Silica Aerogels/Xerogels Modified with Nitrogen-Containing Groups for Heavy Metal Adsorption

Abstract

:1. Introduction

2. Results and Discussion

2.1. Prepared Adsorbents

2.2. Adsorbents Characterization

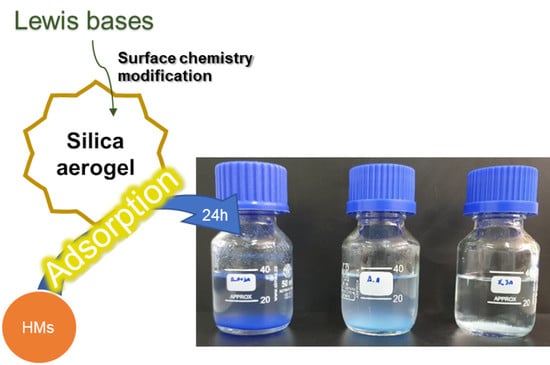

2.3. Preliminary Adsorption Tests

2.4. Effect of pH and Adsorbent Dose

2.5. Adsorption Kinetics

2.6. Adsorption Isotherms

2.7. Adsorption Thermodynamics

3. Materials and Methods

3.1. Materials

3.2. Synthesis of Silica Aerogels and Xerogels

3.3. Adsorption Tests

3.4. Characterization

4. Conclusions

- (1)

- The presence of the N-containing functional groups in the silica backbone impacted the microstructure and the properties of the materials significantly, reducing surface areas and porosity.

- (2)

- The drying conditions, namely at ambient pressure or in supercritical conditions, strongly influenced the materials structure, with aerogels retaining appreciable porosity and surface area and xerogels being more densified materials.

- (3)

- The aforementioned properties affect the adsorption performance and, in general, adsorbents with low porosity were not good adsorbents.

- (4)

- In terms of functional groups, materials derived from formulations TRIS and U were not good adsorbents for the tested cations; for the remaining formulations, with the exception of 3A, aerogels remove more cation than their xerogel counterpart, in agreement with the more extensive porosity of aerogels.

- (5)

- It was found that pH4 is more favorable for the adsorption of the studied metals, in agreement with their speciation diagrams.

- (6)

- The in-depth study of the best samples (A_A, X_3A and A_A+3A) revealed that the Langmuir trend is verified in almost all cases and that the kinetic process can either reach equilibrium very fast or in a two-stage process depending on the adsorbate-adsorbent pair. These two stages may be attributed to the presence of two types of active sites in some of the materials.

- (7)

- The isotherm and kinetic models suggest, in most situations, that the prepared adsorbents removed the cations by chemisorption.

- (8)

- Thermodynamic tests with the A_A+3A adsorbent reveal the spontaneous nature of the adsorption process, being observed that it is exothermic for copper, endothermic for lead and cadmium and athermic for nickel.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Intraparticle Diffusion Model | Pseudo-Second Order | |||||||

|---|---|---|---|---|---|---|---|---|

| k (mg·g−1·h−0.5) | C (mg·g−1) | AIC (a) | BIC (b) | k2 × 103 (g·mg−1·h−1) | qe (mg·g−1) | AIC (a) | BIC (b) | |

| A_A Cu | 13.4 | 11.1 | 39.3 | 26.7 | 4767 | 26.4 | 25.7 | 13.1 |

| X_3A Cu | 10.1 | 3.3 | 28.3 | 15.7 | 997.3 | 13.5 | 12.8 | 0.1 |

| X_3A Pb | 41.3 | 6.3 | 45.9 | 20.7 | 566.6 | 36.6 | 26.4 | 1.2 |

| A_A Cd | 17.4 | 3.8 | 29.1 | 16.4 | 455.5 | 21.7 | 26.4 | 13.7 |

| X_3A Ni | 8.0 | 2.3 | 34.5 | 9.4 | 1461 | 10.5 | 15.0 | −10.2 |

References

- Maleki, H.; Durães, L.; Portugal, A. An overview on silica aerogels synthesis and different mechanical reinforcing strategies. J. Non Cryst. Solids 2014, 385, 55–74. [Google Scholar] [CrossRef] [Green Version]

- Gurav, J.L.; Jung, I.-K.; Park, H.-H.; Kang, E.S.; Nadargi, D.Y. Silica Aerogel: Synthesis and Applications. J. Nanomater. 2010, 2010, 1–11. [Google Scholar] [CrossRef] [Green Version]

- García-González, C.A.; Budtova, T.; Durães, L.; Erkey, C.; Del Gaudio, P.; Gurikov, P.; Koebel, M.; Liebner, F.; Neagu, M.; Smirnova, I. An Opinion Paper on Aerogels for Biomedical and Environmental Applications. Molecules 2019, 24, 1815. [Google Scholar]

- Vareda, J.P.; Lamy-Mendes, A.; Durães, L. A reconsideration on the definition of the term aerogel based on current drying trends. Microporous Mesoporous Mater. 2018, 258, 211–216. [Google Scholar] [CrossRef]

- Eychmüller, A.; Ziegler, C.; Wolf, A.; Liu, W.; Herrmann, A.-K.; Gaponik, N. Modern Inorganic Aerogels. Angew. Chem. Int. Ed. 2017, 56, 13200–13221. [Google Scholar]

- Vareda, J.P.; Valente, A.J.; Durães, L. Heavy metals in Iberian soils: Removal by current adsorbents/amendments and prospective for aerogels. Adv. Colloid Interface Sci. 2016, 237, 28–42. [Google Scholar] [CrossRef] [PubMed]

- Vareda, J.P.; Valente, A.J.M.; Durães, L. Assessment of heavy metal pollution from anthropogenic activities and remediation strategies: A review. J. Environ. Manag. 2019, 246, 101–118. [Google Scholar] [CrossRef] [PubMed]

- Maleki, H. Recent advances in aerogels for environmental remediation applications: A review. Chem. Eng. J. 2016, 300, 98–118. [Google Scholar] [CrossRef]

- Gan, G.; Li, X.; Fan, S.; Wang, L.; Qin, M.; Yin, Z.; Chen, G. Carbon Aerogels for Environmental Clean-Up. Eur. J. Inorg. Chem. 2019, 2019, 3126–3141. [Google Scholar] [CrossRef]

- Filho, C.M.C.; Matias, T.; Durães, L.; Valente, A.J.M. Efficient simultaneous removal of petroleum hydrocarbon pollutants by a hydrophobic silica aerogel-like material. Colloids Surf. A Physicochem. Eng. Asp. 2017, 520, 550–560. [Google Scholar] [CrossRef]

- Cheng, H.; Gu, B.; Pennefather, M.P.; Nguyen, T.X.; Phan-Thien, N.; Duong, H.M. Cotton aerogels and cotton-cellulose aerogels from environmental waste for oil spillage cleanup. Mater. Des. 2017, 130, 452–458. [Google Scholar] [CrossRef]

- Wuana, R.A.; Okieimen, F.E. Heavy Metals in Contaminated Soils: A Review of Sources, Chemistry, Risks and Best Available Strategies for Remediation. ISRN Ecol. 2011, 2011, 1–20. [Google Scholar] [CrossRef] [Green Version]

- Pratush, A.; Kumar, A.; Hu, Z. Adverse effect of heavy metals (As, Pb, Hg, Cr) on health and their bioremediation strategies: A review. Int. Microbiol. 2018, 21, 97–106. [Google Scholar] [CrossRef] [PubMed]

- Burakov, A.E.; Galunin, E.V.; Burakova, I.V.; Kucherova, A.E.; Agarwal, S.; Tkachev, A.G.; Gupta, V.K. Adsorption of heavy metals on conventional and nanostructured materials for wastewater treatment purposes: A review. Ecotoxicol. Environ. Saf. 2018, 148, 702–712. [Google Scholar] [CrossRef] [PubMed]

- Mo, L.; Pang, H.; Tan, Y.; Zhang, S.; Li, J. 3D multi-wall perforated nanocellulose-based polyethylenimine aerogels for ultrahigh efficient and reversible removal of Cu(II) ions from water. Chem. Eng. J. 2019, 378, 122157. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, S.; Cui, S.; Tang, Y.; Pei, Z.; Duan, H. Magnetic-controlled aerogels from carboxylated cellulose and MnFe2O4 as a novel adsorbent for removal of Cu(II). Cellulose 2019, 26, 5051–5063. [Google Scholar] [CrossRef]

- Deze, E.G.; Papageorgiou, S.K.; Favvas, E.P.; Katsaros, F.K. Porous alginate aerogel beads for effective and rapid heavy metal sorption from aqueous solutions: Effect of porosity in Cu2+ and Cd2+ ion sorption. Chem. Eng. J. 2012, 209, 537–546. [Google Scholar] [CrossRef]

- Jiao, C.; Xiong, J.; Tao, J.; Xu, S.; Zhang, D.; Lin, H.; Chen, Y. Sodium alginate/graphene oxide aerogel with enhanced strength-toughness and its heavy metal adsorption study. Int. J. Biol. Macromol. 2016, 83, 133–141. [Google Scholar] [CrossRef] [PubMed]

- Kadirvelu, K.; Goel, J.; Rajagopal, C. Sorption of lead, mercury and cadmium ions in multi-component system using carbon aerogel as adsorbent. J. Hazard. Mater. 2008, 153, 502–507. [Google Scholar] [CrossRef]

- Štandeker, S.; Veronovski, A.; Novak, Z.; Knez, Ž. Silica aerogels modified with mercapto functional groups used for Cu(II) and Hg(II) removal from aqueous solutions. Desalination 2011, 269, 223–230. [Google Scholar] [CrossRef]

- Pouretedal, H.R.; Kazemi, M. Characterization of modified silica aerogel using sodium silicate precursor and its application as adsorbent of Cu2+, Cd2+, Pb2+ ions. Int. J. Ind. Chem. 2012, 3, 20. [Google Scholar] [CrossRef] [Green Version]

- Mirzaee, S.S.; Salahi, E.; Khanlarkhani, A. Kinetics, isotherms and thermodynamic modeling of Mn2+ and Zn2+ single and binary removal using mercapto functionalized silica aerogel. J. Dispers. Sci. Technol. 2019, 40, 657–667. [Google Scholar] [CrossRef]

- Faghihian, H.; Nourmoradi, H.; Shokouhi, M. Performance of silica aerogels modified with amino functional groups in PB(II) and CD(II) removal from aqueous solutions. Pol. J. Chem. Technol. 2012, 14, 50–56. [Google Scholar] [CrossRef] [Green Version]

- Faghihian, H.; Nourmoradi, H.; Shokouhi, M. Removal of copper (II) and nickel (II) from aqueous media using silica aerogel modified with amino propyl triethoxysilane as an adsorbent: Equilibrium, kinetic, isotherms study. Desalin. Water Treat. 2013, 52, 305–313. [Google Scholar] [CrossRef]

- Ali, Z.; Khan, A.; Ahmad, R. The use of functionalized aerogels as a low level chromium scavenger. Microporous Mesoporous Mater. 2015, 203, 8–16. [Google Scholar] [CrossRef]

- Duan, X.; Qi, G.; Wang, P.; Giannelis, E.P. A Highly Efficient and Selective Polysilsesquioxane Sorbent for Heavy Metal. Removal. ChemPhysChem 2012, 13, 2536–2539. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.-D.; Gao, X.-D.; Gu, Z.-Y.; Li, X.-M. Amino-terminated SiO2 aerogel towards highly-effective lead (II) adsorbent via the ambient drying process. J. Non Cryst. Solids 2016, 443, 39–46. [Google Scholar] [CrossRef]

- Fan, H.-T.; Su, Z.-J.; Fan, X.-L.; Guo, M.-M.; Wang, J.; Gao, S.; Sun, T. Sol–gel derived organic–inorganic hybrid sorbent for removal of Pb2+, Cd2+ and Cu2+ from aqueous solution. J. Solgel Sci. Technol. 2012, 64, 418–426. [Google Scholar] [CrossRef]

- Vareda, J.P.; Durães, L. Functionalized silica xerogels for adsorption of heavy metals from groundwater and soils. J. Solgel Sci. Technol. 2017, 84, 400–408. [Google Scholar] [CrossRef]

- Vareda, J.P.; Durães, L. Efficient adsorption of multiple heavy metals with tailored silica aerogel-like materials. Environ. Technol. 2019, 40, 529–541. [Google Scholar] [CrossRef]

- Lamy-Mendes, A.; Torres, R.B.; Vareda, J.P.; Lopes, D.; Ferreira, M.; Valente, V.; Girão, A.V.; Valente, A.J.M.; Durães, L. Amine Modification of Silica Aerogels/Xerogels for Removal of Relevant Environmental Pollutants. Molecules 2019, 24, 3701. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Zhou, Q.; Guo, H.; Yang, P.; Lu, W. Determination of water solubility in supercritical CO2 from 313.15 to 473.15 K and from 10 to 50 MPa by in-situ quantitative Raman spectroscopy. Fluid Phase Equilibria 2018, 476, 170–178. [Google Scholar]

- Reichenauer, G.; Scherer, G.W. Effects upon Nitrogen Sorption Analysis in Aerogels. J. Colloid Interface Sci. 2001, 236, 385–386. [Google Scholar] [CrossRef] [PubMed]

- Tadanaga, K.; Minami, T. Measurements of gas adsorption and permeability of sol-gel materials. In Handbook of Sol-Gel Science and Technology: Processing, Characterization and Applications; Klein, L., Aparicio, M., Jitianu, A., Eds.; Springer International Publishing: Cham, Germany, 2018; pp. 1411–1423. [Google Scholar]

- Reichenauer, G. Structural characterization of aerogels. In Aerogels Handbook; Aegerter, M.A., Leventis, N., Koebel, M.M., Eds.; Springer: New York, NY, USA, 2011; pp. 449–498. [Google Scholar]

- Lamy-Mendes, A.; Girão, A.V.; Silva, R.F.; Durães, L. Polysilsesquioxane-based silica aerogel monoliths with embedded CNTs. Microporous and Mesoporous Mater. 2019, 288, 109575. [Google Scholar] [CrossRef]

- Al-Oweini, R.; El-Rassy, H. Synthesis and characterization by FTIR spectroscopy of silica aerogels prepared using several Si(OR)4 and R′′Si(OR′)3 precursors. J. Mol. Struct. 2009, 919, 140–145. [Google Scholar] [CrossRef]

- Itagaki, A.; Nakanishi, K.; Hirao, K. Phase Separation in Sol.-Gel System Containing Mixture of 3- and 4-Functional Alkoxysilanes. J. Solgel Sci. Technol. 2003, 26, 153–156. [Google Scholar] [CrossRef]

- Burrows, H.D.; Costa, D.; Ramos, M.L.; Miguel, M.d.G.; Teixeira, M.H.; Pais, A.A.C.C.; Valente, A.J.M.; Bastos, M.; Bai, G. Does cation dehydration drive the binding of metal ions to polyelectrolytes in water? What we can learn from the behaviour of aluminium(iii) and chromium(iii). Phys. Chem. Chem. Phys. 2012, 14, 7950–7953. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mihaly-Cozmuta, L.; Mihaly-Cozmuta, A.; Peter, A.; Nicula, C.; Tutu, H.; Silipas, D.; Indrea, E. Adsorption of heavy metal cations by Na-clinoptilolite: Equilibrium and selectivity studies. J. Environ. Manag. 2014, 137, 69–80. [Google Scholar] [CrossRef] [PubMed]

- Icenhower, J.; Dove, P.M. Water behavior at silica surfaces. In Adsorption on Silica Surfaces; Papirer, E., Ed.; Marcel Dekker: New York, NY, USA, 2000; pp. 277–295. [Google Scholar]

- Kosmulski, M. Surface charge and zeta potential of silica in mixtures of organic solvents and water. In Adsorption on Silica Surfaces; Papirer, E., Ed.; Marcel Dekker: New York, NY, USA, 2000; pp. 343–367. [Google Scholar]

- Posada, D.; Buckley, T.R. Model Selection and Model Averaging in Phylogenetics: Advantages of Akaike Information Criterion and Bayesian Approaches Over Likelihood Ratio Tests. Syst. Biol. 2004, 53, 793–808. [Google Scholar] [CrossRef] [PubMed]

- Lagergreen, S. Zur Theorie der sogenannten Adsorption gelöster Stoffe. Zeitschr. f. Chem. und. Ind. der. Kolloide 1907, 2, 15. [Google Scholar]

- Ho, Y.S.; McKay, G. Sorption of dye from aqueous solution by peat. Chem. Eng. J. 1998, 70, 115–124. [Google Scholar] [CrossRef]

- Wilczak, A.; Keinath, T.M. Kinetics of sorption and desorption of copper(II) and lead (II) on activated carbon. Water Environ. Res. 1993, 65, 238–244. [Google Scholar] [CrossRef]

- Chiron, N.; Guilet, R.; Deydier, E. Adsorption of Cu(II) and Pb(II) onto a grafted silica: Isotherms and kinetic models. Water Res. 2003, 37, 3079–3086. [Google Scholar] [CrossRef]

- Piccin, J.S.; Cadaval, T.R.S.A.; de Pinto, L.A.A.; Dotto, G.L. Adsorption isotherms in liquid phase: Experimental, modeling, interpretations. In Adsorption Processes for Water Treatment and Purification; Bonilla-Petriciolet, A., Mendoza-Castillo, D.I., Reynel-Ávila, H.E., Eds.; Springer International Publishing: Cham, Germany, 2017; pp. 19–51. [Google Scholar]

- Pan, A.; Biswas, T.; Rakshit, A.K.; Moulik, S.P. Enthalpy–Entropy Compensation (EEC) Effect: A Revisit. J. Phys. Chem. B 2015, 119, 15876–15884. [Google Scholar] [CrossRef] [PubMed]

- Ingmar, P. Hydrated metal ions in aqueous solution: How regular are their structures? Pure and Appl. Chem. 2010, 82, 1901–1917. [Google Scholar]

- Wang, X.-S.; Huang, J.; Hu, H.-Q.; Wang, J.; Qin, Y. Determination of kinetic and equilibrium parameters of the batch adsorption of Ni(II) from aqueous solutions by Na-mordenite. J. Hazard. Mater. 2007, 142, 468–476. [Google Scholar] [CrossRef]

- Wang, X.S.; Hu, H.Q.; Sun, C. Removal of Copper (II) Ions from Aqueous Solutions using Na—mordenite. Sep. Sci. Technol. 2007, 42, 1215–1230. [Google Scholar] [CrossRef]

- Vareda, J.P.; Matias, T.; Durães, L. Facile preparation of ambient pressure dried aerogel-like monoliths with reduced shrinkage based on vinyl-modified silica networks. Ceram. Int. 2018, 44, 17453–17458. [Google Scholar] [CrossRef]

Sample Availability: Samples of the materials presented are not available. |

| Functional Groups | Molar Composition (%) of the Precursor System (a) | Xerogel | Aerogel |

|---|---|---|---|

| Ref. material (without N-containing groups) | 62.5%MTES/37.5%TEOS | X_B | X_B |

| 3-Aminopropyl | 50%MTES/30%TEOS/20%APTMS | X_A | A_A |

| Propyl diethylenetriamine | 50%MTES/30%TEOS/20%AAAPTMS | X_3A | A_3A |

| 3-Aminopropyl + propyl diethylenetriamine | 50%MTES/30%TEOS/10%APTMS/10%AAAPTMS | X_A+3A | A_A+3A |

| Propyl isocyanurate | 50%MTES/30%TEOS/20%TTMSI | X_TRIS | A_TRIS |

| Propyl urea | 50%MTES/30%TEOS/20%UPTMS | X_U | A_U |

| Formulation | Bulk Density (a)/g cm−3 | Porosity/% | SBET/m2 g−1 | Vpore/cm3 g−1 | Dpore/nm | |

|---|---|---|---|---|---|---|

| B | Xerogel [31] | 1.07 | 24 | 761 | 0.22 | 1 |

| Aerogel | 0.141 | 90 | 1006 | 6.38 | 25 | |

| A | Xerogel [31] | 1.41 | 3 | 28 | 0.02 | 4 |

| Aerogel | 0.134 | 87 | 573 | 6.48 | 45 | |

| 3A | Xerogel | 1.30 | 7 | (b) | 0.05 | - |

| Aerogel | 0.737 | 48 | 14 | 0.64 | 182 | |

| A+3A | Xerogel | 1.12 | 23 | 3 | 0.21 | 268 |

| Aerogel | 0.191 | 86 | 256 | 4.49 | 70 | |

| TRIS | Xerogel | 1.14 | 16 | 634 | 0.14 | 1 |

| Aerogel | 0.132 | 88 | 451 | 6.67 | 59 | |

| U | Xerogel | 1.42 | (c) | (b) | (c) | - |

| Aerogel | 0.430 | 67 | 398 | 1.56 | 16 | |

| Formulation | Sample/Hypothesis (a) | wt% C | wt% H | wt% N |

|---|---|---|---|---|

| B | Exp. Xerogel [31] | 11.87 | 3.52 | 0.58 |

| Exp. Aerogel | 15.41 | 4.05 | 0.85 | |

| CC | 11.64 | 2.93 | - | |

| IC 1OH | 10.22 | 3.94 | - | |

| IC 2OH | 9.10 | 4.73 | - | |

| A | Exp. Xerogel [31] | 15.31 | 4.47 | 3.30 |

| Exp. Aerogel | 19.62 | 4.87 | 3.71 | |

| CC | 17.95 | 4.24 | 3.81 | |

| IC 1OH | 15.99 | 5.00 | 3.39 | |

| IC 2OH | 14.42 | 5.61 | 3.06 | |

| 3A | Exp. Xerogel | 22.16 | 5.94 | 7.91 |

| Exp. Aerogel | 22.07 | 5.60 | 7.14 | |

| CC | 25.12 | 5.66 | 9.25 | |

| IC 1OH | 22.85 | 6.16 | 8.42 | |

| IC 2OH | 20.96 | 6.57 | 7.72 | |

| A+3A | Exp. Xerogel | 19.05 | 5.53 | 6.00 |

| Exp. Aerogel | 20.98 | 5.14 | 5.52 | |

| CC | 21.91 | 5.03 | 6.81 | |

| IC 1OH | 19.75 | 5.63 | 6.14 | |

| IC 2OH | 17.97 | 6.13 | 5.59 | |

| TRIS | Exp. Xerogel | 20.40 | 4.11 | 3.83 |

| Exp. Aerogel | 21.95 | 4.37 | 3.75 | |

| CC | 19.81 | 3.45 | 3.55 | |

| IC 1OH | 18.02 | 4.15 | 3.23 | |

| IC 2OH | 16.12 | 4.89 | 2.89 | |

| U | Exp. Xerogel | 17.06 | 4.38 | 5.60 |

| Exp. Aerogel | 21.41 | 4.86 | 6.45 | |

| CC | 18.99 | 4.05 | 6.81 | |

| IC 1OH | 17.11 | 4.75 | 6.14 | |

| IC 2OH | 15.58 | 5.33 | 5.59 |

| Sample | Copper Removal (%) | Lead Removal (%) | Cadmium Removal (%) | Nickel Removal (%) |

|---|---|---|---|---|

| X_B | 8.8 | 44.5 | 0.9 | 3.3 |

| A_B | 8.7 | 64.2 | (a) | 2.3 |

| X_A | 12.9 | 61.0 | 5.6 | 4.2 |

| A_A | 98.6 | 99.5 | 98.8 | 66.8 |

| X_3A | 59.0 | 98.9 | 6.05 | 6.1 |

| A_3A | 33.4 | 96.9 | 10.5 | 2.5 |

| X_A+3A | 64.7 | 77.7 | 26.6 | 21.8 |

| A_A+3A | 59.4 | 93.0 | 95.0 | 64.0 |

| X_TRIS | 10.1 | 34.0 | (a) | (a) |

| A_TRIS | 8.6 | 51.9 | 3.5 | (a) |

| X_U | 5.2 | 38.1 | 1.8 | (a) |

| A_U | 4.4 | 39.3 | 3.0 | (a) |

| AC | 21.7 | 18.6 | 9.4 | 2.8 |

| Pseudo-First Order (PS1) | Pseudo-Second Order (PS2) | Double-Exponential Model (DEM) | Exp. qe (mg g−1) | Preferred Model | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| k1 (h−1) | qe (mg g−1) | AIC (a) | BIC (b) | k2 × 103 (g mg−1 h−1) | qe (mg g−1) | AIC (a) | BIC (b) | D1 (mg L−1) | KD1 (h−1) | D2 (mg L−1) | KD2 (h−1) | qe (mg g−1) | AIC (a) | BIC (b) | |||

| A_A Cu | 27.6 | 30.9 | 42.7 | 38.5 | 1866 | 31.5 | 39.5 | 35.3 | 45.3 | 102 | 33.6 | 0.18 | 39.5 | 51.2 | 10.3 | 44.0 | DEM |

| X_3A Cu | 0.43 | 26.8 | 43.5 | 40.4 | 36.3 | 27.2 | 39.8 | 36.7 | 21.7 | 11.8 | 63.2 | 4.8E-2 | 42.3 | 31.6 | 5.4 | 46.3 | DEM |

| A_A+3A Cu | 23.8 | 517 | 19.2 | 15.0 | 713 | 54.2 | 16.3 | 12.1 | 87.2 | 32.5 | 18.3 | 4.1 | 52.9 | 49.1 | 8.3 | 47.5 | PS2 |

| A_A Pb | 11.2 | 93.3 | 34.5 | 26.4 | 261 | 97.1 | 26.3 | 18.1 | 161 | 23.4 | 39.1 | 0.73 | 100.0 | 68.7 | -14.8 | 94.3 | PS2 |

| X_3A Pb | 0.87 | 80.4 | 56.8 | 53.7 | 16.1 | 85.9 | 50.9 | 47.3 | 124 | 0.32 | 49.3 | 26.8 | 86.8 | 52.6 | 26.4 | 82.7 | DEM |

| A_A+3A Pb | 1.5 | 96.4 | 28.0 | 23.8 | 18.4 | 106.4 | 37.7 | 33.5 | 191 | 1.5 | 2.2 | 400 | 96.5 | 71.1 | 30.2 | 89.6 | PS1 |

| A_A Cd | 0.93 | 36.9 | 44.5 | 40.3 | 29.0 | 41.5 | 40.1 | 35.9 | 28.6 | 16.0 | 68.7 | 0.14 | 48.9 | 64.0 | 23.2 | 47.9 | DEM |

| X_3A Cd | 1.3 | 19.2 | 22.2 | 16.4 | 96.4 | 20.2 | 18.0 | 12.3 | 1.1E5 | 4.8E-6 | 28.3 | 1.8 | 5.3E4 | 99.7 | 16.2 | 30.0 | PS2 |

| A_A+3A Cd | 1.9 | 53.0 | 36.8 | 28.6 | 48.1 | 58.0 | 28.5 | 20.3 | 68.6 | 0.56 | 48.7 | 7.3 | 59.2 | -- | -- | 58.9 | PS2 |

| A_A Ni | 3.1 | 31.4 | 33.5 | 29.3 | 150 | 32.9 | 26.4 | 22.2 | 24.2 | 4.9E9 | 42.0 | 1.1 | 33.1 | 52.8 | 12.0 | 44.4 | PS2 |

| X_3A Ni | 0.38 | 23.9 | 32.1 | 27.9 | 21.8 | 26.1 | 29.2 | 25.0 | 38.6 | 0.15 | 14.1 | 21.5 | 26.3 | 35.7 | -5.1 | 25.8 | DEM |

| A_A+3A Ni | 1.1 | 42.7 | 32.7 | 24.5 | 40.3 | 45.0 | 29.4 | 21.2 | 17.8 | 25.9 | 71.6 | 0.67 | 44.7 | -- | -- | 43.8 | PS2 |

| Langmuir Model | Freundlich Model | Max Exp. qe (mg·g−1) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| qmax (mg·g−1) | KL × 103 (L·mg−1) | AIC | BIC | 1/nF | KF (mg·g−1). (L·mg-1)1/n | AIC | BIC | ||

| A_A Cu | 43.5 | 2683 | 28.3 | 22.5 | 0.1 | 22.9 | 35.2 | 29.4 | 47.6 |

| X_3A Cu | 105.1 131.0 | 6.8 236 | 30.7 (a) | 22.5 (a) | 0.6 0.1 | 2.3 35.2 | 36.8 (a) | 28.6 (a) | 129.8 |

| A_A+3A Cu | 60.4 | 24.4 | 32.6 | 26.8 | 0.3 | 8.1 | 42.6 | 36.8 | 55.7 |

| A_A Pb | 183.3 | 116 | 52.1 | 46.4 | 0.3 | 42.7 | 61.5 | 55.7 | 172.1 |

| X_3A Pb | 110.6 | 52.4 | 44.2 | 38.5 | 0.3 | 19.9 | 55.6 | 49.8 | 99.9 |

| A_A+3A Pb | 346.9 | 16.9 | 25.7 | 17.5 | 0.7 | 10.0 | 28.6 | 20.5 | 171.8 |

| A_A Cd | 54.0 | 66.7 | 41.9 | 36.1 | 0.2 | 14.9 | 46.6 | 40.9 | 51.2 |

| X_3A Cd | 102.4 | 2.9 | 21.0 | 12.8 | 0.7 | 0.9 | 23.1 | 14.9 | 47.0 |

| A_A+3A Cd | 82.9 | 50.7 | 40.9 | 35.2 | 0.3 | 17.1 | 43.5 | 37.8 | 81.9 |

| A_A Ni | 68.2 | 34.6 | 41.4 | 35.6 | 0.3 | 10.5 | 32.2 | 26.4 | 68.2 |

| X_3A Ni | 69.2 | 4.2 | 22.4 | 9.8 | 0.6 | 1.5 | 29.2 | 16.5 | 42.0 |

| A_A+3A Ni | 65.6 | 21.5 | 31.0 | 25.2 | 0.4 | 7.7 | 39.6 | 33.8 | 61.3 |

| Cation | Temperature /°C | Kd /L·g−1 | ΔG0 /kJ·mol−1 | ΔH0 /kJ·mol−1 | ΔS0 /J·mol−1·K−1 | R2 |

|---|---|---|---|---|---|---|

| Copper | 25 | 0.409 | −8.07 ± 0.07 | −19 ± 3 | −36 ± 9 | 0.956 |

| 30 | 0.326 | −7.64 ± 0.06 | ||||

| 35 | 0.278 | −7.4 ± 0.1 | ||||

| 40 | 0.267 | −7.37 ± 0.02 | ||||

| 45 | 0.250 | −7.3 ± 0.1 | ||||

| Lead | 25 | 2.14 | −15.10 ± 0.08 | 225 ± 18 | 805 ± 58 | 0.987 |

| 30 | 17.2 | −20.6 ± 0.4 | ||||

| 35 | 16.6 | −20.9 ± 0.5 | ||||

| 40 | 160 | −27 ± 1 | ||||

| 45 | 859 | −32 ± 4 | ||||

| Cadmium | 25 | 0.080 | −5.4 ± 0.2 | 62 ± 4 | 226 ± 14 | 0.985 |

| 30 | 0.124 | −6.6 ± 0.1 | ||||

| 35 | 0.161 | −7.4 ± 0.1 | ||||

| 40 | 0.240 | −8.6 ± 0.1 | ||||

| 45 | 0.410 | −10.13 ± 0.00 | ||||

| Nickel | 25 | 0.238 | −6.54 ± 0.08 | (a) | (a) | (a) |

| 30 | 0.250 | −6.8 ± 0.2 | ||||

| 35 | 0.232 | −6.69 ± 0.04 | ||||

| 40 | 0.258 | −7.1 ± 0.2 | ||||

| 45 | 0.263 | −7.24 ± 0.03 |

| Formulation | [Base]/M | Aging Time/days | Gelation Temperature/°C | Gelation Time |

|---|---|---|---|---|

| B | 1 | 6 | 27 | 2 h |

| A | 1 | 6 | 27 | 10 min |

| 3A | 1 | 1 | 60 | 30 min |

| A+3A | 1 | 6 | 27 | 30 min |

| TRIS | 10 | 6 | 60 | 20 min |

| U | 10 | 6 | 27 | 2 h |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vareda, J.P.; Valente, A.J.M.; Durães, L. Silica Aerogels/Xerogels Modified with Nitrogen-Containing Groups for Heavy Metal Adsorption. Molecules 2020, 25, 2788. https://doi.org/10.3390/molecules25122788

Vareda JP, Valente AJM, Durães L. Silica Aerogels/Xerogels Modified with Nitrogen-Containing Groups for Heavy Metal Adsorption. Molecules. 2020; 25(12):2788. https://doi.org/10.3390/molecules25122788

Chicago/Turabian StyleVareda, João P., Artur J. M. Valente, and Luisa Durães. 2020. "Silica Aerogels/Xerogels Modified with Nitrogen-Containing Groups for Heavy Metal Adsorption" Molecules 25, no. 12: 2788. https://doi.org/10.3390/molecules25122788