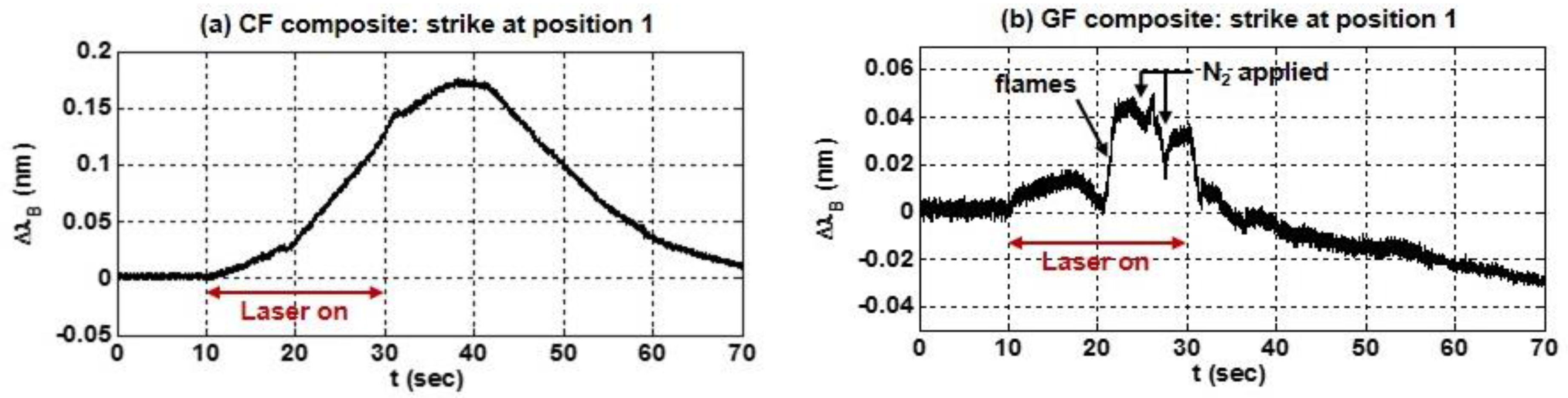

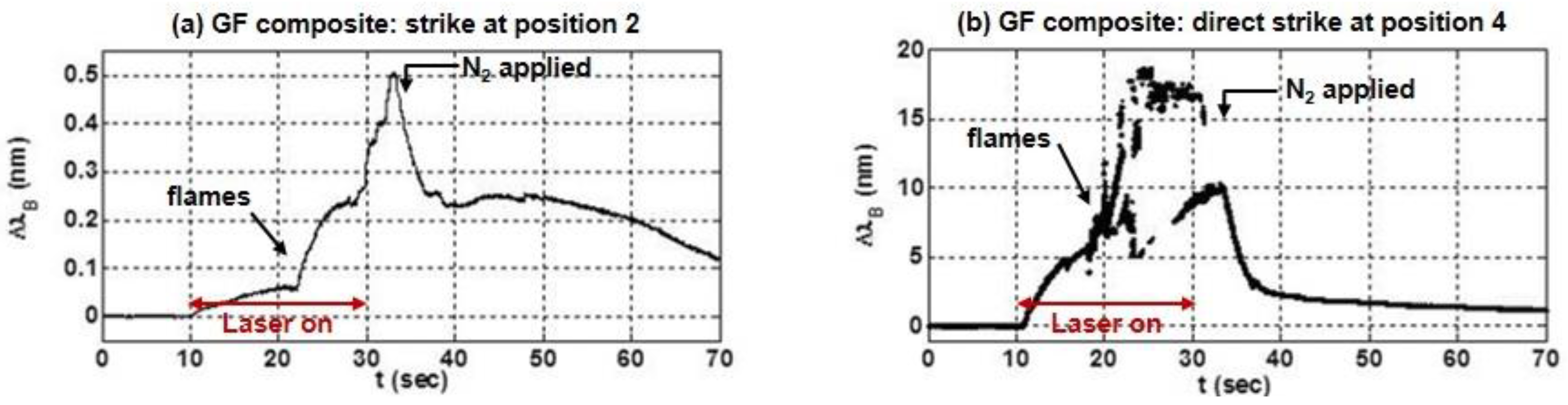

The results in

Figure 6b and

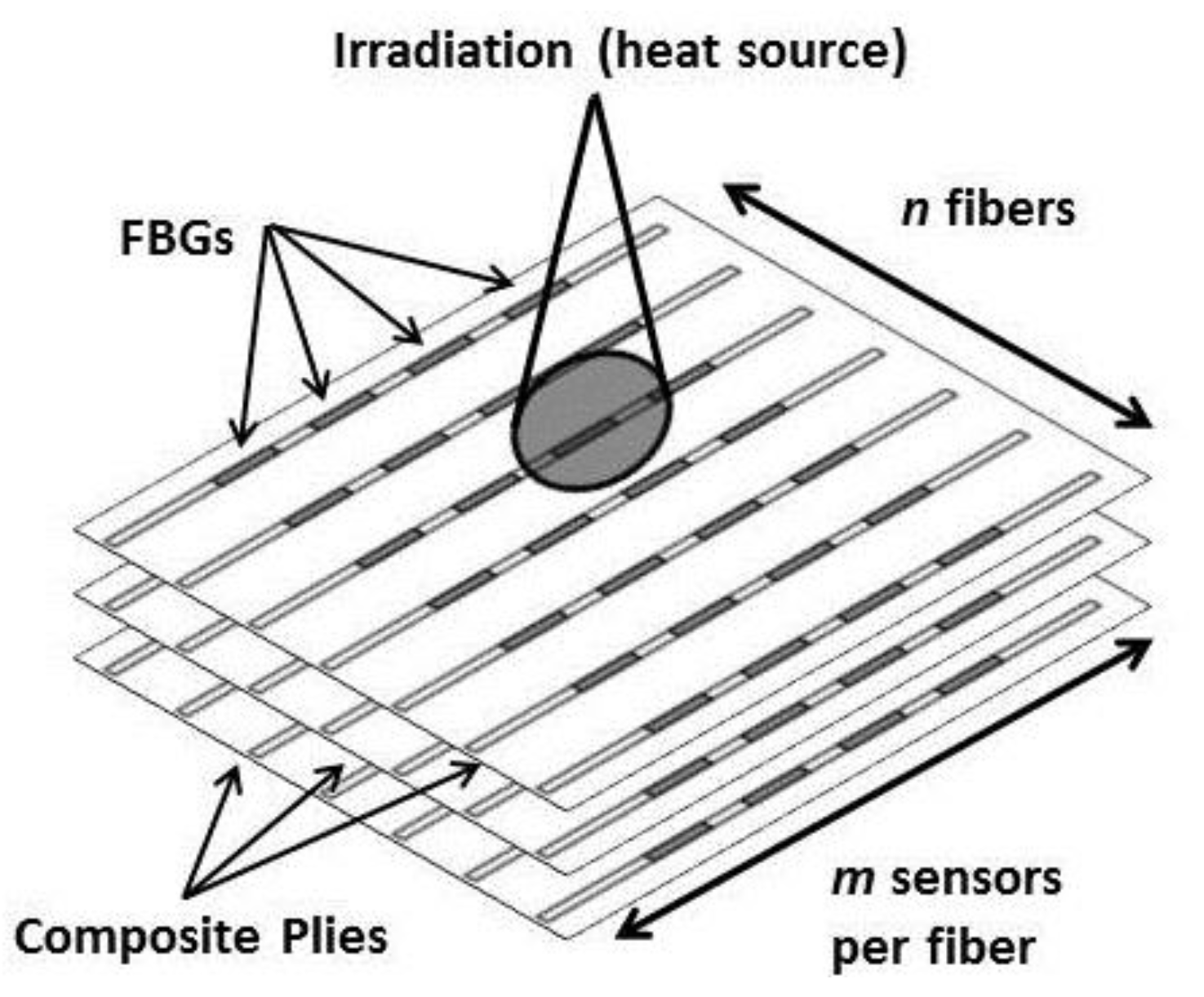

Figure 8 indicate that a large temperature shift could be quickly detected during a direct laser strike on a single sensor embedded in a composite. To more precisely determine how sensor location relates to the speed of detection, a more complex sensor network similar to

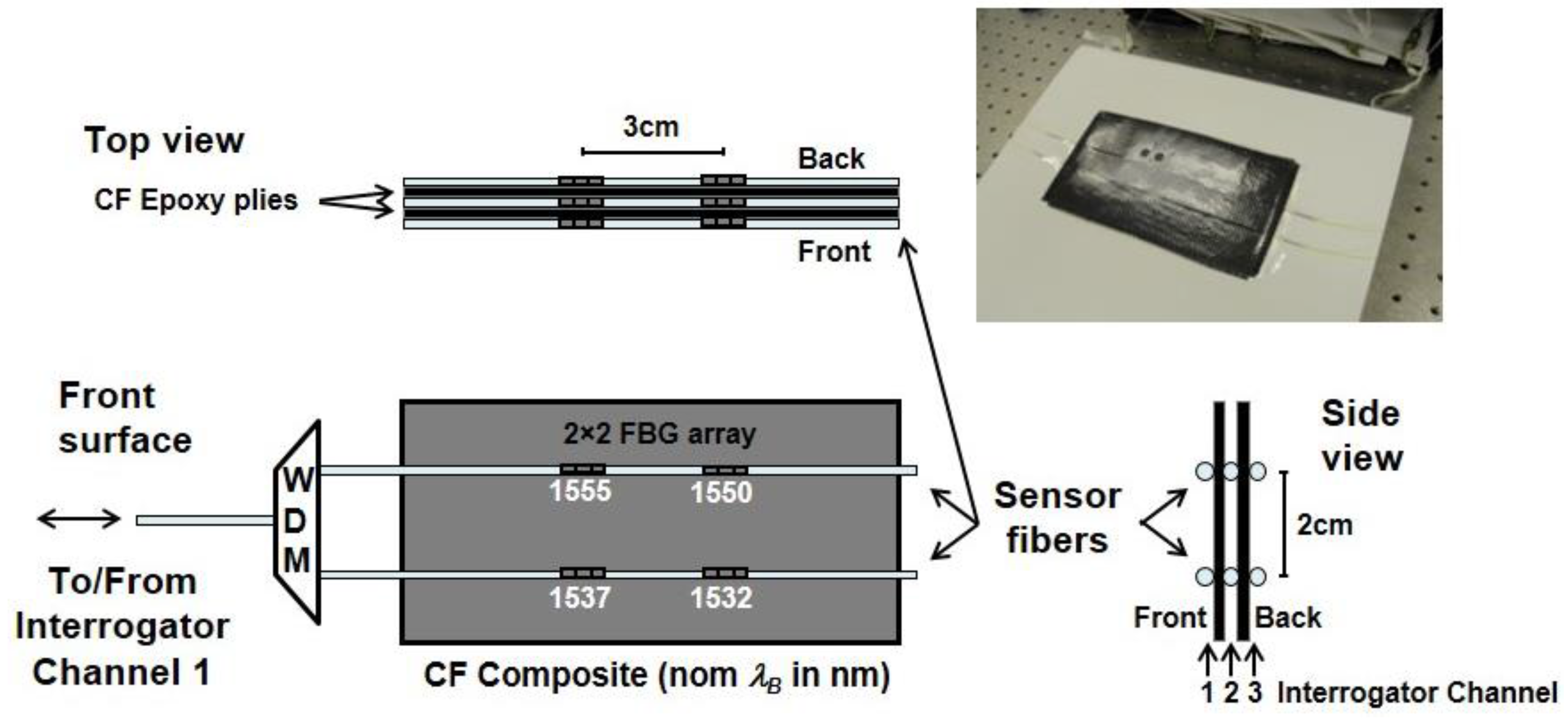

Figure 2 was constructed to obtain multiple sensor measurements in the plane and through the thickness of a CF composite.

Figure 9 shows the structure. The configuration uses a 2 × 2 × 3 array of 12 sensors in six optical fibers, with four sensors embedded on each surface, as well as between two plies of CF composite. As illustrated, two pairs of fibers are embedded on the front and back surfaces of the two-ply CF composite structure (see front surface view). A third pair of fibers is embedded between the two plies (see side view). The two fibers embedded at each layer are 2 cm apart, and the two sensors in each fiber are 1 cm in length, separated by 3 cm on centers. Three wavelength division multiplexers (WDM) route signals to/from the two fibers on each surface to communicate with three channels of the interrogator. The CF composite was fabricated by vacuum bag molding using West System

® 105/206 Epoxy Resin and 3 K Plain Weave Carbon Fiber fabric (5.7 oz./sq.yd, 0.012” thick, 12.5 × 12.5).

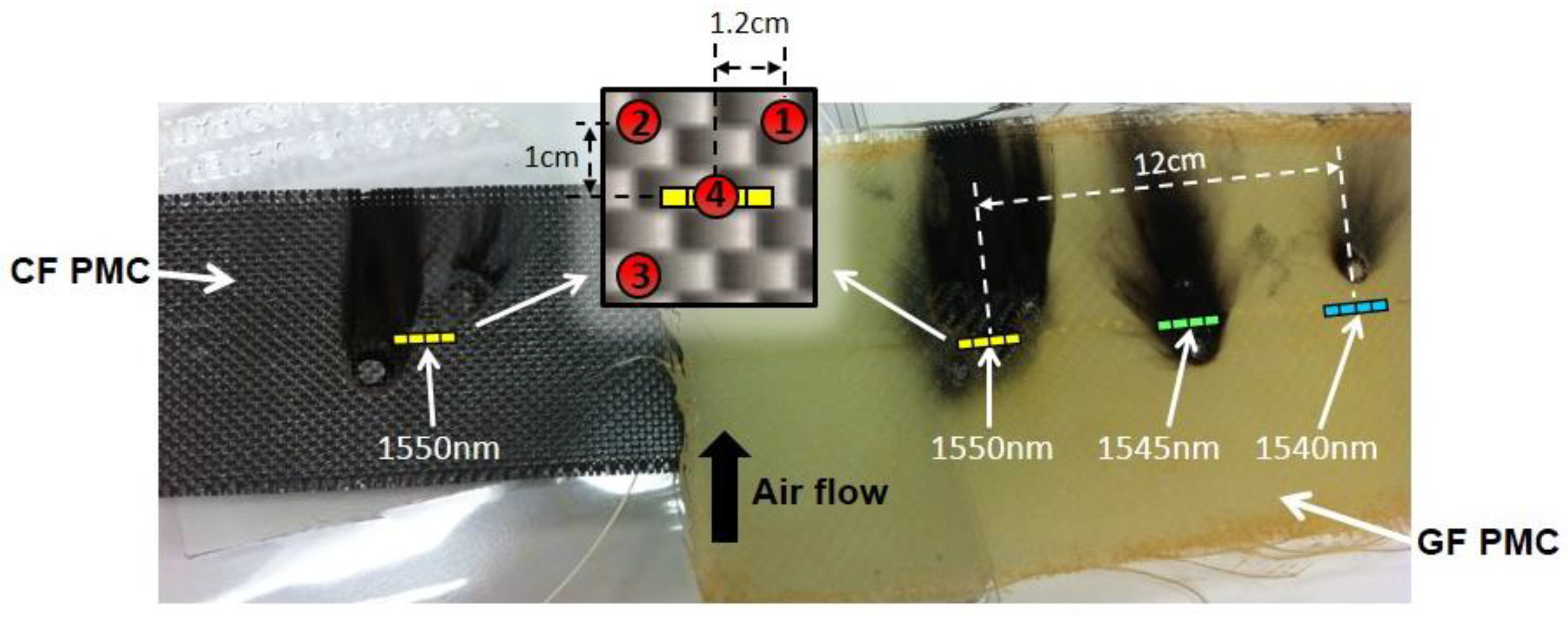

To determine how well an array of sensors can isolate a localized temperature gradient, the high power laser energy was applied to the front surface of the specimen in

Figure 9 using the same test setup as in

Figure 3. As before, the laser was on for 20 s during each strike. The scan rate of the peak interrogator was 2.5 kHz during these tests, so the peak wavelength of each sensor was determined every 400 µs. Numerous tests were run, and the laser was used to assault the composite at many different locations.

Figure 10 shows a representative sampling of positions and test conditions for six laser strikes. The strikes at positions 1–3 were all 1 cm away from the nearest sensor at locations above, in between, and below the 1550-nm and 1532-nm sensors. The tests at positions 4–6 were direct strikes on the 1555-nm, 1550-nm and 1532-nm sensors, respectively. As before, the beam diameter of the laser was 5 mm and the maximum irradiance at 100% power was ~500 W/cm

2. The power level was set to 25% of maximum at positions 1, 4 and 5, 50% of maximum at positions 2 and 6, and 100% at position 3. N

2 gas was applied at each position during the full extent of each strike to prevent flames from erupting.

4.1. Response of 2 × 2 × 3 Embedded Sensor Array to Indirect Laser Irradiation

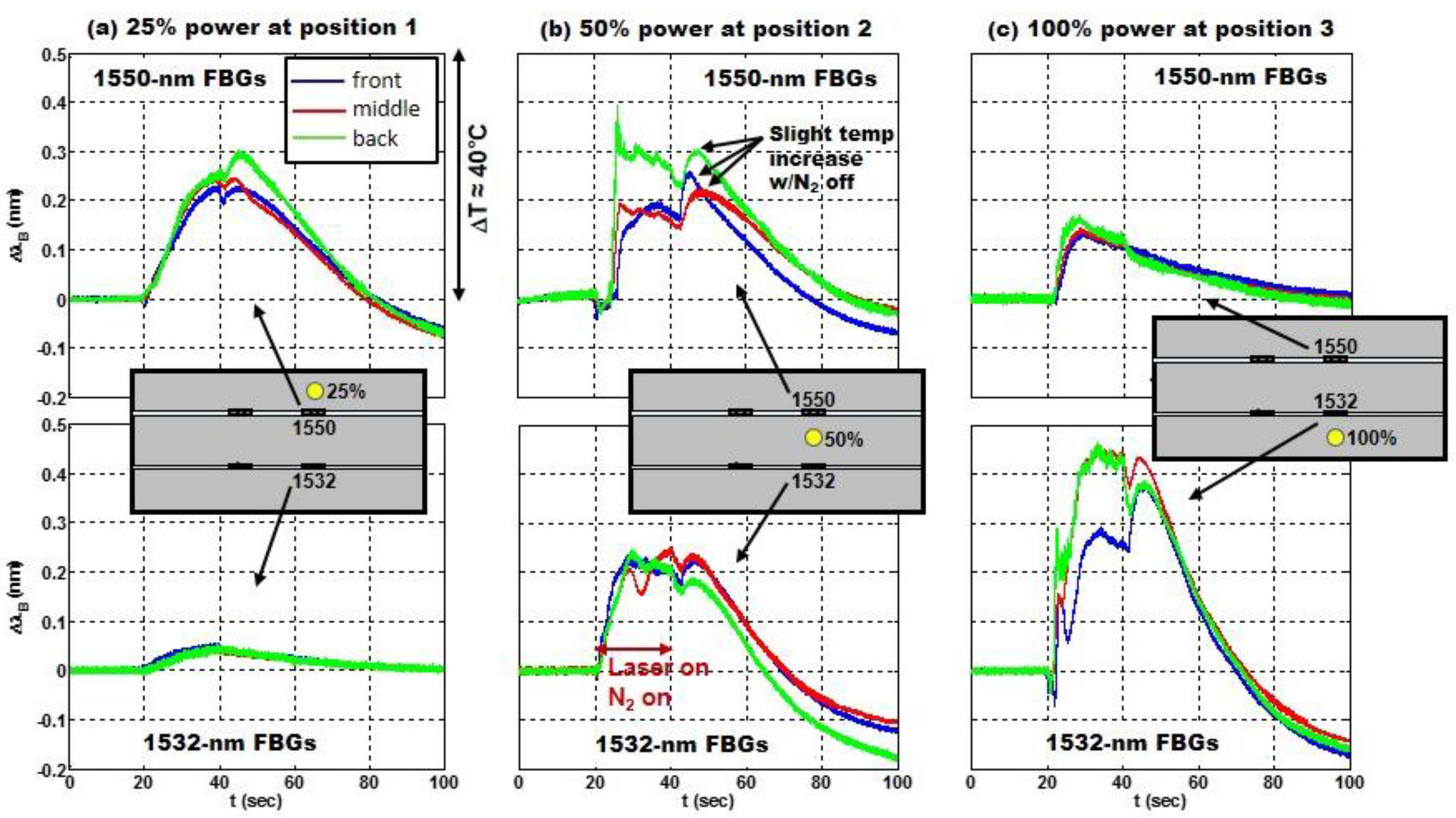

The peak interrogator responses of the three 1550-nm sensors and the three 1532-nm sensors during the laser strikes at positions 1–3 are shown in

Figure 11a–c, respectively. Based on a sensitivity of 11.9 nm/°C for sensors embedded in the CF composite, a shift of

nm on the vertical axis in

Figure 11 corresponds to a temperature shift of just over 40 °C. In each test, the laser turned on at 20 s and off at 40 s. The responses of the sensors embedded on the front surface of the composite are shown in blue. The responses of the sensors embedded in the middle between the two plies of the composite are shown in red, and the sensors embedded on the back respond as shown in green.

Figure 11 illustrates both the effects of radial distance and laser power on the thermal response of the FBG sensors. The closer the sensor is to the laser strike and the greater the laser power the more the Bragg wavelength shifts. In

Figure 11a the 1550-nm sensors exhibit a greater shift than the 1532-nm sensors because they are closer to the laser strike. In

Figure 11c the laser power is increased from 25% to 100% and the Bragg wavelength shift increases irrespective of the sensor location relative to the laser strike, in this case the 1532 sensors are closer to the laser strike and exhibit a greater response. The sensors at 1555 nm and 1537 nm were embedded ~3–4 cm away from the laser strikes at positions 1–3 (see

Figure 10). Their Bragg wavelength shift, not shown here, was relatively small, due to relatively poor thermal conductivity of the CF composite, confirming the localized thermal response to a laser strike and the ability to identify its location.

Figure 11b shows the Bragg wavelength shift for a laser strike at 50% power and equidistant to the 1532-nm and 1550-nm sensors. The responses of the FBGs on the front surface and in the middle are very similar.

Since rapid detection of a laser strike is paramount, the speed of response of the FBG sensors may be of greater concern than either the fidelity of the temperature measurements or even the location information. The results in

Figure 11 clearly show speed of response is dependent both on the power of the laser strike as well as the proximity of the sensor to the laser strike. Only 2 s are required to detect a 10 °C temperature shift in the 1532-nm sensor at 100% power (in

Figure 11c), whereas for the same proximity and 25% power it takes nearly 8 s after the laser strikes the target to effect a 10 °C increase in the 1550-nm sensor (

Figure 11a).

Figure 11 (a and c) also clearly shows a steeper shift in the Bragg wavelength the closer the sensor is to the laser strike.

The previous results in

Figure 6 in the GF composite show the presence of flames (combustion) and air flow (convection) could also impact the speed (and magnitude) of the response. In more than one instance

Figure 11 shows the Bragg wavelength shift or thermal response of the sensor on the back surface (green) is greater or more erratic than that of both the front and the middle (blue and red). Flames were sometimes observed erupting from the back surface of the composite during a strike. The flames appeared like a “blow-torch” projected away from the back of the composite, in contrast to the appearance of the flame that was directed upward by natural convection in

Figure 7. Whereas combustion was suppressed on the front surface using the N

2 gas nothing was done to extinguish the flames on the back surface of the composite.

Heat transfer by conduction can be observed in

Figure 11a–c. When the laser was turned off so was the N

2 gas. Because the sensors in each case are a small distance from the laser strike, the heat of the laser strike is observed to diffuse to the sensor location; this is most evident in the slight temperature increase exhibited by the 1532-nm sensors at 40 s in

Figure 11c. The temperature increase lasted for only ~5 s after the laser (and N

2) was turned off. For these sensors the final wavelength was also less than the initial wavelength, likely due to relaxation of residual strain in the composite. Thru-thickness conduction is also evident in the 1532-nm sensors as the composite returns to thermal equilibrium; observe the temperature rise on the front surface once the N

2 gas is turned off (

Figure 11c).

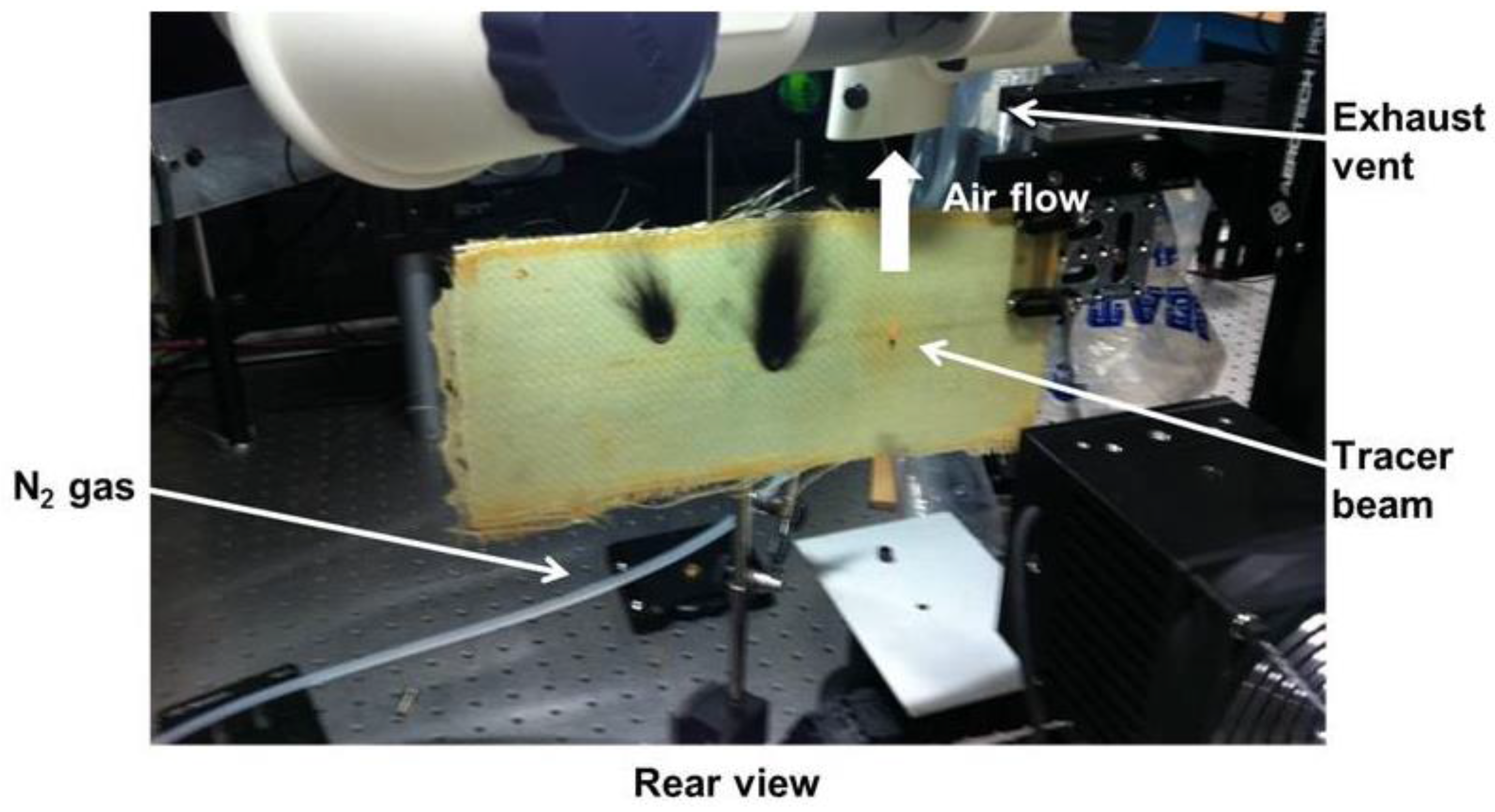

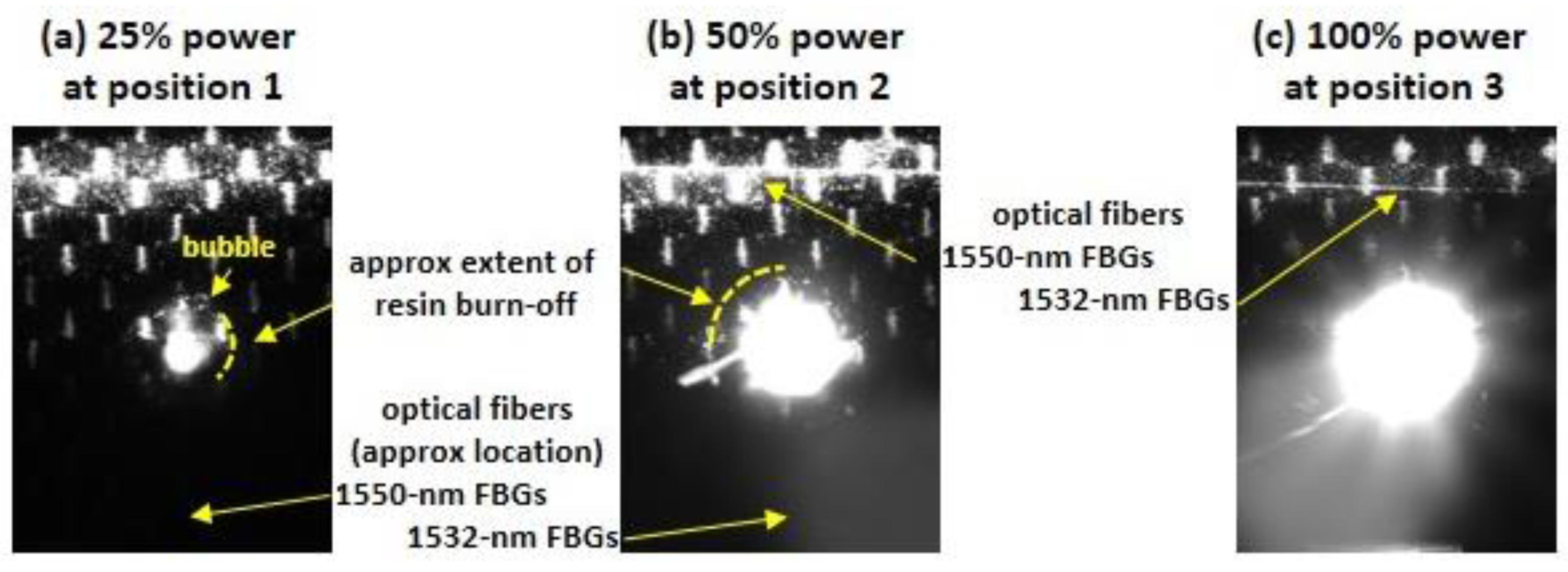

Likewise, in video taken during the tests with N

2 gas, no flames were observed on the front surface.

Figure 12 shows three single frames of the video of the front surface captured around

t = 30 s during the three laser strikes at positions 1–3, respectively. Few flames were observed on the front surface of the composite because they were extinguished by the nitrogen. However, the increasing irradiance associated with each strike is evident, as indicated by progressively larger “hot-spots” at positions 2 and 3. The tows of the carbon fiber fabric in the composite, ~2 mm in width, can be discerned in each frame. The optical fiber 1 cm above the strike at positions 2 and 3 can also be seen. Bubbles of epoxy were also occasionally observed sizzling and burning off at the edge of a circular region that slowly expanded in diameter during the strike.

4.2. Response of 2 × 2 × 3 Embedded Sensor Array to Direct Laser Strikes

More rapid and larger shifts in wavelength and temperature were expected during direct laser strikes on the sensors located at positions 4–6 on the specimen in

Figure 10.

Figure 13 shows results of direct strikes at position 4 (on the 1555-nm sensors) and position 6 (on the 1532-nm sensors).

Figure 13a shows the wavelength shift of the front, middle and back 1555-nm sensors, plotted as blue, red and green curves, respectively, during a direct strike at position 4 at 25% laser power. A ~100 °C shift was measured in ~0.1 s in the front sensor. The temperature shift was somewhat slower in the middle and back sensors. The Bragg wavelength of the back sensor (in green) was relatively stable during the strike, similar to the response of the sensor embedded in the CF composite shown earlier in

Figure 8a. In contrast, the peak Bragg wavelengths of the front and middle sensors were more erratic, since the laser energy was directly concentrated on the front surface of the specimen. At high temperatures, the peak wavelengths of these sensors were observed to hop rapidly between values during a direct strike. The Bragg wavelength of the front sensor (in blue) was indeterminate near

t = 33 s (when no peak could be acquired by the interrogator), similar to the response in

Figure 6b for a direct strike on a sensor in the GF composite, also at 25% laser power.

Though the responses in

Figure 13a of the front and middle sensors (in blue and red) were more erratic during the strike than the response of the back sensor (in green), their Bragg wavelengths also clearly shifted by a larger amount. Extrapolation to higher temperatures of the vendor supplied FBG response [

24] suggests that the temperatures in the composite were between ~600 °C on the back surface (for

nm) and ~700 °C on the front surface (for

nm). These values are well above the specified maximum temperature of 300 °C for the sensors used here. Partial erasure of the grating is expected [

12], and the front and middle sensors were damaged during the strike. Their reflectivity was reduced to only 10% and 20%, respectively, whereas the reflectivity of the back sensor was approximately the same before and after the strike.

To merely detect laser radiation on the composite surface, the precise temperature is not needed. However, reliable estimates of the temperature are helpful to optimize the design of the sensor network. Since the measured sensitivity of 11.9 nm/°C was only accurate at lower temperatures [

19], and the epoxy resin begins to degrade near 250 °C (burning off completely near 400 °C), an independent measurement of temperature was desired. A FLIR

® IR thermal imaging camera (FLIR Systems, Wilsonville, OR, USA), calibrated to higher temperatures, was placed behind the specimen to measure the thermal response on the back surface of the composite.

Figure 13b shows the temperature measured by the IR camera and by the back FBG at position 6 during a direct strike on the 1532-nm sensors at 50% power. The black curve shows the temperature measured on the back surface by the IR camera. The green curve shows the estimated temperature response of the back FBG sensor, again based on an extrapolation of vendor specifications [

24].

The IR camera measurement shows that the FBG sensor temperature response is roughly accurate during and after the laser strike, providing useful information about the sensor network. Both measurements in

Figure 13b demonstrate that the temperature on the back surface approached 1000 °C during the strike and returned to room temperature after the strike. Similar thermal imaging tests with the IR camera during a laser strike on a six-ply CF composite [

14] showed that the temperature on the back surface remained relatively steady in time (at values between 500 °C and 700 °C), depending on the incident laser power (between 30% and 70% of maximum). The shapes of the responses in the thermal imaging measurements in [

14] were nearly identical to the shape of the green curve in

Figure 13a.

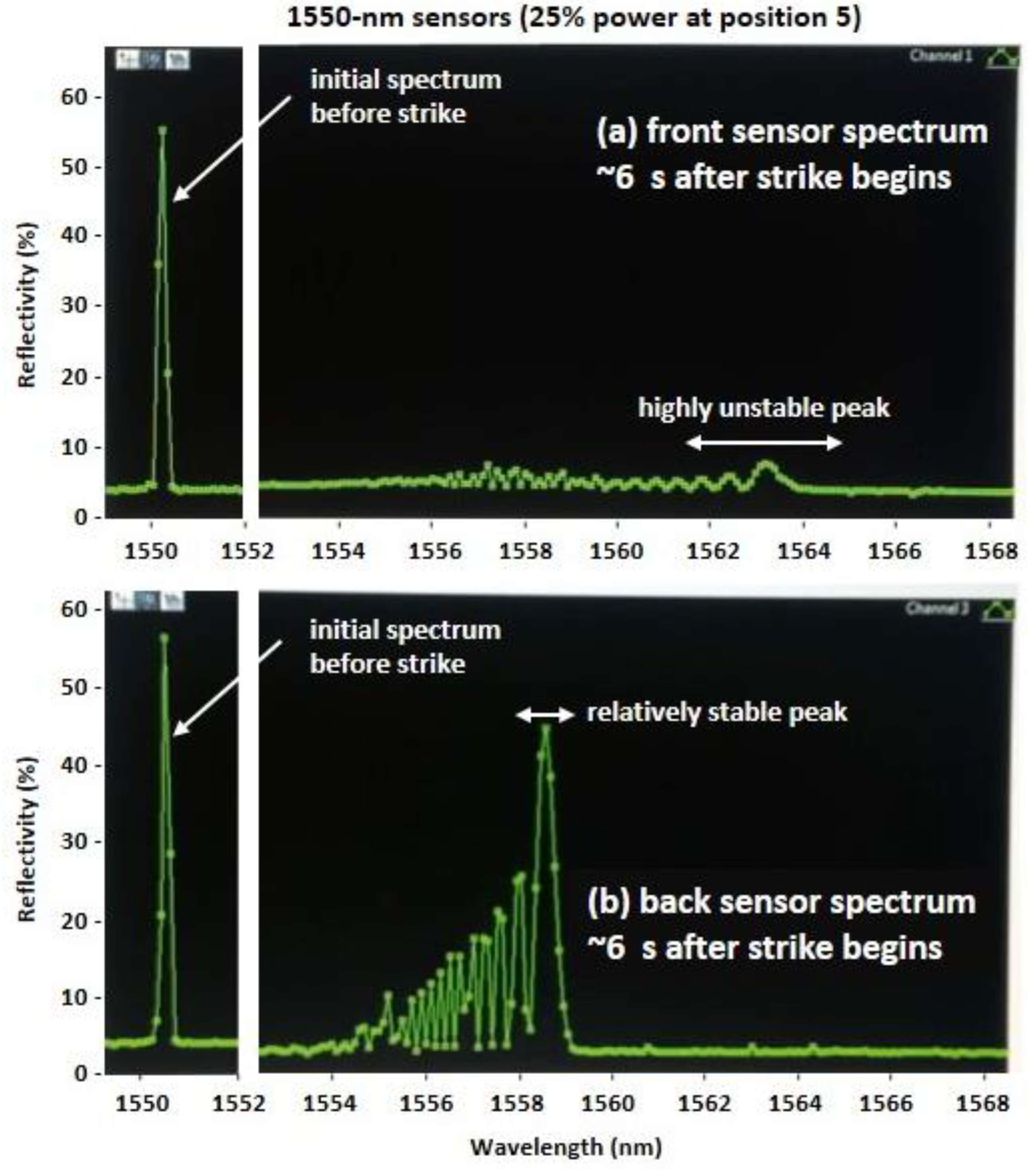

The FBG peak wavelength response in

Figure 13b at higher irradiance, however, is considerably more erratic than the response measured by the IR camera. To understand the cause of fluctuations in the Bragg wavelength

of an FBG during a direct strike, the spectra of several sensors were observed during direct strikes at different power levels. An example of the spectrum (reflectivity vs. wavelength) is shown in

Figure 14 (a and b) for the front and back 1550-nm sensors, respectively, captured ~6 s after the beginning of a direct strike at position 5 (refer to

Figure 10 for location). The laser power was 25% of maximum, so the behavior of the peak wavelengths of the front and back sensors (nominally near 1550 nm) in

Figure 14 should mimic the response observed in the front and back sensors (nominally at 1555 nm) in

Figure 13a.

Based on the spectral responses shown in

Figure 13 and

Figure 14, precise acquisition of a peak wavelength in the FBG response during a direct strike on a sensor can be hindered by two effects: First, highly localized temperature spikes during a direct strike can result in a non-uniform temperature profile across the length of the sensor that can cause erratic fluctuations in the reflection spectrum and in the peak wavelength if the temperature is high enough. The resulting spectrum is similar to that caused when a non-uniform strain field is applied across the length of an FBG sensor [

3,

20,

21,

27,

28]. Secondly, for direct laser strikes at higher power levels, the gratings were often erased soon after the strike began, especially for sensors embedded closer to the front surface of the composite.

Consider the spectral distortion in

Figure 14, which shows one instance of a multi-peaked spectrum in the front and back sensors (nominally at 1550 nm) at a time ~6 s after the beginning of the laser strike. The distortion in this multi-peaked spectrum varied dynamically during a direct strike. For the front sensor in

Figure 14a, the spectral peak with the highest reflectivity hopped rapidly between neighboring peaks [

21], changing in wavelength by several nm, consistent with the behavior of the blue curve in

Figure 13a. For the sensor on the back surface of the composite, shown in

Figure 14b, shifts in the peak wavelength were much smaller, similar to the green curve in

Figure 13a.

Given that the beam profile for the high energy laser was Gaussian with intensity

, during a direct strike the peak irradiance

occurred at position

z = 0 (the center of the grating), and the energy was highly localized with a laser spot size

mm for an FBG gauge length of 10 mm. A precise explanation for the resultant spectral response in

Figure 14 can be developed using a modified transfer matrix approach as described in [

27], used by Prabhugoud and Peters to characterize non-uniform quadratic strain fields on strain sensors. Based on the results in [

27], a transfer matrix analysis using a modified form of the grating period which is here defined consistent with Equation (4),

would demonstrate that the spectrum in

Figure 14b and the incident Gaussian intensity are consistent with the presence of a non-uniform quadratic temperature profile

across the grating length, where

in this experiment. The actual values of

and

would depend on the energy absorbed by the composite, its thermal conductivity, and its coefficient of thermal expansion

.

Based on Equation (5), a non-uniform temperature profile causes non-uniform thermally-induced strain

for any material in which

is not negligible. The spectrum in

Figure 14b shows that a highly localized direct laser strike results in a highly localized, dynamically varying thermal response by the sensor. In the carbon fiber/epoxy composite described by

Figure 14, for which

is small, the dominant contribution is due to changes in the index of refraction

with temperature. In the E-glass fiber/epoxy composite, described earlier in

Figure 6, the non-uniform thermal response also includes thermally induced strain since

is markedly larger.

Finally, although the initial spectrum of the front and back sensors were very similar (a single peak near 1550 nm), the front sensor also experienced a much sharper drop in its reflectivity during the strike, as can be seen by comparing the graphs in

Figure 14a,b. This is likely due to higher temperatures on the front surface than on the back surface of the carbon fiber/epoxy composite. After the strike at position 5, the peak wavelengths of both the front and back sensors returned to values close to their nominal Bragg wavelength, i.e., a single reflection peak near 1550 nm. However, the peak reflectivity of the front sensor was less than 40% after the strike, indicating partial erasure of the front sensor due to high temperature grating decay.

This suggests the second reason it is more difficult to determine a peak wavelength for an FBG sensor experiencing a direct strike. For direct strikes with a power level of 50% or greater on a two-ply composite, the gratings usually erased completely, whether on the front surface, in between the plies, or on the back surface. When this occurred, the peak wavelength measurement was indeterminate. The spectral response looked similar to that in

Figure 14a, but within seconds the small peaks in the spectrum shifted to higher wavelengths (beyond the instrument measurement limit of 1568 nm), and the distorted spectrum gradually dissipated into the noise as the grating decayed completely, with no recovery of a spectral peak at the nominal Bragg wavelength. Interestingly, although the measured temperatures were sometimes quite high at laser power levels of 25%, there was often no significant damage to the sensor after the strike, permitting its reuse. Further tests would be needed to determine the accuracy of the analysis in [

12] (a work describing grating decay at high temperatures) when localized thermal energy is suddenly applied to a grating under laser irradiation. These tests, however, clearly demonstrate the ability to rapidly detect temperature spikes in a composite structure using embedded FBG sensors.