1. Introduction

External quality of an agricultural product is the first criterion used by consumers beforehand in determining its eating quality. External quality can be described as the quality of the fruit as described by its color, texture, size, shape and visual defects [

1]. These parameters are the proper standards for grading and classifying of the product before sale to the consumer. Harumanis mango—which is the most famous fruit at Perlis Province in Malaysia—has a very high value in the export market. The increasing demand from local and overseas consumers requires the process of classifying and sorting the mango to be more stable, accurate, non-destructive and fast. The current method of weighing Harumanis mango is done manually using a scale, while classifying the bad and normal shape was done by human labor. This method proves to be time-consuming, inefficient and labor intensive.

There are two common methods of measuring the volumes of agricultural products and foodstuffs [

2]. First is the liquid displacement method—which is the easiest and simplest way. The object will be immersed in liquid and the displacement will be measured, but the product may be damaged during the process. This method is inaccurate, especially for fragile or porous objects [

3,

4]. The gas displacement method preserves the condition of the food and leaves it intact, but it is not suitable for a fast measurement system. Most fruits have an irregular shape, but they can be described as having a standard shape such as round, oblong, and elliptical. The uniformity of the presumed shape of the fruit will determine the accuracy of the estimated volume. Model equations were developed to estimate the volume of citrus and kiwi fruit by using the length and major and minor diameters [

5,

6]. Another model was developed using geometrical features to estimate the mass of mangoes (cv. ‘Manila’) [

7]. The predicted value and the measured value have a high correlation (

R2 = 0.93). However, both methods used mechanical means to measure the required dimensions. The measurement methods were subject to human error and an inefficient approach for sorting a large quantity of product.

A classifying system which can rapidly calculate the volume is needed by the commercial sorter industry. The system also needs to be cheap and easy to implement in the available machinery. Structured light projection [

8,

9] has the potential to give accurate estimated volumes. However, it needs extra hardware to be interfaced with the computer, leading to additional high costs. Machine vision has gained much interest from many researchers in determining the volume and mass of agricultural products. Forbes developed a machine vision algorithm using a neural network to estimate the volume of pears [

10]. The RMS percentage error was slightly reduced when multiple images were used compared to the single image analysis. Another method to obtain the volume is by using the ellipsoidal method. Omid [

11] divided citrus fruit images into numbers of elliptical frustums. The volume then calculated by summing all the individual volume frustums. The results show that the computed volume has some good agreement with the actual volume. Koc [

12] also used this method to determine the volume of watermelons. Both methods used samples that can be categorized as spherical shapes, thus only one dimension was measured and use to estimate the volume. Chalidabhongse [

13] used multiple cameras to capture multiple silhouette images of mango. These images were then used to obtain a 3D volume reconstruction of the mango. However, the experiment setup can only be applied as an offline system.

Shape is another factor that mostly been used to measure the quality of fruit during the grading and classification process. This process is usually done in the packing house, where the graders will judge the fruit shape base on the difference from the normal characteristic shape of the variety. Abnormality in shape mostly leads to rejection of foreign consignments [

14]. Misshapen and malformation are the most common words to describe a product’s poor symmetry and abnormal concavities [

15]. A fast and effective machine vision system is needed to grade the Harumanis mango. There are two main categories to characterize fruit shape which are size dependent measurements and size independent measurements [

14]. Size-dependent measurements are a combination of size measurement features such as roundness, elongation, eccentricity and others. The combination will form a descriptor which can describe the regularity of the fruit shape. For size independent measurements, boundary-based and region-based method is used to analyze the shape of the fruit. Some methods developed using this concept include the Fourier descriptor (FD), Chain code and Wavelet descriptor. The Fourier descriptor method mostly been used to obtain the shape characteristics of fruit because it is computationally inexpensive, robust and each of its FD have meaning [

16].

The objective of this research was to develop a rapid, real-time automatic classification and grading method for Harumanis mango using machine vision based on its shape pattern and estimated mass. A conveyor machine was used to transport the mango to each station. An algorithm was developed to grab the image and analyzed the shape, volume, and mass of the mangoes on the in-line system. Mango with defective shapes will be classified as reject fruit while the normal shaped fruit will be graded into three categories according to its volume. The system has been fully tested in the Perlis Department of Agriculture to grade their Harumanis mango production.

2. Materials and Methods

One hundred and eighty Harumanis mangoes were randomly picked at an orchard managed by the Perlis Department of Agriculture, Malaysia. All the mangoes picked had been harvested in the past 24 h. Each sample was measured using a caliper to obtain its dimensions including maximum length, maximum wide and maximum height. The measurement was taken with an error of ±1.0 mm. The measurements were used to compare the image measurements with the real measurements. Each mango was weighed using a precision digital scale (PL1502E portable balance, Mettler Toledo, Greifensee, Switzerland) with ±5 g accuracy. The water displacement method was used to measure the actual volume of each mango. A square container was filled full with water. The mangoes were submerged into the container and the volume of water displaced by the mango was measured using a 1000 mL beaker.

2.1. Element of Machine Vision

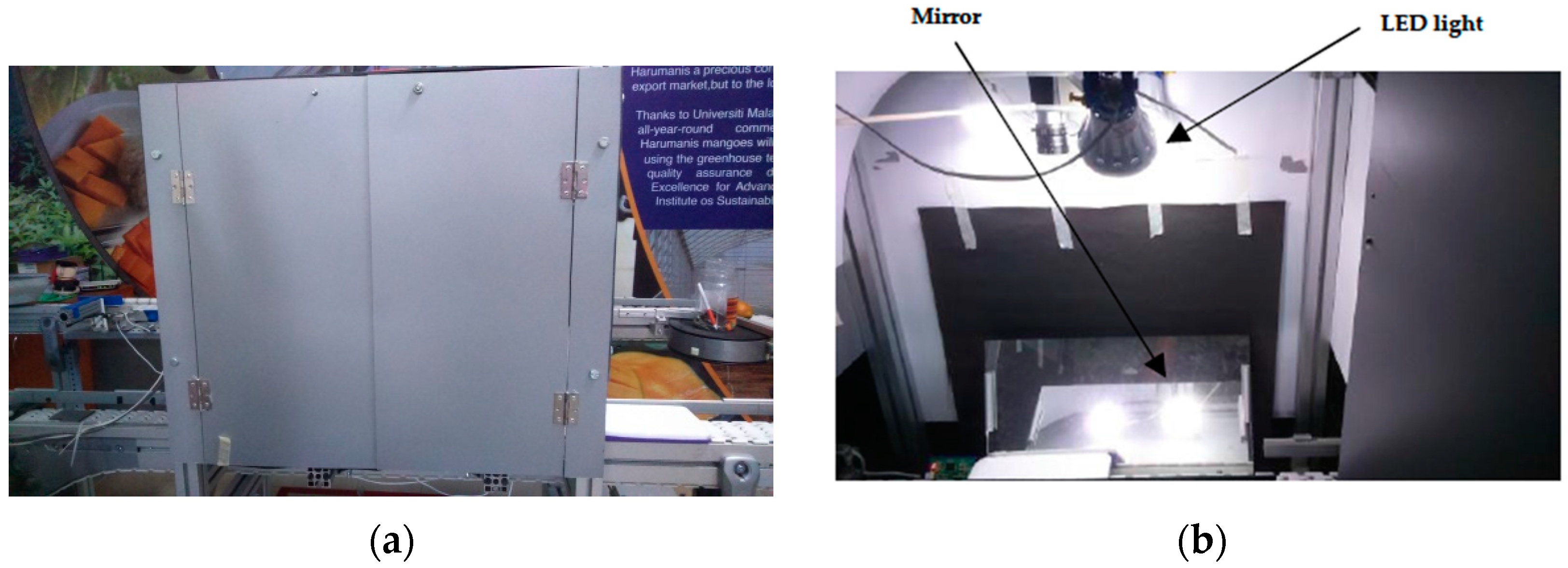

The image capturing platform as shown in

Figure 1a consists of a rectangular box made from PVC-coated aluminum with dimension of 100 cm × 60 cm × 100 cm, a CMOS camera (a 2 megapixel acA1600-60gc digital camera with 4.5 µm × 4.5 µm pixel size, Basler, Ahrensburg, Germany) with a GigE interface and four LED light sources (20 W). A lens with 8 mm focal length was attached to the camera. A computer of 8 GB RAM memory and 3.2 GHz processing speed was installed with the LabVIEW 2012 (National Instruments, Austin, TX, USA) visual programming language. The platform was placed on a conveyor system. The box was made to ensure fully isolated conditions which prevent outside lighting. The camera was mounted perpendicular to the conveyor surface with a height of 45 cm above the conveyor. With the GigE interface, images’ raw data were packed and send through the Ethernet cable to the computer with speeds up to 1000 Mb/s. After a data packet had been received, the NI-IMAQdx driver extracted the image and passed it to the program. The entire light source mounted on top of the box with the direction facing downward to the conveyor surface.

Figure 1b shows the setup inside the platform. The direction was adjusted to avoid any bright spots and specular reflection on the mango. LED bulbs were used rather than compact fluorescent (CFL) bulbs because they did not produce any flicker effect. This allowed each captured image to have a constant luminance which simplifies the process of identifying and analyzing the mango. A plane reflected mirror was mounted on the conveyor with the angle of 65° from the conveyor surface. This mirror provides the side view of the mango, hence allowing the side view to be captured by the camera.

Each mango was placed on white background tray which enhanced the contrast between the object and the background. These trays traveled from loading area to capturing platform and finally to the sorting area by means of a conveyor. The conveyor was designed with a closed loop rectangular path system. The camera has a frame rate up to 60 frames per second (fps) which allows the image to be captured as if it was in a static state. Movement of the conveyor and the actuator was controlled by the computer using the Compact-RIO module (National Instruments, Austin, TX, USA).

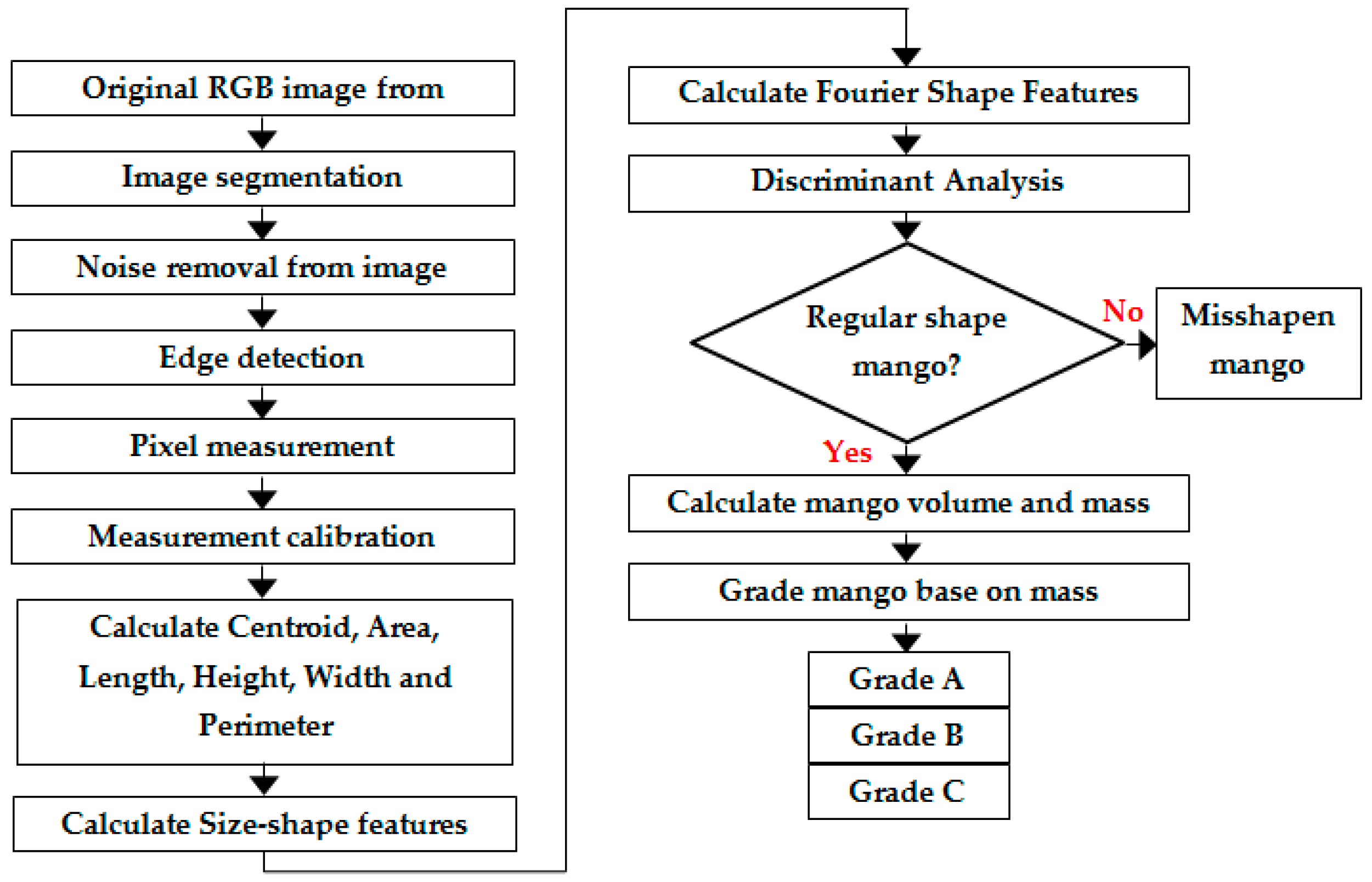

A data flow programming language or known as G-language was developed along with the graphical user interface (GUI) to control the movement of the conveyor and capture the images of the mangoes. The program was constructed and written specifically for this application by optimizing the parallel programming capability of the software to control the hardware and process the data simultaneously. All important steps involved in detecting shape regularity and volume estimation of mango are shown in

Figure 2. The first step was for image acquisition and pre-processing. The second step was for pixel measurement which then used for measurement calibration. The third step was for calculating the physical features extraction such as centroid, area, length, width, height and perimeter. The fourth step was for calculating the size-shape features and Fourier-shape features. Two most important steps were the stepwise discriminant analysis stage and the volume and mass estimation stage. Discriminant analysis was used to select the most important features that can determine the shape regularity of the mango. The misshapen shape mangoes were classified as reject while the regular shape mangoes were analyzed again to determine its volume and mass. Then the mangoes were graded into three grades according to their mass.

2.2. Image Acquisition

Each tray has a RFID card which was used for tray identification and data validation at every station. As soon as a tray is detected by the RFID reader at the image capturing platform, the program will trigger the camera to capture the images. The 2-megapixel camera can capture a high-quality image with a resolution of 1600 pixels × 1200 pixels. The drawback of the high-quality image was the time taken for the data to be transferred to the computer—which can take up to 1 s. This duration is intolerable when developing a rapid online system. By reducing the resolution to 1600 pixels × 850 pixels, it only takes 300 ms to capture and transfer the image data packets.

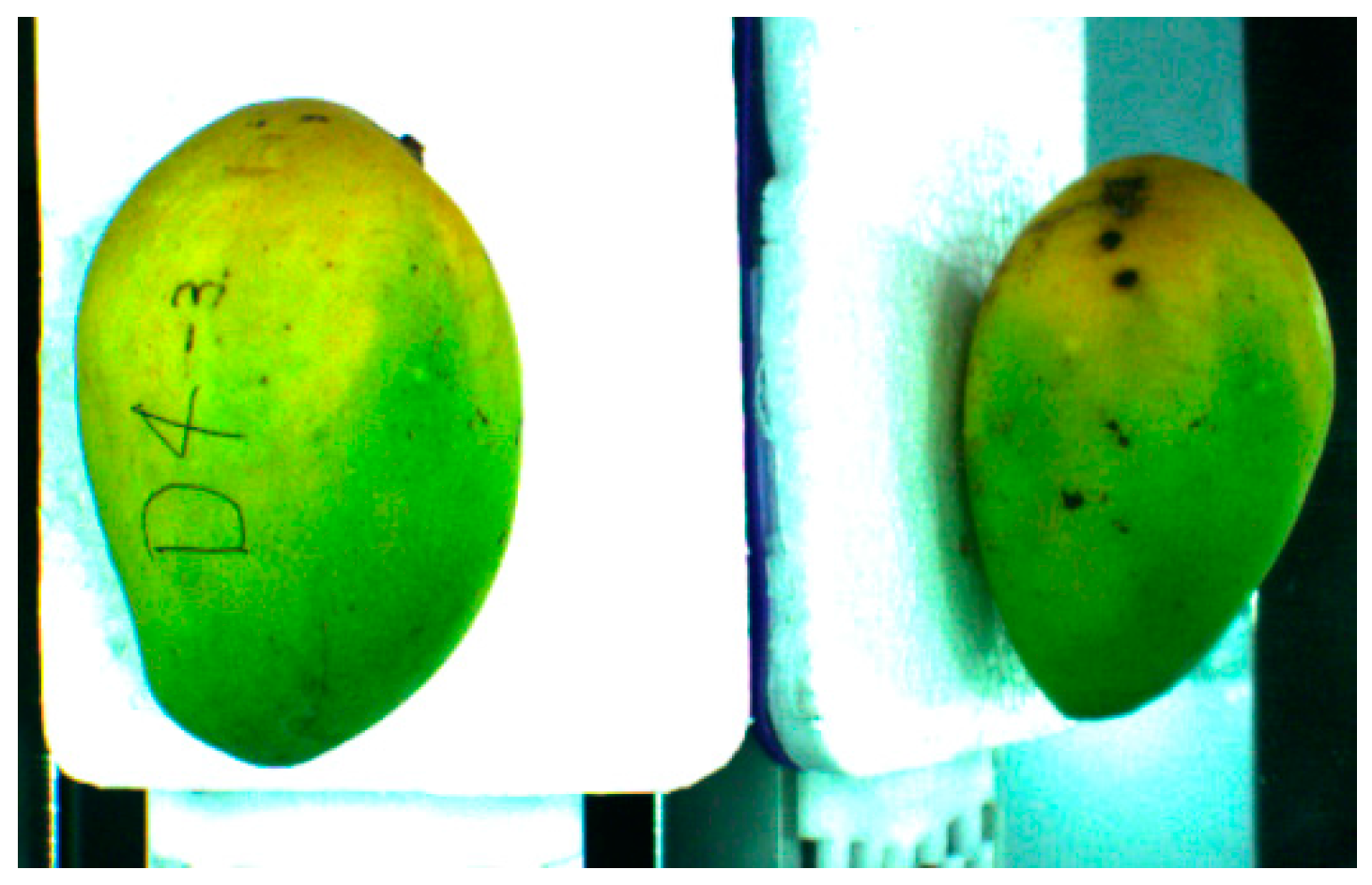

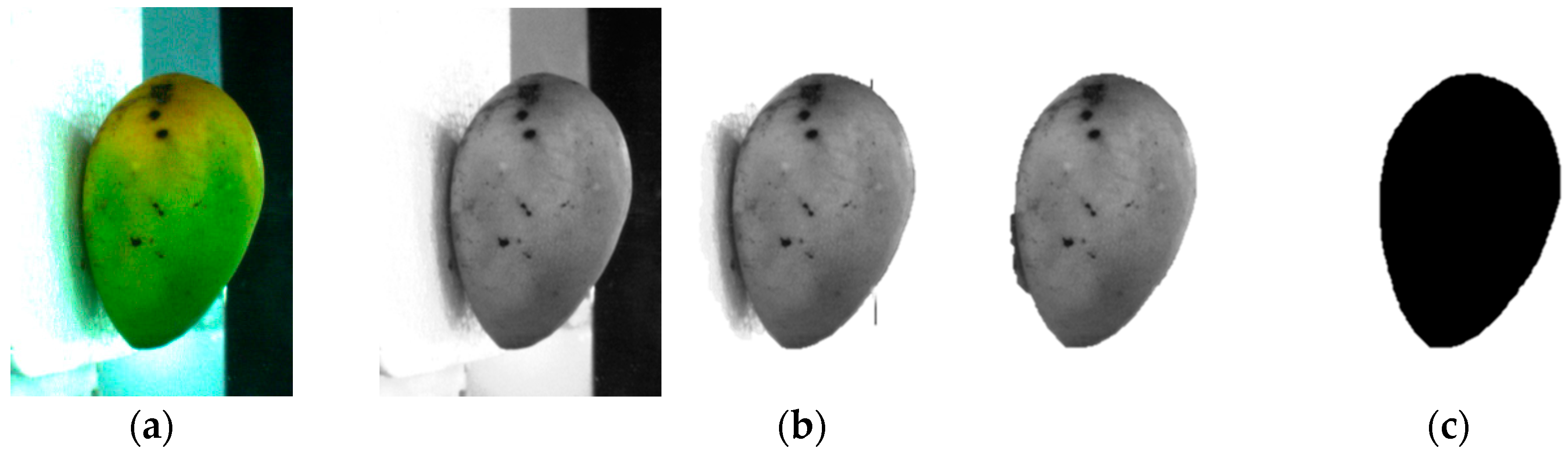

The conveyor did not stop during the acquisition, and the tray traveled along the conveyor with a speed of 0.8 m/s. In each acquisition, two objects were seen in the image which was the view from the top and the view from the side of the mango as in

Figure 3. This was the major achievement of the system which reduced the usage of camera and time needed to obtain two different views at the same time. The side view of mango was obtained from the image reflected by the mirror. The information of each mango was stored in the buffer and tagged with the ID number of the RFID card in their respective tray.

2.3. Image Pre-Processing

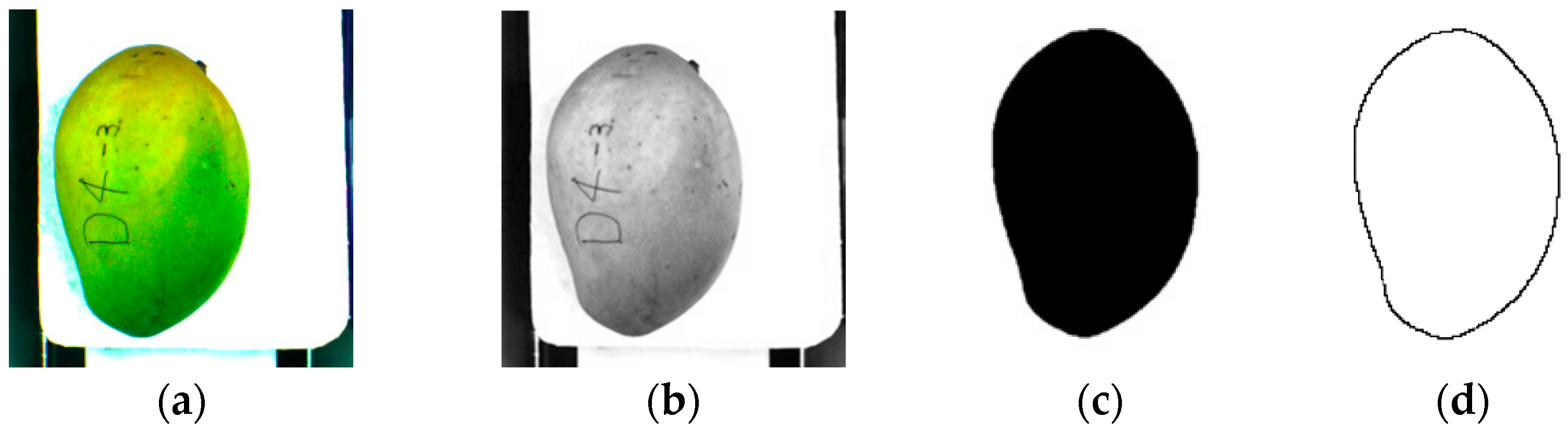

At first, a segmentation process was done to separate the mango from the background. The image was split into two parts. The first part shows the top view of the mango while the second part shows the side view of the mango. The images need to be separated as the pre-processing method is different for each of them. The top view image of a mango has high contrast and very low noise. The white background has high R, G and B values in RGB coordinate while the mango has a low value of B. The original image was converted to a grayscale image by extracting the B value of the image as in

Figure 4b. The B value has a range of 0 to 255. From the grayscale image, the multiple global threshold technique was used to eliminate the background and the stem [

17]. Pixel values less than 90 were converted to 0 (black) and pixel values higher than 90 were converted to 255 (white) [

12]. Another threshold value was selected to eliminate the stem, which pixel values in the range of 0 to 20 were converted to 255 (white). Dark spots and dirt on the mango, and the conveyor belt outside the tray area can produce some random noise on the image. A small particle removal method was used to remove any small connected components that have lower pixel values than a predefined value. This method only retained the large object which was the mango. An image fill holes algorithm was used to fill any holes inside the mango area which might form during elimination of the dark spot and dirt. The resulting image was in binary format image as in

Figure 4c, where the white areas represent the background and the dark areas represent the object which is the mango.

Figure 4d shows the shape boundary of the mango after a thinning process [

18]. The Fourier descriptor method was then used to analyze the shape of mango for any abnormalities by using the thinning image.

The side view image has low contrast as it is the reflection from the mirror. Furthermore, some amount of shadow was seen from the side view as the mango obstructs the light from above. An additional pre-processing step was needed to eliminate the shadow and obtain the shape of the mango. Three repetitive global thresholds, first on the B band, second on G band and last on the B band with different threshold values were applied. A median filter of size 7 pixels × 7 pixels was used to remove the boundary of the shadow [

19]. The binary image was used to crop the original images for the next global threshold step.

Figure 5c shows the final image after the correction process.

2.4. Measurement Calibration

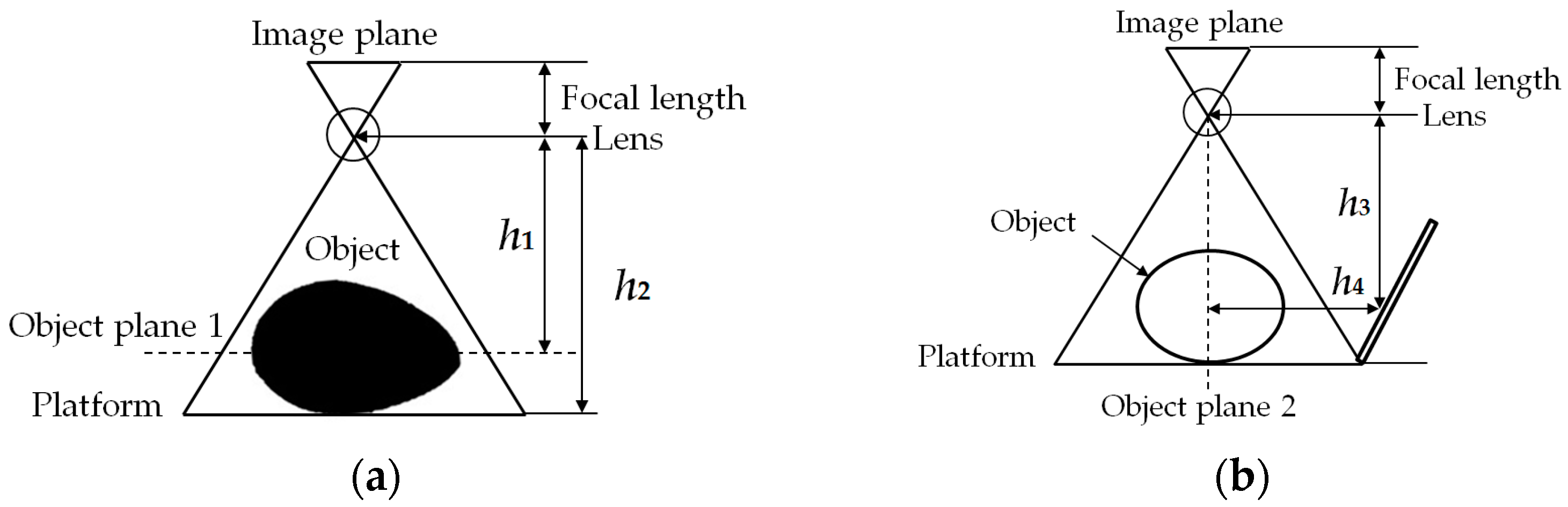

Measurement calibration was determined using the scale of aerial photograph model. Cohen [

20] explained that the scale of aerial photograph is a function of the flying height of the camera and focal length of the camera. It is most referred to as the conversion between the number of units on the ground and the equivalent unit of distance on the photograph. This model can be applied in this research with some modification as the working method for both of them is similar. The model uses focal length of a lens to calculate the magnification of distant object with no image distortion. The equation model as in Equation (1), calculates the object size by using the product of image size (pixels), pixel size, and the distance between the camera lens and object plane then divides it by the focal length of the lens.

Figure 6 shows the concept of scale magnification used in this research.

Koc [

12] in his research indicated that as the size of the object increased, the volume estimated by the image processing was exaggerated. This phenomenon was caused by the change in distance of the object from the camera. Koc calibrated the measurement only once during his research which contributed to the error. In order to eliminate this error, the calibration was done in each image capturing process. The first step was to obtain the height of the mango from the side view image. The calibration for the side view image was done only once as the height between the camera and the mirror was constant as in

Figure 6b. Mango placement was always in the center of the platform. One of the characteristics of the plane mirror is that the distance between the object and the mirror is identical to the distance between the image and the mirror. Hence, the reflected image was calibrated by combining the distance from the camera to mirror and mirror to object (

h3 + h4) to get the total distance. The result then was used to calculate the height of the object plane 1, which was the height of the major length of the mango. Distance from camera to the platform,

h2 was deducted with the previous height to obtain the distance from camera to the object plane 1,

h1. The final equation for each calibration is shown in Equations (2) and (3):

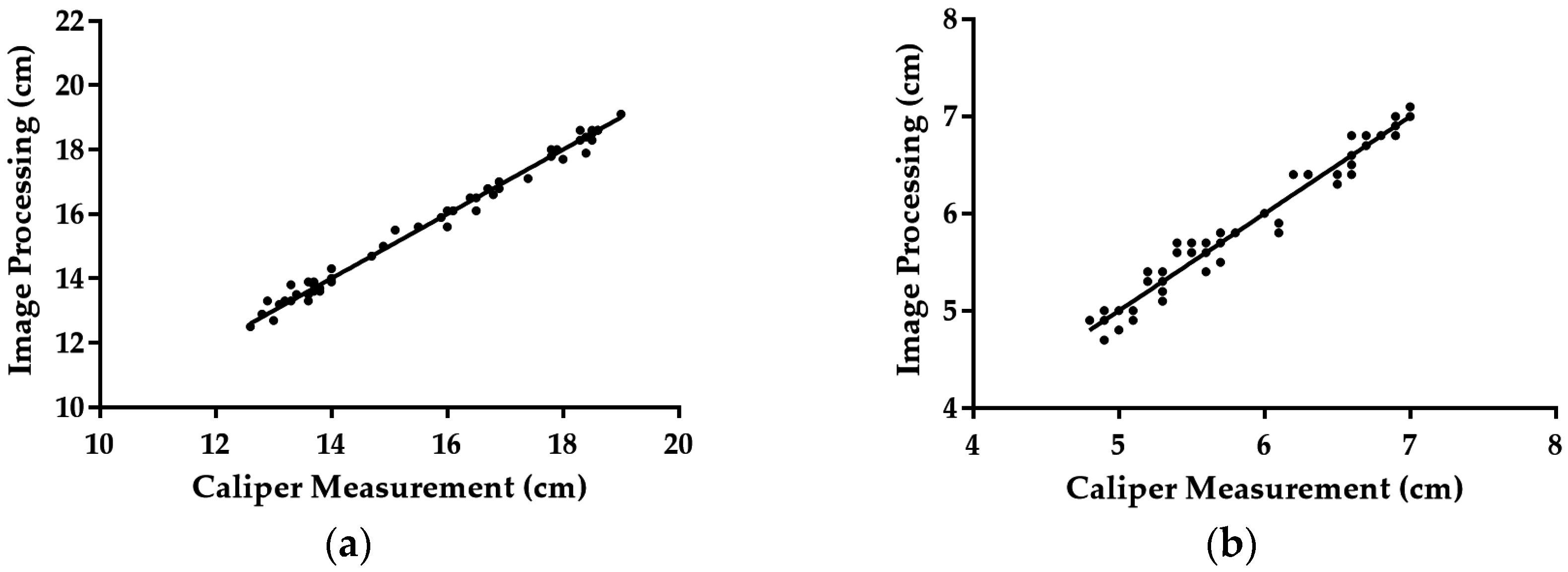

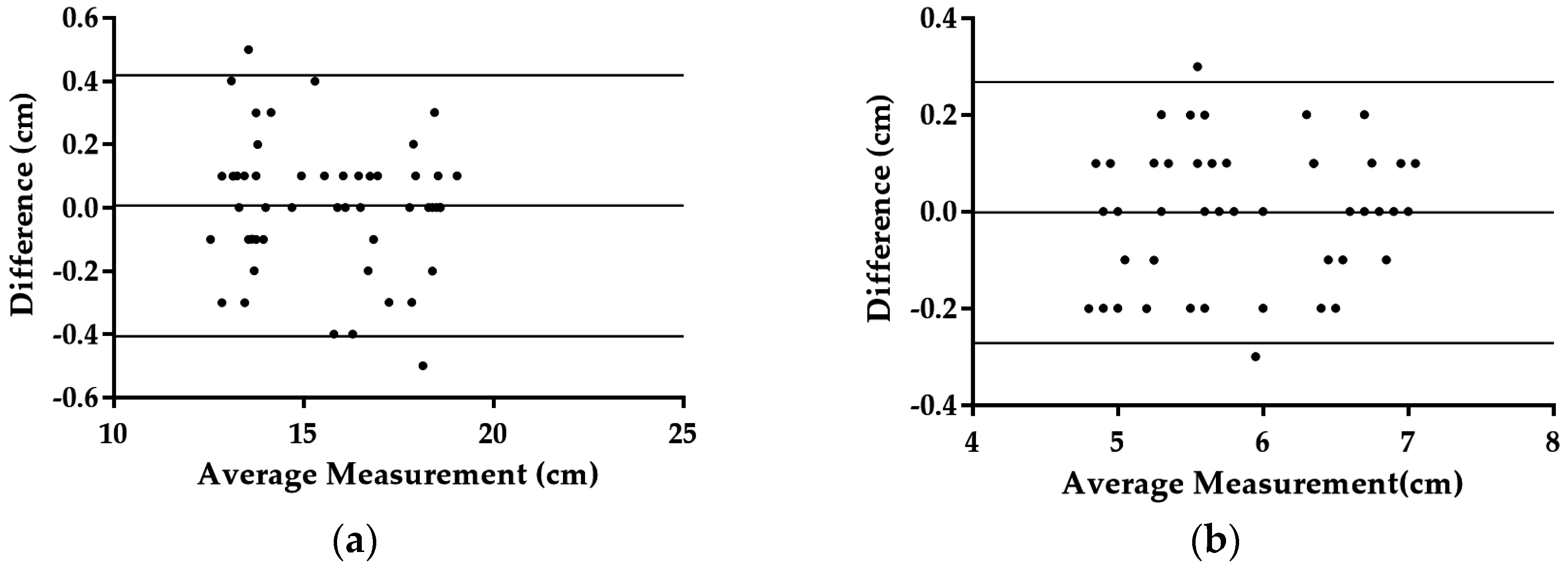

Paired

t-test and mean difference confidence interval approach were used to compare the length and height measured using image processing and caliper. The paired

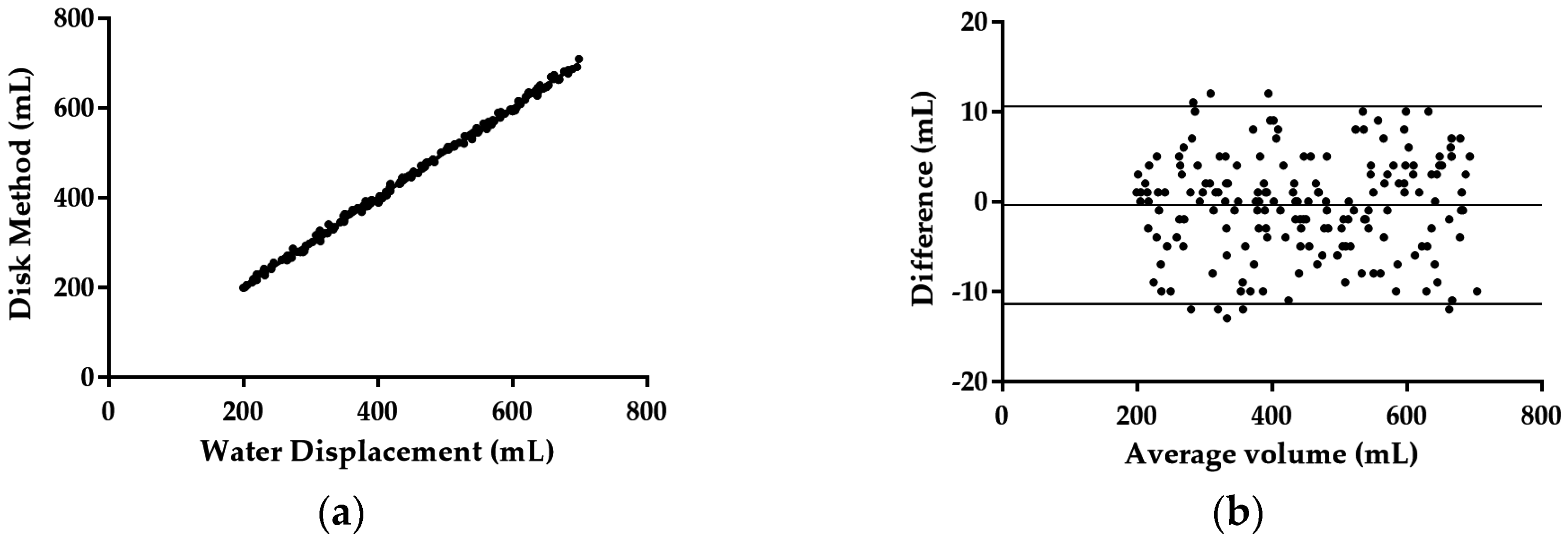

t-test was used to identify the significant difference between the caliper measurement and image processing method. Bland-Altman approach [

21] was used to plot the agreement between both dimension measured by caliper and image processing. Both of the statistical analyses have also been used to find the difference and agreement of the volumes measured using water displacement and the disk method in the later stages of the research. The statistical analyses were performed using GraphPad Prism (GraphPad Software, Inc., La Jolla, CA, USA).

2.5. Shape and Fourier Features Extraction

There are many methods to analyze the shape of an object. Elmasry [

22] stated that a combination of measurement features such as perimeter, area, width, and length are used in the conventional method of shape description. In this research, aspect ratio, area ratio, and roundness were used for features measurement. Equation (4) to Equation (6) show the formulas used to obtain the stated feature measurements:

Another method is using the Fourier descriptor (FD). This method has been used widely to analyze the shape of agricultural products. Agricultural products that have been using this method are including mango [

23,

24], potato [

22] and pistachio nut [

25]. The first step of FD is to find the two-dimensional centroid (X

c,Y

c) which is given by using mathematical equation as in Equations (7) and (8):

N represents the total number of pixel boundaries which defined in a clockwise direction. (X

k,Y

k) are the coordinates of each boundary pixel,

k. After the centroid value is obtained, the distance of each boundary point to the centroid was calculated using Equation (9).

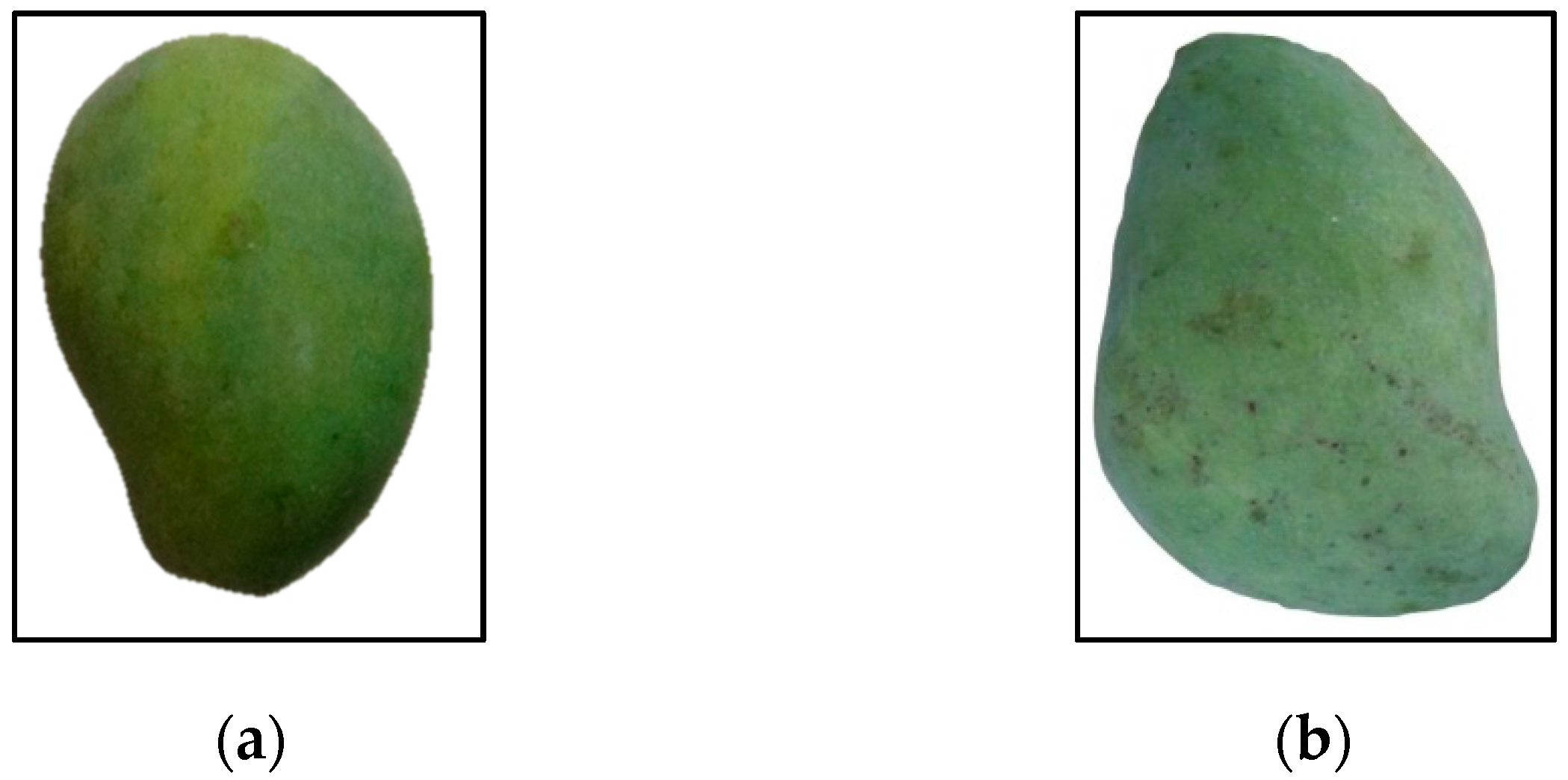

Figure 7 shows the sample of regular and misshapen mango while

Figure 8 shows the distance signature R(k) of the regular and misshapen mango.

ElMasry [

22] linearly normalized the boundary profile to 512 distance points for equal level of comparison.

Figure 8b shows the normalized boundary profile for the mango. The R(k) is then subjected to Discrete Fourier Transform (DFT), yielding a one-dimensional feature vector of the Harumanis mango. Then the transformation is mathematically implemented in the Fourier space using Equation (10):

The descriptors are influenced by the curve shape and the initial point of the curve. Thus, calculating and examining each harmonic component in

provides an indication of the shape. The plot of Fourier descriptors produces a pattern or fingerprint which uniquely describes this shape. In theory, the order of Fourier descriptors ranges from zero to infinity [

26]. Hence, only the first few segments of

are recognizable and generally required to discriminate the difference between mango shapes. In order to extract the information of the shape effectively, a method of harmonics, F(m) multiplied by its magnitude, m was used to obtain the boundary profile of the mango. F(m) × m can be interpreted as the derivative of the boundary signature while F(m) × m

2 is the curvature of the boundary [

22]. The increase power value of h from 1 to 3 contributed to a significant improvement of the higher frequency component which shows the detailed noise in the profile. Hence, parameter S

1, S

2 and S

3 were calculated from the Fourier descriptor using first 10 harmonics to express the shape of mango as in Equation (10) to Equation (13):

2.6. Volume and Mass Evaluation Using Image Processing

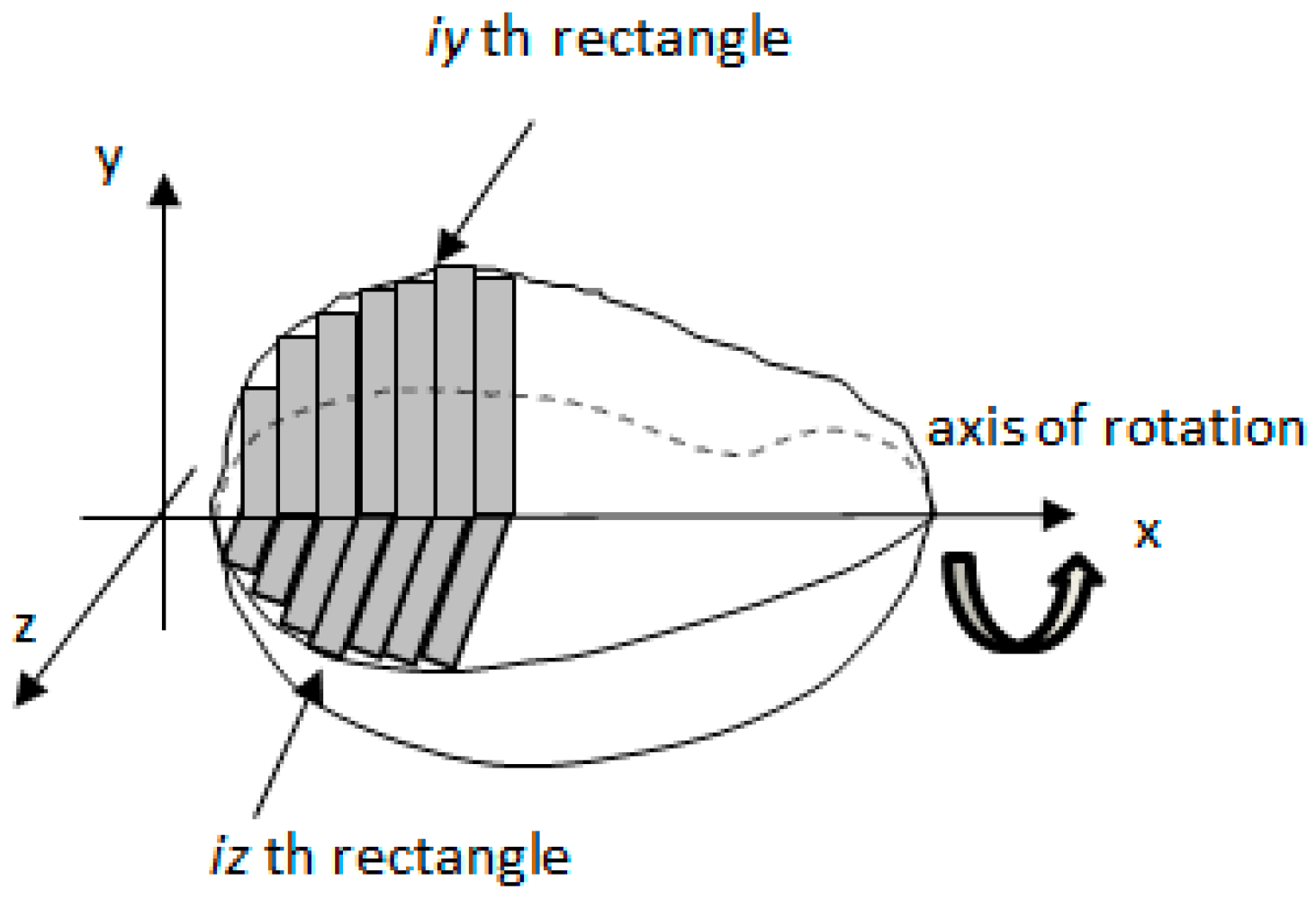

The boundary of the side view image and top view image was used to calculate the total volume of the mango by using the disk method [

27]. Images of the regular mango were calculated for its volume while images of the misshapen mango were discarded. Both mangoes boundary image were combined to obtain a three-dimensional measurement. Each three-dimensional outline image was considered to be the sum of individual rectangular elements as shown in

Figure 9. A cylindrical disk with elliptic shape was produced by revolving each rectangular element around the x-axis as shown in

Figure 10.

The volume of each disk calculated by using Equations (14) and (15). Equation (14) shows the volume, V

i, of one cylindrical disk while Equation (15) shows the cross-sectional area, A

i, of the same disk:

A program was developed using the LabVIEW platform to calculate the area, volume, and sum of all disks volumes. An algorithm was used to obtain the measurements of the mango using the boundary image. Each cylindrical disk was considered to have a thickness of 1 pixel. Based on the diameter of the major axis and minor axis, the volume of each disk was calculated. The total sum value of these volumes was used to obtain the estimated volume by using Equation (16):

The total volume was then used to calculate the mass of each regular mango. The regular mango was categorized into its grade based on the standard set by the Perlis Agriculture Department as in

Table 1. Grade A is the highest grade of mango which mass is more than 400 g, while grade B mass is between 351 g and 399 g. Mangoes which mass are lower than 350 g are categorized as grade C. The mangoes were pre-classified into these grades and the results from the grading system were evaluated.

4. Conclusions

In this work, an image processing techniques to classify Harumanis mangoes based on shape and mass analysis were developed and presented. An image capturing platform was designed and constructed to obtain the images from two different viewpoints. The platform has also been used to test the algorithm’s ability to classify mangoes based on their shape. An algorithm was developed to grab and process the mango images in real time while the mangoes travel along the high-speed conveyor. Stepwise discriminant analysis was used to identify the most effective shape parameters for detecting misshapen mangoes. Three parameters calculated from the Fourier descriptor of the boundary signature of mangoes along with the area ratio size-shape parameters were identified to be effective in describing mango shapes. The in-line assessment of the proposed method showed that the accuracy for detecting mango shapes was 98%.

Another algorithm was developed to automatically calibrate the mango measurement each time a new image was captured. The method used the known distance from the camera to the object plane and related information which extracted from the image. The information was then used to determine the exact measurement of the mango. The relation between the caliper measurement and image processing measurement was high where the R2 values for the length and height measurement were 1.000 and 0.993, respectively.

Next the algorithm was used to determine the mass of the mango. Top and side views of mango were used to estimate the mango volume by using the disk method. The volume estimated using the disk method was compared with the volume measured using the water displacement method. The difference between the volumes estimated using this technique was not statistically significant (P > 0.05). The estimated volume was then used to estimate the mass of the mango. The R2 value between the estimated volume and actual mass was high (R2 = 0.94), thus indicating that there was a strong relationship between those two values. A prediction model was fitted with this algorithm to estimate the mass and tested on the in-line system. The classification result showed an accuracy of 94% when grading mangoes.

From the results, it can be concluded that the proposed integration between Fourier-shape parameters and size-shape parameters was very effective in classifying the mango shape. The combination between an image calibration method, volume estimation method, and mass estimation method has been helpful to classify mangoes according to their grade. This system can be applied at an industrial scale but some modifications need to be done. The image processing method can be improved in order to detect other features such as bruises, defects, cuts and disease. The process of image acquisition could be sped up by adding a frame grabber to the system.