Optical Sensor of Thermal Gas Flow Based on Fiber Bragg Grating

Abstract

:1. Introduction

2. Principle

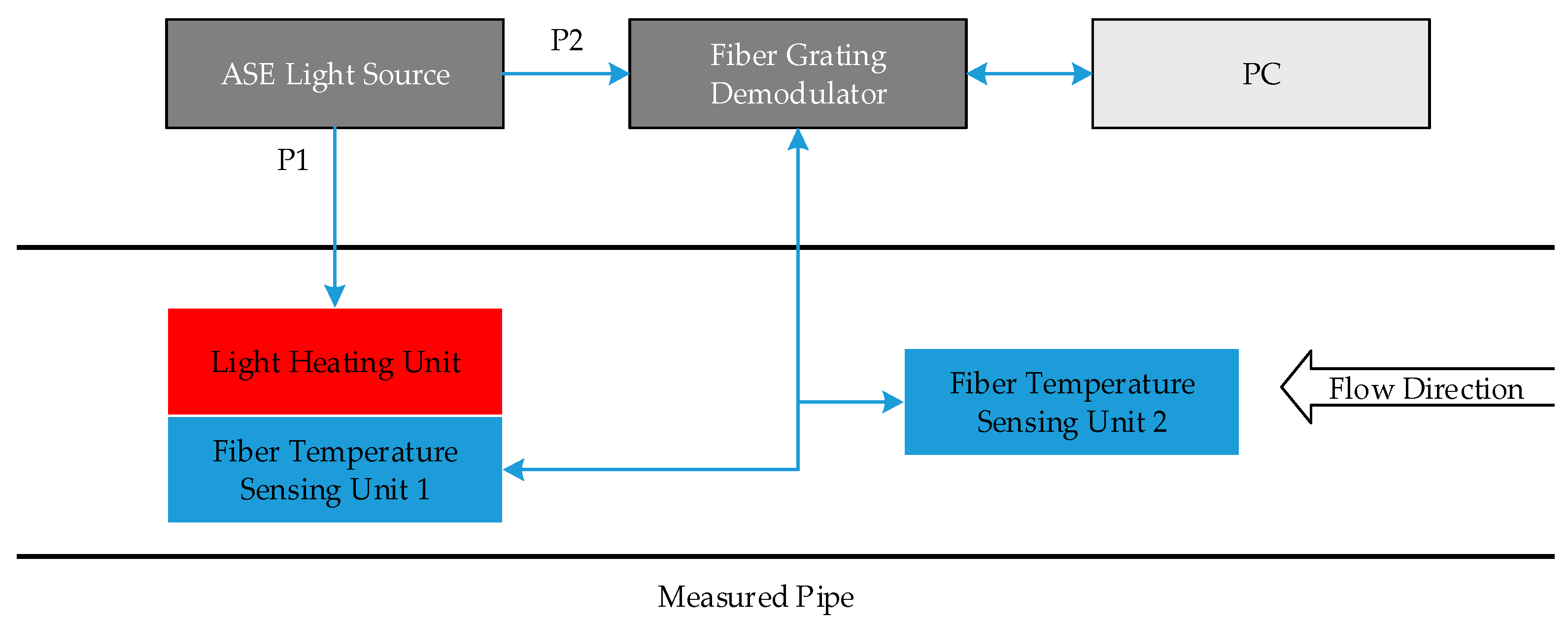

2.1. Scheme of Measurement

2.2. Principle of Measurement

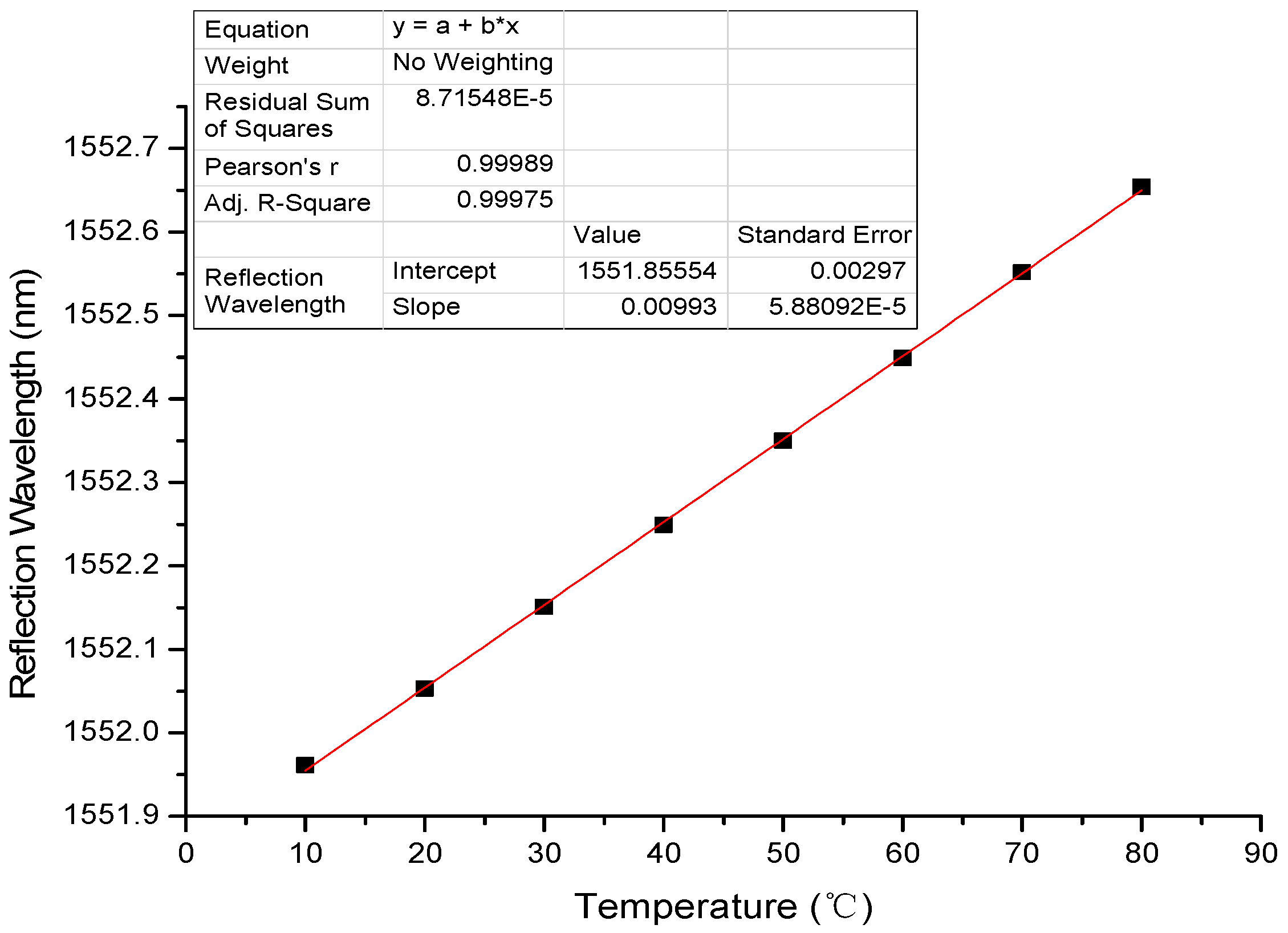

2.3. FBG Temperature Measurement Method

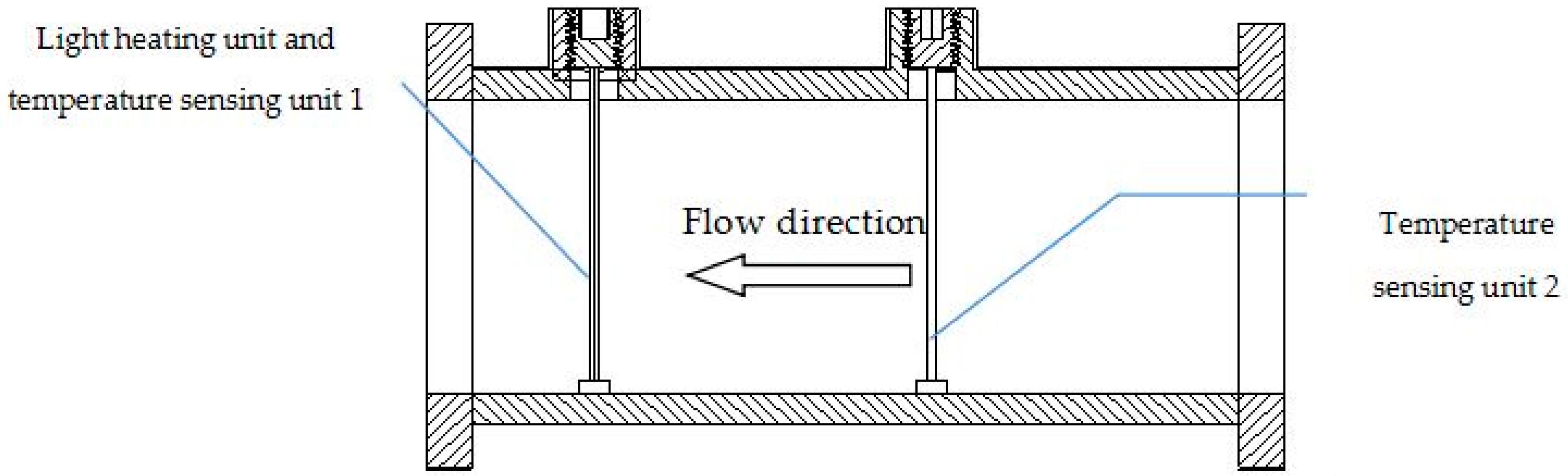

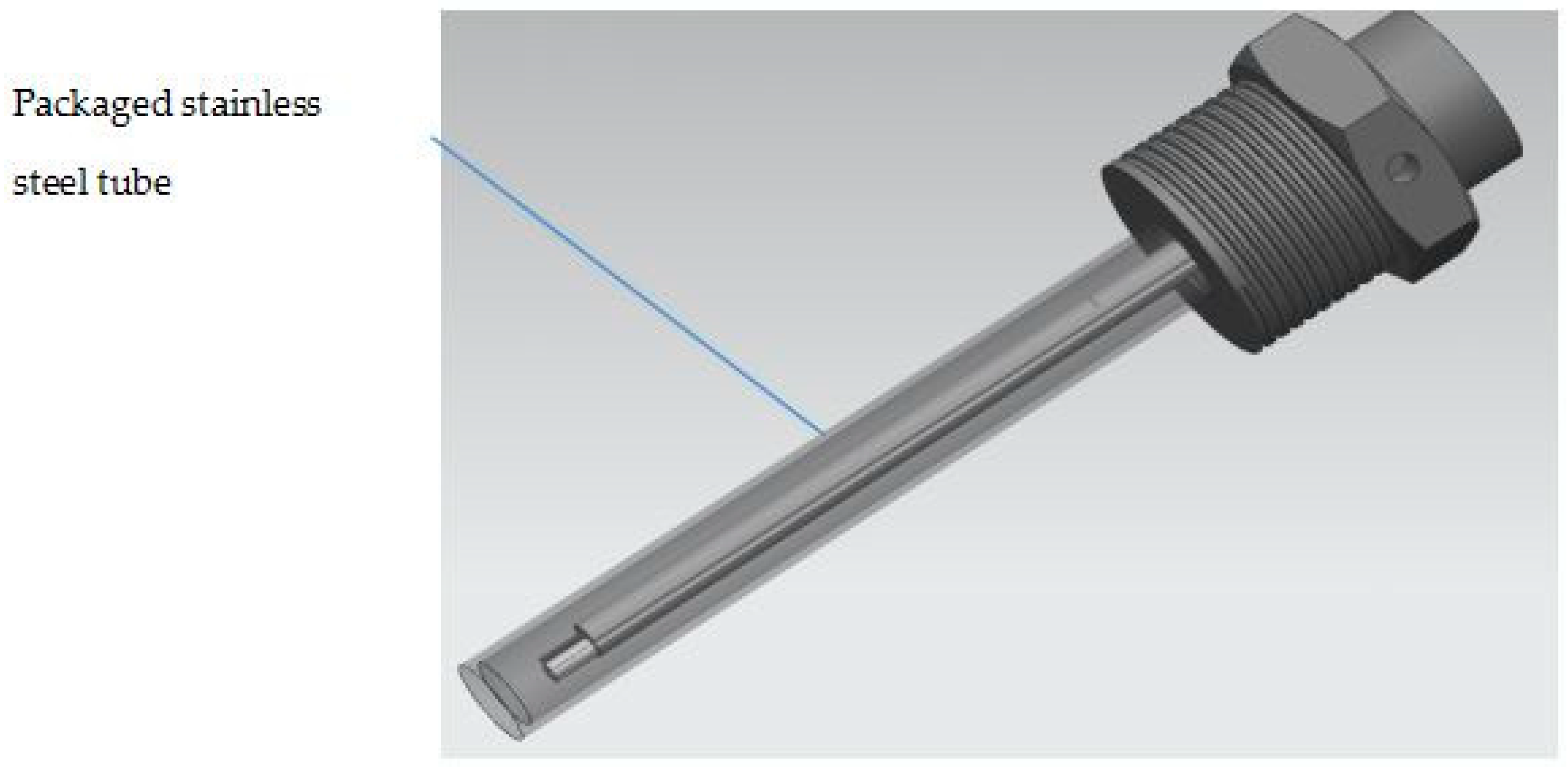

3. Design of Heat Flow Sensor

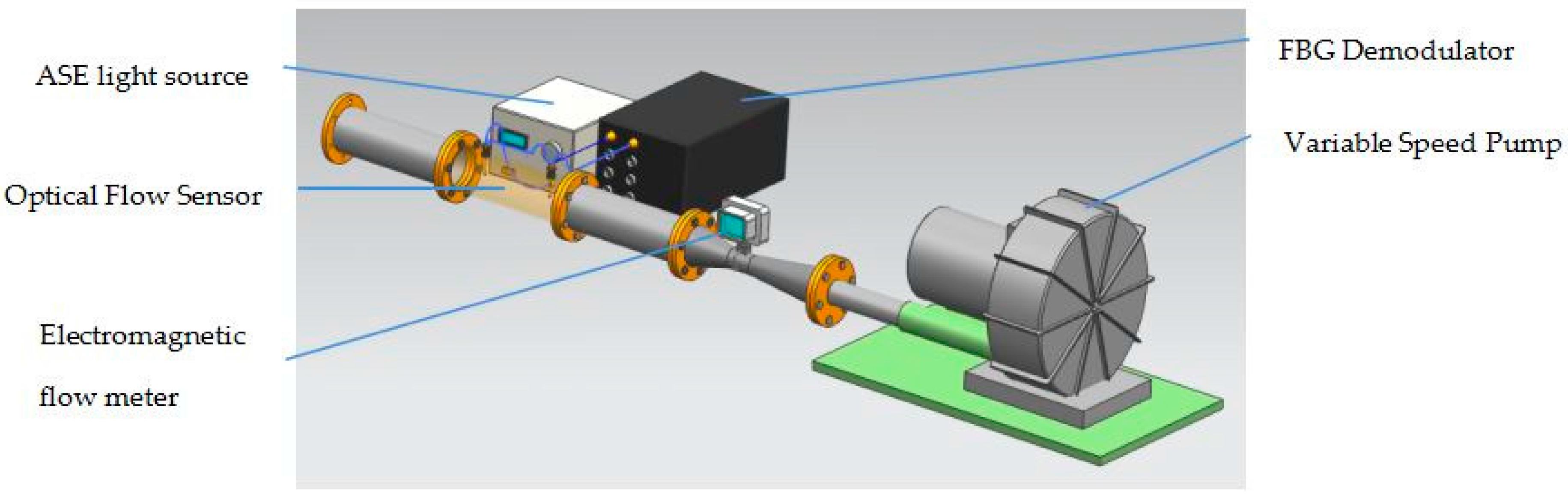

4. Experiment and Analysis

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Huijsing, J.H.; Van Dorp, A.L.C. Thermal mass-flow meter. J. Phys. E Sci. Instrum. 1988, 21, 994–997. [Google Scholar] [CrossRef]

- Olin, J.G. An Engineering Tutorial: Thermal Mass Flow meters. INTECH Eng. Noteb. 1993, 40, 37–41. [Google Scholar]

- Mischler, M.; Tseng, F.G.; Ulmanella, U.; Ho, C.M.; Jiang, F.; Tai, Y.C. A Micro Silicon Hot-Wire anemometer. In Proceedings of the IEEE Region 10 International Conference on Microelectronics and VLSI (TENCON ’95), Hong Kong, China, 6–10 November 1995; pp. 20–23.

- Viswanathan, M. Design and development of thermal mass flowmeters for high pressure applications. Flow Meas. Instrum. 2002, 13, 95–102. [Google Scholar]

- Baker, R.C.; Gimson, C. The effects of manufacturing methods on the precision of insertion and in-line thermal mass flowmeters. Flow Meas. Instrum. 2001, 12, 113–121. [Google Scholar] [CrossRef]

- Grant, K. Thermal mass flow measurement application in the power industry. A dances in instrumentation and control. Int. Conf. Exhib. 1992, 48, 1875–1884. [Google Scholar]

- Liu, Y.; Zhang, J. Model Study of the Influence of Ambient Temperature and Installation Types on Surface Temperature Measurement by Using a Fiber Bragg Grating Sensor. Sensors 2016, 16, 975. [Google Scholar] [CrossRef] [PubMed]

- Cheng, J.; Zhou, Y.; Dong, X.Y. Fiber-optic thermal anemometer based on metallic coated fiber Bragg grating. In Proceedings of the OFS2012 22nd International Conference on Optical Fiber Sensors, Beijing, China, 15–19 October 2012; Volume 8421.

- King, L.V. On the convenction of heat from small cylinders in a stream of fluid Determination of the convenetion constants of small platinum wires with application to hot wires anemometry. Proc. R. Soc. Lond. Ser. A 1914, 214, 563–570. [Google Scholar] [CrossRef]

- Kramers, H. Heat transfer from spheres to flowing media. Physica 1946, 12, 61–80. [Google Scholar] [CrossRef]

- Qiao, X.G.; Jia, Z.A.; Fu, H.W.; Li, M.; Zhou, H. Theory and experiment about in fiber Bragg grating temperature sensing. Acta Phys. Sin. 2004, 53, 494–497. [Google Scholar]

- Wu, J.; Wu, H.; Huang, J.; Gu, H. Research progress in signal demodulation technology of fiber Bragg grating sensors. Chin. Opt. 2014, 7, 519–531. [Google Scholar]

| Parameters | Value |

|---|---|

| Central wavelength | 1550 nm |

| Length of grating region | 10 mm |

| 3 dB bandwidth | ≤0.3 nm |

| Reflectivity | ≥80% |

| Parameters | Value |

|---|---|

| Operating wavelength | 1525~1565 nm |

| Output Power | 10~17 dBm |

| Spectral density | ≥−20 dBm/nm |

| Spectral flatness | ≤2 dB |

| Fiber type | Corning SMF−28 |

| Fiber output end type | FC/APC |

| Parameters | Value |

|---|---|

| Wavelength range | 1525~1565 nm |

| Wavelength resolution | ±1 pm |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, X.; Wang, K.; Li, J.; Zhan, H.; Song, Z.; Che, G.; Lyu, G. Optical Sensor of Thermal Gas Flow Based on Fiber Bragg Grating. Sensors 2017, 17, 374. https://doi.org/10.3390/s17020374

Jiang X, Wang K, Li J, Zhan H, Song Z, Che G, Lyu G. Optical Sensor of Thermal Gas Flow Based on Fiber Bragg Grating. Sensors. 2017; 17(2):374. https://doi.org/10.3390/s17020374

Chicago/Turabian StyleJiang, Xu, Keda Wang, Junqing Li, Hui Zhan, Zhenan Song, Guohang Che, and Guohui Lyu. 2017. "Optical Sensor of Thermal Gas Flow Based on Fiber Bragg Grating" Sensors 17, no. 2: 374. https://doi.org/10.3390/s17020374

APA StyleJiang, X., Wang, K., Li, J., Zhan, H., Song, Z., Che, G., & Lyu, G. (2017). Optical Sensor of Thermal Gas Flow Based on Fiber Bragg Grating. Sensors, 17(2), 374. https://doi.org/10.3390/s17020374