All-lignocellulosic Fiberboard from Steam Exploded Arundo Donax L.

Abstract

:1. Introduction

2. Results and Discussion

2.1. Chemical Composition of Arundo Donax Raw Material and Pulp

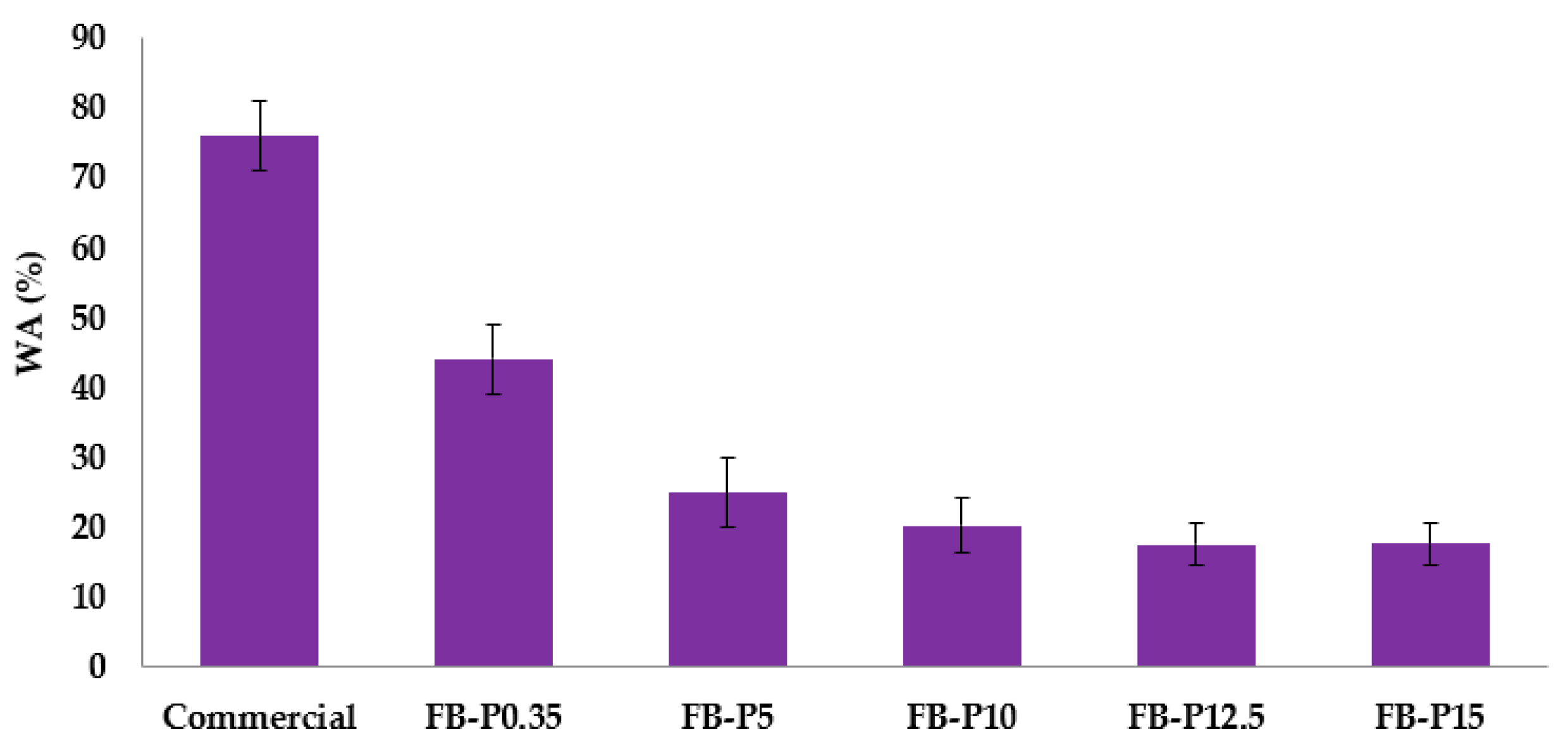

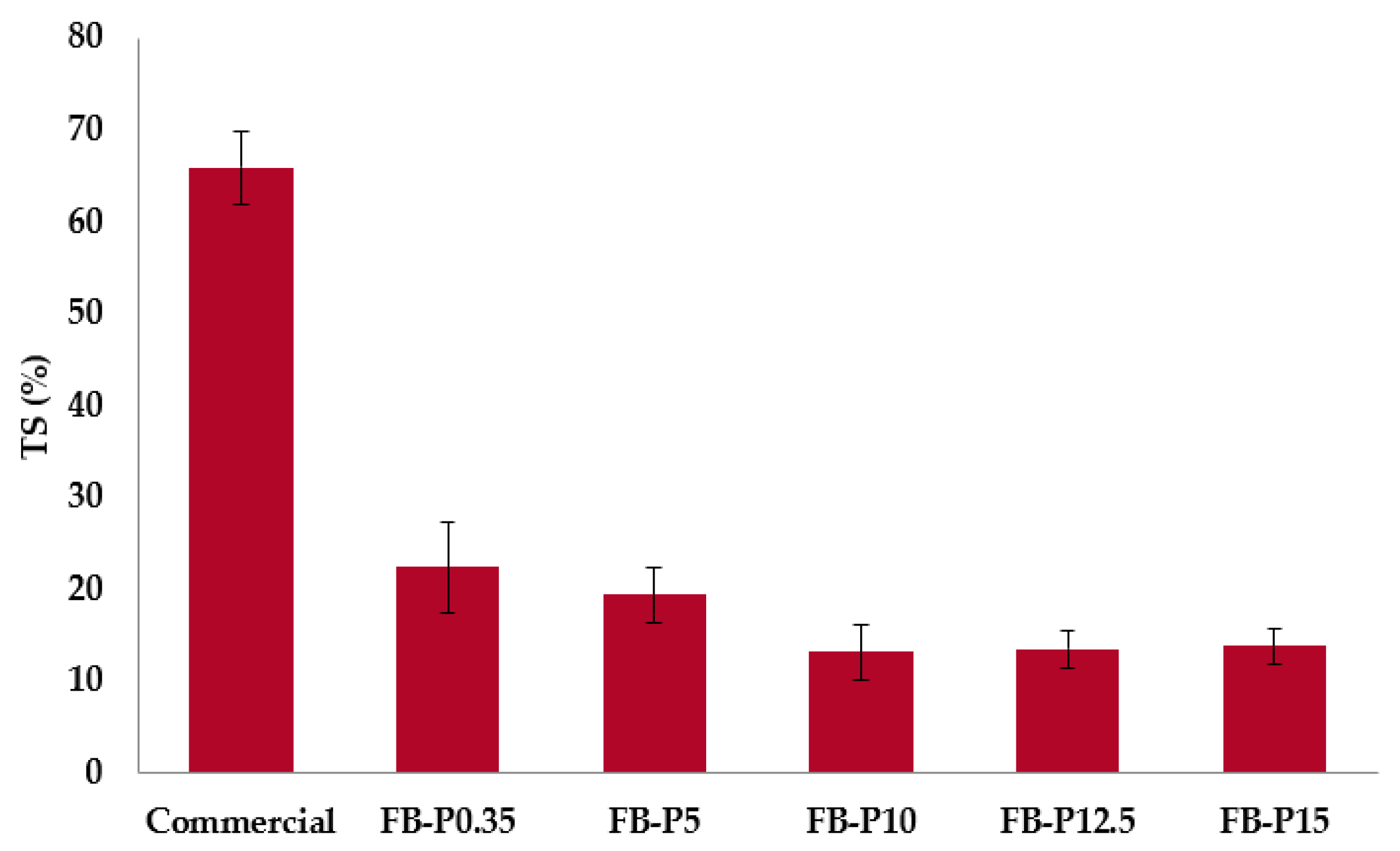

2.2. Effects on Physical Properties

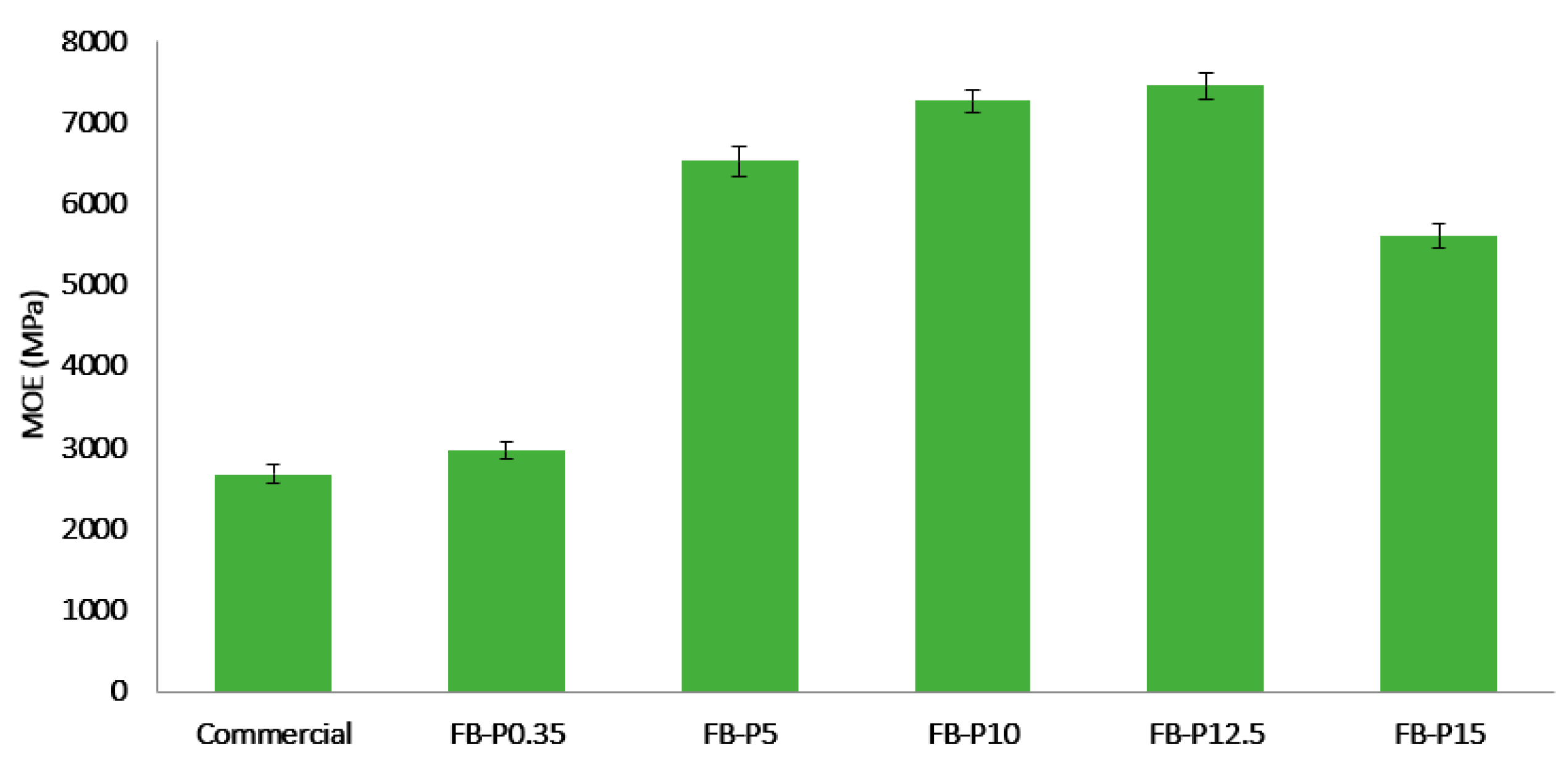

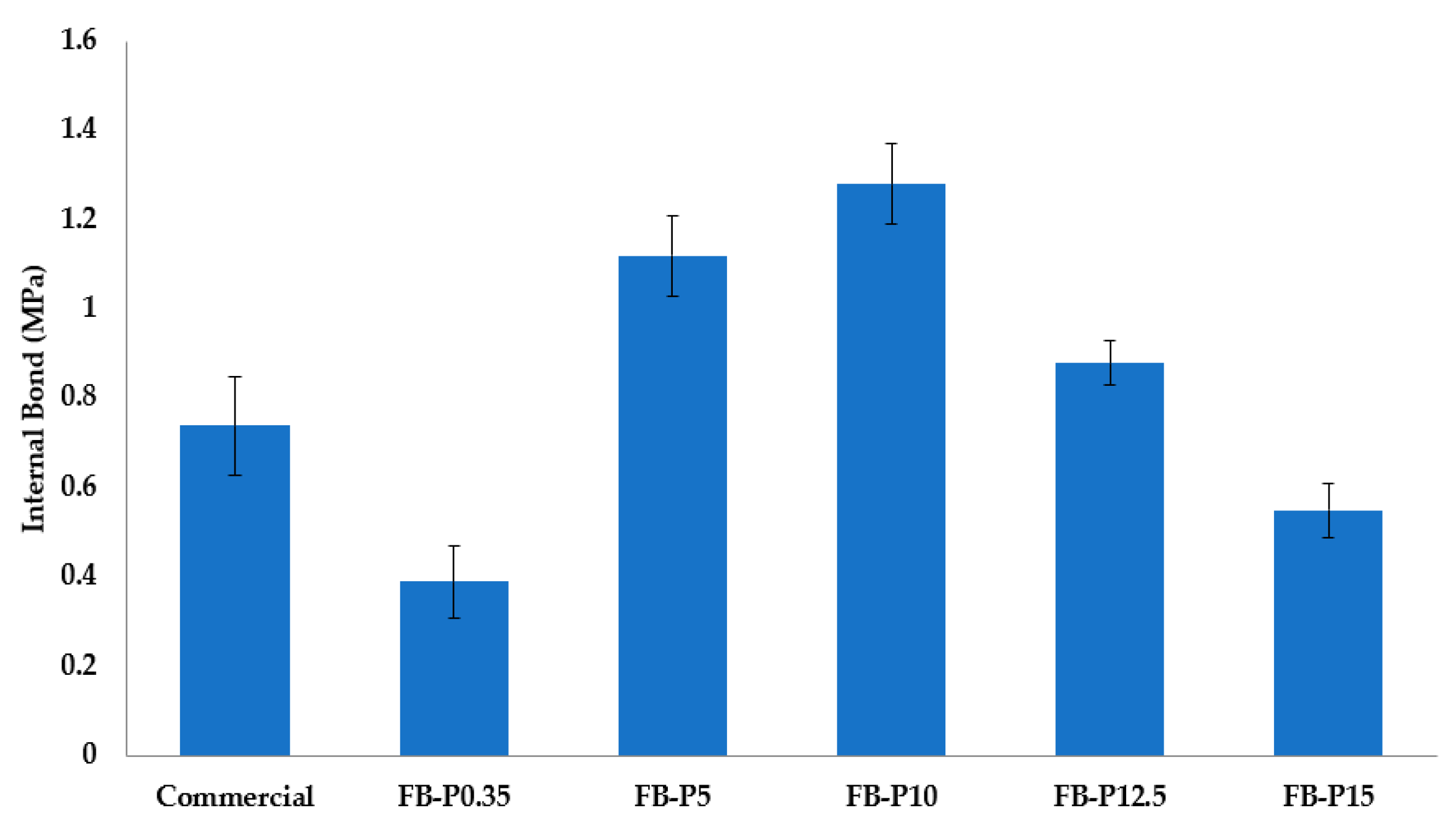

2.3. Effects on Mechanical Properties

3. Materials and Methods

3.1. Materials

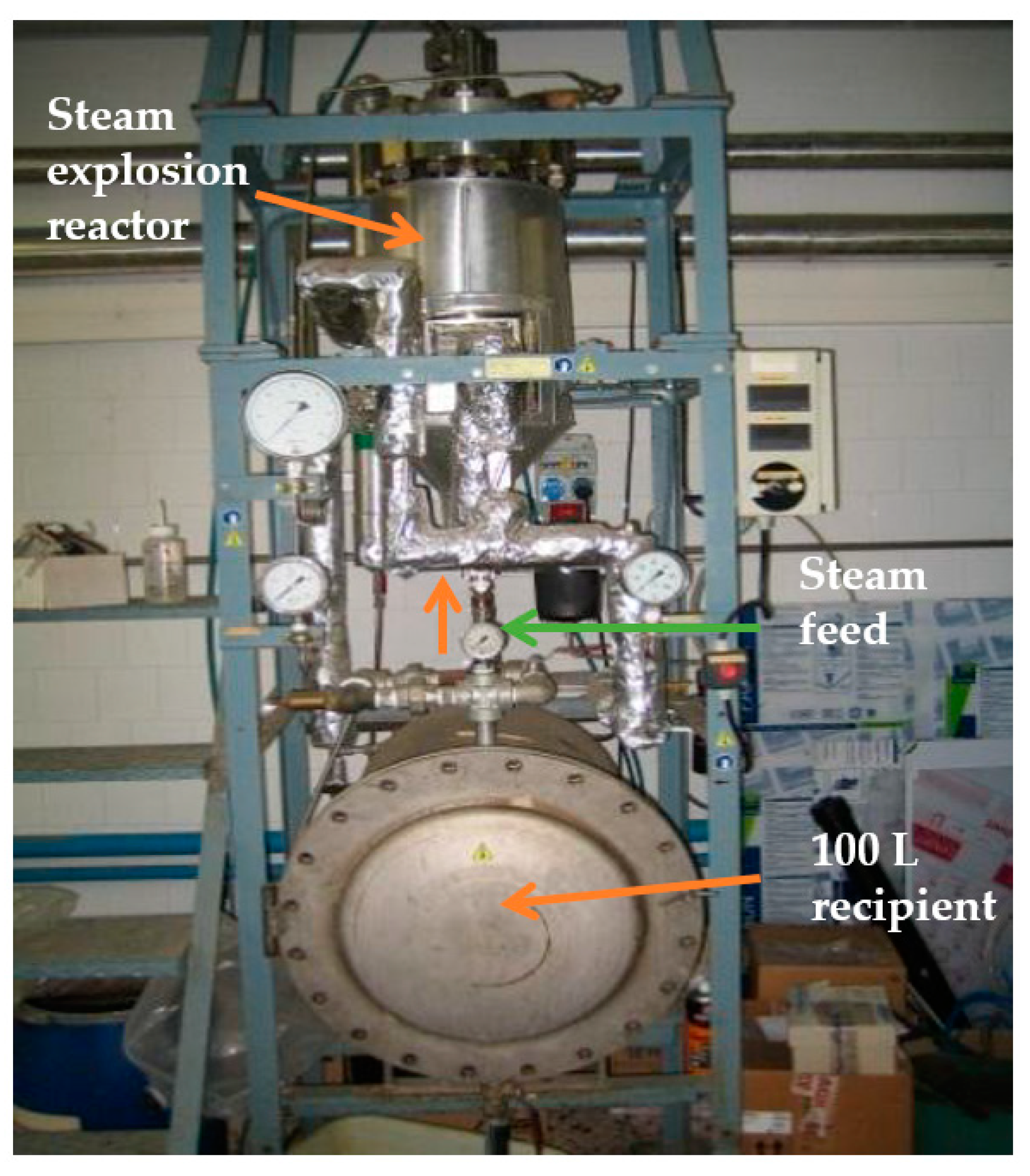

3.2. Steam Explosion and Grinding

3.3. Fiberboard Production

3.4. Chemical Characterization

3.5. Physical and Mechanical Characterization

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Shatalov, A.A.; Pereira, H. Xylose Production from Giant Reed (Arundo Donax L.): Modeling and Optimization of Dilute Acid Hydrolysis. Carbohydr. Polym. 2012, 87, 210–217. [Google Scholar] [CrossRef]

- Corno, L.; Pilu, R.; Adani, F. Arundo Donax L.: A Non-Food Crop for Bioenergy and Bio-Compound Production. Biotechnol. Adv. 2014, 32, 1535–1549. [Google Scholar] [CrossRef] [PubMed]

- Shatalov, A.A.; Pereira, H. Influence of Stem Morphology on Pulp and Paper Properties of Arundo Donax L. Reed. Ind. Crops Prod. 2002, 15, 77–83. [Google Scholar] [CrossRef]

- Monti, A.; Di Virgilio, N.; Venturi, G. Mineral Composition and Ash Content of Six Major Energy Crops. Biomass Bioenergy 2008, 32, 216–223. [Google Scholar] [CrossRef] [Green Version]

- E Silva, C.F.L.; Schirmer, M.A.; Maeda, R.N.; Barcelos, C.A.; Pereira, N. Potential of Giant Reed (Arundo Donax L.) for Second Generation Ethanol Production. Electron. J. Biotechnol. 2015, 18, 10–15. [Google Scholar] [CrossRef]

- Lemões, J.S.; e Silva, C.F.L.; Avila, S.P.F.; Montero, C.R.S.; e Silva, S.D.D.A.; Samios, D.; Peralba, M.D.C.R. Chemical Pretreatment of Arundo Donax L. for Second-Generation Ethanol Production. Electron. J. Biotechnol. 2018, 31, 67–74. [Google Scholar] [CrossRef]

- Caparros, S.; Ariza, J.; Lopez, F.; Diaz, M.J. Optimizing Cellulosic Paper Obtained from Arundo Donax L. under Hydrothermal Treatment. J. Ind. Eng. Chem. 2007, 13, 465–473. [Google Scholar]

- Ramos, D.; Salvadó, J.; Fernando, F. High Mechanical Performance Boards Made from Fibers of Arundo Donax without Added Adhesives. BioResources 2017, 12, 5383–5394. [Google Scholar] [CrossRef]

- Anglès, M.N.; Reguant, J.; Montané, D.; Ferrando, F.; Farriol, X.; Salvadó, J. Binderless Composites from Pretreated Residual Softwood. J. Appl. Polym. Sci. 1999, 73, 2485–2491. [Google Scholar] [CrossRef]

- Anglès, M.; Ferrando, F.; Farriol, X.; Salvadó, J. Suitability of Steam Exploded Residual Softwood for the Production of Binderless Panels. Effect of the Pre-Treatment Severity and Lignin Addition. Biomass Bioenergy 2001, 21, 211–224. [Google Scholar] [CrossRef]

- Velásquez, J.A.; Ferrando, F.; Salvadó, J. Binderless Fiberboard from Steam Exploded Miscanthus Sinensis: The Effect of a Grinding Process. Holz als Roh- und Werkstoff 2002, 60, 297–302. [Google Scholar] [CrossRef]

- Velásquez, J.A.; Ferrando, F.; Farriol, X.; Salvadó, J. Binderless Fiberboard from Steam Exploded Miscanthus Sinensis. Wood Sci. Technol. 2003, 37, 269–278. [Google Scholar] [CrossRef]

- Mancera, C.; El Mansouri, N.-E.; Ferrando, F.; Salvado, J. The suitability of steam exploded vitis vinifera and alkaline lignin for the manufacture of fiberboard. BioResources 2011, 6, 4439–4453. [Google Scholar]

- Shao, S.; Jin, Z.; Wen, G.; Iiyama, K. Thermo Characteristics of Steam-Exploded Bamboo (Phyllostachys Pubescens) Lignin. Wood Sci. Technol. 2009, 43, 643–652. [Google Scholar] [CrossRef]

- Serrano, L.; Egües, I.; Alriols, M.G.; Llano-Ponte, R.; Labidi, J. Miscanthus Sinensis Fractionation by Different Reagents. Chem. Eng. J. 2010, 156, 49–55. [Google Scholar] [CrossRef]

- Mancera, C.; El Mansouri, N.-E.; Pelach, M.A.; Francesc, F.; Salvadó, J. Feasibility of Incorporating Treated Lignins in Fiberboards Made from Agricultural Waste. Waste Manag. 2012, 32, 1962–1967. [Google Scholar] [CrossRef] [PubMed]

- Montané, D.; Farriol, X.; Salvadó, J.; Jollez, P.; Chornet, E. Fractionation of Wheat Straw by Steam-Explosion Pretreatment and Alkali Delignification. Cellulose Pulp and Byproducts from Hemicellulose and Lignin. J. Wood Chem. Technol. 1998, 18, 171–191. [Google Scholar] [CrossRef]

- Xu, J.; Widyorini, R.; Yamauchi, H.; Kawai, S. Development of Binderless Fiberboard from Kenaf Core. J. Wood Sci. 2006, 52, 236–243. [Google Scholar] [CrossRef]

- Mancera, C.; Ferrando, F.; Salvadó, J. Cynara Cardunculus as Raw Material for the Production of Binderless Fiberboards: Optimization of Pretreatment and Pressing Conditions. J. Wood Chem. Technol. 2008, 28, 207–226. [Google Scholar] [CrossRef]

- Jonoobi, M.; Harun, J.; Mathew, A.P.; Hussein, M.Z.B.; Oksman, K. Preparation of Cellulose Nanofibers with Hydrophobic Surface Characteristics. Cellulose 2010, 17, 299–307. [Google Scholar] [CrossRef] [Green Version]

- Ji, X.; Li, B.; Yuan, B.; Guo, M. Preparation and Characterizations of a Chitosan-Based Medium-Density Fiberboard Adhesive with High Bonding Strength and Water Resistance. Carbohydr. Polym. 2017, 176, 273–280. [Google Scholar] [CrossRef] [PubMed]

- Rozman, H.D.; Tan, K.W.; Kumar, R.N.; Abubakar, A.; Mohd Ishak, Z.A.; Ismail, H. The Effect of Lignin as a Compatibilizer on the Physical Properties of Coconut Fiber-Polypropylene Composites. Eur. Polym. J. 2000, 36, 1483–1494. [Google Scholar] [CrossRef]

- Domínguez-Robles, J.; Tarrés, Q.; Delgado-Aguilar, M.; Rodríguez, A.; Espinach, F.X.; Mutjé, P. Approaching a New Generation of Fiberboards Taking Advantage of Self Lignin as Green Adhesive. Int. J. Biol. Macromol. 2018, 108, 927–935. [Google Scholar] [CrossRef] [PubMed]

- Quintana, G.; Velásquez, J.; Betancourt, S.; Gañán, P. Binderless Fiberboard from Steam Exploded Banana Bunch. Ind. Crops Prod. 2009, 29, 60–66. [Google Scholar] [CrossRef]

- Teixeira, D.E.; Moslemi, A. Assessing Modulus of Elasticity of Wood-Fiber Cement (WFC) Sheets Using Nondestructive Evaluation (NDE). Bioresour. Technol. 2001, 79, 193–198. [Google Scholar] [CrossRef]

- Theng, D.; Arbat, G.; Delgado-Aguilar, M.; Vilaseca, F.; Ngo, B.; Mutjé, P. All-Lignocellulosic Fiberboard from Corn Biomass and Cellulose Nanofibers. Ind. Crops Prod. 2015, 76, 166–173. [Google Scholar] [CrossRef]

- Theng, D.; El Mansouri, N.-E.; Arbat, G.; Ngo, B.; Delgado-Aguilar, M.; Pèlach, M.À.; Fullana-i-Palmer, P.; Mutjé, P. Fiberboards Made from Corn Stalk Thermomechanical Pulp and Kraft Lignin as a Green Adhesive. BioResources 2017, 12, 2379–2393. [Google Scholar] [CrossRef]

- Arévalo, R.; Peijs, T. Binderless All-Cellulose Fibreboard from Microfibrillated Lignocellulosic Natural Fibres. Compos. Part A Appl. Sci. Manuf. 2016, 83, 38–46. [Google Scholar] [CrossRef]

- Halvarsson, S.; Edlund, H.; Norgren, M. Manufacture of Non-Resin Wheat Straw Fibreboards. Ind. Crops Prod. 2009, 29, 437–445. [Google Scholar] [CrossRef]

- Velásquez, J.; Ferrando, F.; Salvadó, J. Effects of Kraft Lignin Addition in the Production of Binderless Fiberboard from Steam Exploded Miscanthus Sinensis. Ind. Crops Prod. 2003, 18, 17–23. [Google Scholar] [CrossRef]

- Back, E.L. The Bonding Mechanism in Hardboard Manufacture Review Report. Holzforschung 2009, 41, 247–258. [Google Scholar] [CrossRef]

- Suzuki, S.; Shintani, H.; Park, S.-Y.; Saito, K.; Laemsak, N.; Okuma, M.; Iiyama, K. Preparation of Binderless Boards from Steam Exploded Pulps of Oil Palm (Elaeis Guneensis Jaxq.) Fronds and Structural Characteristics of Lignin and Wall Polysaccharides in Steam Exploded Pulps to Be Discussed for Self-Bindings. Holzforschung 2009, 52, 417–426. [Google Scholar] [CrossRef]

- Okuda, N.; Hori, K.; Sato, M. Chemical Changes of Kenaf Core Binderless Boards during Hot Pressing (I): Influence of the Pressing Temperature Condition. J. Wood Sci. 2006, 52, 244–248. [Google Scholar] [CrossRef]

- Okuda, N.; Hori, K.; Sato, M. Chemical Changes of Kenaf Core Binderless Boards during Hot Pressing (II): Effects on the Binderless Board Properties. J. Wood Sci. 2006, 52, 249–254. [Google Scholar] [CrossRef]

- Zhou, X.; Tang, L.; Zhang, W.; Lv, C.; Zheng, F.; Zhang, R.; Du, G.; Tang, B.; Liu, X. Enzymatic hydrolysis lignin derived from corn stover as an intrinstic binder for bio-composites manufacture: Effect of fiber moisture content and pressing temperature on boards’ properties. BioResources 2010, 6, 253–264. [Google Scholar]

- Zhang, D.; Zhang, A.; Xue, L. A Review of Preparation of Binderless Fiberboards and Its Self-Bonding Mechanism. Wood Science and Technology 2015, 49, 661–679. [Google Scholar] [CrossRef]

- El Mansouri, N.-E.; Salvadó, J. Structural Characterization of Technical Lignins for the Production of Adhesives: Application to Lignosulfonate, Kraft, Soda-Anthraquinone, Organosolv and Ethanol Process Lignins. Ind. Crops Prod. 2006, 24, 8–16. [Google Scholar] [CrossRef]

- Yuan, J.-P.; Chen, F. Simultaneous Separation and Determination of Sugars, Ascorbic Acid and Furanic Compounds by HPLC–dual Detection. Food Chem. 1999, 64, 423–427. [Google Scholar] [CrossRef]

- Kaar, W.E.; Brink, D.L. Simplified Analysis of Acid Soluble Lignin. J. Wood Chem. Technol. 1991, 11, 465–477. [Google Scholar] [CrossRef]

Sample Availability: Samples of the compounds are available from the authors. |

| Raw Materials | Ash-C (%) | Extract (%) | Lignin (%) | Cellulose (%) | HMC (%) | H-Cell (%) |

|---|---|---|---|---|---|---|

| Arundo donax | 3.8 ± 0.5 | 9.3 ± 0.3 | 22.4 ± 0.2 | 43.1 ± 0.5 | 21.9 ± 0.2 | 65 ± 0.5 |

| Arundo donax pulp | 1.2 ± 0.2 | 5.9 ± 0.5 | 29 ± 0.9 | 55.4 ± 0.9 | 5.2 ± 0.8 | - |

| Arundo biomass [2,6] | 4.2–6.1 | 11.2–21.6 | 19.2–24.3 | 29.2–39.1 | 14.5–32.0 | - |

| Miscanthus sinensis [12] | 0.7 | 4.7 | 19.9 | 42.6 | 21.1 | - |

| Vitis vinifera [16] | 3.70 | 13.30 | 24 | 43.60 | 19.10 | 62.70 |

| Pine pinaster [15] | 0.54 | -- | 26.20 | 55.90 | 13.70 | 69.60 |

| Eucalyptus globulus [15] | 0.57 | -- | 20.00 | 52.80 | 27.70 | 80.50 |

| Samples | d (kg/m3) | WA (%) | TS (%) | MOR (MPa) | MOE (MPa) | IB (MPa) |

|---|---|---|---|---|---|---|

| Commercial [27] | 893 ± 19 | 76.0 ± 5.0 | 66.0 ± 4.0 | 41.7 ± 1.6 | 2670 ± 110 | 0.74 ± 0.11 |

| FB-P0.35 | 1042 ± 38 | 44.1 ± 5.0 | 22.5 ± 5.0 | 13.9 ± 0.7 | 2955 ± 100 | 0.39 ± 0.08 |

| FB-P5 | 1138 ± 24 | 25.0 ± 5.0 | 19.5 ± 5.0 | 38.5 ± 0.4 | 6516 ± 190 | 1.12 ± 0.09 |

| FB-P10 | 1202 ± 14 | 20.3 ± 4.0 | 13.3 ± 3.0 | 40.5 ± 0.4 | 7256 ± 140 | 1.28 ± 0.09 |

| FB-P12.5 | 1222 ± 12 | 17.6 ± 2.0 | 13.6 ± 2.0 | 40.4 ± 0.3 | 7439 ± 160 | 0.88 ± 0.05 |

| FB-P15 | 1231 ± 18 | 17.7 ± 2.0 | 13.9 ± 2.0 | 23.1 ± 0.8 | 5598 ± 150 | 0.55 ± 0.06 |

| Samples | Specific-MOR (MPa·m3/kg) | Specific-MOE (MPa·m3/kg) | Specific-IB (MPa·m3/kg) |

|---|---|---|---|

| Commercial | 4.67 × 10−2 | 2.99 | 5.26 × 10−4 |

| FB-P0.35 | 1.33 × 10−2 | 2.84 | 3.74 × 10−4 |

| FB-P5 | 3.21 × 10−2 | 5.73 | 9.84 × 10−4 |

| FB-P10 | 3.37 × 10−2 | 6.04 | 10.65 × 10−4 |

| FB-P12.5 | 3.31 × 10−2 | 6.09 | 7.20 × 10−4 |

| FB-P15 | 1.88 × 10−2 | 4.55 | 4.47 × 10−4 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramos, D.; El Mansouri, N.-E.; Ferrando, F.; Salvadó, J. All-lignocellulosic Fiberboard from Steam Exploded Arundo Donax L. Molecules 2018, 23, 2088. https://doi.org/10.3390/molecules23092088

Ramos D, El Mansouri N-E, Ferrando F, Salvadó J. All-lignocellulosic Fiberboard from Steam Exploded Arundo Donax L. Molecules. 2018; 23(9):2088. https://doi.org/10.3390/molecules23092088

Chicago/Turabian StyleRamos, Diego, Nour-Eddine El Mansouri, Francesc Ferrando, and Joan Salvadó. 2018. "All-lignocellulosic Fiberboard from Steam Exploded Arundo Donax L." Molecules 23, no. 9: 2088. https://doi.org/10.3390/molecules23092088