Synthesis and Hydrogen Production Performance of MoP/a-TiO2/Co-ZnIn2S4 Flower-like Composite Photocatalysts

Abstract

:1. Introduction

2. Results and Discussions

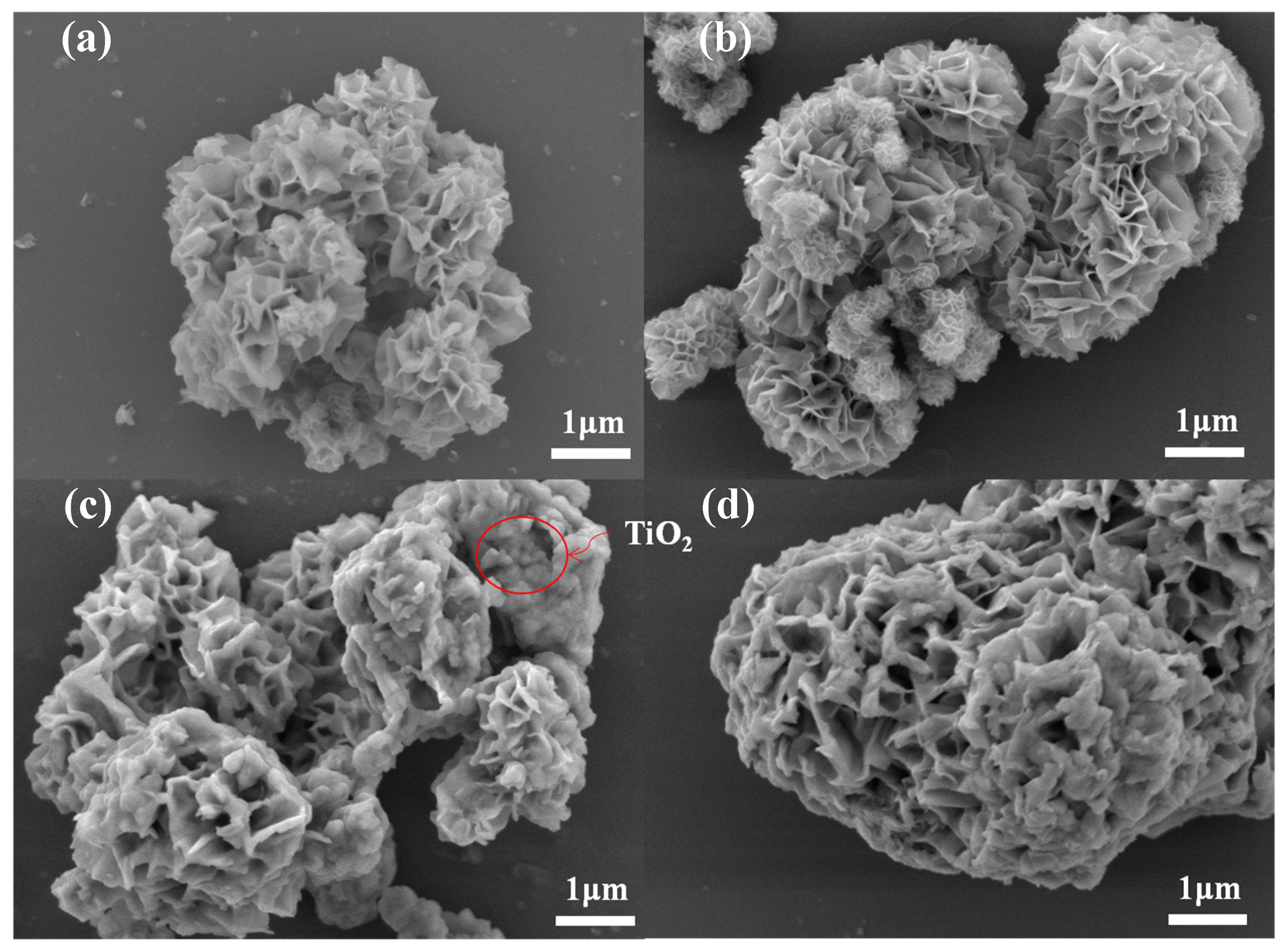

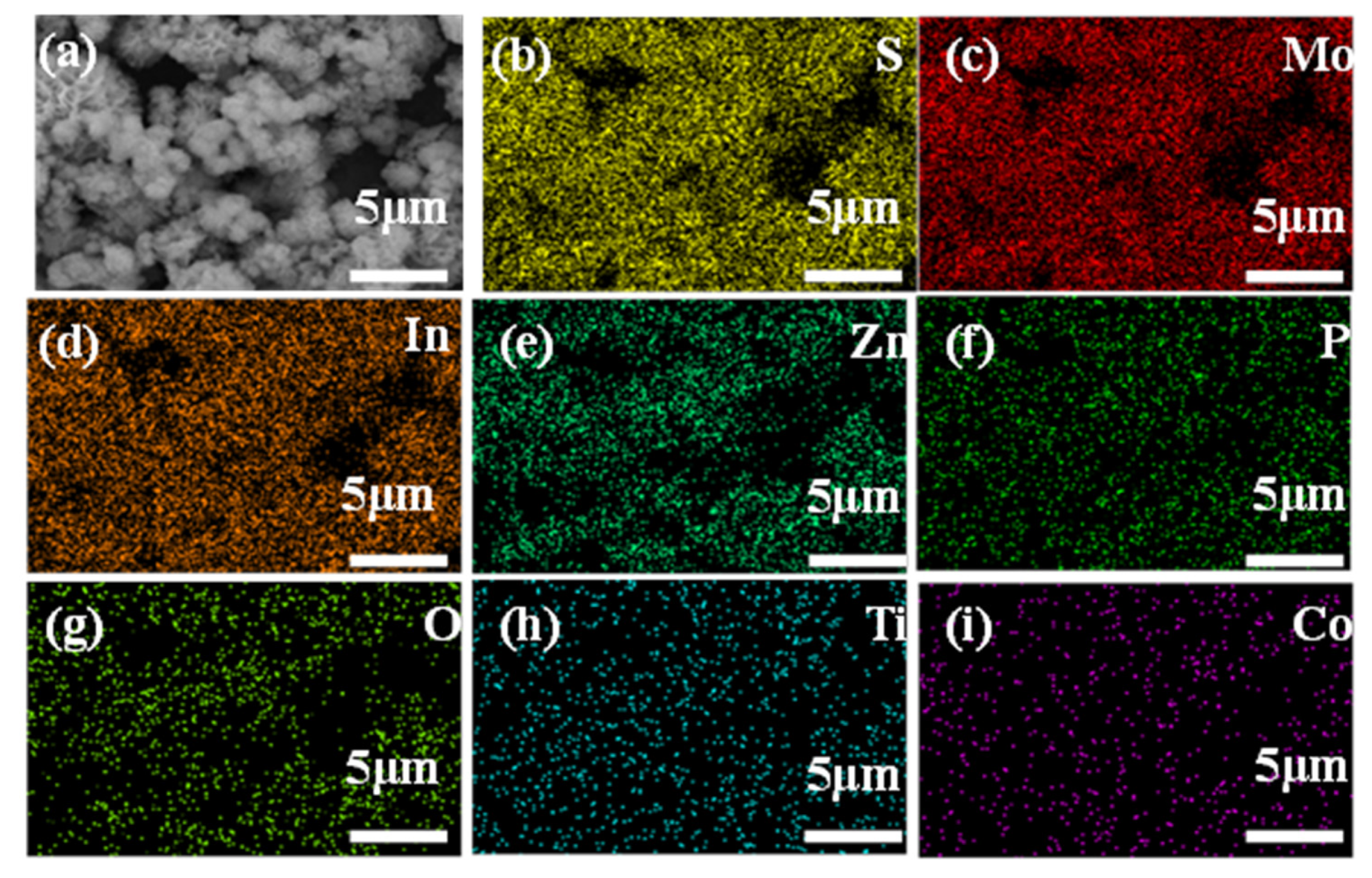

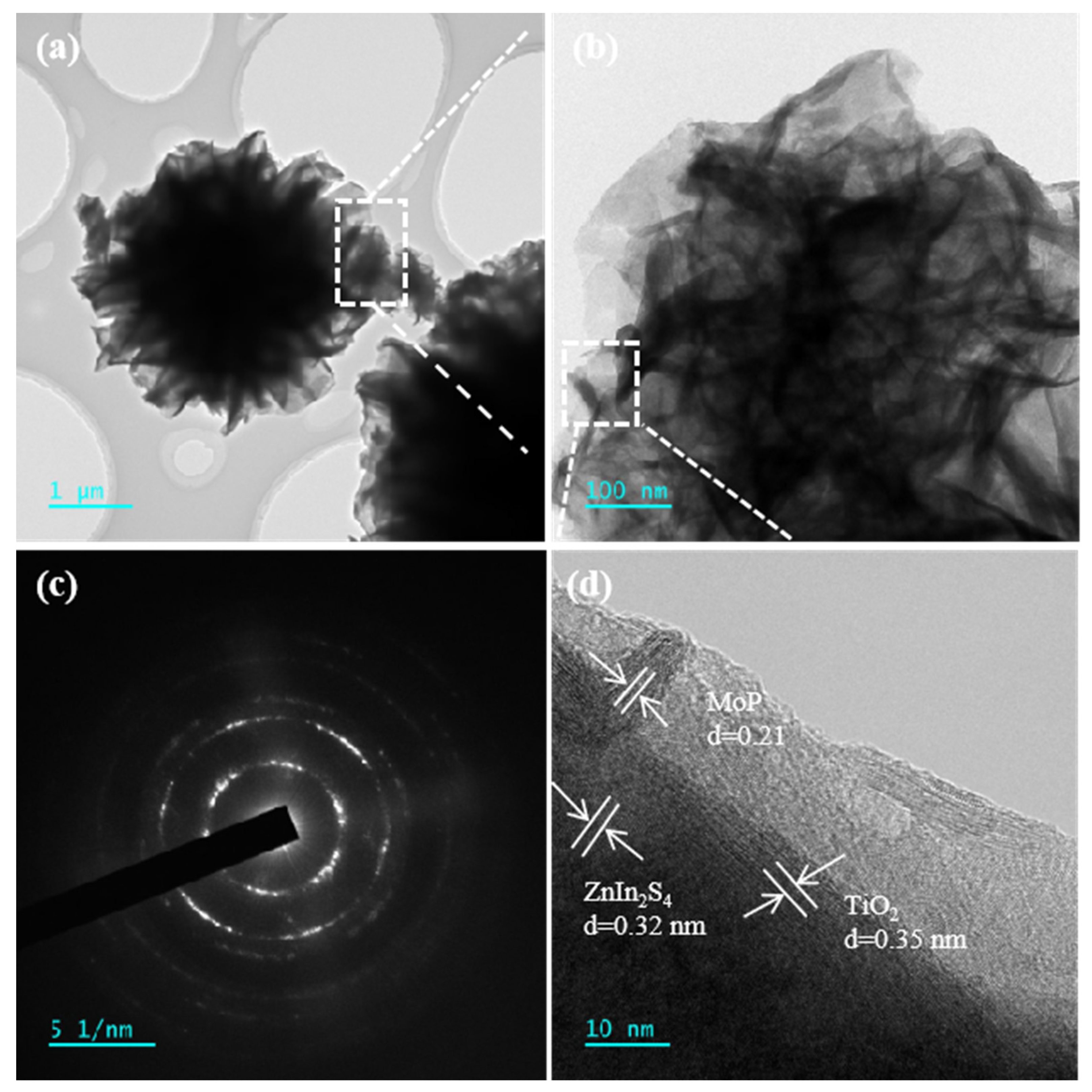

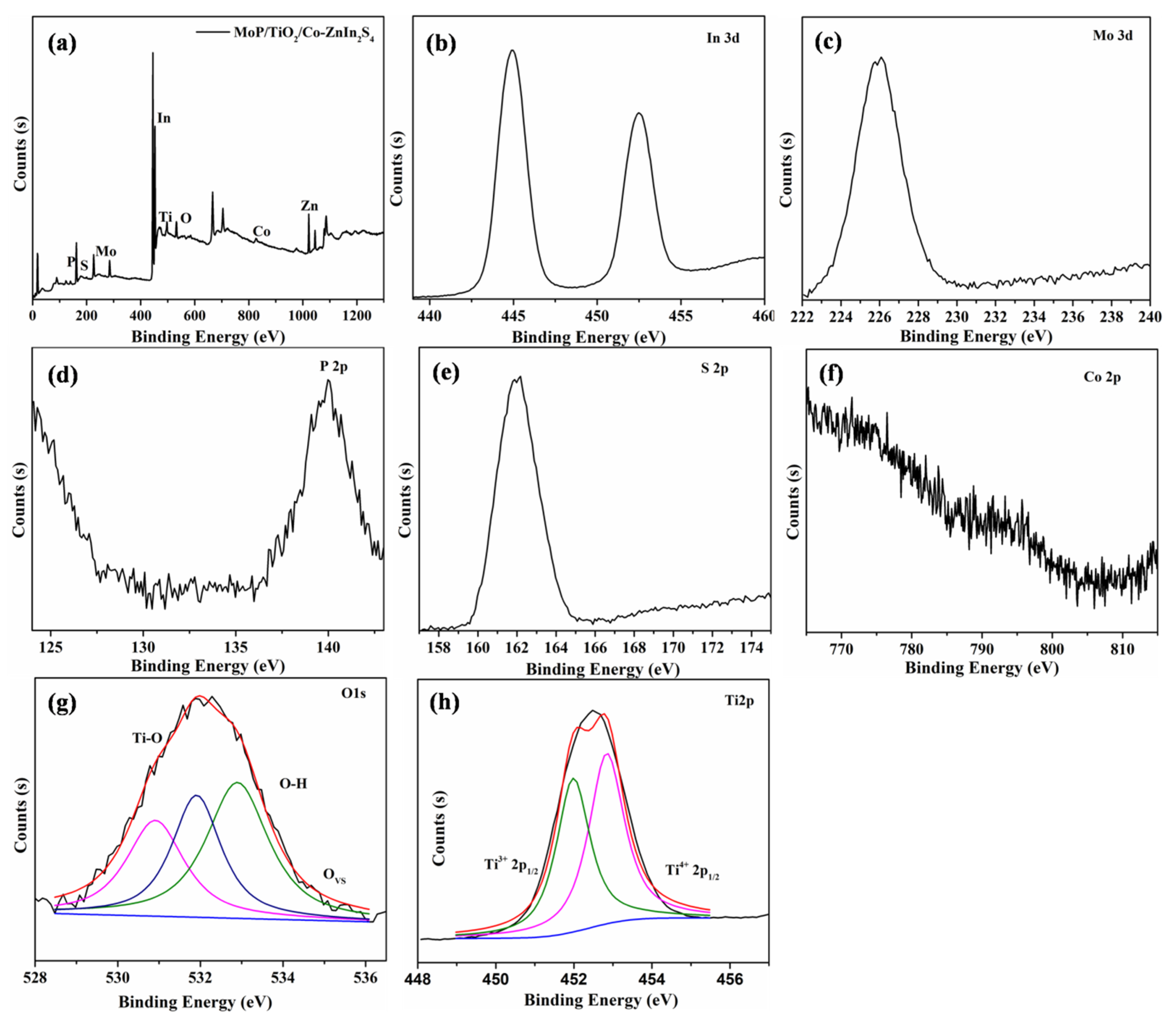

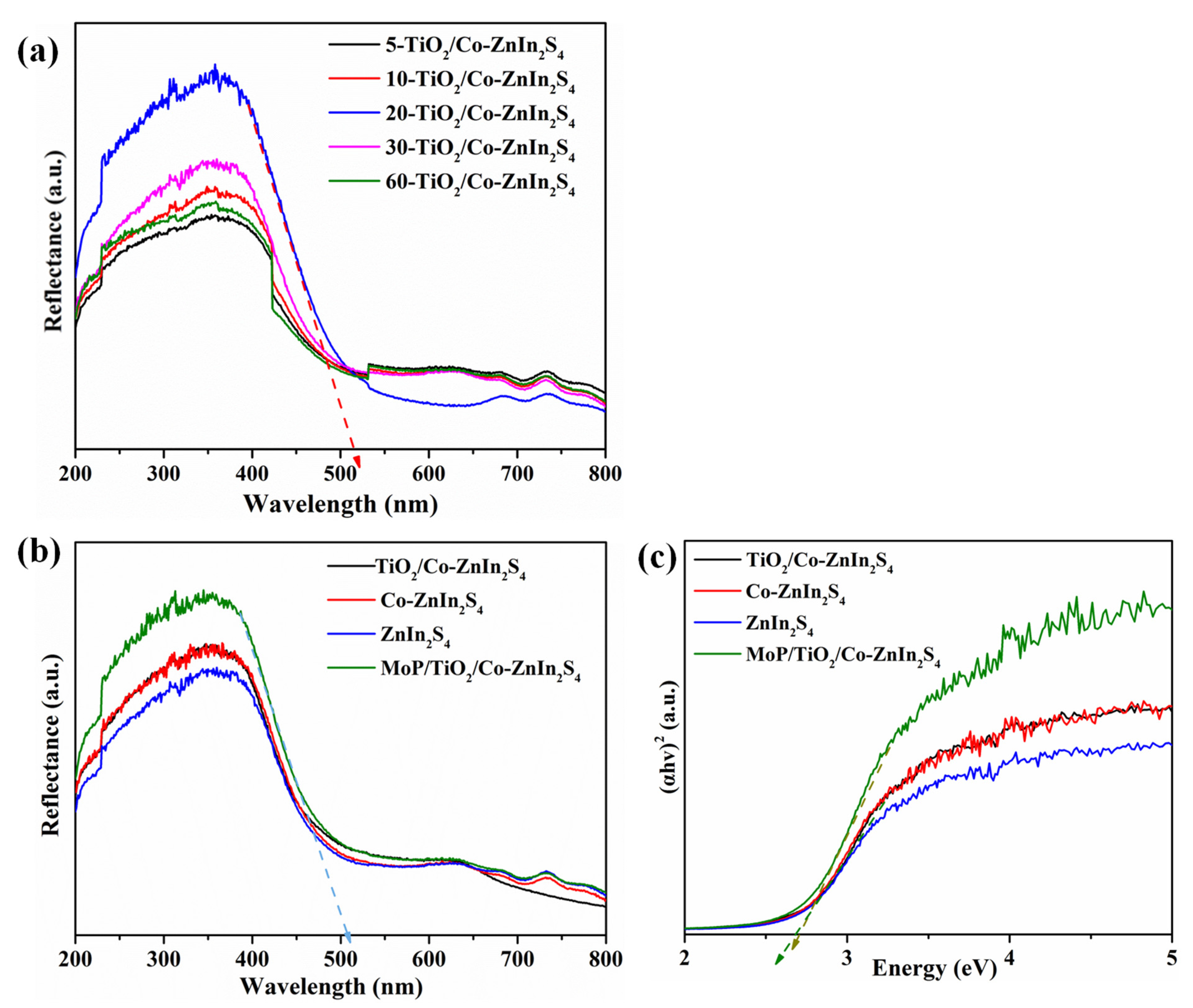

2.1. Structure, Morphology and Composition of Composite Photocatalysts

2.2. Photoelectrochemical Performance

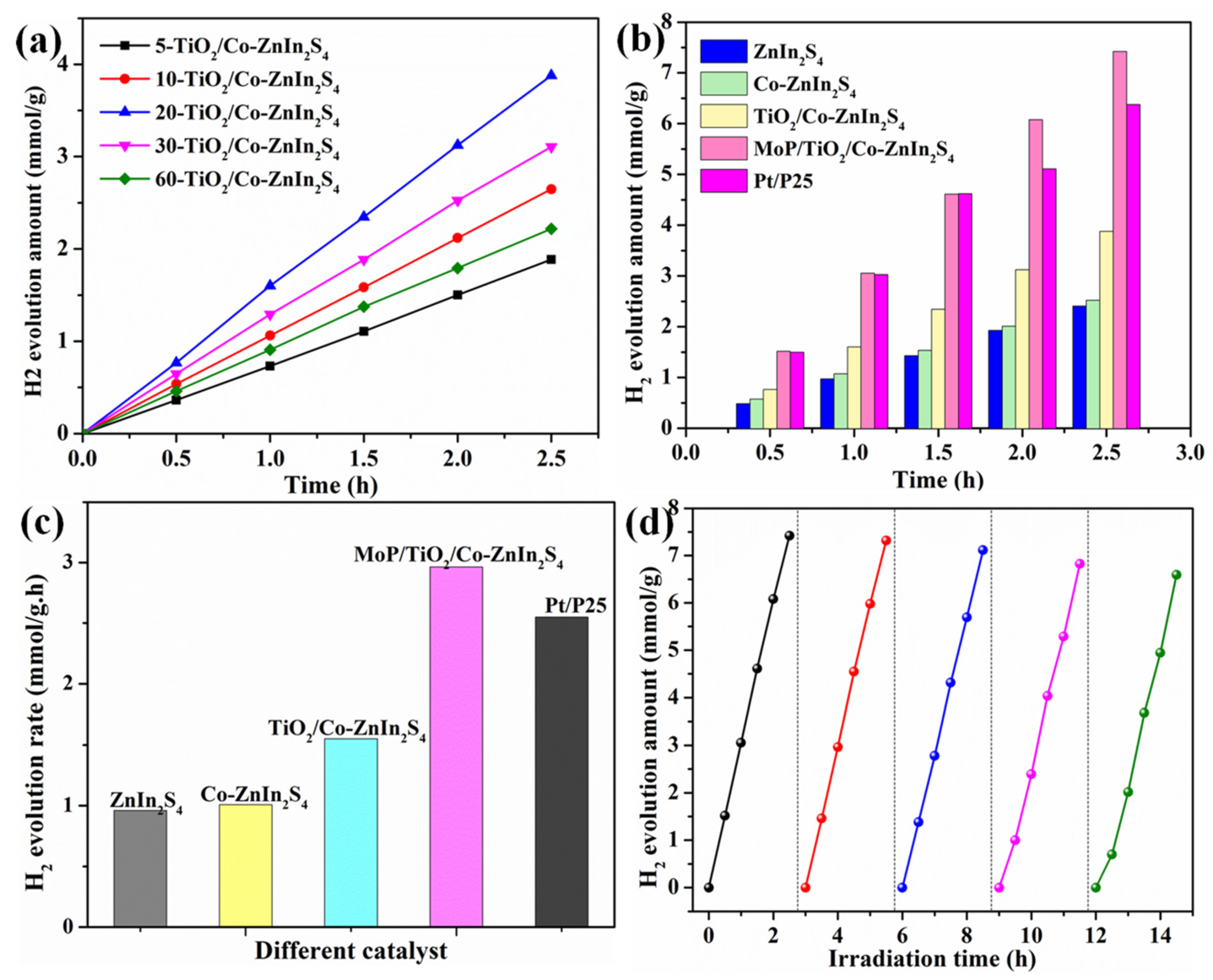

2.3. Photocatalytic Hydrogen Production Performance

2.4. Mechanism of Photocatalytic Hydrogen Evolution

3. Experimental Section

3.1. Materials and Characterization

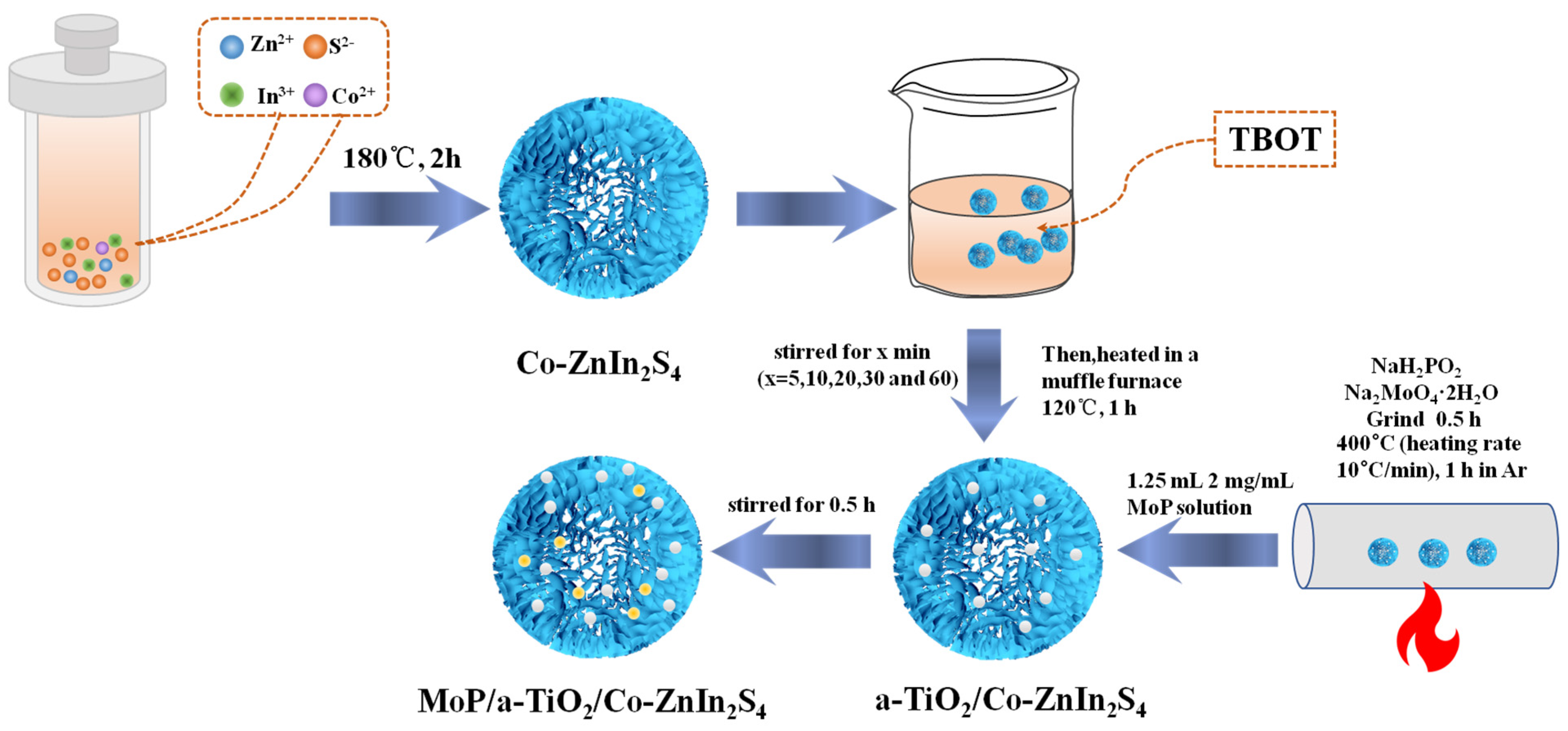

3.2. Steps for Preparation of MoP/a-TiO2/Co-ZnIn2S4 Flower-like Composite Photocatalysts

3.2.1. Preparation of Co-ZnIn2S4 Catalyst

3.2.2. Preparation of a-TiO2/Co-ZnIn2S4 Catalyst

3.2.3. Preparation of MoP/a-TiO2/Co-ZnIn2S4 Catalyst

3.3. Photocatalysis and Photoelectrochemical Performance Measurements

3.3.1. Hydrogen Production Performance

3.3.2. Photoelectrochemical Performance

4. Summary

Author Contributions

Funding

Conflicts of Interest

Sample Availability

References

- Wang, Z.; Li, C.; Domen, K. Recent developments in heterogeneous photocatalysts for solar-driven overall water splitting. Chem. Soc. Rev. 2019, 48, 2109–2125. [Google Scholar] [CrossRef] [PubMed]

- Paula, L.F.; Hofer, M.; Lacerda, V.P.; Bahnemann, D.W.; Patrocinio, A.O.T. Unraveling the photocatalytic properties of TiO2/WO3 mixed oxides. Photochem. Photobiol. 2019, 18, 2469–2483. [Google Scholar] [CrossRef] [PubMed]

- Richards, B.S.; Hudry, D.; Busko, D.; Turshatov, A.; Howard, I.A. Photon Upconversion for Photovoltaics and Photocatalysis: A critical review. Chem. Rev. 2021, 15, 9165–9195. [Google Scholar] [CrossRef] [PubMed]

- Hong, M.; Zhang, L.; Fang, H.; Feng, X.; Li, Z. Surface engineering of CdS quantum dots modified SiO2@C3N4 nanospheres for effective photocatalytic hydrogen evolution. Mater. Sci. Semicond. Process 2021, 136, 106134–106142. [Google Scholar] [CrossRef]

- Meng, S.; Chen, C.; Gu, X.; Wu, H.; Meng, Q.; Zhang, J.; Chen, S.; Fu, X.; Liu, D.; Lei, W. Efficient photocatalytic H2 evolution, CO2 reduction and N2 fixation coupled with organic synthesis by cocatalyst and vacancies engineering. Appl. Catal. B 2021, 285, 119789. [Google Scholar] [CrossRef]

- Yang, Z.; Wang, Y.; Liu, Y. Stability and charge separation of different CH3NH3SnI3/TiO2 interface: A first-principles study. Appl. Surf. Sci. 2018, 441, 394–400. [Google Scholar] [CrossRef]

- Sun, M.; Wang, X.; Chen, Z.; Murugananthan, M.; Chen, Y.; Zhang, Y. Stabilized oxygen vacancies over heterojunction for highly efficient and exceptionally durable VOCs photocatalytic degradation. Appl. Catal. B 2020, 273, 119061–119072. [Google Scholar] [CrossRef]

- Gu, X.; Chen, T.; Lei, J.; Yang, Y.; Zheng, X.; Zhang, S.; Zhu, Q.; Fu, X.; Meng, S.; Chen, S. Self-assembly synthesis of S-scheme g-C3N4/Bi8(CrO4)O11 for photocatalytic degradation of norfloxacin and bisphenol A. Chin. J. Catal. 2022, 43, 2569–2580. [Google Scholar] [CrossRef]

- Mao, S.; Zou, Y.; Sun, G.; Zeng, L.; Wang, Z.; Ma, D.; Guo, Y.; Cheng, Y.; Wang, C.; Shi, J.-W. Thio linkage between CdS quantum dots and UiO-66-type MOFs as an effective transfer bridge of charge carriers boosting visible-light-driven photocatalytic hydrogen production. J. Colloid Interface Sci. 2021, 581, 1–10. [Google Scholar] [CrossRef]

- Zhao, W.; Li, J.; She, T.; Ma, S.; Cheng, Z.; Wang, G.; Zhao, P.; Wei, W.; Xia, D.; Leung, D.Y. Study on the Photocatalysis Mechanism of the Z-Scheme Cobalt Oxide Nanocubes/Carbon Nitride Nanosheets Heterojunction Photocatalyst with High Photocatalytic Performances. J. Hazard. Mater. 2021, 402, 123839–123845. [Google Scholar] [CrossRef]

- Min, F.; Wei, Z.; Yu, Z.; Xiao, Y.; Guo, S.; Song, R.; Li, J. Construction of a hierarchical ZnIn2S4/g-C3N4 heterojunction for the enhanced photocatalytic degradation of tetracycline. Dalton Trans. 2022, 51, 535–547. [Google Scholar] [CrossRef]

- Liang, Q.; Zhang, C.; Xu, S.; Zhou, M.; Zhou, Y.; Li, Z. In situ growth of CdS quantum dots on phosphorus-doped carbon nitride hollow tubes as active 0D/1D heterostructures for photocatalytic hydrogen evolution. J. Colloid Interface Sci. 2020, 577, 1–11. [Google Scholar] [CrossRef]

- Min, F.; Wei, Z.; Yu, Z.; Xiao, Y.; Guo, S.; Song, R.; Li, J. Cubic quantum dot/hexagonal microsphere ZnIn2S4 heterophase junctions for exceptional visible-light-driven photocatalytic H2 evolution. J. Mater. Chem. A 2017, 5, 8451–8460. [Google Scholar]

- Lei, Z.B.; You, W.S.; Liu, M.Y.; Li, C. Preparation of ZnIn2S4 and the photocatalytic splitting water to produce hydrogen. In Proceedings of the Asia-Pacific Congress on Catalysis, Dailan, China, 13–15 March 2003; pp. 2142–2143. [Google Scholar]

- Guo, X.; Liu, Y.; Yang, Y.; Mu, Z.; Wang, Y.; Zhang, S.; Wang, S.; Hu, Y.; Liu, Z. Effective visible-light excited charge separation in all-solid-state Ag bridged BiVO4/ZnIn2S4 core-shell structure Z-scheme nanocomposites for boosting photocatalytic organics degradation. J. Alloys Compd. 2021, 887, 161389–161395. [Google Scholar] [CrossRef]

- Chachvalvutikul, A.; Luangwanta, T.; Pattisson, S.; Hutchings, G.J.; Kaowphong, S. Enhanced photocatalytic degradation of organic pollutants and hydrogen production by a visible light–responsive Bi2WO6/ZnIn2S4 heterojunction. Appl. Surf. Sci. 2020, 544, 148885–148892. [Google Scholar] [CrossRef]

- Tu, X.; Lu, J.; Li, M.; Su, Y.; Yin, G.; He, D. Hierarchically ZnIn2S4 nanosheet-constructed microwire arrays: Template-free synthesis and excellent photocatalytic performances. Nanoscale 2018, 10, 4735–4744. [Google Scholar] [CrossRef]

- Si, M.; Zhang, J.; He, Y.; Yang, Z.; Yan, X.; Liu, M.; Zhuo, S.; Wang, S.; Min, X.; Gao, C.; et al. Synchronous and rapid preparation of lignin nanoparticles and carbon quantum dots from natural lignocellulose. Green Chem. 2018, 20, 3414–3419. [Google Scholar] [CrossRef]

- Yuan, W.H.; Liu, X.C.; Li, L. Improving Photocatalytic Performance for Hydrogen Generation over Co-Doped ZnIn2S4 under Visible Light. Acta Phys.-Chim. Sin. 2013, 29, 151–156. [Google Scholar]

- Jing, D.; Liu, M.; Guo, L. Enhanced Hydrogen Production from Water over Ni Doped ZnIn2S4 Microsphere Photocatalysts. Catal. Lett. 2010, 140, 167–171. [Google Scholar] [CrossRef]

- Niu, B.; Cao, Y.L.; Xiao, J.F.; Lu, Z.; Xu, Z.M. Waste for Construction of Magnetic and Core–Shell Z-Scheme Photocatalysts: An Effective Approach to E-Waste Recycling. Environ. Sci. Technol. 2021, 55, 1279–1289. [Google Scholar] [CrossRef]

- Xia, Y.; Li, Q.; Lv, K.; Tang, D.; Li, M. Superiority of graphene over carbon analogs for enhanced photocatalytic H2-production activity of ZnIn2S4. Appl. Catal. B 2017, 206, 344–352. [Google Scholar] [CrossRef]

- Xu, C.; Li, D.; Liu, X.; Ma, R.; Sakai, N.; Yang, Y.; Lin, S.; Yang, J.; Pan, H.; Huang, J.; et al. Direct Z-scheme construction of g-C3N4 quantum dots/TiO2 nanoflakes for efficient photocatalysis. Chem. Eng. J. 2021, 430, 132861–132870. [Google Scholar] [CrossRef]

- Tong, R.; Ng, K.W.; Wang, X.; Wang, S.; Wang, X.; Pan, H. Two-dimensional materials as novel co-catalysts for efficient solar-driven hydrogen production. J. Mater. Chem. A 2020, 44, 23202–23230. [Google Scholar] [CrossRef]

- Nasir, M.S.; Yang, G.; Ayub, I.; Wang, S.; Yan, W. Tin diselinide a stable co-catalyst coupled with branched TiO2 fiber and g-C3N4 quantum dots for photocatalytic hydrogen evolution. Appl. Catal. B 2020, 270, 118900–118909. [Google Scholar] [CrossRef]

- Li, H.; Li, Y.; Wang, X.; Hou, B. 3D ZnIn2S4 nanosheets/TiO2 nanotubes as photoanodes for photocathodic protection of Q235 CS with high efficiency undervisible light. J. Alloys Compd. 2019, 771, 892–899. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Z.; Piao, C.; Li, S.; Tang, J.; Fang, D.; Zhang, Z.; Wang, J. Construction of fixed Z-scheme Ag|AgBr/Ag/TiO2 photocatalyst composite film for malachite green degradation with simultaneous hydrogen production. J. Power Sources 2020, 469, 228430–228438. [Google Scholar] [CrossRef]

- Li, W.; Wang, Z.; Kong, D.; Du, D.; Zhou, M.; Du, Y.; Yan, T.; You, J.; Kong, D. Visible-light-induced dendritic BiVO4/TiO2 composite photocatalysts for advanced oxidation process. J. Alloys Compd. 2016, 688, 703–711. [Google Scholar] [CrossRef]

- Liu, Y.; Hong, Z.; Chen, Q.; Chen, H.; Chang, W.H.; Yang, Y.; Song, T.-B.; Yang, Y. Perovskite Solar Cells Employing Dopant-Free Organic Hole Transport Materials with Tunable Energy Levels. Adv. Mater. 2016, 28, 440–447. [Google Scholar] [CrossRef]

- Zywitzki, D.; Jing, H.; Tüysüz, H.; Chan, C.K. High surface area, amorphous titania with reactive Ti3+ through a photo-assisted synthesis method for photocatalytic H2 generation. J. Mater. Chem. A 2017, 5, 10957–10967. [Google Scholar] [CrossRef]

- Yu, Z.Y.; Duan, Y.; Gao, M.R.; Lang, C.C.; Zheng, Y.R.; Yu, S.H. One-Dimensional Porous Carbon-Supported Ni/Mo2C Dual Catalyst for Efficient Water Splitting. Chem. Sci. 2017, 8, 968–973. [Google Scholar] [CrossRef]

- Xu, Y.; Li, N.; Wang, R.; Xu, L.; Liu, Z.; Jiao, T.; Liu, Z. Self-assembled FeP/MoP co-doped nanoporous carbon matrix for hydrogen evolution application. Colloids Surf. A Physicochem. Eng. Asp. 2022, 636, 128206–128212. [Google Scholar] [CrossRef]

- Shen, Y.; Li, D.; Dang, Y.; Zhang, J.; Wang, W.; Ma, B. A ternary calabash model photocatalyst (Pd/MoP)/CdS for enhancing H2 evolution under visible light irradiation. Appl. Surf. Sci. 2021, 564, 150432–150440. [Google Scholar] [CrossRef]

- Zhang, L.; Fu, X.; Meng, S.; Jiang, X.; Wang, J.; Chen, S. Ultra-low content of Pt modified CdS nanorods: One-pot synthesis and high photocatalytic activity for H2 production under visible light. J. Mater. Chem. A 2015, 3, 10360–10367. [Google Scholar] [CrossRef]

- Du, C.; Shang, M.; Mao, J.; Song, W. Hierarchical MoP/Ni2P heterostructures on nickel foam for efficient water splitting. J. Mater. Chem. A 2017, 5, 15940–15949. [Google Scholar] [CrossRef]

- Yang, W.; Liu, B.; Fang, T.; Jennifer, W.A.; Christophe, L.; Li, Z.; Zhang, X.; Jiang, X. Layered crystalline ZnIn2S4 nanosheets: CVD synthesis and photo-electrochemical properties. Nanoscale 2016, 8, 18197–18203. [Google Scholar] [CrossRef]

- Mora-Seró, I.; Bisquert, J. Fermi Level of Surface States in TiO2 Nanoparticles. Nano Lett. 2003, 3, 945–949. [Google Scholar] [CrossRef]

- Cao, S.; Yu, J.; Wageh, S.; Al-Ghamdi, A.A.; Mousavi, M.; Ghasemi, J.B.; Xu, F. H2-production and electron-transfermechanism of a noble-metal-free WO3@ZnIn2S4 S-scheme heterojunction photocatalyst. J. Mater. Chem. A 2022, 10, 17174–17184. [Google Scholar] [CrossRef]

| In | S | Zn | Mo | P | Ti | O | Co | |

|---|---|---|---|---|---|---|---|---|

| wt% | 53.2 | 26.0 | 10.2 | 2.5 | 0.3 | 1.1 | 6.2 | 0.5 |

| Sample | Specific Surface Area (m2/g) | Pore Volume (cm3/g) | Average Pore Diameter (nm) |

|---|---|---|---|

| ZnIn2S4 | 41.293 | 0.3346 | 162.1 |

| Co-ZnIn2S4 | 53.453 | 0.3242 | 121.3 |

| TiO2/Co-ZnIn2S4 | 46.669 | 0.3346 | 143.4 |

| MoP/a-TiO2/Co-ZnIn2S4 | 53.250 | 0.3703 | 139.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, K.; Shang, Y.; Li, H.; Wu, P.; Li, S.; Ye, H.; Jian, F.; Zhu, J.; Yang, D.; Li, B.; et al. Synthesis and Hydrogen Production Performance of MoP/a-TiO2/Co-ZnIn2S4 Flower-like Composite Photocatalysts. Molecules 2023, 28, 4350. https://doi.org/10.3390/molecules28114350

Wu K, Shang Y, Li H, Wu P, Li S, Ye H, Jian F, Zhu J, Yang D, Li B, et al. Synthesis and Hydrogen Production Performance of MoP/a-TiO2/Co-ZnIn2S4 Flower-like Composite Photocatalysts. Molecules. 2023; 28(11):4350. https://doi.org/10.3390/molecules28114350

Chicago/Turabian StyleWu, Keliang, Yuhang Shang, Huazhen Li, Pengcheng Wu, Shuyi Li, Hongyong Ye, Fanqiang Jian, Junfang Zhu, Dongmei Yang, Bingke Li, and et al. 2023. "Synthesis and Hydrogen Production Performance of MoP/a-TiO2/Co-ZnIn2S4 Flower-like Composite Photocatalysts" Molecules 28, no. 11: 4350. https://doi.org/10.3390/molecules28114350