Development of a Sequential Injection Analysis System for the Determination of Saccharin

Abstract

:1. Introduction

2. Materials and Methods

2.1. Reagents

2.2. Sample Preparation

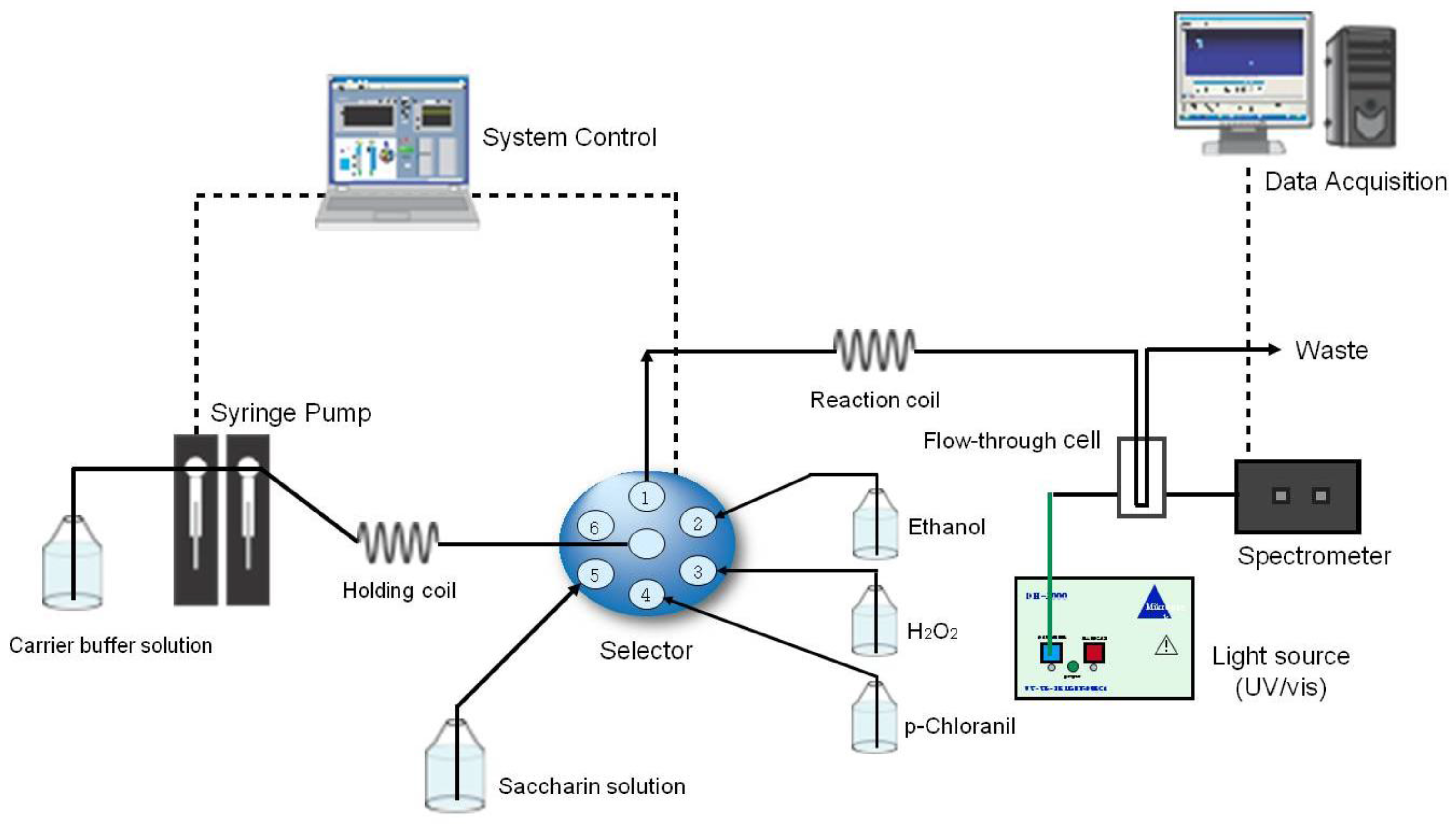

2.3. The SIA System

2.4. Construction of the Calibration Curves

2.5. Reference Method

3. Results and Discussion

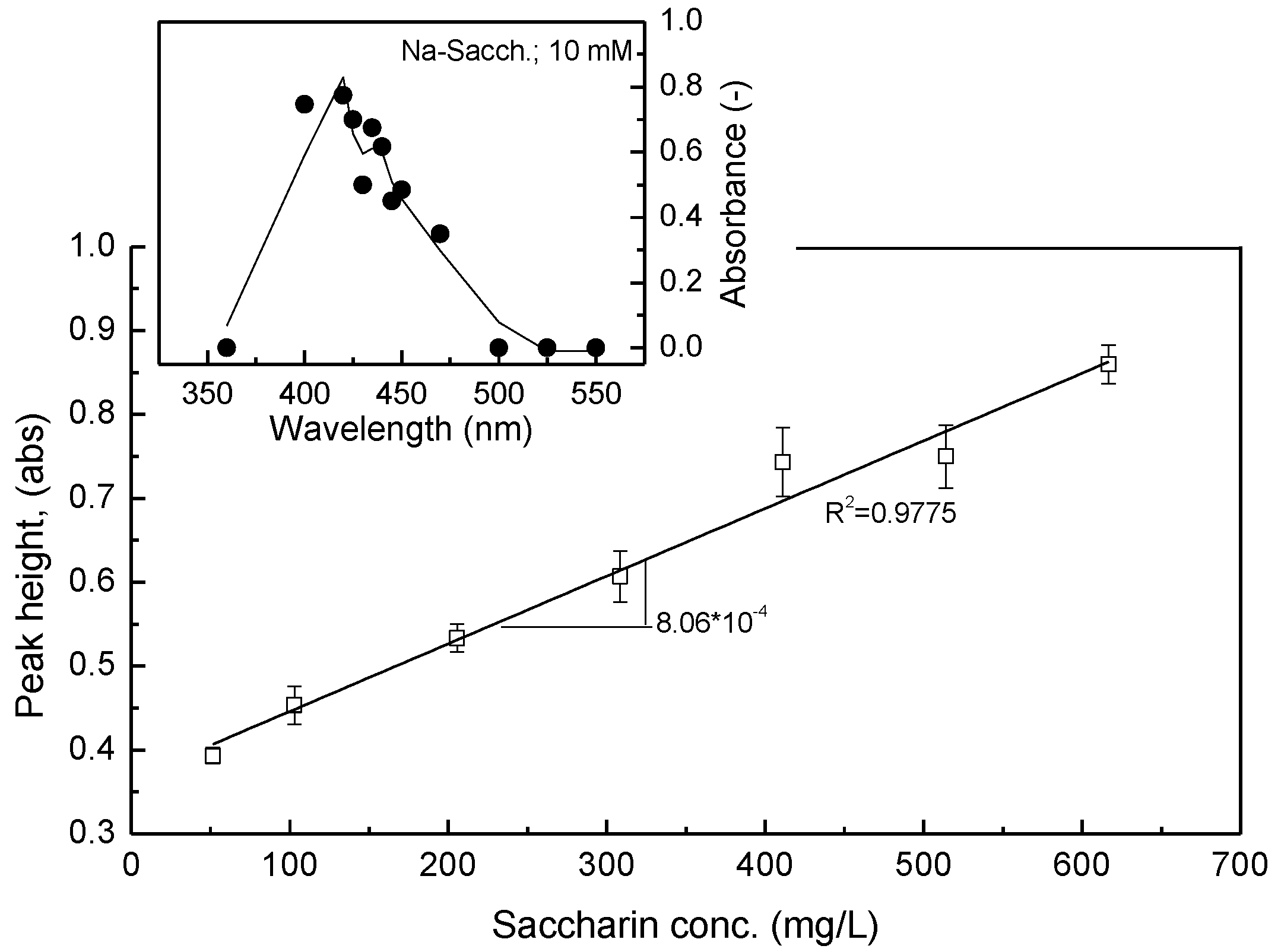

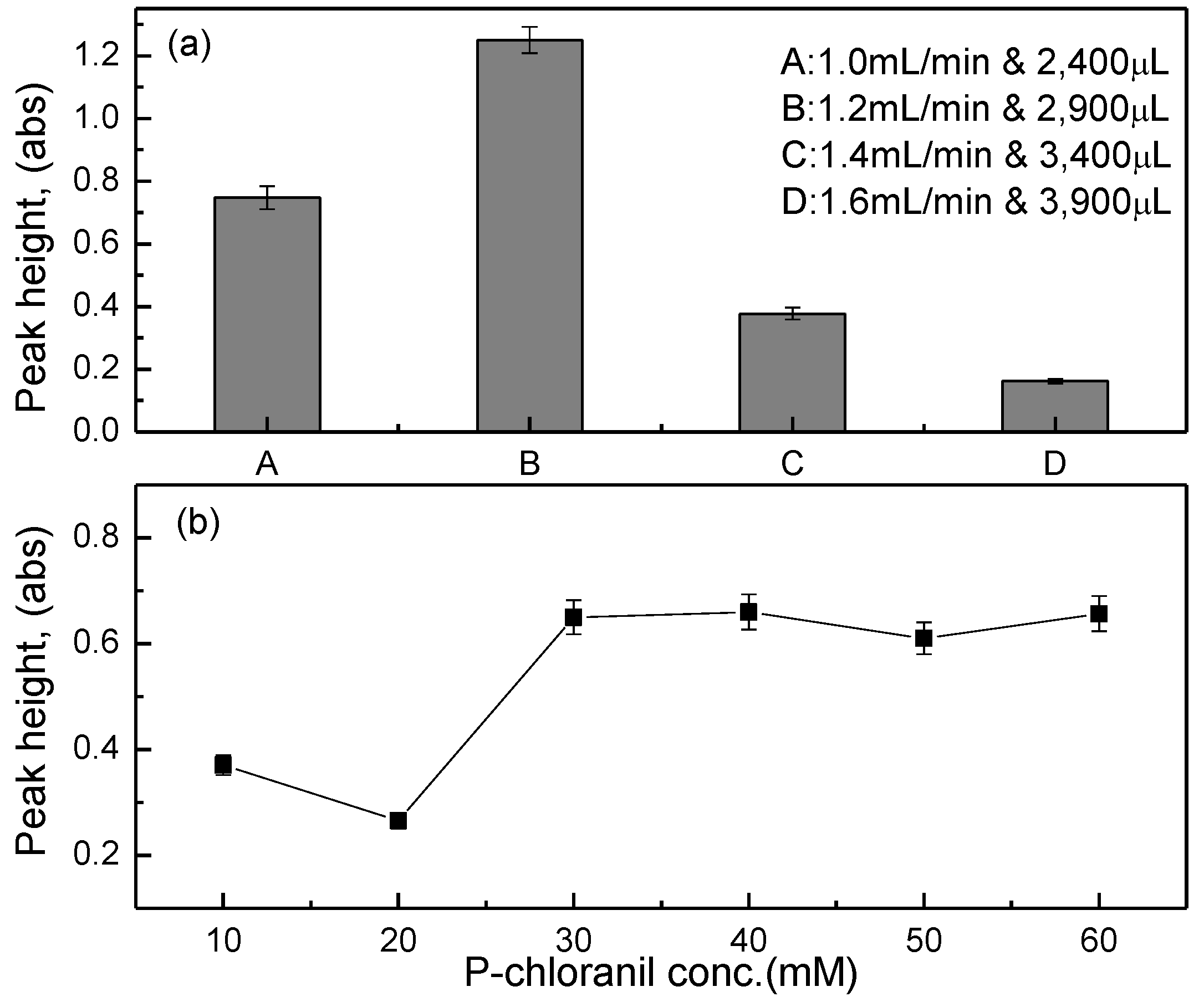

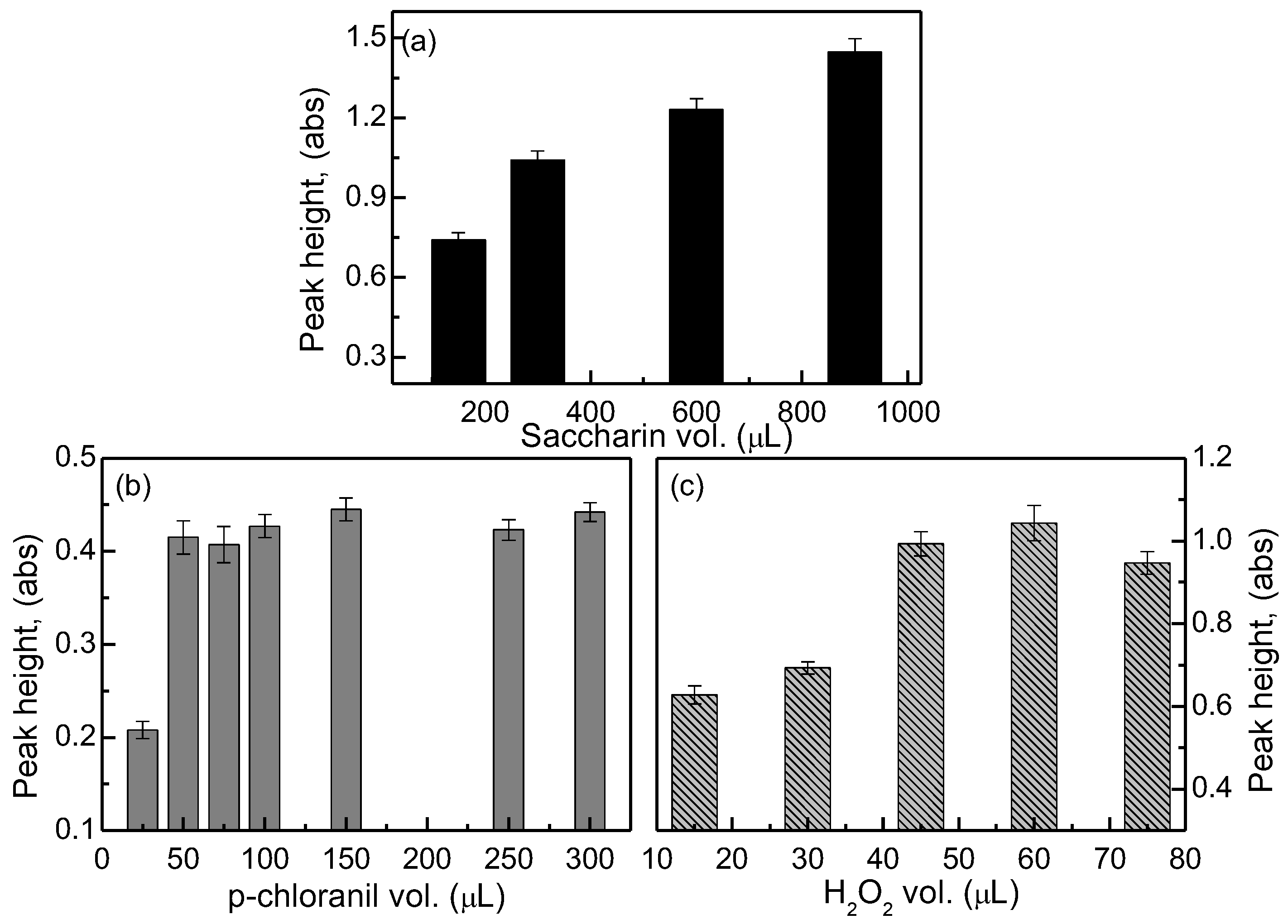

3.1. Characterization of the Saccharin-SIA System

3.2. Analytical Application

4. Conclusions

Author Contributions

Conflicts of Interest

References

- Varzakas, T.; Labropoulos, A.; Anestis, S. Sweeteners: Nutritional Aspects, Applications, and Production Technology; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Nabors, L.O.; Gelardi, A.E. Alternative Sweeteners; CRC Press: Boca Raton, FL, USA, 1991. [Google Scholar]

- American Dietetic Association. Position of the American Dietetic Association: Use of nutritive and nonnutritive Sweeteners. J. Am. Diet. Assoc. 2004, 104, 255–275. [Google Scholar]

- Wang, Y.; Xu, Z.L.; Xie, Y.Y.; Tian, Y.X.; Shen, Y.D.; Young, G.M.; Wang, H.; Lei, H.T.; Sun, Y.M. Development of polyclonal antibody-based indirect competitive enzyme-linked immunosorbent assay for sodium saccharin residue in food samples. Food Chem. 2011, 126, 815–820. [Google Scholar] [CrossRef]

- European Commission. Directive 96/83/EC of the European Parliament and of the Council; European Commission: Brussels, Belgium, 1996; Volume 3. [Google Scholar]

- FAO; WHO. Summary of Evaluations Performed by the Joint FAO/WHO Expert Committee on Food Additives (JECFA) 1956–1997 (First through Forty-Ninth Meetings) FAO & WHO; ILSI Press: Washington, DC, USA, 1999. [Google Scholar]

- CODEX Alimentarius Commission. Saccharin: Joint FAO/WHO Food Standards Programme. In Proceedings of the GSFA Online Updated up to the 38th Session of the Codex Committee, Geneva, Switzerland, 6–11 July 2015. [Google Scholar]

- Lee, Y.; Kim, B.; Kim, J.; Ahn, S. Accurate quantification of saccharin using isotope dilution liquid chromatography mass spectrometry (ID-LC/MS). Mass Spectrom. Lett. 2011, 2, 37–40. [Google Scholar] [CrossRef]

- Chang, C.-S.; Yeh, T.S. Detection of 10 sweetners in various foods by liquid chromatography/tandem mass spectrometry. J. Food Drug Anal. 2014, 22, 318–328. [Google Scholar] [CrossRef] [PubMed]

- Kritsunankula, O.; Jakmunee, J. Simultaneous determination of some food additives in soft drinks and other liquid foods by flow injection on-line dialysis coupled to high performance liquid chromatography. Talanta 2011, 84, 1342–1349. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.H.; Sohn, O.J.; Yim, Y.S.; Han, K.A.; Hyung, G.W.; Chough, S.H.; Rhee, J.I. Sequential injection analysis system for on-line monitoring of l-cysteine concentration in biological processes. Talanta 2005, 68, 187–192. [Google Scholar] [CrossRef] [PubMed]

- Fatibello-Filho, O.; Nóbrega, J.A.; Guaritá-Santos, A.J.M. Flow injection potentiometric determination of saccharin in dietary products with relocation of filtration unit. Talanta 1994, 41, 731–734. [Google Scholar] [CrossRef]

- Mendes, C.; Laignier, E.; Brigago, M.; Luccas, P.; Tarley, C. A simple turbidimetric flow injection system for saccharin determination in sweetener products. Chem. Pap. 2010, 64, 285–293. [Google Scholar] [CrossRef]

- Yebra, M.C.; Gallego, M.; Valcárcel, M. Precipitation flow-injection method for the determination of saccharin in mixtures of sweeteners. Anal. Chim. Acta 1995, 308, 275–280. [Google Scholar] [CrossRef]

- Capitán-Vallvey, L.F.; Valencia, M.C.; Arana-Nicolás, E.; García-Jiménez, J.F. Resolution of an intense sweetener mixture by use of a flow injection sensor with on-line solid-phase extraction: Application to saccharin and aspartame in sweets and drinks. Anal. Bioanal. Chem. 2006, 385, 385–391. [Google Scholar] [CrossRef] [PubMed]

- Pérez-Olmos, R.; Soto, J.C.; Zárate, N.; Araújo, A.N.; Lima, J.L.F.C.; Saraiva, M.L.M.F.S. Application of sequential injection analysis (SIA) to food analysis. Food Chem. 2005, 90, 471–490. [Google Scholar] [CrossRef]

- Laiwattanapaisala, W.; Kunanuvat, U.; Intharachutia, W.; Chinvongamornb, C.; Hannongbuac, S.; Chailapakuld, O. Simple sequential injection analysis system for rapid determination of microalbuminuria. Talanta 2009, 79, 1104–1110. [Google Scholar] [CrossRef] [PubMed]

- Weinert, P.L.; Pezza, H.R.; De Oliveira, J.E.; Pezza, L. A simplified spectrophotometric method for routine analysis of saccharin in commercial noncaloric sweeteners. J. Agric. Food Chem. 2004, 52, 7788–7792. [Google Scholar] [CrossRef] [PubMed]

- Gotardo, M.A.; Lima, L.S.; Sequinel, R.; Rufino, J.L.; Pezza, L.; Pezza, H.R. A simple spectrophotometric method for the determination of methyldopa using ρ-chloranil in the presence of Hydrogen Peroxide. Eclet. Quim. 2008, 33, 7–12. [Google Scholar] [CrossRef]

- Marshall, G.D. Sequential Injection Analysis. Ph.D. Thesis, University of Pretoria, Pretoria, South Africa, 1994. [Google Scholar]

- Ruzicka, J.; Hansen, E.H. Flow-Injection Analysis, 2nd ed.; John Wiley & Sons, Inc.: New York, NY, USA, 1998. [Google Scholar]

| Time (s) | Pump 1 | Pump 2 | Valve | Description |

|---|---|---|---|---|

| 0 | Reverse | Off | Drawn up carrier buffer solution | |

| 30 | Off | Position 2 | Pump-stop, select solvent | |

| 35 | Reverse | Position 2 | Drawn up solvent (ethanol) | |

| 68 | Off | Position 1 | Pump-stop, select assay line | |

| (to HC = holding coil) | ||||

| 73 | Reverse | Position 3 | Drawn up reagent 1 (H2O2) | |

| 89 | Off | Position 1 | Pump-stop, select assay line | |

| (to HC = holding coil) | ||||

| 94 | Reverse | Position 4 | Drawn-up reagent 2 (p-chloranil) | |

| 116 | Off | Position 1 | Pump-stop, select assay line | |

| (to HC = holding coil) | ||||

| 121 | Reverse | Position 5 | Drawn-up sample solution (saccharin) | |

| 132 | Off | Position 1 | Pump-stop | |

| 137 | Forward | Position 1 | Pump stack of zones to the reactor | |

| (RC = reaction coil) and detector | ||||

| 282 | Off | Pump-stop | ||

| 287 | Forward | Position 1 | Pump stack of zones to the reactor | |

| (RC = reaction coil) and detector | ||||

| 332 | Off | Pump-stop | ||

| 337 | Position 2 | Return to starting position |

| Sample | Labeled a | Proposed SIA Method | HPLC Method | ||

|---|---|---|---|---|---|

| Found d | Recovery (%) d | Found d | Recovery (%) d | ||

| Food sweetener b | 50,000.0 | 55,774.0 ± 2946.0 | 111.5 ± 5.9 | 46,170.7 ± 616.0 | 92.3 ± 1.2 |

| Food in brine b | 500.0 | 496.1 ± 33.7 | 99.2 ± 6.7 | 554.3 ± 79.0 | 110.9 ± 15.8 |

| Soft drink 500 c | 500.0 | 465.4 ± 14.1 | 93.1 ± 2.8 | 550.6 ± 7.6 | 110.1 ± 1.5 |

| Pudding 500 c | 500.0 | 477.9 ± 34.2 | 95.6 ± 6.8 | 528.3 ± 25.7 | 105.7 ± 5.1 |

| Steamed-bread 500 c | 500.0 | 535.0 ± 74.0 | 107.0 ± 14.8 | 517.56 ± 36.0 | 103.5 ± 7.2 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wibowotomo, B.; Eun, J.-B.; Rhee, J.I. Development of a Sequential Injection Analysis System for the Determination of Saccharin. Sensors 2017, 17, 2891. https://doi.org/10.3390/s17122891

Wibowotomo B, Eun J-B, Rhee JI. Development of a Sequential Injection Analysis System for the Determination of Saccharin. Sensors. 2017; 17(12):2891. https://doi.org/10.3390/s17122891

Chicago/Turabian StyleWibowotomo, Budi, Jong-Bang Eun, and Jong Il Rhee. 2017. "Development of a Sequential Injection Analysis System for the Determination of Saccharin" Sensors 17, no. 12: 2891. https://doi.org/10.3390/s17122891