Sub-Pixel Extraction of Laser Stripe Center Using an Improved Gray-Gravity Method †

Abstract

:1. Introduction

2. Methods for Center Extraction

2.1. Traditional Gray-Gravity Method (GGM)

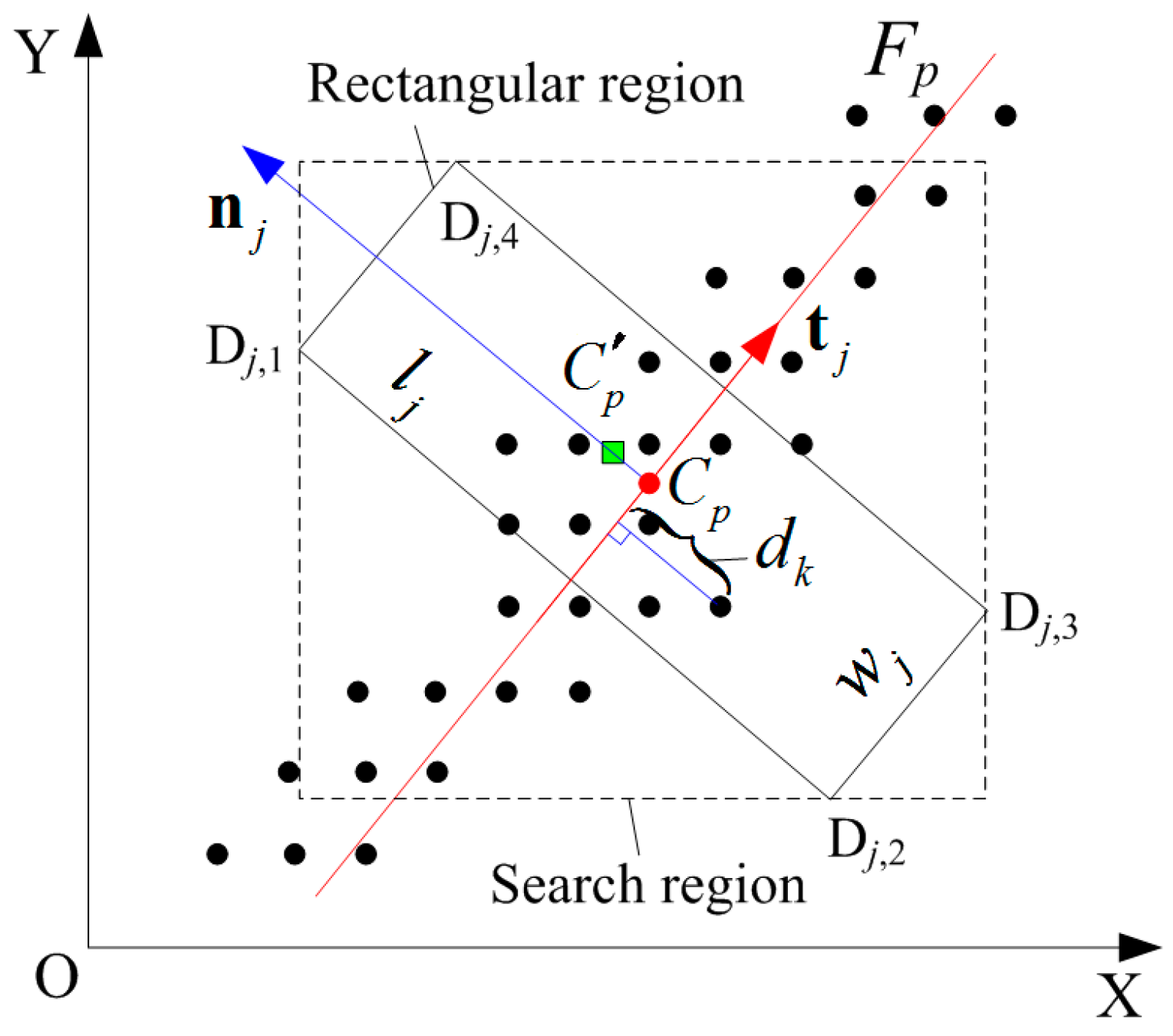

2.2. Improved Gray-Gravity Method (IGGM)

2.3. Model of Uncertainty Analysis

3. Experiment Results and Discussion

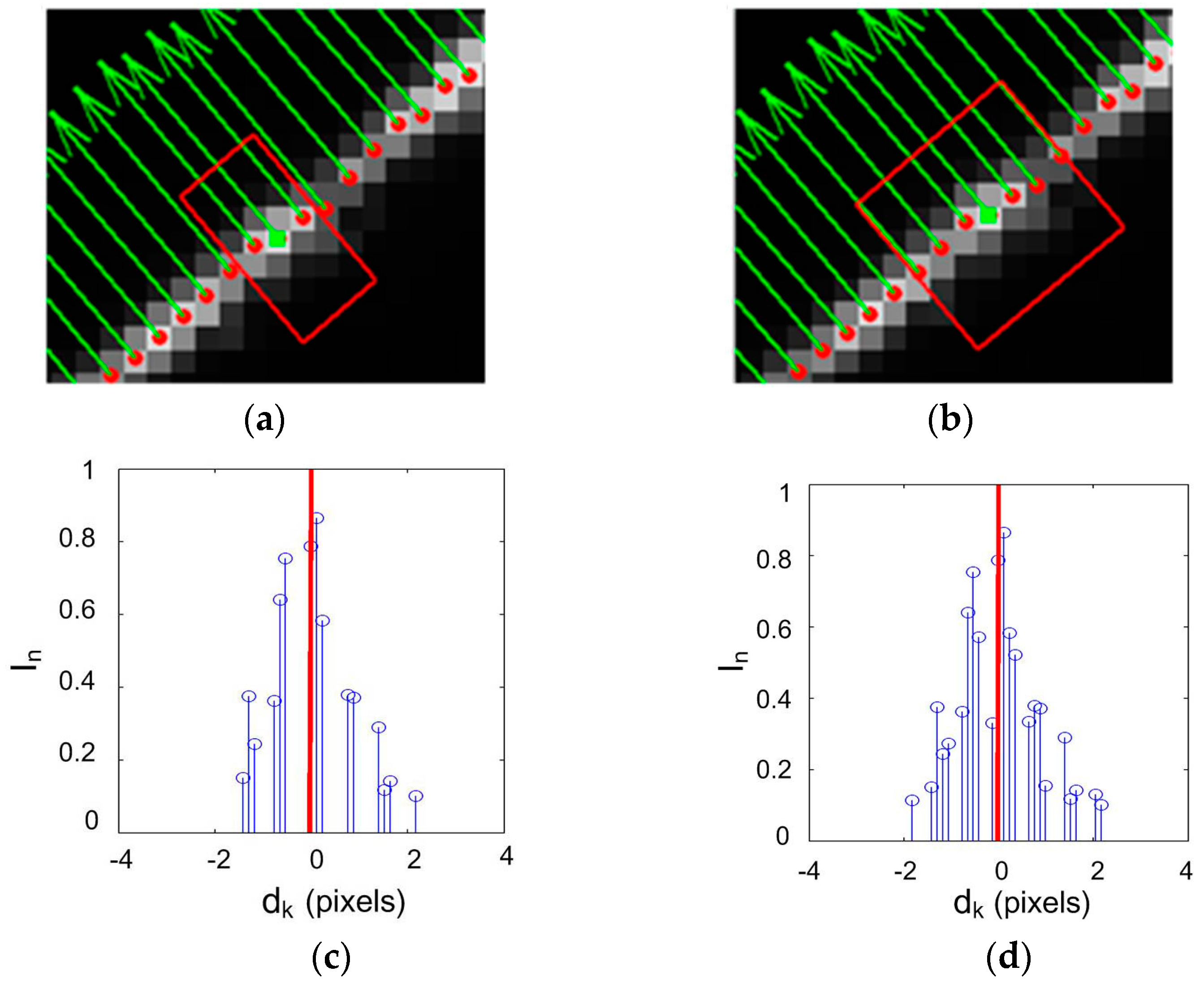

3.1. Uncertainty Analysis for Center Extraction

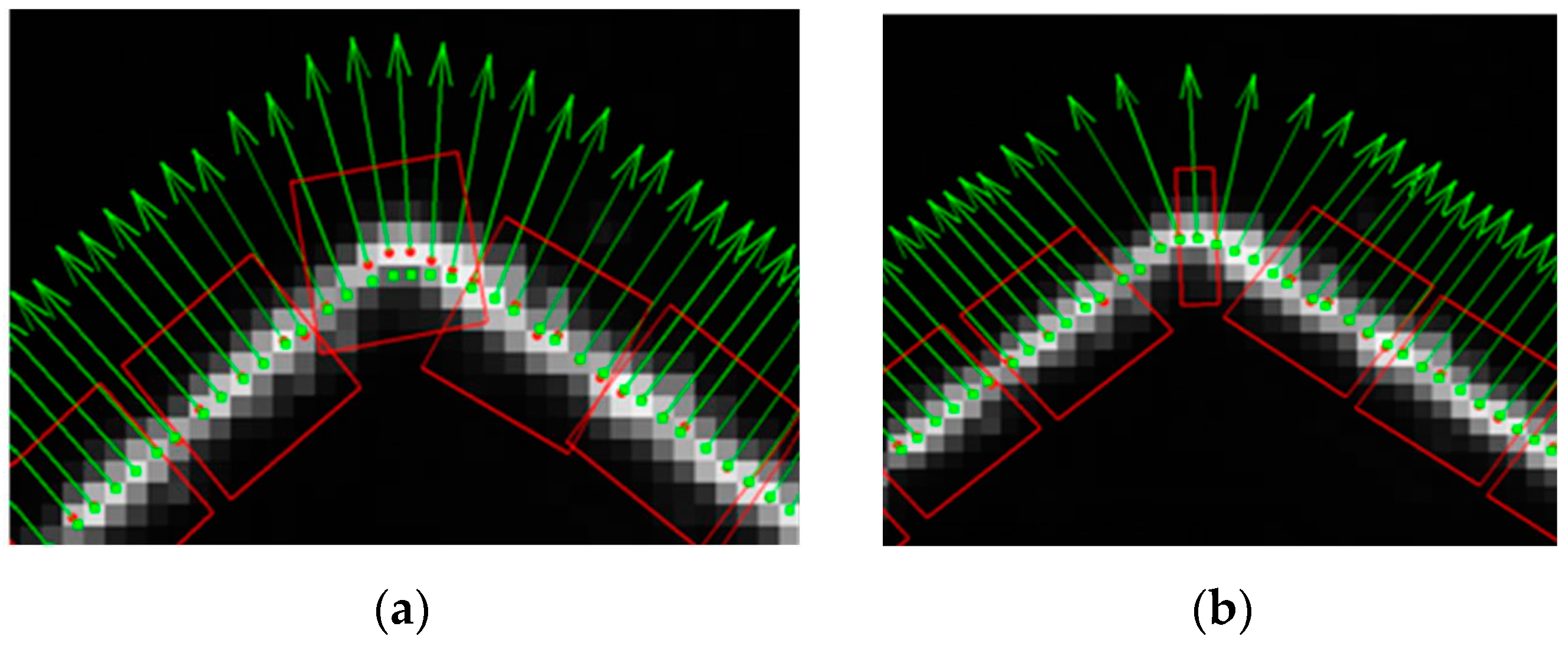

3.2. Center Extraction of Laser Stripes

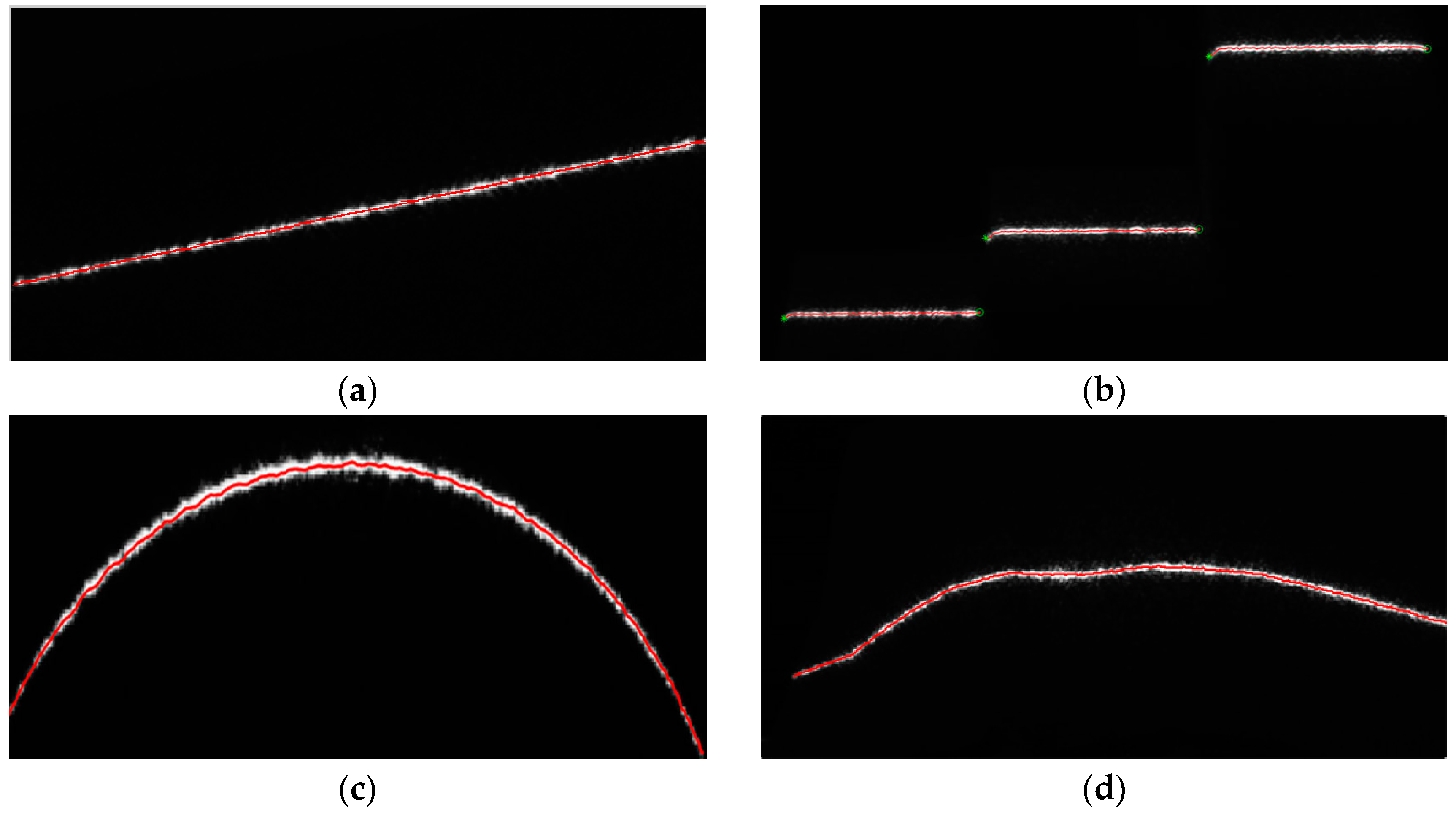

3.3. Accuracy Analysis

3.4. Run Time

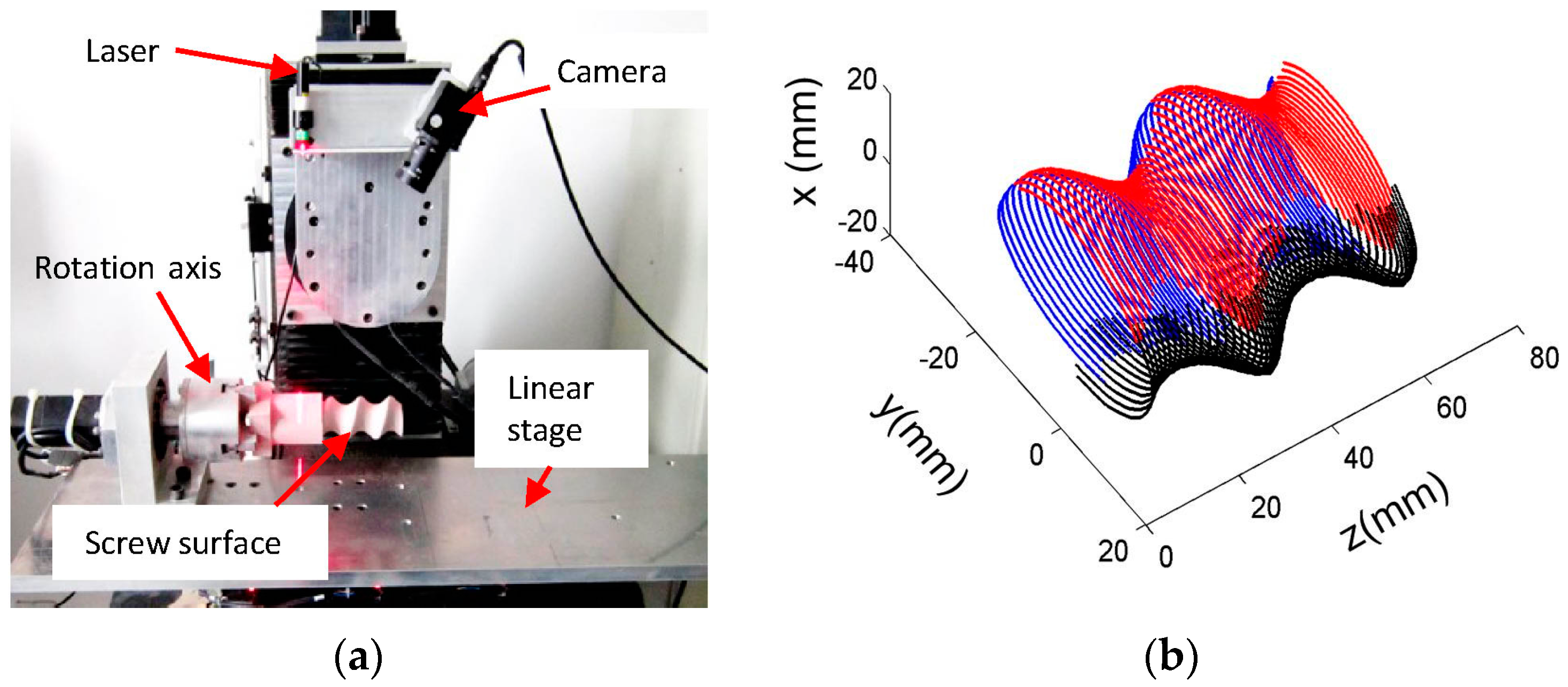

4. 2D and 3D Measurement

4.1. 2D Profile Measurement

4.2. 3D Measurement

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhan, D.; Yu, L.; Xiao, J.; Chen, T. Multi-camera and structured-light vision system (MSVS) for dynamic high-accuracy 3d measurements of railway tunnels. Sensors 2015, 15, 8664–8684. [Google Scholar] [CrossRef] [PubMed]

- Carbone, V.; Carocci, M.; Savio, E.; Sansoni, G.; De Chiffre, L. Combination of a vision system and a coordinate measuring machine for the reverse engineering of freeform surfaces. Int. J. Adv. Manuf. Technol. 2001, 17, 263–271. [Google Scholar] [CrossRef]

- Shen, H.; Lin, T.; Chen, S.; Li, L. Real-time seam tracking technology of welding robot with visual sensing. J. Intell. Robot. Syst. 2010, 59, 283–298. [Google Scholar] [CrossRef]

- Zhang, L.; Sun, J.; Yin, G.; Zhao, J.; Han, Q. A cross structured light sensor and stripe segmentation method for visual tracking of a wall climbing robot. Sensors 2015, 15, 13725–13751. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Zhou, J.; Huang, F. High precision calibration of line structured light sensors based on linear transformation over triangular domain. Proc. SPIE 2016, 9684, 968407. [Google Scholar]

- Zhang, Z.; Lin, Y. Building a 3D scanner system based on monocular vision. Appl. Opt. 2012, 51, 1638–1644. [Google Scholar] [CrossRef] [PubMed]

- Perona, P.; Malik, J. Scale-space and edge detection using anisotropic diffusion. IEEE Trans. Pattern Anal. Mach. Intell. 1990, 12, 629–639. [Google Scholar] [CrossRef]

- Hu, B.; Li, D.; Jin, G.; Hu, H. New method for obtaining the center of the structured light stripe by direction template. Comput. Eng. Appl. 2002, 38, 59–60. [Google Scholar]

- Lei, H.; Li, D.; Wang, J.; Hu, B. A method for fast detecting the center of structured light stripe. J. Huazhong. Univ. Sci. Technol. 2003, 31, 74–76. [Google Scholar]

- Subbarao, M.; Choi, T. Accurate recovery of three-dimensional shape from image focus. IEEE Trans. Pattern Anal. Mach. Intell. 1995, 17, 266–274. [Google Scholar] [CrossRef]

- Lv, Z.; Zhang, Z. Build 3D scanner system based on binocular stereo vision. J. Comput. 2012, 7, 399–404. [Google Scholar] [CrossRef]

- Usamentiaga, R.; Molleda, J.; García, D.F. Fast and robust laser stripe extraction for 3D reconstruction in industrial environments. Mach. Vis. Appl. 2012, 23, 179–196. [Google Scholar] [CrossRef]

- Forest, J.; Salvi, J.; Cabruja, E.; Pous, C. Laser stripe peak detector for 3D scanners. A FIR filter approach. In Proceedings of the ICPR 2004—the 17th International Conference on Pattern Recognition, Cambridge, UK, 23–26 August 2004; pp. 646–649. [Google Scholar]

- Goshtasby, A.; Shyu, H.L. Edge detection by curve fitting. Image Vis. Comput. 1995, 13, 169–177. [Google Scholar] [CrossRef]

- Steger, C. An unbiased detector of curvilinear structures. IEEE Trans. Pattern Anal. Mach. Intell. 1998, 20, 113–125. [Google Scholar] [CrossRef]

- Wei, Z.; Zhou, F.; Zhang, G. 3D coordinates measurement based on structured light sensor. Sens. Actuators A Phys. 2005, 120, 527–535. [Google Scholar] [CrossRef]

- Qi, L.; Zhang, Y.; Zhang, X.; Wang, S.; Xie, F. Statistical behavior analysis and precision optimization for the laser stripe center detector based on Steger’s algorithm. Opt. Express. 2013, 21, 13442–13449. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Zhang, G.; Sun, J. An efficient and accurate method for real-time processing of light stripe images. Adv. Mech. Eng. 2013, 5, 56927. [Google Scholar] [CrossRef]

- Liu, X.; Zhao, H.; Zhan, G.; Zhong, K.; Li, Z.; Chao, Y.; Shi, Y. Rapid and automatic 3D body measurement system based on a GPU—Steger line detector. Appl. Opt. 2016, 55, 5539–5547. [Google Scholar] [CrossRef] [PubMed]

- Jiang, J.; Deng, J.; Zhang, G.; Zhou, F. Real-time implementation of light stripe center extraction. Opt. Tech. 2008, 34, 170–173. [Google Scholar]

- Xu, G.; Sun, L.; Li, X.; Su, J.; Hao, Z.; Lu, X. Adaptable center detection of a laser line with a normalization approach using Hessian-matrix eigenvalues. J. Opt. Soc. Korea 2014, 18, 317–329. [Google Scholar] [CrossRef]

- Zhou, F.; Wang, F.; Zhang, G. Three-step extraction method for line-stripe in structured light vision. Chin. J. Mech. Eng. 2008, 11, 038. [Google Scholar] [CrossRef]

- Cai, H.; Feng, Z.; Huang, Z. Centerline extraction of structured light stripe based on principal component analysis. Chin. J. Lasers 2015, 42, 0308006. [Google Scholar] [CrossRef]

- Sun, Q.; Chen, J.; Li, C. A robust method to extract a laser stripe centre based on grey level moment. Opt. Lasers. Eng. 2015, 67, 122–127. [Google Scholar] [CrossRef]

- Liu, Z.; Li, S.; Feng, C. Laser stripe center extraction based on cross-correlation algorithm. Chin. J. Lasers 2013, 40, 0508004. [Google Scholar]

- Li, F.; Li, X.; Liu, Z. A multi-scale analysis based method for extracting coordinates of laser light stripe centers. Acta. Opt. Sin. 2014, 34, 1110002. [Google Scholar]

- Li, G.; Meng, Z.; Ma, F.; Zhao, H.; Ding, D.; Liu, Q.; Cheng, W. Calculation of stratum surface principal curvature based on a moving least square method. J. China Univ. Min. Technol. 2008, 18, 59–63. [Google Scholar] [CrossRef]

- Kamran, S.; Pooneh, N. A new optimized uncertainty evaluation applied to the Monte-Carlo simulation in platinum resistance thermometer calibration. Measurement. 2010, 43, 901–911. [Google Scholar]

- ISO/IEC. Uncertainty of measurement, Part 3: Guide to the Expression of Uncertainty in Measurement (GUM: 1995), Supplement 1: Propagation of distributions using a Monte Carlo method. Available online: https://www.iso.org/standard/50461.html (accessed on 30 March 2017).

- Wang, S.; Xu, J.; Zhang, Y.; Zhang, X.; Xie, F. Reliability evaluation method and application for light-stripe-center extraction. Acta. Opt. Sin. 2011, 31, 1115001. [Google Scholar] [CrossRef]

| No. | Maximum | Mean | Root Mean Square | ||||||

|---|---|---|---|---|---|---|---|---|---|

| UM | IGGM | RER | UM | IGGM | RER | UM | IGGM | RER | |

| Figure 6a | 0.908 | 0.662 | 27.1% | 0.205 | 0.152 | 25.9% | 0.266 | 0.192 | 27.8% |

| Figure 6b | 0.752 | 0.723 | 3.9% | 0.204 | 0.184 | 9.8% | 0.264 | 0.241 | 8.7% |

| Figure 6c | 2.805 | 1.325 | 52.8% | 0.661 | 0.267 | 59.6% | 0.799 | 0.345 | 56.8% |

| Figure 6d | 1.196 | 0.960 | 19.7% | 0.249 | 0.205 | 17.7% | 0.328 | 0.268 | 18.3% |

| No. | Steger | GGM | UM | IGGM |

|---|---|---|---|---|

| Figure 6a | 2.806 | 0.006 | 0.015 | 0.091 |

| Figure 6b | 2.811 | 0.006 | 0.023 | 0.089 |

| Figure 6c | 2.802 | 0.005 | 0.020 | 0.095 |

| Figure 6d | 2.819 | 0.006 | 0.047 | 0.096 |

| No. | CMM (mm) | LSLS (mm) | Error (mm) | Relative Error (%) |

|---|---|---|---|---|

| H1 | 10.0021 | 9.9851 | −0.0170 | −0.1700 |

| H2 | 18.0027 | 18.0375 | 0.0348 | 0.1933 |

| H3 | 24.0039 | 23.9687 | −0.0352 | −0.1466 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Zhou, J.; Huang, F.; Liu, L. Sub-Pixel Extraction of Laser Stripe Center Using an Improved Gray-Gravity Method †. Sensors 2017, 17, 814. https://doi.org/10.3390/s17040814

Li Y, Zhou J, Huang F, Liu L. Sub-Pixel Extraction of Laser Stripe Center Using an Improved Gray-Gravity Method †. Sensors. 2017; 17(4):814. https://doi.org/10.3390/s17040814

Chicago/Turabian StyleLi, Yuehua, Jingbo Zhou, Fengshan Huang, and Lijian Liu. 2017. "Sub-Pixel Extraction of Laser Stripe Center Using an Improved Gray-Gravity Method †" Sensors 17, no. 4: 814. https://doi.org/10.3390/s17040814