VineSens: An Eco-Smart Decision-Support Viticulture System

Abstract

:1. Introduction

2. Related Work: Academic and Commercial Systems for Vineyard Monitoring

3. Epidemiological Models for Preventing Downy Mildew

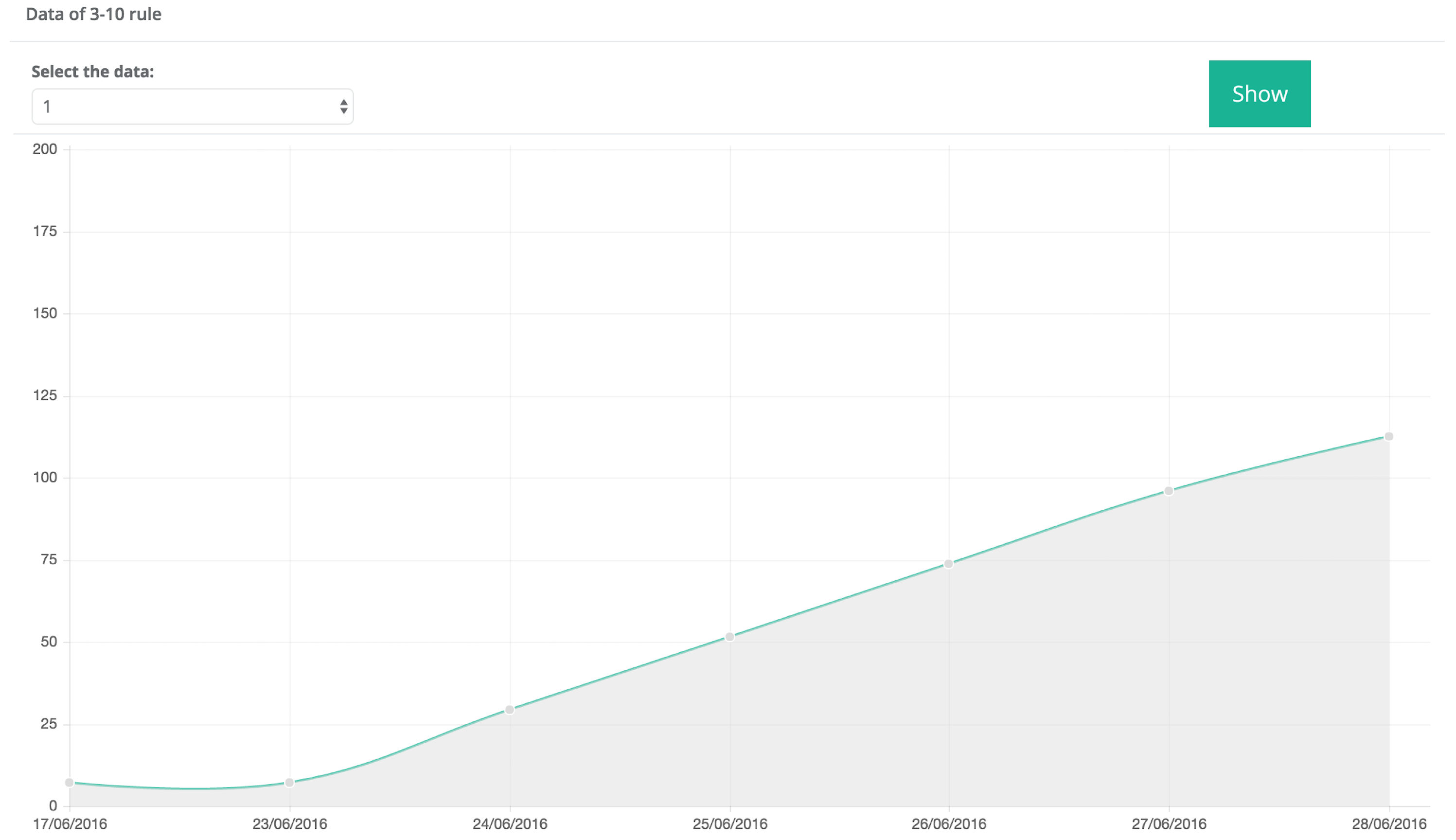

3.1. Rule 3-10

3.2. EPI Model

3.3. DMCast Model

3.4. UCSC Model

3.5. Model Comparison

4. VineSens Design

4.1. Functionality of the System

- It keeps a record of the main parameters that affect the development of the vine, being able to consult them through the Internet by using a wide range of devices.

- It assists in preventing diseases through predictive models, obtaining ad-hoc alerts from the farm. Specifically, a software algorithm based on the Rule 3-10 was devised and implemented. The algorithm automates the detection of both primary and secondary downy mildew infections and sends alerts to the users. Such an algorithm is hosted on a central server that once a day checks the status of the infection using the environmental parameters collected from the nodes. Then, the Rule 3-10 index is calculated according to Table 1. When the accumulated index value exceeds a threshold (e.g., 80%), an alert is sent to the user. A complete flow diagram of the algorithm that illustrates its inner workings and complexity is depicted in Figure 1.

- It helps to reduce and prevent environmental pollution, rationalizing the application of treatments to avoid over-treatment and the presence of harmful environmental agents.

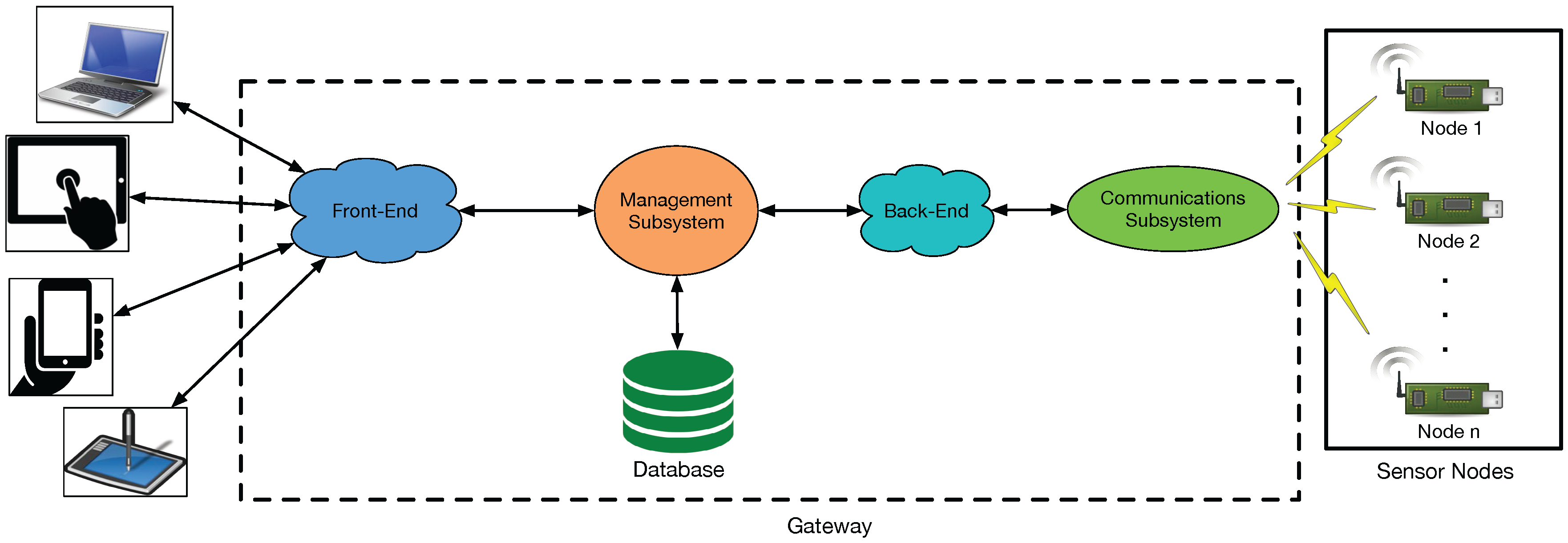

4.2. VineSens Architecture

4.2.1. Global Overview

- Communications subsystem. It is responsible for transferring the information collected from the sensor nodes to the management subsystem. Communications are performed through a Representational State Transfer (REST) Application Programming Interface (API).

- Management subsystem. This subsystem is divided into two parts. On the one hand, it provides a back-end server to manage the data obtained through the communications subsystem. On the other hand, it provides a front-end server to offer access to VineSens to remote users. It also manages a database that stores the collected data and all the necessary data structures of the back-end and the front-end.

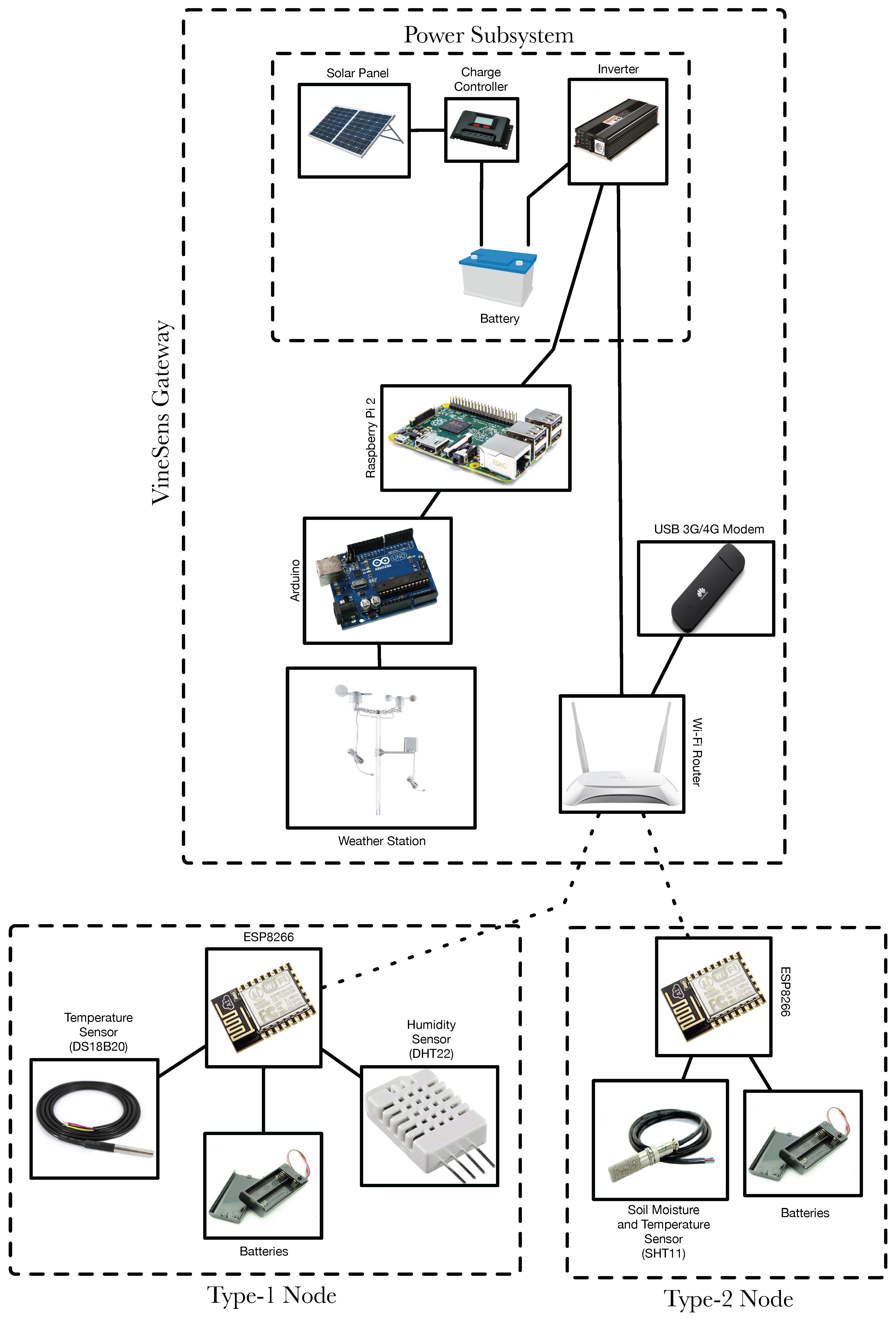

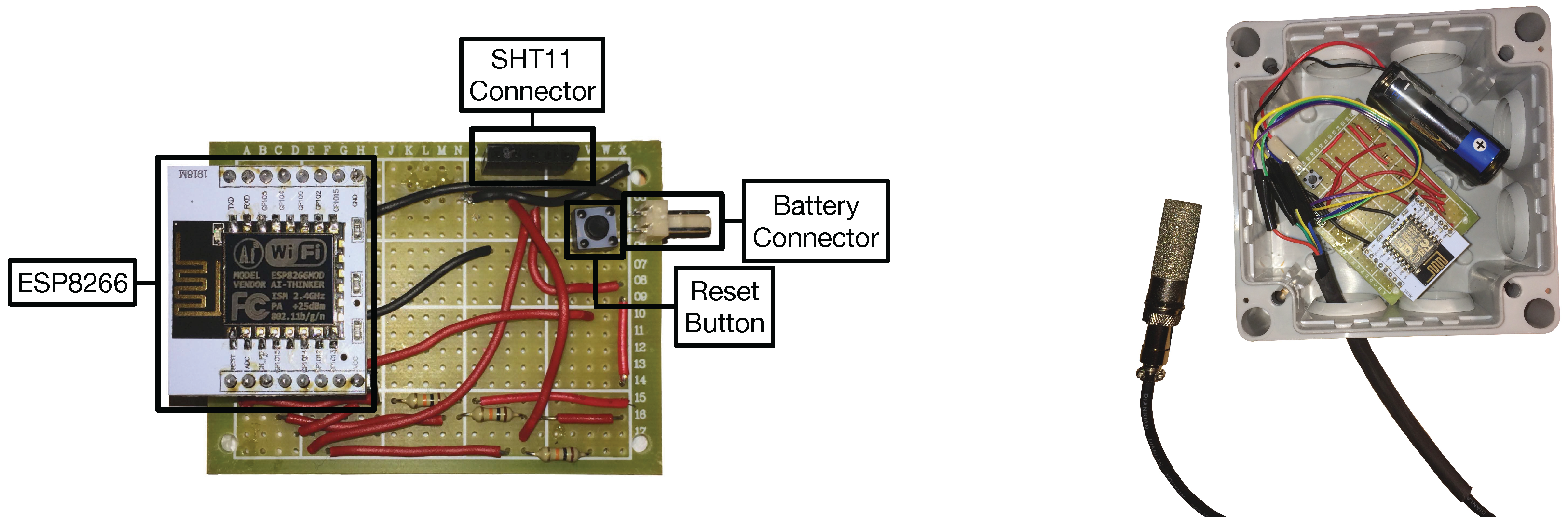

4.2.2. Sensor Nodes

4.2.3. Gateway Hardware

Gateway Control Hardware

Communications Subsystem Technology

Weather Station

Gateway Power Subsystem

- A 160 W solar polycrystalline panel with a 12 V output and an internal regulator for the battery. This kind of panel was chosen because it gives a good trade-off between cost, weight, and efficiency.

- A 90 Ah lead-acid battery. This kind of battery would last three successive days without sun, what is considered enough for the place where VineSens was deployed.

- A 300 W power inverter (MJ-300-12, Xunzel, Mendaro, Spain) to convert from 12 V to 220 V. Note that it would be also valid to use a 12 V/5 V DC converter if the Raspberry Pi-based gateway was the only device actually powered, but it was selected the DC/AC inverter to increase the scalability of the system and allow us to add other AC-powered devices easily (like the TP-LINK Wi-Fi router used by the gateway).

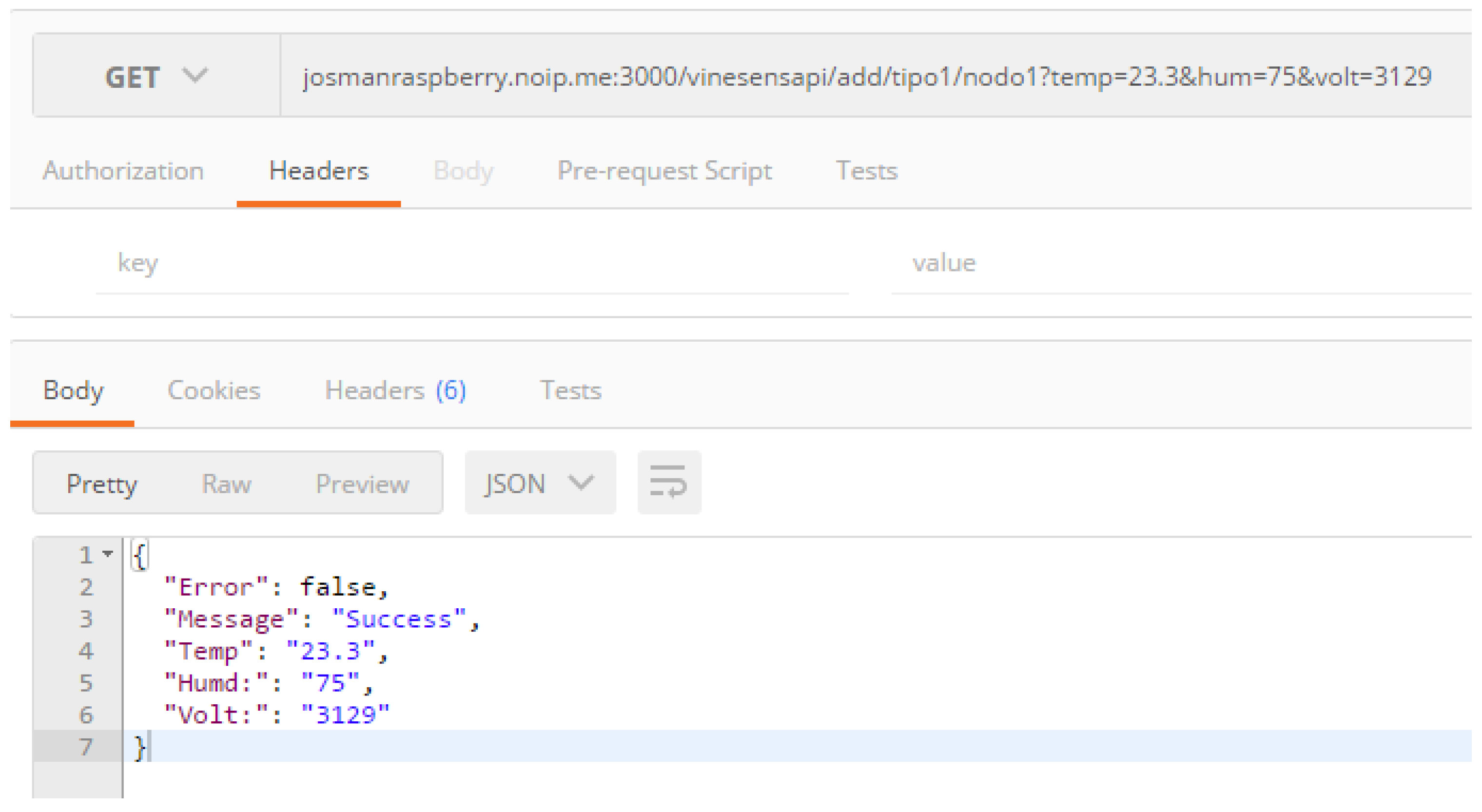

4.2.4. Gateway Software

- A REST API that monitors and stores the data collected by the sensor nodes and that acts as a back-end, which has been implemented using Node.js [63]. The back-end could be potentially on the cloud, but it is actually on the Raspberry Pi (i.e., on the crop) to be able to access it from the farm without requiring an Internet access.

- A front-end that allows users to visualize the stored data and notifications through a web application.

- A data validation service and a mechanism for notifying alerts.

- /add/type1/:node. GET and POST requests that are used to manage Type-1 node data. It supports the following key-value pairs:

- (a)

- temp: temperature.

- (b)

- hum: relative humidity.

- (c)

- volt: voltage.

- /add/type2/:node. GET and POST requests. Similar to the previous request, but for Type-2 nodes (it supports the same key-value pairs as the previous Type-1 node request).

- /add/weather-station. GET and POST requests. It is used for storing data related to the weather station. It supports the following key-value pairs:

- (a)

- rain: accumulated rain in L/.

- (b)

- wind: wind speed in km/h.

- (c)

- dirWind: direction of the wind in degrees.

- /nodes/:node. GET request. It allows for obtaining the data of one specific node. It only supports one key-value pair:

- (a)

- limit: number of results to be shown.

5. Results

5.1. Sensor Network Deployment

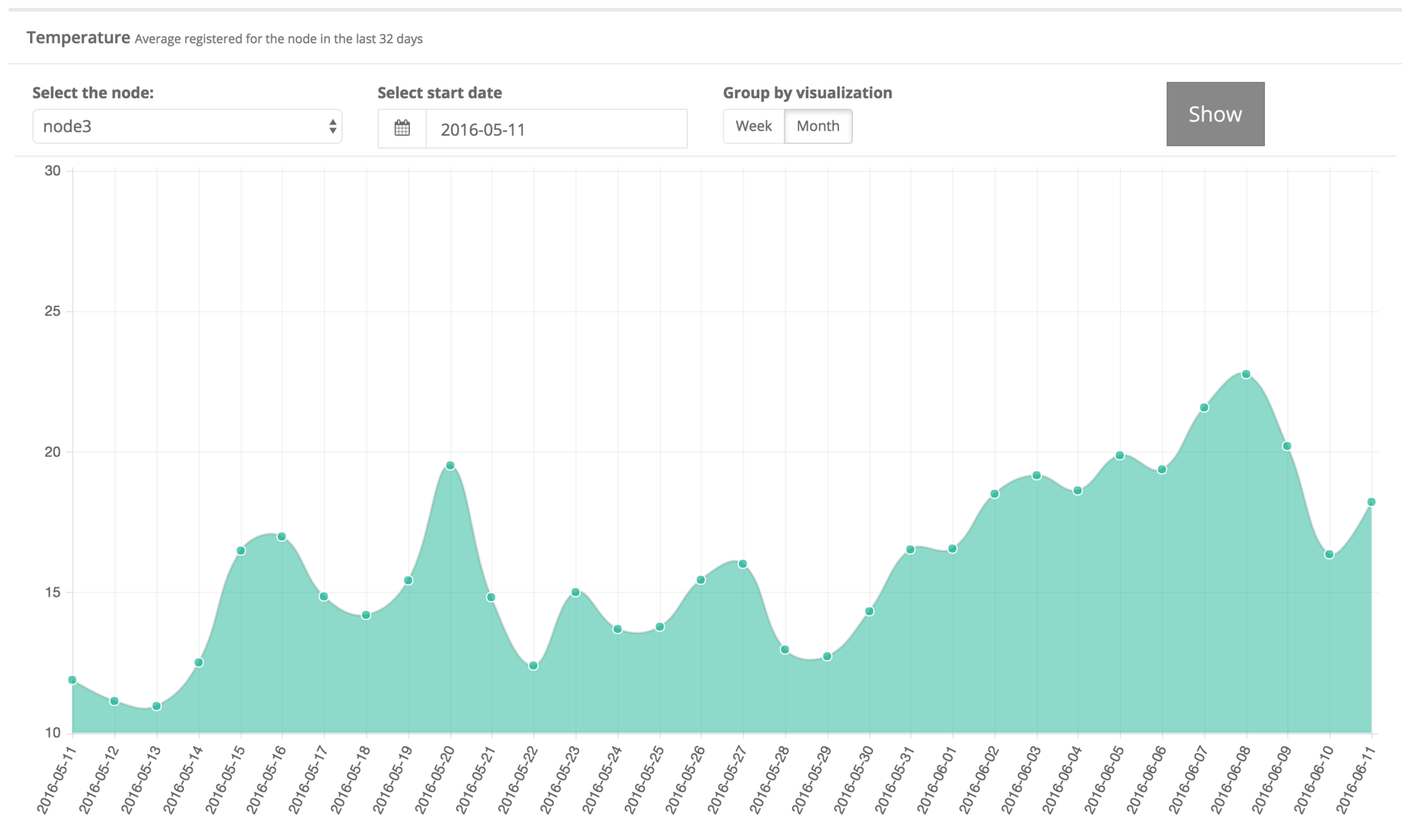

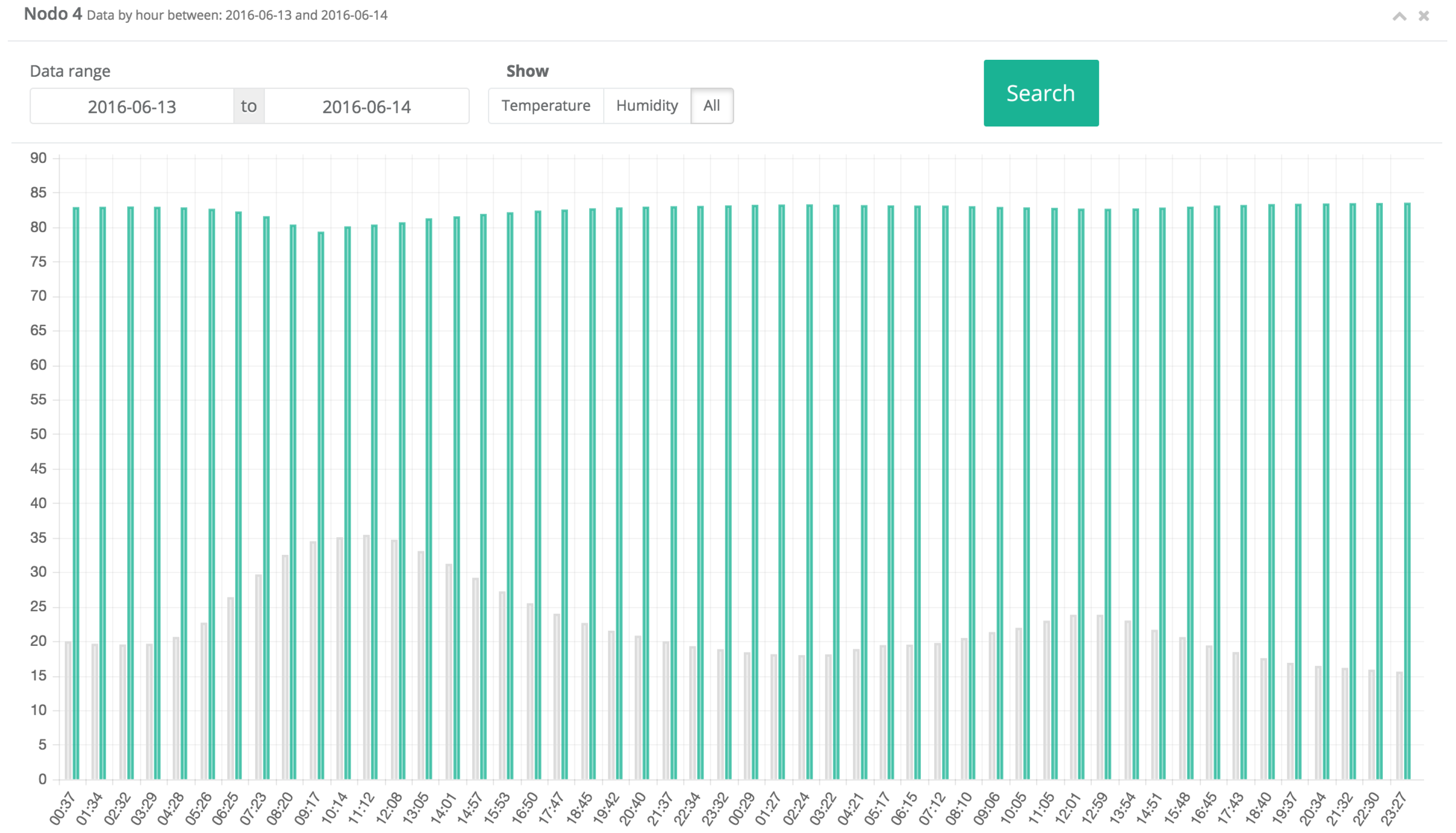

5.2. Data Visualization

5.3. Alert Notifications

- Downy mildew alerts.

- Power alerts. It warns about energy outages on the nodes.

- Ambient temperature alerts.

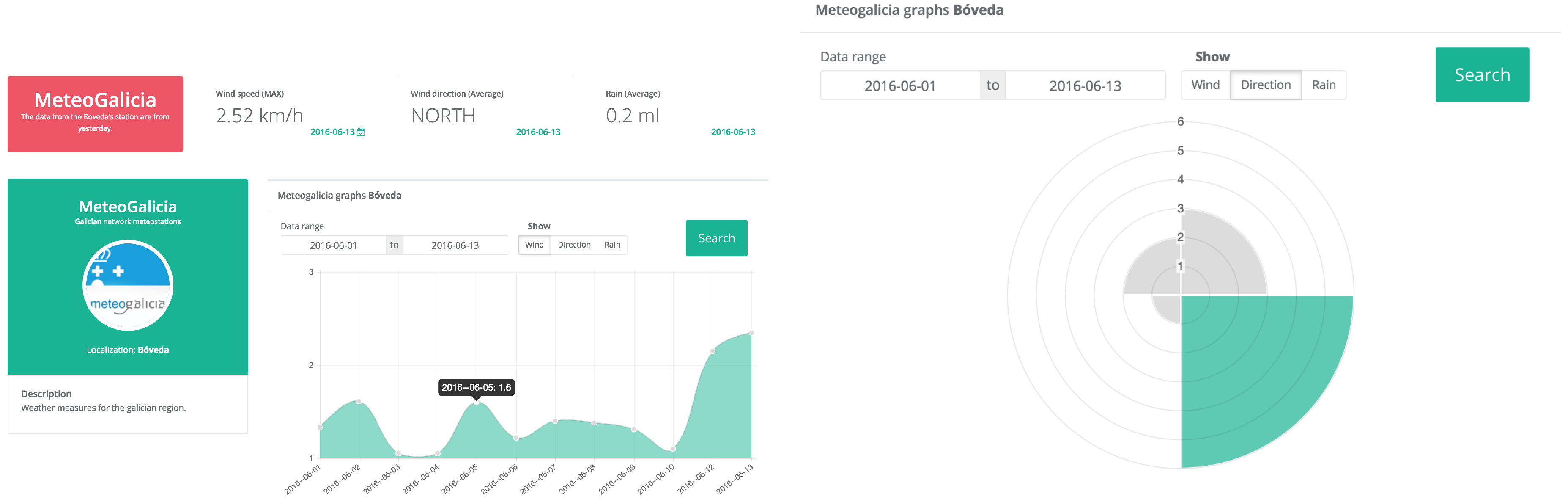

5.4. Weather Station

5.5. Node Energy Consumption

5.6. Phytosanitary tReatment Use

- Spraying according to phytosanitary warnings. Every week the CSIC (Spanish National Research Council) publishes online recommendations for the vine growers on the treatments to be performed. In particular, the CSIC has control vineyards in an area that is 80 km from the place where VineSens was deployed, so warnings can be considered valid since weather in both areas is similar.

- Traditional spraying. It consists in following the spraying recommendations previously mentioned: farmers have to apply treatments every 12–15 days from April–May and, during the period with the highest risk, they should reduce the spraying period to 5–7 days. In Table 6 and Table 7 two variants of traditional spraying are considered: conservative and relaxed. The conservative approach tends to spray as much as possible according to the traditional schedule, while the relaxed approach tends to spray the least, but respecting CSIC recommendations.

- VineSens recommendations. VineSens algorithms estimate spraying by calculating the downy mildew development index. When such an index is high enough, VineSens sends a warning to the farmer, who sprays and resets the index. Two versions are illustrated to compare with the other systems: a conservative approach that suggests spraying when the downy mildew development index reaches 80 %, and a more relaxed approach that waits until the index is greater than 90 %.

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| API | Application Programming Interface |

| CSIC | Spanish National Research Council |

| DSS | Decision Support System |

| GHG | Greenhouse Gas |

| IDE | Integrated Development Environment |

| ISM | Industrial, Scientific and Medical |

| LAI | Leaf Area Index |

| REST | Representational State Transfer |

| RH | Relative Humidity |

| RPAS | Remotely Piloted Aerial Systems |

| SBC | Single-Board Computer |

| SoC | System-on-Chip |

| WSN | Wireless Sensor Network |

References

- Evans, R.G. The art of protecting grapevines low temperature injury. In Proceedings of the ASEV (American Society for Enology and Viticulture) 50th Anniversary Annual Meeting, Seattle, WA, USA, 19–23 June 2000.

- Granett, J.; Walker, M.A.; Kocsis, L.; Omer, A.D. Biology and management of grape phylloxera. Annu. Rev. Entomol. 2001, 46, 387–412. [Google Scholar] [CrossRef] [PubMed]

- Gadoury, D.M.; Cadle-Davidson, L.; Wilcox, W.F.; Dry, I.B.; Seem, R.C.; Milgroom, M.G. Grapevine powdery mildew (Erysiphe necator): A fascinating system for the study of the biology, ecology and epidemiology of an obligate biotroph. Mol. Plant Pathol. 2012, 13, 1–16. [Google Scholar] [CrossRef] [PubMed]

- Gessler, C.; Pertot, I.; Perazzoll, M. Plasmopara viticola: A review of knowledge on downy mildew of grapevine and effective disease management. Phytopathol. Mediterr. 2011, 50, 3–44. [Google Scholar]

- Nito, N.; Kuraishi, S. Abnormal auxin distribution and poor berry setting (coulure) in grapes. Sci. Hortic. 1979, 10, 63–72. [Google Scholar] [CrossRef]

- Williamson, B.; Tudzynski, B.; Tudzynski, P.; van Kan, J.A. Botrytis cinerea: The cause of grey mould disease. Mol. Plant Pathol. 2007, 8, 561–580. [Google Scholar] [CrossRef] [PubMed]

- Williams, P.H. Black rot: A continuing threat to world crucifers. Plant Dis. 1980, 64, 736–742. [Google Scholar] [CrossRef]

- Phillips, A.J. Excoriose, cane blight and related diseases of grapevines: A taxonomic review of the pathogens. Phytopathol. Mediterr. 2000, 39, 341–356. [Google Scholar]

- Spencer-Phillips, P.; Jeger, M. Advances in Downy Mildew Research, Volumen 2, 1st ed.; Springer Science+Business Media, Kluwer Academic Publishers: Berlin, Germany, 2004. [Google Scholar]

- Gerling, C. Environmentally Sustainable Viticulture: Practices and Practicality; Apple Academic Press, Inc.: Oakville, Canada, 2015. [Google Scholar]

- Christ, K.L.; Burritt, R.L. Critical environmental concerns in wine production: An integrative review. J. Clean. Prod. 2013, 53, 232–242. [Google Scholar] [CrossRef]

- Arnó, J.; Escolà, A.; Vallès, J.M.; Llorens, J.; Sanz, R.; Masip, J.; Palacín, J.; Rosell-Polo, J.R. Leaf area index estimation in vineyards using a ground-based LiDAR scanner. Precis. Agric. 2013, 14, 290–306. [Google Scholar] [CrossRef] [Green Version]

- Sepúlveda-Reyes, D.; Ingram, B.; Bardeen, M.; Zúñiga, M.; Ortega-Farías, S.; Poblete-Echeverría, C. Selecting Canopy Zones and Thresholding Approaches to Assess Grapevine Water Status by Using Aerial and Ground-Based Thermal Imaging. Remote Sens. 2016, 8, 822. [Google Scholar] [CrossRef]

- Sepúlveda-Reyes, D.; Ingram, B.; Bardeen, M.; Zúñiga, M.; Ortega-Farías, S.; Poblete-Echeverría, C. Predicting Grapevine Water Status Based on Hyperspectral Reflectance Vegetation Indices. Remote Sens. 2015, 7, 16460–16479. [Google Scholar]

- Rey-Caramés, C.; Diago, M.P.; Martín, M.P.; Lobo, A.; Tardaguila, J. Using RPAS Multi-Spectral Imagery to Characterise Vigour, Leaf Development, Yield Components and Berry Composition Variability within a Vineyard. Remote Sens. 2015, 7, 14458–14481. [Google Scholar] [CrossRef]

- Turner, D.; Lucieer, A.; Watson, C. Development of an unmanned aerial vehicle (UAV) for hyper resolution vineyard mapping based on visible, multispectral, and thermal imagery. In Proceedings of the 34th International Symposium on Remote Sensing of Environment, Sydney, Australia, 10–15 April 2011.

- Karakizi, C.; Oikonomou, M.; Karantzalos, K. Vineyard Detection and Vine Variety Discrimination from Very High Resolution Satellite Data. Remote Sens. 2016, 8, 235. [Google Scholar] [CrossRef]

- Luvisi, A.; Panattoni, A.; Bandinelli, R.; Rinaldelli, E.; Pagano, M.; Triolo, E. Ultra-High Frequency transponders in grapevine: A tool for traceability of plants and treatments in viticulture. Biosyst. Eng. 2012, 113, 129–139. [Google Scholar] [CrossRef]

- Rossi, V.; Salinari, F.; Poni, S.; Caffi, T.; Bettati, T. Addressing the implementation problem in agricultural decision support systems: The example of vite.net®. Comput. Electron. Agric. 2014, 100, 88–99. [Google Scholar] [CrossRef]

- Kampianakis, E.; Kimionis, J.; Tountas, K.; Konstantopoulos, C.; Koutroulis, E.; Bletsas, A. Wireless Environmental Sensor Networking With Analog Scatter Radio and Timer Principles. IEEE Sens. J. 2014, 14, 3365–3376. [Google Scholar] [CrossRef]

- Fernández-Caramés, T.M. An Intelligent Power Outlet System for the Smart Home of the Internet of Things. Int. J. Distrib. Sens. Netw. 2015, 2015, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Suárez-Albela, M.; Fraga-Lamas, P.; Fernández-Caramés, T.M.; Dapena, A.; González-López, M. Home Automation System Based on Intelligent Transducer Enablers. Sensors 2016, 16, 1595. [Google Scholar] [CrossRef] [PubMed]

- Fraga-Lamas, P.; Fernández-Caramés, T. M.; Suárez-Albela, M.; Castedo, L.; González-López, M. A Review on Internet of Things for Defense and Public Safety. Sensors 2016, 16, 1644. [Google Scholar] [CrossRef] [PubMed]

- Fraga-Lamas, P.; Castedo-Ribas, L.; Morales-Méndez, A.; Camas-Albar, J.M. Evolving military broadband wireless communication systems: WiMAX, LTE and WLAN. In Proceedings of the International Conference on Military Communications and Information Systems (ICMCIS), Brussels, Belgium, 23–24 May 2016; pp. 1–8.

- Camas-Albar, J.M.; Morales-Méndez, A.; Castedo-Ribas, L.; Fraga-Lamas, P.; Brown, C.; Tschauner, M.; Hayri-Kucuktabak, M. NATO Task Group ET-IST-068, IST (Information Systems Technology) panel of NATO STO (Science and Technology Organization). In LTE vs. WiMAX for Military Applications; Technical Report; NATO: Brussels, Belgium, 2015. [Google Scholar]

- Fraga-Lamas, P.; Noceda-Davila, D.; Fernández-Caramés, T.M.; Díaz-Bouza, M.A.; Vilar-Montesinos, M. Smart Pipe System for a Shipyard 4.0. Sensors 2016, 16, 2186. [Google Scholar] [CrossRef] [PubMed]

- Fernández, T.M.; Rodas, J.; Escudero, C.J.; Iglesia, D.I. Bluetooth Sensor Network Positioning System with Dynamic Calibration. In Proceedings of the International Symposium on Wireless Communications Systems, Trondheim, Norway, 16–19 October 2007.

- Barro, S. J.; Fernández-Caramés, T. M.; Escudero, C.J. Enabling Collaborative Musical Activities through Wireless Sensor Networks (WSN). Int. J. Distrib. Sens. Netw. 2012, 36, 42–50. [Google Scholar]

- Barro-Torres, S.J.; Fernández-Caramés, T.M.; Pérez-Iglesias, H.J.; Escudero, C.J. Real-Time Personal Protective Equipment Monitoring System. Comput. Commun. 2012, 36, 42–50. [Google Scholar] [CrossRef]

- Lloret, J.; Bosch, I.; Sendra, S.; Serrano, A. A Wireless Sensor Network for Vineyard Monitoring That Uses Image Processing. Sensors 2011, 11, 6165–6196. [Google Scholar] [CrossRef] [PubMed]

- Matese, A.; Di Gennaro, S.F.; Zaldei, A.; Genesio, L.; Vaccari, F.P. A wireless sensor network for precision viticulture: The NAV system. Comput. Electron. Agric. 2009, 69, 51–58. [Google Scholar] [CrossRef]

- Zhang, X.; Wen, Q.; Tian, D.; Hu, J. PVIDSS: Developing a WSN-based Irrigation Decision Support System (IDSS) for Viticulture in Protected Area, Northern China. Appl. Math. Inf. Sci. 2015, 9, 669–679. [Google Scholar]

- Morais, R.; Fernandes, M.A.; Matos, S.G.; Serôdio, C.; Ferreira, P.J.S.G.; Reis, M.J.C.S. A ZigBee multi-powered wireless acquisition device for remote sensing applications in precision viticulture. Comput. Electron. Agric. 2008, 62, 94–106. [Google Scholar] [CrossRef]

- Blauth, D.A.; Ducati, J.R. A Web-based system for vineyards management, relating inventory data, vectors and images. Comput. Electron. Agric. 2010, 2, 182–188. [Google Scholar] [CrossRef]

- VintiOS. Available online: http://www.vintios.com (accessed on 15 December 2016).

- Monet. Available online: http://monet-ti.com (accessed on 15 December 2016).

- Save Official Web Page. Available online: http://www.auroras.eu/save-the-proactive-monitoring-system-for-the-vineyard (accessed on 15 December 2016).

- Ranch Systems. Available online: http://marius.ranchsystems.com/wp/vineyards (accessed on 15 December 2016).

- Smart Vineyard. Available online: http://smartvineyard.com/ (accessed on 15 December 2016).

- Baldacci, E. Epifitie di Plasmopara viticola (1941-46) nell’Oltrepó Pavese ed adozione del calendario di incubazione come strumento di lotta. Atti Istituto Botanico, Laboratorio Crittogamico 1947, 8, 45–85. [Google Scholar]

- Stryzik, S. Modéle d’état potentiel d’infection: Application a Plasmopara viticola. In Association de Coordination Technique Agricole, Maison Nationale des Eleveurs; Maison Nationale des Eleveurs: Paris, France, 1983; pp. 1–46. [Google Scholar]

- Park, E.W.; Seem, R.C.; Gadoury, D.M.; Pearson, R.C. DMCAST: A prediction model for grape downy mildew development. Vitic. Enol. Sci. 1997, 52, 182–189. [Google Scholar]

- Rossi, V.; Caffi, T.; Giosué, S.; Bugiani, R. A mechanist model simulating primary infections of downy mildew in grapevine. Ecol. Model. 2008, 212, 480–491. [Google Scholar] [CrossRef]

- Rabbinge, R.; De Wit, C.T. Theory of modelling and systems management. 1989. Available online: http://library.wur.nl/WebQuery/wurpubs/fulltext/171916 (accessed on 15 December 2016).

- Rossi, V.; Giosué, S.; Caffi, T. Modelling plant diseases for decision making in crop protection. In Precision Crop Protection—The Challenge and Use of Heterogeneity; Springer: Dordrecht, The Netherlands, 2010; pp. 241–258. [Google Scholar]

- Rossi, V.; Caffi, T.; Salinari, F. Helping farmers face the increasing complexity of decision-making for crop protection. Phytopathol. Mediterr. 2012, 51, 480–491. [Google Scholar]

- Caffi, T.; Rossi, V.; Cossu, A.; Fronteddu, F. Empirical vs. mechanistic models for primary infections of Plasmopara viticola. EPPO Bull. 2007, 37, 261–271. [Google Scholar] [CrossRef]

- Seeed Studio Official Webpage. Available online: https://www.seeedstudio.com (accessed on 15 December 2016).

- ANSI/IEC 60529-2004. Degrees of Protection Provided by Enclosures (IP Code) (iDentical National Adoption). In National Electrical Manufacturers Association; American National Standard (ANSI/IEC): Rosslyn, Virginia, 2004. [Google Scholar]

- Raspberry Pi 1 Model B. Available online: https://www.raspberrypi.org/products/model-b-plus (accessed on 15 December 2016).

- Raspberry Pi 2 Model B. Available online: https://www.raspberrypi.org/products/raspberry-pi-2-model-b (accessed on 15 December 2016).

- Raspberry Pi 3 Model B. Available online: https://www.raspberrypi.org/products/raspberry-pi-3-model-b (accessed on 15 December 2016).

- HummingBoard Specifications. Available online: https://www.solid-run.com/freescale-imx6-family/hummingboard/hummingboard-specifications (accessed on 15 December 2016).

- BeagleBone Black. Available online: https://beagleboard.org/black (accessed on 15 December 2016).

- Banana Pi. Available online: http://www.bananapi.org (accessed on 15 December 2016).

- IEEE Standard for Information Technology–Telecommunications and Information Exchange Between Systems Local and Metropolitan Area Networks–Specific Requirements Part 11. Available online: https://standards.ieee.org/about/get/802/802.11.html (accessed on 15 December 2016).

- Chang, H.; Zhou, N.; Zhao, X.; Cao, Q.; Tan, M.; Zhang, Y. A new agriculture monitoring system based on WSNs. In Proceedings of the 2014 12th International Conference on Signal Processing (ICSP), Hangzhou, China, 19–23 October 2014.

- Boquete, L.; Cambralla, R.; Rodríguez-Ascariz, J.M.; Miguel-Jiménez, J.M.; Cantos-Frontela, J.J.; Dongil, J. Portable system for temperature monitoring in all phases of wine production. ISA Trans. 2009, 49, 270–276. [Google Scholar] [CrossRef] [PubMed]

- Piromalis, D. D.; Arvanitis, K. G.; Sigrimis, N. DASH7 Mode 2: A Promising Perspective for Wireless Agriculture. In Proceedings of the 4th IFAC Conference on Modelling and Control in Agriculture, Horticulture and Post Harvest Industry, Espoo, Finland, 28–29 August 2013.

- Fernández-Caramés, T.M.; Fraga-Lamas, P.; Suárez-Albela, M.; Castedo, L. A methodology for evaluating security in commercial RFID systems. In Radio Frequency Identification, 1st ed.; Crepaldi, P.C., Pimenta, T.C., Eds.; INTECH: Rijeka, Croatia, 2016. [Google Scholar]

- Fernández-Caramés, T.M.; Fraga-Lamas, P.; Suárez-Albela, M.; Castedo, L. Reverse Engineering and Security Evaluation of Commercial Tags for RFID-Based IoT Applications. Sensors 2017, 17, 28. [Google Scholar] [CrossRef] [PubMed]

- Arduino Official Web Page. Available online: https://www.arduino.cc (accessed on 15 December 2016).

- Node.js. Available online: https://nodejs.org/en (accessed on 15 December 2016).

- Bryant, J.; Jones, M. Responsive Web Design. In Pro HTML5 Performance; Apress: New York, NY, USA, 2012; pp. 37–49. [Google Scholar]

- Australian Government, Bureau of Meteorology: The Stevenson Screen. Available online: http://www.bom.gov.au/climate/cdo/about/airtemp-measure.shtml (accessed on 15 December 2016).

- Vivir Galicia Turismo. Available online: http://www.vivirgaliciaturismo.com/category/a-ribeira-sacra/ (accessed on 15 December 2016).

- Instituto Nacional de Estadística. Available online: http://www.ine.es (accessed on 15 December 2016).

- Unións Agrarias (Agricultural Union) Web Page. Available online: http://www.unionsagrarias.org (accessed on 15 December 2016).

| Average Temperature (°C) | Daily Development (%) RH < 75% | Daily Development (%) RH ≥ 75% | Average Temperature (°C) | Daily Development (%) RH < 75% | Daily Development (%) RH ≥ 75% | ||

|---|---|---|---|---|---|---|---|

| 12. | 0 | 0 | 5.25 | 19. | 0 | 12.5 | 16.6 |

| 25 | 4.4 | 5.75 | 25 | 12.9 | 17.5 | ||

| 50 | 4.7 | 6.2 | 50 | 13.4 | 18.3 | ||

| 75 | 5 | 6.7 | 75 | 13.7 | 19.3 | ||

| 13. | 0 | 5.3 | 7.1 | 20. | 0 | 14.2 | 20 |

| 25 | 5.7 | 7.7 | 25 | 14.5 | 20.5 | ||

| 50 | 6 | 8 | 50 | 14.8 | 21 | ||

| 75 | 6.4 | 8.5 | 75 | 15 | 21.5 | ||

| 14. | 0 | 6.6 | 9 | 21. | 0 | 15.3 | 22.2 |

| 25 | 6.8 | 9.4 | 25 | 15.7 | 22.2 | ||

| 50 | 7.1 | 9.7 | 50 | 16 | 22.2 | ||

| 75 | 7.3 | 10.2 | 75 | 16.3 | 22.2 | ||

| 15. | 0 | 7.6 | 10.6 | 22. | 0 | 16.6 | 22.2 |

| 25 | 7.8 | 10.8 | 25 | 17 | 22.2 | ||

| 50 | 8.1 | 11.1 | 50 | 17.3 | 23.5 | ||

| 75 | 8.3 | 11.3 | 75 | 17.7 | 24.4 | ||

| 16. | 0 | 8.5 | 11.7 | 23. | 0 | 18.1 | 25 |

| 25 | 9 | 12 | 25 | 18.1 | 25 | ||

| 50 | 6.3 | 12.5 | 50 | 18.1 | 25 | ||

| 75 | 9.6 | 12.9 | 75 | 18.1 | 25 | ||

| 17. | 0 | 10 | 13.25 | 24. | 0 | 18.1 | 25 |

| 25 | 10.3 | 13.6 | 25 | 17.7 | 24.3 | ||

| 50 | 10.5 | 14.3 | 50 | 17.3 | 23.5 | ||

| 75 | 10.75 | 14.75 | 75 | 17 | 23.2 | ||

| 18. | 0 | 11.1 | 15.3 | 25. | 0 | 16.6 | 22.2 |

| 25 | 11.48 | 15.2 | |||||

| 50 | 11.7 | 16 | |||||

| 75 | 12.1 | 16.3 | |||||

| Model | Type | Advantages | Drawbacks |

|---|---|---|---|

| Rule 3-10 (Baldacci, 1947) | Empirical | Well-known, simplicity | The model does not take oospore maturing into account and does not distinguish among the different stages of the infection process |

| EPI model (Stryzik, 1983) | Empirical | Good trade-off between complexity and performance | False negatives, it requires the weather record |

| DMCast (Park et al., 1997) | Empirical | Good trade-off between complexity and performance | False negatives |

| UCSC (Rossi et al., 2008) | Mechanistic | It does not require calibration or correction and provides an accurate, detailed, and dynamic simulation of the sexual stage | Very complex |

| Technology | Frequency Band | Data rate | Range | Power | Battery Operation | Nodes |

|---|---|---|---|---|---|---|

| Wi-Fi/IEEE 802.11b/g/n [30,56] | 2.4 GHz, 5.8 GHz | 11 - 105 Mbit/s | 10-100 m | High | Rechargeable (hours) | 32 |

| ZigBee/IEEE 802.15.4 [32,33] | 868 MHz, 2.4 GHz | 250 kbit/s | 10-300 m | Very low | Alkaline (months to years) | 65000 |

| Bluetooth/IEEE 802.15.1 [57,58] | 2.4 GHz | 723 kbit/s | 10 m | Low | Rechargeable (days to weeks) | 8 |

| UWB/IEEE 802.15.3a | 3.1-10.6 GHz | >110 Mbit/s | 4-20 m | Low | Rechargeable (hours to days) | 128 |

| DASH7/ISO 18000-7 [59] | 433 MHz | 27.8 kbit/s | 250 m | Very Low | Alkaline (months to years) | Many |

| Z-Wave | 900 MHz | 40 kbit/s | 100 m | Very Low | Alkaline (months to years) | 232 |

| 6LowPAN | 2.4 GHz | 200 kbit/s | 200 m | Very Low | Alkaline (months to years) | 100 |

| RFID [60,61] | 30 KHz-3 GHz | <640 kbit/s | 1 cm-10 m | Very Low | Alkaline (months to years) | Many |

| Node Type | Sensors | Consumption | |

|---|---|---|---|

| Type 2 | SHT11 | Transmission | 93.5 mA |

| Deep-sleep | A | ||

| Type 1 | DS18B20, DHT22 | Transmission | 75 mA |

| Deep-sleep | A |

| Node | Total per Hour | Total per Day | Batteries | Estimated Duration (Full Discharge) | Actual Duration |

|---|---|---|---|---|---|

| Type 2 | 0.266 mA/h | 6.384 mA | 2 × 2100 mAh AA batteries in series | 328 days | 93 days |

| 4 × 2100 mAh AA batteries in parallel (2 to 2) | 657 days | 182 days | |||

| Type 1 | 0.214 mA/h | 5.143 mA | 2 × 2100 mAh AA batteries in series | 408 days | 93 days |

| 4 × 2100 mAh AA batteries in parallel (2 to 2) | 816 days | 182 days |

| Phytosanitary Warning | Traditional (Conservative) | Traditional (Relaxed) | VineSens (80%) | VineSens (90%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Date | Event | #Dose | Event | #Dose | Event | #Dose | Event | Downy Mildew Index | #Dose | Event | Downy Mildew Index | #Dose |

| 03/01/16 | Start monitoring. | 0 | Start monitoring. | 0 | ||||||||

| 03/28/16 | Oosphore maturation detected due to high temperature during winter. | 0 | 0 | |||||||||

| 04/01/16 | Beginning of the treatment. | 1 | 0 | 0 | ||||||||

| 04/15/16 | Next dose. | 2 | 0 | 0 | ||||||||

| 04/19/16 | Detected favorable development conditions. | 5.75 | Detected favorable development conditions. | 5.75 | ||||||||

| 04/20/16 | First clear symptoms manifested in the farms monitored. Beginning of the treatment recommended. | 1 | 11.05 | 11.05 | ||||||||

| 04/29/16 | Cool nights are slowing the development of the disease. Remain vigilant. | 16.8 | 16.8 | |||||||||

| 05/01/16 | Next dose. | 3 | Begining of the treatment. | 1 | 16.8 | 16.8 | ||||||

| 05/06/16 | Increased risk of outbreaks due to high nocturnal temperatures and the increase in RH. | 2 | 55.9 | 55.9 | ||||||||

| 05/13/16 | Increased risk, but treatment is only needed on vines that show obvious signs. | Optional | 55.9 | 55.9 | ||||||||

| 05/15/16 | Next dose. | 4 | Next dose. | 2 | 66.1 | 66.1 | ||||||

| 05/17/16 | Downy mildew alert: index over 80%. | 81.0 | 1 | 81.0 | ||||||||

| 05/18/16 | Treatment applied.Index reset. | 6.2 | 87.2 | |||||||||

| 05/19/16 | Downy mildew alert: index over 90%. | 97.4 | 1 | |||||||||

| 05/20/16 | A new dose of the treatment should be applied due to the beginning of the flowering. | 3 | 27.88 | Treatment applied. Index reset. | 11.48 | |||||||

| 05/27/16 | Weather is favoring the development of the disease, but only the vines already infected should be treated. | Optional | 79.88 | 62.98 | ||||||||

| 05/28/16 | Downy mildew alert: index over 80%. | 84.63 | 2 | 68.23 | ||||||||

| 06/01/16 | Next dose. | 5 | Next dose. | 3 | 26.35 | Downy mildew alert: index over 90%. | 94.58 | 2 | ||||

| 06/03/16 | Increased risk of infection. A new dose of the treatment should be applied. | 4 | 49.35 | 23.0 | ||||||||

| 06/07/16 | Downy mildew alert: index over 80%. | 95.15 | 3 | 68.8 | ||||||||

| 06/09/16 | Downy mildew alert: index over 90%. | 99.5 | 3 | |||||||||

| 06/10/16 | High risk of infection. Renew the dose if the treatment was not successful. | Optional | Next dose (high risk). | 6 | Next dose (high risk). | 4 | 39.0 | 8.3 | ||||

| 06/14/16 | Downy mildew alert: index over 80%. | 82.78 | 4 | 52.08 | ||||||||

| 06/17/16 | Numerous farmers have reported damage in their vineyards. Renew the dose. | 5 | Next dose (high risk). | 7 | Next dose (high risk). | 5 | 11.45 | 63.53 | ||||

| Phytosanitary Warning | Traditional (Conservative) | Traditional (Relaxed) | VineSens (80%) | VineSens (90%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Date | Event | #Dose | Event | #Dose | Event | #Dose | Event | Downy Mildew Index | #Dose | Event | Downy Mildew Index | #Dose |

| 06/20/16 | Downy mildew alert: index over 90%. | 98.43 | 4 | |||||||||

| 06/22/16 | Downy mildew alert: index over 80%. | 88.85 | 5 | 42.5 | ||||||||

| 06/23/16 | The high risk of infection remains. Renew the dose on plants already showing clear damage. | Optional | Next dose (high risk). | 8 | Next dose (high risk). | 6 | 21.0 | 63.5 | ||||

| 06/26/16 | Downy mildew alert: index over 90%. | 91.4 | 5 | |||||||||

| 06/29/16 | Downy mildew alert: index over 80%. | 87.8 | 6 | 38.9 | ||||||||

| 07/01/16 | [Missing report due to the IT problems in the phytosanitary news server] | Next dose (high risk). | 9 | Next dose (high risk). | 7 | 23.58 | 62.48 | |||||

| 07/04/16 | Downy mildew alert: index over 90%. | 104.98 | 6 | |||||||||

| 07/05/16 | Downy mildew alert: index over 80%. | 87.08 | 7 | 21.0 | ||||||||

| 07/08/16 | High risk continuous. Renew the treatment. | 6 | Next dose (high risk). | 10 | Next dose (high risk). | 8 | 55.1 | 76.1 | ||||

| 07/09/16 | Downy mildew alert: index over 90%. | 93.4 | 7 | |||||||||

| 07/10/16 | Downy mildew alert: index over 80%. | 88.7 | 8 | 16.3 | ||||||||

| 07/15/16 | Optimal infection conditions. Renew the treatment. | 7 | Next dose (high risk). | 11 | Next dose (high risk). | 9 | 52.5 | 68.8 | ||||

| 07/17/16 | Downy mildew alert: index over 90%. | 103.5 | 8 | |||||||||

| 07/19/16 | Downy mildew alert: index over 80%. | 87.2 | 9 | 33.6 | ||||||||

| 07/22/16 | Slight decrease in risk of infection, but it is still high. Apply only the treatment to infected plants. | Optional | Next dose (high risk). | 12 | Next dose (high risk). | 10 | 47.0 | 73.3 | ||||

| 07/23/16 | Downy mildew alert: index over 80%. | 86.7 | 10 | 86.7 | ||||||||

| 07/24/16 | Downy mildew alert: index over 90%. | 102.4 | 9 | |||||||||

| 07/29/16 | Final dose. | 13 | Final dose. | 11 | Downy mildew alert: index over 80%. | 91.7 | 11 | 76.0 | ||||

| 07/30/16 | Downy mildew alert: index over 90%. | 91.3 | 10 | |||||||||

| 07/04/16 | Downy mildew alert: index over 80%. | 85.7 | 12 | 70.4 | ||||||||

| 08/05/16 | The risk remains low. No treatment should be applied except in very specific situations. | 13.4 | 83.8 | |||||||||

| 08/06/16 | Downy mildew alert: index over 90%. | 100.4 | 11 | |||||||||

| 08/10/16 | Downy mildew alert: index over 80%. | 89.3 | 13 | |||||||||

| 08/12/16 | In most areas, bunches are already insensible to the disease. No further actions need to be taken. | |||||||||||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pérez-Expósito, J.P.; Fernández-Caramés, T.M.; Fraga-Lamas, P.; Castedo, L. VineSens: An Eco-Smart Decision-Support Viticulture System. Sensors 2017, 17, 465. https://doi.org/10.3390/s17030465

Pérez-Expósito JP, Fernández-Caramés TM, Fraga-Lamas P, Castedo L. VineSens: An Eco-Smart Decision-Support Viticulture System. Sensors. 2017; 17(3):465. https://doi.org/10.3390/s17030465

Chicago/Turabian StylePérez-Expósito, Josman P., Tiago M. Fernández-Caramés, Paula Fraga-Lamas, and Luis Castedo. 2017. "VineSens: An Eco-Smart Decision-Support Viticulture System" Sensors 17, no. 3: 465. https://doi.org/10.3390/s17030465