Design of a Hybrid (Wired/Wireless) Acquisition Data System for Monitoring of Cultural Heritage Physical Parameters in Smart Cities

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sensors

2.2. Wired Transmission Protocols

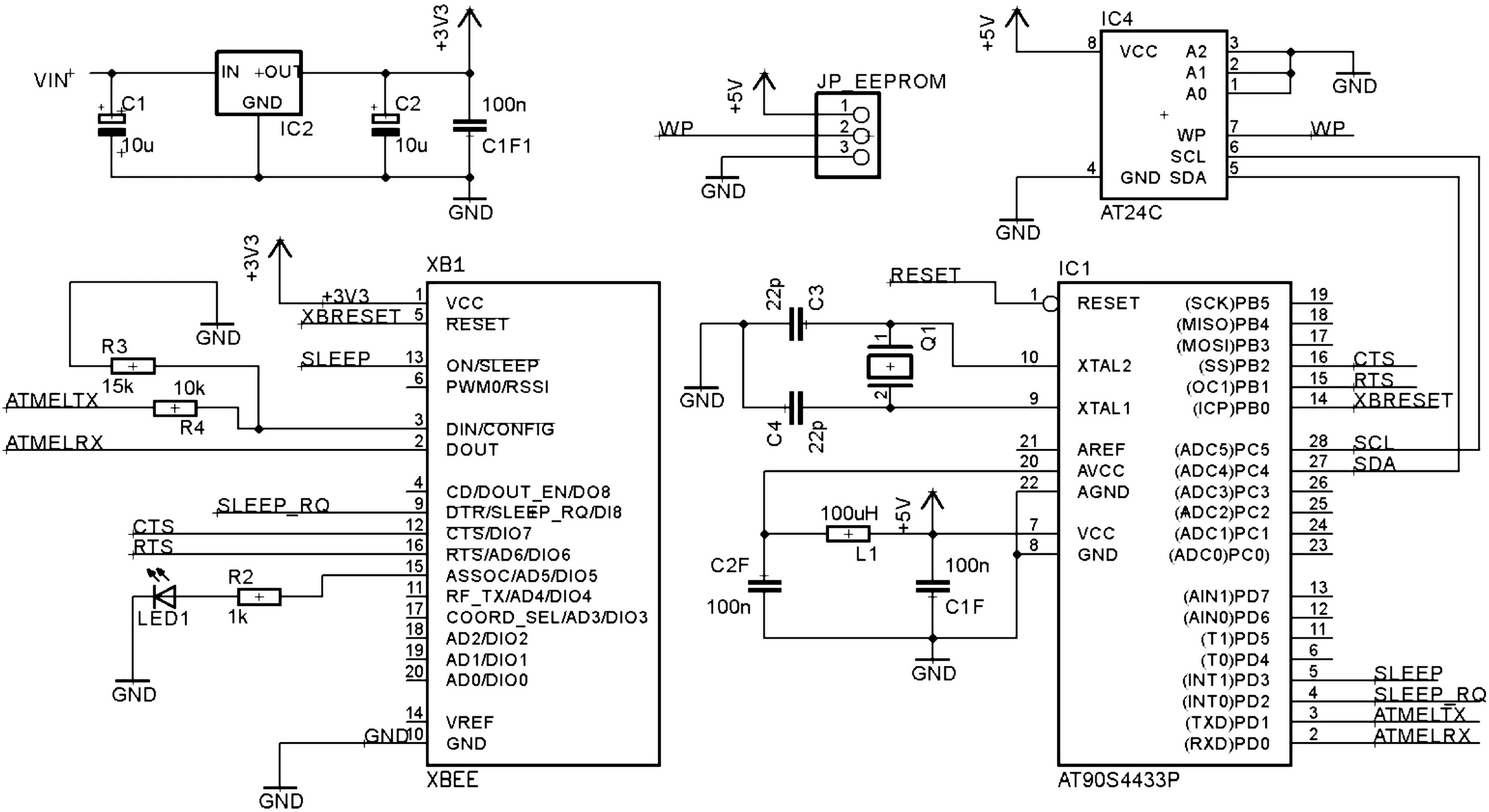

2.3. Wireless Transmission Protocol

2.4. Microcontroller ATmega328

2.5. External Clock

2.6. External USB Memory

2.7. DC Power Supply

2.8. The Failure Management

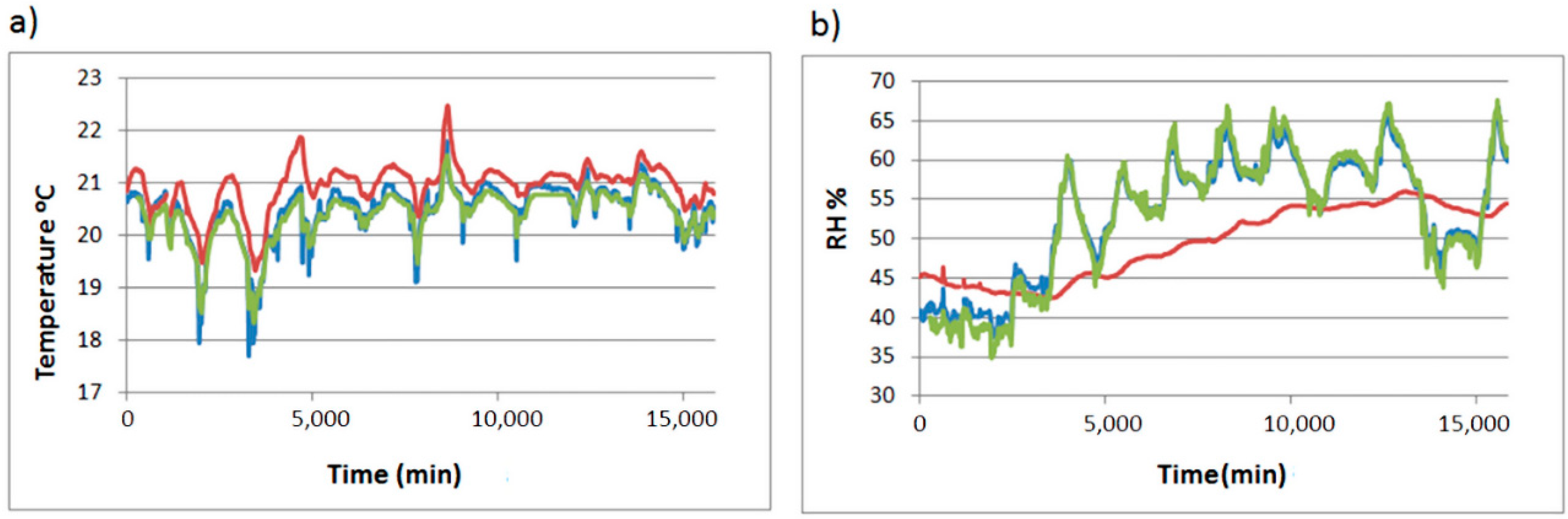

2.9. Description of the Testing Experiment

3. Design of Hardware and Software for the Data Monitoring System

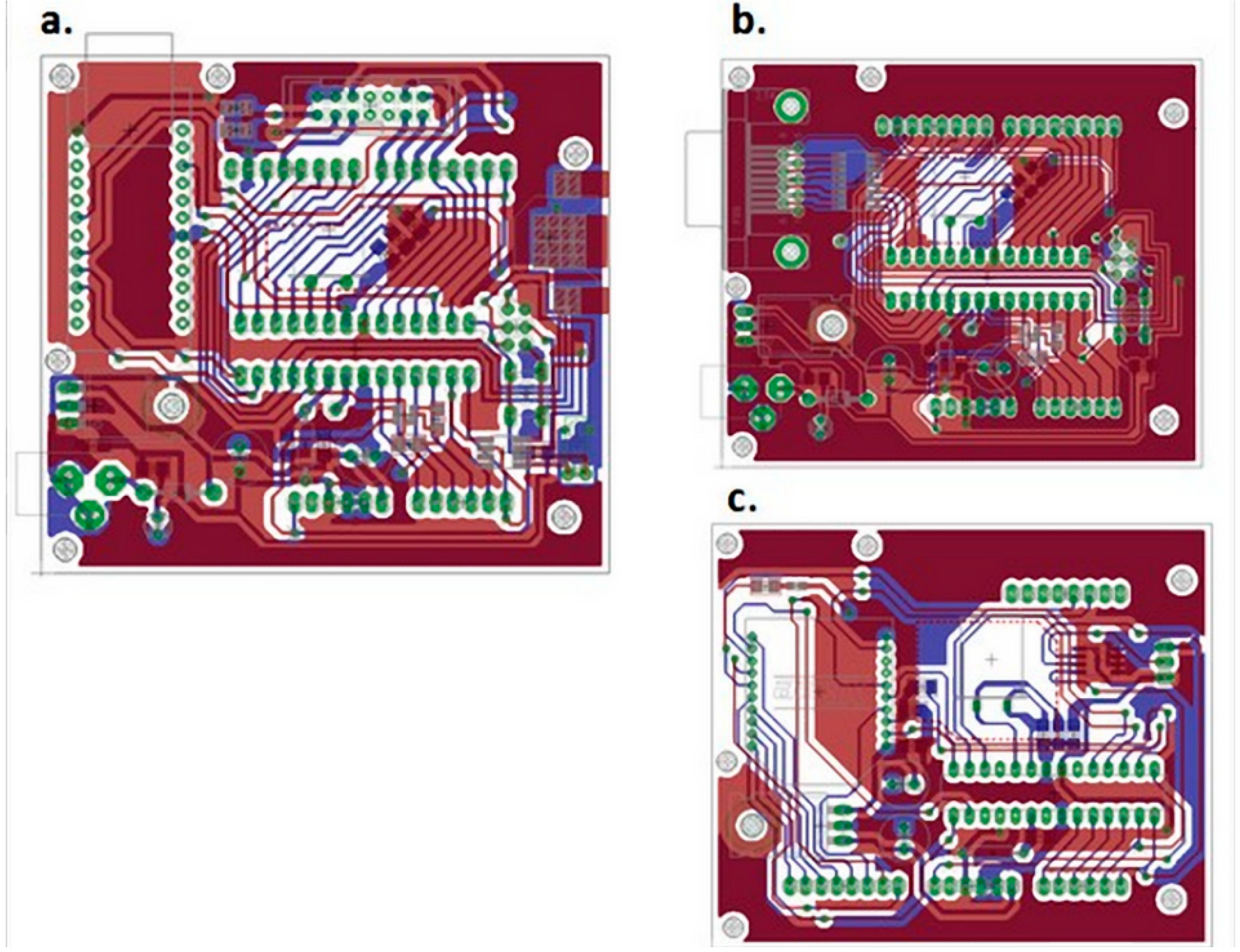

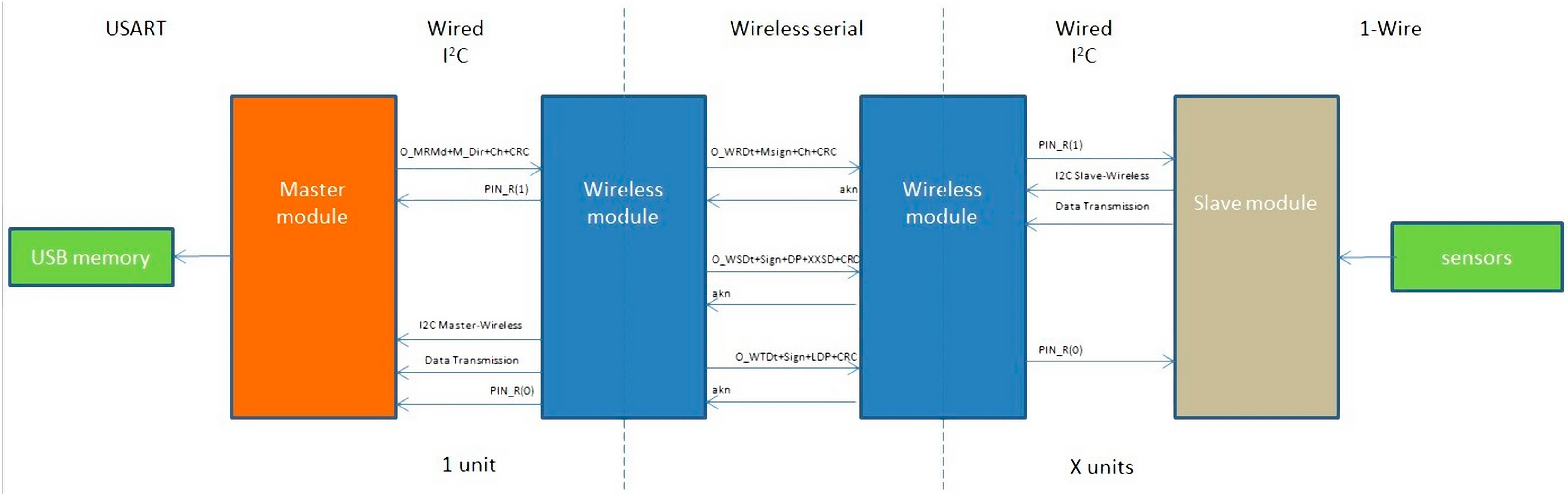

3.1. Design of Hardware for the Data Monitoring System

3.1.1. Design of the Power Track

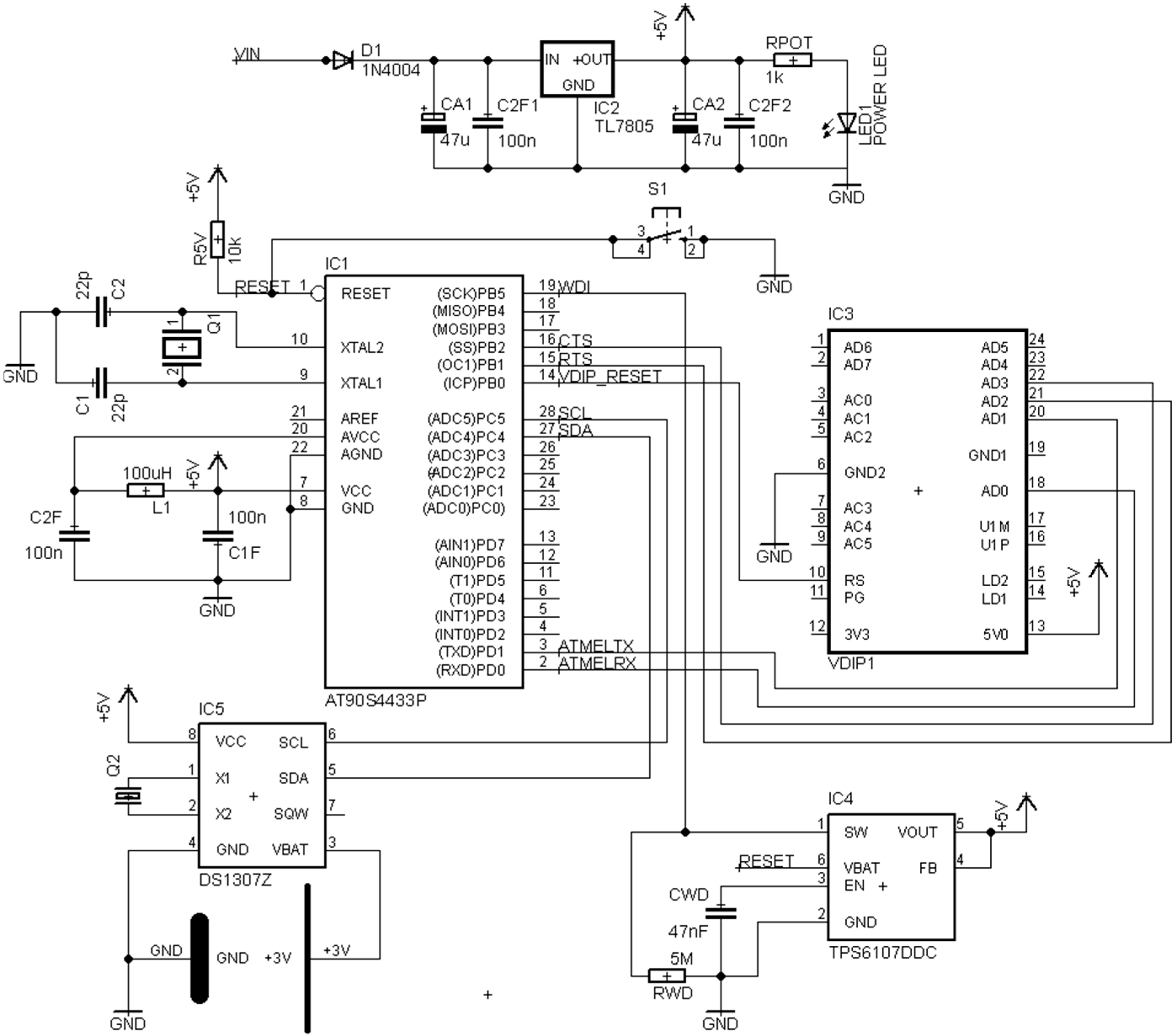

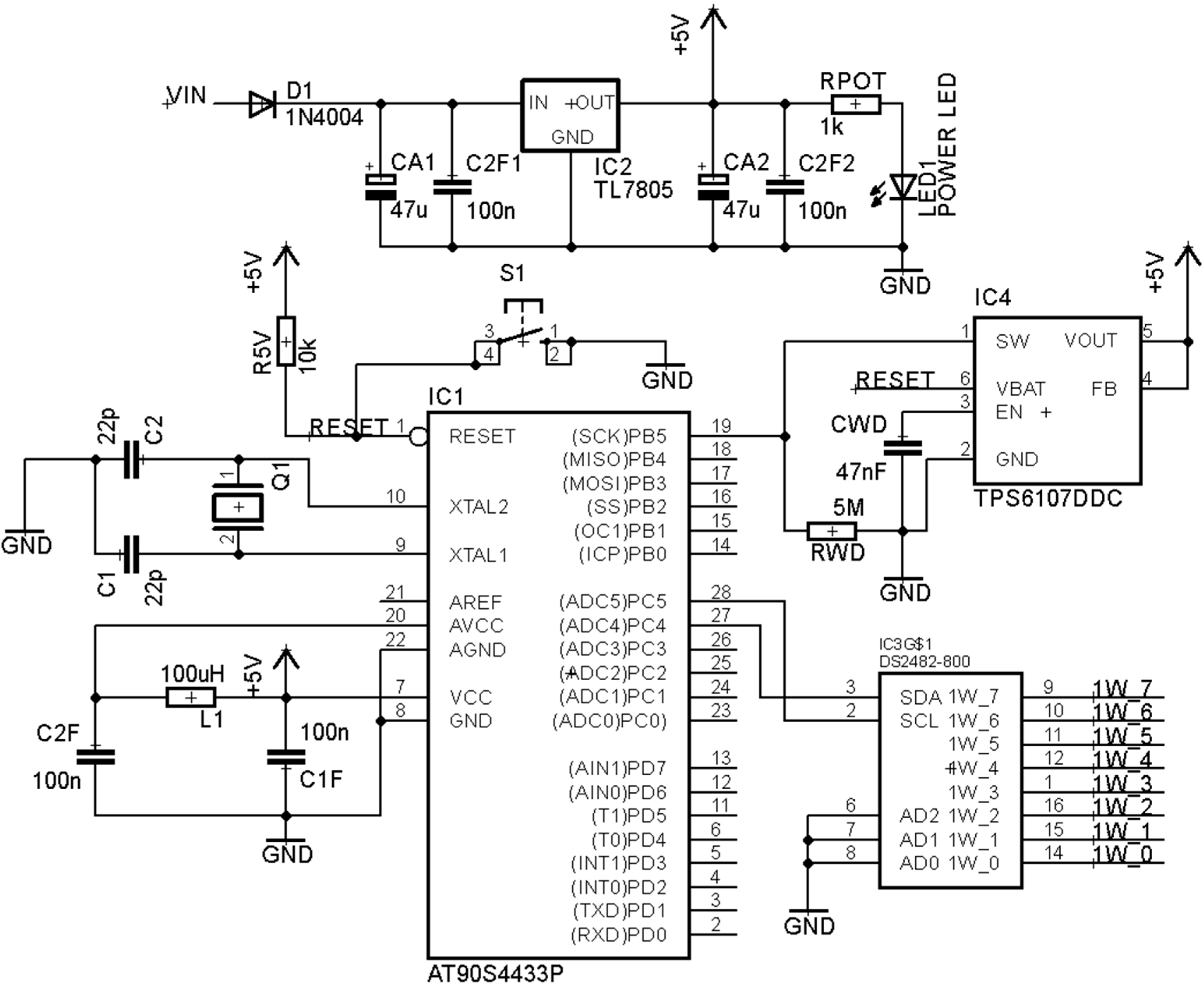

3.1.2. Final Boards and Schematics

3.1.3. External Clock

3.1.4. External USB Memory

3.2. Design of Software for the Data Monitoring

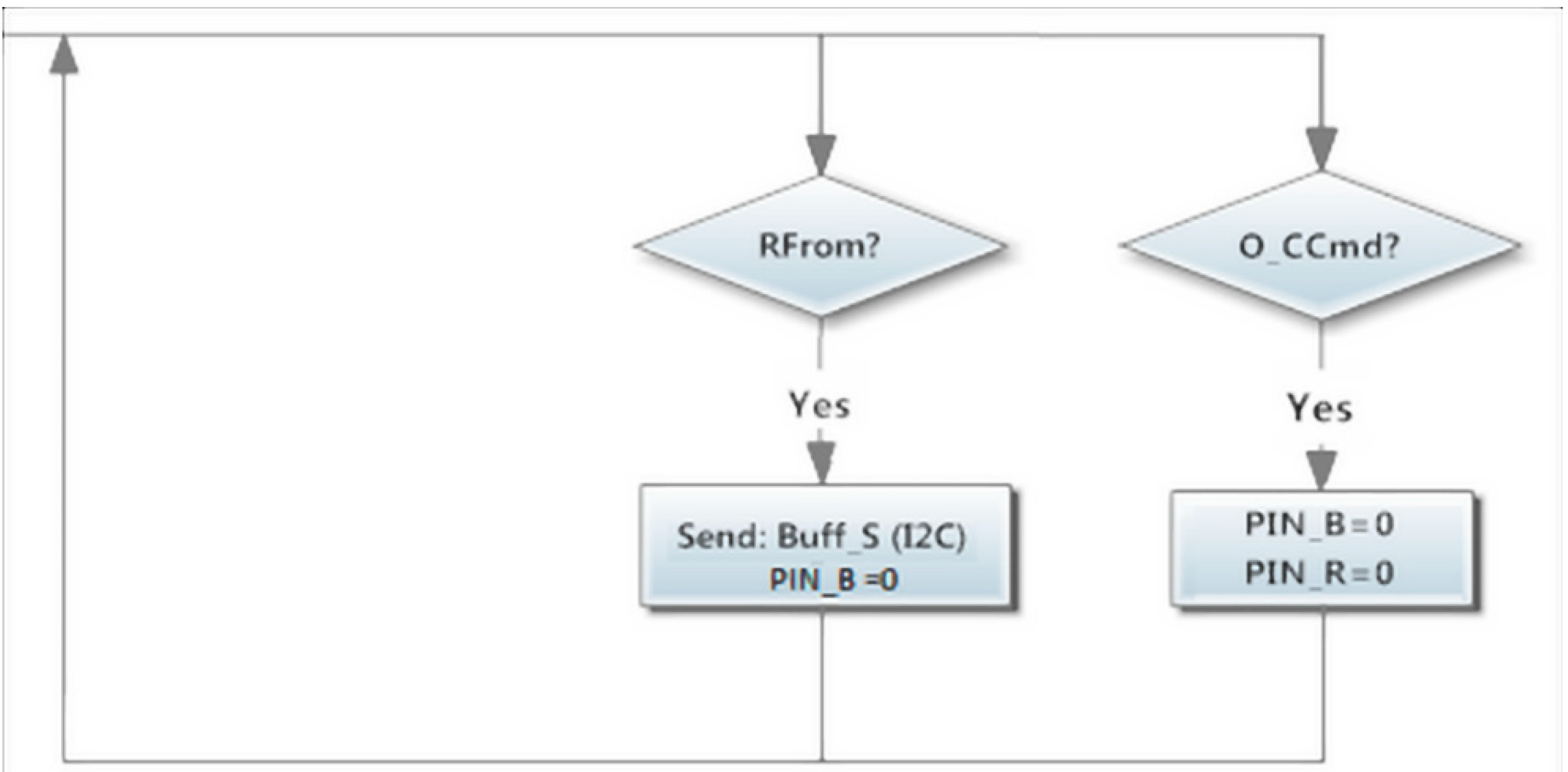

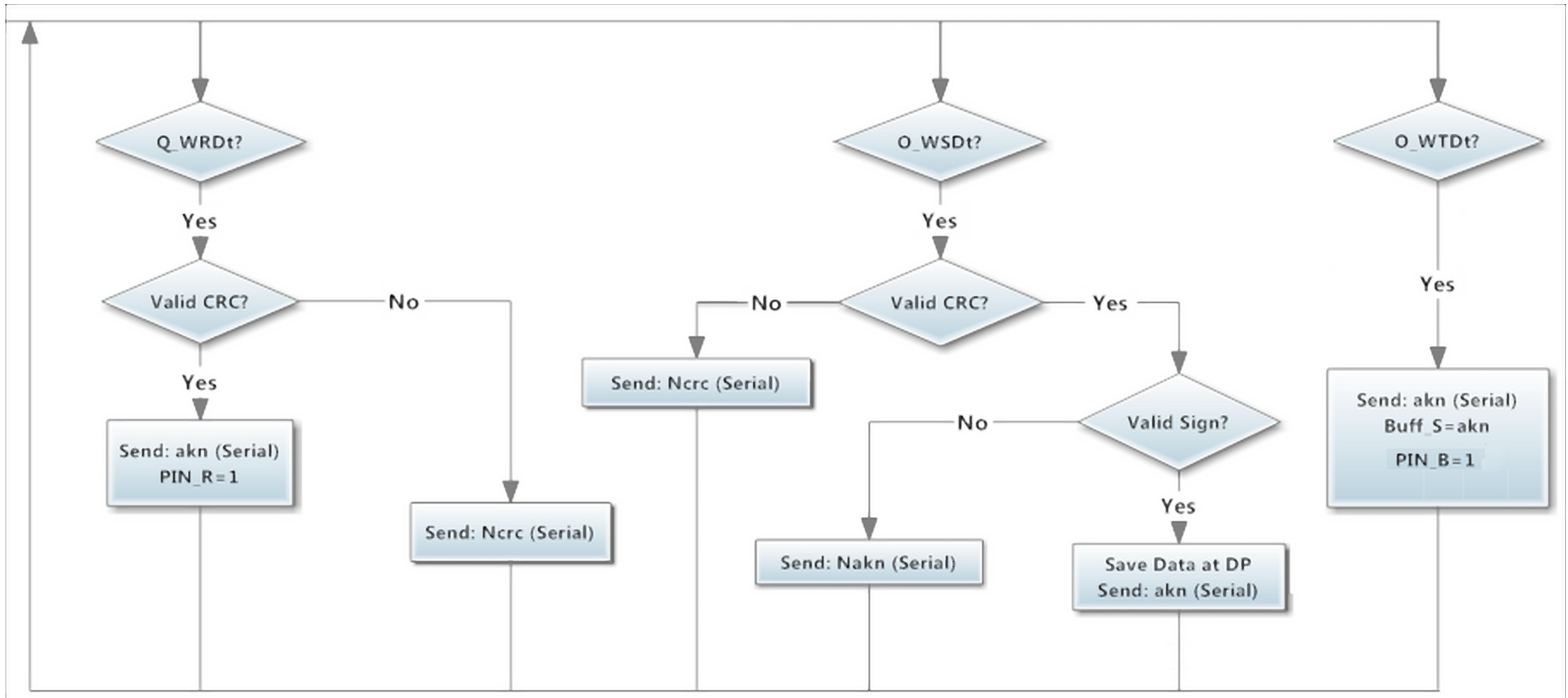

3.2.1. Control Algorithms of Modules

3.2.2. Communication Protocols

| Symbol | Description |

|---|---|

| akn | Acknowledge byte |

| Buff_S | Serial buffer |

| Ch | Sensors Channel |

| CRC | Cyclic Redundancy Check |

| DP | Data Positions (2 bytes: [First_Byte_Position, Last_Byte_Position]) |

| H_Ch | Channel header for the transmission of the selected channel |

| H_Dt | Data header for the transmission of the Data from Sensors |

| H_FDt | Data header for the transmission of the last message of Data from Sensors |

| LDP | Last sensor data |

| M_Dir | Wireless Module Address |

| MSign | “Sign” always checked as correct coming from a Master Wireless |

| Nakn | Negative Acknowledge byte |

| Ncrc | Negative Cyclic Redundancy Check Validation |

| O_CCmd | Order of Canceling Command, also used at the end of an instruction |

| O_MRDt | Order from Master to Request Data from his Wireless Module |

| O_MRMd | Order from Master to Request Data from a Module of Sensors |

| O_SRCh | Order from Slave to Request the channel to read the Data from Sensors |

| O_SSDt | Order from Slave to Save the Data from Sensors |

| O_STDt | Order from Slave to Transmit the Data from Sensors |

| O_WRDt | Order from Wireless to Request Data from a Channel of Sensors |

| O_WSDt | Order from Wireless to Save Data from a Channel of Sensors |

| O_WTDt | Order from Wireless to Transmit the Data from Sensors |

| PIN_B | Send Buffer PIN |

| PIN_R | Request PIN |

| RFrom | Request From |

| Sign | Validation bytes for the transmission of Data |

| XXSD | Information Bytes (XX means de number of bytes) |

3.3. Communication between Wireless Modules

3.4. Master Module to Wireless Module Communication

3.5 Slave Module to Wireless Module Communication

3.5. System Testing

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Koller, M. Learning from the History of Preventive Conservation. In Preventive Conservation: Practice, Theory and Research; Ashok, R., Smith, P., Eds.; International Institute for Conservation of Historic and Artistic Works: London, UK, 1994. [Google Scholar]

- National Gallery of Australia. Preventive Conservation. Available online: http://nga.gov.au/Conservation/prevention/index.cfm (accessed on 16 September 2014).

- UNI 10829. In Works of Art of Historical Importance. Ambient Conditions for the Conservation. Measurement and Analysis; UNI Ente Nazionale Italiano di Unificazione: Milano, Italy, 1999.

- Ministero per i Beni e le Attività Culturali. DM 10/2001 Atto. di Indirizzo. sui Criteri. Tecnico.-Scientifici e Sugli. Standard di Funzionamento. e Sviluppo. dei Musei. Gazzetta Ufficiale: Rome, Italy, 19 October 2001; n. 244, DL 112/1998 art. 150.6. [Google Scholar]

- García-Diego, F.J.; Merello, P.; D’Antoni, P.; Fernández Navajas, A.; Ribera i Lacomba, A.; Ferrazza, L.; Pérez Miralles, J.; Baro, J.L.; Merce, P.; D’Antoni, H.; et al. Ariadne’s house (Pompeii, Italy) wall paintings: A multidisciplinary study of its present state focused on a future restoration and preventive conservation. Mater. Constr. 2013, 63, 449–467. [Google Scholar] [CrossRef]

- Valero, M.Á.; Merello, P.; Navajas, Á.F.; García-Diego, F.-J. Statistical Tools Applied in the Characterisation and Evaluation of a Thermo-Hygrometric Corrective Action Carried out at the Noheda Archaeological Site (Noheda, Spain). Sensors 2014, 14, 1665–1679. [Google Scholar]

- García-Diego, F.-J.; Fernández-Navajas, Á.; Beltrán, P.; Merello, P. Study of the Effect of the Strategy of Heating on the Mudejar Church of Santa Maria in Ateca (Spain) for Preventive Conservation of the Altarpiece Surroundings. Sensors 2013, 13, 11407–11423. [Google Scholar]

- Fernández-Navajas, Á.; Merello, P.; Beltrán, P.; García-Diego, F.-J. Software for Storage and Management of Microclimatic Data for Preventive Conservation of Cultural Heritage. Sensors 2013, 13, 2700–2718. [Google Scholar]

- Caragliu, A.; Del Bo, C.; Nijkamp, P. Smart cities in Europe. J. Urban Technol. 2011, 18, 65–82. [Google Scholar] [CrossRef]

- Su, K.; Li, J.; Fu, H. Smart city and the applications. In Proceedings of the International Conference on Electronics, Communications and Control (ICECC ’2011), Zhejiang, China, 9–11 September 2011; pp. 1028–1033.

- Merello, P.; Fernandez-Navajas, A.; Curiel-Esparza, J.; Zarzo, M.; Garcia-Diego, F.-J. Characterisation of thermo-hygrometric conditions of an archaeological site affected by unlike boundary weather conditions. Build. Environ. 2014, 76, 125–133. [Google Scholar] [CrossRef]

- Lillie, M.; Smith, R.; Reed, J.; Inglis, R. Southwest scottish crannogs: Using in situ studies to assess preservation in wetland archaeological contexts. J. Archaeol. Sci. 2008, 35, 1886–1900. [Google Scholar] [CrossRef]

- Camuffo, D.; Bernardi, A.; Sturaro, G.; Valentino, A. The microclimate inside the pollaiolo and botticelli rooms in the Uffizi Gallery, Florence. J. Cult. Herit. 2002, 3, 155–161. [Google Scholar] [CrossRef]

- Al-Omari, A.; Brunetaud, X.; Beck, K.; Al-Mukhtar, M. Effect of thermal stress, condensation and freezing–thawing action on the degradation of stones on the Castle of Chambord, France. Environ. Earth Sci. 2014, 71, 3977–3989. [Google Scholar] [CrossRef]

- Brunetaud, X.; de Luca, L.; Janvier-Badosa, S.; Beck, K.; Al-Mukhtar, M. Application of digital techniques in monument preservation. Eur. J. Environ. Civ. Eng. 2012, 16, 543–556. [Google Scholar] [CrossRef]

- Visco, G.; Plattner, S.H.; Fortini, P.; Di Giovanni, S.; Sammartino, M.P. Microclimate monitoring in the Carcer Tullianum: Temporal and spatial correlation and gradients evidenced by multivariate analysis; first campaign. Chem. Cent. J. 2012, 6 (Suppl. 2), S11. [Google Scholar] [CrossRef] [PubMed]

- Onset USA. Hobo Data Loggers. Available online: http://www.onsetcomp.com/ (accessed on 20 October 2014).

- Merello, P.; García-Diego, F.-J.; Zarzo, M. Diagnosis of abnormal patterns in multivariate microclimate monitoring: A case study of an open-air archaeological site in Pompeii (Italy). Sci. Total Environ. 2014, 488–489, 14–25. [Google Scholar] [CrossRef] [PubMed]

- Temperature Logger iButton with 8KB Data-Log Memory. Available online: http://datasheets.maxim-ic.com/en/ds/DS1922L-DS1922T.pdf (accessed on 25 November 2014).

- Hygrochron Temperature/Humidity Logger iButton with 8KB Data-Log Memory. Available online: http://datasheets.maxim-ic.com/en/ds/DS1923.pdf (accessed on 25 November 2014).

- García-Diego, F.J.; Zarzo, M. Microclimate monitoring by multivariate statistical control: The renaissance frescoes of the Cathedral of Valencia (Spain). J. Cult. Herit. 2010, 11, 339–344. [Google Scholar] [CrossRef]

- SDI-12 Support Group. SDI-12 Org. Available online: http://www.sdi-12.org/ (accessed on 16 September 2014).

- Jiang, P.; Xia, H.; He, Z.; Wang, Z. Design of a water environment monitoring system based on wireless sensor networks. Sensors 2009, 9, 6411–6434. [Google Scholar] [CrossRef] [PubMed]

- Leccese, F.; Cagnetti, M.; Calogero, A.; Trinca, D.; Di Pasquale, S.; Giarnetti, S.; Cozzella, L. A New Acquisition and Imaging System for Environmental Measurements: An Experience on the Italian Cultural Heritage. Sensors 2014, 14, 9290–312. [Google Scholar] [CrossRef] [PubMed]

- Mecocci, A.; Abrardo, A. Monitoring Architectural Heritage by Wireless Sensors Networks: San Gimignano: A Case Study. Sensors 2014, 14, 770–778. [Google Scholar] [CrossRef] [PubMed]

- Maxim Integrated. Programmable Resolution 1-Wire Digital Thermometer. Available online: http://www.maximintegrated.com/en/products/analog/sensors-and-sensor-interface/DS18B20.html (accessed on 16 September 2014).

- Maxim Integrated. 1-Wire Quad A/D Converter DS2450. Available online: http://www.maximintegrated.com/en/products/comms/one-wire/DS2450.html (accessed on 16 September 2014).

- Honeywell. HIH 4030. Available online: http://sensing.honeywell.com/honeywell-sensing-hih4030-4031%20series-product-sheet-009021-4-en.pdf?name=HIH-4030-001 (accessed on 16 September 2014).

- ASTME 104–02. Standard Practice for Maintaining Constant Relative Humidity by Means of Aqueous Solutions. ASTM Intl.: West Conshohocken, PA, USA, 2012.

- Libelium Connecting. Sensors Development to the Cloud RSS. Available online: http://www.libelium.com/development/waspmote/documentation/802-15-4-networking-guide/ (accessed on 16 September 2014).

- Maxim Integrated. DS2482-800. Available online: http://www.maximintegrated.com/en/products/interface/controllers-expanders/DS2482-800.html (accessed on 16 September 2014).

- Maxim Integrated. DS1307. 64 × 8, Serial, I2C Real-Time Clock. Available online: http://www.maximintegrated.com/en/products/digital/real-time-clocks/DS1307.html (accessed on 16 September 2014).

- FTDI. Development Modules. Available online: http://www.ftdichip.com/Products/Modules/DevelopmentModules.htm (accessed on 16 September 2014).

- Mouser Electronics. NCP7805TG ON Semiconductor | Mouser. Available online: http://www.mouser.es/ProductDetail/ON-Semiconductor/NCP7805TG/?qs=lYuAOLy5nvboAruYeXBD4A== (accessed on 16 September 2014).

- Mouser Electronics. UA78M33CKCS Texas Instruments | Mouser. Available online: http://www.mouser.es/ProductDetail/Texas-Instruments/UA78M33CKCS/?qs=0O/ZFlpUpJW16wrDG1C6LA== (accessed on 16 September 2014).

- Texas Instruments. TPS3813J25 (ACTIVE). Available online: http://www.ti.com/product/tps3813j25 (accessed on 16 September 2014).

- Instituto Valenciano de Conservacion y Restauracion de Bienes Culturales. Real Senyera: Investigación, conservación y restauración del patrimonio textil de la Comunitat Valenciana. Available online: http://www.ivcr.es/media/descargas/monografia-valencia-generalitat-senyera-w.pdf (accessed on 22 December 2014).

- CADSOFT. The Best PCB Design Software. Available online: http://www.cadsoftusa.com/ (accessed on 16 September 2014).

- ATMEL. Available online: http://www.atmel.com/images/avr_3_04.pdf (accessed on 16 September 2014).

- Arduino. Language Reference. Available online: http://arduino.cc/en/pmwiki.php?n=Reference/HomePage (accessed on 16 September 2014).

- Maxim Integrated. Application Notes. Available online: http://www.maximintegrated.com/en/app-notes/index.mvp/id (accessed on 16 September 2014).

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Diego, F.-J.G.; Esteban, B.; Merello, P. Design of a Hybrid (Wired/Wireless) Acquisition Data System for Monitoring of Cultural Heritage Physical Parameters in Smart Cities. Sensors 2015, 15, 7246-7266. https://doi.org/10.3390/s150407246

Diego F-JG, Esteban B, Merello P. Design of a Hybrid (Wired/Wireless) Acquisition Data System for Monitoring of Cultural Heritage Physical Parameters in Smart Cities. Sensors. 2015; 15(4):7246-7266. https://doi.org/10.3390/s150407246

Chicago/Turabian StyleDiego, Fernando-Juan García, Borja Esteban, and Paloma Merello. 2015. "Design of a Hybrid (Wired/Wireless) Acquisition Data System for Monitoring of Cultural Heritage Physical Parameters in Smart Cities" Sensors 15, no. 4: 7246-7266. https://doi.org/10.3390/s150407246

APA StyleDiego, F.-J. G., Esteban, B., & Merello, P. (2015). Design of a Hybrid (Wired/Wireless) Acquisition Data System for Monitoring of Cultural Heritage Physical Parameters in Smart Cities. Sensors, 15(4), 7246-7266. https://doi.org/10.3390/s150407246