Recent Advances of MEMS Resonators for Lorentz Force Based Magnetic Field Sensors: Design, Applications and Challenges

Abstract

:1. Introduction

2. Design and Fabrication

- (1)

- Application specification. In this stage, designers must know all the technical information of the sensor application such as magnetic field range, environmental conditions, response time and resolution.

- (2)

- Conceptual design. This stage includes several conceptual designs of magnetic field sensors to satisfy the requirements of the applications. Next, these designs are evaluated to select the best conceptual design.

- (3)

- Detailed design. Analytical and numerical methods are used to predict the sensor’s performance. These designs must incorporate the sensor packaging, which depends of different factors such as materials, operation pressure, cost, sensing technique and environmental conditions. High temperatures can be generated during the sensor packaging, affecting its behavior. For this, element finite method (FEM) models can be used to estimate the packaging temperature effect on the sensor behavior.

- (4)

- Fabrication process. Designers identify the sensor requirements and characteristics of potential fabrication processes. Next, the designer selects the best fabrication process or develops a new process, in which must consider the materials, etching steps, design rules, technical limitations and cost.

- (5)

- Material properties verification. Test structures can be fabricated on the same sensor wafer to measure several materials properties of the sensors such as Young’s modulus, facture strength, thermal conductivity, electrical resistivity and dielectric constant.

2.1. Performance of MEMS Magnetic Field Sensors

2.2. Quality Factor

2.3. Sensing Techniques

3. Potential Applications

4. Comparisons and Challenges

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Senturia, S.D. Microsystem Design; Kluwer Academic Publishers: New York, NY, USA, 2002. [Google Scholar]

- Allen, J.M. Mechanical System Design; Taylor & Francis: Boca Raton, FL, USA, 2005. [Google Scholar]

- Acevedo-Mijangos, J.; Soler-Balcázar, C.; Vazquez-Leal, H.; Martínez-Castillo, J.; Herrera-May, A.L. Design and modeling of a novel microsensor to detect magnetic fields in two orthogonal directions. Microsyst. Technol. 2013, 19, 1897–1912. [Google Scholar] [CrossRef]

- Dominguez-Nicolas, S.M.; Juárez-Aguirre, R.; García-Ramírez, P.J.; Herrera-May, A.L. Signal Conditioning System with a 4–20 mA Output for a Resonant Magnetic Field Sensor Based on MEMS Technology. IEEE Sens. J. 2012, 12, 935–942. [Google Scholar] [CrossRef]

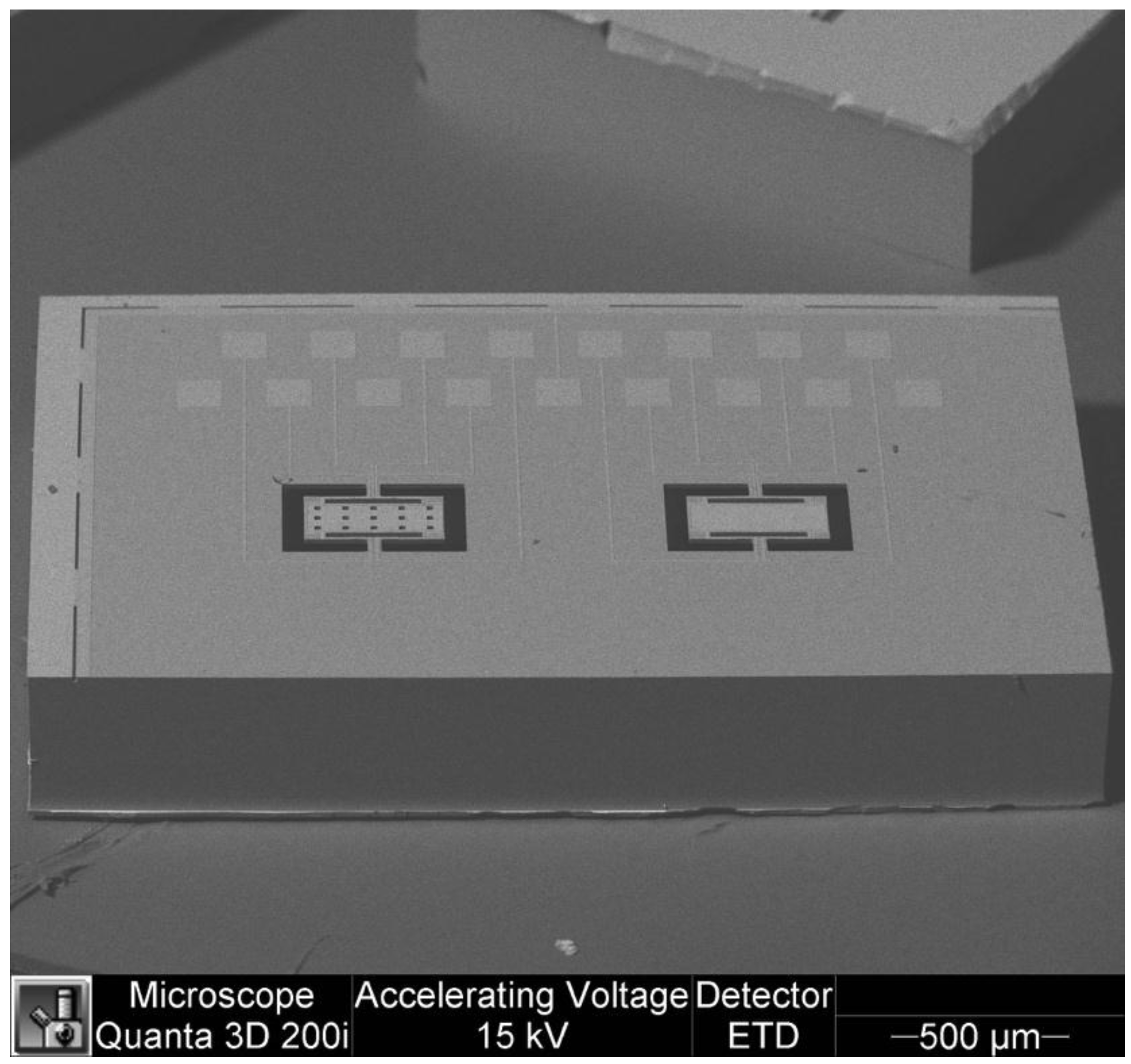

- Wu, G.Q.; Xu, D.H.; Xiong, B.; Che, L.F.; Wang, Y.L. Design, fabrication and characterization of a resonant magnetic field sensor based on mechanically coupled dual-microresonator. Sens. Actuators A 2016, 248, 1–5. [Google Scholar] [CrossRef]

- Bagherinia, M.; Bruggi, M.; Corigliano, A.; Mariani, S.; Horsley, D.A.; Li, M.; Lasalandra, E. An efficient earth magnetic field MEMS sensor: Modeling, experimental results, and optimization. J. Microelectromech. Syst. 2015, 24, 887–895. [Google Scholar] [CrossRef]

- Sonmezoglu, S.; Li, M.; Horsley, D.A. Force-rebalanced Lorentz force magnetometer based on a micromachined oscillator. Appl. Phys. Lett. 2015, 106. [Google Scholar] [CrossRef]

- Li, M.; Sonmezoglu, S.; Horsley, D.A. Extended bandwidth Lorentz force magnetometer based on quadrature frequency modulation. J. Micromech. Microeng. 2015, 24, 333–342. [Google Scholar] [CrossRef]

- Herrera-May, A.L.; Aguilera-Cortés, L.A.; García-Ramírez, P.J.; Manjarrez, E. Resonant magnetic field sensors based on MEMS technology. Sensors 2009, 9, 7785–7813. [Google Scholar] [CrossRef] [PubMed]

- Terauchi, N.; Noguchi, S.; Igarashi, H. Numerical simulation of DC SQUID taking into account quantum characteristic of Josephson junction. IEEE Trans. Magn. 2015, 51. [Google Scholar] [CrossRef]

- Mohamadabadi, K.; Jeandet, A.; Hillion, M.; Coillot, C. Autocalibration method for anisotropic magnetoresistive sensors using offset coils. IEEE Sens. J. 2013, 13, 772–776. [Google Scholar] [CrossRef]

- Popovic, R.S.; Drljaca, P.M.; Schott, C. Bridging the Gap between AMR, GMR, and Hall Magnetic Sensors. In Proceedings of the 23rd International Conference on Microelectronics, Nis, Yugoslavia, 12–15 May 2002; pp. 55–58.

- Lei, C.; Lei, J.; Yang, Z.; Wang, T.; Zhou, Y. A low power micro fluxgate sensor with improved magnetic core. Microsyst. Technol. 2013, 19, 591–598. [Google Scholar] [CrossRef]

- Zha, X.F. Manufacturing advisory service system for concurrent and collaborative design of MEMS devices. In MEMS/NEMS Handbook; Leondes, C.T., Ed.; Springer: New York, NY, USA, 2006; Volume 1, pp. 1–34. [Google Scholar]

- MEMS CAP Inc. Available online: http://www.memscap.com/ (accessed on 22 March 2016).

- Coventor Inc. Available online: http://www.coventor.com/ (accessed on 22 March 2016).

- IntelliSense Inc. Available online: http://intellisense.com/ (accessed on 22 March 2016).

- Sandia National Laboratories. Available online: http://www.sandia.gov/mstc/_assets/documents/design_docu-ments/SUMMiT_V_Dmanual.pdf (accessed on 16 October 2015).

- Acevedo-Mijangos, J.; Vázquez-Leal, H.; Martínez-Castillo, J.; Herrera-May, A.L. Theoretical design and simulation of a novel 2D magnetic field sensor with linear response and low power consumption. Micro Nanosyst. 2013, 5, 70–79. [Google Scholar] [CrossRef]

- Allen, J.J. Micro Electro Mechanical System Design; Taylor and Francis Group: Boca Raton, FL, USA, 2005; pp. 68–84. [Google Scholar]

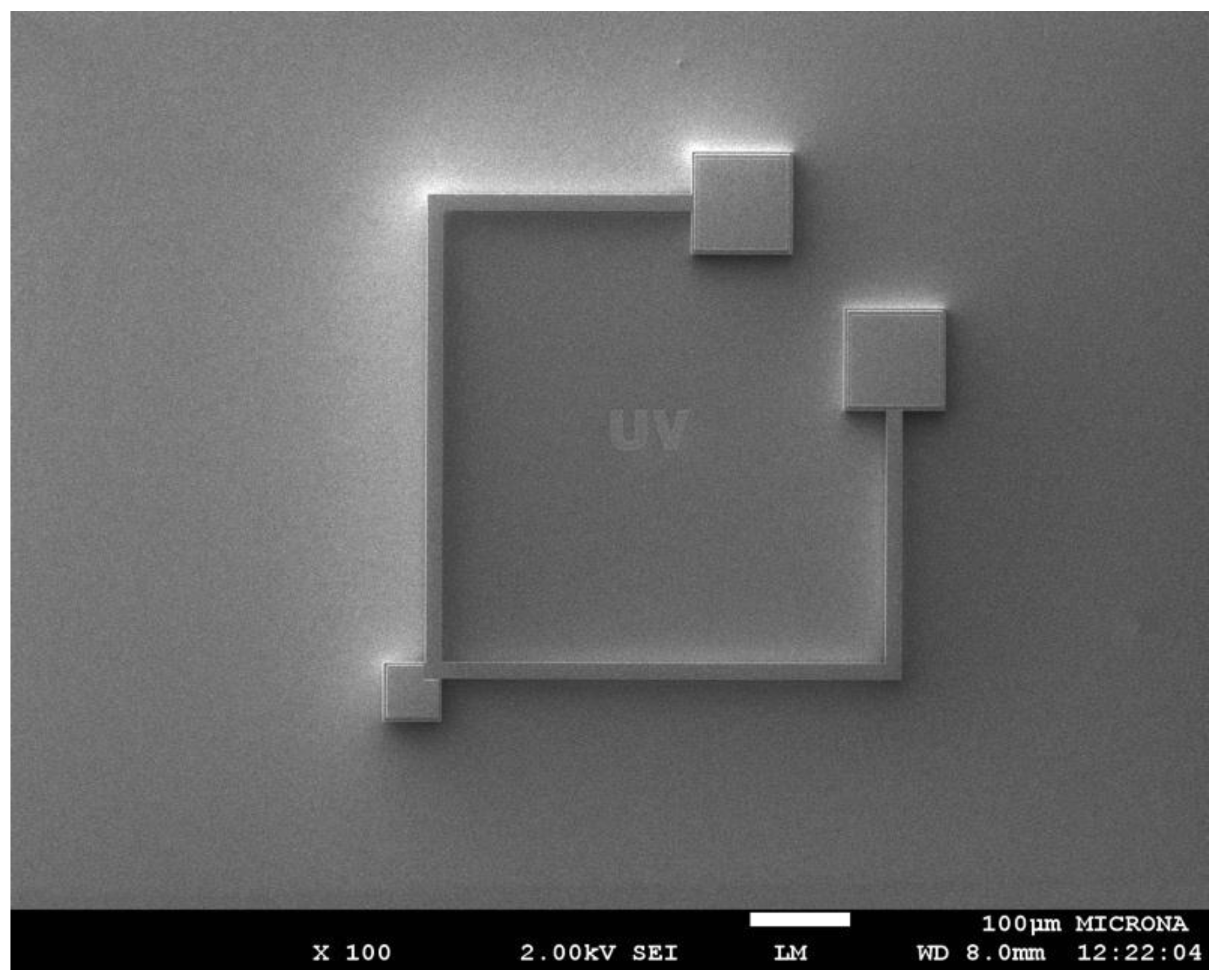

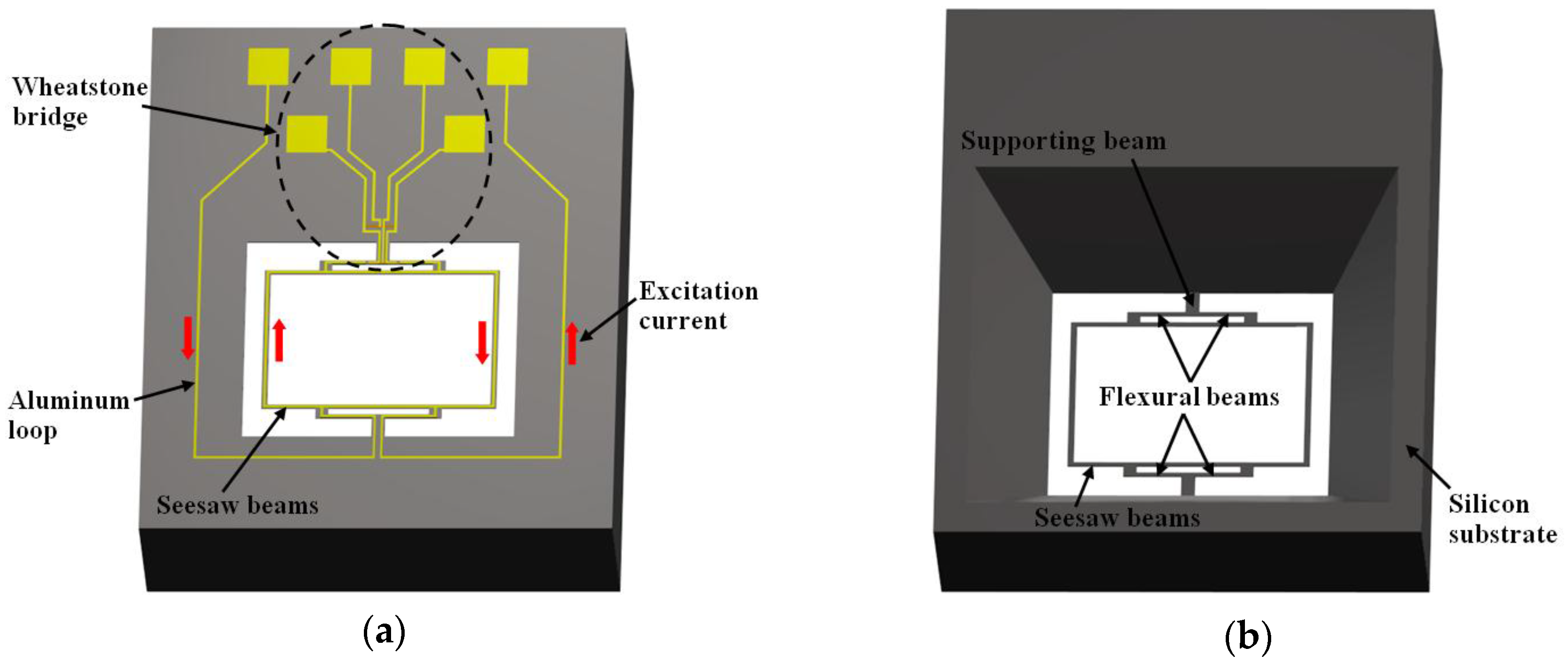

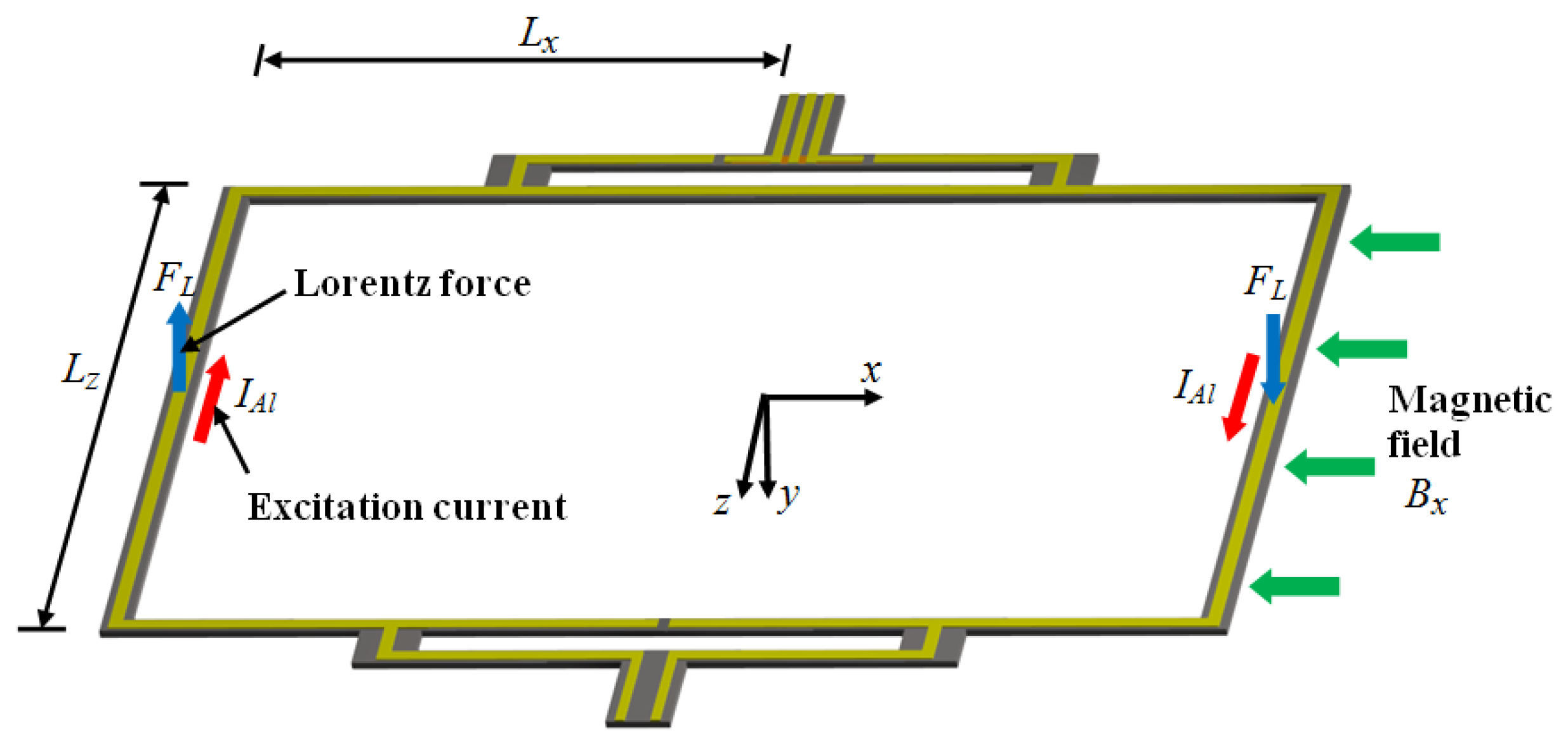

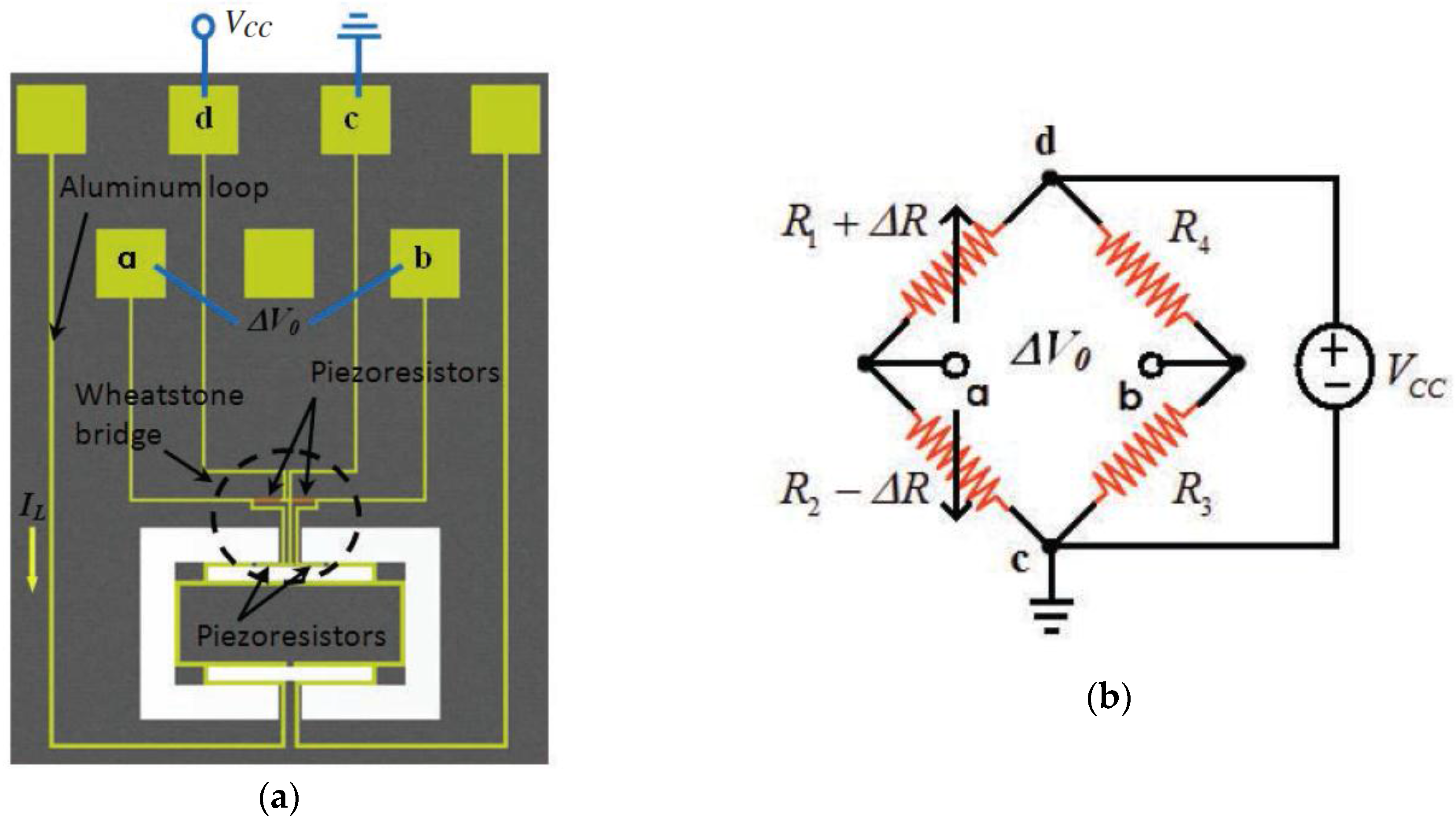

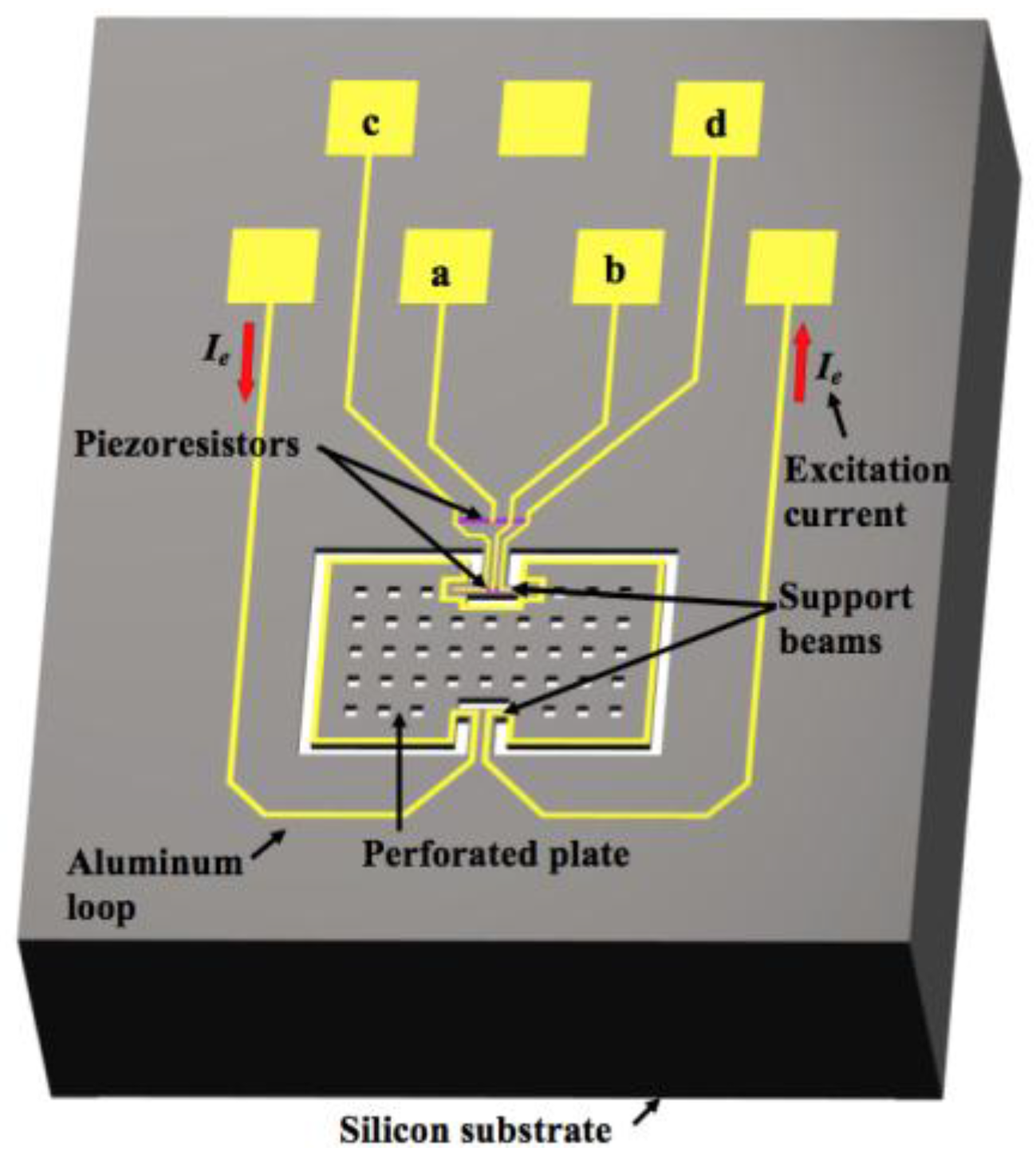

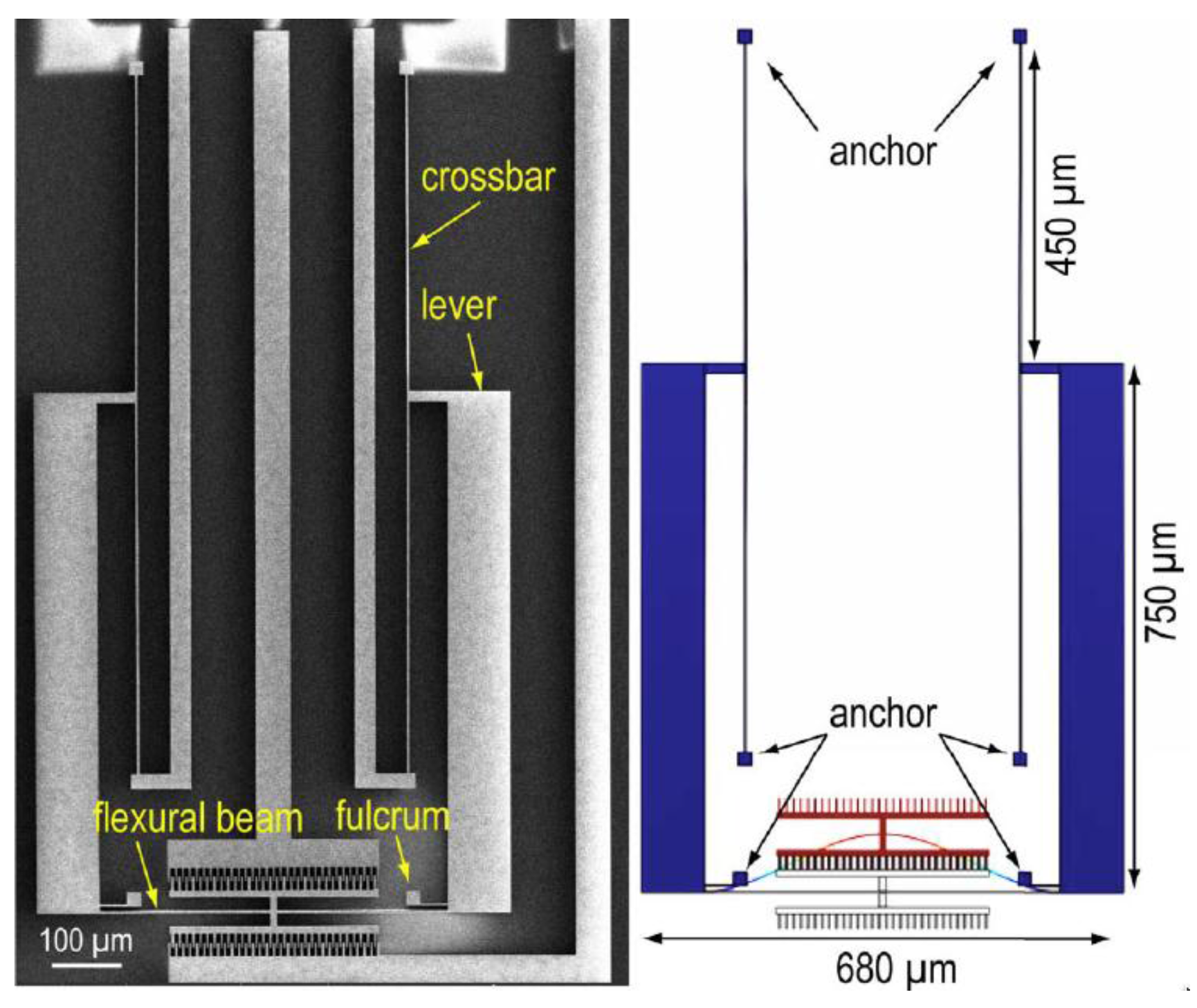

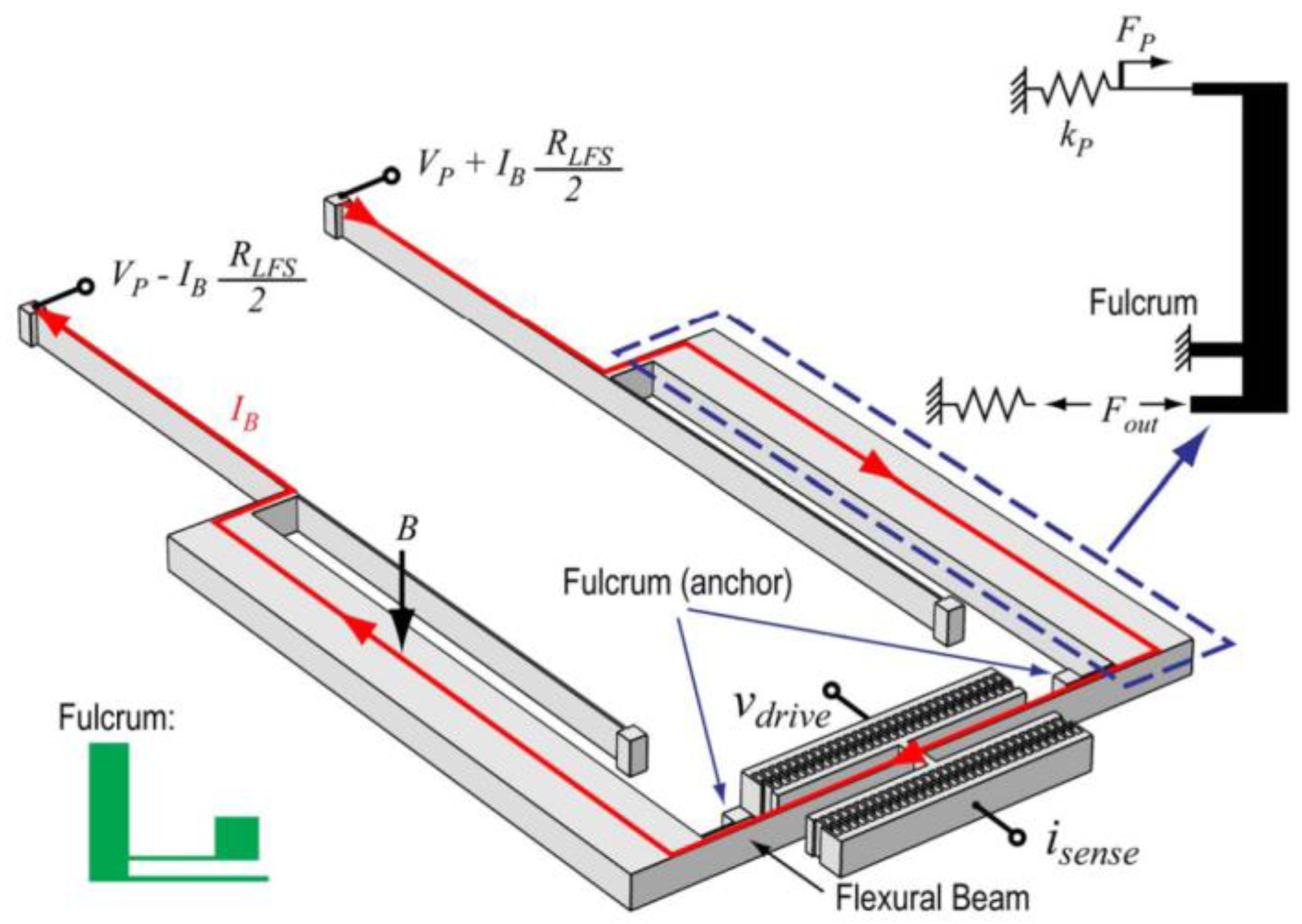

- Herrera-May, A.L.; García-Ramírez, P.J.; Aguilera-Cortés, L.A.; Figueras, E.; Martínez-Castillo, J.; Manjarrez, E.; Sauceda, A.; García-González, L.; Juárez-Aguirre, R. Mechanical design and characterization of a resonant magnetic field microsensor with linear response and high resolution. Sens. Actuators A 2011, 165, 399–409. [Google Scholar] [CrossRef]

- Beeby, S.; Ensell, G.; Kraft, M.; White, N. MEMS Mechanical Sensors; Artech House: Norwood, MA, USA, 2004. [Google Scholar]

- Hao, Z.; Erbil, A.; Ayazi, F. An analytical model for support loss in micromachined beam resonators with in-plane flexural vibrations. Sensors 2003, 109, 156–164. [Google Scholar] [CrossRef]

- Turvir, K.; Ru, C.Q.; Mioduchowski, A. Thermoelastic dissipation of hollow micromechanical resonators. Phys. E Low Dimens. Syst. Nanostruct. 2010, 42, 2341–2352. [Google Scholar]

- Herrera-May, A.L.; García-Ramírez, P.J.; Aguilera-Cortés, P.J.; Martínez-Castillo, J.; Sauceda-Carvajal, A.; García-González, L.; Figueras-Costa, E. A resonant magnetic field microsensor with high quality factor at atmospheric pressure. J. Micromech. Microeng. 2009, 19. [Google Scholar] [CrossRef]

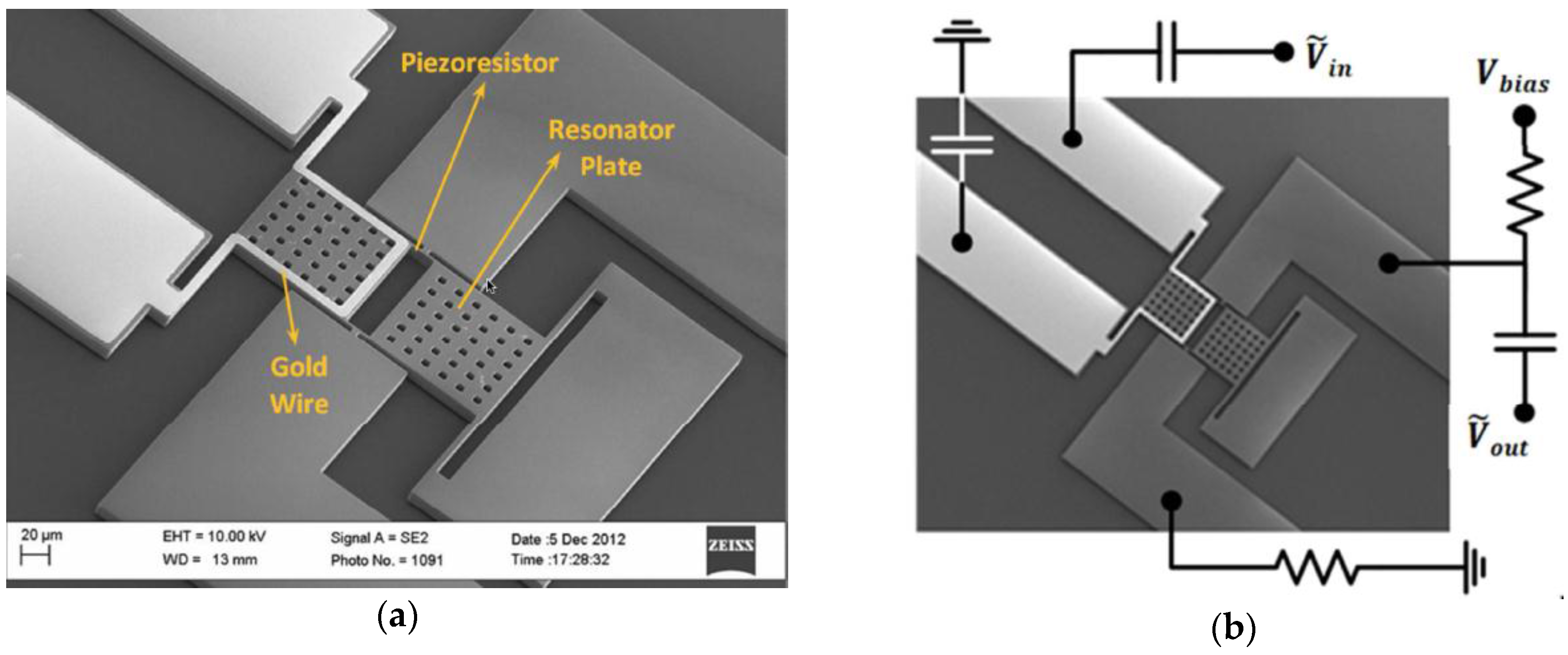

- Mehdizadeh, E.; Kumar, V.; Pourkamali, S. Sensitivity enhancement of Lorentz force MEMS resonant magnetometers via internal thermal-piezoresistive amplification. IEEE Eectron Device Lett. 2014, 35, 268–270. [Google Scholar] [CrossRef]

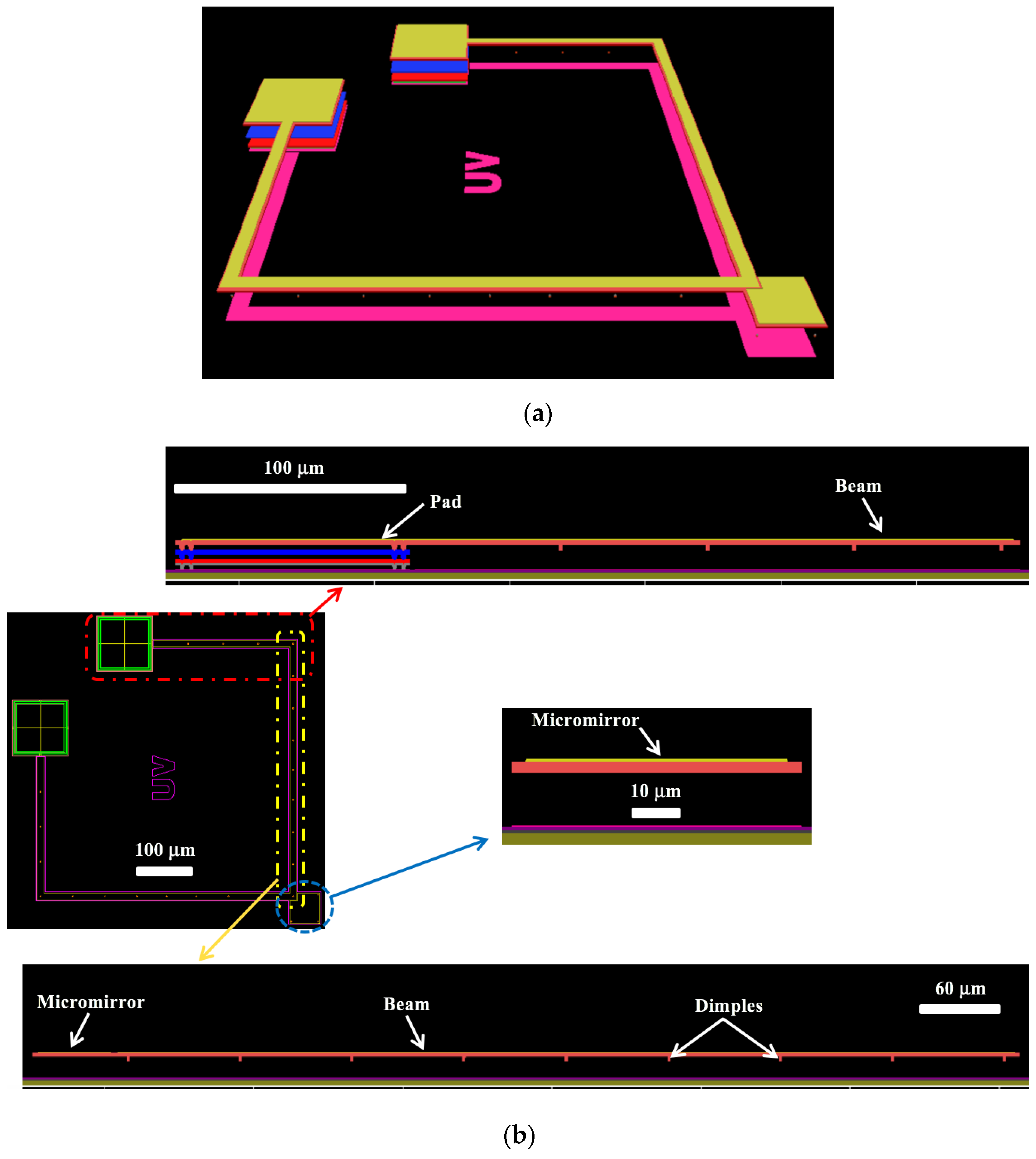

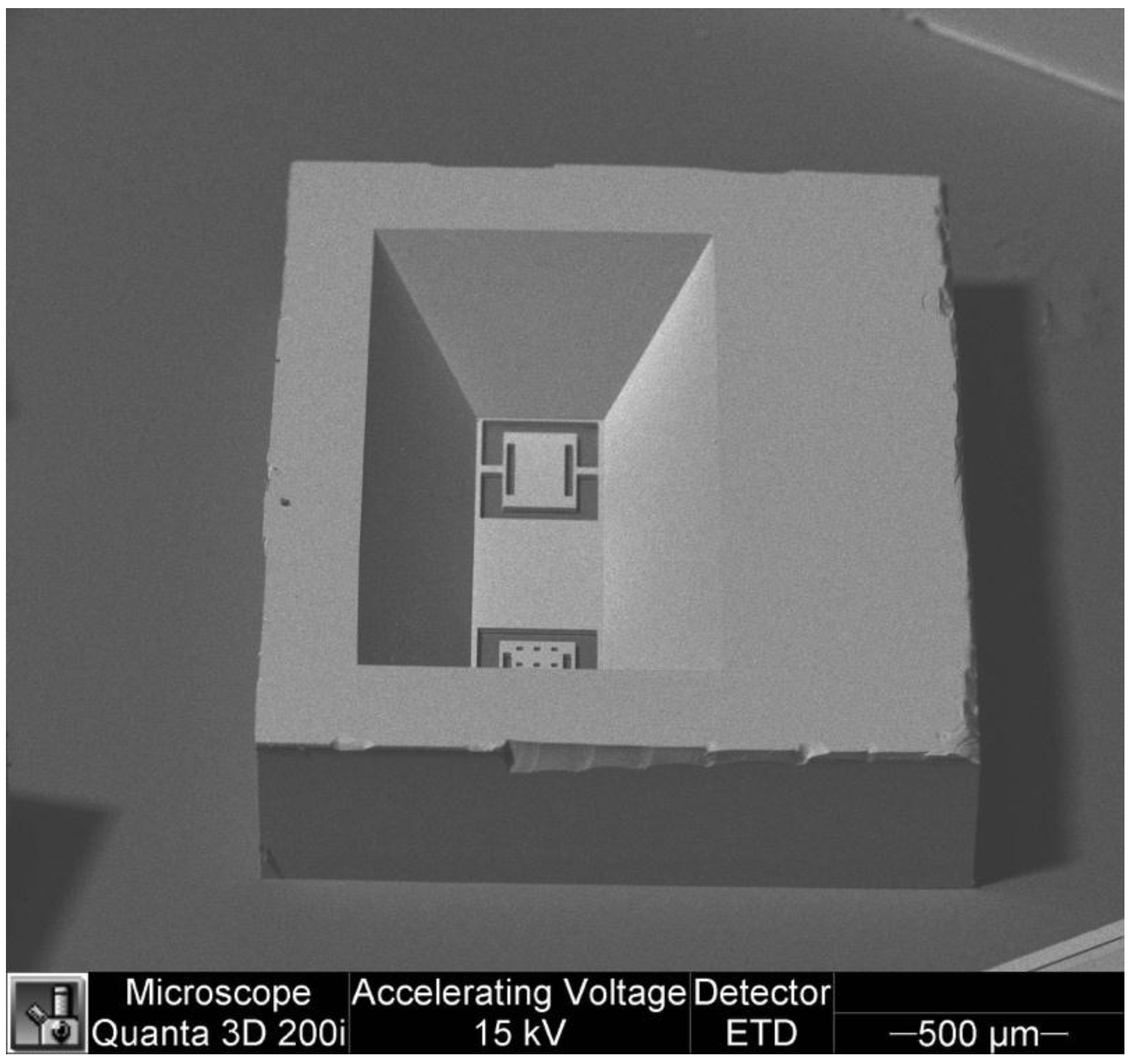

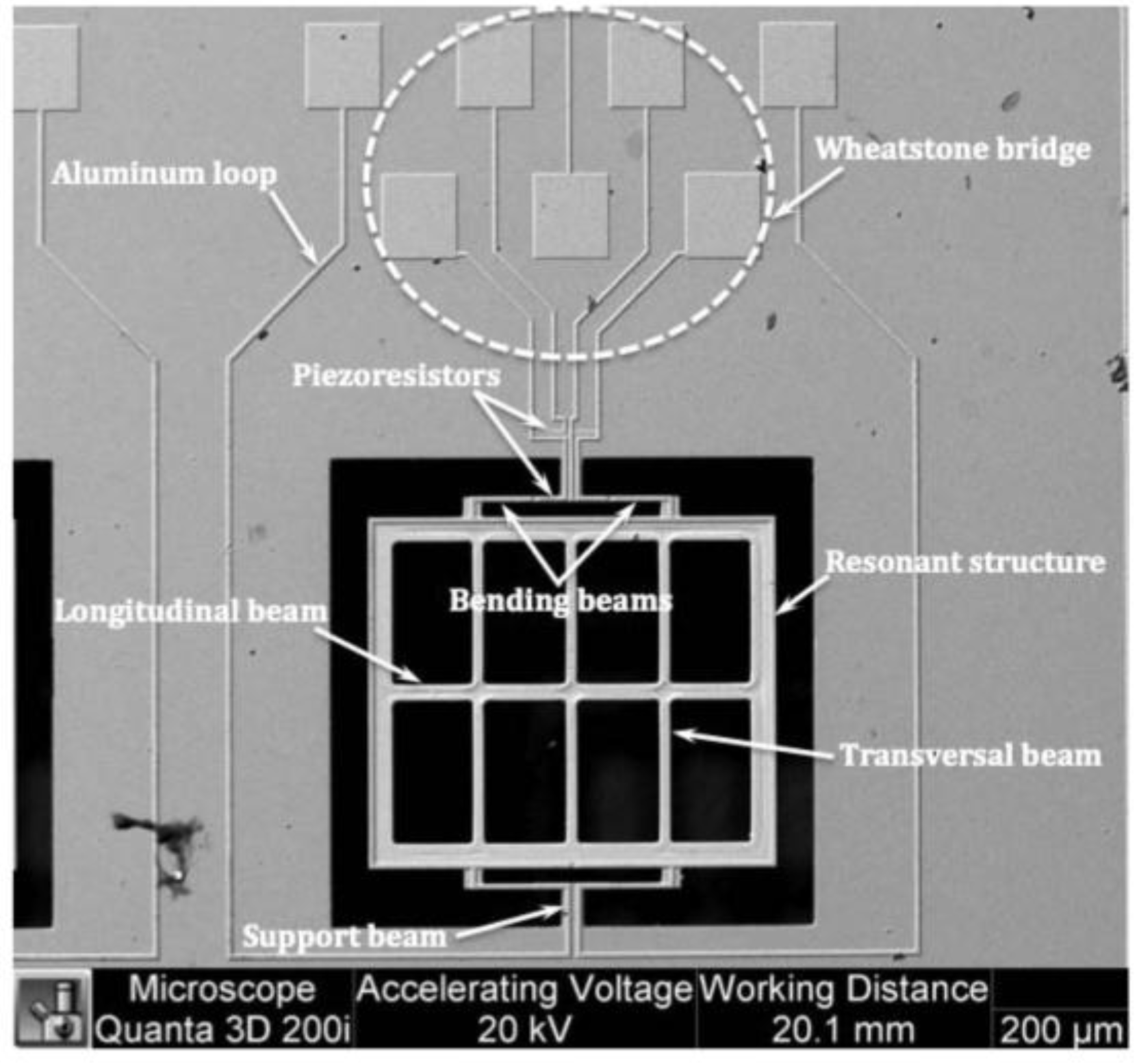

- Herrera-May, A.L.; Lara-Castro, M.; López-Huerta, F.; Gkotsis, P.; Raskin, J.-P.; Figueras, E. A MEMS-based magnetic field sensor with simple resonant structure and linear electrical response. Microelectron. Eng. 2015, 142, 12–21. [Google Scholar] [CrossRef]

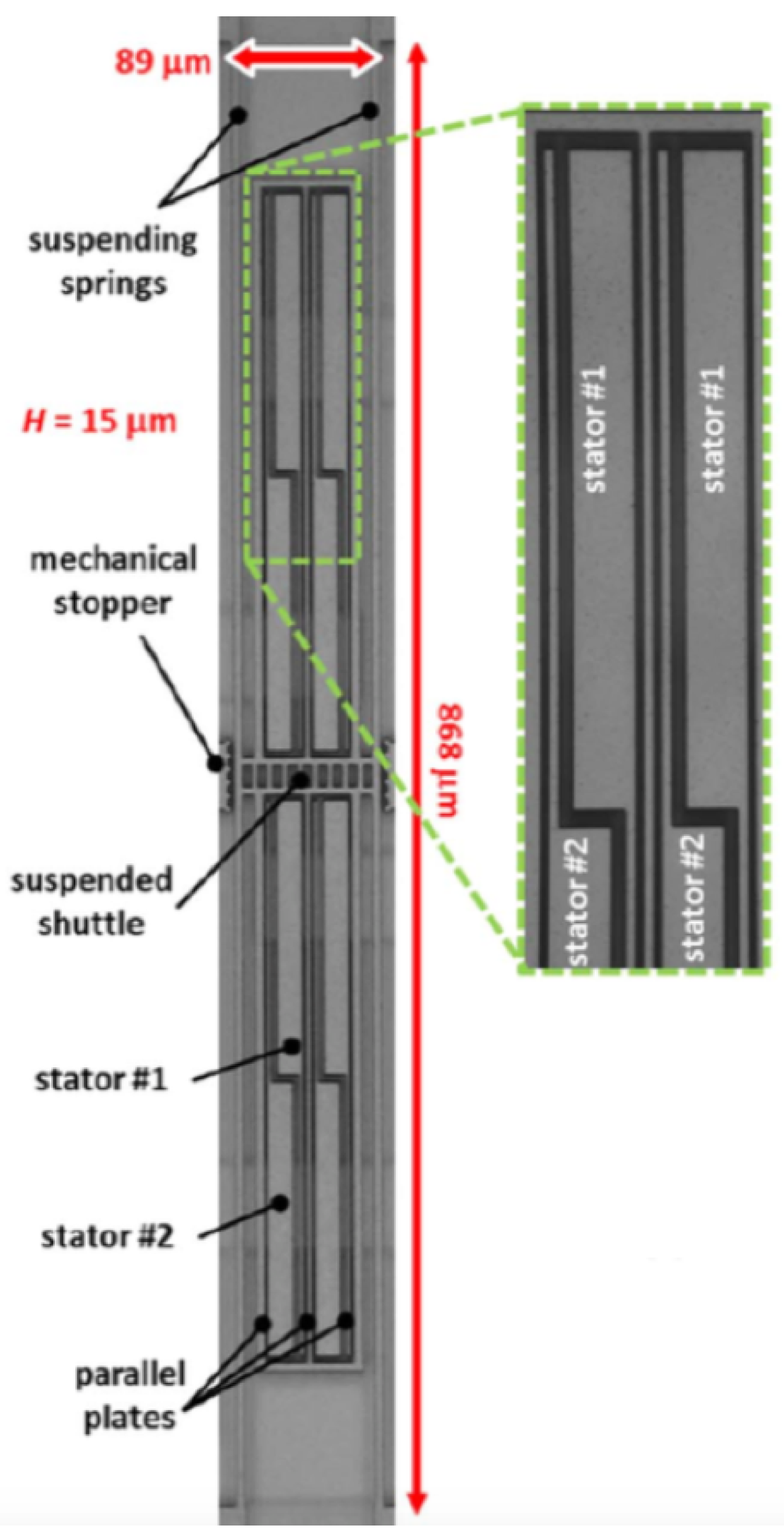

- Langfelder, G.; Buffa, C.; Frangi, A.; Tocchio, A.; Lasandra, E.; Longoni, A. Z-axis magnetometers for MEMS inertial measurement units using an industrial process. IEEE Trans. Ind. Electron. 2013, 60, 3983–3990. [Google Scholar] [CrossRef]

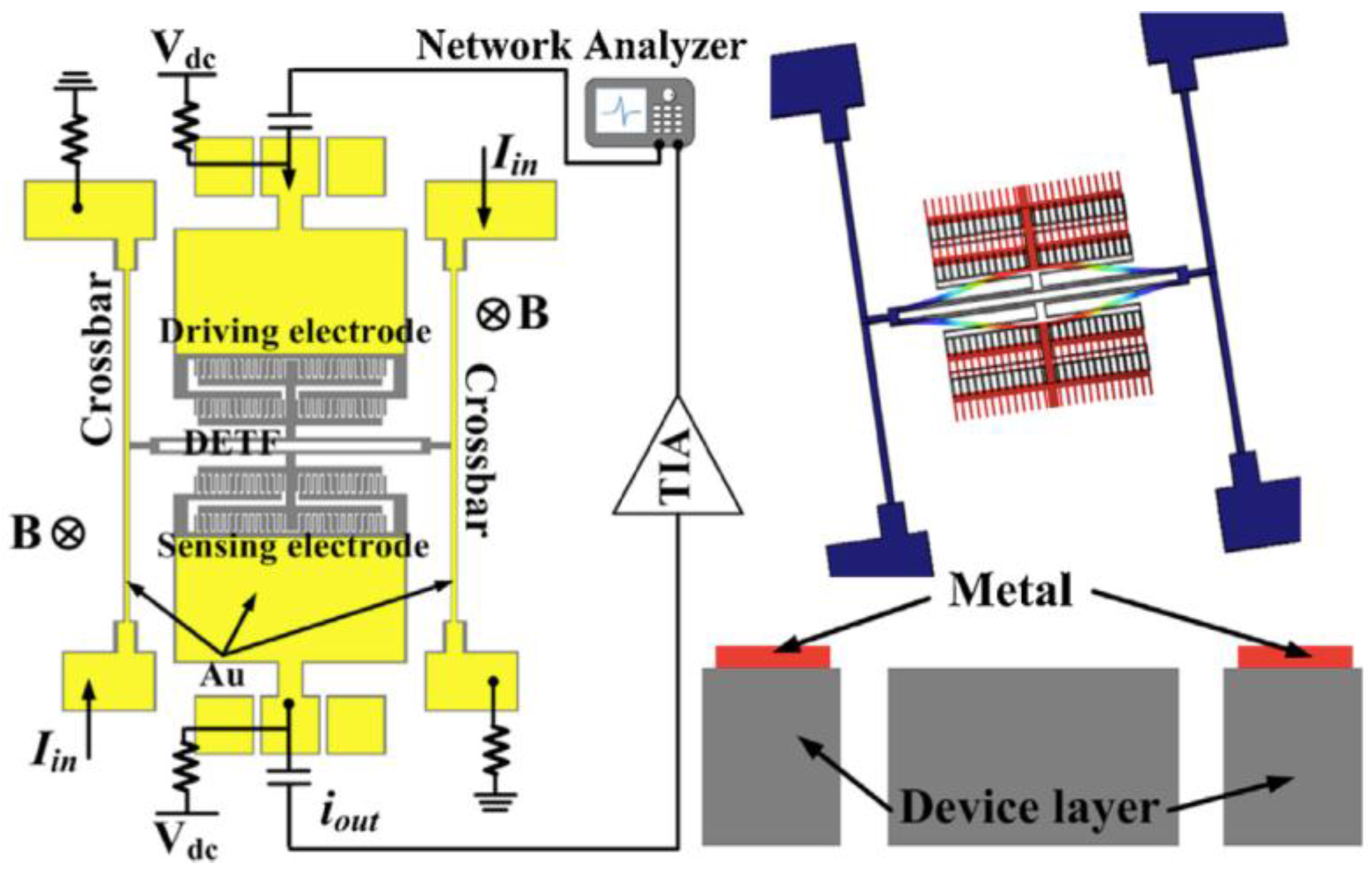

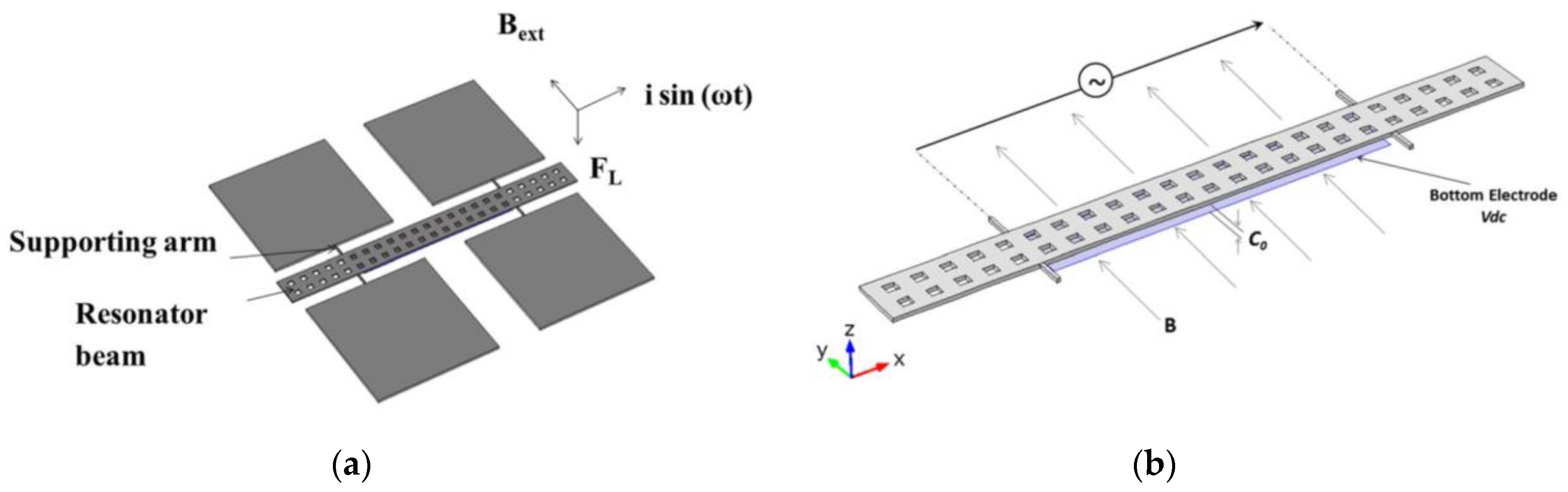

- Zhang, W.; Lee, J.E.-Y. Frequency-based magnetic field sensing Lorentz force axial strain modulation in a double-ended tuning fork. Sens. Actuators A 2014, 211, 145–152. [Google Scholar] [CrossRef]

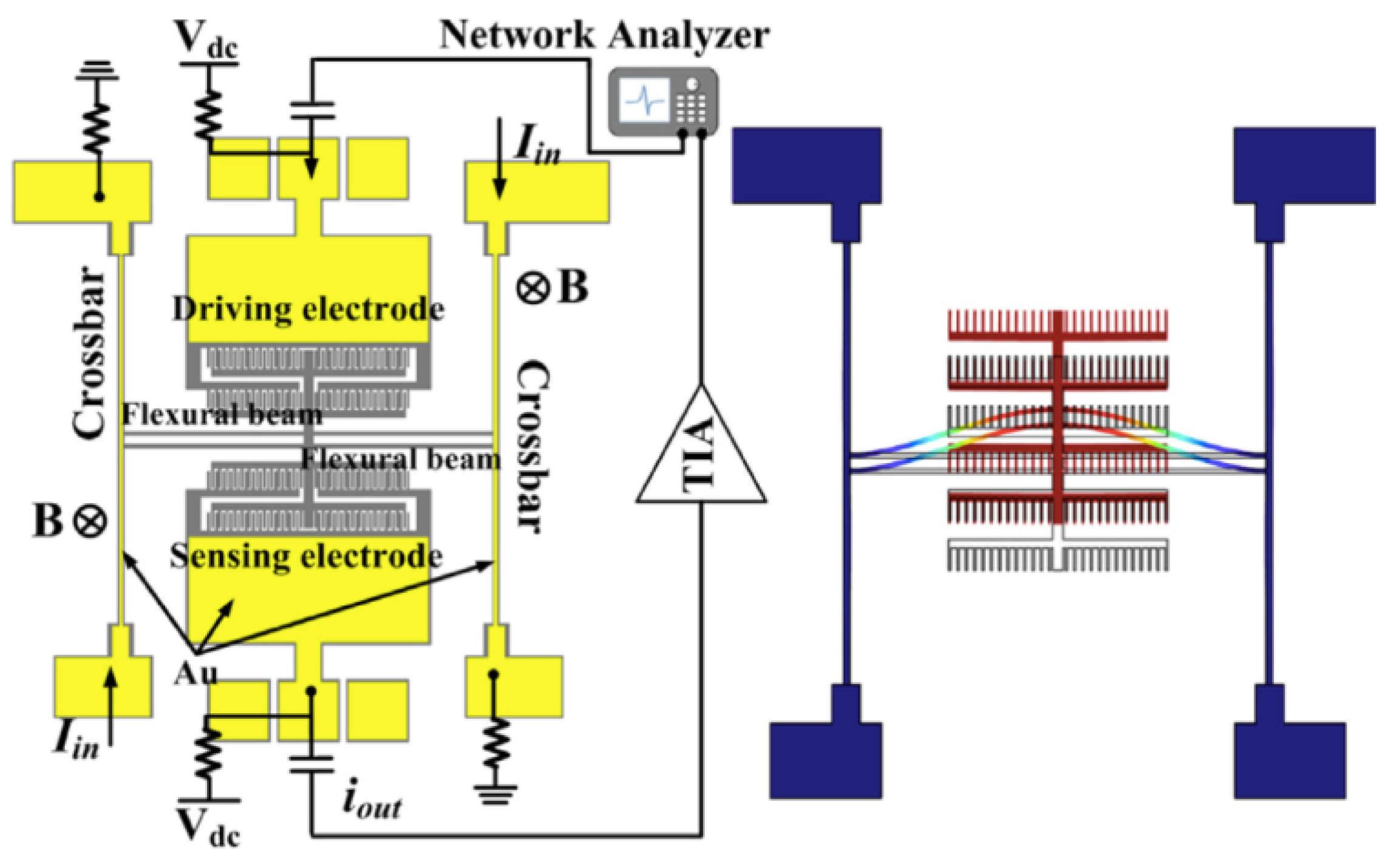

- Li, M.; Nitzan, S.; Horsley, D.A. Frequency-modulated Lorentz force magnetometer with enhanced sensitivity via mechanical amplification. IEEE Electron Device Lett. 2015, 36, 62–64. [Google Scholar]

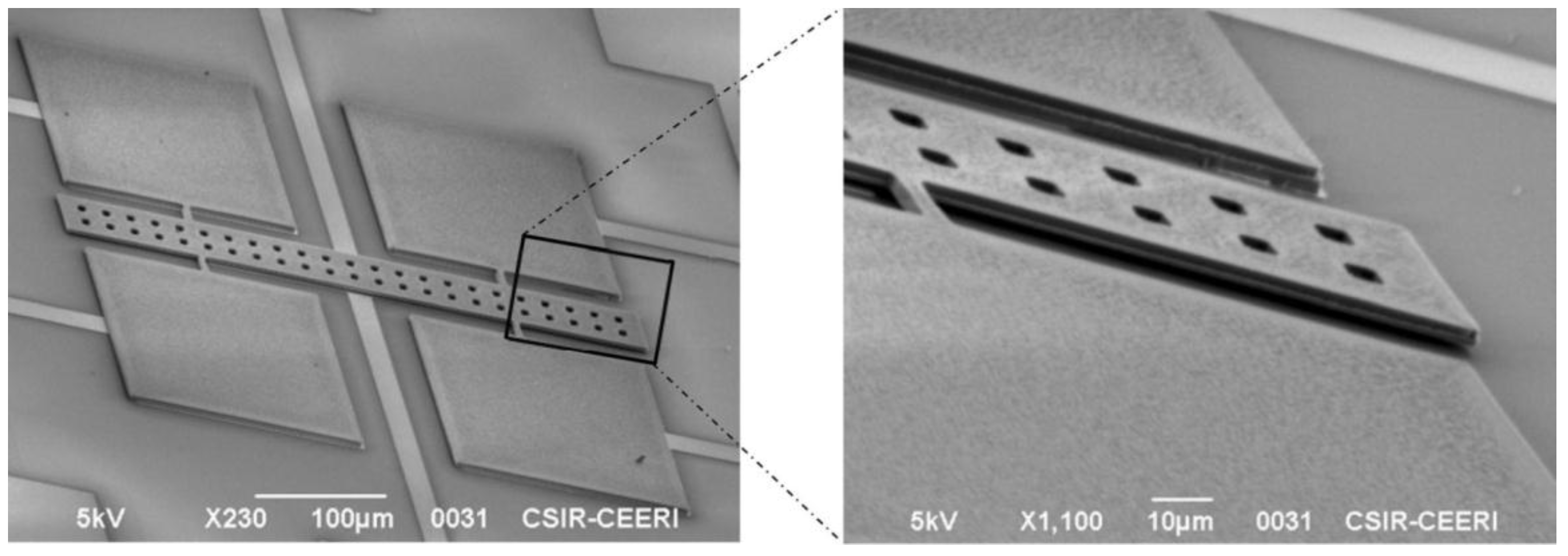

- Aditi; Gopal, R. Fabrication of MEMS xylophone magnetometer by anodic bonding technique using SOI wafer. Microsyst. Technol. 2016. [Google Scholar] [CrossRef]

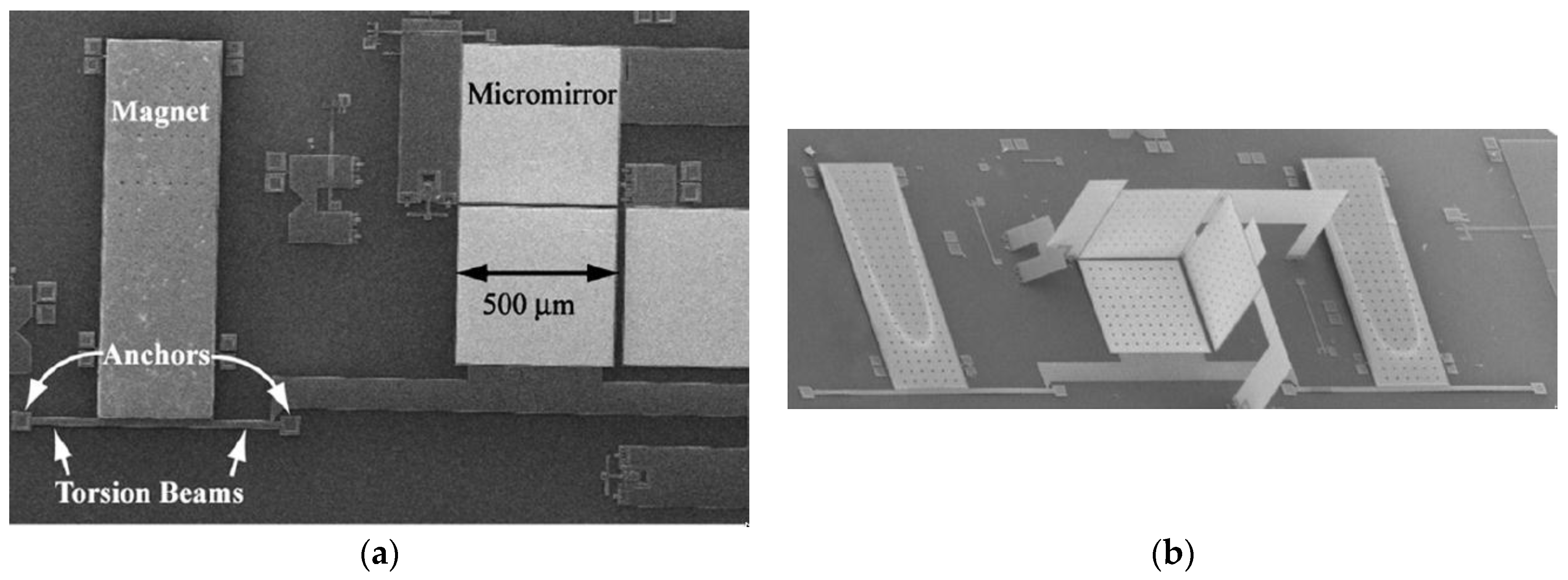

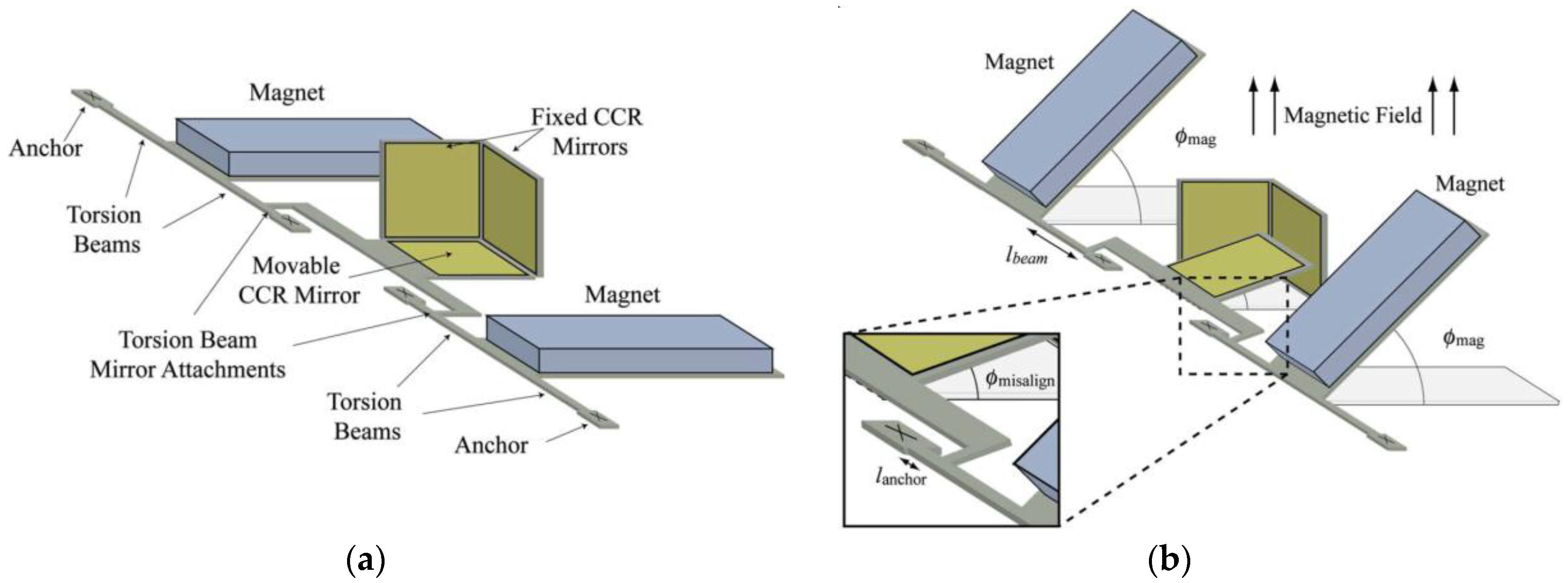

- Vasquez, D.J.; Judy, J.W. Optically-interrogated zero-power MEMS magnetometer. J. Microelectromech. Syst. 2007, 16, 336–343. [Google Scholar] [CrossRef]

- Markus, K.W.; Koester, D.A.; Cowen, A.; Mahadevan, R.; Dhuler, V.R.; Roberson, D.; Smith, L. MEMS Infrastructure: The Multiuser MEMS process (MUMPs). In Proceedings of the SPIE Micromachining and Microfabrication Process Technology, Austin, TX, USA, 23–24 October 1995; Volume 2639, pp. 54–63.

- Park, B.; Li, M.; Lyyanage, S.; Shafai, C. Lorentz force based resonant MEMS magnetic-field sensor with optical readout. Sens. Actuators A 2016, 241, 12–18. [Google Scholar] [CrossRef]

- Dubov, A.; Dubov, A.; Kolokolnikov, S. Application of the metal magnetic memory method for detection of defects at the initial stage of their development for prevention of failures of power engineering welded steel structures and steam turbine parts. Weld. Word 2014, 58, 225–236. [Google Scholar] [CrossRef]

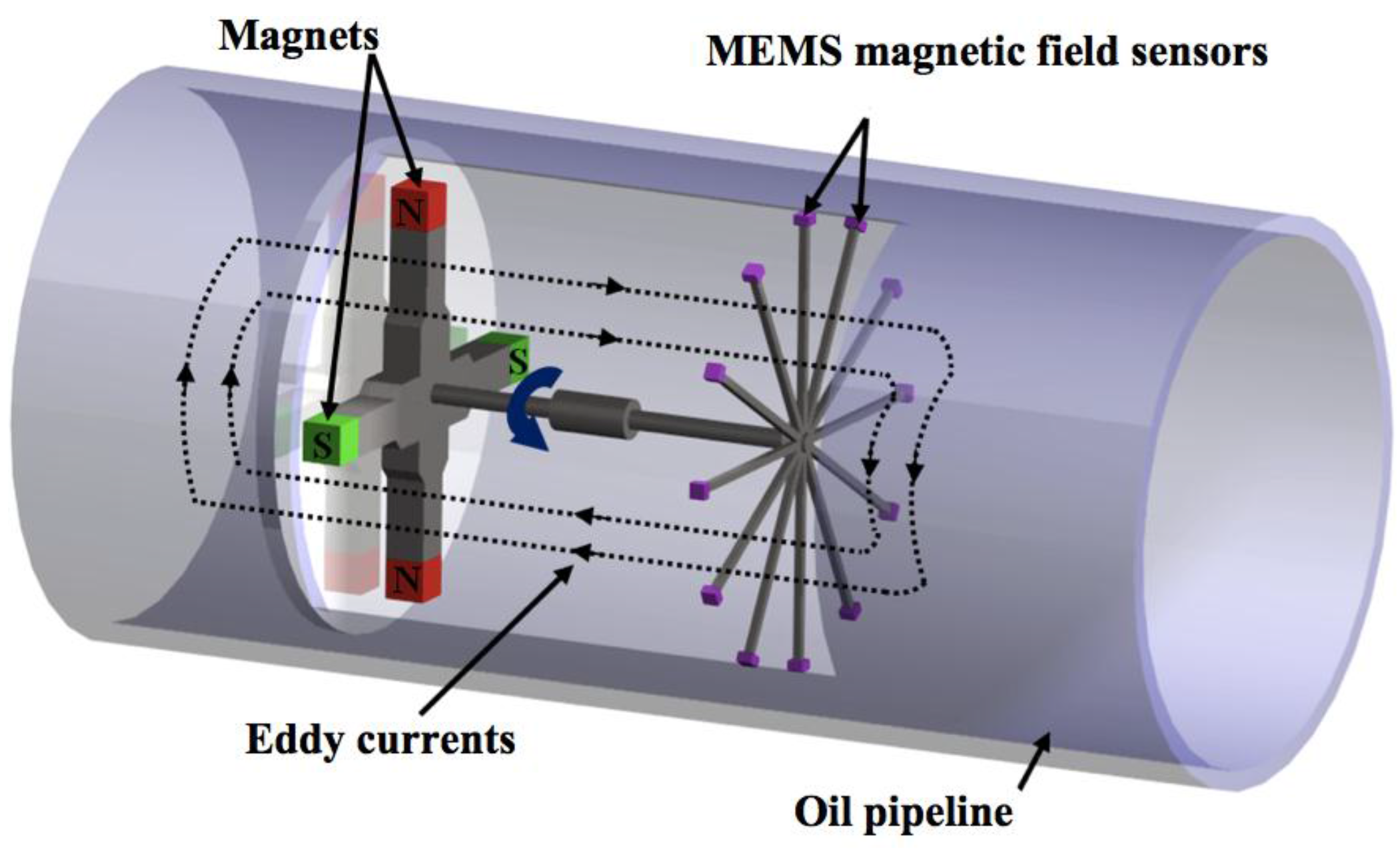

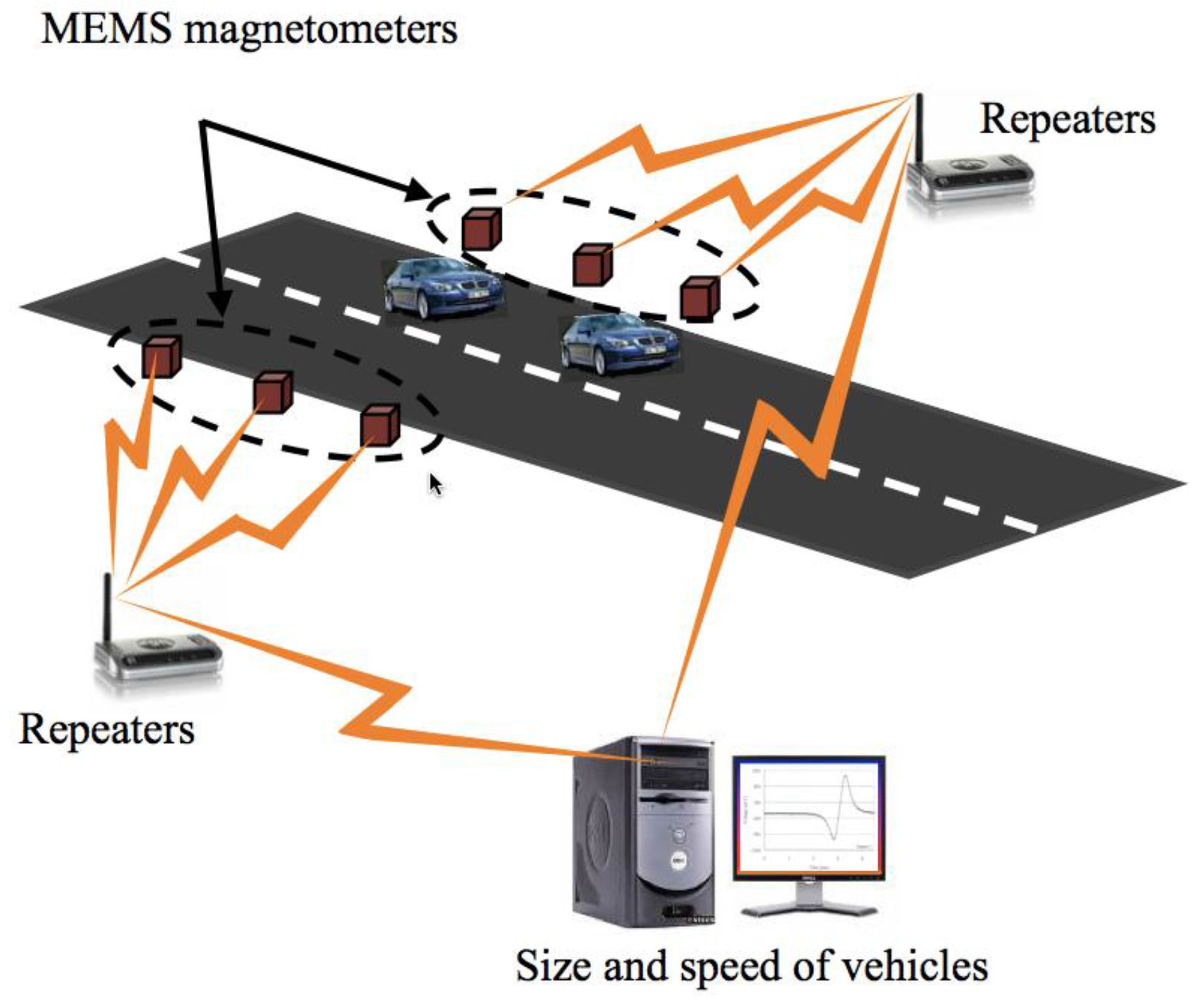

- Herrera-May, A.L.; Aguilera-Cortés, L.A.; García-Ramírez, P.J.; Mota-Carrillo, N.B.; Padrón-Hernández, W.Y.; Figueras, E. Development of Resonant Magnetic Field Microsensors: Challenges and Future Applications. In Microsensors; InTech: Rijeka, Croatia, 2011; pp. 65–84. [Google Scholar]

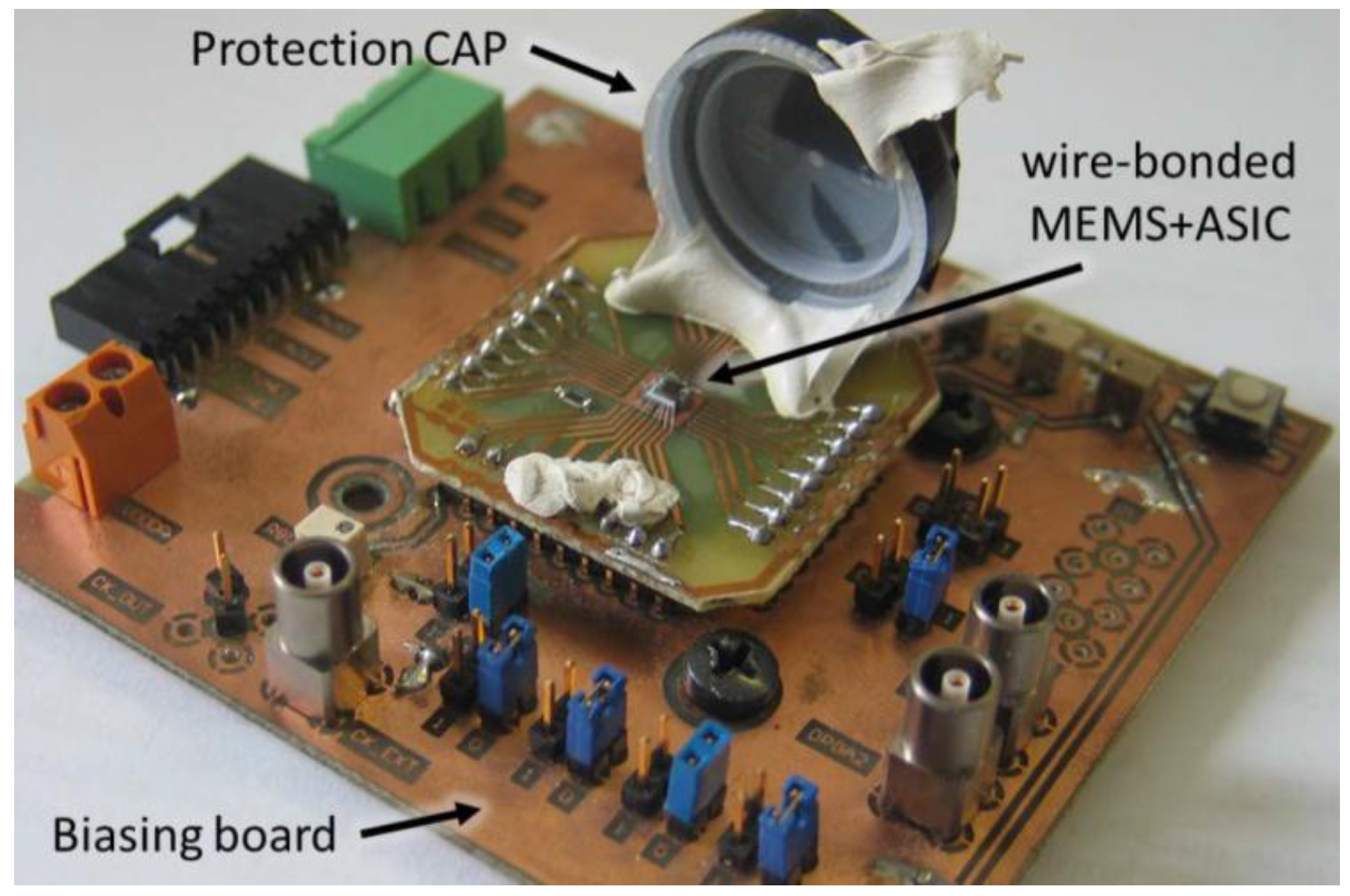

- Lara-Castro, M.; Herrera-May, A.L.; Juárez-Aguirre, R.; López-Huerta, F.; Ceron-Alvarez, C.A.; Cortés-Mestizo, I.E.; Morales-González, E.A.; Vazquez-Leal, H.; Dominguez-Nicolas, S.M. Portable signal conditioning system of a MEMS magnetic field sensor for industrial applications. Microsyst. Technol. 2016. [Google Scholar] [CrossRef]

- Domínguez-Nicolás, S.M.; Juárez-Aguirre, R.; Herrera-May, A.L.; García-Ramírez, P.J.; Figueras, E.; Gutierrez, E.; Tapia, J.A.; Trejo, A.; Manjarrez, E. Respiratory magnetogram detected with a MEMS device. Int. J. Med. Sci. 2013, 10, 1445–1450. [Google Scholar] [CrossRef] [PubMed]

- Juárez-Aguirre, R.; Domínguez-Nicolás, S.M.; Manjarrez, E.; Tapia, J.A.; Figueras, E.; Vázquez-Leal, H.; Aguilera-Cortés, L.A.; Herrera-May, A.L. Digital signal processing by virtual instrumentation of a MEMS magnetic field sensor for biomedical applications. Sensors 2013, 13, 15068–15084. [Google Scholar] [CrossRef] [PubMed]

- Tapia, J.A.; Herrera-May, A.L.; García-Ramírez, P.; Martínez-Castillo, J. Sensing magnetic flux density of artificial neurons with a MEMS device. Biomed. Microdevices 2011, 13, 303–313. [Google Scholar] [CrossRef] [PubMed]

- Lamy, H.; Rochus, V.; Niyonzima, I.; Rochus, P. A xylophone bar magnetometer for micro/pico satellites. Acta Astronaut. 2010, 67, 793–809. [Google Scholar] [CrossRef]

- Ranvier, S.; Rochus, V.; Druart, S.; Lamy, H.; Rochus, P.; Francis, L.A. Detection methods for MEMS-Based xylophone bar magnetometer for pico satellites. J Mech. Eng. Autom. 2011, 1, 342–350. [Google Scholar]

- Brigante, C.M.N.; Abbate, N.; Basile, A.; Faulisi, A.C.; Sessa, S. Towards miniaturization of a MEMS-based wearable motion capture systems. IEEE Trans. Ind. Electron. 2011, 58, 3234–3241. [Google Scholar] [CrossRef]

- Won, S.P.; Golnaraghi, F.; Melek, W.W. A fastening tool tracking system using an IMU and a position sensor with Kalman filters and a fuzzy expert system. IEEE Trans. Ind. Electron. 2009, 56, 1782–1792. [Google Scholar] [CrossRef]

- Dean, R.N.; Luque, A. Applications of microelectromechanical systems in industrial processes and services. IEEE Trans. Ind. Electron. 2009, 56, 913–925. [Google Scholar] [CrossRef]

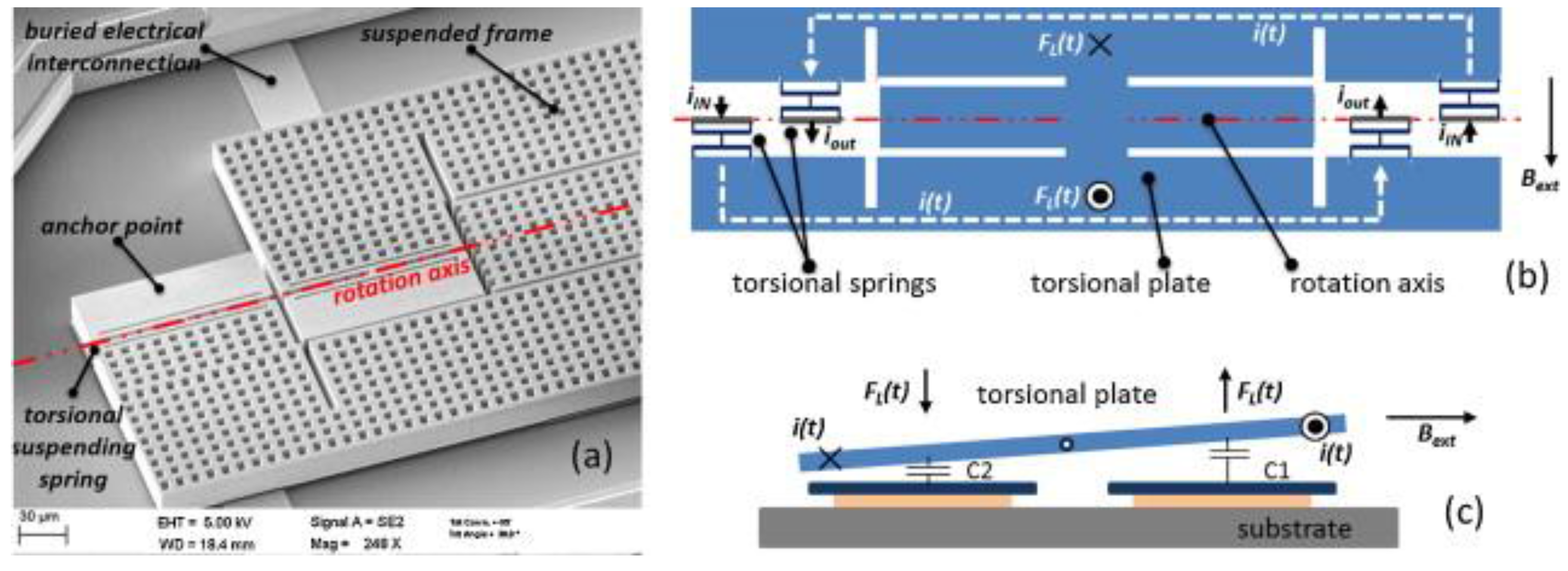

- Laghi, G.; Dellea, S.; Longoni, A.; Minotti, P.; Tocchio, A.; Zerbini, S.; Lagfelder, G. Torsional MEMS magnetometer operated off-resonance for in-plane magnetic field detection. Sens. Actuators A 2015, 229, 218–226. [Google Scholar] [CrossRef]

- Minotti, P.; Brenna, S.; Laghi, G.; Bonfanti, A.G.; Langfelder, G.; Lacaita, A.L. A sub-400-nT/, 775-μm, multi-loop MEMS magnetometer with integrated readout electronics. J. Microelectromech. Syst. 2015, 24, 1938–1950. [Google Scholar] [CrossRef]

- Langfelder, G.; Tocchio, A. Operation of Lorentz-force MEMS magnetometers with a frequency offset between driving current and mechanical resonance. IEEE Trans. Magn. 2014, 50. [Google Scholar] [CrossRef]

- Herrera-May, A.L.; Aguilera-Cortés, L.A.; García-González, L.; Figueras-Costa, E. Mechanical behavior of a novel resonant microstructure for magnetic applications considering the squeeze-film damping. Microsyst. Technol. 2009, 15, 259–268. [Google Scholar] [CrossRef]

- Gkotsis, P.; Lara-Castro, M.; López-Huerta, F.; Herrera-May, A.L.; Raskin, J.-P. Mechanical characterization and modelling of Lorentz force based MEMS magnetic field sensors. Solid State Electron. 2015, 112, 68–77. [Google Scholar] [CrossRef]

- Herrera-May, A.L.; Tapia, J.A.; Domínguez-Nicolás, S.M.; Juárez-Aguirre, R.; Gutierrez-D, E.A.; Flores, A.; Figueras, E.; Manjarrez, E. Improved detection of magnetic signals by a MEMS sensor using stochastic resonance. PLoS ONE 2014, 9, e109534. [Google Scholar]

| Magnetic Field Sensor | Resonator Size (μm × μm) | Resonant Frequency (kHz) | Quality Factor | Noise | Detection Limit | Sensitivity |

|---|---|---|---|---|---|---|

| Herrera-May et al. [25] | 400 × 150 | 136.52 | 842 | 57.5 nV∙Hz−1/2 * | 143 nT∙Hz−1/2 * | 403 mV∙T−1 |

| Mehdizadeh et al. [26] | 500 × 1400 | 2550 | 16,900 | --- ** | ---** | 262 mV∙T−1 |

| Herrera-May et al. [27] | 472 × 300 | 100.7 | 419.6 | 37.1 nV∙Hz−1/2 * | 161 nT∙Hz−1/2 * | 230 mV∙T−1 |

| Zhang et al. [29] | 600 × 800 | 49.3 | 100,000 | --- ** | --- ** | 215.74 ppm∙T−1 |

| Langfelder et al. [28] | 89 × 868 | 28.3 | 327.9 | 557.2 μV∙Hz−1/2 * | 520 nT∙mA∙Hz−1/2 | 150 μV∙μT−1 |

| Li et al. [30] | 1200 × 680 | 21.9 | 540 | 0.5 ppm∙Hz−1/2 | --- ** | 6687 ppm∙mA−1∙T−1 |

| Laghi et al. [46] | 282 × 1095 | 19.95 | 2,500 | --- ** | 120 nT∙mA∙Hz−1/2 | 0.85 V∙mT−1 |

| Minotti et al. [47] | 1700 × 750 | 20 | 460 | 30 zF∙Hz−1/2 | 40 nT∙mA∙Hz−1/2 | 0.75 zF∙nT−1∙mA−1 |

| Park et al. [34] | 3000 × 3000 | 0.36 | 116 | 1.78 nT∙Hz−1/2 | 0.4 nT with BW = 53 mHz | 62 mV∙μT−1 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Herrera-May, A.L.; Soler-Balcazar, J.C.; Vázquez-Leal, H.; Martínez-Castillo, J.; Vigueras-Zuñiga, M.O.; Aguilera-Cortés, L.A. Recent Advances of MEMS Resonators for Lorentz Force Based Magnetic Field Sensors: Design, Applications and Challenges. Sensors 2016, 16, 1359. https://doi.org/10.3390/s16091359

Herrera-May AL, Soler-Balcazar JC, Vázquez-Leal H, Martínez-Castillo J, Vigueras-Zuñiga MO, Aguilera-Cortés LA. Recent Advances of MEMS Resonators for Lorentz Force Based Magnetic Field Sensors: Design, Applications and Challenges. Sensors. 2016; 16(9):1359. https://doi.org/10.3390/s16091359

Chicago/Turabian StyleHerrera-May, Agustín Leobardo, Juan Carlos Soler-Balcazar, Héctor Vázquez-Leal, Jaime Martínez-Castillo, Marco Osvaldo Vigueras-Zuñiga, and Luz Antonio Aguilera-Cortés. 2016. "Recent Advances of MEMS Resonators for Lorentz Force Based Magnetic Field Sensors: Design, Applications and Challenges" Sensors 16, no. 9: 1359. https://doi.org/10.3390/s16091359