Optimization of Scorpion Protein Extraction and Characterization of the Proteins’ Functional Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Chemicals

2.2. Total Extraction of Proteins from Scorpion Bodies

2.3. Methods for the Determination of Protein Extraction Indexes

2.3.1. Determination of Protein Contents (%)

2.3.2. Determination of Yields (%)

2.4. Single-Factor Experiments

2.5. Gel Electrophoresis Analysis

2.6. Box–Behnken of RSM and Statistical Analysis

2.7. Functional Properties

2.7.1. Protein Solubility Analyses

2.7.2. Foaming Properties

2.7.3. Water Absorption Capacity (WAC)

2.7.4. Oil Absorption Capacity (OAC)

2.7.5. Emulsifying Properties

2.8. Scanning Electron Microscopy (SEM) Analysis

2.9. Statistical Analysis

3. Results and Discussion

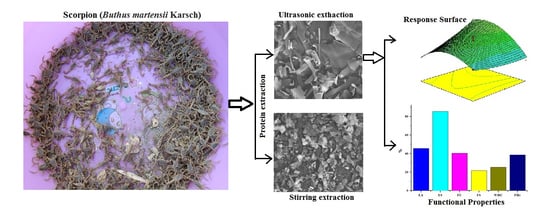

3.1. Analysis of Scorpion Protein Extraction Method

3.2. Analysis of a Single Factor Results

3.2.1. Effect of Extraction Time on Yield and Protein Content

3.2.2. Effect of Ultrasonic Power on Yield and Protein Content

3.2.3. Effect of Liquid/Solid Ratio on Yield and Protein Content

3.3. Optimization of Extraction Parameters by RSM

3.3.1. Analysis of the Influence of Various Factors on the Extraction of Scorpion Proteins

3.3.2. Interactions of Variables

3.3.3. Determination and Validation of Optimal Extraction Conditions

3.4. Functional Properties of Scorpion Proteins

3.4.1. Protein Solubility (PS)

3.4.2. Water and Oil Absorption Capacity

3.4.3. Emulsifying Properties

3.4.4. Foaming Properties

3.5. Scanning Electron Microscopy Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Cologna, C.T.; Silvana, M.; Giglio, J.R.; Soares, A.M.; Arantes, E.C. Tityus serrulatus scorpion venom and toxins: An overview. Protein Pept. Lett. 2009, 16, 920–932. [Google Scholar] [CrossRef]

- Asmari, A.K.A.; Zahrani, A.G.A.; Said, A.J.; Mohammed, A. Clinical aspects and frequency of scorpion stings in the Riyadh Region of Saudi Arabia. Saudi Med. J. 2012, 33, 852–858. [Google Scholar] [PubMed]

- Shi, L.; Zhang, T.X.; Du, C.Y.; Yuan, R.; Wang, C.C.; Li, F. Research Progress on Chemical Constituents, Pharmacological Effects and Clinical Applications of Scorpio. J. Liaoning Univ. Tradit. Chin. Med. 2015, 4, 31. [Google Scholar]

- Yu, M.; Liu, S.L.; Sun, P.B.; Pan, H.; Tian, C.L.; Zhang, L.H. Peptide toxins and small-molecule blockers of BK channels. Acta Pharmacol. Sin. 2016, 37, 56–66. [Google Scholar] [CrossRef] [PubMed]

- Machado, R.J.A.; Estrela, A.B.; Nascimento, A.K.L.; Melo, M.M.A.; Torres-Rêgo, M.; Lima, E.O.; Rocha, H.A.O.; Carvalho, E.; Silva-Junior, A.A.; Fernandes-Pedrosa, M.F. Characterization of TistH, a multifunctional peptide from the scorpion Tityus stigmurus: Structure, cytotoxicity and antimicrobial activity. Toxicon Off. J. Int. Soc. Toxinol. 2016, 119, 362–370. [Google Scholar] [CrossRef]

- Ortiz, E.; Gurrola, G.B.; Schwartz, E.F.; Possani, L.D. Scorpion venom components as potential candidates for drug development. Toxicon 2015, 93, 125–135. [Google Scholar] [CrossRef]

- Melo, E.T.D.; Estrela, A.B.; Santos, E.C.G.; Machado, P.R.L.; Farias, K.J.S.; Torres, T.M.; Carvalho, E.; Lima, J.P.M.S.; Silva-Júnior, A.A.; Barbosa, E.G. Structural characterization of a novel peptide with antimicrobial activity from the venom gland of the scorpion Tityus stigmurus: Stigmurin. Peptides 2015, 68, 3–10. [Google Scholar] [CrossRef]

- Amorim, F.G.; Cordeiro, F.A.; Pinheiro-Júnior, E.L.; Boldrini-França, J.; Arantes, E.C. Microbial production of toxins from the scorpion venom: Properties and applications. Appl. Microbiol. Biotechnol. 2018, 102, 6319–6331. [Google Scholar] [CrossRef]

- Pimenta, A.M.; StöCklin, R.; Favreau, P.; Bougis, P.E.; Martin-Eauclaire, M.F. Moving pieces in a proteomic puzzle: Mass fingerprinting of toxic fractions from the venom of Tityus serrulatus (Scorpiones, Buthidae). Rapid Commun. Mass Spectrom. Rcm 2010, 15, 1562–1572. [Google Scholar] [CrossRef]

- Shao, J.; Rong, Z.; Xin, G.; Yang, B.; Zhang, J. Analgesic Peptides in Buthus martensii Karsch: A Traditional Chinese Animal Medicine The Analgesic Peptides in Scorpion Venoms. Asian J. Tradit. Med. 2007, 2, 45–50. [Google Scholar]

- Pei, W.; Jie, T.; Yi, Z. Recombinant Expression and Functional Characterization of Martentoxin: A Selective Inhibitor for BK Channel (α + β4). Toxins 2014, 6, 1419–1433. [Google Scholar]

- Goudet, C.; Chi, C.W.; Tytgat, J. An overview of toxins and genes from the venom of the Asian scorpion Buthus martensi Karsch. Toxicon 2002, 40, 1239–1258. [Google Scholar] [CrossRef]

- Gupta, S.D.; Debnath, A.; Saha, A.; Giri, B.; Tripathi, G.; Vedasiromoni, J.R.; Gomes, A.; Gomes, A. Indian black scorpion (Heterometrus bengalensis Koch) venom induced antiproliferative and apoptogenic activity against human leukemic cell lines U937 and K562. Leuk. Res. 2007, 31, 817–825. [Google Scholar] [CrossRef] [PubMed]

- Díaz-García, A.; Morier-Díaz, L.; Frión-Herrera, Y.; Rodríguez-Sánchez, H.; Caballero-Lorenzo, Y.; Mendoza-Llanes, D.; Riquenes-Garlobo, Y.; Fraga-Castro, J.A. In vitro anticancer effect of venom from Cuban scorpion Rhopalurus junceus against a panel of human cancer cell lines. J. Venom Res. 2013, 4, 5–12. [Google Scholar]

- Guo, X.; Ma, C.; Du, Q.; Wei, R.; Wang, L.; Zhou, M.; Chen, T.; Shaw, C. Two peptides, TsAP-1 and TsAP-2, from the venom of the Brazilian yellow scorpion, Tityus serrulatus: Evaluation of their antimicrobial and anticancer activities. Biochimie 2013, 95, 1784–1794. [Google Scholar] [CrossRef]

- He, Y.; Zhao, R.; Di, Z.; Li, Z.; Xu, X.; Hong, W.; Wu, Y.; Zhao, H.; Li, W.; Cao, Z. Molecular diversity of Chaerilidae venom peptides reveals the dynamic evolution of scorpion venom components from Buthidae to non-Buthidae. J. Proteom. 2013, 89, 1–14. [Google Scholar] [CrossRef]

- Ali, S.A.; Alam, M.; Abbasi, A.; Kalbacher, H.; Schaechinger, T.J.; Hu, Y.; Zhijian, C.; Li, W.; Voelter, W. Structure–Activity Relationship of a Highly Selective Peptidyl Inhibitor of Kv1.3 Voltage-Gated K+-Channel from Scorpion (B. sindicus) Venom. Int. J. Pept. Res. 2014, 20, 19–32. [Google Scholar] [CrossRef]

- Hoang, N.A.; Maksimov, G.V.; Berezin, B.B.; Piskarev, V.E.; Yamskov, I.A. Isolation of toxins from buthus occitanus sp. scorpion and their action on excitability of myelinated nerve. Bull. Exp. Biol. Med. 2001, 132, 953–955. [Google Scholar] [CrossRef]

- Hoang, N.A.; Berezin, B.B.; Lakhtin, V.M.; Yamskov, I.A. Isolation and partial characterization of lectin from the venom of vietnamese scorpion buthus occitanussp. Appl. Biochem. Microbiol. 2001, 37, 534–537. [Google Scholar] [CrossRef]

- Ren, Y.; Wu, H.; Lai, F.; Yang, M.; Li, X.; Tang, Y. Isolation and identification of a novel anticoagulant peptide from enzymatic hydrolysates of scorpion (buthus martensii karsch) protein. Food Res. Int. 2014, 64, 931–938. [Google Scholar] [CrossRef]

- Ma, T.; Zhu, H.; Jing, W.; Qiang, W.; Yu, L.; Sun, B. Influence of extraction and solubilizing treatments on the molecular structure and functional properties of peanut protein. Lwt Food Sci. Technol. 2017, 79, 197–204. [Google Scholar] [CrossRef]

- Ahmedna, M.; Prinyawiwatkul, W.; Rao, R.M. Solubilized wheat protein isolate: Functional properties and potential food applications. J. Agric. Food Chem. 1999, 47, 1340–1345. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Zhang, J.; Sheng, W.; Wang, S.; Fu, T.J. Effects of heat and high-pressure treatments on the solubility and immunoreactivity of almond proteins. Food Chem. 2015, 199, 856–861. [Google Scholar] [CrossRef] [PubMed]

- Thaiphanit, S.; Anprung, P. Physicochemical and emulsion properties of edible protein concentrate from coconut (Cocos nucifera L.) processing by-products and the influence of heat treatment. Food Hydrocoll. 2016, 52, 756–765. [Google Scholar] [CrossRef]

- Feng, X.L.; Liu, H.Z.; Shi, A.M.; Liu, L.; Wang, Q.; Adhikari, B. Effects of transglutaminase catalyzed crosslinking on physicochemical characteristics of arachin and conarachin-rich peanut protein fractions. Food Res. Int. 2014, 62, 84–90. [Google Scholar] [CrossRef]

- Jeong, H.J.; Park, J.H.; Lam, Y.; de Lumen, B.O. Characterization of lunasin isolated from soybean. J. Agric. Food Chem. 2003, 51, 7901–7906. [Google Scholar] [CrossRef]

- Lin, X.S.; Wen, Q.; Huang, Z.L.; Cai, Y.Z.; Halling, P.J.; Yang, Z. Impacts of ionic liquids on enzymatic synthesis of glucose laurate and optimization with superior productivity by response surface methodology. Process. Biochem. 2015, 50, 1852–1858. [Google Scholar] [CrossRef]

- Mao, X.; Hua, Y. Composition, Structure and Functional Properties of Protein Concentrates and Isolates Produced from Walnut (Juglans regia L.). Int. J. Mol. Sci. 2012, 13, 1561–1581. [Google Scholar] [CrossRef]

- Arcan, I.; Yemenicioğlu, A. Effects of controlled pepsin hydrolysis on antioxidant potential and fractional changes of chickpea proteins. Food Res. Int. 2010, 43, 140–147. [Google Scholar] [CrossRef]

- Chityala, P.K. Effect of xanthan/enzyme-modified guar gum mixtures on the stability of whey protein isolate stabilized fish oil-in-water emulsions. Food Chem. 2016, 212, 332–340. [Google Scholar] [CrossRef]

- Gong, K.J.; Shi, A.M.; Liu, H.Z.; Liu, L.; Hu, H.; Adhikari, B.; Wang, Q. Emulsifying properties and structure changes of spray and freeze-dried peanut protein isolate. J. Food Eng. 2016, 170, 33–40. [Google Scholar] [CrossRef]

- Wu, H.; Wang, Q.; Ma, T.; Ren, J. Comparative studies on the functional properties of various protein concentrate preparations of peanut protein. Food Res. Int. 2009, 42, 343–348. [Google Scholar] [CrossRef]

- Jianmei, Y.; Mohamed, A.; Ipek, G. Peanut protein concentrate: Production and functional properties as affected by processing. Food Chem. 2007, 103, 121–129. [Google Scholar]

- Kadam, S.U.; Tiwari, B.K.; Álvarez, C.; O’Donnell, C.P. Ultrasound applications for the extraction, identification and delivery of food proteins and bioactive peptides. Trends Food Sci. Technol. 2015, 46, 60–67. [Google Scholar] [CrossRef]

- Liu, T.H.; Zhang, C.X.; Zhuang, F.J.; Xu, X.P.; Chi, Y.S. A Review on the Chemical Components and the Edible and Medicinal Value of Scorpion. Hans. J. Food Nutr. Sci. 2017, 6, 165–174. [Google Scholar] [CrossRef]

- Wu, F.L.; Dong, Q.H.; Wang, H.; Tan, J.; Lin, H.Q.; Li, P.Y.; Li, Y.J. Research Progress of Chinese Scorpion. J. Liaoning Univ. TCM 2018, 20, 108–111. [Google Scholar]

Sample Availability: Samples of the compounds are available from the authors. |

| Extraction Method | Yield (%) | Protein Content (%) | ||

|---|---|---|---|---|

| Ultrasonic Extraction | Stirring Extraction | Ultrasonic Extraction | Stirring Extraction | |

| Water | 34.85 ± 0.06 | 34.15 ± 0.09 | 31.14 ± 0.04 | 18.08 ± 0.06 |

| 0.5 M NaCl | 14.64 ± 0.08 | 11.80 ± 0.03 | 79.06 ± 0.05 | 35.26 ± 0.08 |

| 20 mM PBS | 18.29 ± 0.05 | 13.45 ± 0.10 | 60.98 ± 0.07 | 37.25 ± 0.09 |

| 0.02 M NaOH | 7.70 ± 0.11 | 7.57 ± 0.13 | 50.87 ± 0.07 | 51.91± 0.17 |

| Runs | Extraction Time (min) X1 | Liquid/Solid Ratio (mL/g) X2 | Ultrasonic Power (W) X3 | Protein Content/% | Yield /% |

|---|---|---|---|---|---|

| 1 | 60 | 15 | 400 | 75.23 | 24.32 |

| 2 | 40 | 20 | 400 | 69.01 | 21.41 |

| 3 | 20 | 10 | 300 | 59.31 | 17.76 |

| 4 | 40 | 15 | 300 | 55.98 | 19.53 |

| 5 | 40 | 15 | 300 | 56.39 | 18.89 |

| 6 | 60 | 10 | 300 | 64.09 | 16.62 |

| 7 | 40 | 20 | 200 | 44.01 | 14.84 |

| 8 | 40 | 10 | 200 | 49.4 | 16.25 |

| 9 | 60 | 15 | 200 | 50.17 | 17.04 |

| 10 | 40 | 10 | 400 | 55.70 | 17.74 |

| 11 | 40 | 15 | 300 | 55.70 | 19.31 |

| 12 | 60 | 20 | 300 | 70.00 | 20.78 |

| 13 | 40 | 15 | 300 | 53.58 | 19.52 |

| 14 | 20 | 20 | 300 | 46.01 | 17.37 |

| 15 | 20 | 15 | 200 | 45.49 | 18.31 |

| 16 | 20 | 15 | 400 | 50.66 | 18.39 |

| 17 | 40 | 15 | 300 | 60.52 | 20.04 |

| Source | Protein Content | Yield | ||

|---|---|---|---|---|

| F-Value | p-Value | F-Value | p-Value | |

| Model | 17.49 | 0.0005 | 34.12 | < 0.0001 |

| X1 | 53.50 | 0.0002 | 23.98 | 0.0018 |

| X2 | 4.46 | 0.9486 | 18.15 | 0.0037 |

| X3 | 60.17 | 0.0001 | 118.71 | < 0.0001 |

| X1× 2 | 11.73 | 0.0111 | 20.67 | 0.0026 |

| X1× 3 | 12.57 | 0.0094 | 51.76 | 0.0002 |

| X2× 3 | 11.11 | 0.0125 | 25.77 | 0.0014 |

| X12 | 2.45 | 0.1617 | 1.67 | 0.2378 |

| X22 | 0.88 | 0.3800 | 45.25 | 0.0003 |

| X32 | 5.43 | 0.0526 | 1.12 | 0.3256 |

| Lack of Fit | 1.54 | 0.3354 | 2.04 | 0.2506 |

| R2 | 0.9574 | 0.9777 | ||

| Adj-R2 | 0.9027 | 0.9491 | ||

| Properties | Ultrasonic Extraction | Stirring Extraction |

|---|---|---|

| Water holding capacity (g/g) | 25.25 ± 0.21 | 20.45 ± 0.07 |

| Oil holding capacity (g/g) | 38.50 ± 0.14 | 30.65 ± 0.64 |

| Emulsifying activity (%) | 45.55 ± 0.64 | 40.25 ± 0.07 |

| Emulsion stability (%) | 85.50 ± 0.28 | 69.45 ± 0.35 |

| Foam capacity (%) | 40.30 ± 0.28 | 33.45 ± 0.07 |

| Foam stability (%) | 21.70 ± 0.14 | 18.80 ± 0.15 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wali, A.; Wubulikasimu, A.; Mirzaakhmedov, S.; Gao, Y.; Omar, A.; Arken, A.; Yili, A.; Aisa, H.A. Optimization of Scorpion Protein Extraction and Characterization of the Proteins’ Functional Properties. Molecules 2019, 24, 4103. https://doi.org/10.3390/molecules24224103

Wali A, Wubulikasimu A, Mirzaakhmedov S, Gao Y, Omar A, Arken A, Yili A, Aisa HA. Optimization of Scorpion Protein Extraction and Characterization of the Proteins’ Functional Properties. Molecules. 2019; 24(22):4103. https://doi.org/10.3390/molecules24224103

Chicago/Turabian StyleWali, Ahmidin, Atikan Wubulikasimu, Sharafitdin Mirzaakhmedov, Yanhua Gao, Adil Omar, Amina Arken, Abulimiti Yili, and Haji Akber Aisa. 2019. "Optimization of Scorpion Protein Extraction and Characterization of the Proteins’ Functional Properties" Molecules 24, no. 22: 4103. https://doi.org/10.3390/molecules24224103

APA StyleWali, A., Wubulikasimu, A., Mirzaakhmedov, S., Gao, Y., Omar, A., Arken, A., Yili, A., & Aisa, H. A. (2019). Optimization of Scorpion Protein Extraction and Characterization of the Proteins’ Functional Properties. Molecules, 24(22), 4103. https://doi.org/10.3390/molecules24224103