Self-Powered WSN for Distributed Data Center Monitoring

Abstract

:1. Introduction

2. Related Work

3. Thermoelectric Harvesting

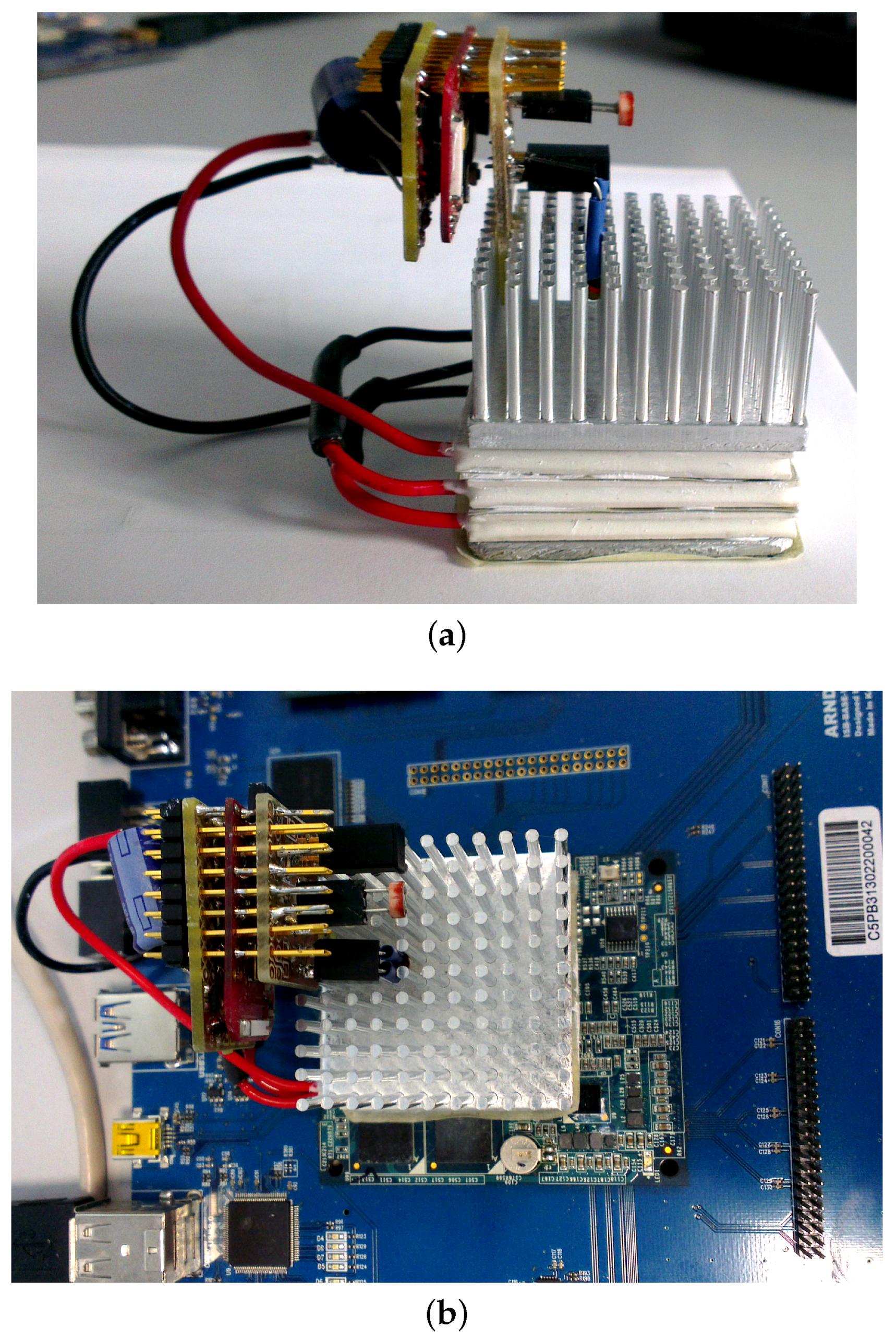

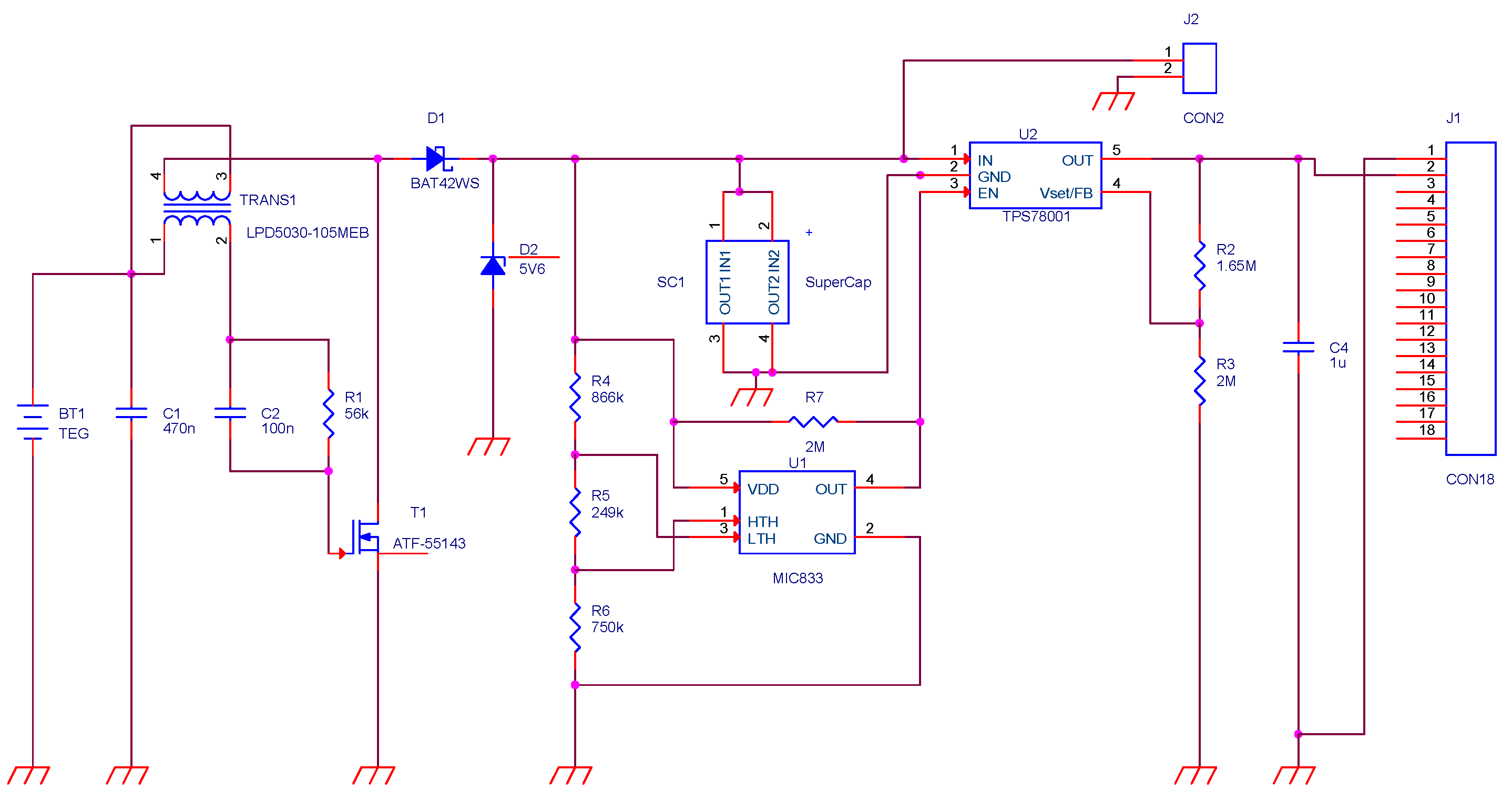

3.1. Conditioning Hardware

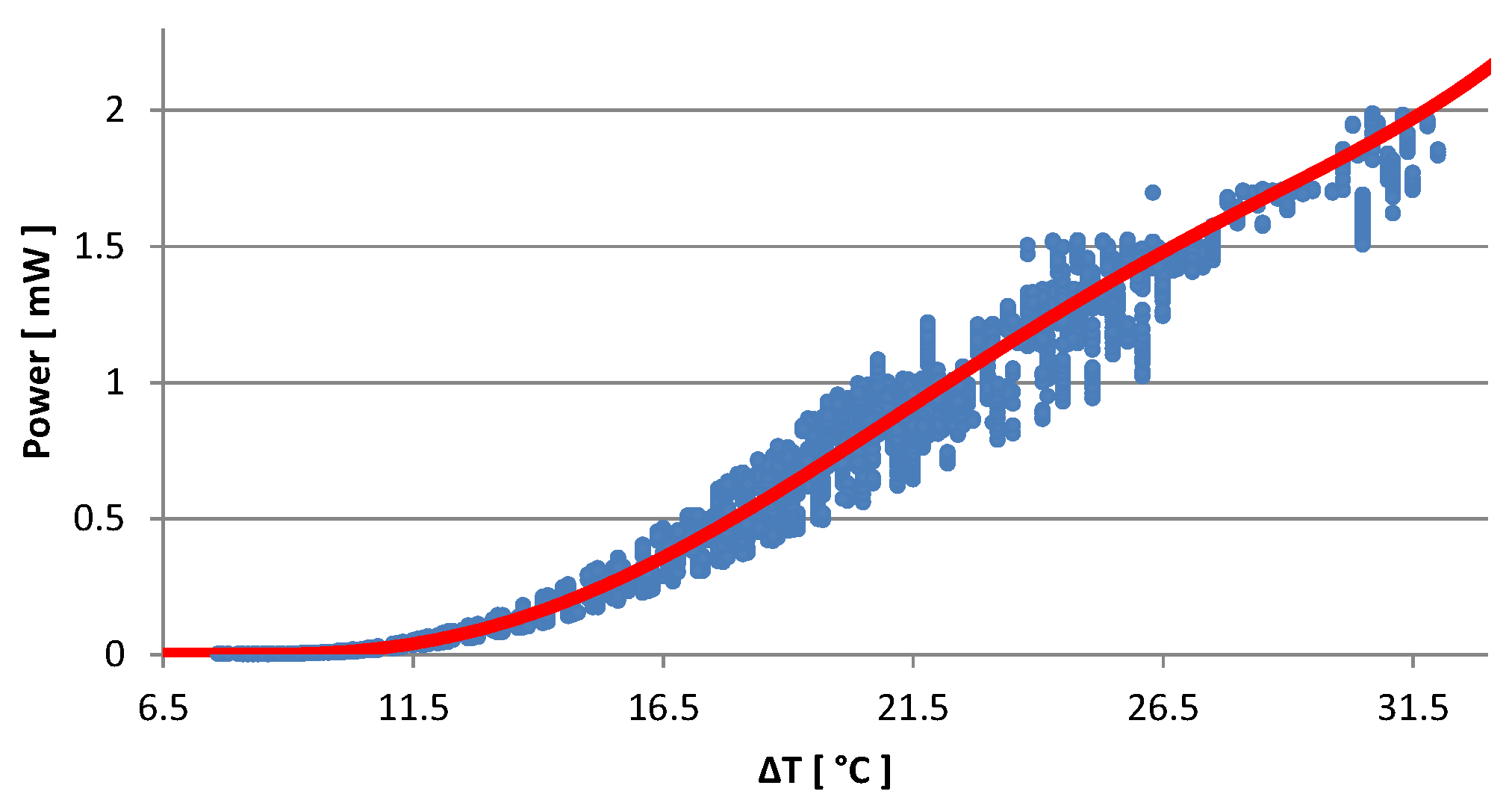

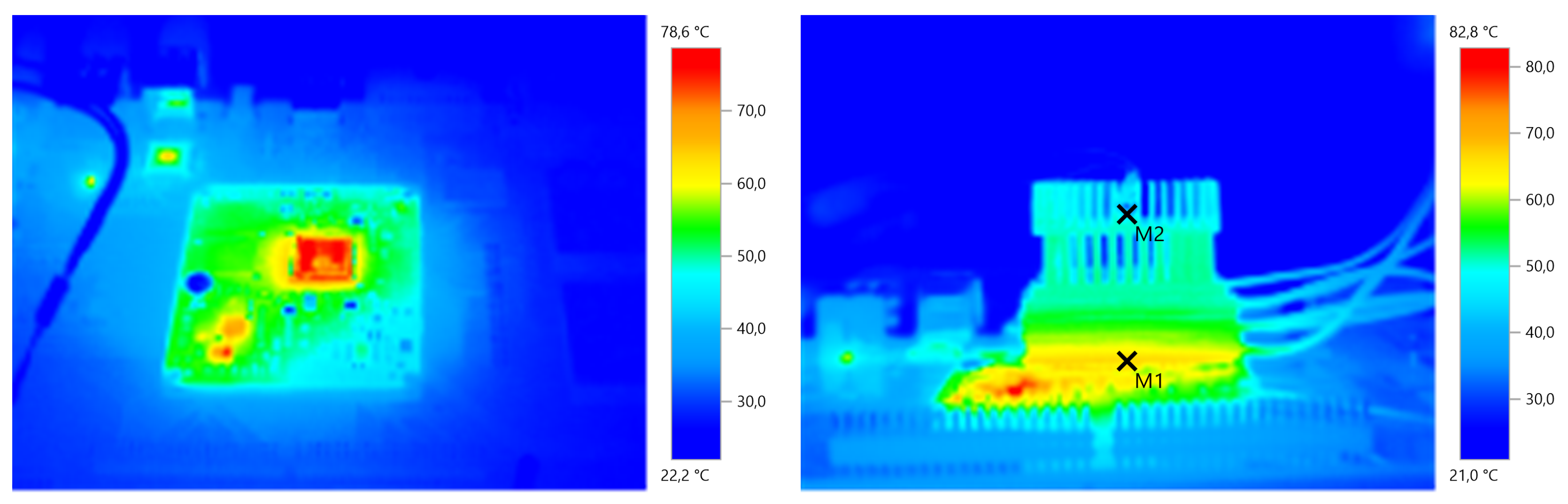

3.2. Harvester Characterization

4. Case Study

4.1. Prototype Design

4.2. Prototype Development

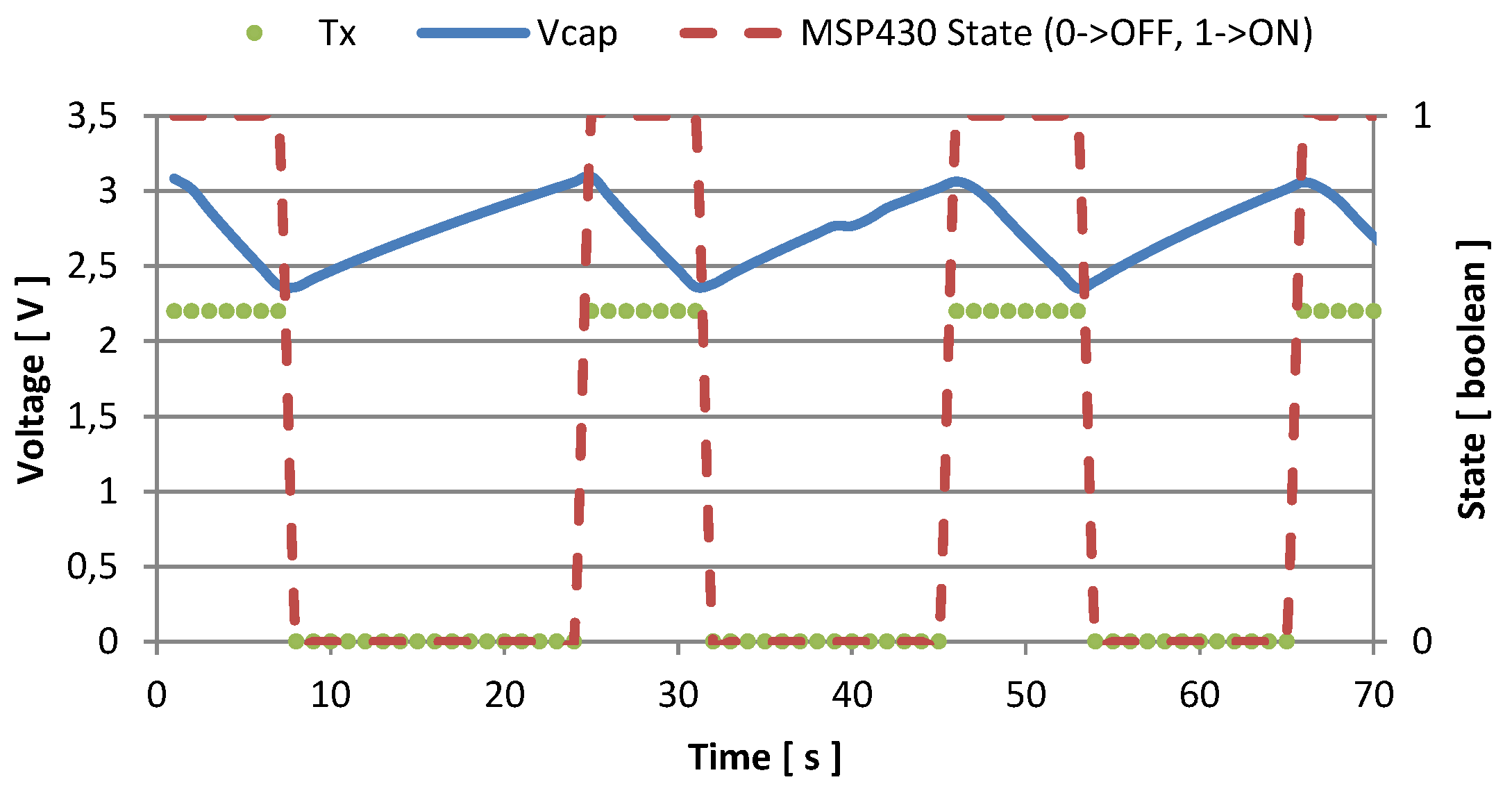

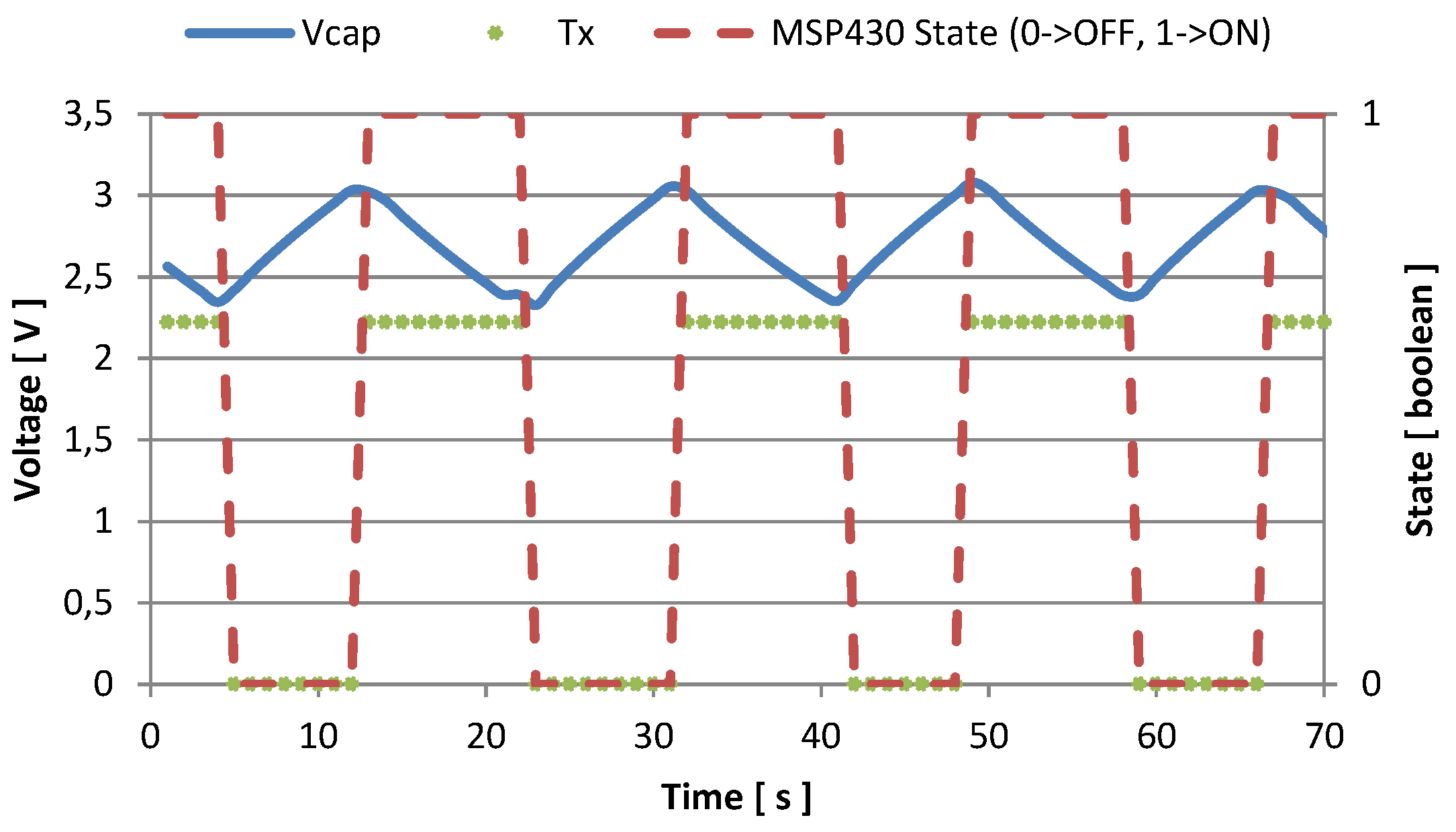

- Fixed time:

- in this implementation is fixed, and set equal to one second in our experiments. Therefore, if the supercapacitor contains enough power to supply the node, the node continuously transmits with a constant data rate;

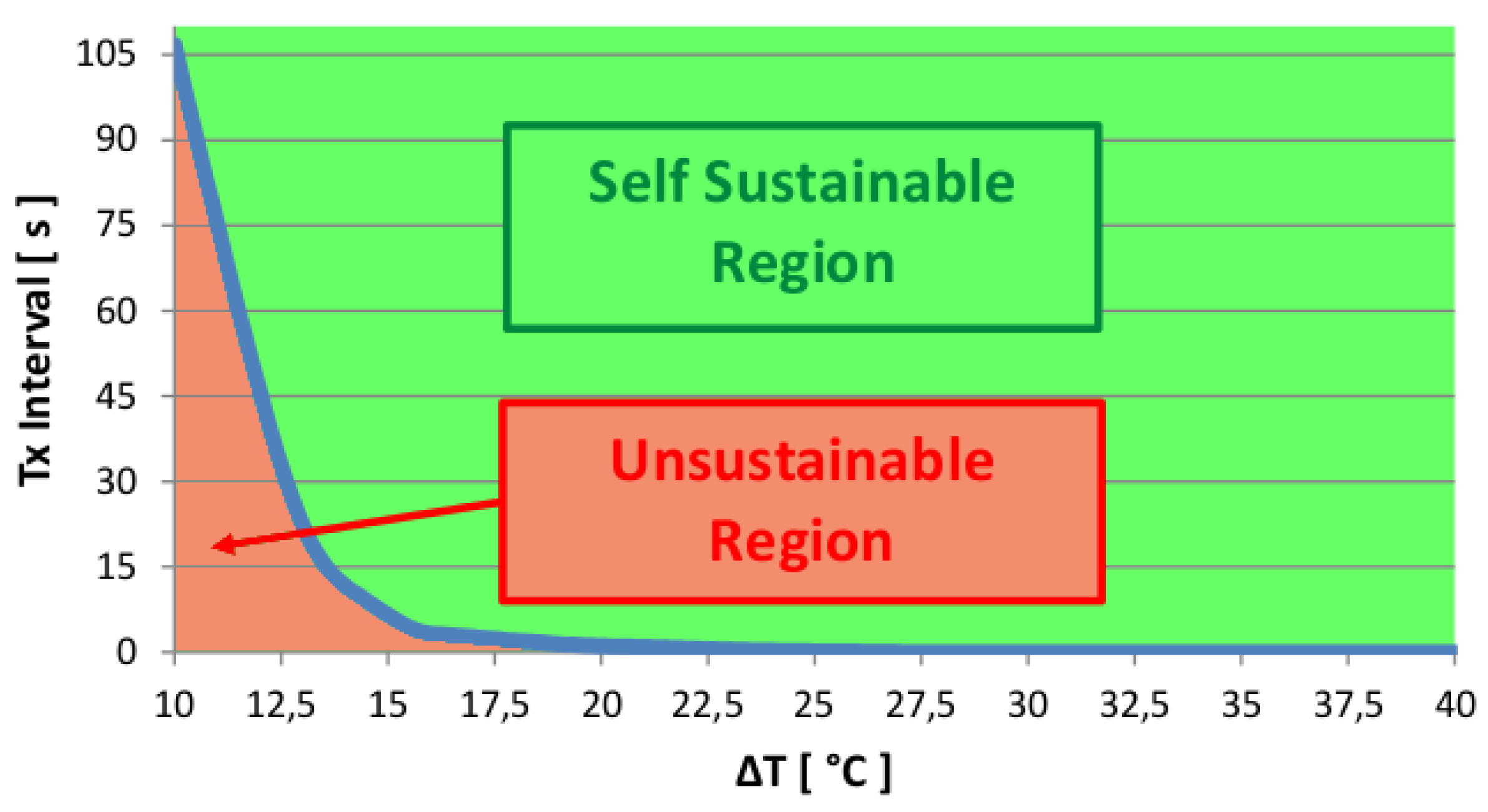

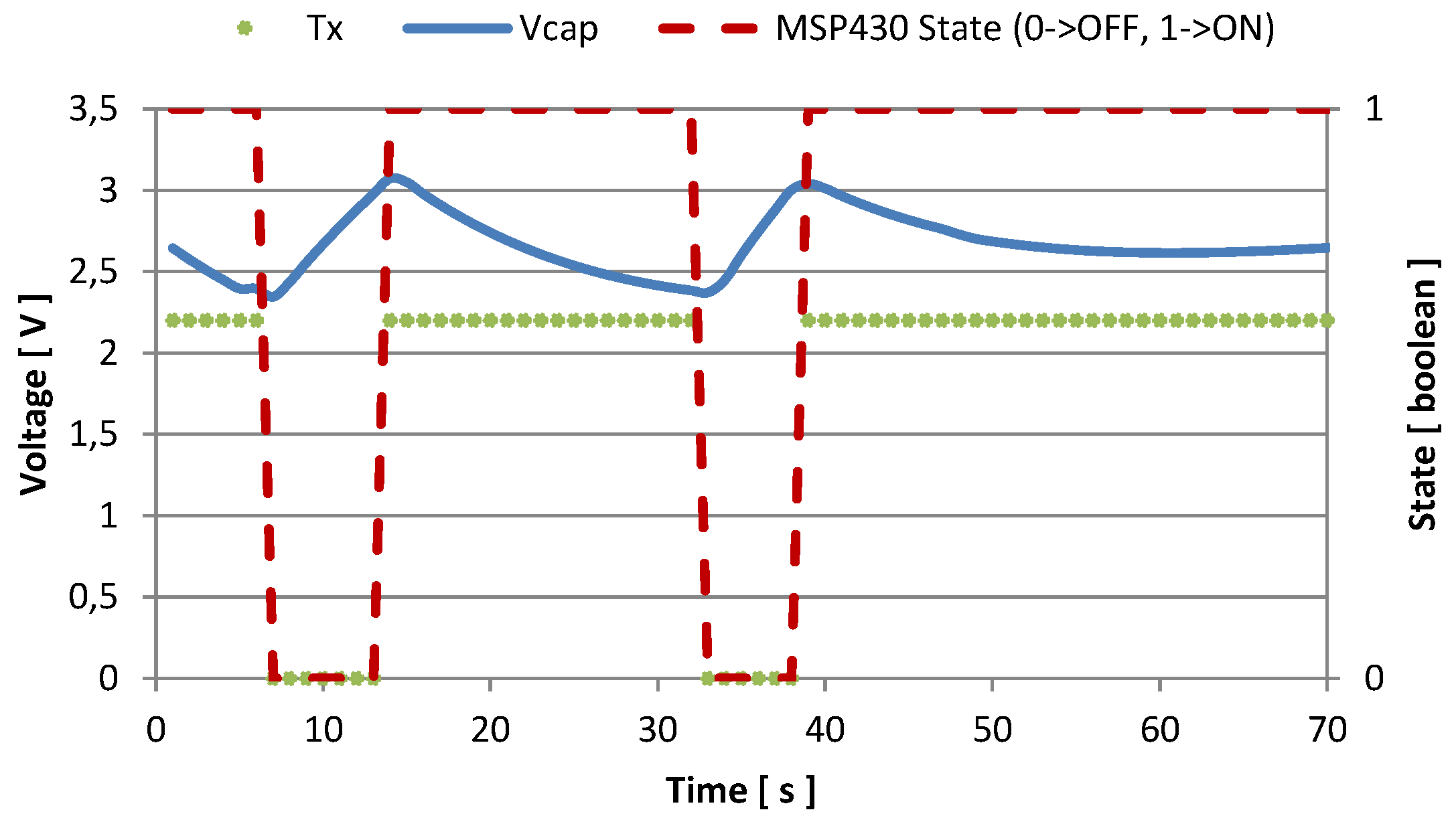

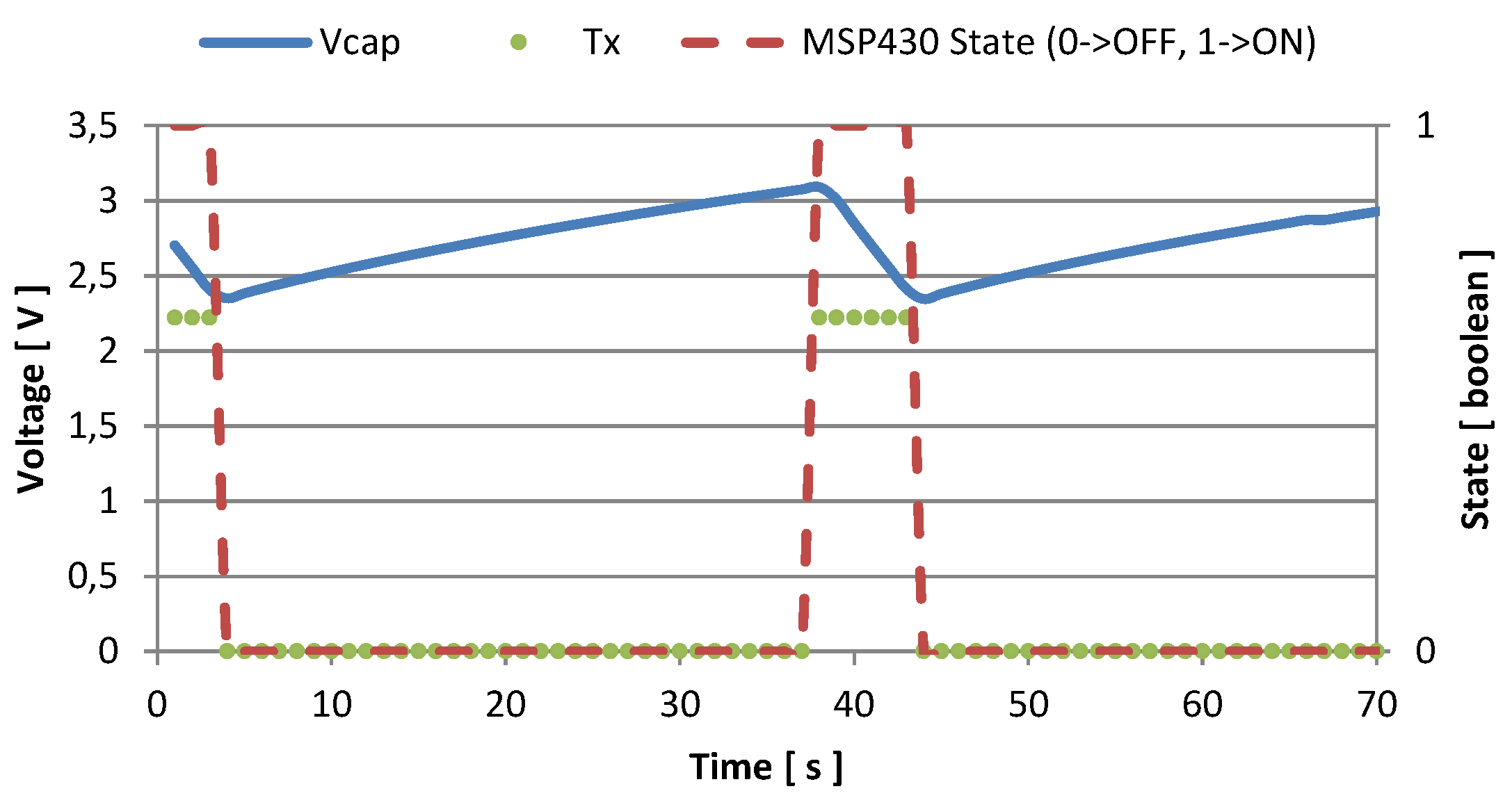

- Temperature dependent:

- in the second implementation, the time between two successive transmissions is chosen by the sensor node according to the temperature measured on the heat sink of the harvester, which provides an indication of the amount of scavenged energy, used to estimate an optimal communication interval as described below.

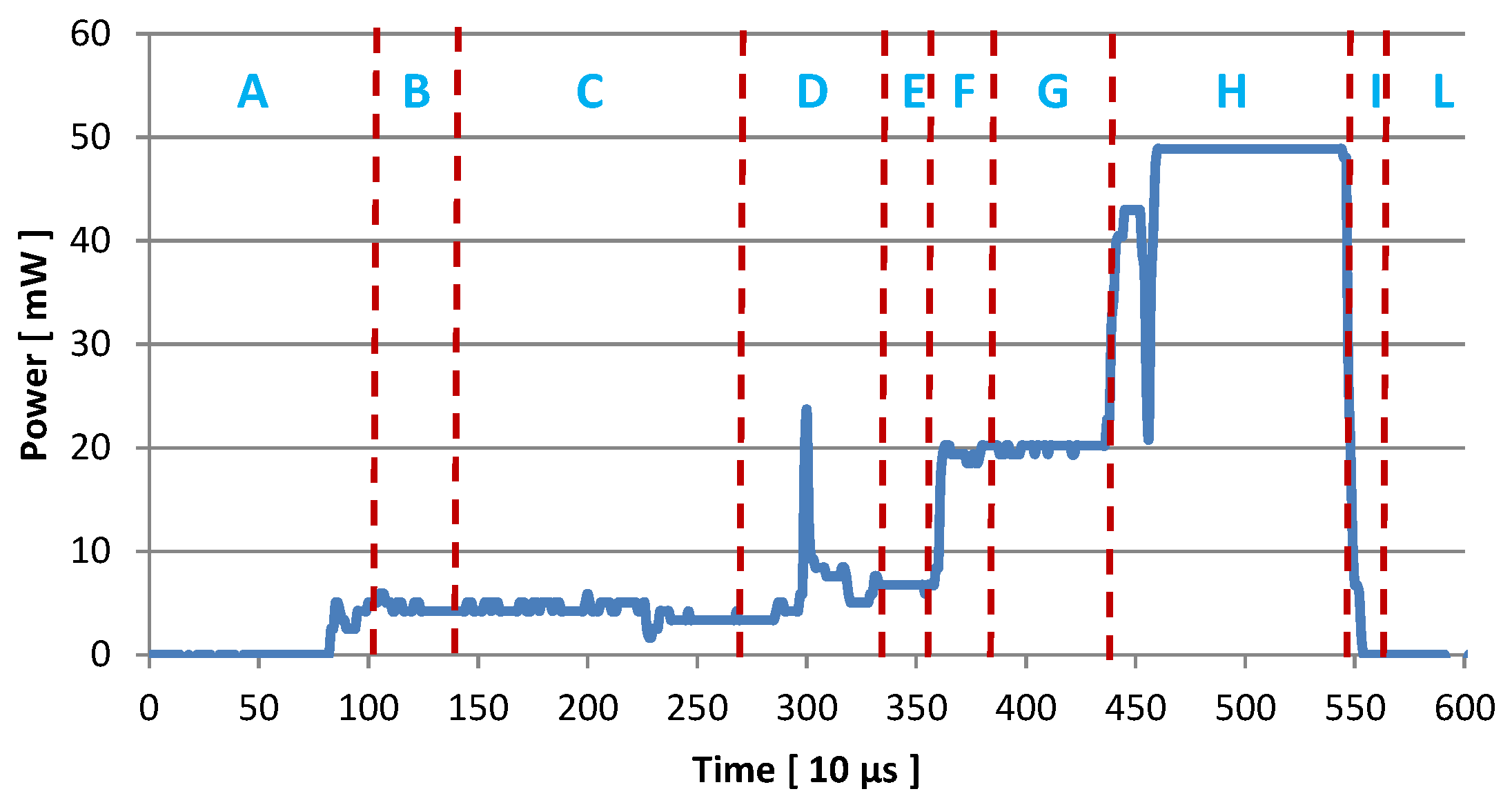

| Symbol | Event | mA | Time ms | P mW | E μJ |

|---|---|---|---|---|---|

| A-L | Idle | - | - | - | |

| B | Temp & Vcc | 1.94 | 0.38 | 4.26 | 1.61 |

| C | NTC Temp | 1.94 | 1.37 | 4.26 | 5.83 |

| D | Calc & XOSC Startup | 2.56 | 0.70 | 5.63 | 3.94 |

| E | Ripple Counter | 3.02 | 0.21 | 6.64 | 1.39 |

| F-G | Msg & PLL calib. | 8.29 | 0.87 | 18.23 | 15.86 |

| H | Tx Mode | 20.95 | 1.19 | 46.09 | 54.84 |

| I | Switch LPM | 3.95 | 0.14 | 8.69 | 1.21 |

5. Results

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Press Release. IDC Finds Growth, Consolidation, and Changing Ownership Patterns in Worldwide Datacenter Forecast. IDC Corporate, 10 November 2014. Available online: http://www.idc.com/getdoc.jsp?containerId=prUS25237514 (accessed on 31 December 2015).

- The Guardian, 8 June, 2015. G7 Leaders Agree to Phase out Fossil Fuel Use by End of Century. Available online: http://www.theguardian.com/world/2015/jun/08/g7-leaders-agree-phase-out-fossil-fuel-use-end-of-century (accessed on 31 December 2015).

- Piper Jaffray CIO Survey. Technology, Media & Telecom 2015. Available online: https://piper2.bluematrix.com/sellside/EmailDocViewer?encrypt=7856c68e-3f1a-4ce9-a7e7-99fe25145cd9&mime=pdf (accessed on 31 December 2015).

- Amazon.com, Inc. (Amazon Web Services). Amazon Initiatives for Sustainable Energy. Available online: http://aws.amazon.com/it/about-aws/sustainable-energy/ (accessed on 31 December 2015).

- Google Inc. Google Green. Available online: http://www.google.com/green/ (accessed on 31 December 2015).

- Apple Inc. Environmental Responsibility. Available online: http://www.apple.com/environment/our-progress/ (accessed on 31 December 2015).

- Microsoft Corporation. Microsoft Environment. Available online: https://www.microsoft.com/environment/ (accessed on 31 December 2015).

- Rackspace Global. Understanding Our Environmental Impact. Available online: http://responsibility.rackspace.com/planet/energy/renewables (accessed on 31 December 2015).

- International Business Machines Corporation (IBM). Energy, the Environment and IBM. Available online: http://www.ibm.com/ibm/green/ (accessed on 31 December 2015).

- Microsoft Corporation. Data Center Genome Project. Available online: http://research.microsoft.com/en-us/projects/dcgenome/ (accessed on 31 December 2015).

- Dell Inc. OpenManage Power Center Temperature Monitoring. Available online: http://www.dell.com/support/article/us/en/19/SLN283321/EN (accessed on 31 December 2015).

- IDTechEx Ltd. Thermoelectric Energy Harvesting 2014-2024: Devices, Applications, Opportunities. Available online: http://www.marketresearch.com/IDTechEx-Ltd-v3153/Thermoelectric-Energy-Harvesting-Devices-Applications-8506004/ (accessed on 31 December 2015).

- Zervos, H. Energy Harvesting for Automotive Applications; IDTechEx: Cambridge, MA, USA, 2011; Available online: http://media.idtechex.com/pdfs/en/S2142B5538.pdf (accessed on 15 April 2015).

- Lee, S.; Phelan, P.E.; Wu, C.J. Hot Spot Cooling and Harvesting CPU Waste Heat Using Thermoelectric Modules. In Proceedings of the ASME 2014 International Mechanical Engineering Congress and Exposition, Montreal, QC, Canada, 14–20 November 2014.

- Jayakumar, S.; Reda, S. Making Sense of Thermoelectrics for Processor Thermal Management and Energy Harvesting. In Proceedings of the International Symposium on Low Power Electronics and Design, Rome, Italy, 22–24 July 2015.

- Rossi, M.; Rizzon, L.; Fait, M.; Passerone, R.; Brunelli, D. Energy Neutral Wireless Sensing for Server Farms Monitoring. IEEE J. Emerg. Sel. Top. Circuits Syst. 2014, 4, 324–335. [Google Scholar] [CrossRef]

- Zhou, Y.; Paul, S.; Bhunia, S. Harvesting Wasted Heat in a Microprocessor Using Thermoelectric Generators: Modeling, Analysis and Measurement. In Proceedings of the Design, Automation and Test in Europe, Munich, Germany, 10–14 March 2008; pp. 98–103.

- Gould, C.; Shammas, N.; Grainger, S.; Taylor, I. Thermoelectric cooling of microelectronic circuits and waste heat electrical power generation in a desktop personal computer. Mater. Sci. Eng. B 2011, 176, 316–325. [Google Scholar] [CrossRef]

- Rizzon, L.; Rossi, M.; Passerone, R.; Brunelli, D. Energy Neutral Hybrid Cooling System for High Performance Processors. In Proceedings of the 2014 International Green Computing Conference (IGCC), Dallas, TX, USA, 3–5 November 2014.

- Kiflemariam, R.; Lin, C.X. Numerical simulation and parametric study of heat-driven self-cooling of electronic devices. J. Therm. Sci. Eng. Appl. 2015, 7, 011008. [Google Scholar] [CrossRef]

- Rizzon, L.; Rossi, M.; Passerone, R.; Brunelli, D. Self-powered Heat-Sink SoC as Temperature Sensors with wireless interface: Design and validation. In Proceedings of the IEEE SENSORS 2014, Valencia, Spain, 2–5 November 2014; pp. 1575–1578.

- Gates, R. Data Center Physical Security Gets a Tougher Look. Available online: http://searchdatacenter.techtarget.com/news/4500248374/Data-center-physical-security-gets-a-tougher-look (accessed on 31 December 2015).

- Rodriguez, M.; Ortiz Uriarte, L.; Jia, Y.; Yoshii, K.; Ross, R.; Beckman, P. Wireless sensor network for data-center environmental monitoring. In Proceedings of the 2011 Fifth International Conference on Sensing Technology (ICST), Palmerston North, New Zealand, 28 November–1 December 2011; pp. 533–537.

- Excelitas Tech. Photoconductive Cell, VT900 Series. Available online: http://www.farnell.com/datasheets/612931.pdf (accessed on 31 December 2015).

- Oncque. DIP - RBS07 Series. Available online: http://www.oncque.com/05-tilt_switch.html?CID=1 (accessed on 31 December 2015).

- Vishay. NTCLE100E3 Datasheet. Available online: http://www.vishay.com/docs/29049/ntcle100.pdf (accessed on 31 December 2015).

- Texas Instruments. Mixed Signal Microcontroller. Available online: http://www.ti.com.cn/cn/lit/ds/slas504g/slas504g.pdf (accessed on 31 December 2015).

- Texas Instruments. CC2500 Low-Cost Low-Power 2.4 GHz RF Transceiver. Available online: http://www.ti.com.cn/cn/lit/ds/swrs040c/swrs040c.pdf (accessed on 31 December 2015).

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brunelli, D.; Passerone, R.; Rizzon, L.; Rossi, M.; Sartori, D. Self-Powered WSN for Distributed Data Center Monitoring. Sensors 2016, 16, 57. https://doi.org/10.3390/s16010057

Brunelli D, Passerone R, Rizzon L, Rossi M, Sartori D. Self-Powered WSN for Distributed Data Center Monitoring. Sensors. 2016; 16(1):57. https://doi.org/10.3390/s16010057

Chicago/Turabian StyleBrunelli, Davide, Roberto Passerone, Luca Rizzon, Maurizio Rossi, and Davide Sartori. 2016. "Self-Powered WSN for Distributed Data Center Monitoring" Sensors 16, no. 1: 57. https://doi.org/10.3390/s16010057