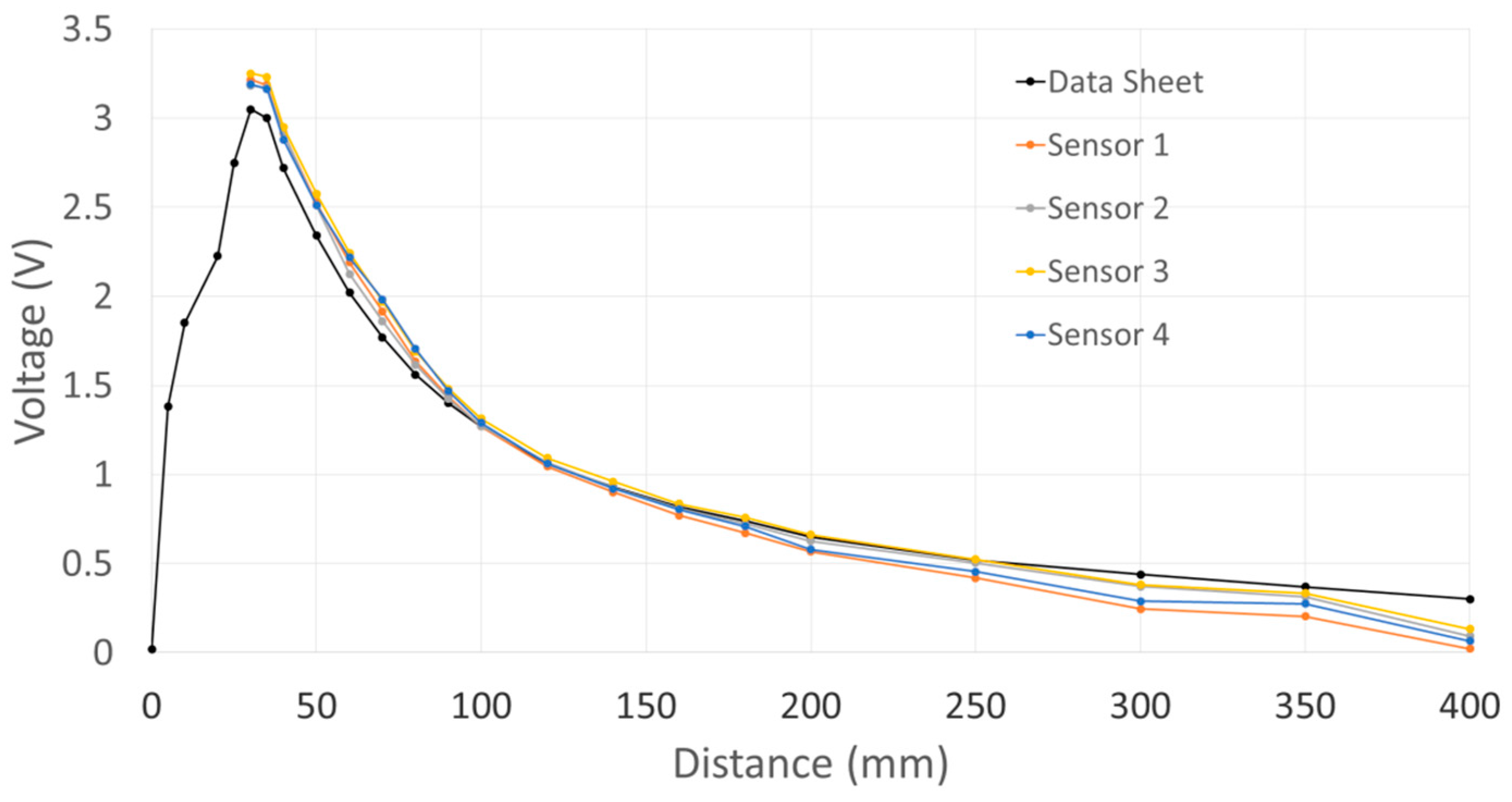

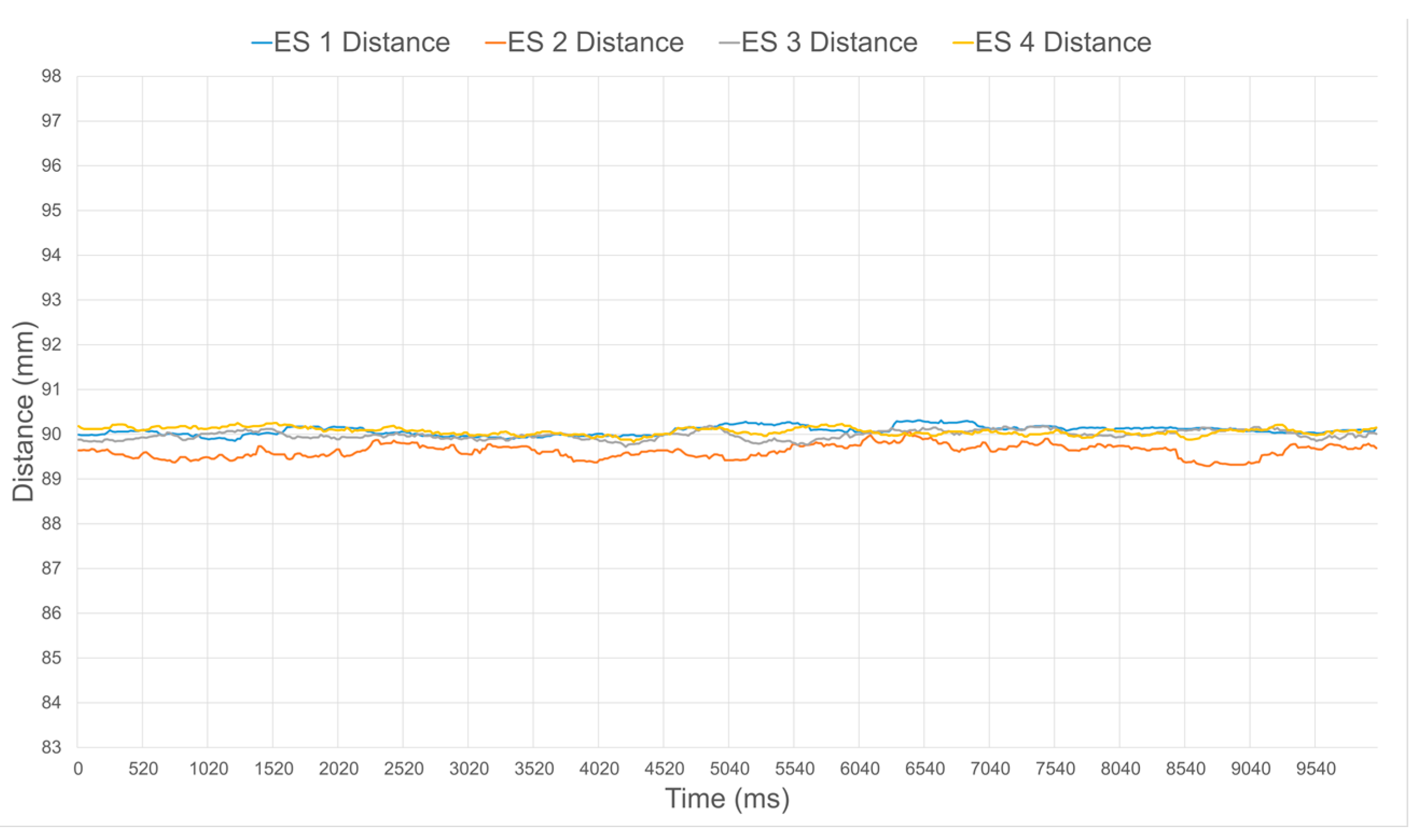

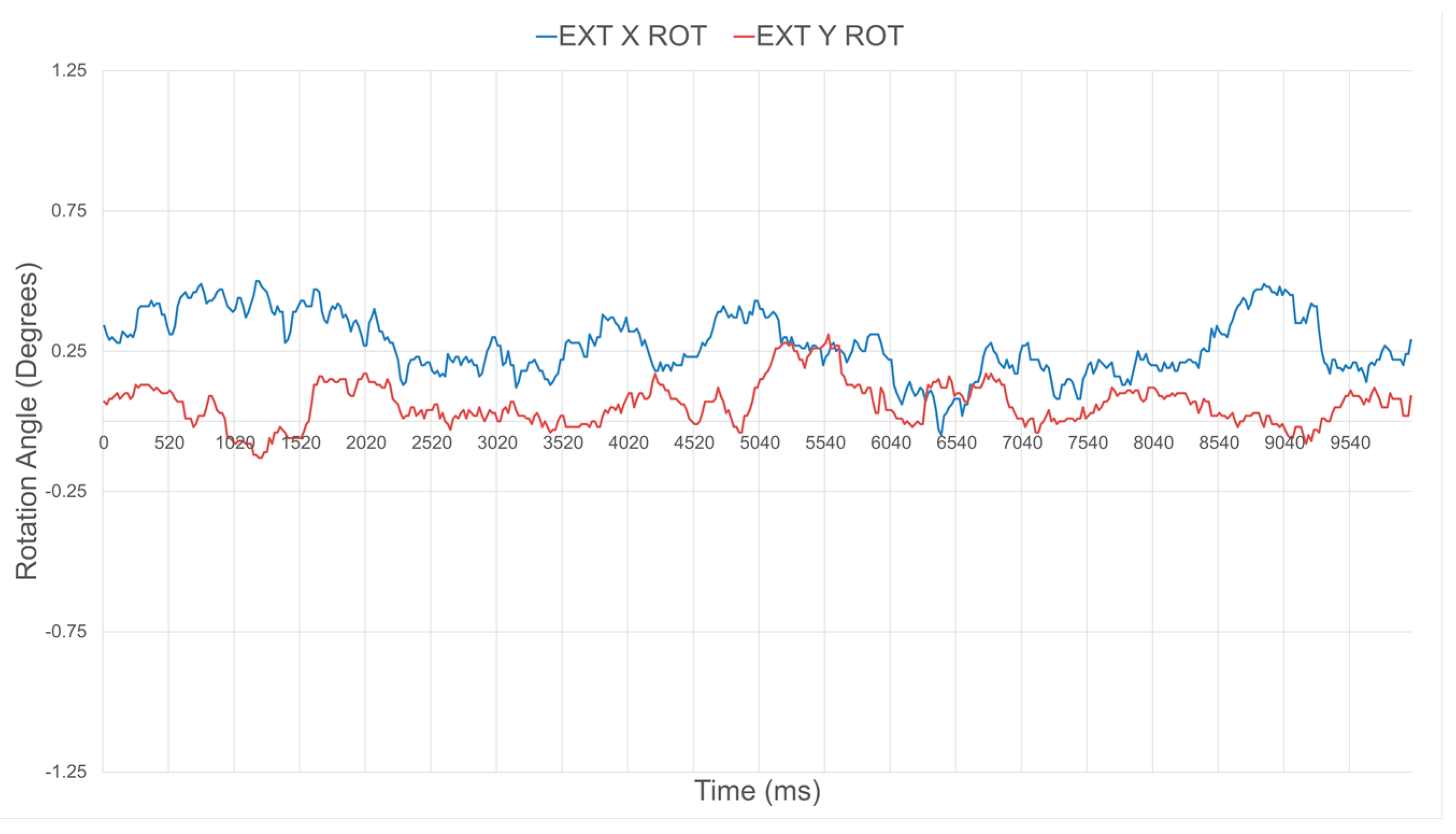

4.3. Sensors Calibration

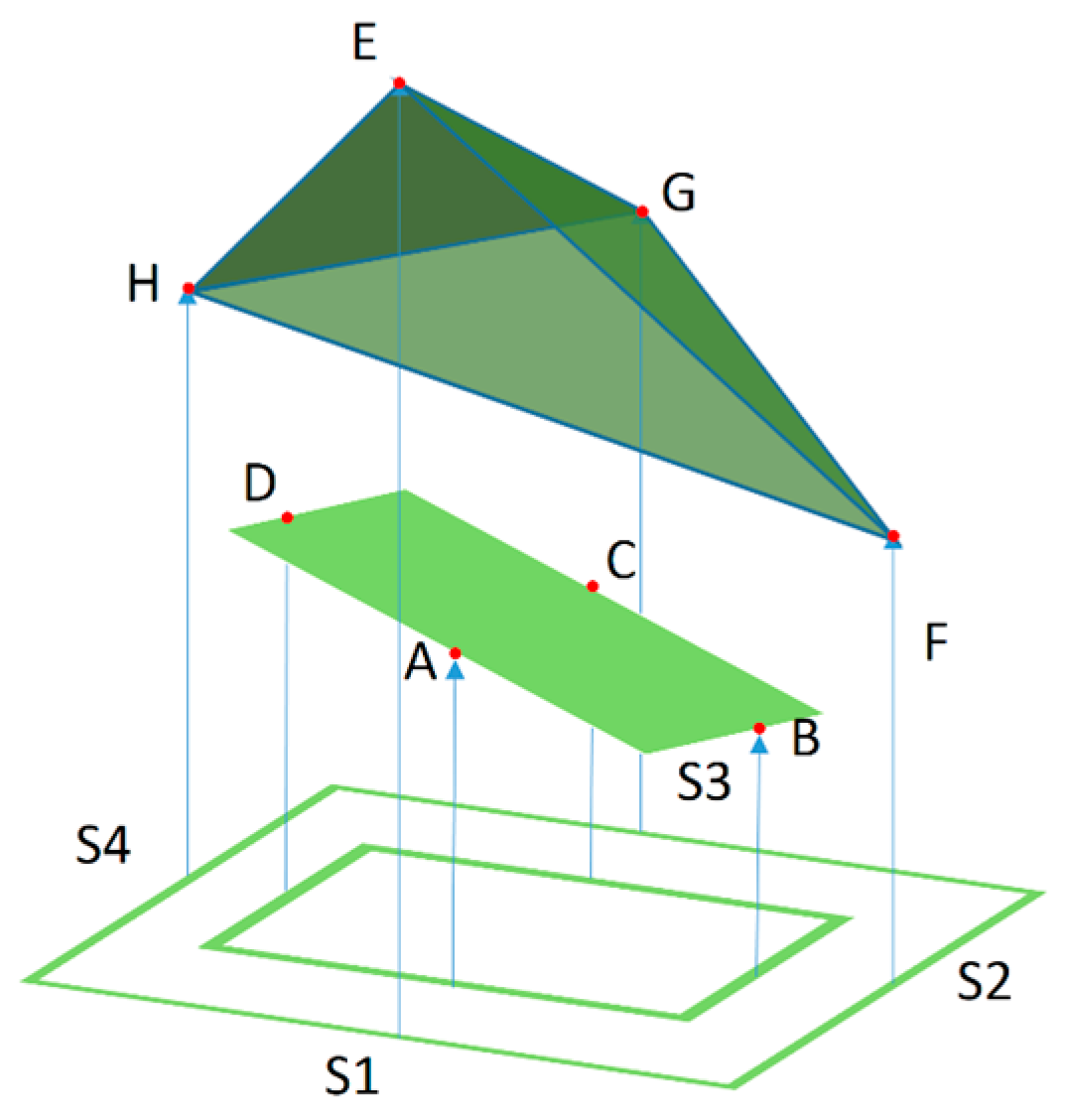

4.4. Kinematic Representation

5. Compliant Wrist Experimental Characterization and Performance Evaluation

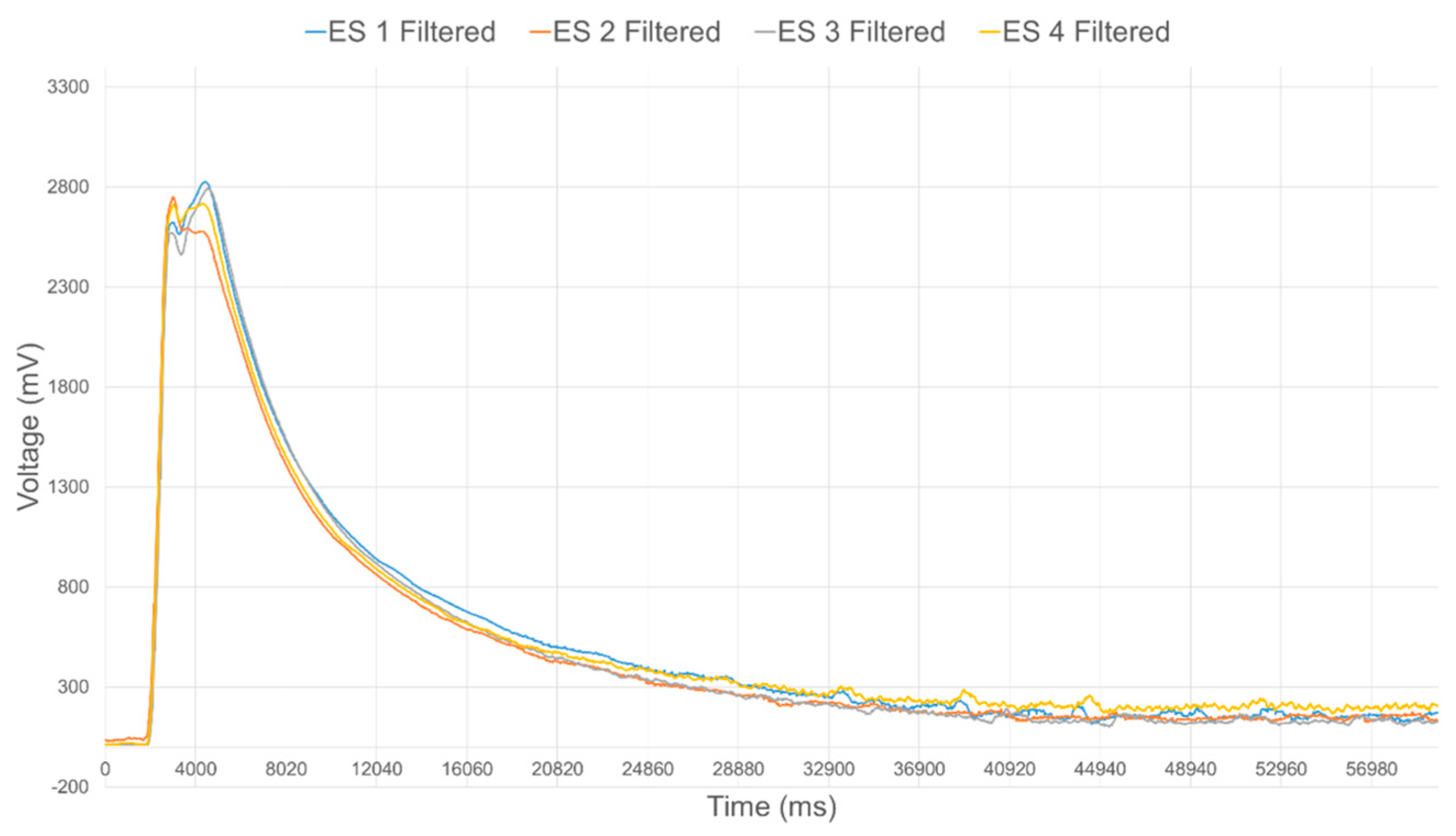

5.1. Range Sensor Layers Characterization

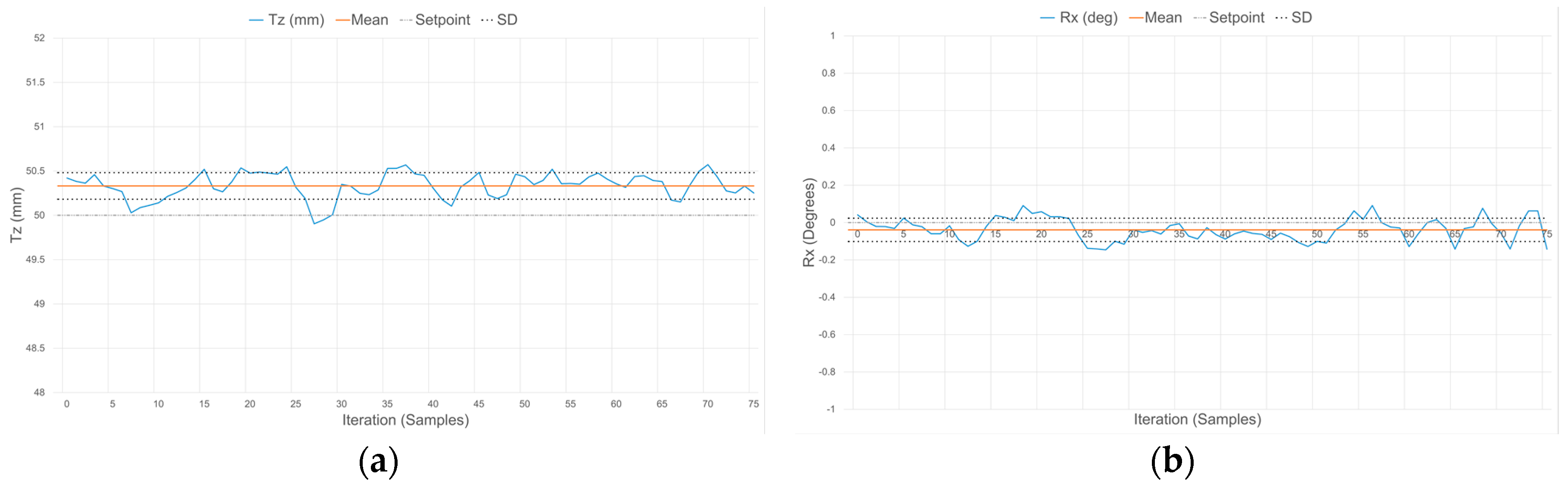

5.2. Compliant Wrist Performance Experimental Evaluation

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Laferrière, P.; Payeur, P. Proximity and Contact Sensing with Instrumented Compliant Wrist for Close Guicance of Robotic Manipulators. In Proceedings of the 3rd International Electronic Conference on Sensors and Applications, Sciforum Electronic Conference Series, 15–30 November 2016. [Google Scholar]

- Quigley, M.; Asbeck, A.; Ng, A. A Low-Cost Compliant 7-DOF Robotics Manipulator. In Proceedings of the IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011; pp. 6051–6058. [Google Scholar]

- Pratt, G.A.; Williamson, M.M. Series of Elastic Actuators. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems—Human Robot Interaction and Cooperative Robots, Pittsburgh, PA, USA, 5–9 August 1995; pp. 399–406. [Google Scholar]

- Bach-y-Rita, P.; Kercel, S.W. Sensory Substitution and the Human-Machine Interface. Trends Cognit. Sci. 2003, 7, 541–546. [Google Scholar] [CrossRef]

- Torres-Jara, E. Obrero: A Platform for Sensitive Manipulation. In Proceedings of the IEEE-RAS International Conference on Humanoid Robotics, Tsukuba, Japan, 5 December 2005; pp. 327–332. [Google Scholar]

- Bicchi, A.; Peshkin, M.A.; Colgate, J.E. Safety for Physical Human-Robot Interaction. In Springer Handbook of Robotics; Springer: Berlin/Heidelberg, Germany, 2008; pp. 1335–1348. [Google Scholar]

- Siciliano, B.; Villani, L. Robot Force Control; Springer Science & Business Media: New York, NY, USA, 1999. [Google Scholar]

- Siciliano, B.; Sciavico, L.; Villani, L.; Oriolo, J. Robotics: Modelling, Planning and Control, 1st ed.; Springer: London, UK, 2009. [Google Scholar]

- Li, E.C.; Li, Z.M. Surface Tracking with Robot Force Control in Unknown Environment. Adv. Mater. Res. 2011, 328–330, 2140–2143. [Google Scholar] [CrossRef]

- Ibrayev, R.; Jia, Y.B. Recognition of Curved Surfaces from “One-dimensional” Tactile Data. IEEE Trans. Autom. Sci. Eng. 2012, 9, 613–621. [Google Scholar] [CrossRef]

- Payeur, P.; Pasca, C.; Cretu, A.-M.; Petriu, E.M. Intelligent Haptic Sensor System for Robotic Manipulation. IEEE Trans. Instrum. Measurem. 2005, 54, 1583–1592. [Google Scholar] [CrossRef]

- Hutchinson, S.; Hager, G.; Corke, P. A tutorial on visual servo control. IEEE Trans. Robot. Autom. 1996, 12, 651–670. [Google Scholar] [CrossRef]

- Hosoda, K.; Igarashi, K.; Asada, M. Adaptive Hybrid Visual Servoing/Force Control in Unknown Environment. In Proceedings of the International Conference on Intelligent Robots and Systems, Osaka, Japan, 4–8 November 1996; pp. 1097–1103. [Google Scholar]

- Siradjuddin, I.; Behera, L.; McGinnity, T.M.; Coleman, S. A position based visual tracking system for a 7 DOF robot manipulator using a Kinect camera. In Proceedings of the 2012 International Joint Conference on Neural Networks, Brisbane, Australia, 10–15 June 2012; pp. 1–7. [Google Scholar]

- García, G.J.; Gil, P.; Llácer, D.; Torres, F. Guidance of Robot Arms using Depth Data from RGB-D Camera. In Proceedings of the 10th International Conference on Informatics in Control, Automation and Robotics, Reykjavík, Iceland, 29 July 2013; pp. 315–321. [Google Scholar]

- Castano, A.; Hutchinson, S. Visual Compliance: Task-directed Visual Servo Control. IEEE Trans. Robot. Autom. 1994, 10, 334–342. [Google Scholar] [CrossRef]

- Fisher, W.D.; Mujtaba, M.S. Hybrid Position/Force Control: A Correct Formulation. Int. J. Robot. Res. 1992, 11, 299–311. [Google Scholar] [CrossRef]

- Fomena, R.T.; Quintero, C.P.; Gridseth, M.; Jagersand, M. Towards Practical Visual Servoing in Robotics. In Proceedings of the 10th Conference on Computer and Robot Vision, Regina, Saskatchewan, 28–31 May 2013; pp. 303–310. [Google Scholar]

- Cutkosky, M.R.; Wright, P.K. Position Sensing Wrists for Industrial Manipulators. In Proceedings of the 12th International Symposium on Industrial Robotics, Paris, France, 15 June 1982; pp. 427–438. [Google Scholar]

- Wolffenbuttel, R.F.; Mahmoud, K.M.; Regtien, P.P.L. Compliant Capacitive Wrist Sensor for Use in Industrial Robots. IEEE Trans. Instrum. Measurem. 1990, 39, 991–997. [Google Scholar] [CrossRef]

- Wolffenbuttel, R.F.; Mahmoud, K.M.; Regtien, P.P.L. Multiaxis Compliant Capacitive Wrist Sensor for Use in Automated Assembly with Industrial Robots. In Proceedings of the IEEE International Conference on Instrumentation and Measurement Technology, San Jose, CA, USA, 13–15 February 1990; pp. 54–59. [Google Scholar]

- Choi, S.W.; Choi, Y.J.; Kim, S. Using a Compliant Wrist for a Teleoperated Robot. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, Kyongju, Korea, 17–21 October 1999; pp. 585–589. [Google Scholar]

- Hashimoto, M.; Imanura, Y. Design and Characteristics of a Parallel Link Compliant Wrist. In Proceedings of the IEEE International Conference on Robotics and Automation, San Diego, CA, USA, 8–13 May 1994; pp. 2457–2462. [Google Scholar]

- Sergi, F.; Lee, M.M.; O’Malley, M.K. Design of a Series Elastic Actuator for a Compliant Parallel Wrist Rehabilitation Robot. In Proceedings of the IEEE International Conference on Rehabilitation Robotics, Seattle, WA, USA, 24–26 June 2013; pp. 1–6. [Google Scholar]

- Lindsay, T.S.; Sinha, P.R.; Paul, R.P. An Instrumented Compliant Wrist for Robotics Applications. In Proceedings of the IEEE International Conference on Robotics and Automation, Atlanta, GA, USA, 2–6 May 1993; pp. 648–653. [Google Scholar]

- Sinha, P.R.; Xu, Y.; Bajcsy, R.K.; Paul, R.P. Robotic Exploration of Surfaces with a Compliant Wrist Sensor. Int. J. Robot. Res. 1993, 12, 107–120. [Google Scholar] [CrossRef]

- Petriu, E.; McMath, W.S.; Yueng, S.S.K.; Trif, N. Active Tactile Perception of Object Surface Geometric Profiles. IEEE Trans. Instrum. Measurem. 1992, 41, 87–92. [Google Scholar] [CrossRef]

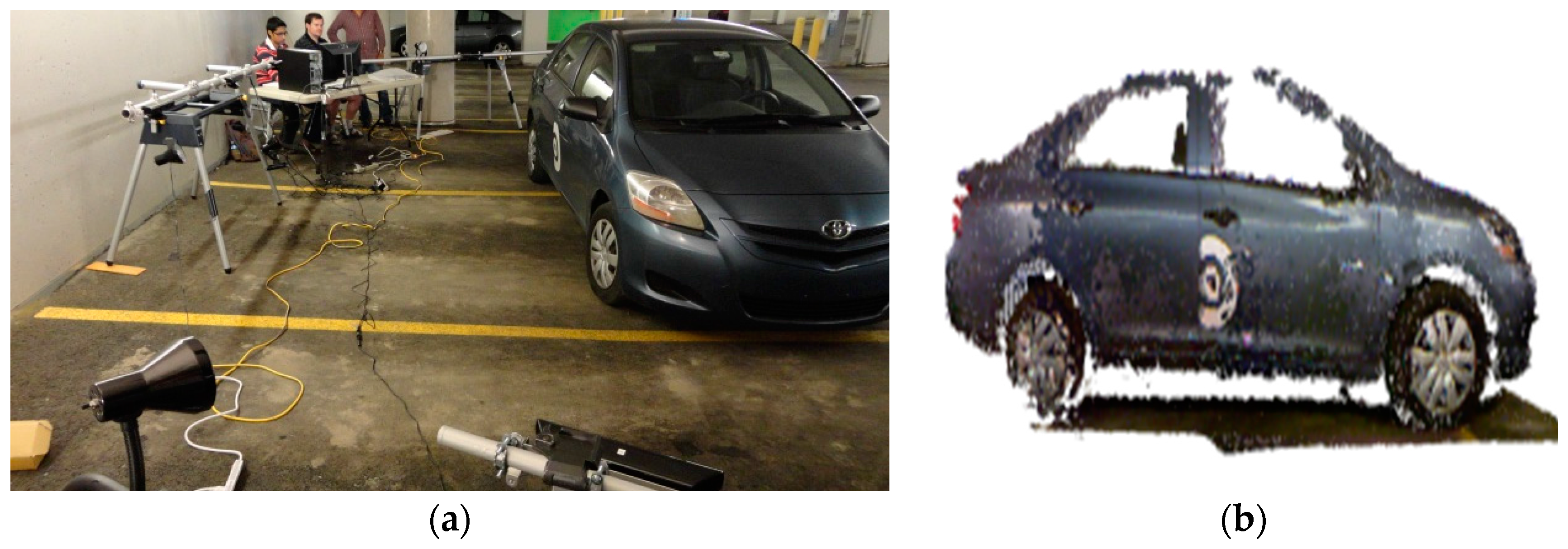

- Fareh, R.; Payeur, P.; Nakhaeinia, D.; Macknojia, R.; Chavez-Aragon, A.; Cretu, A.-M.; Laferrière, P.; Laganière, R.; Toledo, R. An Integrated Vision-Guided Robotic System for Rapid Vehicle Inspection. In Proceedings of the IEEE Intl Systems Conference, Ottawa, ON, Canada, 31 March–3 April 2014; pp. 446–451. [Google Scholar]

- Chavez-Aragon, A.; Macknojia, R.; Payeur, P.; Laganière, R. Rapid 3D Modeling and Parts Recognition on Automotive Vehicles using a Network of RGB-D Sensors for Robot Guidance. J. Sens. 2013, 2003, 1–16. [Google Scholar] [CrossRef]

- Nakhaeinia, D.; Laferrière, P.; Payeur, P.; Laganière, R. Safe Close-Proximity and Physical Human-Robot Interaction Using Industrial Robots. In Proceedings of the 12th Conference on Computer and Robot Vision, Halifax, NS, Canada, 3–5 June 2015; pp. 237–244. [Google Scholar]

- Laferrière, P. Instrumented Compliant Wrist System for Enhanced Robotic Interaction. Master’s Thesis, University of Ottawa, Ottawa, ON, Canada, 5 November 2016. [Google Scholar]

| Sensor 1 (mm) | Sensor 2 (mm) | Sensor 3 (mm) | Sensor 4 (mm) | |

|---|---|---|---|---|

| Without calibration | 99.09 ± 0.10 | 109.15 ± 0.13 | 99.97 ± 0.13 | 105.65 ± 0.12 |

| With calibration | 90.08 ± 0.10 | 89.62 ± 0.15 | 89.98 ± 0.10 | 90.07 ± 0.08 |

| Rotation about X (°) | Rotation about Y (°) | |

|---|---|---|

| Without calibration | −2.17 ± 0.09 | −0.54 ± 0.10 |

| With calibration | 0.27 ± 0.11 | 0.06 ± 0.08 |

| Without Relative Rotation (Rx = 0°; Ry = 0°) | With Set Rotation of −30° (Rx = −30°; Ry = 0°) | |||||

|---|---|---|---|---|---|---|

| Set Distance | Measured Tz (mm) | Measured Rx (°) | Measured Ry (°) | Measured Tz (mm) | Measured Rx (°) | Measured Ry (°) |

| Tz = 50 mm | 50.33 ± 0.15 | −0.04 ± 0.06 | 0.01 ± 0.12 | 49.32 ± 0.49 | −30.62 ± 0.33 | −0.16 ± 0.04 |

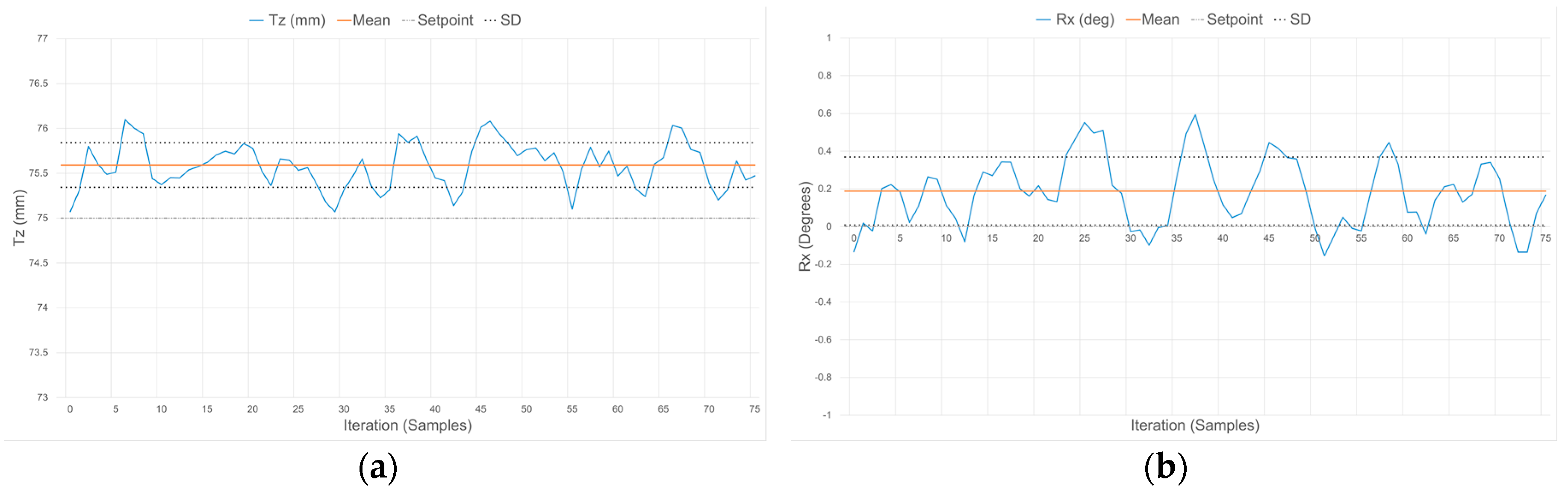

| Tz = 75 mm | 75.59 ± 0.25 | 0.19 ± 0.18 | 0.06 ± 0.24 | 75.47 ± 0.74 | −29.97 ± 0.40 | 0.09 ± 0.19 |

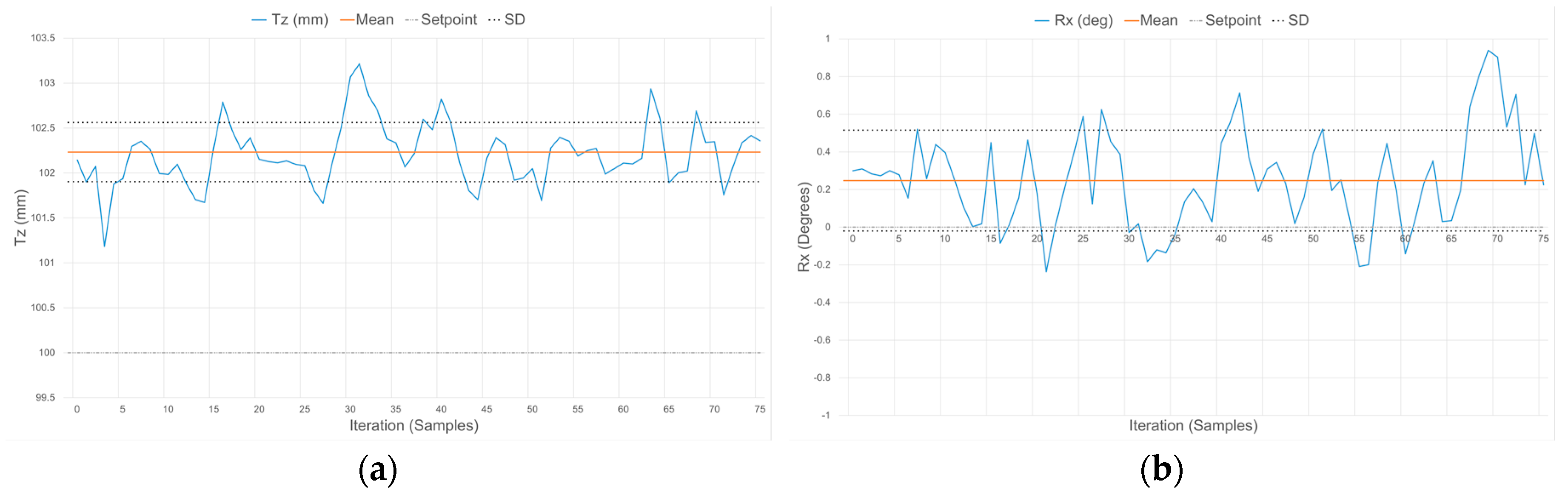

| Tz = 100 mm | 102.23 ± 0.33 | 0.25 ± 0.27 | −0.06 ± 0.22 | 101.60 ± 0.62 | −30.47 ± 0.33 | 0.38 ± 0.22 |

| Without Relative Rotation (Rx = 0°; Ry = 0°) | With Set Rotation of −10° (Rx = −10°; Ry = 0°) | |||||

|---|---|---|---|---|---|---|

| Set Distance | Measured Tz (mm) | Measured Rx (°) | Measured Ry (°) | Measured Tz (mm) | Measured Rx (°) | Measured Ry (°) |

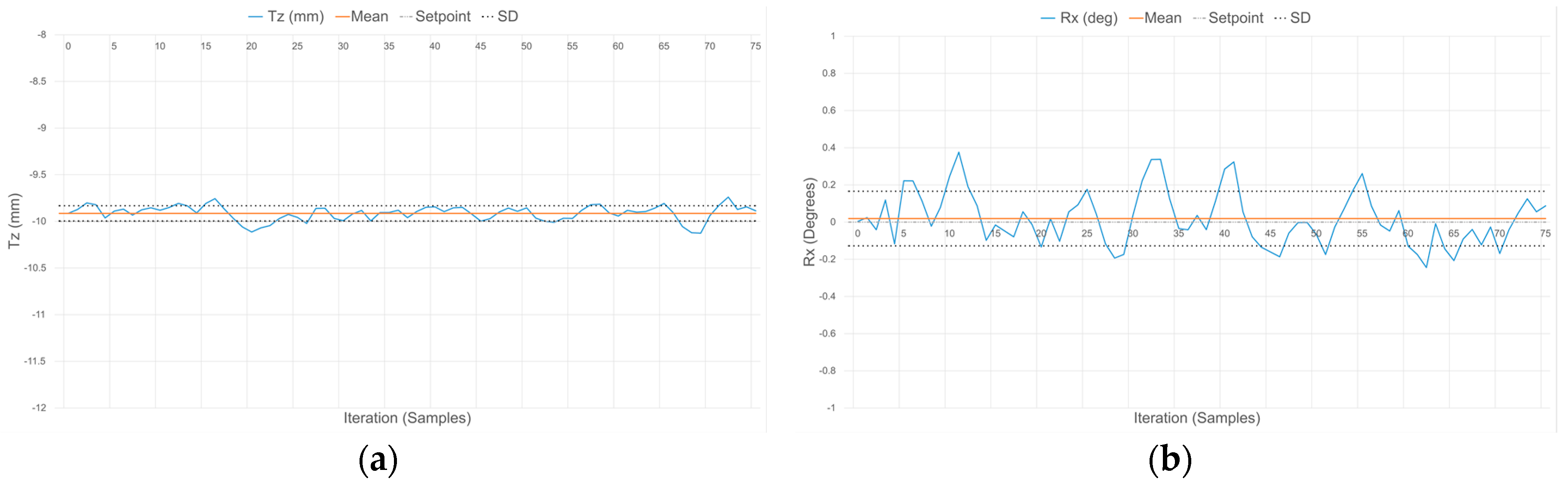

| Tz = −10 mm | −9.91 ± 0.08 | 0.02 ± 0.14 | 0.05 ± 0.15 | −9.88 ± 0.09 | −10.36 ± 0.13 | −0.10 ± 0.19 |

| Tz = −20 mm | −19.91 ± 0.07 | −0.08 ± 0.08 | −0.01 ± 0.08 | −20.01 ± 0.07 | −10.21 ± 0.11 | 0.13 ± 0.14 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Laferrière, P.; Payeur, P. Instrumented Compliant Wrist with Proximity and Contact Sensing for Close Robot Interaction Control. Sensors 2017, 17, 1384. https://doi.org/10.3390/s17061384

Laferrière P, Payeur P. Instrumented Compliant Wrist with Proximity and Contact Sensing for Close Robot Interaction Control. Sensors. 2017; 17(6):1384. https://doi.org/10.3390/s17061384

Chicago/Turabian StyleLaferrière, Pascal, and Pierre Payeur. 2017. "Instrumented Compliant Wrist with Proximity and Contact Sensing for Close Robot Interaction Control" Sensors 17, no. 6: 1384. https://doi.org/10.3390/s17061384