2. Results and Discussion

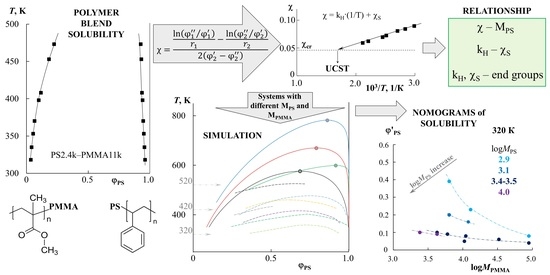

Figure 1 shows the data on the solubility of PS and PMMA of various molecular weights (PS0.8k–PMMA89k, PS2.4k–PMMA11k, PS2.4k–PMMA33k, PS2.4k–PMMA89k), obtained under isothermal conditions for a temperature range limited by the glass transition temperatures of polymers (bottom) and degradation temperatures (top). It should be especially noted that the difference in the refractive indices of the studied polymers was approximately Δ

n = 0.07–0.09, which made it possible to form about 25–30 interference fringes in the interdiffusion zone with a concentration increment per fringe of the order of 0.25–0.3 volume fractions. Based on this, we were able to observe the entire concentration range at once with a step of 2.5–3%. It has been established that the oligomer blend PS0.8k–PMMA2k is characterized by a complete compatibility over the entire temperature range. Such behavior is often expected for oligomer components; for example, for the polystyrene–polyethylene system of similar molecular weights, we obtained data on limited solubility in the range of 390–410 K and constructed a phase diagram with UCST [

21]. Systems such as epoxy oligomers with nitrile butadiene rubber behave similarly [

22].

It is clearly seen (

Figure 1) that the solubility of PS and PMMA decreases with an increasing molecular weight of the components. For example, when going from PS0.8k to PS2.4k, their solubility in the PMMA89k matrix at 400 K decreases from 6 to 4%. And, for PS2.4k at the same temperature, the solubility in PMMA decreases from 10 to 4% with an increase in the PMMA molecular weight from 11 to 89 kDa. In this case, the phase state diagram is not symmetrical; the left branch of the binodal is located in the region from 2 to 25% PS in the mixture and shows a high solubility, while the right branch is shifted to the region of dilute solutions relative to PMMA, and the solubility of PMMA in PS tends to zero. With an increase in temperature, for all the studied systems, the mutual solubility of the components increases, which suggests the presence of UCST. However, fragments of the obtained binodal curves in this temperature range reach the zone of the thermal degradation of polymers (gray zone), which makes it difficult to experimentally determine the parameters of the critical point and estimate the position of the binodal curves’ dome and the two-phase state regions at elevated temperatures. Nevertheless, we tried to estimate the position of the binodal dome because it is at such temperatures that the industrial processing of polymer mixtures can take place.

Previously, we proposed a new approach to simulation phase diagrams from fragments of experimental binodal curves [

23,

24], which is based on the Flory–Huggins theory and involves the extrapolation of the temperature dependence of the interaction parameter

. In accordance with this approach (detailed in

supplementary materials), using the experimental data on the compositions of coexisting phases (

) at different temperatures and the values of the degrees of polymerization (

), the interaction parameters χ were calculated using Equation (1), and the numerical values of the interaction parameter (

) and concentration at the critical point (

) were estimated using Equations (2) and (3), respectively (

Table 1). The error in calculating these quantities directly depends on the error in determining the compositions of coexisting phases. Accordingly, if for

it is 2.5–3%, then for

it is 5–6%. At the same time, three significant digits were retained for the numerical values of the calculated values.

where

and

are the volume fractions of the first (PS) and second (PMMA) components in the system, ′ and ″ refer to different coexisting phases,

and

are their degrees of polymerization, and

is the average Flory–Huggins parameter that evaluates the interaction between the components.

Figure 2 shows the temperature dependences of the parameter

for all systems studied (solid lines), as well as the value of

(dashed lines). It can be seen that the values of

, in accordance with theoretical assumptions, decrease with an increase in the molecular weight of the components. The values of the interaction parameter

for all systems show a linear dependence for the coordinates

, and a directly proportional dependence for similar coordinates indicates a system with a UCST. The localization of the straight lines differs greatly for the

MPS; for PS0.8k it is located noticeably higher and has a larger slope than for PS2.4k. At the same time, a change in

MPMMA from 11 to 89 kDa has practically no effect on the position of the straight lines. The least squares interpolation made it possible to obtain a mathematical expression for these temperature dependences in the format

, where A and B are some numerical values (

Figure 2 and

Table 1). The value of the approximation reliability R

2 (

Table 1) evaluates the accuracy of the adequacy of the linear dependence. For all systems, it is in the range from 0.95 to 0.99, which indicates a high approximation accuracy. The extrapolation of these dependencies to the values of

made it possible to obtain approximate calculated values of UCST for each system. The exact value of the UCST (

Table 1) was estimated from the convergence of the binodal curves during the simulation in the resulting range.

The extrapolation of

to a larger temperature range in the framework of the proposed approach [

24], with calculations by the equations for the spinodal and binodal curves in the framework of the Flory–Huggins theory, made it possible to construct complete binodal (solid lines) and spinodal curves (dashed lines) for PS–PMMA systems (

Figure 3). It can be seen that the phase diagrams obtained are characterized by UCST in the temperature range from 550 to 800 K. Above the binodal curves, we obtain regions of homogeneous solutions; inside the spinodal curve there are heterophase regions, and between the binodal and spinodal curves there are fields of the metastable state. The correlation with experimental data (indicated by square dots in

Figure 3) is quite good, especially with the right branch of the diagram. As for the left branch of the binodal curves, the correlation between the calculated binodal curves and the experimental points is satisfactory, but not ideal. It seems to us that this is due to the error of extrapolation to a very remote temperature range. It can be seen that the correlation of the black dots (PS2.4k–PMMA11k) in

Figure 3 is better than that of the blue ones (PS2.4k–PMMA89k). At the same time, the extrapolation was carried out for black dots by about 100 K, and for blue dots by almost 300 K.

To test the adequacy of the prediction technique used, published numerical data on solubility in the PS0.8k-PMMA6.35k and PS0.8k-PMMA12.9k systems, obtained by the cloud point method by Ougizawa et al. [

11], were selected and rearranged in other coordinates (

Figure 4). They contained experimental data on complete diagrams and critical points. Also, the solid green and dotted green lines indicated the result of modeling the phase diagram in these systems based on the equation of state theory, performed by the authors in the same article. According to our methodology, data on the compositions of coexisting phases were used to construct the temperature dependence of

, to determine the linear equation describing this dependence, to determine the parameters of the critical point (the data are presented in

Table 1), and to simulate the binodal and spinodal curves (shown in solid black and dotted black lines, respectively, in

Figure 4). It is clearly seen that in contrast to the calculation within the framework of the equation of state theory used by the authors of [

11], the phase diagrams constructed by us perfectly correlate with the experimental data on solubility.

Solubility data and binodal fragments in PS–PMMA systems were processed similarly by a number of other authors [

12,

13,

14], who mainly used the average molecular weights of polymers. The calculated results of all characteristics for these systems are presented in

Table 1.

Figure 5 contains a graphical representation of all the calculated binodal curves obtained by us (solid lines), as well as the literature data on solubility (dashed lines). The numbering of these curves is shown in

Table 1. It can be seen that the literature data complement the temperature–concentration field of the phase diagram well, with data on the solubility of PS and PMMA across a wide range of molecular weights. It is interesting to note that the approach to assessing the solubility of polymers based on their solubility parameters [

3,

25] generally did not take into account the effect of molecular weight, and only the chemical nature of the components. Thus, its calculated value according to the van Krevelen’s method for PS was 9.4 cal

1/2/cm

3/2, and for PMMA 9.14 cal

1/2/cm

3/2, and, according to other calculation methods, the range for PS was 9.0–9.4 cal

1/2/cm

3/2, and for PMMA 8.9–9.15 cal

1/2/cm

3/2 [

25]. This difference suggested good polymer affinity and excellent solubility, which is not entirely true in practice and is highly dependent on molecular weight.

Figure 5 shows that with an increase in

MPS and

MPMMA, the region of the two-phase state increases, the solubility of polymers in each other decreases, the UCST shifts to the region of high temperatures, and the position of the critical point shifts from the region of medium concentrations towards a concentrated mixture with a strong divergence of the molecular weights of the components. At the same time, a full correlation is maintained between systems characterized by the same molecular weight of one of the components. For example, curves 1, 10, and 11 correspond to PS0.8k and the change in

MPMMA from 89k to 12.9k and 6.35k, respectively. A similar example can be given for

MPS 2.4–2.5k; these are curves 9, 2, 3, and 4, where the

MPMMA is 6k, 11k, 33k, and 89k, respectively.

For a qualitative assessment of the effect of the molecular weight of the components, the data of the phase diagram were rebuilt along the cross section of three isotherms (320, 420 and 520 K) in the

coordinates for different

and the

coordinates for different

(

Figure 6). To build these dependencies, only the data on the solubility of the left branch of the diagram (in the PMMA matrix) were used, since the right side of the diagram shows extremely low solubility for different systems at different temperatures. Dotted lines, without additional mathematical calculations, combine points of the same molecular weight value of the second component and show a trend in the solubility of the components. The arrow indicates the shift of these curves in the transition from the data group for one molecular weight of the second component to the data group on the other. It is clearly seen that the change in

MPS affects the solubility of these polymers to a greater extent than the change in

MPMMA. For example, at 320 K, the

of order 4

changes from 0.23 to 0.07 with an increase in

from 2.9 to 3.5. In this case, even for

of the order of 3.5,

changes only from 0.1 to 0.04 as

increases from 3.4 to 4.9. When passing from 320 to 420 K, and then to 520 K, the solubility curves shift from left to right in the presented coordinates, which is associated with an increase in the solubility of the components and the formation of completely homogeneous solutions of a number of mixtures. This dependence can serve as a nomogram for estimating and predicting the solubility in the PS–PMMA system of various ratios of the molecular weights of PS and PMMA at different temperatures.

The obtained data do not show a good correlation with the calculated values of the limiting solubility of PS at room temperature [

26], calculated from ternary mixtures in a common solvent based on the affinity of polymers and solvent, and the effect of this affinity on the total solubility. Thus, for PMMA87k, it was expected that the limiting solubility of PS in it would vary from 0.9 to 44.5% with a change in

from 370 to 2.66 kDa.

To assess the thermodynamics of mixing PS and PMMA, we constructed a generalized temperature dependence of the interaction parameter in accordance with the data for all systems (

Figure 7). It can be seen that all dependences are straightforward and can be described by an equation of the

type, where

and is the enthalpy contribution to the Flory–Huggins parameter, and

is the entropy contribution [

3,

23,

27]. The numerical values of

and

are presented in

Table 1. The correlation between

and

is shown in

Figure 8B. It is linear, as was noted earlier for many other systems [

23], which corresponds to a change in the predominance of the contribution of the enthalpy and entropy components during the transition of the system from one

Mw to another. In fact,

corresponds to the tangent of a slope of such dependence, and, according to

Figure 7, changes little for a larger number of systems. PS0.8k behaves well, for which the angle of inclination of the straight lines sharply increases. It can be seen that for PS0.8k, the change in

has a stronger effect on the position of the straight line than for other

. Within the previously indicated error in determining the solubility parameters, linear interpolation can fluctuate in a certain range of values. This will affect the spread of

and

data. We noted that for successful simulation of phase diagrams and convergence of binodal curves at the critical point, the average values of the approximating straight lines (presented in

Table 1) are best suited. We used them for subsequent calculations. To assess the influence of molecular weight, the dependence

was rebuilt in the form of conditional zones (

Figure 8A). To perform this, all systems were divided into groups with a common

, and the boundaries of each conditional zone were the extreme temperature dependences of the interaction parameter of this group. The molecular weight of the PS of each group is indicated on the schematic diagram. So, the zone for PS0.8k is much wider than for the rest. And, if for PS1.2k and PS9k this could be attributed to insufficient data, then the sample of systems with PS2.4k is quite representative. Rebuilding this dependence over several isothermal sections, we obtained a schematic dependence of

on

(

Figure 8C). In this case, a range of potential values was used for each point. It can be seen that such dependences are almost linear for

from 1 to 10 kDa. And, only when

approaches 0.8 kDa, a sharp increase in the

values is observed. Moreover, if we evaluate the lower limit of values in this region, then

fits well with the continuation of the linear dependence. It turns out that only the most oligomeric (

M < 1 kDa) representatives of the homologous series have an excellent effect on the mixing of polymers. We believe that this may be due to the increasing influence of end groups for such low-molecular-weight objects, similarly to what can be seen in the glass transition temperature of PS with a sharp decrease in its molecular weight down to 0.8 kDa [

25].

Previously, work has already been carried out to assess the effect of end groups on the Flory–Huggins interaction parameter, not only in polymer–polymer systems, but also in more complex polymer–copolymer systems [

28]. The presence of end groups at a short length of the macromolecular chain (oligomers) can introduce more disorder into the conformation of the polymer, and, consequently, affect its thermodynamics when mixed with another polymer. The entropy parameter

just estimates the measure of order–disorder in the system. To quantify the effect of end groups on the entropy component of the interaction parameter, a dependence was constructed in the coordinates

(

Figure 9, blue curve), where

is the proportion of end groups, calculated from the assumption that each macromolecular chain has two groups. Then, the proportion of end groups is the ratio of the number of end groups to the number of repeating units in accordance with the degree of polymerization, r. It can be seen that such a dependence has a broken character and allows one to conditionally estimate the values of

of the order of −0.02 and

of the order of 0.08, up to which the influence of the end groups has almost no effect on the conformational stacking of macromolecular chains. After that, even a slight increase in the proportion of end groups leads to a sharp change in

, and, consequently, to a conformational rearrangement of the entire mixture. It is especially worth noting that such changes in

occur symbatically with changes in the ratio

(black broken curves in

Figure 9). It can be seen that a sharp increase in

and a decrease in

are replaced by a weak effect with an increase in

. The numerical value of the break area corresponds to

for both

and

. The orange curve shows the dependence of

on the inverse value of

and in fact is directly proportional to the increase in the proportion of end groups. Additionally, red dots are marked in

Figure 9, which correspond to the systems we studied and one system of the authors. For these points, the range of fluctuations in the values of

and

was calculated in the case of maximum deviations in one direction and the other in the approximating temperature dependence of the interaction parameter within the known calculated error. It can be seen that the trend towards a broken or curvilinear character of the change in the values of

and

from the content of end groups or the reciprocal of the

remains.

Figure 10 shows IR spectroscopy data for PS1.2k (red spectrum) and PMMA15k (blue spectrum). These spectra are characterized by standard absorption bands for these polymers [

29,

30]. In the range of 3100–2800 cm

–1, there are stretching vibrations between carbon and hydrogen, and, unlike PMMA, PS has vibrations near the double bonds of the benzene ring (3100–3000 cm

−1). The most intense absorption peaks of PMMA correspond to the C=O carbonyl group (1729 cm

−1) and C–O stretching vibrations (1200–1100 cm

−1). For PS, the most recognizable are the bands of double bonds of the benzene ring in the region of 1900–1600 cm

−1 and the band of bending vibrations of this ring at 699 cm

–1. To study the IR spectrum of the mixture, such a PS–PMMA composition was chosen, which corresponded to a homogeneous region in the phase diagram at 400 K. The spectrum of the PS1.2k/PMMA15k blend in the ratio 25/75 (black) repeats the spectra of the initial polymers in terms of the position of the absorption bands. For a quantitative analysis of the mixture spectrum, the spectra of the initial polymers were subjected to special mathematical treatment—the mathematical addition of the spectra in a given proportion. Such an addition spectrum is also shown in

Figure 10 (orange spectrum inset). It is clearly seen that it is in full correlation with the experimentally obtained IR spectrum of the mixture (black), including in the range of 1125–1060 cm

−1, which according to [

29,

31] is especially sensitive to conformational rearrangements of PMMA. This indicates the absence of any interactions between the functional groups of PS and PMMA upon mixing; additionally, the benzene ring and the carbonyl group are inert to each other.