Micromachined Fluid Inertial Sensors

Abstract

:1. Introduction

2. Working Principles of Micromachined Fluid Inertial Sensors

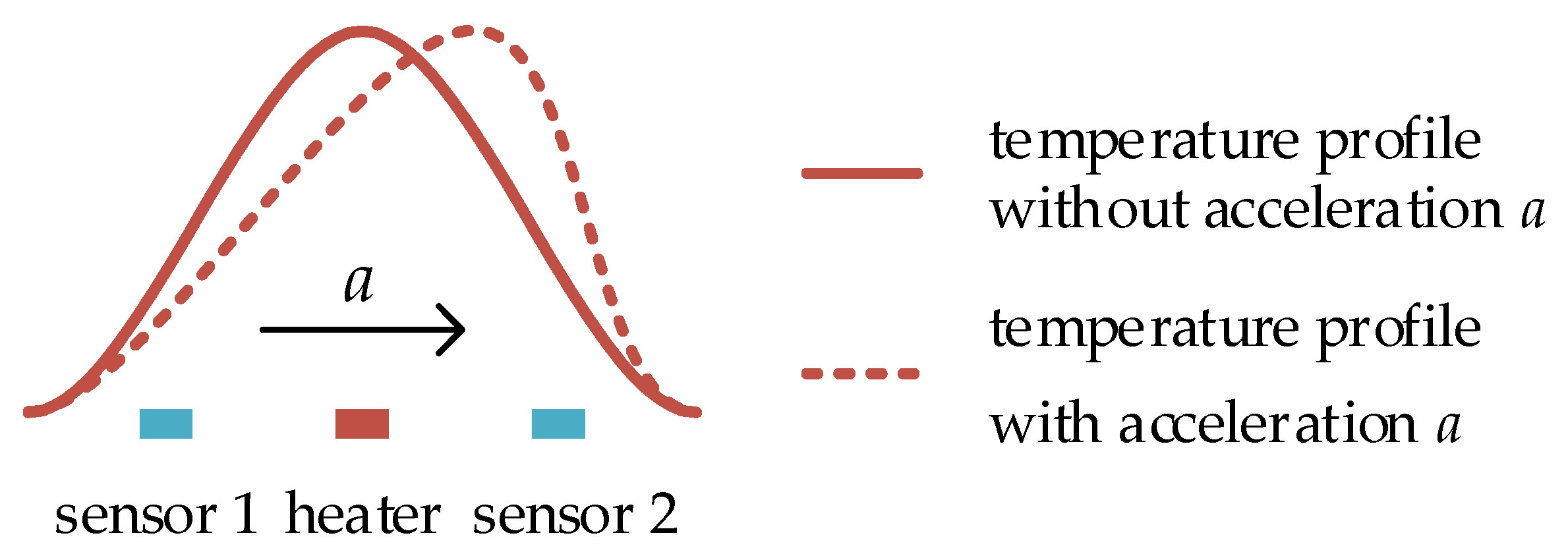

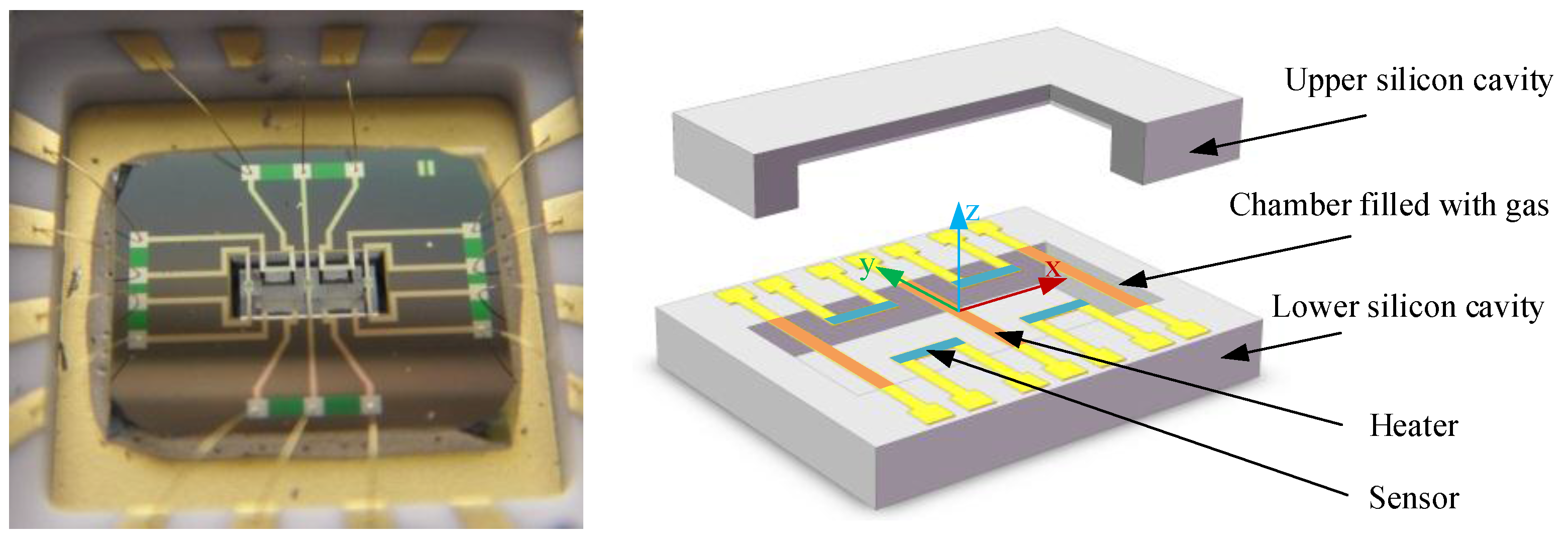

2.1. Micromachined Thermal Accelerometers

2.2. Micromachined Fluid Gyroscopes

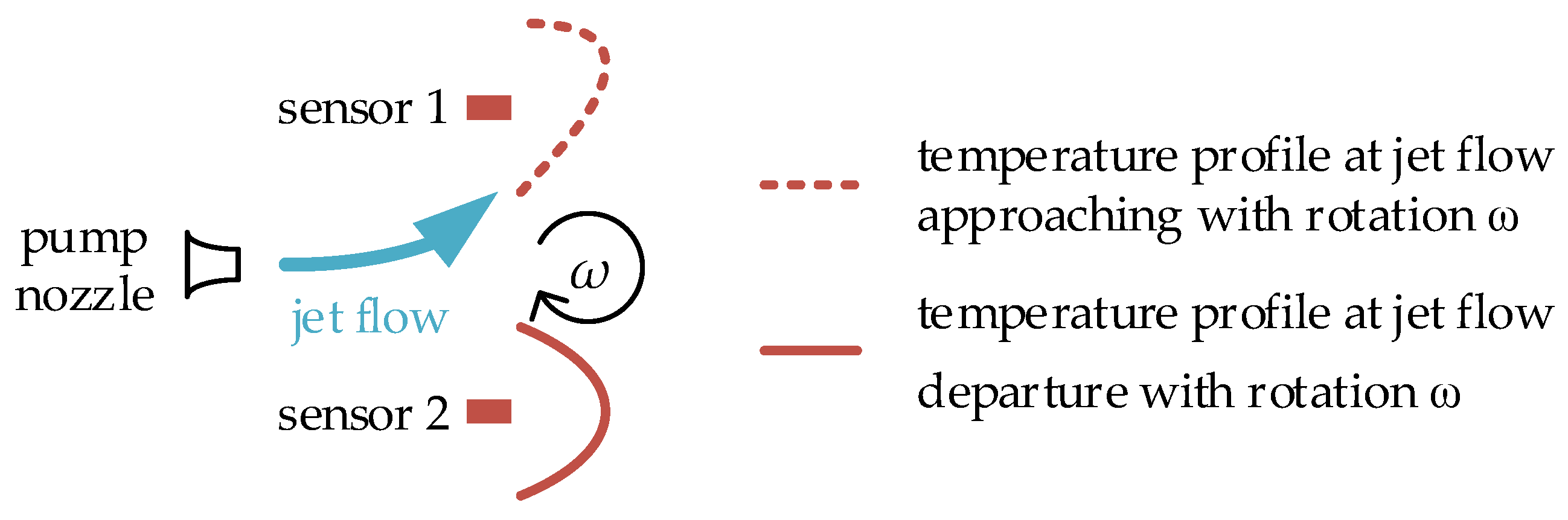

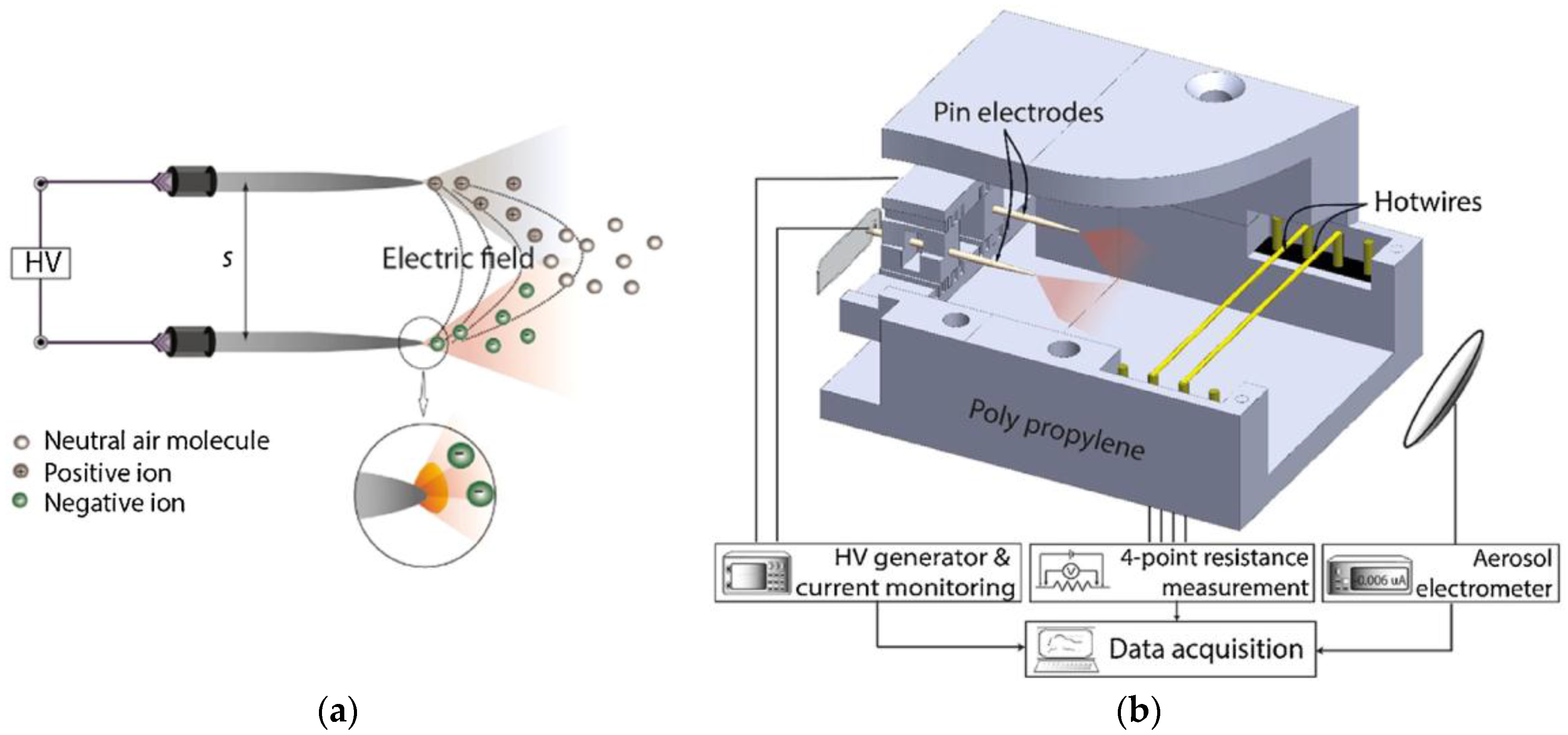

2.2.1. The Jet Flow Gyroscope

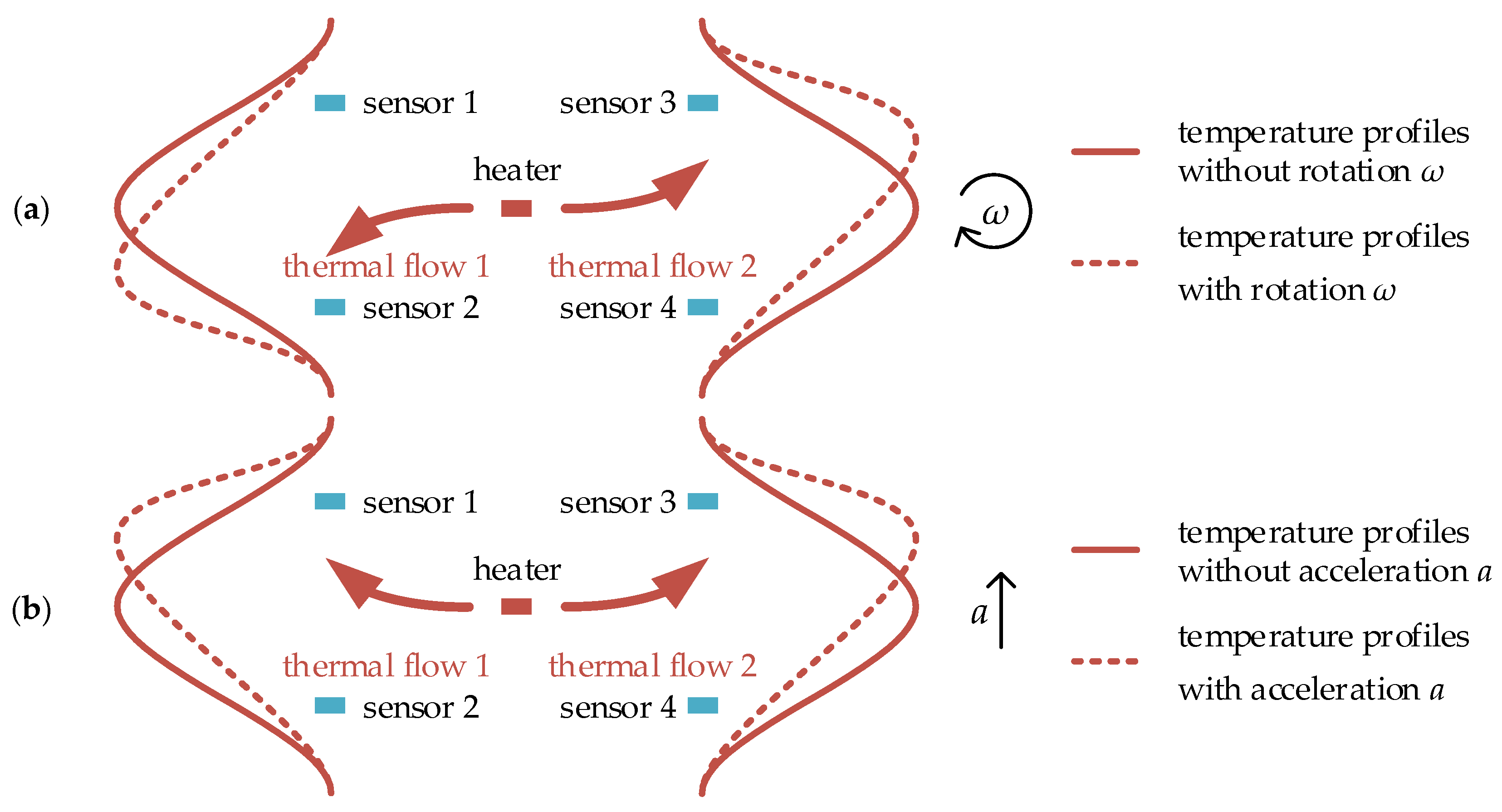

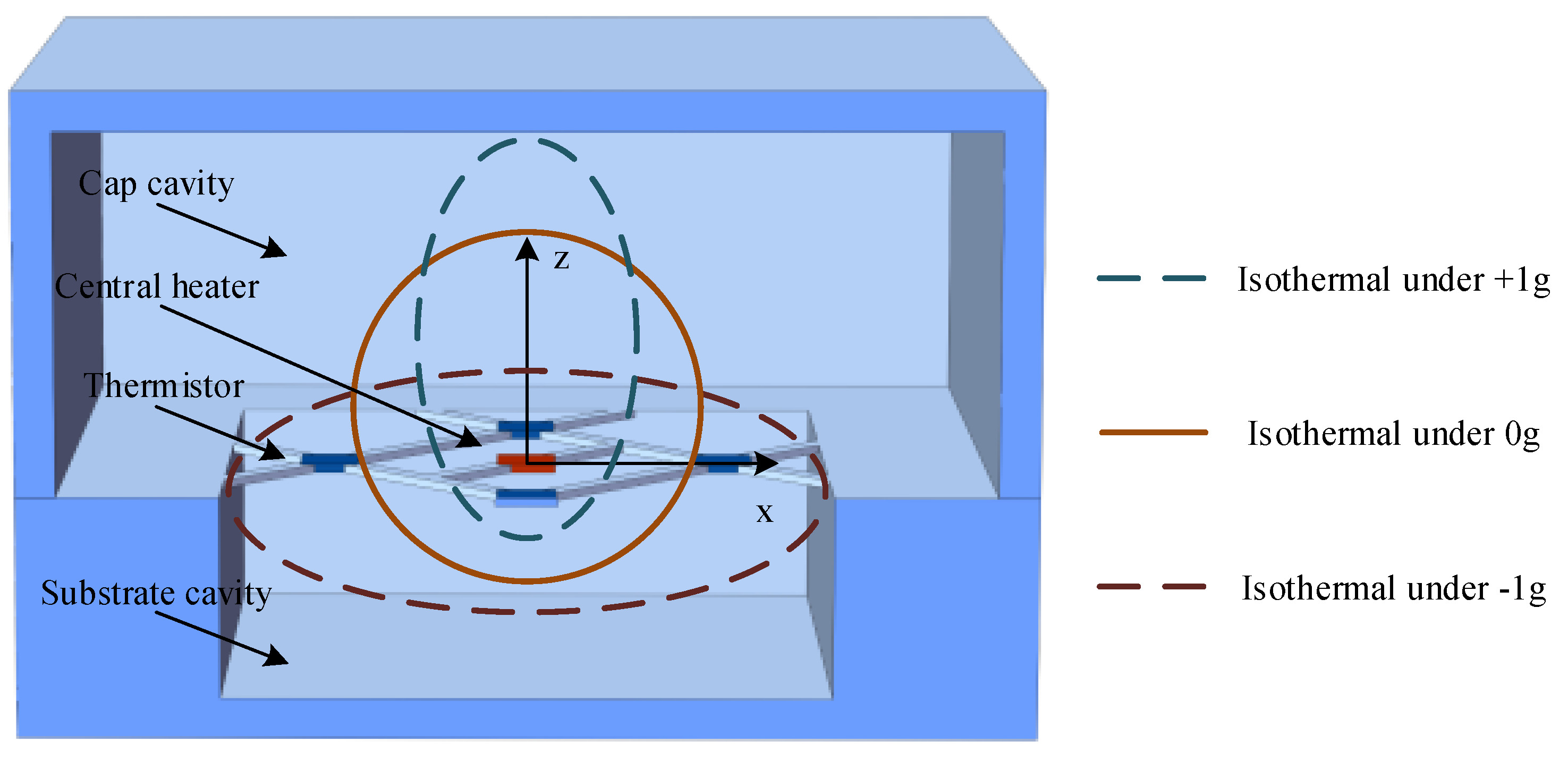

2.2.2. The Thermal Gas Gyroscope

3. Developments of Micromachined Fluid Inertial Sensors

3.1. Micromachined Thermal Accelerometers

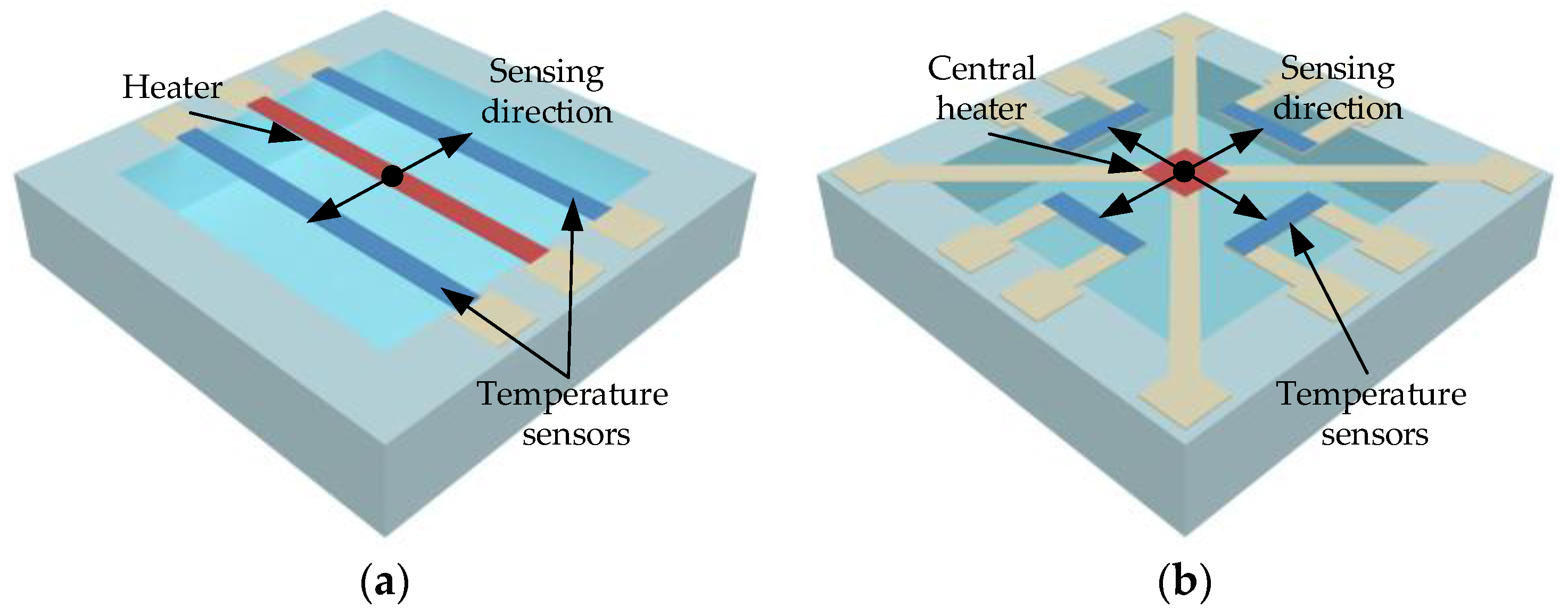

3.1.1. Uniaxial and Dual-Axis Micromachined Thermal Accelerometers

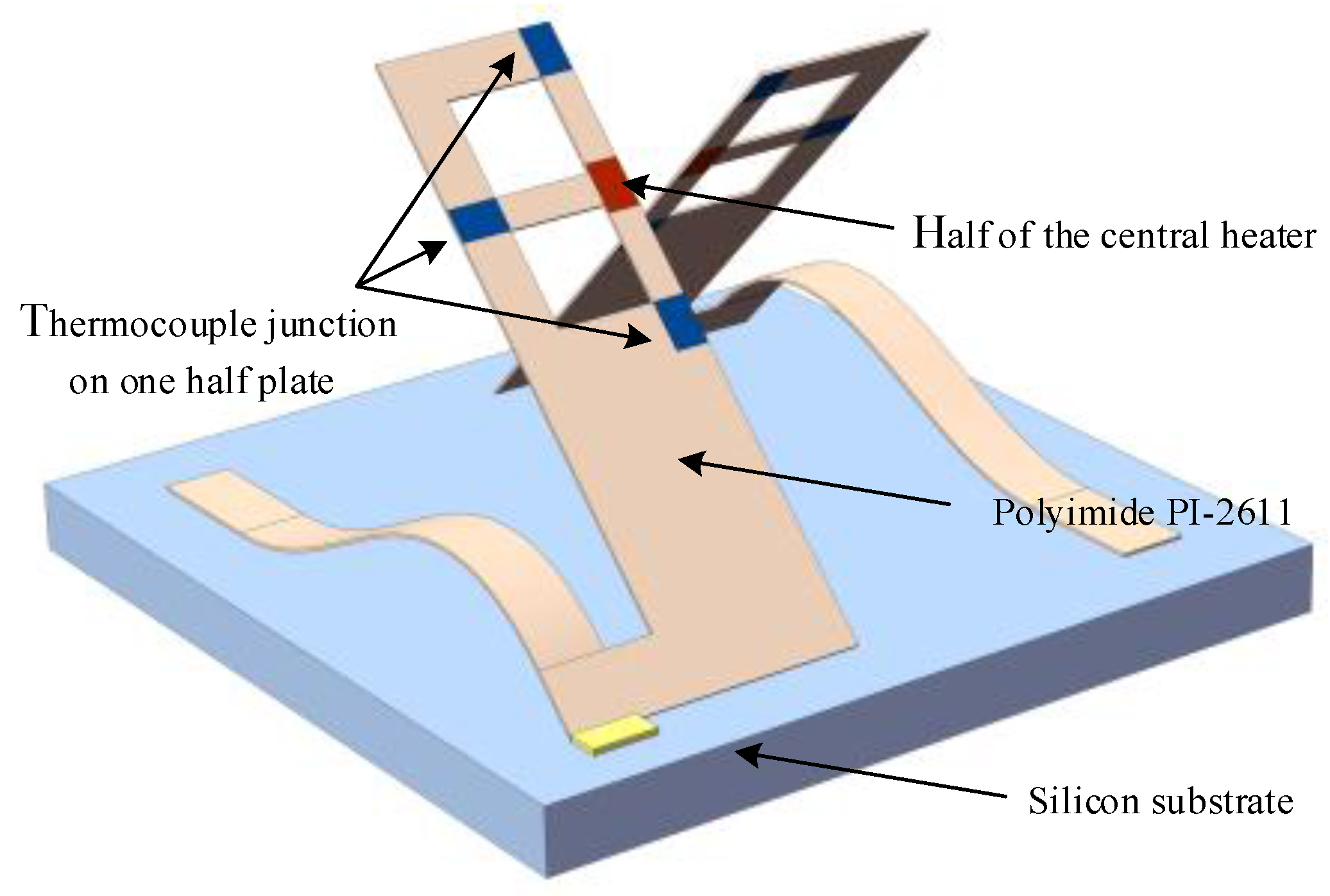

3.1.2. Tri-Axis Micromachined Thermal Accelerometers

3.2. Micromachined Fluid Gyroscopes

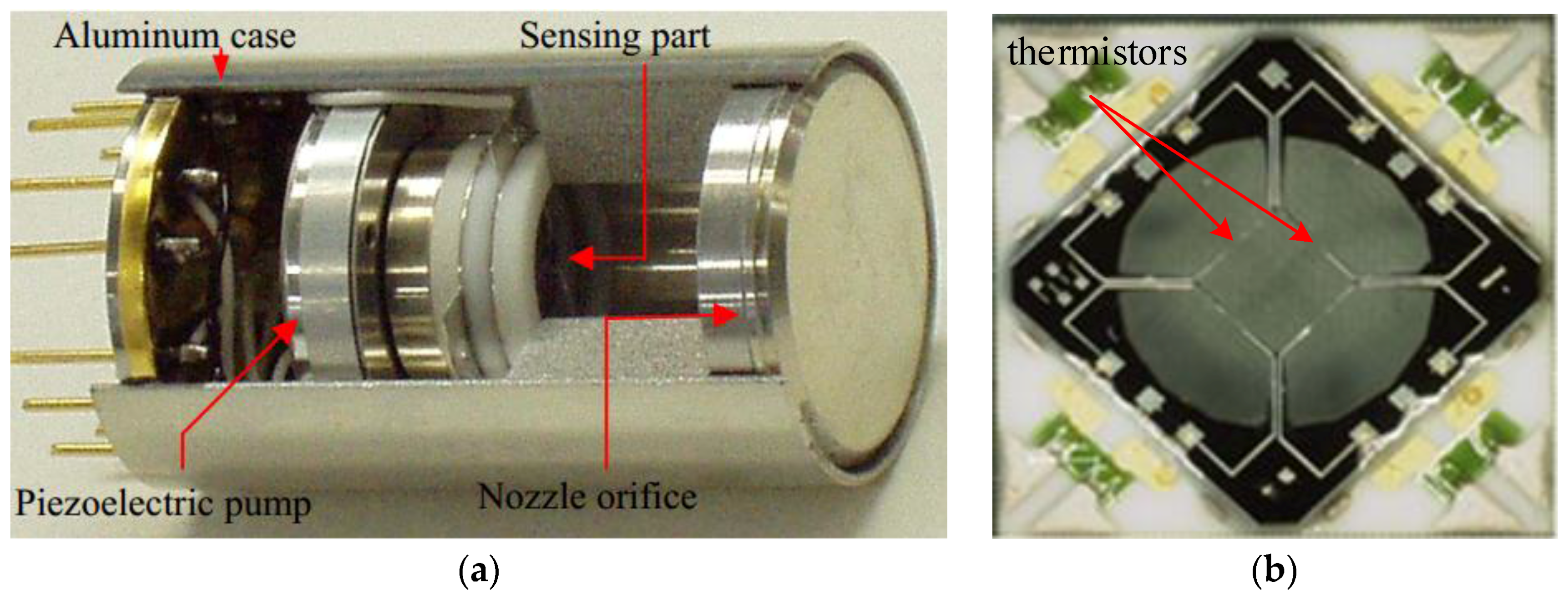

3.2.1. Micromachined Jet Flow Gyroscope

3.2.2. Micromachined Thermal Gas Gyroscope

4. Key Technologies of Micromachined Fluid Inertial Sensors

4.1. Micromachined Thermal Accelerometers

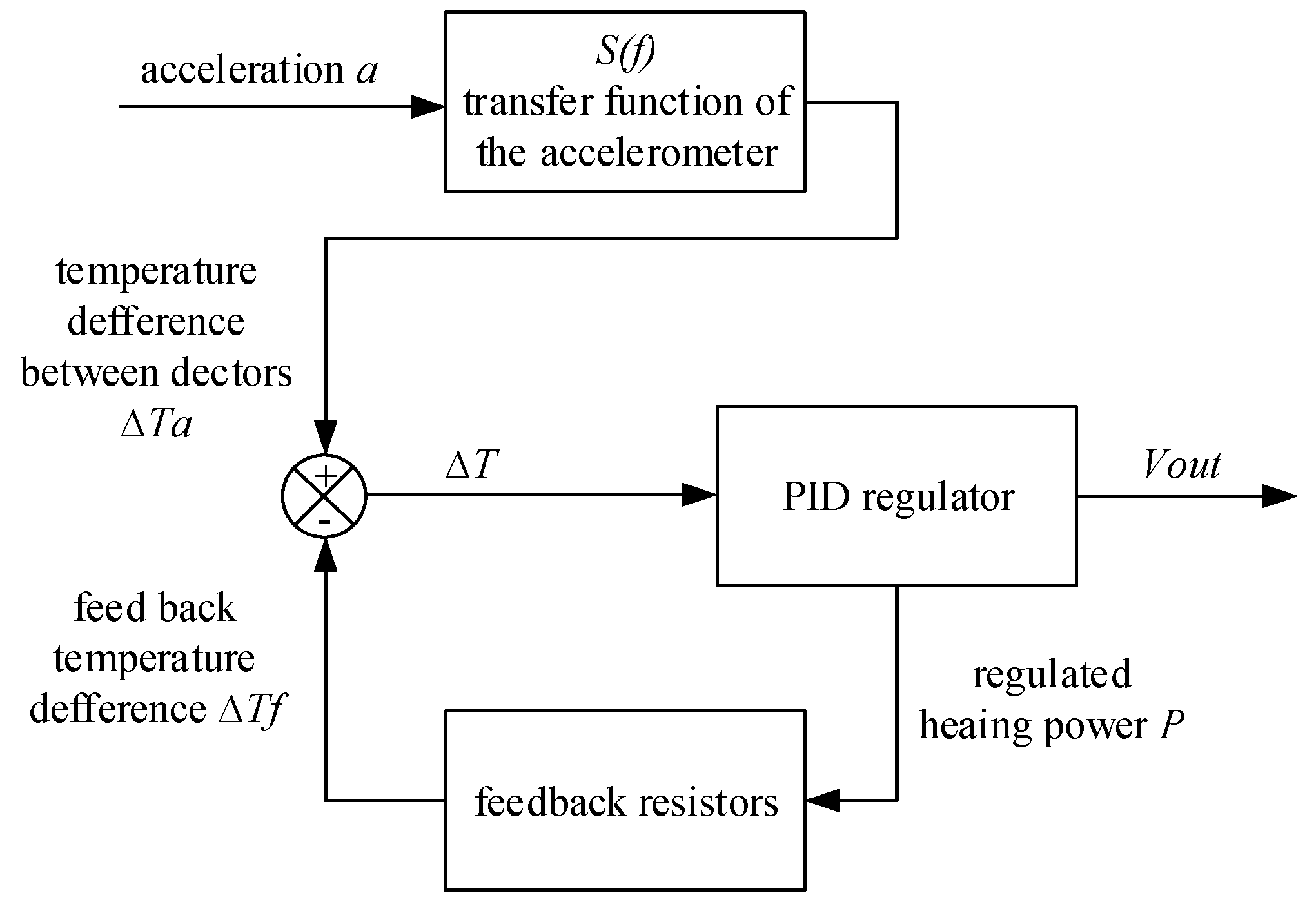

4.1.1. Bandwidth

4.1.2. Temperature Compensation

4.1.3. Out-of-Plane Performance of Planar Tri-Axis Micromachined Thermal Accelerometers

4.1.4. Test and Calibration Strategy for Batch Fabrication

4.2. Micromachined Fluid Gyroscopes

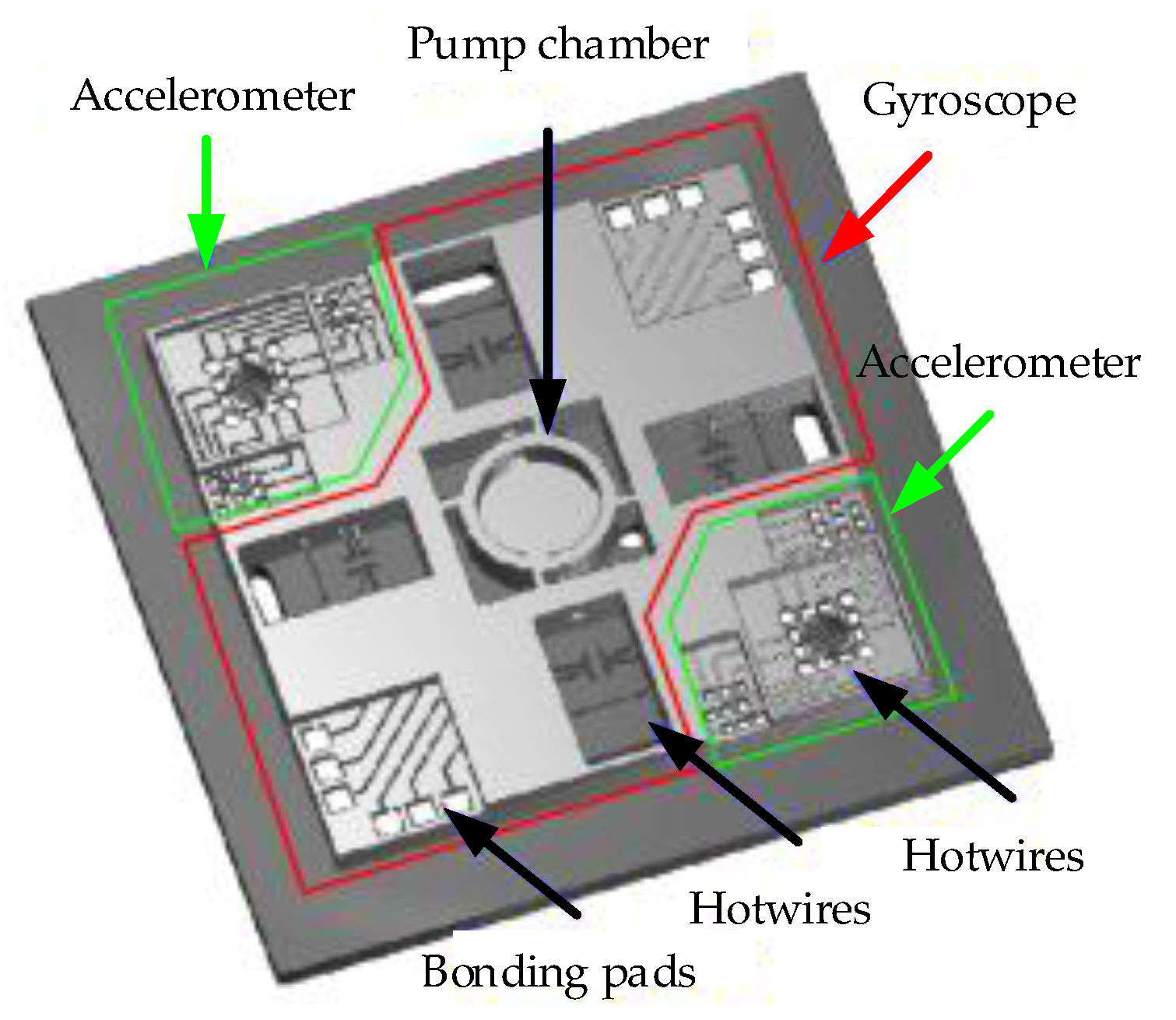

4.2.1. Integration of Micro Jet Gyroscope

4.2.2. Thermal Compensation

4.2.3. Cross Coupling Error Compensation

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Maluf, N. An Introduction to Microelectromechanical Systems Engineering, 2nd ed.; IOP Publishing: Bristol, UK, 2002. [Google Scholar]

- Barbour, N.; Schmidt, G. Inertial sensor technology trends. IEEE Sens. J. 2001, 1, 332–339. [Google Scholar] [CrossRef]

- Höflinger, F.; Müller, J.; Zhang, R.; Reindl, L.M.; Burgard, W. A wireless micro inertial measurement unit (IMU). IEEE Trans. Instrum. Meas. 2013, 62, 2583–2595. [Google Scholar] [CrossRef]

- Brown, A.; Lu, Y. Performance Test Results of an Integrated GPS/MEMS Inertial Navigation Package. In Proceedings of the ION GNSS, Tampa, FL, USA, 8–12 September 2004; pp. 21–24.

- Hanse, J.G. Honeywell MEMS Inertial Technology & Product Status. In Proceedings of the Position Location and Navigation Symposium (PLANS 2004), Monterey, CA, USA, 26–29 April 2004; pp. 43–48.

- Billat, S.; Glosch, H.; Kunze, M.; Hedrich, F.; Frech, J.; Auber, J.; Sandmaier, H.; Wimmer, W.; Lang, W. Micromachined inclinometer with high sensitivity and very good stability. Sens. Actuators A Phys. 2002, 97, 125–130. [Google Scholar] [CrossRef]

- Lin, L.; Jones, J. A liquid-filled buoyancy-driven convective micromachined accelerometer. J. Microelectromech. Syst. 2005, 14, 1061–1069. [Google Scholar] [CrossRef]

- Kaltsas, G.; Goustouridis, D.; Nassiopoulou, A. A thermal convective accelerometer system based on a silicon sensor—Study and packaging. Sens. Actuators A Phys. 2006, 132, 147–153. [Google Scholar] [CrossRef]

- Petropoulos, A.; Moschos, A.; Athineos, S.; Kaltsas, G. A thermal accelerometer directly integrated on organic substrate. Procedia Eng. 2011, 25, 643–646. [Google Scholar] [CrossRef]

- Dau, V.; Shiozawa, T.; Dao, D.; Kumagai, H.; Sugiyama, S. A Dual Axis Gas Gyroscope Utilizing Low-Doped Silicon Thermistor. In Proceedings of the 18th IEEE International Conference on Micro Electro Mechanical Systems (MEMS 2005), Miami Beach, FL, USA, 30 January–3 February 2005; pp. 626–629.

- Garraud, A.; Combette, P.; Gosalbes, J.; Charlot, B.; Giani, A. First High-g Measurement by Thermal Accelerometers. In Proceedings of the 2011 16th International Solid-State Sensors, Actuators and Microsystems Conference, Beijing, China, 5–9 June 2011.

- Sun, S.-C.; Shi, G.-C. Research on the Output Characteristics of MEMS Convective Accelerometer under Heavy Impact. In Proceedings of the 4th IEEE International Conference on Nano/Micro Engineered and Molecular Systems (NEMS 2009), Shenzhen, China, 5–8 January 2009; pp. 33–36.

- Zhao, Y.; Zhu, R.; Ye, X.-Y.; Yang, Y.-Z. Analysis on Shock Resistance of Micromachined Angular Rate Sensor Based on Convection Heat Transfer. Chin. J. Sens. Actuators 2008, 21, 628–631. [Google Scholar]

- Leung, A.M.; Jones, J.; Czyzewska, E.; Chen, J.; Pascal, M. Micromachined Accelerometer with No Proof Mass. In Proceedings of the International Electron Devices Meeting, Technical Digest (IEDM’97), Austin, TX, USA, 10 December 1997; pp. 899–902.

- Leung, A.; Jones, J.; Czyzewska, E.; Chen, J.; Woods, B. Micromachined Accelerometer Based on Convection Heat Transfer. In Proceedings of the Eleventh Annual International Workshop on Micro Electro Mechanical Systems (MEMS 98), Heidelberg, Germany, 25–29 January 1998; pp. 627–630.

- Bahari, J.; Jones, J.D.; Leung, A.M. Sensitivity improvement of micromachined convective accelerometers. J. Microelectromech. Syst. 2012, 21, 646–655. [Google Scholar] [CrossRef]

- Mailly, F.; Martinez, A.; Giani, A.; Pascal-Delannoy, F.; Boyer, A. Design of a micromachined thermal accelerometer: Thermal simulation and experimental results. Microelectron. J. 2003, 34, 275–280. [Google Scholar] [CrossRef]

- Mailly, F.; Martinez, A.; Giani, A.; Pascal-Delannoy, F.; Boyer, A. Effect of gas pressure on the sensitivity of a micromachined thermal accelerometer. Sens. Actuators A Phys. 2003, 109, 88–94. [Google Scholar] [CrossRef]

- Mailly, F.; Giani, A.; Martinez, A.; Bonnot, R.; Temple-Boyer, P.; Boyer, A. Micromachined thermal accelerometer. Sens. Actuators A Phys. 2003, 103, 359–363. [Google Scholar] [CrossRef]

- Courteaud, J.; Crespy, N.; Combette, P.; Sorli, B.; Giani, A. Studies and optimization of the frequency response of a micromachined thermal accelerometer. Sens. Actuators A Phys. 2008, 147, 75–82. [Google Scholar] [CrossRef]

- Courteaud, J.; Combette, P.; Crespy, N.; Cathebras, G.; Giani, A. Thermal simulation and experimental results of a micromachined thermal inclinometer. Sens. Actuators A Phys. 2008, 141, 307–313. [Google Scholar] [CrossRef]

- Garraud, A.; Giani, A.; Combette, P.; Charlot, B.; Richard, M. A dual axis CMOS micromachined convective thermal accelerometer. Sens. Actuators A Phys. 2011, 170, 44–50. [Google Scholar] [CrossRef]

- Garraud, A.; Combette, P.; Courteaud, J.; Giani, A. Effect of the detector width and gas pressure on the frequency response of a micromachined thermal accelerometer. Micromachines 2011, 2, 167–178. [Google Scholar] [CrossRef]

- Garraud, A.; Combette, P.; Pichot, F.; Courteaud, J.; Charlot, B.; Giani, A. Frequency response analysis of an accelerometer based on thermal convection. J. Micromech. Microeng. 2011, 21, 035017. [Google Scholar] [CrossRef]

- Mezghani, B.; Brahim, A.; Tounsi, F.; Masmoudi, M.; Rekik, A.; Nouet, P. From 2D to 3D FEM Simulations of a CMOS MEMS Convective Accelerometer. In Proceedings of the ICM 2011, Istanbul, Turkey, 13–15 April 2011; pp. 1–5.

- Rekik, A.; Mezghani, B.; Azaïs, F.; Dumas, N.; Masmoudi, M.; Mailly, F.; Nouet, P. Investigation on the Effect of Geometrical Dimensions on the Conductive Behaviour of a MEMS Convective Accelerometer. In Proceedings of the 2011 Symposium on Design, Test, Integration and Packaging of MEMS/MOEMS (DTIP), Aix-en-Provence, France, 11–13 May 2011; pp. 14–17.

- Mezghani, B.; Tounsi, F.; Masmoudi, M.; Rekik, A.; Mailly, F.; Nouet, P. Efficiency Modeling of a CMOS MEMS Convective Accelerometer. In Proceedings of the 2012 7th International Conference on Design & Technology of Integrated Systems in Nanoscale Era (DTIS), Tunis, Tunisia, 16–18 May 2012; pp. 1–5.

- Mezghani, B.; Tounsi, F.; Rekik, A.A.; Mailly, F.; Masmoudi, M.; Nouet, P. Sensitivity and power modeling of CMOS MEMS single axis convective accelerometers. Microelectron. J. 2013, 44, 1092–1098. [Google Scholar] [CrossRef]

- Luo, X.; Yang, Y.; Zheng, F.; Li, Z.; Guo, Z. An optimized micromachined convective accelerometer with no proof mass. J. Micromech. Microeng. 2001, 11, 504. [Google Scholar] [CrossRef]

- Luo, X.; Li, Z.; Guo, Z.; Yang, Y. Thermal optimization on micromachined convective accelerometer. Heat Mass Transf. 2002, 38, 705–712. [Google Scholar] [CrossRef]

- Luo, X.; Li, Z.; Guo, Z.; Yang, Y. Study on linearity of a micromachined convective accelerometer. Microelectron. Eng. 2003, 65, 87–101. [Google Scholar] [CrossRef]

- Liao, K.-M.; Chen, R.; Chou, B.C. A novel thermal-bubble-based micromachined accelerometer. Sens. Actuators A Phys. 2006, 130, 282–289. [Google Scholar] [CrossRef]

- Chen, S.-J.; Shen, C.-H. A novel two-axis CMOS accelerometer based on thermal convection. IEEE Trans. Instrum. Meas. 2008, 57, 1572–1577. [Google Scholar] [CrossRef]

- Park, U.; Kim, D.; Kim, J.; Moon, I.-K.; Kim, C.-H. Development of a Complete Dual-Axis Micromachined Convective Accelerometer with High Sensitivity. In Proceedings of the 2008 IEEE Sensors, Lecce, Italy, 26–29 October 2008; pp. 670–673.

- Park, U.; Park, B.; Moon, I.-K.; Kim, D.; Kim, J. Development of a dual-axis micromachined convective accelerometer with an effective heater geometry. Microelectron. Eng. 2011, 88, 276–281. [Google Scholar] [CrossRef]

- Milanovi, V.; Bowen, E.; Tea, N.; Suehle, J.; Payne, B.; Zaghloul, M.; Gaitan, M. Convection-Based Accelerometer and Tilt Sensor Implemented in Standard CMOS. In Proceedings of the 1998 International Mechanical Engineering Congress and Exposition, Anaheim, CA, USA, 15–20 November 1998.

- Milanović, V.; Bowen, E.; Zaghloul, M.E.; Tea, N.H.; Suehle, J.S.; Payne, B.; Gaitan, M. Micromachined convective accelerometers in standard integrated circuits technology. Appl. Phys. Lett. 2000, 76, 508–510. [Google Scholar] [CrossRef]

- Dao, D.V.; van Dau, T.; Hayashida, M.; Dinh, T.; Shiozawa, T.; Sugiyama, S. Fabrication and Characterization of 2-DOF Micro Convective Accelerometer. In Proceedings of the 2006 5th IEEE Conference on Sensors, Daegu, Korea, 22–25 October 2006; pp. 1353–1356.

- Goustouridis, D.; Kaltsas, G.; Nassiopoulou, A. A CMOS Compatible Thermal Accelerometer without Solid Proof Mass, Based on Porous Silicon Thermal Isolation. In Proceedings of the 2004 IEEE Sensors, Vienna, Austria, 24–27 October 2004; pp. 848–851.

- Goustouridis, D.; Kaltsas, G.; Nassiopoulou, A.G. A Silicon Thermal Accelerometer without Solid Proof Mass Using Porous Silicon Thermal Isolation. IEEE Sens. J. 2007, 7, 983–989. [Google Scholar] [CrossRef]

- Leman, O.; Mailly, F.; Latorre, L.; Nouet, P. A Wide-Bandwidth, Wide Dynamic-Range Thermal ΣΔ Architecture for Convective Accelerometers. In Proceedings of the 2009 IEEE Sensors, Canterbury, New Zealand, 25–28 October 2009; pp. 1828–1831.

- Leman, O.; Mailly, F.; Latorre, L.; Nouet, P. Noise analysis of a first-order thermal ΣΔ architecture for convective accelerometers. Analog Integr. Circuits Signal Process. 2010, 63, 415–423. [Google Scholar] [CrossRef]

- Garraud, A.; Combette, P.; Deblonde, A.; Loisel, P.; Giani, A. Closed-loop micromachined accelerometer based on thermal convection. IET Micro Nano Lett. 2012, 7, 1092–1093. [Google Scholar] [CrossRef]

- Sameoto, D.; Ma, A.H.; Parameswaran, M.; Leung, A.M. Assembly and Characterization of Buckled Cantilever Platforms for Thermal Isolation in a Polymer Micromachining Process. In Proceedings of the 2007 Canadian Conference on Electrical and Computer Engineering, Vancouver, BC, Canada, 22–26 April 2007; pp. 296–299.

- Ma, A.H.; Leung, A.M. Three-Axis Thermal Accelerometer Based on Buckled Cantilever Microstructure. In Proceedings of the 2008 IEEE Sensors, Lecce, Italy, 26–29 October 2008; pp. 1492–1495.

- Tsang, S.-H.; Ma, A.H.; Karim, K.S.; Parameswaran, A.; Leung, A.M. Monolithically Fabricated Polymermems 3-Axis Thermal Accelerometers Designed for Automated Wirebonder Assembly. In Proceedings of the IEEE 21st International Conference on Micro Electro Mechanical Systems (MEMS 2008), Tucson, AZ, USA, 13–17 January 2008; pp. 880–883.

- Bahari, J.; Leung, A.M. Micromachined three-axis thermal accelerometer with a single composite heater. J. Micromech. Microeng. 2011, 21, 075025. [Google Scholar] [CrossRef]

- Chaehoi, A.; Mailly, F.; Latorre, L.; Nouet, P. Experimental and finite-element study of convective accelerometer on CMOS. Sens. Actuators A Phys. 2006, 132, 78–84. [Google Scholar] [CrossRef]

- Rekik, A.; Azaïs, F.; Dumas, N.; Mailly, F.; Nouet, P. Modeling the Influence of Etching Defects on the Sensitivity of MEMS Convective Accelerometers. In Proceedings of the 2010 IEEE 16th International Mixed-Signals, Sensors and Systems Test Workshop (IMS3TW), La Grande Motte, France, 7–9 June 2010; pp. 1–6.

- Rocha, L.A.; Silva, C.; Cerqueira, M.; Ribeiro, J.; Gonçalves, L.; Pontes, A.; Viana, J. A microinjected 3-axis thermal accelerometer. Procedia Eng. 2011, 25, 607–610. [Google Scholar] [CrossRef]

- Silva, C.; Pontes, J.; Viana, J.; Rocha, L.A.; Gaspar, J. A Fully Integrated Three-Axis Thermal Accelerometer. In Proceedings of the 2013 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Minneapolis, MN, USA, 6–9 May 2013; pp. 963–966.

- Noh, J.; Fonseca, H.; Rocha, L.A. Fabrication and characterization of polymeric three-axis thermal accelerometers. J. Micromech. Microeng. 2015, 25, 085005. [Google Scholar]

- Mezzhani, B.; Tounsi, F.; Masmoudi, M. Sensitivity Modeling of Dual-Axis CMOS MEMS Convective Accelerometers Using FEM and Spherical Model. In Proceedings of the 2013 Symposium on Design, Test, Integration and Packaging of MEMS/MOEMS (DTIP), Barcelona, Spain, 16–18 April 2013; pp. 1–6.

- Mezghani, B.; Tounsi, F.; Masmoudi, M. Convection behavior analysis of CMOS MEMS thermal accelerometers using FEM and Hardee’s model. Analog Integr. Circuits Signal Process. 2014, 78, 301–311. [Google Scholar] [CrossRef]

- Mezghani, B.; Tounsi, F.; Masmoudi, M. Development of an accurate heat conduction model for micromachined convective accelerometers. Microsyst. Technol. 2015, 21, 345–353. [Google Scholar] [CrossRef]

- Leman, O.; Mailly, F.; Latorre, L.; Nouet, P. HDL modeling of convective accelerometers for system design and optimization. Sens. Actuators A Phys. 2008, 142, 178–184. [Google Scholar] [CrossRef]

- Rekik, A.; Azaïs, F.; Dumas, N.; Mailly, F.; Nouet, P. Investigations on Electrical-Only Test Setup for MEMS Convective Accelerometer. In Proceedings of the 2009 3rd International Conference on Signals, Circuits and Systems (SCS), Medenine, Tunisia, 6–8 November 2009; pp. 1–6.

- Rekik, A.A.; Azaïs, F.; Dumas, N.; Mailly, F.; Nouet, P. A behavioral model of MEMS convective accelerometers for the evaluation of design and calibration strategies at system level. J. Electron. Test. 2011, 27, 411–423. [Google Scholar] [CrossRef]

- Rekik, A.A.; Azaïs, F.; Dumas, N.; Mailly, F.; Nouet, P. A MEMS Convective Accelerometer Equipped with on-Chip Facilities for Sensitivity Electrical Calibration. In Proceedings of the 2011 IEEE 17th International Mixed-Signals, Sensors and Systems Test Workshop (IMS3TW), Santa Barbara, CA, USA, 16–18 May 2011; pp. 82–87.

- Rekik, A.A.; Azaïs, F.; Dumas, N.; Mailly, F.; Nouet, P. An Electrical Test Method for MEMS Convective Accelerometers: Development and Evaluation. In Proceedings of the 2011 Design, Automation & Test in Europe, Grenoble, France, 14–18 March 2011; pp. 1–6.

- Rekik, A.; Azaïs, F.; Dumas, N.; Mailly, F.; Nouet, P. Test and Calibration of MEMS Convective Accelerometers with a Fully Electrical Setup. In Proceedings of the 2011 12th Latin American Test Workshop (LATW), Porto de Galinhas, Brazil, 27–30 March 2011; pp. 1–6.

- Rekik, A.; Azaïs, F.; Mailly, F.; Nouet, P. Design-for-Manufacturability of MEMS Convective Accelerometers through Adaptive Electrical Calibration Strategy. In Proceedings of the 2012 13th Latin American Test Workshop (LATW), Quito, Ecuador, 10–13 April 2012; pp. 1–6.

- Ding, H.G.; Zhu, R.; Hao, Y.L. Micro Jet Gyro. CN Patent 01,119,802.8, 29 June 2001. [Google Scholar]

- Shiozawa, T.; Dau, V.; Dao, D.V.; Kumagai, H.; Sugiyama, S. A Dual Axis Thermal Convective Silicon Gyroscope. In Proceedings of the 2004 International Symposium on Micro-Nanomechatronics and Human Science and the Fourth Symposium Micro-Nanomechatronics for Information-Based Society, Nagoya, Japan, 31 October–3 November 2004; pp. 277–282.

- Dao, D.V.; Dau, V.T.; Shiozawa, T.; Kumaga, H.; Sugiyama, S. A dual Axis Gas Gyroscope Based on Convective and Thermo-Resistive Effects in Silicon with Low Thermal-Induced Stress Sensing Element. In Proceedings of the 19th IEEE International Conference on Micro Electro Mechanical Systems, Istanbul, Turkey, 22–26 January 2006; pp. 594–597.

- ThanhDau, V.; Dao, D.V.; Shiozawa, T.; Sugiyama, S. Convective Gas Gyroscope Based on Thermo-Resistive Effect in Si Pn Junction. In Proceedings of the 2007 International Solid-State Sensors, Actuators and Microsystems Conference (TRANSDUCERS 2007), Lyon, France, 10–14 June 2007; pp. 2525–2528.

- Dau, V.T.; Dao, D.V.; Shiozawa, T.; Sugiyama, S. Simulation and fabrication of a convective gyroscope. IEEE Sens. J. 2008, 8, 1530–1538. [Google Scholar] [CrossRef]

- Zarei, N.; Leung, A.M.; Jones, J.D. Design Principles of the Thermal MEMS Gyroscope. In Proceedings of the ASME 2012 International Mechanical Engineering Congress and Exposition, Houston, TX, USA, 9–15 November 2012; pp. 357–361.

- Zarei, N.; Leung, A.; Jones, J.D. Design and Analysis of a Micromachined Gyroscope. In Proceedings of the SPIE MOEMS-MEMS, San Francisco, CA, USA, 2012; p. 82510X.

- Bahari, J.; Feng, R.; Leung, A.M. Robust MEMS gyroscope based on thermal principles. J. Microelectromech. Syst. 2014, 23, 100–116. [Google Scholar] [CrossRef]

- Zhu, R.; Su, Y.; Ding, H. A MEMS Hybrid Inertial Sensor Based on Convection Heat Transfer. In Proceedings of the 13th International Conference on Solid-State Sensors, Actuators and Microsystems, Digest of Technical Papers (TRANSDUCERS’05), Seoul, Korea, 2005; pp. 113–116.

- Zhu, R.; Ding, H.; Su, Y.; Zhou, Z. Micromachined gas inertial sensor based on convection heat transfer. Sens. Actuators A Phys. 2006, 130, 68–74. [Google Scholar] [CrossRef]

- Zhu, R.; Ding, H.; Su, Y.; Yang, Y. Modeling and experimental study on characterization of micromachined thermal gas inertial sensors. Sensors 2010, 10, 8304–8315. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.; Yan, G.; Zhu, Y.; Xiao, Z.; Fan, J. Design and Fabrication of a Microfluid Angular Rate Sensor. In Proceedings of the 18th IEEE International Conference on Micro Electro Mechanical Systems (MEMS 2005), Miami Beach, FL, USA, 30 January–3 February 2005; pp. 363–366.

- Ai, Y.; Luo, X.; Liu, S. Design of a Novel Micro Thermo-Fluidic Gyroscope. In Proceedings of the 7th International Conference on Electronic Packaging Technology (ICEPT’06), Shanghai, China, 26–29 August 2006; pp. 1–4.

- Ai, Y.; Luo, X.; Liu, S. Design and Modeling of Micromachined Thermal Convective Gyroscope with Bidirectional Jets. In Proceedings of the 8th International Conference on Proceedings of the Electronic Packaging Technology (ICEPT 2007), Shanghai, China, 14–17 August 2007; pp. 1–5.

- Zarei, N.; Leung, A.M.; Jones, J.D. High Performance MEMS Thermal Gyroscope. In Proceedings of the ASME 2012 International Mechanical Engineering Congress and Exposition, Houston, TX, USA, 9–15 November 2012; pp. 931–936.

- Dao, D.V.; Dau, V.T.; Dinh, T.X.; Sugiyama, S. A Fully Integrated MEMS-Based Convective 3-DOF Gyroscope. In Proceedings of the 2007 International Solid-State Sensors, Actuators and Microsystems Conference (TRANSDUCERS 2007), Lyon, France, 10–14 June 2007; pp. 1211–1214.

- Dau, V.T.; Dinh, T.X.; Dao, D.V.; Tomonori, O.; Sugiyama, S. Design and Fabrication of a Convective 3-DOF Angular Rate Sensor. In Proceedings of the 2007 IEEE Sensors, Atlanta, GA, USA, 28–31 October 2007; pp. 915–918.

- Dau, V.T.; Tomonori, O.; Dinh, T.X.; Dao, D.V.; Sugiyama, S. A Multi Axis Fluidic Inertial Sensor. In Proceedings of the 2008 IEEE Sensors, Lecce, Italy, 26–29 October 2008; pp. 666–669.

- Dau, V.T.; Dinh, T.X.; Dao, D.V.; Amarashinge, R.; Tung, B.T.; Susumu, S. Design and Simulation of Convective Inertial Sensor. In Proceedings of the International Symposium on Micro-NanoMechatronics and Human Science (MHS 2008), Nagoya, Japan, 6–9 November 2008; pp. 33–36.

- Dau, V.; Otake, T.; Dinh, T.; Sugiyama, S. Design and Fabrication of Convective Inertial Sensor Consisting of 3DOF Gyroscope and 2DOF Accelerometer. In Proceedings of the 2009 International Solid-State Sensors, Actuators and Microsystems Conference (TRANSDUCERS 2009), Denver, CO, USA, 21–25 June 2009; pp. 1170–1173.

- Dinh, T.X.; Ogami, Y. A triple-Axis Fluidic Angular Rate Sensor. In Proceedings of the 2012 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Kaohsiung, Taiwan, 11–14 July 2012; pp. 748–752.

- Dinh, T.X.; Ogami, Y. Design of a Triple-Axis MEMS-Based Fluidic Gyroscope. In Proceedings of the 2012 IEEE Sensors, Taipei, Taiwan, 28–31 October 2012; pp. 1–4.

- Dinh, T.X.; Ogami, Y. Design and simulation of MEMS-based dual-axis fluidic angular velocity sensor. Sens. Actuators A Phys. 2013, 189, 61–66. [Google Scholar] [CrossRef]

- Hoa, P.T.; Dinh, T.X.; Dau, V.T. Design Study of Multidirectional Jet Flow for a Triple-Axis Fluidic Gyroscope. IEEE Sens. J. 2015, 15, 4103–4113. [Google Scholar] [CrossRef]

- Dau, V.; Dinh, T. Numerical study and experimental validation of a valveless piezoelectric air blower for fluidic applications. Sens. Actuators B Chem. 2015, 221, 1077–1083. [Google Scholar] [CrossRef]

- Bui, T.T.; Dinh, T.X.; Hoa, P.T.; Dau, V.T. Study on the PZT Diaphragm Actuated Multiple Jet Flow in a Circulatory Miniaturized System. In Proceedings of the 2015 IEEE Sensors, Busan, Korea, 1–4 November 2015; pp. 1–4.

- Dau, V.T.; Dinh, T.X.; Bui, T.T. Jet flow generation in a circulatory miniaturized system. Sens. Actuators B Chem. 2016, 223, 820–826. [Google Scholar] [CrossRef]

- Dau, V.T.; Dinh, T.X.; Bui, T.T.; Terebessy, T. Bipolar corona assisted jet flow for fluidic application. Flow Meas. Instrum. 2016, 50, 252–260. [Google Scholar] [CrossRef]

- Dau, V.T.; Dinh, T.X.; Terebessy, T.; Bui, T.T. Bipolar corona discharge based air flow generation with low net charge. Sens. Actuators A Phys. 2016, 244, 146–155. [Google Scholar] [CrossRef]

- Dau, V.T.; Dinh, T.X.; Terebessy, T.; Bui, T.T. Ion Wind Generator Utilizing Bipolar Discharge in Parallel Pin Geometry. IEEE Trans. Plasma Sci. 2016, 44, 2979–2987. [Google Scholar] [CrossRef]

- Ding, H.G.; Zhu, R.; Yang, Y.J. Micro Thermal Gas Gyro. CN Patent 01,129,700.X, 29 June 2001. [Google Scholar]

- Zhu, R.; Ding, H.; Su, Y.; Yang, Y. A Study of Cross-axis Effect for Micromachined Thermal Gas Inertial Sensor. In Proceedings of the 2007 IEEE Sensors, Atlanta, GA, USA, 28–31 October 2007; pp. 840–843.

- Zhu, R.; Ding, H.; Yang, Y.; Su, Y. Sensor fusion methodology to overcome cross-axis problem for micromachined thermal gas inertial sensor. IEEE Sens. J. 2009, 9, 707–712. [Google Scholar] [CrossRef]

- Cai, S.L.; Zhu, R.; Ding, H.G.; Yang, Y.J.; Su, Y. A Micromachined Integrated Gyroscope and Accelerometer Based on Gas Thermal Expansion. In Proceedings of the 2013 Transducers & Eurosensors XXVII: The 17th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS & EUROSENSORS XXVII), Barcelona, Spain, 16–20 June 2013; pp. 50–53.

- Zhu, R.; Cai, S.; Ding, H.; Yang, Y.J.; Su, Y. A micromachined gas inertial sensor based on thermal expansion. Sens. Actuators A Phys. 2014, 212, 173–180. [Google Scholar] [CrossRef]

- Liu, S.Q.; Zhu, R. System Error Compensation Methodology Based on a Neural Network for a Micromachined Inertial Measurement Unit. Sensors 2016, 16, 175. [Google Scholar] [CrossRef] [PubMed]

- Shooshtari, P.; Bahari, J.; Khosraviani, K.; Leung, A.; Jones, J. Spurious Signals in the Thermal MEMS Gyroscope. In Proceedings of the ASME 2012 International Mechanical Engineering Congress and Exposition, Houston, TX, USA, 9–15 November 2012; pp. 587–596.

- Shooshtari, P.; Leung, A.; Jones, J. Suppression of Spurious Signals in Thermal MEMS Gyroscope. In Proceedings of the 2012 IEEE Sensors, Taipei, Taiwan, 28–31 October 2012; pp. 1–4.

- Zarei, N.; Leung, A.M.; Jones, J.D. Modeling a Three-Axis Thermal MEMS Gyroscope. In Proceedings of the ASME 2012 International Mechanical Engineering Congress and Exposition, Houston, TX, USA, 9–15 November 2012; pp. 241–248.

- Feng, R.; Bahari, J.; Jones, J.D.; Leung, A.M. MEMS Thermal gyroscope with self-compensation of the linear acceleration effect. Sens. Actuators A Phys. 2013, 203, 413–420. [Google Scholar] [CrossRef]

- Liu, S.Q.; Zhu, R.; Ding, H.G. A Temperature Compensation Method for Micromachined Thermal Gas Gyroscope. In Proceedings of the 2015 IEEE Sensors, Busan, Korea, 1–4 November 2015; pp. 1–4.

- Dao, R. Mechanical Shock Test Report: Accelerometer Model MXR7202ML. MEMSIC Application Note. 2003. Available online: http://www.memsic.com (accessed on 1 October 2016).

- Jiang, L.; Cai, Y.; Liu, H.; Zhao, Y. A Micromachined Monolithic 3 Axis Accelerometer Based on Convection Heat Transfer. In Proceedings of the 8th Annual IEEE International Conference on Nano/Micro Engineered and Molecular Systems, Suzhou, China, 7–10 April 2013.

- MXR9500G/M Datasheet. Available online: www.memsic.com (accessed on1 October 2016).

- Mailly, F.; Nguyen, H.B.; Latorre, L.; Nouet, P. CMOS Implementation of a 3-Axis Thermal Convective Accelerometer. In Proceedings of the 2014 IEEE Sensors, Valencia, Spain, 2–5 November 2014; pp. 1471–1474.

- MXC6235xQB Datasheet. Available online: www.memsic.com (accessed on 1 October 2016).

- MXP7205VF Datasheet. Available online: www.memsic.com (accessed on 1 October 2016).

- MXR9150MZ Datasheet. Available online: www.memsic.com (accessed on 1 October 2016).

- Ding, H.G.; Zhu, R. Micro Jet Gyro with Channels. CN Patent 10,091,707.4, 25 November 2004. [Google Scholar]

- Xie, Z.; Chang, H.; Yang, Y.; Li, X.; Zhou, P.; Yuan, W. Design and Fabrication of a Vortex Inertial Sensor Consisting of 3-DOF Gyroscope and 3-DOF Accelerometer. In Proceedings of the 2012 IEEE 25th International Conference on Micro Electro Mechanical Systems (MEMS 2012), Paris, France, 29 January–2 February 2012; pp. 551–554.

- Chang, H.; Gong, X.; Wang, S.; Zhou, P.; Yuan, W. On Improving the Performance of a Triaxis Vortex Convective Gyroscope through Suspended Silicon Thermistors. IEEE Sens. J. 2015, 15, 946–955. [Google Scholar] [CrossRef]

- Dao, R. Thermal Accelerometers Temperature Compensation. MEMSIC Application Note. 2002. Available online: http://www.memsic.com (accessed on 1 October 2016).

| Year | Research Institute | Structure | Fluid | Sensitivity | Resolution/Noise | Bandwidth | Measurement Range | Shock Survival | Reference |

|---|---|---|---|---|---|---|---|---|---|

| 1997~2012 | Simon Fraser University, Burnaby, BC, Canada | uniaxial | Air, isopropanol | 7 V/g | 0.6 mg | 20 Hz | ±1 mg~1 g | [7,14,16] | |

| 1998 | Simon Fraser University | dual-axis | air | 0.6 mg | 20 Hz | [15] | |||

| 1998 | George Washington University, Washington, DC, USA | uniaxial | 185 µV/g 1 | 600 Hz 1 | 0~7 g | [36] | |||

| 115 µV/g 2 | 100 Hz 2 | ||||||||

| 2001 | Hebei Semiconductor Research Institute, Shijiazhuang, China | uniaxial | 600 µV/g | 1 mg·Hz−1/2 | 75 Hz | 10 g | [29] | ||

| 2002 | HSG-IMIT, Villingen-Schwenningen, Germany | uniaxial | SF6 | 6.6 mV/° | 0.003° | [6] | |||

| 2003~2016 | MEMSIC, Wuxi, China | uniaxial & dual- axis | air | 1 V/g | 0.4 mg RMS | 160 Hz | ±1~100 g | 50,000 g | [104,108,109] |

| 2003~2011 | University Montpellier 2, Montpellier, France | uniaxial | Air, CO2, helium | 58 µV/g | 0.3 mg RMS | 320 Hz | 0~3 g | [19,20,21,23] | |

| 2004~2011 | TEI of Athens, Athens, Greece | uniaxial | Air, water | 32 mV/g | 12 Hz | [9,39] | |||

| 2006 | Ritsumeikan University, Kyoto, Japan | dual-axis | 13 mV/g | ±5 g | [38] | ||||

| 2007~2016 | MEMSIC, Wuxi, China | tri-axis | xenon | 0.5 V/g | 2.5 mg RMS | 17 Hz | ±8 g | 50,000 g | [105,106,110] |

| 2008~2011 | Simon Fraser University | tri-axis | SF6 | XYZ: 66, 64, 25 μV/g | ±1 g | [45,47] | |||

| 2011 | University Montpellier 2 | uniaxial | gas | 10,000 g | [11] | ||||

| 2012 | University Montpellier 2 | uniaxial | nitrogen | 0.034 °C/g | 1025 Hz | [43] | |||

| 2014 | University Montpellier 2 | tri-axis | air | XY: 2.6 mg, Z: 60 mg | 20 Hz | [107] | |||

| 2015 | University of Minho, Braga, Portugal | tri-axis | air | XY: 8 µV/g, Z: 2.2 µV/g | 4 Hz 3 | [52] |

| Year | Research Institute | Working Principle | Sensitivity | Resolution | Measurement Range | Shock Survival | Reference |

|---|---|---|---|---|---|---|---|

| 2001~2016 | Tsinghua University, Beijing, China | Thermal gas MIMU | 95 μV/°/s (Gain 36,000) | 0.5°/s 1 mg | ±4000°/s ± 10 g | >20,000 g | [13,71,72,73,93,94,95,96,97,98] |

| 300 mV/g (Gain 10,000) | |||||||

| 2004~2016 | Ritsumeikan University, Kyoto, Japan | Jet flow | X: 0.082 mV/(°/s) | 0.5°/s | [65] | ||

| Y: 0.078 mV/(°/s) | |||||||

| 2010~2014 | Simon Fraser University, Burnaby, BC, Canada | Thermal gas | 0.947 mV/°/s (Gain 18,742) | ±1260°/s | 16,398 g | [70] | |

| 2012~2015 | Northwestern Polytechnical University, Xi‘an, China | Vortex jet flow | X: 0.642 mV/°/s | X: 0.04°/s 1 | ±100°/s | [112,113] | |

| Y: 0.528 mV/°/s | Y: 0.05°/s 1 | ||||||

| Z: 0.241 mV/°/s | Z: 0.2°/s 1 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, S.; Zhu, R. Micromachined Fluid Inertial Sensors. Sensors 2017, 17, 367. https://doi.org/10.3390/s17020367

Liu S, Zhu R. Micromachined Fluid Inertial Sensors. Sensors. 2017; 17(2):367. https://doi.org/10.3390/s17020367

Chicago/Turabian StyleLiu, Shiqiang, and Rong Zhu. 2017. "Micromachined Fluid Inertial Sensors" Sensors 17, no. 2: 367. https://doi.org/10.3390/s17020367