An Integrated Simulation Module for Cyber-Physical Automation Systems †

Abstract

:1. Introduction

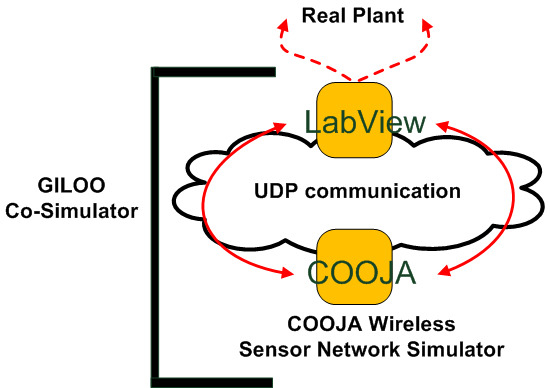

- The GISOO interface between COOJA and Simulink via UDP communication and time synchronization has been analyzed.

- LabVIEW has been used to design the necessary software interface.

- A hardware layer interface, compatible with Texas Instruments platforms, has been realized for CPS prototyping.

2. Architecture Concept Layout

- the physical process, including the motes, which can be divided into:

- -

- sensor motes for acquisition and reading data from the physical field;

- -

- actor motes for implementation of distributed or centralized control techniques and direct interaction with the physical-devices;

- -

- repeater motes, which extend the wireless communication distance and permit one to supervise the entire plant.

- the WSN, operating according to the IEEE 802.15.4 radio communication standard;

- the control hardware, performing the desired control law (e.g., SCADA, PLC, etc.).

3. GILOO Software Module

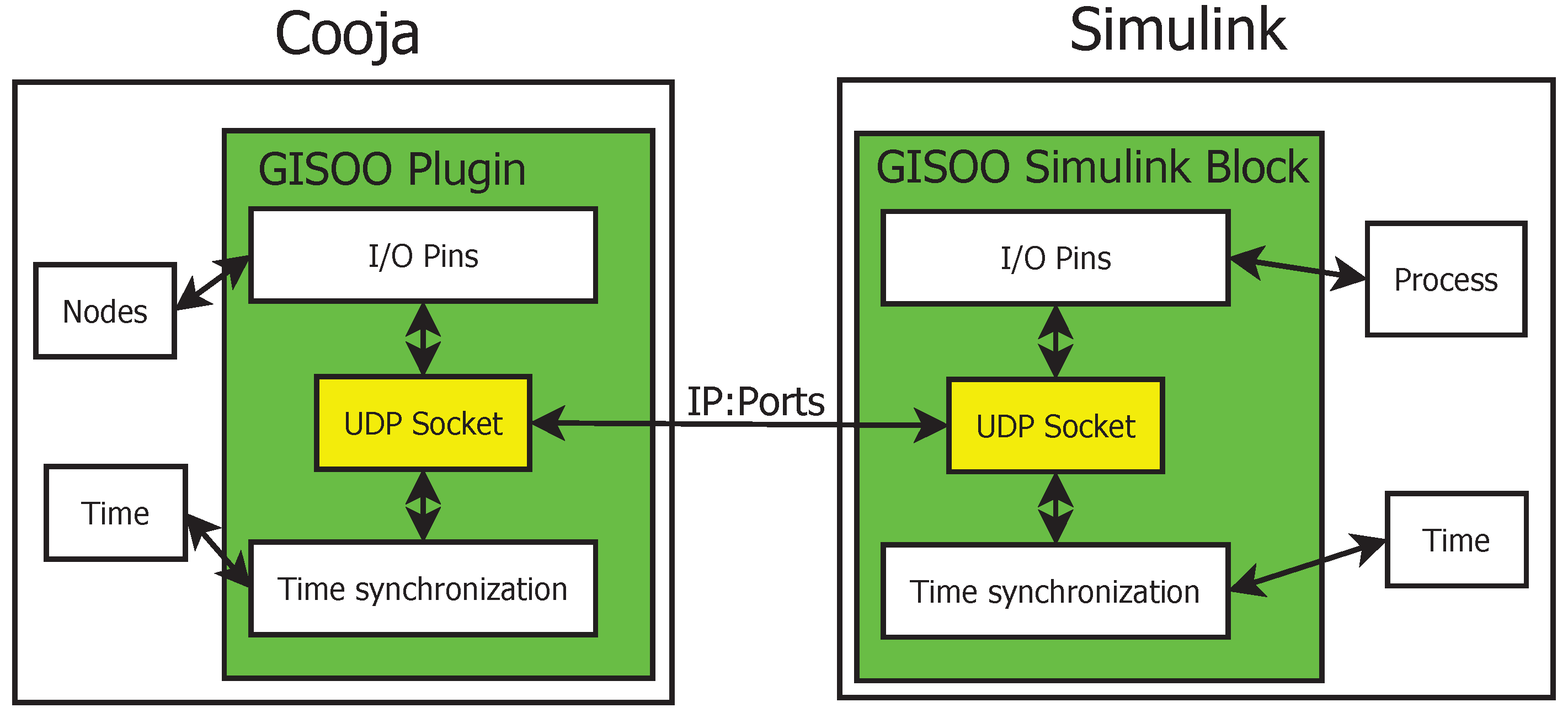

- The COOJA plugin manages the ADC, DAC, I/O, serial, etc., of the emulated nodes through the instruction set of the microcontroller and the state machine of the simulation environment, in order to preserve both time synchronization and data consistency between the two simulators. The interaction of COOJA with Simulink is managed by exchanging special UDP packets. A formatted frame within a custom protocol realizes a complete set of information, which is needed to ensure that the process operates correctly.

- The Simulink architecture blocks permit one to create a bidirectional communication channel with COOJA, to control the analogue and digital pins of the simulated nodes, both for the input (ADC) and the output (DAC). Simulink transfers data and time synchronization information by using UDP (reader and receiver) blocks, which manage packets on a specific port.

3.1. GILOO Architecture

3.2. Communication Messages

- Simulation TimeThis defines the simulation time of COOJA, and it is used to manage the synchronization with LABVIEW.

- Mote Pin IDThis represents the unique identifier of the mote in LabVIEW, and it is a required setting to correctly redirect the request of a node in LABVIEW (it selects both the pin and the mote).

- Actuation value (uValue)It refers to the DAC value and its related mote pin. This value, coded with three bytes, is contained from the eighth to eleventh position of the message.

- Serial DataTo permit data exchange in serial communication, sixteen bytes of the UDP message have been reserved, and if the serial data are more than serial bytes allocation, a segmentation technique is required. The structure of the serial message is based on the TinyOS specification, so that a mote can support multiple UART packet formats at the same time [38]. In addition, the serial bus can send or receive only messages formatted like the frame, and it is not possible to exchange raw data from motes. This specification defines a platform-independent active message layer, which works at the high level of the serial communication stack of TinyOS.

3.3. Time Synchronization

4. Sky DAC Driver

4.1. Contiki OS Kernel

const extern struct sensors_sensor sensors[] - Every sensors is associated with a sensors_sensor struct, a sensor’s pointers array, and each pointer is referred to a specific function in the driver files: struct sensors_sensor { char * type; int (* value ) (int type ); int (* conf igure ) (int type , int value ); int (* status ) (int type ); }; extern unsigned char sensors_flags[] - The attached sensors are identified by flags and are used when the function sensor_changed() is called.

4.2. Driver Implementation

- #define OUTPUT_CHANNEL (1 << INCH_7)

- #define INPUT_REFERENCE SREF_0

- #define DACDAT1 DAC12_1DAT

static int value(int input) - The variable input is used to change the value in the DAC data register. static int configure(int type, int c) - The configuration parameters are the OUTPUT_CHANNEL and INPUT_REFERENCE, the SENSORS_ACTIVE or SENSORS_DEACTIVATE information and the status value of the DAC (i.e., on or off). static int status(int type)

static CC_INLINE void startDAC(void) - This function manages the start of DAC functionality. The procedure to enable DAC0 registers differs from that of DAC1 registers. A special function has been included in order to control the port selection. static CC_INLINE void stopDAC(void) - This function turns off the reference voltage and stops DAC operations. It may be used to operate a sensor configuration change.

5. Advanced Sky GUI Module

((ADC12)skyMote. getCPU(). getIOUnit(“ADC12”)). setADCInput(...); ((DAC12)skyMote. getCPU(). getIOUnit(“DAC12”)). setDACOutput(...);while the interaction for the mote movement within the environment through the COOJA interfaces are provided by:

double x = mMotePosition. getXCoordinate() + xIncr / speedMove; double y = mMotePosition. getYCoordinate() + yIncr / speedMove;

6. Experimental Results

- GL LED Panel, 1200 mm × 300 mm, cold light, 50 W of nominal power and light intensity of 4350 lm.

- DLC1248 single channel LED dimmer, driven by a 0–10-V analogue signal.

- ADAM-4019 universal analogue input module by Advantech, a eight-port ADC-to-serial converter. The ADAM Series covers a set of sensor-to-computer interface modules that contain a microprocessor, use a set of ASCII format commands, an RS-485 bus and can be remotely controlled.

- ADAM-4024 analogue output module by Advantech, a four analogue output and four isolated digital input port DAC-to-serial converter. It uses ASCII format commands, an RS-485 bus and can be remotely controlled.

- The ANS-LUX-A lux meter by NESA for acquiring a high accuracy level of the environment illuminance.

7. Conclusions

Author Contributions

Conflicts of Interest

Abbreviations

| ADC | Analog (to) Digital Converter |

| COOJA | COntiki OS JAva Simulator |

| CPS | Cyber Physical System |

| DAC | Digital (to) Analog Converter |

| FPGA | Field Programmable Gate Array |

| GILOO | Graphical Integration of Labview and cOOja |

| GUI | Graphical User Interface |

| HLA | High Level Architecture |

| LED | Light Emitting Diode |

| MSPSIM | MSP430 SIMulator |

| NCSWT | Networked Control System Wind Tunnel |

| NS-2 | Network Simulator series 2 |

| PiccSIM | Platform for integrated communications and control design, Simulation, Implementation and Modeling |

| PLC | Programmable Logic Controller |

| PWM | Pulse Width Modulation |

| SCADA | Supervisory Control And Data Acquisition |

| TOSSIM | TinyOS SIMulator |

| UART | Universal Asynchronous Receiver Transmitter |

| UDP | User Datagram Protocol |

| WCPS | Wireless Cyber-Physical Simulator |

| WNCS | Wireless Network Control System |

| WSAN | Wireless Sensor and Actor Network |

| WSN | Wireless Sensor Network |

References

- Lee, E. Cyber Physical Systems: Design Challenges. In Proceedings of the 11th IEEE International Symposium on Object Oriented Real-Time Distributed Computing, Orlando, FL, USA, 5–7 May 2008; pp. 363–369.

- Lee, E. The past, present and future of cyber-physical systems: A focus on models. Sensors 2015, 15, 4837–4869. [Google Scholar] [CrossRef] [PubMed]

- Rezgui, A.; Eltoweissy, M. Service-oriented sensor-actuator networks [Ad Hoc and Sensor Networks]. IEEE Commun. Mag. 2007, 45, 92–100. [Google Scholar] [CrossRef]

- Poovendran, R. Cyber Physical Systems: Close Encounters Between Two Parallel Worlds [Point of View]. IEEE Proc. 2010, 98, 1363–1366. [Google Scholar] [CrossRef]

- Khakpour, K.; Shenassa, M. Industrial control using wireless sensor networks. In Proceedings of the 3rd International Conference on Information and Communication Technologies: From Theory to Applications, Damascus, Syria, 7–11 April 2008; pp. 1–5.

- Wan, J.; Zhang, D.; Sun, Y.; Lin, K.; Zou, C.; Cai, H. VCMIA: A novel architecture for integrating vehicular cyber-physical systems and mobile cloud computing. J. Mob. Netw. Appl. 2014, 19, 153–160. [Google Scholar] [CrossRef]

- Wan, J.; Zhang, D.; Zhao, S.; Yang, L.T.; Lloret, J. Context-aware vehicular cyber-physical systems with cloud support: Architecture, challenges, and solutions. IEEE Commun. Mag. 2014, 52, 106–113. [Google Scholar] [CrossRef]

- Ciabattoni, L.; Freddi, A.; Longhi, S.; Monteriù, A.; Pepa, L.; Prist, M. An open and modular hardware node for wireless sensor and body area networks. J. Sens. 2016, 1–16. [Google Scholar] [CrossRef]

- Longhi, S.; Marzioni, D.; Alidori, E.; Di Buo, G.; Prist, M.; Grisostomi, M.; Pirro, M. Solid waste management architecture using wireless sensor network technology. In Proceedings of the 5th International Conference on New Technologies, Mobility and Security, Istanbul, Turkey, 7–10 May 2012; pp. 1–5.

- Grisostomi, M.; Ciabattoni, L.; Prist, M.; Romeo, L.; Ippoliti, G.; Longhi, S. Modular design of a novel wireless sensor node for smart environments. In Proceedings of the IEEE/ASME 10th International Conference on Mechatronic and Embedded Systems and Applications, Senigallia, Italy, 10–12 September 2014; pp. 1–5.

- Ahmed, M.A.; Kim, Y.C. Communication network architectures for smart-wind power farms. Energies 2014, 7, 3900–3921. [Google Scholar] [CrossRef]

- Akyildiz, I.F.; Kasimoglu, I.H. Wireless sensor and actor networks: Research challenges. Ad Hoc Netw. 2004, 2, 351–367. [Google Scholar] [CrossRef]

- Teng, R.; Li, H.B.; Miura, R.; Yamazaki, T.; Davis, P. Matching of energy provisions in multihop wireless infra-structures. Energies 2016, 9, 1–23. [Google Scholar] [CrossRef]

- Tati, R.; Ahmadi, F.; Rashidy, R.; Ashkoti, F. Designing and simulation of a distributed algorithm for quality of service in wireless sensor networks. In Proceedings of the International Conference on Application of Information and Communication Technologies, Baku, Azerbaijan, 14–16 October 2009; pp. 1–5.

- Rhee, S.; Seetharam, D.; Liu, S. Techniques for minimizing power consumption in low data-rate wireless sensor networks. In Proceedings of the Wireless Communications and Networking Conference, Atlanta, GA, USA, 21–25 March 2004; pp. 1727–1731.

- Modares, H.; Salleh, R.; Moravejosharieh, A. Overview of security issues in wireless sensor networks. In Proceedings of the 3rd International Conference on Computational Intelligence, Modelling and Simulation (CIMSiM), Langkawi, Malaysia, 20–22 September 2011; pp. 308–311.

- Yang, T.C. Networked control system: A brief survey. IEE Proc. Control Theory Appl. 2006, 153, 403–412. [Google Scholar] [CrossRef]

- Chow, M.Y.; Tipsuwan, Y. Network-based control systems: A tutorial. In Proceedings of the 27th Annual Conference of the IEEE Industrial Electronics Society, Denver, CO, USA, 29 November–1 December 2001; pp. 1593–1602.

- Melodia, T.; Pompili, D.; Akyldiz, I. Handling mobility in wireless sensor and actor networks. IEEE Trans. Mob. Comput. 2010, 9, 160–173. [Google Scholar] [CrossRef]

- Heidemann, J.; Mills, K.; Kumar, S. Expanding confidence in network simulations. IEEE Netw. 2001, 15, 58–63. [Google Scholar] [CrossRef]

- Breslau, L.; Estrin, D.; Fall, K.; Floyd, S.; Heidemann, J.; Helmy, A.; Huang, P.; McCanne, S.; Varadhan, K.; Xu, Y.; et al. Advances in network simulation. Computer 2000, 33, 59–67. [Google Scholar] [CrossRef]

- Imran, M.; Said, A.; Hasbullah, H. A survey of simulators, emulators and testbeds for wireless sensor networks. In Proceedings of the International Symposium in Information Technology, Kualalumpur, Malaysia, 15–17 June 2010; pp. 897–902.

- ISIS Tools/Frameworks. Available online: http://repo.isis.vanderbilt.edu/ (accessed on 4 May 2016).

- Levis, P.; Lee, N.; Welsh, M.; Culler, D. TOSSIM: Accurate and scalable simulation of entire TinyOS applications. In Proceedings of the 1st International Conference on Embedded Networked Sensor Systems, Los Angeles, CA, USA, 5–7 November 2003.

- Li, B.; Sun, Z.; Mechitov, K.; Hackmann, G.; Lu, C.; Dyke, S.; Agha, G.; Spencer, B. Realistic case studies of wireless structural control. In Proceedings of the ACM/IEEE International Conference on Cyber-Physical Systems, Philadelphia, PA, USA, 8–11 April 2013; pp. 179–188.

- TOSSIM Simulator Lessons. Available online: http://tinyos.stanford.edu/tinyos-wiki/index.php/TOSSIM (accessed on 4 May 2016).

- Eyisi, E.; Bai, J.; Riley, D.; Weng, J.; Wei, Y.; Xue, Y.; Koutsoukos, X.; Sztipanovits, J. NCSWT: An integrated modeling and simulation tool for networked control systems. In Proceedings of the 15th ACM International Conference on Hybrid Systems: Computation and Control, Beijing, China, 17–19 April 2012; pp. 90–111.

- Nethi, S.; Pohjola, M.; Eriksson, L.; Jantti, R. Platform for emulating networked control systems in laboratory environments. In Proceedings of the IEEE International Symposium on a World of Wireless, Mobile and Multimedia Networks, Helsinki, Finland, 18–21 June 2007; pp. 1–8.

- Aminian, B.; Araujo, J.; Johansson, M.; Johansson, K. GISOO: A virtual testbed for wireless cyber-physical systems. In Proceedings of the 39th Annual Conference of the IEEE Industrial Electronics Society, Vienna, Austria, 10–13 November 2013; pp. 5588–5593.

- Musznicki, B.; Zwierzykowski, P. Survey of simulators for wireless sensor networks. Int. J. Grid Distrib. Comput. 2012, 5, 23–50. [Google Scholar]

- KTH—GISOO: A Virtual Testbed for Wireless Cyber-Physical Systems. Here You Can Find the Simulator’s Code, Examples and Documentation. KTH—Automatic Control Lab. Available online: https://code.google.com/p/kth-gisoo/ (accessed on 4 May 2016).

- PiccSIM Simulation of Wireless Control Systems. Available online: http://wsn.aalto.fi/en/tools/piccsim/ (accessed on 4 May 2016).

- Prist, M.; Freddi, A.; Longhi, S.; Monteriù, A. An integrated simulation module for wireless cyber-physical system. In Proceedings of the 15th IEEE International Conference on Environment and Electrical Engineering (EEEIC), Rome, Italy, 10–13 June 2015; pp. 1397–1402.

- Polastre, J.; Szewczyk, R.; Culler, D. Telos: Enabling ultra-low power wireless research. In Proceedings of the 4th International Symposium on Information Processing in Sensor Network, Los Angeles, CA, USA, 24–27 April 2005; pp. 364–369.

- Dunkels, A.; Gronvall, B.; Voigt, T. Contiki—A lightweight and flexible operating system for tiny networked sensors. In Proceedings of the 29th Annual IEEE International Conference on Local Computer Networks, Tampa, FL, USA, 16–18 November 2004; pp. 455–462.

- Advanced Sky GUI Plugin: An Interactive Graphic Interface. Here You Can Find the Plugin’s Code. UnivPM—Department of Information Engineering. Available online: http://marioros.github.io/ advanced-sky-gui-cooja-plugin/ (accessed on 4 May 2016).

- Prist, M.; Longhi, S.; Monteriù, A.; Giuggioloni, F.; Freddi, A. An integrated simulation environment for Wireless Sensor Networks. In Proceedings of the 16th IEEE International Symposium on a World of Wireless, Mobile and Multimedia Networks (WoWMoM), Boston, MA, USA, 14–17 June 2015; pp. 1–3.

- TinyOs Serial Communication. Available online: http://www.tinyos.net/tinyos-2.x/doc/txt/tep113.txt (accessed on 4 May 2016).

- Mobility of Nodes in Cooja. Available online: http://anrg.usc.edu/contiki/index.php/ (accessed on 4 May 2016).

- Cimini, G.; Freddi, A.; Ippoliti, G.; Pirro, M.; Monteriù, A. A smart lighting system for visual comfort and energy savings in industrial and domestic use. Electr. Power Compon. Syst. 2015, 43, 1696–1706. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferracuti, F.; Freddi, A.; Monteriù, A.; Prist, M. An Integrated Simulation Module for Cyber-Physical Automation Systems. Sensors 2016, 16, 645. https://doi.org/10.3390/s16050645

Ferracuti F, Freddi A, Monteriù A, Prist M. An Integrated Simulation Module for Cyber-Physical Automation Systems. Sensors. 2016; 16(5):645. https://doi.org/10.3390/s16050645

Chicago/Turabian StyleFerracuti, Francesco, Alessandro Freddi, Andrea Monteriù, and Mariorosario Prist. 2016. "An Integrated Simulation Module for Cyber-Physical Automation Systems" Sensors 16, no. 5: 645. https://doi.org/10.3390/s16050645