Application of the Swimming Pool Backwash Water Recovery System with the Use of Filter Tubes

Abstract

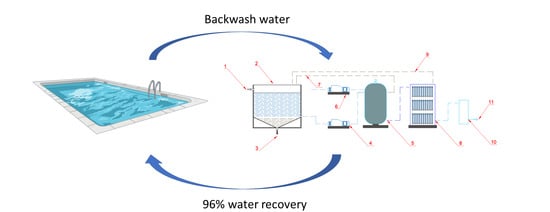

:1. Introduction

2. Results and Discussion

Cost Efficiency

3. Materials and Methods

3.1. Characteristics of Backwash Water

3.2. Microbiological and Physicochemical Tests of Raw and Treated Backwash Water

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Reißmann, F.; Schulze, E.; Albrecht, V. Application of a combined UF/RO system for the reuse of filter backwash water from treated swimming pool water. Desalination 2005, 178, 41–49. [Google Scholar] [CrossRef]

- Alansari, A.; Amburgey, J.; Madding, N. A quantitative analysis of swimming pool recirculation system efficiency. J. Water Health 2018, 16, 449–459. [Google Scholar] [CrossRef] [Green Version]

- Tang, H.L.; Xie, Y.F. Biologically active carbon filtration for haloacetic acid removal from swimming pool water. Sci. Total Environ. 2016, 541, 58–64. [Google Scholar] [CrossRef]

- Zhou, X.; Peng, F.; Luo, Z.; Li, Y.; Li, H.; Yang, Z. Assessment of water contamination and health risk of endocrine disrupting chemicals in outdoor and indoor swimming pools. Sci. Total Environ. 2020, 704, 135277. [Google Scholar] [CrossRef] [PubMed]

- Glauner, T.; Waldmann, P.; Frimmel, F.H.; Zwiener, C. Swimming pool water—Fractionation and genotoxicological characterization of organic constituents. Water Res. 2005, 39, 4494–4502. [Google Scholar] [CrossRef]

- Yang, L.; Chen, X.; She, Q.; Cao, G.; Liu, Y.; Chang, V.W.-C.; Tang, C.Y. Regulation, formation, exposure, and treatment of disinfection by-products (DBPs) in swimming pool waters: A critical review. Environ. Int. 2018, 121, 1039–1057. [Google Scholar] [CrossRef] [PubMed]

- Brandt, M.J.; Johnson, K.M.; Elphinston, A.J.; Ratanyaka, D.D. Water Filtration (Chapter 9). In Twort’s Water Supply; Butterworth-Heinemann: Oxford, UK, 2017; p. 367. [Google Scholar]

- Łaskawiec, E.; Dudziak, M.; Wyczarska-Kokot, J. An evaluation of the phytotoxicity of filter backwash water coagulation products from a pool water system. Environ. Prot. Eng. 2018, 44, 43–56. [Google Scholar] [CrossRef]

- Wyczarska-Kokot, J.; Lempart, A. The reuse of washings from pool filtration plants after the use of simple purification processes. Archit. Civ. Eng. Environ. 2018, 11, 163–170. [Google Scholar] [CrossRef] [Green Version]

- United States Environmental Protection Agency. Filter Backwash Recycling Rule. Technical Guidance Manual (EPA 816-R-02-014). 2002. Available online: https://nepis.epa.gov/Exe/ZyPDF.cgi?Dockey=200025V5.txt (accessed on 29 October 2012).

- World Health Organization. Guidelines for Safe Recreational Water Environments (Vol. 2: Swimming Pools and Similar Environments). 2006. Available online: https://apps.who.int/iris/handle/10665/43336 (accessed on 29 October 2012).

- ANSI/APSP-11. American National Standard for Water Quality in Public Pools and Spas. 2009. Available online: http://standards.nsf.org/apps/group_public/download.php/17496/ANSI-APSP-11%202009-for-apspstore.pdf (accessed on 29 October 2012).

- Deutsches Institut für Normung e., V. Aufbereitung von Schwimm und Badebeckenwasser (Water Treatment for Swimming and Bathing Pools) (DIN 19643); Deutsches Institut für Normung e. V.: Berlin, Germany, 2012. [Google Scholar]

- Wyczarska-Kokot, J. The study of possibilities for reuse of washings from swimming pool circulation systems. Ecol. Chem. Eng. 2016, 23, 447–459. [Google Scholar] [CrossRef] [Green Version]

- Piche, A.; Campbell, A.; Cleary, S.; Douglas, I.; Basu, O.D. Investigation of backwash strategy on headloss development and particle release in drinking water biofiltration. J. Water Process. Eng. 2019, 32, 100895. [Google Scholar] [CrossRef]

- Aani, S.A.; Mustafa, T.N.; Hilal, N. Ultrafiltration membranes for wastewater and water process engineering: A comprehensive statistical review over the past decade. J. Water Process. Eng. 2020, 35, 101241. [Google Scholar] [CrossRef]

- Chang, H.; Liu, B.; Yang, P.; Wang, Q.; Li, K.; Li, G.; Liang, H. Salt backwashing of organic-fouled ultrafiltration membranes: Effects of feed water properties and hydrodynamic conditions. J. Water Process. Eng. 2019, 30, 100429. [Google Scholar] [CrossRef]

- Sher, F.; Hanif, K.; Iqbal, S.Z.; Imran, M. Implications of advanced wastewater treatment: Electrocoagulation and electroflocculation of effluent discharged from a wastewater treatment plant. J. Water Process. Eng. 2020, 33, 101101. [Google Scholar] [CrossRef]

- Barbot, E.; Moulin, P. Swimming pool water treatment by ultrafiltration–adsorption process. J. Membr. Sci. 2008, 314, 50–57. [Google Scholar] [CrossRef]

- Ozbey-Unal, B.; Omwene, P.I.; Yagcioglu, M.; Balcik Canbolat, Ç.; Karagunduz, A.; Keskinler, B.; Dizge, N. Treatment of organized industrial zone wastewater by microfiltration/reverse osmosis membrane process for water recovery: From lab to pilot scale. J. Water Process. Eng. 2020, 38, 101646. [Google Scholar] [CrossRef]

- Sun, F.; Xu, Y.; Li, M.; Zhang, Y.; Wang, Y.; Zhang, Y.; Zhang, D. Membrane cleaning of ultrafiltration in the combined membrane filtration processes and health risk assessment. J. Water Process. Eng. 2020, 38, 101584. [Google Scholar] [CrossRef]

- Yamazaki, I.M.; Paterson, R.; Geraldo, L.P. A new generation of track etched membranes for microfiltration and ultrafiltration. Part I. Preparation and characterisation. J. Membr. Sci. 1996, 118, 239–245. [Google Scholar] [CrossRef]

- Yang, Y.; Ma, S.; Xie, Y.; Wang, M.; Cai, T.; Li, J.; Guo, D.; Zhao, L.; Xu, Y.; Liang, S.; et al. Inactivation of Pseudomonas aeruginosa biofilms by 405-nm LED illumination. Am. Soc. Microbiol. J. 2020, 86, e00092-20. [Google Scholar] [CrossRef]

- Simpson, D.R. Biofilm processes in biologically active carbon water purification. Water Res. 2008, 42, 2839–2848. [Google Scholar] [CrossRef]

- Shoemaker, T. Determining the Viability and Effectiveness of a Roughing Biofilter for Use in Drinking Water Treatment Plants. Ph.D. Thesis, University of Missouri, Columbia, MO, USA, 2014. [Google Scholar]

- Yusuf, K.O.; Adio-Yusuf, S.I.; Obalowu, R.O. Development of a Simplified Slow Sand Filter for Water Purification. J. Appl. Sci. Environ. Manag. 2019, 23, 389. [Google Scholar] [CrossRef]

- Bolster, C.H. Comparing unamended and Fe-coated biochar on removal efciency of bacteria, microspheres, and dissolved phosphorus in sand flters. Biochar 2021, 3, 329–338. [Google Scholar] [CrossRef]

- Bagundol, T.B.; Awa, A.L. and Enguito, M.R.C. Efficiency of Slow Sand Filter in Purifying Well Water. J. Multidiscip. Stud. 2013, 2, 86–102. [Google Scholar] [CrossRef]

- Podaru, C.; Manea, F.; Vlaicu, I.; Patroescu, V.; Danielescu, C.; Burtica, G. Studies regarding surface water treatment using a microfiltration-ultrafiltration pilot plant. Environ. Eng. Manag. J. 2008, 7, 711–715. [Google Scholar] [CrossRef]

- Ayrapetyan, M.; Williams, T.C.; Oliver, J.D. Interspecific quorum sensing mediates the resuscitation of viable but nonculturable vibrios. Appl. Environ. Microbiol. 2014, 80, 2478–2483. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xiea, M.; Xua, L.; Zhanga, R.; Zhoub, Y.; Xiaod, Y.; Su, X.; Shen, C.; Suna, F.; Hashmif, M.Z.; Lina, H.; et al. Viable but Nonculturable State of Yeast Candida sp. Strain LN1 Induced by High Phenol Concentrations. Environ. Microbiol. 2021, 87, e01110-21. [Google Scholar]

- Ye, C.; Lin, H.; Zhang, M.; Chen, S.; Yu, X. Characterization and potential mechanisms of highly antibiotic tolerant VBNC Escherichia coli induced by low level chlorination. Sci. Rep. 2020, 10, 1957. [Google Scholar] [CrossRef]

- Wyczarska-Kokot, J.; Piechurski, F. Application of pre-ozonation process in swimming pool water treatment Technology. Desalination Water Treat. 2020, 186, 382–393. [Google Scholar] [CrossRef]

- Zabava, B.S.; Voicu, G.; Ungureanu, N.; Dinca, M.; Ferdes, M.; Vladut, V. Advanced technologies for wastewater treatment by ozonation—A review. Ann. Fac. Eng. Hunedoara-Int. J. Eng. 2018, 17, 603–608. [Google Scholar]

- Tardif, R.; Rodriguez, M.; Catto, C.; Charest-Tardif, G.; Simard, S. Concentrations of disinfection by-products in swimming pool following modifications of the water treatment process: An exploratory study. J. Environ. Sci. 2017, 58, 163–172. [Google Scholar] [CrossRef]

- Gackowska, A.; Studzinski, W.; Gaca, J. Effect of sodium hypochlorite on conversions of octyl-dimethyl-para-aminobenzoic acid. Desalination Water Treat. 2016, 57, 1429–1435. [Google Scholar] [CrossRef]

- Studzinski, W.; Gackowska, A.; Przybylek, M.; Gaca, J. Studies on the formation of formaldehyde during 2-ethylhexyl 4-(dimethylamino)benzoate demethylation in the presence of reactive oxygen and chlorine species. Environ. Sci. Pollut. Res. 2017, 24, 8049–8061. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Christensen, M.L.; Klausen, M.M.; Christensen, P.V. Test of precoat filtration technology for treatment of swimming pool water. Water Sci. Technol. 2018, 77, 748–758. [Google Scholar] [CrossRef] [PubMed]

- Corina-Petronela, M.; Teodosiu, C. Experimental Assesment of Nanofiltration for the Removal of Chlorophenols from Aqueous Effluents. Environ. Eng. Manag. J. 2017, 16, 793–800. [Google Scholar]

- Leszczyński, J. Color Removal from Groundwater by Coagulation and Oxidation Processes. J. Ecol. Eng. 2019, 20, 138–144. [Google Scholar] [CrossRef]

- Yari, A.; Jafari Mansoorian, H.; Gholami Yengeje, S.; Nazari, G. Removal of turbidity and suspended solids backwash water from rapid sand filter by using electrocoagulation. Toloo-e-Behdasht 2016, 15, 114–126. [Google Scholar]

- European Standards. Norm DIN 19643-1:2012-11. Treatment of Water of Swimming Pools and Baths. Part 1. General Requirements; European Standards: Geneva, Switzerland, 2012. (In German) [Google Scholar]

- Regulation of the Minister of Health from November 2015 on the Requirements That Water in Swimming Pools Should Meet. J. Laws 2015, 2016. (In Poland)

- Down, R.D.; Lehr, J.H. Environmental Instrumentation and Analysis Handbook; Wiley: Hoboken, NJ, USA, 2005. [Google Scholar]

- Kaul, K. Handbook of Water and Wastewater Analysis; Atlantic Publishers and Dist: New Delhi, India, 2007. [Google Scholar]

| Without System | With System | Reduction | Price per Unit, EUR | Annual Savings, EUR | |

|---|---|---|---|---|---|

| Wastewater discharge, m3/y | 3989 | 159 | 3830 | 1.2 | 4596 |

| Drinking water supply, m3/y | 3989 | 159 | 3830 | 0.8 | 3064 |

| Energy consumption, kWh/y | 88,082 | 9125 | 78,957 | 0.04 | 3158 |

| Fibers Material | Cut-Off Molar Mass, kDalton | Filtration Area, m2 | Specific Flux (Water) at 0.6 atm., Lt/hr/m2 | Working Pressure, Atm. | Filtration Rate (Absolute), nm |

|---|---|---|---|---|---|

| Polysulfone/ Polynephron | 67 | 1.8–2.0 | 60–80 | 0.3–0.6 | 30 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Studziński, W.; Poćwiardowski, W.; Osińska, W. Application of the Swimming Pool Backwash Water Recovery System with the Use of Filter Tubes. Molecules 2021, 26, 6620. https://doi.org/10.3390/molecules26216620

Studziński W, Poćwiardowski W, Osińska W. Application of the Swimming Pool Backwash Water Recovery System with the Use of Filter Tubes. Molecules. 2021; 26(21):6620. https://doi.org/10.3390/molecules26216620

Chicago/Turabian StyleStudziński, Waldemar, Wojciech Poćwiardowski, and Weronika Osińska. 2021. "Application of the Swimming Pool Backwash Water Recovery System with the Use of Filter Tubes" Molecules 26, no. 21: 6620. https://doi.org/10.3390/molecules26216620