Development of a Fast and Robust UHPLC Method for Apixaban In-Process Control Analysis

Abstract

:1. Introduction

2. Results

2.1. Sample

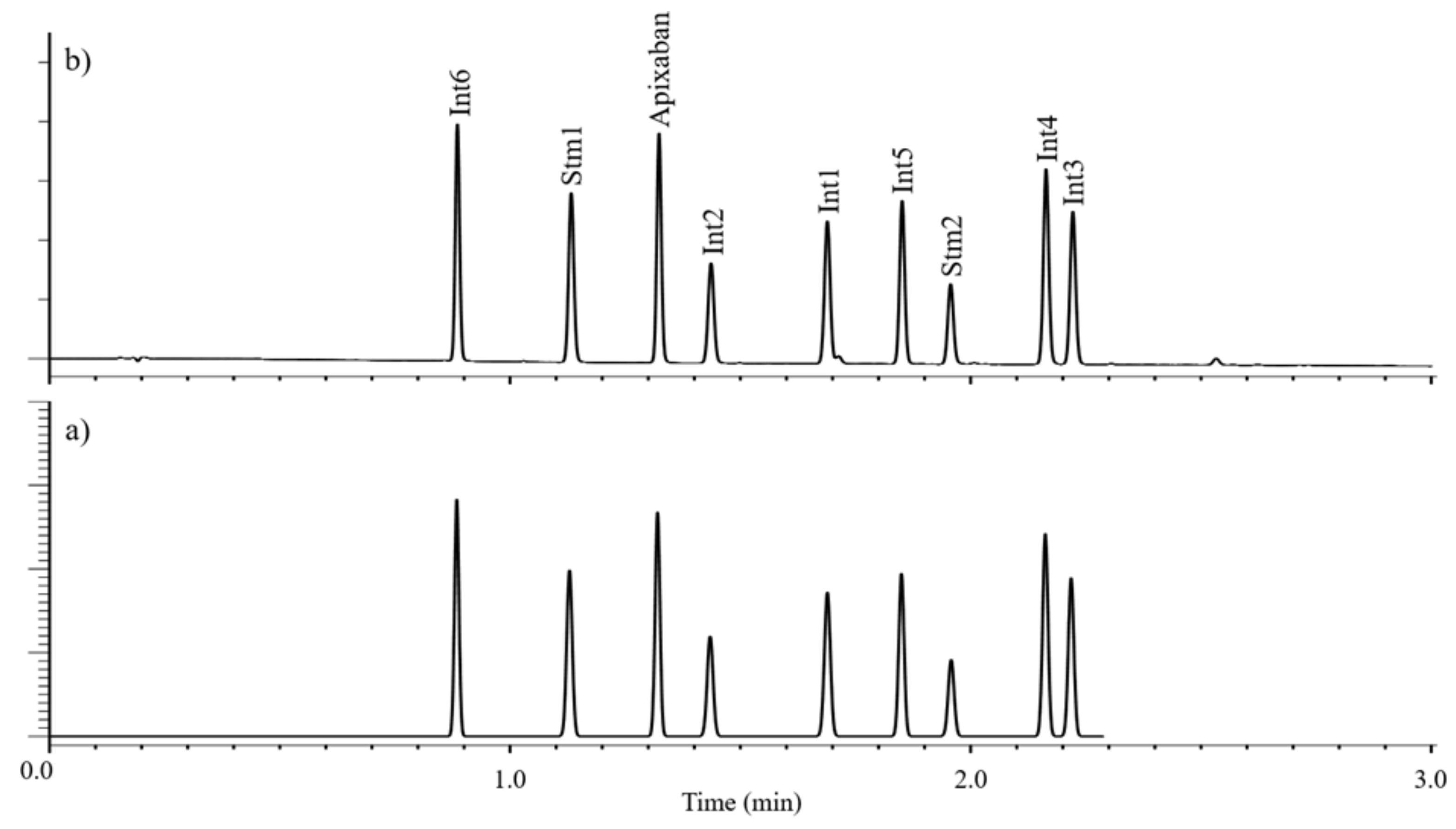

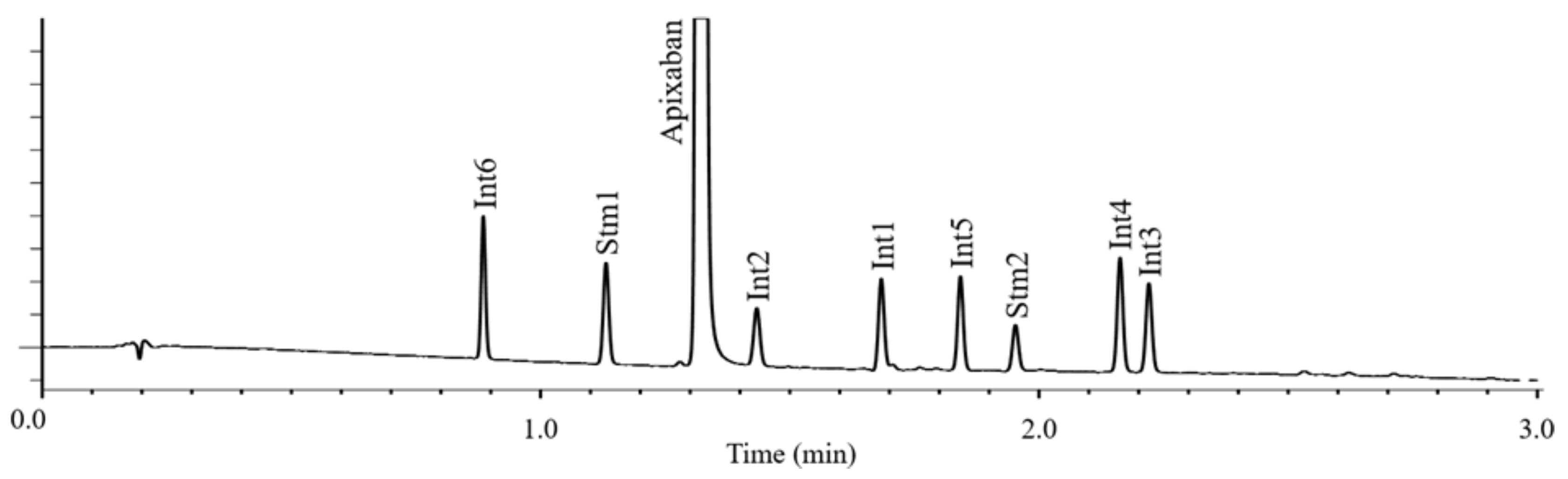

2.2. Liquid Chromatographic Method Development

- -

- = 1.5 min; = 4.5 min / = 20 C; = 80 C / pH = 2.8; pH = 4.0; pH = 5.2

- -

- = 1.5 min; = 4.5 min / = 20 C; = 50 C / pH = 2.8; pH = 4.6; pH = 6.4

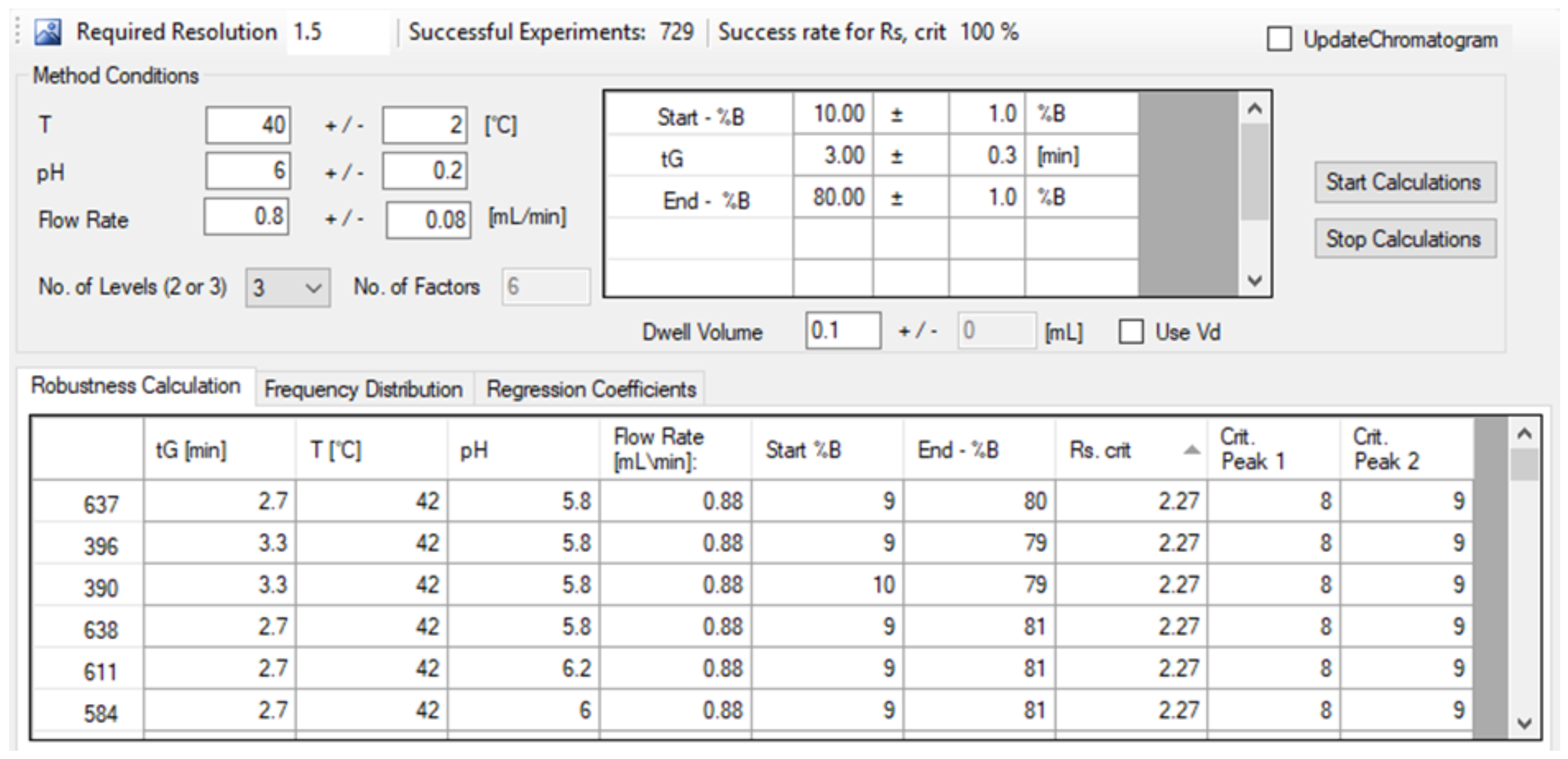

2.3. Robustness Testing

3. Materials and Methods

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

Abbreviations

| DOAJ | Directory of open access journals |

| ACN | Acetonitrile |

| API | Active Pharmaceutical Ingredient |

| DoE | Design of Experiment |

| HPLC | High-Performance Liquid Chromatography |

| IPC | In-Process Control |

| QbD | Quality by Design |

| RPLC | Reversed Phase Liquid Chromatography |

| UHPLC | Ultra-High-Performance Liquid Chromatography |

References

- International Council for Harmonisation Guideline Q8 (R2) on Pharmaceutical Devlopment, Step 5 Version 2017. Available online: https://www.ema.europa.eu/en/documents/scientific-guideline/international-conference-harmonisation-technical-requirements-registration-pharmaceuticals-human-use_en-11.pdf (accessed on 22 June 2017).

- Rácz, N.; Kormány, R. Retention Modeling in an Extended Knowledge Space. Chromatographia 2018, 81, 585–594. [Google Scholar] [CrossRef]

- Snyder, L.R.; Dolan, J.W.; Carr, P.W. The hydrophobic-subtraction model of reversed-phase column selectivity. J. Chromatogr. A 2004, 1060, 77–116. [Google Scholar] [CrossRef]

- Molnár, I. Computerized design of separation strategies by reversed-phase liquid chromatography: Development of DryLab software. J. Chromatogr. A 2002, 965, 175–194. [Google Scholar] [CrossRef]

- Fekete, S.; Molnár, I. (Eds.) Software-Assisted Method Development in High Performance Liquid Chromatography; World Scientific: Singapore, 2018; ISBN 978-1-78634-545-5. [Google Scholar]

- Molnár, I.; Rieger, H.J.; Monks, K.E. Aspects of the “Design Space” in High Pressure Liquid Chromatography Method Development. J. Chromatogr. A 2010, 1217, 3193–3200. [Google Scholar] [CrossRef] [PubMed]

- Komárny, R.; Molnár, I.; Rieger, H. Exploring better column selectivity choices in ultra-high perfomace liquid chromatography using Quality by Design principles. J. Pharm. Biomed. Anal. 2013, 80, 79–88. [Google Scholar]

- Agrawal, R.; Jain, P.; Dikshit, S.N. Apixaban: A new player in the anticoagulant class. Curr. Drug Targets 2012, 13, 863–875. [Google Scholar] [CrossRef] [PubMed]

- Mravik, A.; Nagy, T.; Faragó, J.; Volk, B.; Lukács, G.; Németh, G.; Czoborné Hatvári, I.; Slégel, P.; Csonka-Kis, G.; Kormány, R. Process for the Preparation of Apixaban. Patent Cooperation Treaty WO2016020711A1, 11 February 2016. [Google Scholar]

- Schmidt, A.; Molnár, I. Using an innovative Quality-by-Design approach for development of stability indicating UHPLC method for ebastine in the API and pharmaceutical formulations. J. Pharm. Biomed. Anal. 2013, 78–79, 65–74. [Google Scholar] [CrossRef] [PubMed]

- Kormány, R.; Molnár, I.; Fekete, J.; Guillarme, D.; Fekete, S. Robust UHPLC Separation Method Development for Multi-API Product Amlodipine and Bisoprolol: The Impact of Column Selection. Chromatographia 2014, 77, 1119–1127. [Google Scholar] [CrossRef]

- Enesei, D.; Kapui, I.; Fekete, S.; Kormány, R. Updating the European Pharmacopoeia impurity profiling method for terazosin and suggesting alternative columns, using quality by design principle. J. Pharm. Biomed. Anal. 2020, 187, 113371. [Google Scholar] [CrossRef] [PubMed]

| Stm1 | Int1 | Int2 | Stm2 | Int3 | Int4 | Int5 | Int6 | Apixaban | |

|---|---|---|---|---|---|---|---|---|---|

| Stm1 | 1.00 | 0.87 | 0.64 | — | 0.92 | 1.13 | 0.90 | 0.98 | 1.16 |

| Int1 | — | 1.00 | 0.73 | — | 1.06 | 1.30 | 1.03 | 1.13 | 1.34 |

| Int2 | — | — | 1.00 | — | 1.44 | 1.77 | 1.41 | 1.54 | 1.82 |

| Stm2 | — | — | — | 1.00 | 1.88 | 2.32 | 1.84 | 2.01 | 2.38 |

| Int3 | — | — | — | — | 1.00 | 1.23 | 0.98 | 1.07 | 1.27 |

| Int4 | — | — | — | — | — | 1.00 | 0.79 | 0.87 | 1.03 |

| Int5 | — | — | — | — | — | — | 1.00 | 1.09 | 1.29 |

| Int6 | — | — | — | — | — | — | — | 1.00 | 1.19 |

| Apixaban | — | — | — | — | — | — | — | — | 1.00 |

| OP | 637 | 396 | 390 | 638 | 611 | 584 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pred. | Exp. | Pred. | Exp. | Pred. | Exp. | Pred. | Exp. | Pred. | Exp. | Pred. | Exp. | Pred. | Exp. | |

| Int6 | 0.88 | 0.89 | 0.83 | 0.83 | 0.93 | 0.94 | 0.89 | 0.89 | 0.82 | 0.83 | 0.82 | 0.83 | 0.82 | 0.82 |

| Stm1 | 1.13 | 1.13 | 1.05 | 1.04 | 1.16 | 1.16 | 1.12 | 1.12 | 1.04 | 1.03 | 1.04 | 1.04 | 1.04 | 1.03 |

| Apixaban | 1.32 | 1.32 | 1.22 | 1.21 | 1.40 | 1.40 | 1.36 | 1.36 | 1.21 | 1.22 | 1.21 | 1.22 | 1.21 | 1.21 |

| Int2 | 1.43 | 1.44 | 1.31 | 1.31 | 1.48 | 1.46 | 1.44 | 1.42 | 1.30 | 1.30 | 1.30 | 1.32 | 1.30 | 1.31 |

| Int1 | 1.69 | 1.69 | 1.54 | 1.55 | 1,76 | 1.75 | 1.72 | 1.72 | 1.53 | 1.53 | 1.53 | 1.53 | 1.53 | 1.53 |

| Int5 | 1.85 | 1.85 | 1.69 | 1.67 | 1.96 | 1.98 | 1.93 | 1.94 | 1.67 | 1.68 | 1.67 | 1.68 | 1.67 | 1.67 |

| Stm2 | 1.96 | 1.96 | 1.78 | 1.77 | 2.06 | 2.05 | 2.03 | 2.05 | 1.77 | 1.79 | 1.77 | 1.78 | 1.77 | 1.78 |

| Int4 | 2.16 | 2.16 | 1.96 | 1.95 | 2.30 | 2.30 | 2.28 | 2.29 | 1.94 | 1.95 | 1.94 | 1.94 | 1.94 | 1.95 |

| Int3 | 2.22 | 2.22 | 2.01 | 1.98 | 2.35 | 2.37 | 2.33 | 2.34 | 1.99 | 2.00 | 1.99 | 1.99 | 1.99 | 1.99 |

Int4-Int3 | 2.40 | 2.37 | 2.27 | 2.24 | 2.27 | 2.25 | 2.27 | 2.24 | 2.27 | 2.23 | 2.27 | 2.23 | 2.27 | 2.23 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kormány, R.; Rácz, N.; Fekete, S.; Horváth, K. Development of a Fast and Robust UHPLC Method for Apixaban In-Process Control Analysis. Molecules 2021, 26, 3505. https://doi.org/10.3390/molecules26123505

Kormány R, Rácz N, Fekete S, Horváth K. Development of a Fast and Robust UHPLC Method for Apixaban In-Process Control Analysis. Molecules. 2021; 26(12):3505. https://doi.org/10.3390/molecules26123505

Chicago/Turabian StyleKormány, Róbert, Norbert Rácz, Szabolcs Fekete, and Krisztián Horváth. 2021. "Development of a Fast and Robust UHPLC Method for Apixaban In-Process Control Analysis" Molecules 26, no. 12: 3505. https://doi.org/10.3390/molecules26123505