1. Introduction

Imagine there’s a product that starts collecting data from the moment that it’s being made—a product that collects, then evaluates these data, and passes the results on into the cloud: information that describes its making and its everyday experiences. In the cloud, this evidence is matched with what other individual products of identical type and make provide, and scrutinized on an item and a type level. In the cloud, this information is processed to automatically adapt design and dimensioning of coming product generations. But why wait until a coming generation? And, why, specifically, do so if all the information needed is readily at hand to optimize the product not only for some general set of requirements, as sophisticated as they may be, but for an individual customer, and an individual use pattern? Why not allow the product to evolve, not from generation to generation, but from item to item? And do so differently from individual customer to individual customer, too?

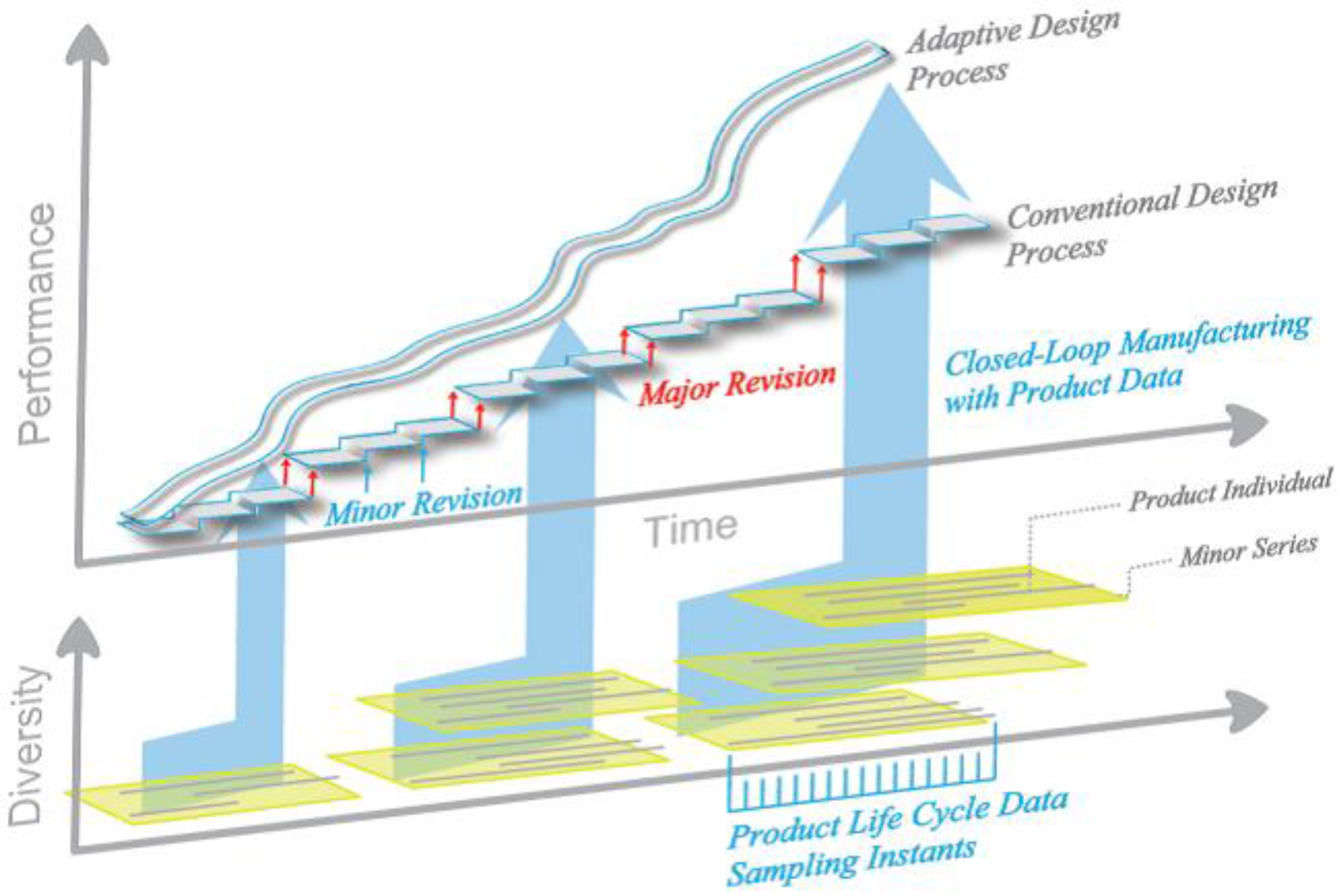

Figure 1 graphically represents the impact of this concept on product generations and diversity, with continuous change replacing the major revisions (these are retained in the new approach on lower level with e.g., feature addition as discriminator, leading to product groups with close internal and more remote external relation) as well as the minor ones of a more common organization of the process. Conventional production technology, specifically in mass production, is not matched easily with this vision. Mass production typically relies on complex manufacturing equipment and thus high investment costs to reduce part costs based on an economy of scales approach: Flexibility is sacrificed for the sake of productivity. Tools are matched to products, causing adaptation of the latter to be costly. What, then, if production processes provided boundless flexibility, and changes to the product could be realized virtually, as changes to its digital representation, and at virtually no cost?

Figure 1.

Consequences of the basic concept visualized: From product generations to continuous optimization through gathering and usage of life cycle data in conjunction with flexible production.

Figure 1.

Consequences of the basic concept visualized: From product generations to continuous optimization through gathering and usage of life cycle data in conjunction with flexible production.

In a manufacturing environment of this kind, the making of the product would not be linked to the physical site at which dedicated tools and machinery were kept, simply because no such tools and machinery would be needed. Instead, availability of the digital product information alone would enable countless manufacturing centers worldwide to create the product without lead-time. This is why such approaches have been termed Direct Digital Manufacturing [

1].

A global manufacturing environment like this could transform the way we make things. The paradigm shifts implied are manifold: For one thing, as product development would not require parallel development of production equipment, design and production could move further apart. At the same time, and as described above, flexibility in manufacturing could be used to optimize products on a customer or customer group basis, and furthermore, to implement a continuous design optimization. Practically this means nothing less than brushing aside the fundamental concept of individual product generations. Since optimization needs a basis, a primary prerequisite is a usage data link allowing backflow of information from product to designer. Equally important is a legally and technically secure access for the various potential producers and service providers to initial and optimized product design and manufacturing information. This global access to (general product and usage) data, software tools and finally manufacturing resources is the primary link of our scenario to the concept of the cloud (please consider also

Figure 8 in

Section 3 in this respect). Cloud-based manufacturing (CBM), sometimes also designated Cloud Manufacturing (CMfg), in general is currently the object of intense study [

2,

3,

4,

5] Xu

et al., to give an example, introduced cloud manufacturing via the earlier-adopted concept of cloud computing, defined by the National Institute of Standards and Technology (NIST) as “a model for enabling ubiquitous, convenient, on-demand network access to a shared pool of configurable computing resources (e.g., networks, servers, storage, applications, and services) that can be rapidly provisioned and released with minimal management effort or service provider interaction.’’ [

6]. Cloud manufacturing extends Cloud Computing by including production processes (scheduling, resource planning

etc.) and related Cyber-Physical Systems (CPS) as active units [

3]. Another definition has been provided by Wu

et al., who discuss whether CBM is indeed the paradigm change as which it is currently being advertised. Their answer is in the affirmative: By reviewing the suggested definitions of the field and adding their own perspective, they manage to delimit CBM both from earlier concepts like flexible and redistributable manufacturing systems and intermediate development stages like web- and agent-based manufacturing (WBM, ABM) [

7]. A true CBM approach, in their eyes, needs to integrate “Infrastructure-as-a-Service (IaaS), Platform-as-a-Service (PaaS), Hardware-as-a-Service (HaaS), and Software-as-a-Service (SaaS)” elements and is distinguished from WBM and ABM by its capability of facilitating new business models through such elements [

7,

8]. In further publications, Wu

et al. have linked their studies to additive manufacturing and looked at product design, too, thus extending the original term CBM to cloud-based design and manufacturing (CBDM) [

9,

10]. Interestingly, however, the usage data feedback is not considered a core feature of CBM in these definitions: Data from the usage or Middle-of-Life (MoL) phase is included in some of the projections offered, though not in an automated fashion, but solely by way of direct end user (customer) feedback and integration in the design process (customer co-design). The practical implementation of such end user-centered feedback facilities is seen as major research issue. Besides, as we will show later in case study 2 (

Section 4.2), the notion of separated ABM and CBM approaches brought forward by Wu

et al. can be overcome [

9,

10].

All the aforementioned capabilities require sophisticated analysis of data as glue between the various enablers on technological level. On a more generic level, Artificial Intelligence (AI), Machine Learning (ML) and advanced ICT are already integrated in most areas of daily life, as well as in industrial production and product development. In parallel, the value of information and data is rapidly increasing—more so if they help in satisfying customer needs. Companies who understand the needs of their customers and at the same time are capable of translating them in a timely manner into new products and product enhancements, have a competitive advantage in the global business environment.

This statement accepted, several equally important aspects are required to succeed in the future:

Availability of information about the usage of individual product items.

Capability to analyze and translate this information into technical requirements.

Capability to map these requirements to product design (e.g., CAD model).

Capability to economically manufacture the products designed accordingly.

Capability to increasingly automate these steps to realize fast time-to-market.

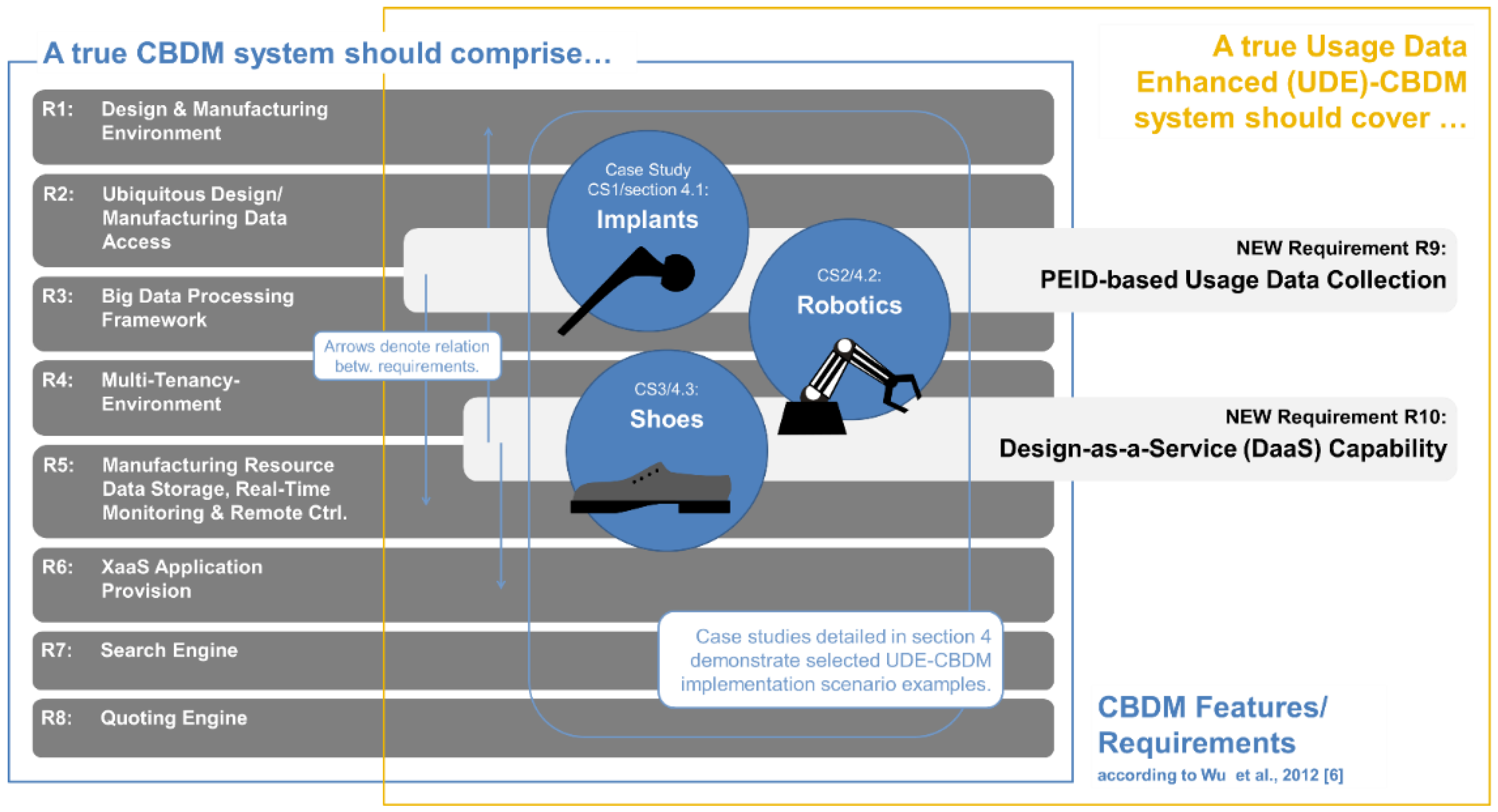

That said, we may match our own perspective of what might be called “Usage Data-Enhanced Cloud-based Design and Manufacturing” or UDE-CBDM to the requirements proposed in the literature to distinguish cloud-based from conventional manufacturing. We have done so in

Figure 2, contrasting the set of eight requirements a CBDM approach has to meet according to Wu

et al. [

8] with two additional requirements that together with the initial ones constitute the UDE-CBDM case.

Figure 2.

Requirements or criteria which characterize a CBDM approach, and additional ones which constitute its extension to Usage Data-enhanced (UDE)-CBDM.

Figure 2.

Requirements or criteria which characterize a CBDM approach, and additional ones which constitute its extension to Usage Data-enhanced (UDE)-CBDM.

The additions we suggest are defined as follows:

Requirement 9, PEID-based Usage Data Collection, requires that perceptive product usage data should continuously be collected and stored in a cloud-based data repository.

Requirement 10, Design-as-a-Service (DaaS) Capability, requires that a cloud-based service and the associated tools should be established that retrieves data from the aforementioned repository and transforms it into an adaptation of the products original root design that reflects the usage information contained in the data by improving product performance, economy or the like on this basis.

The reader should note that these are minimum requirements constituting a UDE-CBDM scenario. We have deliberately dispensed with including AM or automated design approaches on this level—ultimately, we believe these techniques to be a necessity (in case of AM) or a logical development (automated design)—but they can still be omitted in a formal definition, as solutions that do not build on them can theoretically be envisaged.

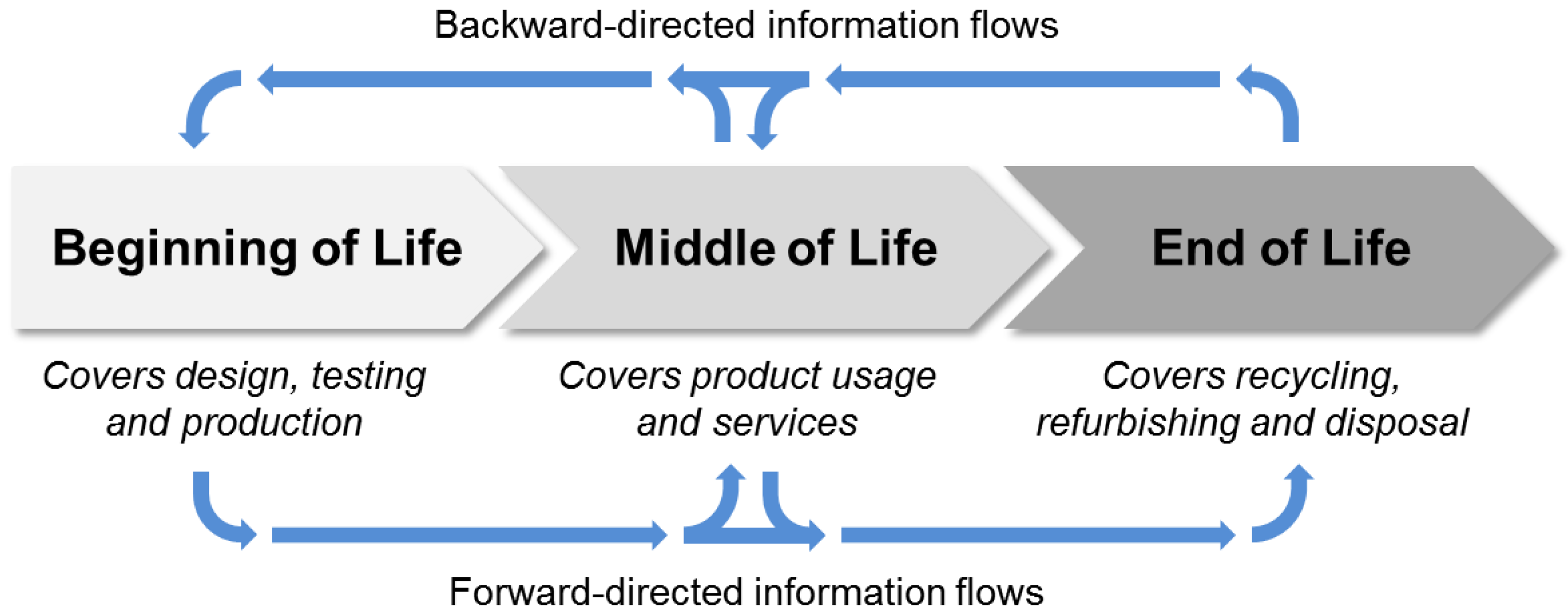

In practical implementations of this framework, given that (consumer and professional) products are often used in a rather unique way by the customers, the usage information obtained is most likely on an item-level. Today’s research in Product Lifecycle Management (PLM) is focusing on the rather complex problem of how to capture, organize and present information along the complete lifecycle. In the vision of this paper, PLM is the conceptual foundation providing the necessary information to the other processes, e.g., from usage to design and manufacturing. On a technological level, combinations of products with so-called product-embedded information devices (PEIDs) are required. PEIDs can be seen as smart sensor systems or cyber-physical systems (CPS, which brings the topic of their integration into products down to the field of sensor integration and material-integrated intelligent systems.

Once the information is obtained and analyzed, which is far from trivial [

11,

12], the design and manufacturing of highly individualized products adds further complexity. Whereas one-of-a-kind-production and similar concepts have been discussed for years, today’s advanced tools incorporate the opportunity to automate many of the time-consuming steps involved. Knowledge-based engineering [

13] and adaptive design [

14] automate specific tasks in the engineering domain while additive manufacturing gives designers and manufacturers more freedom to realize products.

The only suitable manufacturing process class that may provide the flexibility our vision requires is additive manufacturing (AM), which is capable of producing a part directly from a digital model. This way, product modifications can in principle be handled entirely in the virtual world, allowing economic definition and production of individual product variants. However, this choice of a process class has implications for sensor integration, since there is the need to link both topics. Thus in our vision, additive manufacturing is important in two different ways, firstly, regarding the aforementioned degrees of freedom during production and, secondly, by facilitating the integration of the necessary sensors to capture usage information. Additive manufacturing thus becomes the link that closes the loop: The capturing of information during the usage phase is a prerequisite for the whole vision to work, and sensors are required to obtain this information, even though complementary information can be collected from other sources as well [

15].

With this overall vision in mind, the different areas and their current state of the art are illustrated in the second chapter. In its first

Section 2.1, product life cycle management (PLM) and item-level information flows, as well as Intelligent Products as one way of capturing information, are introduced. Following this, in

Section 2.2 the focus is put specifically on product usage information, based on its key role in our concept, before the topic of sensor-integration in additive manufacturing is touched upon in

Section 2.3. Within it, additive manufacturing is described in greater detail, looking into the current ability to create complex and multi-material structures.

Section 2.4 explores how automated design, based on PLM data, may be capable of creating customized products in an efficient and timely way. The synthesis of all elements contributing to our concept is explained in more detail, though still on a level of principles, in

Section 3. It is further illustrated via three comprehensive case studies, which together form

Section 4. The first of these is focused on medical implants. In this application, the generation-to-generation adaptation based on strictly individual use patterns is a challenge that links up to our vision especially in terms of the need for customization. Besides, the application as such is already associated to AM, which is an established manufacturing process in this field, and to sensor integration, though in the latter case mainly on an academic level. The second case addresses robots as products that are integrated in a closed-loop adaptive design and manufacturing process. They contribute their inherent connectivity and sensor integration to support the cloud-based manufacturing vision. The third case represents a near-complete implementation study of our vision, using the shoe industry as example. Except for an extensive automation of the usage data-driven design processes, all elements of the present study’s underlying notions are reflected in this example.All case studies are critically discussed in

Section 5, alternately assuming the positions of the various stakeholders involved.

Section 6 concludes our paper and provides an outlook on further paths of research in the area.

3. Usage-Data Enhanced (UDE-) CBDM: A New Process Model Rooted in Cloud-Based Services

The underlying concepts of CBM, CMfg and CBDM have been discussed in the introductory section. The proposed criteria, describing the extensions we recommend, have also been formulated in that section (

Figure 2). Based on these added requirements, the state of the art in the respective technological domains has been scrutinized in

Section 2: apparently, most of the basic ingredients needed for an extension of CBDM towards UDE-CBDM are already available or at the very least under development. Despite this encouraging fact, we hope to be able to pinpoint a number of white spots that still deserve further research efforts, and more that need development towards commercialization: These will in part be introduced here, illustrated by the case studies, and detailed in the discussion.

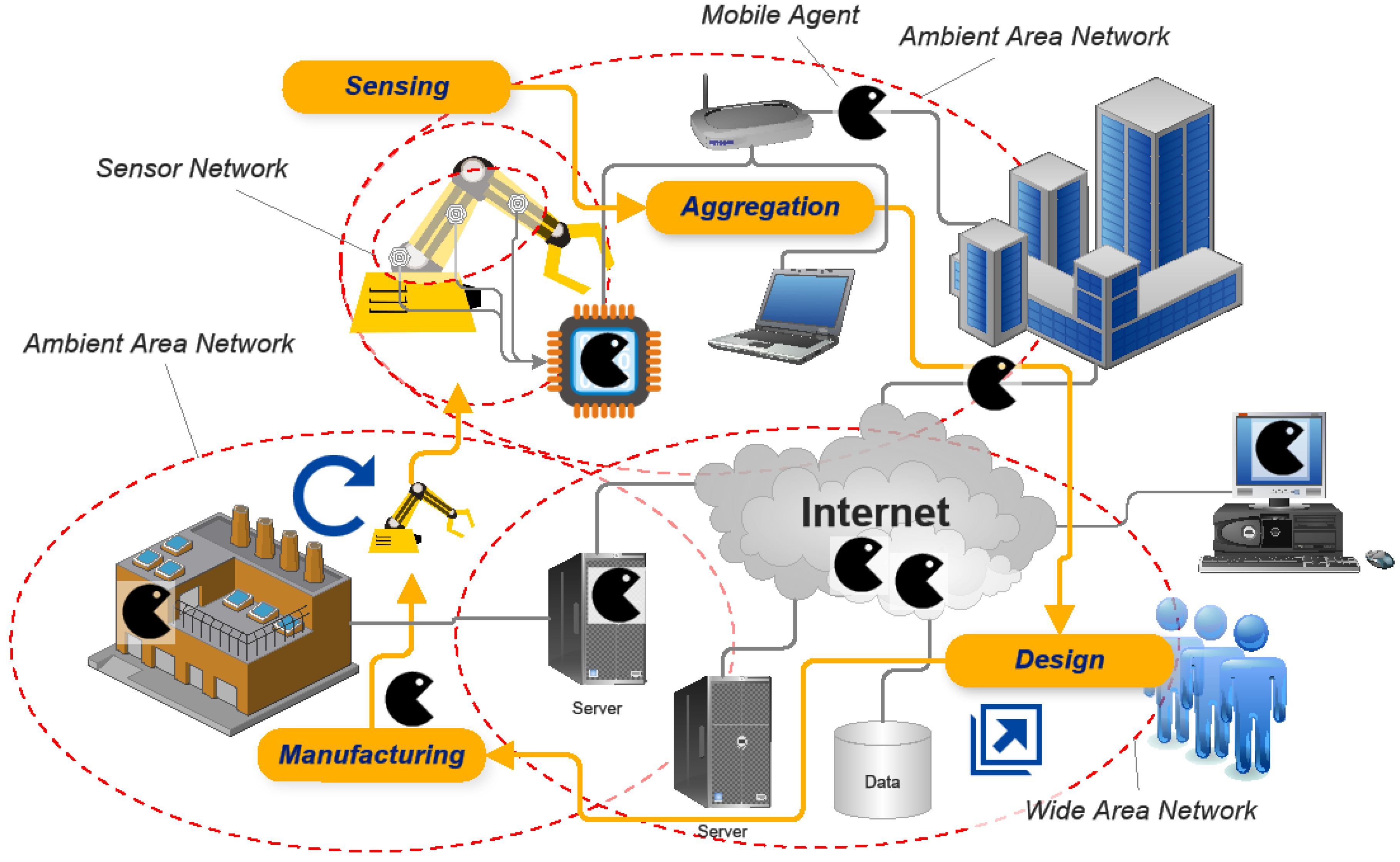

Figure 8 outlines the process sequence we proposed in terms of a process direction and data flows linked to the individual process steps.

We assume that the initial motivation to introduce a new product, as well as its initial design, both follow conventional approaches: We call this initial design the root design, as it is the common ancestor and thus the foundation of all variants that may be generated at later stages within the scheme. This root design may, in a subsequent, optional step, be customized to meet the requirements of a specific individual user, or a user group. Descriptions of both designs will then, as the vertical data flow paths suggest, be added, as initial entries, to a related data repository: In it, the root design description is of global character, whereas a possible adaptation to a user or user group would bear some reference to these. The provision of the respective data repository denotes the first cloud-based service encountered in the processing sequence.

Figure 8.

Process scheme describing main activities and data flows in usage-data enhanced cloud based design and manufacturing (UDE-CBDM).

Figure 8.

Process scheme describing main activities and data flows in usage-data enhanced cloud based design and manufacturing (UDE-CBDM).

In the case of the initial product variant, the next steps would focus on tasks directly associated to the manufacturing processes. This includes the identification of suitable manufacturing resources and the allocation of the manufacturing task to these, based e.g., on a cloud-based quoting system as suggested in several CBDM definitions. An added feature in a real-world implementation of UDE-CBDM is that manufacturing would heavily rely on AM processes. These would contribute their generic flexibility, thus facilitating almost immediate fabrication of product variants representing new adaptations of the root design. The “almost” in the preceding sentence is owing to the fact that new geometries will require a revision of the manufacturing, i.e., build-up, strategies (e.g., scanning patterns in SLS, SLM or SLA processes), in order to minimize adverse effects like residual stresses and the like: The assumption is that initial information on this issue may have been provided with the root design, but any geometry or material-related alteration would require further checking, and almost invariably updating of the respective information for the adapted design. The general UDE-CBDM concept leaves open whether such tasks are associated with the DaaS toolset, or alternatively with the manufacturing side. Handling this at the design stage would be the preferred option, though, to make sure that no design unfit for production is issued. Any design adapted by the DaaS tool would be added to the UDE-CBDM data repository. Assuming a highly parametric design, this could be done, for instance, through storage of the relevant design parameter values—or at least of those that deviate from the root design. The adapted design should then also be linked to the data set on which it had been based. The reasoning behind this measure is that a new design for the same user or user group could potentially be derived more easily from an evolved product state than from the initial, root design.

Collection of usage data would start at the latest following the delivery of the product to the customer. This data would again find entry into the aforementioned data repository, where it would be associated with the root design and any pre-existing design variant, as well as to the individual user and/or to the user group he/she belongs to.

Any triggering event that would initiate production of a second variant of the root design would not be channeled into the conventional design path, but would rather be diverted to the DaaS tool offered as a cloud-based service. This tool would draw on root design information and usage information available from the UDE-CBDM data repository. Besides, direct user feedback and information might be available from the latter. Finally, if connections between product usage data and other cloud-based sources of information can be made, additional information, e.g., on the usage context, could be gathered. Interfacing and mapping between the data repository and DaaS tool would require a dedicated tool, which would constitute a central element of the entire concept.

Depending on the capabilities of the DaaS toolset, the concept could allow the customer to directly trigger the manufacturing process simply by placing his order, up to a level without any human intervention in a fully automated design process linked to a likewise automated process handling the manufacturing organization up to the final logistics that would guarantee that the product reaches the user. From a business model perspective, this notion has several interesting implications—companies that originally developed the root design might not be selling products then, but licensing designs instead. Alternative DaaS provides might compete for customers. Access to usage and associated data might become a trading good and as such be offered by specialized service providers. We will discuss such issues in a little more detail in

Section 5, and specifically in

Section 5.1 and

Section 5.2.

With more and more products sharing a common root design on the market, the UDE-CBDM data repository would grow, allowing more and more discrimination between user groups etc.

The separation between the establishment of a root design on the one hand and an initial customization on the other makes sense because, in order to facilitate the later design adaptation, definition of this root design must be flexible in any case. Enhanced parametric design could be a useful approach in this respect, as it would provide the main design parameters as initial, primary handles for adaptation. Foreseeing this facility from the start could then also support any initial customization, if needed. In an implementation of this kind, however, the initial designer must have in mind that the way in which his root design is parameterized may determine the envelope within which future design adaptations can occur, as any deviation from this framework might require a partial re-parameterization of the design, and thus a considerable extension of both width and depth of the design adaptation task. In practice, this would imply that automated design adaptation might only reach local, not a global optimum, depending on the level and extent of any pre-determination contained in the fabric of the root design.

The DaaS toolset itself can be seen as a very specific and very complex example of (at least) a SaaS system. Due to the complexity, which will be discussed in

Section 5, where we intend to show that not only the designer perspective, but also the regulatory one is of primary importance with respect to this service, we have nevertheless opted to coin the DaaS label here.

4. Case Studies

In this section, three case studies transfer the previously presented UDE-CBDM concept to actual application environments. The aim of this section is not to present a comprehensive and evaluated “ready-to-use” solution, but to show the potential of the vision and provide a basis for future critical discussion of the topic. The first case study focuses on medical implants, which are by definition one-of-a-kind and highly customized based on the users’ preferences, state and physique. At the same time, they are not extremely complex compared to other multi-component products. Hence, this environment provides a solid frame for the envisioned application, and a frame at that in which Additive Manufacturing is already a competitive production process and sensor integration has been used to derive valuable usage information on a general, not individual level in the course of several research projects. The second case study describes “the other extreme”, with a scenario set in the robotics domain. In this case, the natural ability of robots to collect and communicate usage data through their own, not necessarily monitoring-, but task-oriented sensors and communication equipment is used in order to enhance this implementation. The focus is very much on data processing techniques, with agent-based solutions identified as the method of choice, and the linking of these to the overall scenario as laid out.in

Section 3.The section is closed by a third case study representing a more detailed study of a scenario based on the design and production of shoes which foresees usage data backflow and personalized design solutions based on these. This example is based on a dedicated research project conducted in Japan, which as such goes beyond the preceding studies in being much nearer to implementation. Not covered at present is the envisaged automated redesign capability provided by the DaaS toolset.

4.1. Case Study 1: Medical Implants—Generation-to-Generation Adaption Based on Strictly Individual Use Patterns

For several types of medical implants, consideration and even practical application of AM processes is commonplace, as by definition, they need to be individual in their adaption to an individual patient [

109,

110,

111]. Business cases in this respect have been highlighted in

Section 2.

A general aspect of several types of implants is that they are subject to influences like wear and degradation and thus may need replacement. Any such replacement means surgery, with all the risks this entails for the patient. This constitutes a strong motivation for increasing the lifespan of an implant. Hip implants, to consider a concrete example, are both common (at 300,000 replacements performed in the United States in 2010 alone and 80,000 annually in the UK, according to Kandala

et al. [

112]) and heavily loaded. At the same time, they are subject to revision surgery in a relevant number of cases. Studies from the UK have considered revision rates after a given time as a benchmark for different products and indicate that an aim should be set to achieve, for a given product, a likelihood of revision of less than 5% within a 10 year period [

112].

If production of the implant in question is AM based anyway, manufacturing of an altered part is a realistic option, if there is a sound justification of a redesign, and if economics of the redesign process can be covered: manufacturing costs, in contrast, are unlikely to change significantly compared to the initial part. However, the primary concern when it comes to redesigning an implant for the individual patient is the availability of personal data. The High Road to gathering such data is equipment of the implant with a suitable set of sensors allowing read-out of raw data or processed information at any time. Smart implants of this kind have been realized for several body areas, including the aforementioned case of a hip replacement, but also the shoulder, spine or knee, as bone or cartilage substitutions—an overview in this respect has recently been published by Ledet

et al. [

113]. Sensor-integrated systems of this kind have provided extremely valuable information for guiding implant design in general terms by measuring forces, moments or temperatures associated with different designs and different use patterns. They have furthermore contributed to an improved understanding of the musculoskeletal system, and of healing processes following the implantation—all this on a level that would hardly have been accessible through other means. However, in performing these tasks, up to the present day, they have remained tools for research rather than becoming a standard aid to the implant designer, far less the average patient.

Going back to the example of the hip implant, typical early smart implant designs incorporated three-axis force measurements [

114], later ones recorded bending moments and temperature, too [

115]. In the latter variant, sensor system and signal processing are integrated in the hip implant’s neck, while the antenna used for telemetric data transmission to an external evaluation unit is located inside its ceramic head. The implanted system receives the necessary power via inductive coupling using a coil linked to the external evaluation and power supply unit, and a matching one again integrated with the implant [

115,

116,

117]. System sizes have dropped from cm to the mm length scale reached today.

Besides smartness, adaptation of implants to the specific requirements of individual patients is a constantly studied issue, but the point of attack is typically not information on the patient-specific usage: In a recent study, Campoli

et al. report about reconstruction of the link between internal bone structure and musculoskeletal forces using CT data, FEM modelling and optimization techniques for a scapula [

118,

119]. Similar principles could be used to determine likely implant loads and in this role might at least partly replace direct measurement of forces through smart implants, or compensate their non-availability when first implanting the respective bone or joint replacement. However, approaches of this kind, though building on observable individual structures and geometries, have to rely on load cases that are mere conjectures. Besides, they are extremely complex and incorporate several assumptions e.g., in terms of

in vivo mechanical characteristics of bones and tissue, which makes automation a major area of study in this field [

120]. In effect, this means that nowadays patient-oriented implant adaptation primarily addresses the geometry of interacting surfaces, as in the case of the hip joint, or the geometry of the bone in which the implant would be embedded,

i.e., the femur in the case of a hip replacement. Consideration of local density variation of the femur may similarly be taken into account based on CT measurements and associated local density derivation [

121].

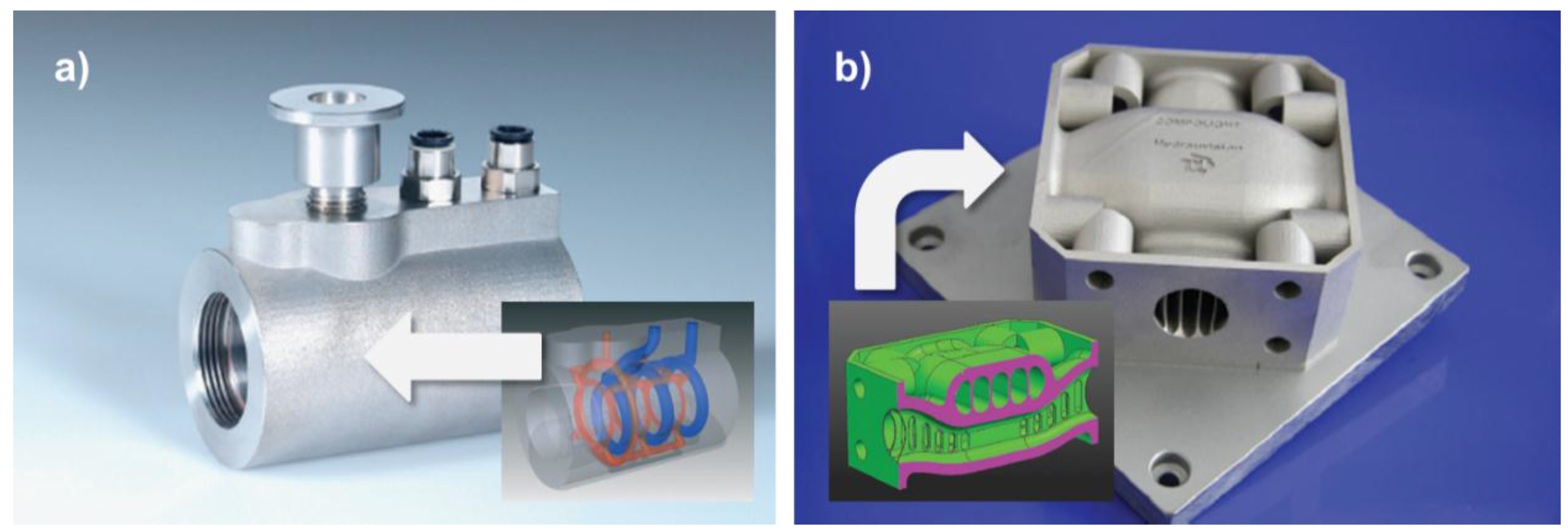

Additive manufacturing of various types of implants has gained in importance in parallel to the rise to maturity and fame of the technology and as a means towards realizing the aforementioned patient-specific adaptations. A recent study by Cronskär

et al. has demonstrated a cost advantage of 35% when manufacturing a series of 7 hip stem implants using EBM-AM rather than conventional (subtractive) manufacturing techniques [

121]. The basis for implant layout, irrespective of the production path chosen, is a CT scan and a derived 3D representation of the receiving bone (femur). This established design approach is illustrated in

Figure 9 and contrasted to its UDE-CBDM counterpart.

Figure 9.

Typical design flow for implant layout according to Cronskär

et al. [

121] with additions introduced by a PLM-data supported approach combining item and subgroup/population level information. The diagram assumes PEID integration as integral part of the AM process.

Figure 9.

Typical design flow for implant layout according to Cronskär

et al. [

121] with additions introduced by a PLM-data supported approach combining item and subgroup/population level information. The diagram assumes PEID integration as integral part of the AM process.

What is currently still missing is the suggested combination of all three of the above elements,

i.e., the integration of sensors and sensor systems, the optimization of structural build-up, and the realization via AM processes. In an implementation of the scenario proposed in the present study, the initial design of an individual hip implant could be optimized according to information from a general pool of data on hip implant use patterns. For a specific patient, information from the respective database could be filtered based on the patient’s physical attributes and general knowledge about use patterns. In the latter respect, personal data from other sources, such as body area networks or smart watches, could also be drawn upon. Data sources would thus be both the UDE-CBDM and the “other” data repositories included in

Figure 8. The implant itself would be produced by means of a suitable AM process including the integration of the required set of sensors, plus peripheral electronics, energy supply systems (e.g., harvesting and storage-based) and wireless communication hardware. Here, the remaining limitations of AM processes in terms of sensor integration come into play. Information extraction could be permanent and patient centered, or performed during checkups. In case of a pending replacement, the next generation implant could either be designed in direct accordance with what the collected data suggests, or using predictions that derive trends from the individual’s data. These data would originate from a larger database, from which, depending on the specific case, comparable and matching data (e.g., age, gender and use pattern) could be derived. The new implant would once again contain sensor systems for a further iteration. The aim, however, would be to increase the timespan between replacements with this new design.

What makes this scenario a relatively simple one is the fact that the boundary conditions are mostly static here,

i.e., it is unlikely that the collected user data will suggest switching the principal load cases that governs dimensioning. Instead, the accumulated data will only modify the loads themselves, and thus change the design criteria merely on a parameter level, rather than on any disruptive one. Reversing this argument, we have to conclude that optimization must be realized on a very fundamental level in this case, like local variation of material properties, which can be achieved via control of porosity levels. Such designed local porosity levels have already been the object of intense study in the context of implants, and tools exist that are capable of optimizing them in relation to the relevant load cases and with AM the method of choice for production [

122].

For the maker of the implant, the implied business model is attractive, too, because the need to retrieve and evaluate data from the previous device can be exploited to establish a customer tie, to a mutual benefit: What is sold with the first implant is not only a physical product, but a product with associated services, which open up an additional source of revenue for the vendor, and ensure optimum product performance for the bearer. What the scenario still lacks in practice is the technological capability of extending the data collection to any implant produced, and to do so in an AM approach. Besides, the automated DaaS toolset and the connection between it and the collected usage data plus associated information is not available yet. Well-matched optimization techniques, in contrast, have already been demonstrated as stand alone solution.

4.2. Case Study 2: Robots as Intelligent Products—Agent-Based Cloud-Manufacturing Supported by Product-Inherent Perception

This second case study outlines approaches for unified information processing architectures that are suitable for additive and adaptive manufacturing based on a closed-loop sensor processing approach,

i.e., PLM by back propagation of inherent product perception. This approach combines distributed data mining concepts (big data), sensor data processing, and the cloud computing (Internet-of-Things) paradigm. Additive and adaptive cloud-based design and manufacturing are attractive for the field of robotics, targeting both industrial and service robots as well as semi-autonomous carrier robots. In cloud-based manufacturing, the user of the product is integrated in the distributed design and production process [

9] through cloud-integrated computing and storage solutions.

Robots can be considered as active, mobile, and autonomous data processing units,

i.e., hardware agents that are commonly already connected to computer networks and information processing infrastructures. Robots use inherent sensing capabilities for their control and task satisfaction, commonly delivered by integrated sensing networks with sensor preprocessing. These derive some inner state of the robot, for example, mechanical loads applied to structures of the robot or operational parameters like motor power and temperature. The availability of the inner perceptive information of robots enables the estimation of working and health conditions initially not fully considered at design time. The next layer in the cloud-based adaptive manufacturing process can be the inclusion of the products themselves delivering operational feedback to the current design and manufacturing process, leading to a closed-loop evolving design and manufacturing process with an evolutionary touch, shown in

Figure 10 below. This evolutionary process adapts the product design, for example the mechanical construction, for future product manufacturing processes based on a back propagation of the perception information (

i.e., recorded load histories, working and health conditions of the product) collected by living systems at run-time. The currently deployed and running series of the product enhances future series, but not in the traditional coarse-grained discrete series iteration. This process can be considered as a continuously evolving improvement of the robot by refining and adapting design parameters and constraints that are immediately migrated to the manufacturing process. A robot consists of a broad range of parts, most of which are critical for system reliability. The most prominent failures are related to mechanical and electromechanical components, and are typically caused by overload conditions at run-time under real conditions not considered or unknown at initial design time. Furthermore, monitoring and profiling of the embedded software can be used for improvement and revision processes in the software design, which can be correlated with other perceptive data.

Figure 10.

Additive and adaptive Manufacturing with back propagation of sensing data using mobile agents from robots to the design and iteration process resulting in continuous series improvements.

Figure 10.

Additive and adaptive Manufacturing with back propagation of sensing data using mobile agents from robots to the design and iteration process resulting in continuous series improvements.

The integration of robots as products and their condition monitoring in a closed-loop design and manufacturing process is a challenge and introduces new distributed computing and data distribution architectures in strong heterogeneous processing and network environments. One major question to be answered is the sensing of meaningful condensed product condition information and the delivery to the designer and factory. It is a similar issue that arises in the Internet-of-Things domain. New unified data processing and communication methodologies are required to overcome different computer architecture and network barriers. One common distributed and unified data processing model is the mobile agent, a self-contained and autonomous virtual processing unit. The mobile agent represents a mobile computational process that can migrate in the Internet domain and in sensor networks as well. Multi-agent systems (MAS) represent self-organizing societies consisting of individuals following local and global tasks and goals. A MAS is a collection of autonomous or semi-autonomous problem solvers [

123], often working proactively. This includes, for example, the coordination of information exchange in the design and manufacturing process [

124]. The agent’s action and behavior depends on an abstract model of the environment described by ontologies. A MAS relies on communication, negotiation, collaboration, and delegation with specialization including instantiation of new agents.

Agents are already deployed successfully for scheduling tasks in production and manufacturing processes [

125], and newer trends enquire into the suitability of distributed agent-based systems for the control of manufacturing processes in a wider sense [

126], facing not only manufacturing itself, but maintenance, evolvable assembly systems, quality control, and energy management aspects, finally introducing the paradigm of industrial agents meeting the requirements of modern industrial applications. The MAS paradigm offers a unified data processing and communication model suitable to be employed in the design, the manufacturing, logistics, and the products themselves.

The scalability of complex industrial applications using such large-scale cloud-based and wide-area distributed networks deals with systems deploying thousands and up to a million agents. But the majority of current laboratory prototypes of MAS deal with less than 1000 agents [

126]. Currently, many traditional processing platforms cannot yet handle big numbers with the robustness and efficiency required by industry [

127,

128]. In the past decade the capabilities and the scalability of agent-based systems have increased substantially, especially addressing efficient processing of mobile agents.

There are programmable agent processing platforms that can be deployed in strong heterogeneous network environments [

129], ranging from single microchip up to WEB JavaScript implementations, all being fully compatible on operational and interface level, and hence agents can migrate between these different platforms. A distributed coordination and management layer enables the composition of large-scale agent processing networks [

130] including WEB browsers creating one big virtual machine. Multi-agent systems can be successfully deployed in sensing applications, for example, structural load and health monitoring, with a partition in off- and online computations [

131]. Distributed data mining and Map-Reduce algorithms are well suited for self-organizing MAS. Cloud-based computing, as a base for cloud-based manufacturing, means the virtualization of resources,

i.e., storage, processing platforms, sensing data or generic information.

Traditional closed-loop processes request data from sources (products, robots) by using continuous request-reply message streams. This approach leads to a significantly large amount of data and communication activity in large-scale networks. Event-based sensor data and information distribution from the sources of sensing events, triggered by the data sources (the robots) themselves, can improve the allocation of computational, storage, and communication resources significantly and limit the need for these.

A cloud in terms of data processing and computation is characterized by and composed of

a parallel and distributed system architecture,

a collection of interconnected virtualized computing entities that are dynamically provisioned,

a unified computing environment and unified computing resources based on a service-level architecture, and

a dynamic reconfiguration capability of the virtualized resources(computing, storage, connectivity and networks)

Cloud-based design and manufacturing is composed of knowledge management, collaborative design, and distributed manufacturing. Adaptive design and manufacturing enhanced with perception delivered by the products incorporates finally the products in the cloud-based design and manufacturing process.

Agent Classes. The entire MAS society is composed of different agent classes that satisfy different sub-goals and reflect the sensing-aggregation-application layer model: event-based sensor acquisition including sensor fusion (Sensing), aggregation and distribution of data, preprocessing of data and information mapping, search of information sources and sinks, information delivery to databases, delivery of sensing, design, and manufacturing information, propagation of new design data to and notification of manufacturing processes, notification of designer, end users, update of models and design parameters. Most of the agents can be transferred in code frames with a size lower than 4kB, and depends on the data pay-load they carry. At run-time, agents are instantiated from these different classes, and agents can change to a subclass behavior depending on current sensing, goals, and their inner state.

4.3. Case Study 3: Tailor-Made Shoes—Value Co-Creation Approach with Reactive Rubber 3D Printer

The present case study details a consumer product scenario (shoes and the shoe industry) studied in some detail in the course of a publically-financed project inspired by the needs of a local industry and aiming at the validation of a smart factory concept that incorporates many features of UDE-CBDM as discussed here.

Because of current trends in modern life and longevity, it has become common to wear shoes daily for long periods. Consumers devote great concern to “foot comfort” or “shoes fit feeling” in various life scenes, such as health promotion, rehabilitation, running or other athletics, business use, etc. Rubber is an important material used to develop shoes of various types to achieve comfort levels and/or customer satisfaction.Kobe, the birthplace of the rubber industry in Japan, is still the country's largest base of chemical shoes despite damage caused by the Great Hanshin-Awaji Earthquake. Therefore it is important for the Kobe area to realize and maintain the innovative capabilities of the rubber industry to secure its footing in the global competition. The current study’s target is the athletic shoe industry as the first step to validate a smart factory concept with user involvement.

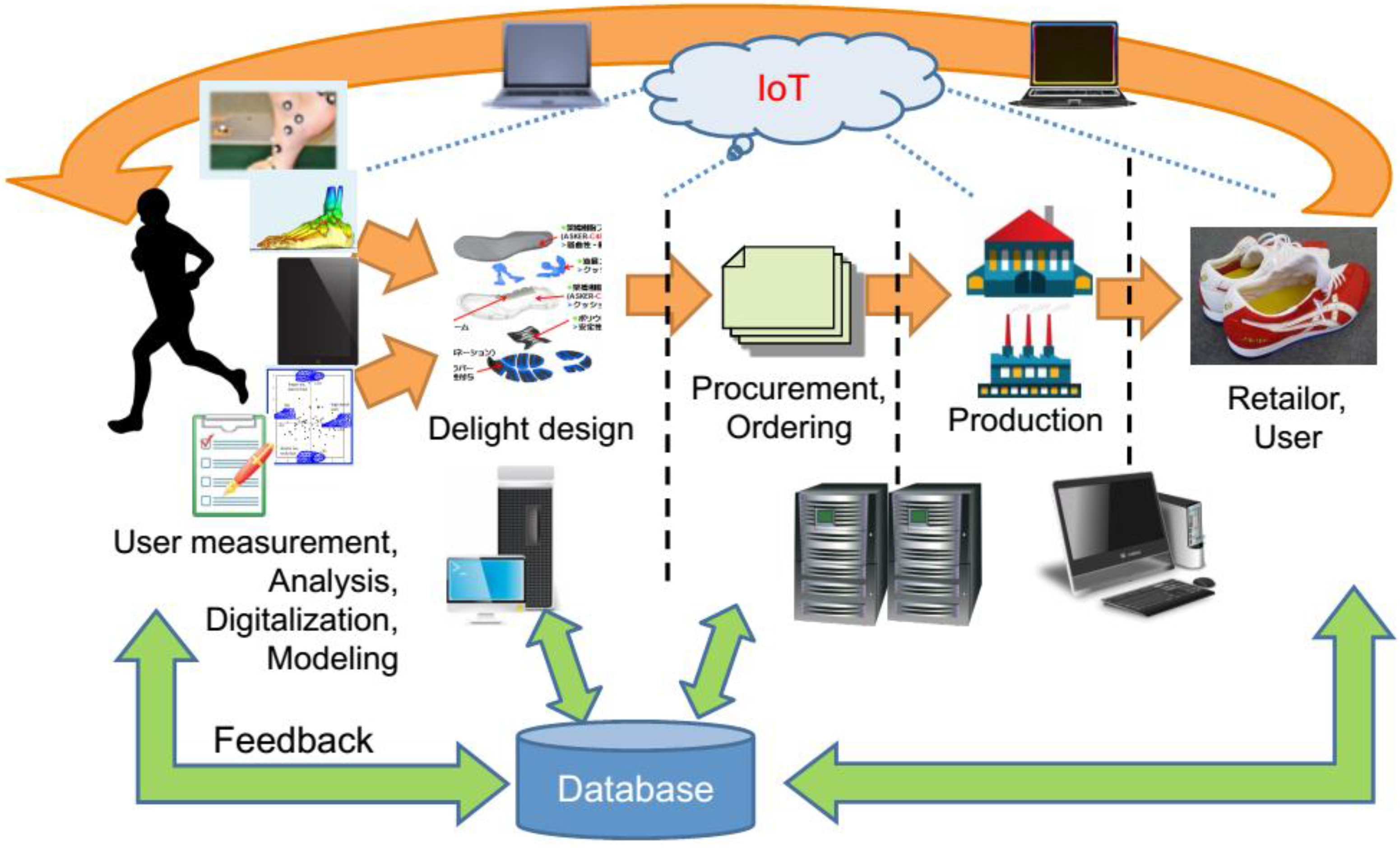

The value co-creation loop in our project is presented in

Figure 11. The loop consists of four major processes: Analysis, Design, Operation and Application.

Figure 11.

Proposed value co-creation loop.

Figure 11.

Proposed value co-creation loop.

Digital human technology is applied to conduct comprehensive analyses based on market data. User motion data and biological data are obtained precisely from the user market with sensing devices such as motion capture or CT scan equipment. Then interactive communication design is done based on the analytic data. Communication is realized with several smart devices under an IoT environment. Service applications connect producers and users, who can send attributes or preferences to producers, who provide tailor-made product design services including athletic functions and surface design.

The diversity of products is increased greatly by tailor-made production. This implies that the smart factory technology for mass customization production is operated from the design to operation phase as process innovation. Distributed and autonomous production mechanisms are implemented transparently within the smart factory to correspond with several levels of user satisfaction in an IoT environment. AM has a major role in this concept, as it is mandatory to achieve the required customization levels: We can attempt to invent a new reactive 3D printer for rubber materials to attain tailor-made rubber products in the production phase. Rubber products with functionally graded materials are realized with embedded pressure-sensitive sensors. Consequently, any kind of users’ personal comfort related to shape and function of athletic shoes (i.e., inner/mid/outer soles) is attainable with the reactive rubber 3D printer.

Rubber products can be integrated into the soles of running shoes of professional athletes (lead users). Then the information collected through the sensor under an IoT environment should be applied to shoe design for the more casual runners (semi-lead users), and eventually for mass users in society. The level of each phase in the loop differs according to the loop hierarchy. Design intellectual transformation from lead users to mass users is executed via a three-layered-business system.

The entire project design, particularly the iterative data collection and the tailoring process for customers, involves “service design”. Subconscious user delight is extracted using the proposed continuous interactions amongst users of several kinds and producers in the business system. User centered-innovation is achieved in our project with reactive rubber 3D printing technology.

A new smart factory including the concept of “value in use” is realized in this research project. As an example of our development, our smart factory structure for mass customization of the athletic shoe industry is presented in

Figure 12.

Figure 12.

Proposed smart factory structure.

Figure 12.

Proposed smart factory structure.

A smart factory encompasses all business layers in the industrial value chain including consumers with IoT environment. Most software modules are integrated in manufacturing management and control, such as ERP, SCM, MES, and SFA. Then a multi-agent based intelligent CPS system, named a Real-Virtual fusion System [

132], is implemented into the smart factory to realize distributed and autonomous factory management and control. Thus apart from the fully-automated cloud-based design and optimization system, which forms the core of the suggested DaaS system, all aspects of theUDE-CBDM concept proposed are reflected in this case study, including the gathering of usage data through lead users. Effectively, this constitutes the definition of a distinct user group, the data gathered by which is intended to support optimization tasks for additional user groups. Contrary to the full UDE-CBDM concept, secondary and ternary user groups will not be drawn on to a similar degree,

i.e., no sensor integration is foreseen in their case. Of specific interest, however, is the fact that the smart factory concept does include user feedback, and even indirectly so, through the establishment of communication links between users and producers, potentially on social network level or using similar concepts, and the analysis of this communication.

5. Discussion

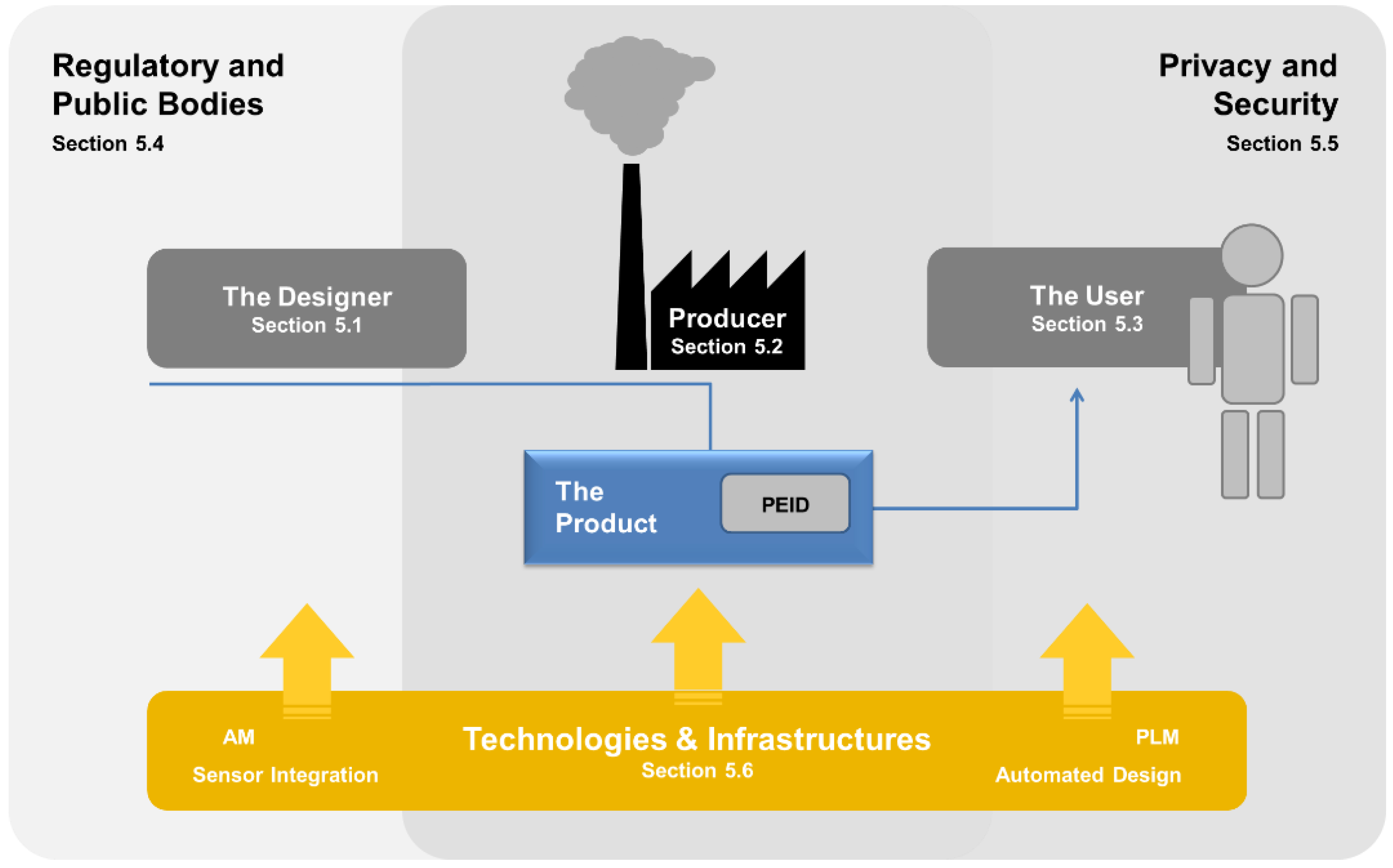

As presented above, the UDE-CBDM scenario defines and demonstrates a trend affecting several stakeholders. In the present section, a critical reflection of assumptions made in this context and their implications is presented using the main stakeholder’s perspectives (

i.e., designer, producer, user and regulatory or public bodies) as structuring element. In addition, general challenges related to privacy and security concerns are highlighted.

Figure 13 denotes these various points of view, adding technologies and infrastructure as their common foundation. The discussion itself will not be dogmatic in the sense that only a full realization of the UDE-CBDM scenario is considered worth discussing. In practice, several prior, intermediate levels can be envisaged.

Figure 13.

The main stakeholders and perspectives and their relation to each other.

Figure 13.

The main stakeholders and perspectives and their relation to each other.

5.1. Designer’s Perspective

With the notion of products being continuously adapted depending on how they are actually used, designers have to acquire additional skills and knowledge in several different domains. Selected examples are explained in the following.

First, the ability of production to adapt to and thus facilitate variation from product item to product item requires that products are designed with extensive flexibility in mind [

133]. A similar development was necessary for the transition from mass production towards mass customization, where the intense use of modular product architectures and parametric design allows customers to select those system configurations that would fit their purpose best [

134]. For reason of such characteristics, parametric design has been linked to both simulation and design optimization [

135,

136] and digital,

i.e., additive manufacturing [

137]. In principle, however, it remains a way to describe, on different levels, the geometry of a product as function of a set of parameters that can be treated as variables for creating design variants [

138]. The present UDE-CBDM approach needs flexibility on a much finer level. Consider a design that is controlled by the ability to withstand certain mechanical loads as main requirement. Typically, information derived from usage data will “refine” these requirements, suggesting limited change to a preceding or to the initial “root design” set to achieve improved performance—e.g., weight-specific strength. Modularity alone will not suffice to fine-tune such a design, specifically if it is already nearing saturation on a generation-to-generation, or rather item-to-item, performance increase curve. Effectively, parametric design needs to be extended to incorporate additional features such as local material properties—provided that these can be accessed by the manufacturing process chosen. AM has this potential: Developments like the so-called Digital Materials approach [

139] are currently being commercialized by companies like Stratasys. In this latter case, under the trade name PolyJet, a material jetting technology based on inkjet printing using multiple print heads is employed. Within the boundary conditions of the process in general, this strategy permits voxel-to-voxel change of materials and thus properties, allowing design of materials e.g., with tailored mechanical performance [

140,

141]. Similarly, process classes like directed energy deposition or 3D printing as example of the binder jetting approach may develop in this direction, as they allow either switching between materials (DED) or controlled modification through additives for which the binder serves as carrier medium [

81]. Integrating such local material behavior in the design workflow will afford several changes, including the representation of the product as a CAD model and the translation of the latter to a production oriented format: For this purpose, the standard solution in AM, the STL file format, is not suitable anymore [

140]. In terms of simulation-based optimization, established approaches like shape or topology optimization likewise fail to capture the added complexity. Further advancement of methods like Multi-Phase Topology Optimization (MPTO) introduced by Burblies

et al. can help close this gap: The methods provides optimum distributions of porosity levels within mechanically loaded components [

122] and has been demonstrated to be transferable to AM-based implementations. The envisaged DaaS toolset, in its optimization and CAD modelling capabilities as well as in its output to the manufacturing system, will have to apply such features, and allow their modification in response to usage data input.

Secondly, with an increasing flexibility in design, an extensive knowledge of the dependencies among different system components is needed. Making one part flexible might lead to immediate or long-term consequences for related elements of the whole system. The same holds true for solely component-centered optimization which ignores interdependencies within the overall system and may thus lead to performance reduction or even premature failure on system level.

Thirdly, a critical aspect of adaptive products is that adaptations must meet high quality standards at any moment of the product life. In contrast to biological systems, that perform a trial-and-error approach of which death is just a necessary and accepted concept, technical systems must avoid costly failures. In order to guarantee such levels of quality, testing procedures have to be applied during product design and development. However, physical testing fails to fulfil the basic demands of our suggested approach for two reasons: Since it requires production of prototypes and availability of test facilities it contradicts the notion of individually optimized products on a level of principle, and it eliminates much of the advantage in lead time reduction that AM as production method offers. Furthermore, it would limit the choice of possible production sites to those that have the right test equipment at hand, and would thus cancel out the envisaged decentralized production option. For these reasons, affordable personalized and individually optimized products as foreseen in this paper must make extensive, if not exclusive, use of virtual testing methods and environments.

Fourthly, taking usage information into account during design decisions requires knowledge in representation and interpretation of the information. Representation is bound to data analysis techniques ranging from basic statistics to complex data mining approaches. In using the gathered data, distinctions have to be made regarding the level on which optimization is implemented. The following main categories can be identified:

Optimization on individual/item level: A follow-up product serving the same purpose for the same user can be optimized to meet an adapted, personalized set of requirements.

Optimization on subgroup level: Collection of PLM data may reveal certain recurring types of usage, allowing identification of and thus product optimization for certain user subgroups. As in the previous case, this implies that additional, defined sets of requirements can be formulated on subgroup level that deviate from and/or add to the generalized set.

Optimization on population level: On a general level, collection of PLM data will establish a major step forward in terms of usage patterns and thus help to focus and/or boil down the set of requirements all individuals/items of a product (on product definition in this context, see statements below) have to conform to.

Distinction between these levels needs to be reflected in the data analysis techniques employed. An additional aspect worth mentioning in this context is the fact that in a scenario with item-level optimization, all data will be gathered by slightly deviating individual products. Thus it is necessary to distinguish the lessons to be learned from the usage data. One part concerns lessons about the use case (e.g., involved actors and product functions), and a second part concerns those about the actual product item that gathered the respective data set. It is furthermore important to derive rules that allow combination of data originating from different product items, and thus different expressions of a common “root design”. Capabilities of this kind would be associated to the interfacing and mapping element specifically highlighted in

Figure 8.

More generally speaking, the interpretation of information is a matter of human experience and understanding of context. Advances in data analytics techniques created a new profession, the data scientist [

142]. In order to learn from usage data, designers must collaborate with data scientists to find appropriate answers for design problems within the data. Typical examples are the search for new requirements or the validation of existing requirements typically documented before starting to create or alter a product’s design. Besides technical and collaboration challenges related to the analysis of usage information, it is also necessary for designers to understand the limitations of data analytics. An important concept that must be considered in this respect is information quality [

143]. Any piece of usage information is created within a certain context and used for one or more specific purposes. In the case of sensor data, a specific class and make of sensor is operated to acquire the raw data. The context of each sensor (e.g., whether it was calibrated or not) is needed to correctly interpret the resulting data. Without this information, designers and data scientists must be careful concluding on the data. In addition, the understanding of complex usage patterns from sensor data may require complementary information, such as user-authored information in discussion forums, social networking services, maintenance reports and product reviews. Besides that, information from complementarily used products should be taken into account to gain a better understanding of user problems. The improvement of shoes, for instance, might need to take data from a backpack (e.g., load during movement) or umbrella into account (e.g., local weather). Such complementary information sources add to the context of a specific design decision and may thus reduce uncertainty—though here, too, quality of information has to be taken into account.

All the above needs to be considered beforehand and designed into any future system capable of automating the design optimization process, thus taking central decisions in this field out of the hands of human designers. Automated design must evolve to deliver valid solutions fast and in a directly applicable manner based on the growth and evolution of the available usage data. This implies first the connection of the relevant tools applied in the design process to these data, secondly the feeding of these with knowledge and rules on AM processes. Today, the latter is still seen as a major obstacle to the distribution of AM technologies even in a conventional design and development process, since many of the specific rules of “design for AM” have not been formulated, let alone spread widely yet.

5.2. Producer’s Perspective

Before discussing the producer’s perspective in the following, the difference from the designer’s perspective has to be elaborated. In the described scenario, this differentiation is more fluid than is known from the related traditional structures in industry. In UDE-CBDM, design and manufacturing is a continuous effort, which requires exchange of information and transparency throughout the value-chain. Thinking this even further, the “producer” might even be the user him/her-self, employing decentralized AM capabilities at home or in the local Maker-Space. In such a case, the “traditional” producers responsibilities may be reduced to supplying the material (if that is the case at all), or to serving as an intermediary supplying the parameters/specification for the AM process at the users site—or his role might even become completely obsolete.

However, this extreme example is still far from reality. Industrial AM equipment is still rather costly, not only regarding the tools themselves but also the service contracts required to keep the system in a working condition. Therefore, the role of the producer is valid and an important component of the value chain in this vision. The re-shuffling of the latter will also open up new business opportunities both for the producer, and for third parties that have access to the usage data that product and product groups supply.

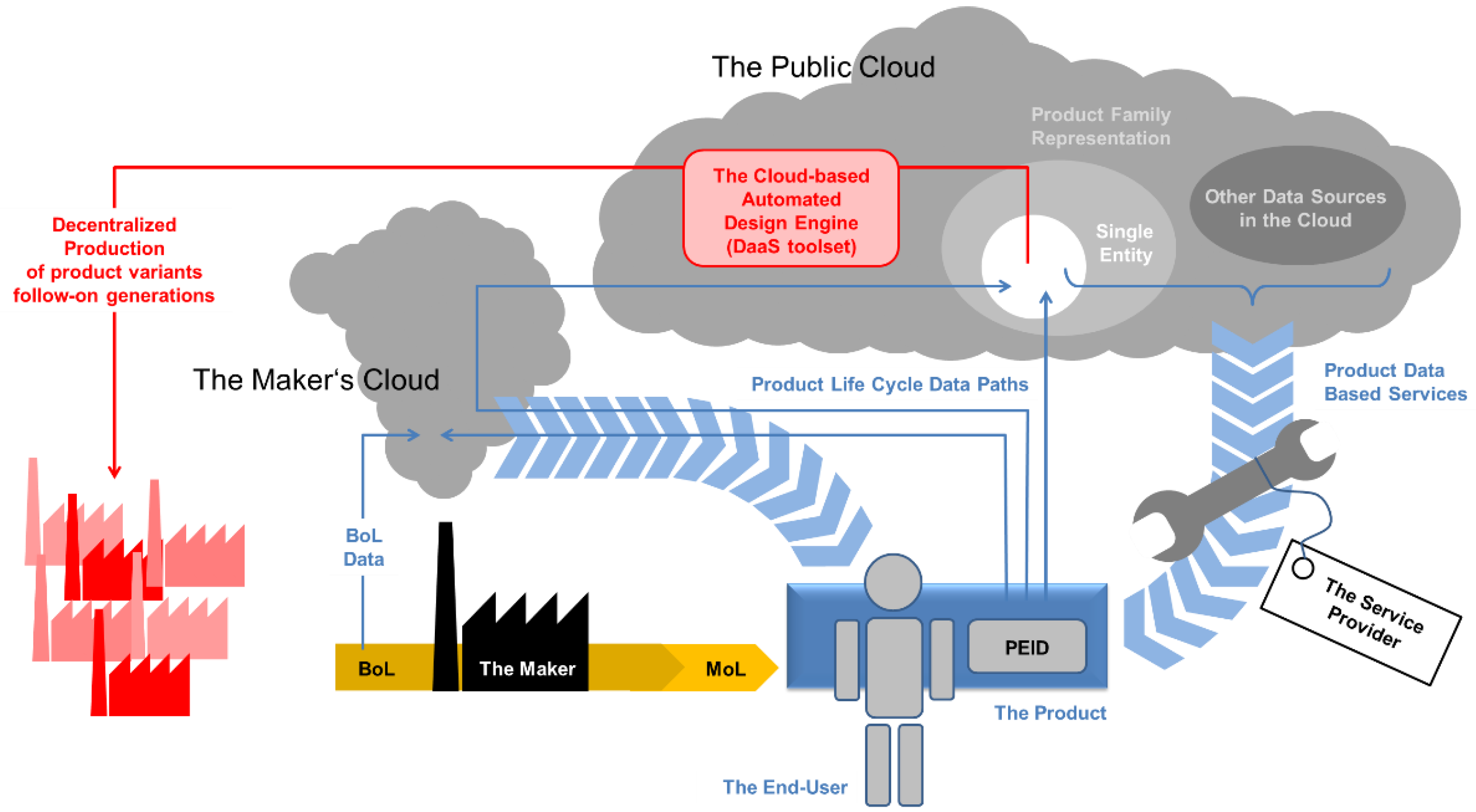

Figure 7 illustrates some of the potential connections in this respect.

The basic assumption is that usage data gathered by the product can either stay within the maker’s realm, where it is accompanied by data associated with the manufacturing of the part,

i.e., BoL data, or it can be passed on into a “public” cloud, naturally assuming that all necessary steps for ensuring security and privacy (see

Section 5.5) have been taken. The availability of such data facilitates several potential product-related services, which may be offered by the maker or by third parties if these have legal access to the data: The fundamental business case for the original producer of a part could thus be the provision of a (personalized or non-personalized) optimization service to the customer. Further product-related services may include maintenance, which could be handled by the maker, or left to third parties. In the latter case, depending on the legal situation in that respect, the producer might enter into a business relationship with the services provider, granting him access to standard or extended product-related data. In parallel, the service provider could use other cloud-based resources to add to the product-specific data and thus enhance or extend his services. A special case is the full-fledged scenario assuming an automated design engine, the DaaS toolset, that creates the subsequent product generation automatically (note that the optimization service could also be envisaged following a conventional design approach), once again making use of available data on the preceding generations. Here, redesign could be a service offered via the cloud, with not so much the primary, but potentially secondary producers acquiring access to the redesign and optimization tool, which might be offered by a software developer. Since the original maker would not be involved here, Beginning of Life (BoL) data as a additional source of information would probably be lacking, however, for the new product entity, its new, originally secondary, producer would assume the role of primary maker, with all the facets this entails according to

Figure 14.

Figure 14.

An overview of data flows between stakeholders integrating the cloud and highlighting possibilities of cloud-based product-related services.

Figure 14.

An overview of data flows between stakeholders integrating the cloud and highlighting possibilities of cloud-based product-related services.

Being responsible for transforming the virtual design in a physical product, the producer’s responsibility includes ensuring that the manufacturing processes deliver the required quality as it is the case today. Due to the flexibility of AM and the availability of the design in the required format, the impact of the producers’ expertise will shift slightly towards supporting the designers from an early stage on. This support includes but is not limited to: Design for Manufacturability (DfM), choice of available material, dimensioning (based on available equipment).

Besides, defining the new role of the producer requires answering a multitude of open questions. Decentralization of production, including item-to-item adaptation of design will require formulations that clearly define responsibilities along this process chain: If a product fails on item-level, who is to blame? Will it always be possible to associate the cause of failure with either root design, collection of usage data, interpretation of it, transfer of data (cyber security aspects), product optimization or production? In this context, we need to take into account that it might not be practically feasible to establish an answer on a case-by-case level. Thus there might be a need for generalized rules, which would mean that the relationship between, for instance, designer, manufacturer and service provider may have to be re-thought and cast into a working formalism, be it on a contract or licensing level, or another suitable mode.

Finally, the producer, bound by current regulations, may also find him-/herself responsible for the recycling of the products after they reach the end of their service life. As each product is unique in the most advanced scenario, this might add additional challenges. These challenges include dismantling in case sensors are implemented (at different, item-specific locations), hazardous materials, precious metals and others.

5.3. User’s Perspective

For a user, our scenario has several benefits in store, not the least among them the chance to obtain optimized follow-up products adapted to his personal needs. There is, however, no rose without thorns, and in the present case, to realize these advantages, the user may have to become an active partner of the producer. Currently this must seem an uncommon relationship thinking of everyday goods like shoes, and it must be taken into account in this context that even if the individual task may seem negligible from a single product perspective, it will accumulate the more candidate products the user chooses to maintain in this same way. The actual tasks the user might be entrusted with may include the read-out of data, the added, personal evaluation of product performance and performance change, as well as maintenance tasks that are aimed at ensuring the quality of data to stay on a constant, high level throughout the product’s lifetime.

A side aspect of the implied personalization of products may be the impossibility of allowing them to be used by other people aside from the owner. Both in private life and in a sharing or collaborative consumption economy, which currently seems to evolve in several fields, this may prove a restriction felt severely by many users.

Finally, the big issues when it comes to usage data are privacy and ownership of data: These will be treated in more detail in

Section 5.5, since they touch upon the realm of users and other stakeholders alike.

Considered along the above lines, the user is the end user or customer that will directly utilize the final product—wear the shoes, if we refer to case study 3, or the smart implant, if we consider case study 1. In practice, the interface between this user and the cloud-based services that lead to his personal product might often be provided by a dedicated service provider. For both, the customer or end-user and for any intermediary, it is very important to gain an idea of the reliability of the manufacturing chain behind the interface to service provider (as potential intermediary), or the cloud-based services themselves. In a conventional production scenario, the end-user would base his trust e.g., on the reputation of a brand,

i.e., an OEM. In CBDM in general, and thus also in its UDE-CBDM variant, the manufacturing chain is much more susceptible to change, as the model implies choice of manufacturing opportunities based on factors like availability and price raised almost in real time at the instant an order for a product is placed. Thus instead of fixed, well established supplier relations, a constant reconfiguration of the chain is possible from single order to another single order. In such an environment, subjectively building up trust is rendered difficult if not impossible. In consequence, as Li

et al. point out, some formal, more objective mechanism for evaluation of trustworthiness needs to be established [

144].

5.4. Regulatory or Public Bodies

In its practical implementation, the final consequence of our approach will be a certain loss of meaning for the term product series. Many of the above statements imply that products can be identified on population level as belonging together through a set of measurable—and this means measurable on the product—parameters that for this population take on the same value. This is certainly true in conventional manufacturing, when e.g., the same die is used to cast a series of wheels. However, according to our present approach, such commonalities are lost because in the extreme case, a redesign process is initiated prior to the manufacturing of each individual and based on the usage data available at that specific moment in time: For a product made a few minutes later, the data base may already have changed. What constitutes a product in this world could then only be a generalized description of purpose, i.e., of the application scenario, and a set of equally general common requirements. Neither of these would suffice to actually explain all the specific properties of an individual product, because these would be based partly on the general requirements, and partly on individual- or subgroup-related ones. It would thus only be possible to speak of a product in the broader sense of a group of objects built to meet a common class of general requirements, and having a common “root design”.

Considering the practical implications of the above conjecture, it is obvious that under such circumstances, the concept of type approval and homologation cannot be maintained. On the other hand, it is similarly obvious that it is impossible for economic reasons to seek approval on a single item level.

Here, a solution comes to mind which has already been discussed in terms of its role in the design process in

Section 5.1: If physical testing is out of question, virtual testing must take its place. This, however, does not eliminate the practical issue that not every individual product entity can be virtually tested by a certifying authority. Thus wherever certification of products is an issue, this means that the virtual test procedures themselves must first be acknowledged and certified, to guarantee their correct application, and to allow the results to be accepted as proof of the product’s adherence to the relevant rules and standards. Similarly, it might be possible to evaluate the optimization procedures that govern entity-to-entity product evolution. In this case, a conventional certification of a “root design” could be implemented and “measures of change” developed: Their limiting values would then define a corridor the violation of which by product characteristics would set the mark for recertification, turning the then-current product design stage into the new root design with respect to certification. To make such a process calculable for the producer, predictive tools might be needed allowing an estimate of levels of change to be expected within a given period of time, in order to identify the tipping points in advance and prepare for the recertification effort in time.

The fundamental assumption in the discussion above is that certification authorities and regulatory bodies have to deal with a single, combined designer and producer. Needless to say, the issue becomes more complex once the elements of decentralized production and cloud-based optimization are added. Design evolutions would then occur independent of the “root designer”, which would raise additional liability issues. Once again a step towards a solution could be to certify the methods and their use, and not the product, or rather product state. However, as already mentioned in

Section 4.2, even if this approach proved possible, liability issues along the chain or rather network of designer, initial producer, optimizer, secondary producer and customer would still need to be clarified, and accepted, and potentially globally enforced rules in this respect laid down.

5.5. Privacy and Security

Another general challenge beyond our specific scenario is the question of data ownership and privacy, which has been introduced already in

Section 4.3. Usage data is by definition generated when the product is used, and by the user. Our model assumes, for example, that the original designer of the product, or rather those group that provides the optimization service, has full access to the collected data, or at least the information derived from it. This access may or may not include additional information about the user of a specific product entity, again with a possible differentiation in personal/individual or user group data. Access to this data is likely to allow its evaluator to derive several conclusions on user or user group that go far beyond the needs for product optimization. Thus the user has to be convinced that he/she should share his/her data with the manufacturer/designer—either for his personal (item-level approach), or for the mutual benefit of broader user communities (subgroup and/or population level approach). This entails legal issues, like misuse of sensitive data

etc. However, as this is a strongly discussed topic today, there is a large chance that this issue will be solved one way or another within the foreseeable future. In any case, it is clear that a legal framework has to be created that clearly define the involved parties’ rights as well as their limitations.

Besides privacy, cyber security is becoming more and more of a concern both in the area of networked smart systems and objects (from cars to IoT) and in that of Additive Manufacturing. Here, we combine both aspects. New issues include questions such as product identification and protection against plagiarism, but also the issue of assuring that data has not been corrupted in some way or another on its path from designer to producer, with potentially critical consequences for product safety, to give but one example. Consistency of data thus needs to be ensured.

An increasing degree and complexity of networking and information exchange between a large number of computers, mobile devices, sensor networks, individual smart sensors, products and machines induce new challenges in the handling of privacy of data, privacy of users, authorization, and authentication in a mostly anonymous Internet-of-Things (IoT) domain. New concepts and methodologies are required for binding and granting access rights to data, creating access roles based on application rather than on user level, traditionally managed by higher communication layers like WEB servers or databases providing account services. Considering consumer products that deliver lifecycle data, the users and their location are mainly unknown. By enabling usage data delivery from products to manufacturers these anonymous users get a virtual identity encapsulating private user data, for example, their geographic location (that can be accurately determined by network services and fusing of other data), the usage behavior, and so on. In the proposed design and manufacturing clouds, which are integrated in the vulnerable Internet, Cyber Attacks can significantly disturb the processes or spy sensitive or confidential data. If sensor, product, and user data is autonomously transferred, for example, by mobile agents, the data become self-contained units that can be processed on any platform, ranging from embedded systems up to servers. It is relatively easy for intruders to include Man-of-the-Middle attacks to retrieve and spy secured data, and in service-orientated processing environments Denial-of-Service (DoS) attacks can prevent an overall system operation. Currently the security issues concerning stealing data or attacking services are not addressed properly in the IoT community. Security issues are related to the user (data producer) and service provider (data consumer) side, though both sides have different goals and constraints in mind.

Looking at cyber security specifically from a producer’s perspective, as Lu

et al. point out, it must be taken into account that the importance of intangible knowledge assets, in other words, of data, for organizational success in industry is clearly on the rise, while at the same time, the accessibility of data and thus vulnerability of the respective assets is increasing with any bit of data that is mirrored in the cloud. The dilemma for the producer is between the wish to raise the potential of cloud-based services and keep track of his competitors in that respect, and the risks that goes with moving business into the cloud. Consequently, dedicated strategies for ensuring cyber security are mandatory [

145].

6. Conclusions and Outlook

In the present work, we have outlined the characteristics of a new manufacturing paradigm designated as Usage Data-Enhanced Cloud-based Design and Manufacturing (UDE-CBDM). We have explained why we believe

usage data collection and analysis, facilitated by

sensor integration in

additive manufacturing and fed into

automated design processes