Fabrication of High Gas Barrier Epoxy Nanocomposites: An Approach Based on Layered Silicate Functionalized by a Compatible and Reactive Modifier of Epoxy-Diamine Adduct

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

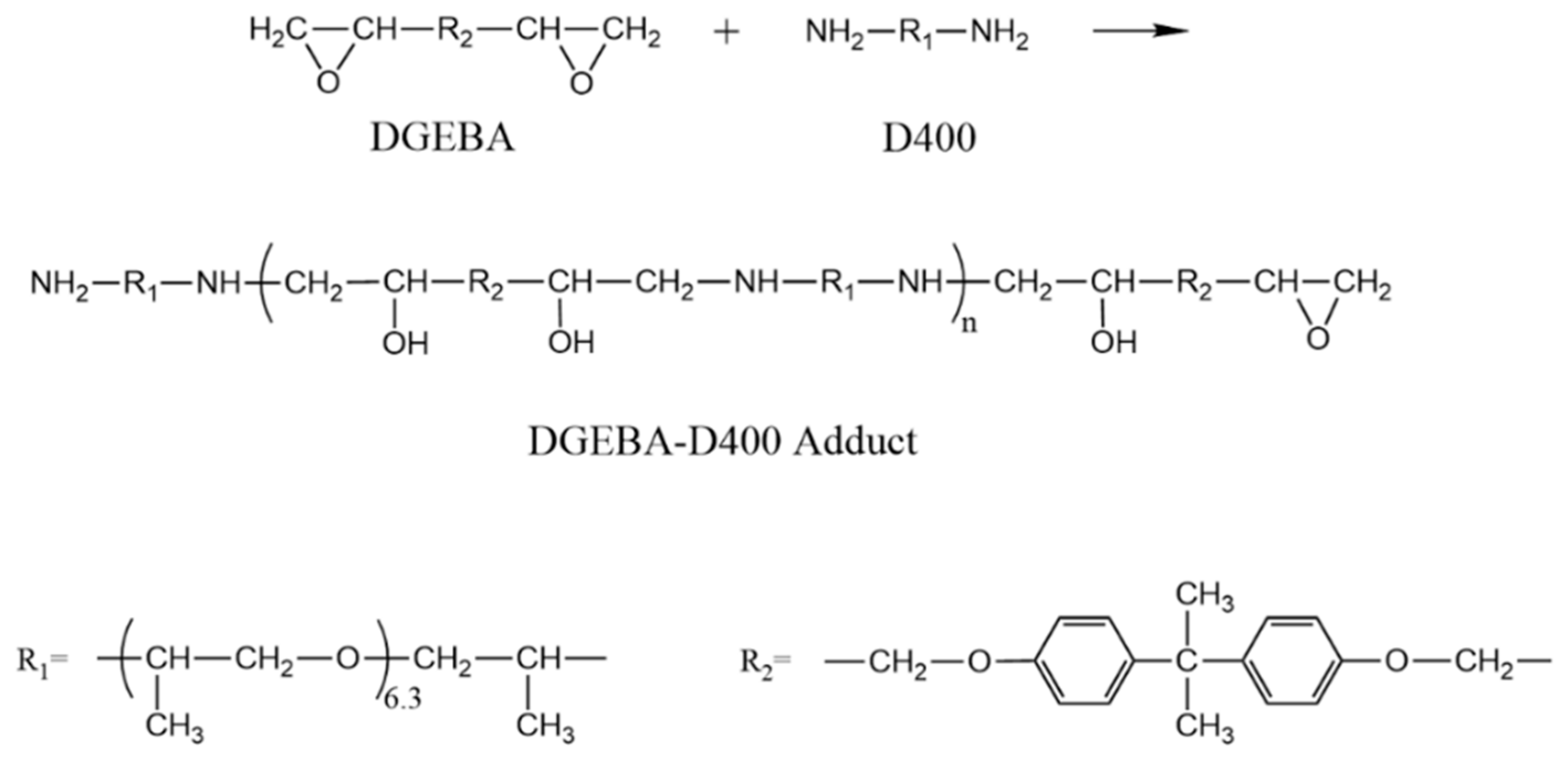

2.2.1. Synthesis of DGEBA-D400 Adduct (DDA)

2.2.2. Functionalization of MMT

2.2.3. Manufacture of MMT/DGEBA Nanocomposite

2.3. Characterization of Materials

2.3.1. Characterization

2.3.2. Gas Permeability Test

3. Results and Discussion

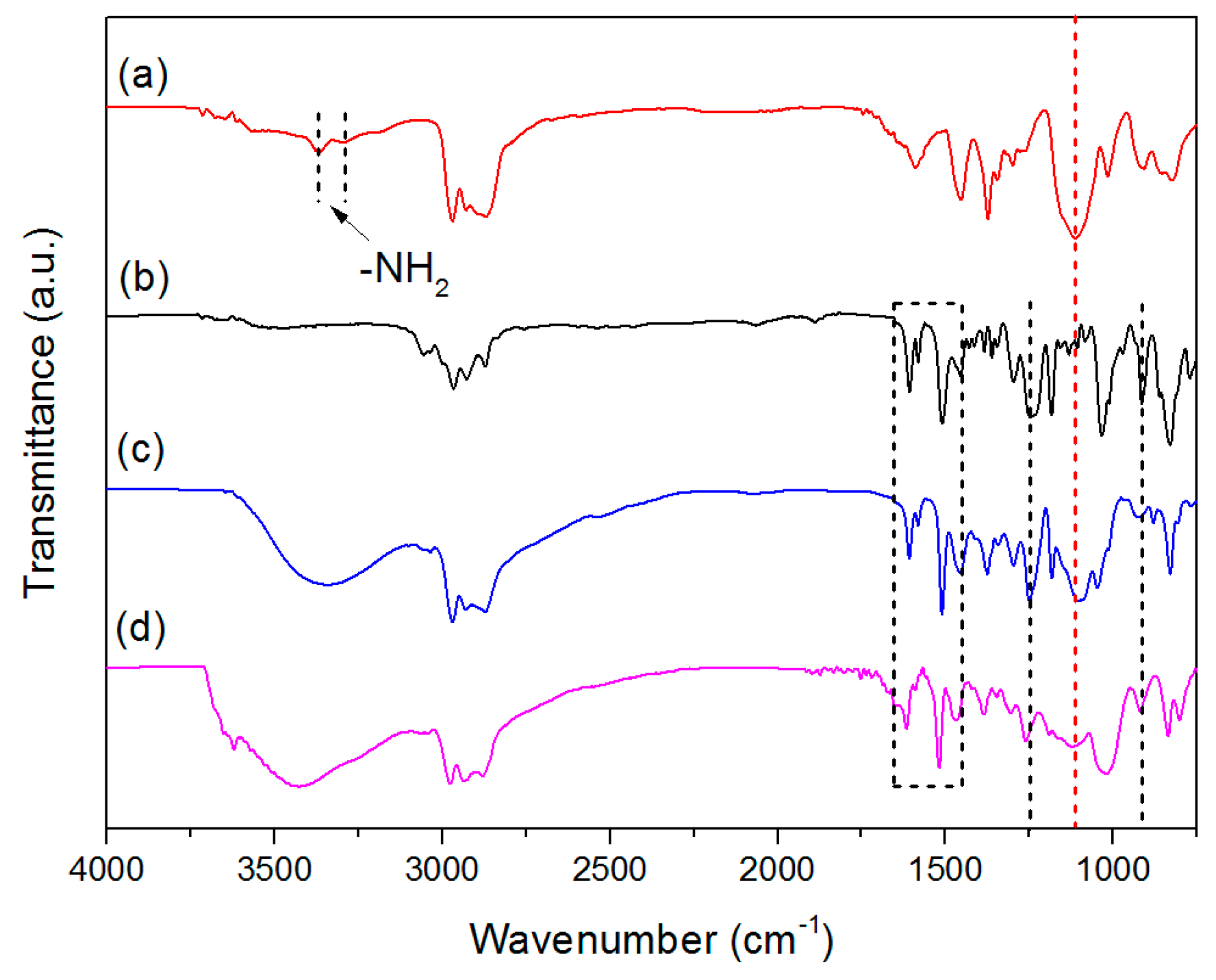

3.1. Characterization of DGEBA-D400 Adduct (DDA) and DDA-MMT

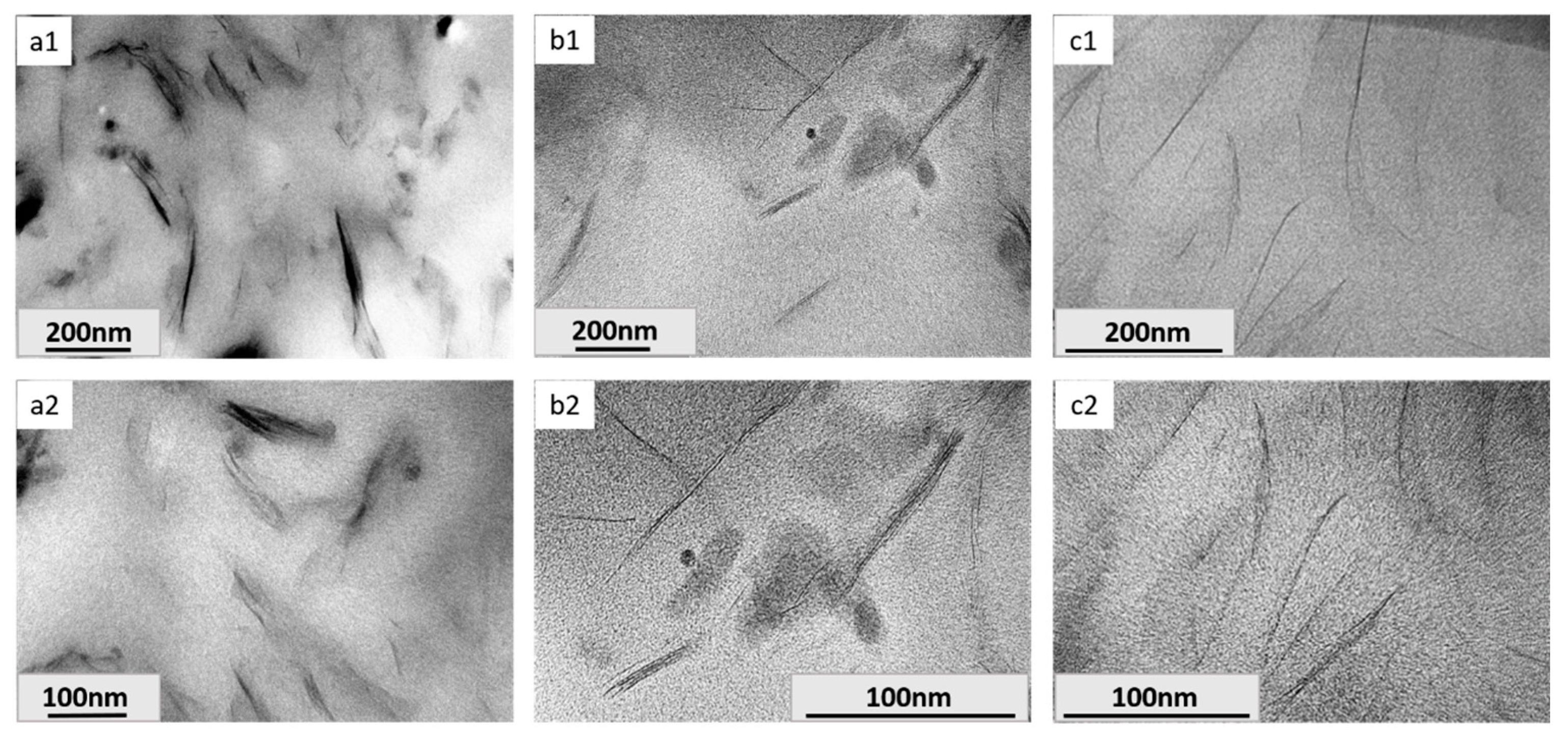

3.2. Microstructure of MMTs in Suspension

3.3. Morphology of Nanocomposites

3.4. Thermal Properties of Nanocomposites

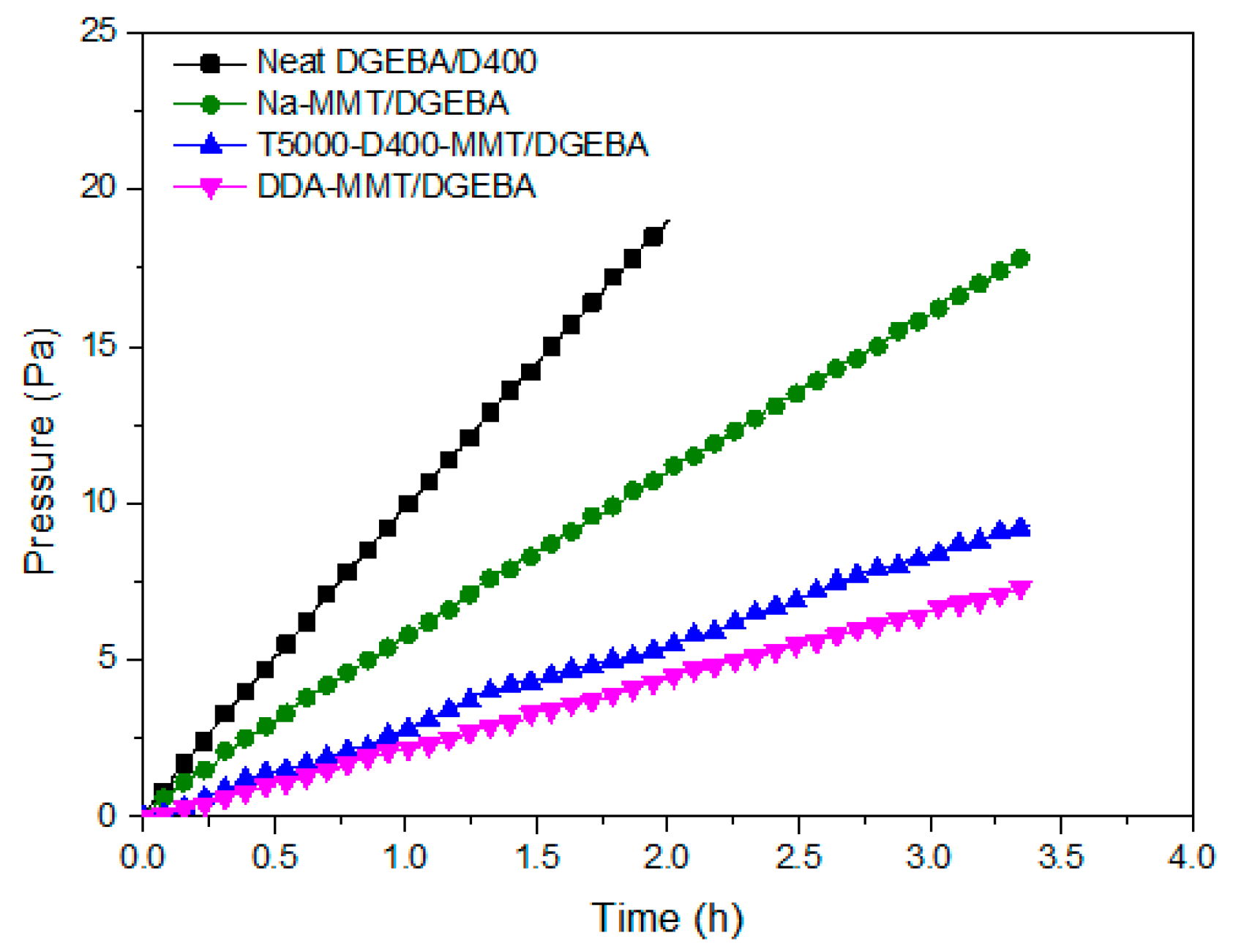

3.5. Gas Permeability of Nanocomposites

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Ayman, M.A.; Ashraf, M.E.; Hamad, A.A.; Mohamed, W. Effect of montmorillonite nanogel composite fillers on the protection performance of epoxy coatings on steel pipelines. Molecules 2017, 22, 905. [Google Scholar]

- Jin, F.L.; Li, X.; Park, S.J. Synthesis and application of epoxy resins: A review. J. Ind. Eng. Chem. 2018, 29, 1–11. [Google Scholar] [CrossRef]

- Patil, P.N.; Roilo, D.; Brusa, R.S.; Miotello, A.; Aghion, S.; Ferragut, R.; Checchetto, R. Free volumes and gas transport in polymers: amine-modified epoxy resins as a case study. Phys. Chem. Chem. Phys. 2016, 18, 3817–3824. [Google Scholar] [CrossRef] [PubMed]

- Jiao, W.; Shioy, M.; Wang, R.; Yang, F.; Hao, L.; Niu, Y.; Liu, W.; Zheng, L.; Yuan, F.; Wan, L.; et al. Improving the gas barrier properties of Fe3O4/graphite nanoplatelet reinforced nanocomposites by a low magnetic field induced alignment. Compos. Sci. Technol. 2014, 99, 124–130. [Google Scholar] [CrossRef]

- Zhang, G.; Lee, P.C.; Jenkins, S.; Dooley, J.; Baer, E. The effect of confined spherulite morphology of high-density polyethylene and polypropylene on their gas barrier properties in multilayered film systems. Polymer 2014, 55, 4521–4530. [Google Scholar] [CrossRef]

- Wei, R.; Wang, X.Q.; Chen, C.; Zhang, X.; Xu, X.H.; Du, S.Y. Effect of surface treatment on the interfacial adhesion performance of aluminum foil/CFRP laminates for cryogenic propellant tanks. Mater. Des. 2017, 116, 188–198. [Google Scholar] [CrossRef]

- Ding, F.C.; Liu, J.J.; Zeng, S.S.; Xia, Y.; Wells, K.M.; Nieh, M.P.; Sun, L.Y. Biomimetic nanocoatings with exceptional mechanical, barrier, and flame-retardant properties from large-scale one-step coassembly. Sci. Adv. 2017, 3, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Azeez, A.A.; Rhee, K.Y.; Park, S.J.; Hui, D. Epoxy clay nanocomposites-processing, properties and applications: A review. Compos. Part B 2013, 45, 308–320. [Google Scholar] [CrossRef]

- Kuilla, T.; Bhadra, S.; Yao, D.; Kim, N.H.; Bose, S.; Lee, J.H. Recent advances in graphene based polymer composites. Prog. Polym. Sci. 2010, 35, 1350–1375. [Google Scholar] [CrossRef]

- Bitinis, N.; Hernandez, M.; Verdejo, R.; Kenny, J.M.; Lopez-Manchado, M.A. Recent advances in clay/polymer nanocomposites. Adv. Mater. 2011, 23, 5229–5236. [Google Scholar] [CrossRef] [PubMed]

- Jia, X.L.; Zheng, J.Y.; Lin, S.; Li, W.B.; Cai, Q.; Sui, G.; Yang, X.P. Highly moisture-resistant epoxy composites: An approach based on liquid nano-reinforcement containing well-dispersed activated montmorillonite. RSC Adv. 2015, 5, 44853–44864. [Google Scholar] [CrossRef]

- Roilo, D.; Patil, P.N.; Brusa, R.S.; Miotello, A.; Aghion, S.; Ferragut, R.; Checchetto, R. Polymer rigidification in graphene based nanocomposites: Gas barrier effects and free volume reduction. Polymer 2017, 121, 17–25. [Google Scholar] [CrossRef]

- Cui, Y.B.; Kundalwal, S.I.; Kumar, S. Gas barrier performance of graphene/polymer nanocomposites. Carbon 2016, 98, 313–333. [Google Scholar] [CrossRef]

- Keledi, G.; Hári, J.; Pukánszky, B. Polymer nanocomposites: Structure, interaction, and functionality. Nanoscale 2012, 4, 1919–1938. [Google Scholar] [CrossRef] [PubMed]

- Carter, L.W.; Hendricks, J.G.; Bolley, D.S. Elastomer Reinforced with a Modified Clay. U.S. Patent 2531396, 28 November 1950. [Google Scholar]

- Lagaly, G. Interaction of alkylamines with different types of layered compounds. Solid State Ionics 1986, 22, 43–51. [Google Scholar] [CrossRef]

- Kwolek, T.; Hodorowicz, M.; Standnick, K.; Czapkiewicz, J. Immunoglobulin free light chains reduce in an antigen-specific manner the rate of rise of action potentials of mouse non-nociceptive dorsal root ganglion neurons. J. Colloid Interface Sci. 2003, 264, 14–23. [Google Scholar] [CrossRef]

- Huskić, M.; Brnardić, I.; Žigon, M.; Ivanković, M. Modification of montmorillonite by quaternary polyesters. J. Non-Cryst. Solids 2008, 354, 3326–3331. [Google Scholar] [CrossRef]

- Lin, J.J.; Cheng, I.J.; Wang, R.; Lee, R.J. Tailoring basal spacings of montmorillonite by poly(oxyalkylene)diamine intercalation. Macromolecules 2001, 34, 8832–8834. [Google Scholar] [CrossRef]

- Lin, J.J.; Chen, Y.M.; Yu, M.H. Hydrogen-bond driven intercalation of synthetic fluorinated mica by poly(oxypropylene)-amidoamine salts. Colloids Surf. A 2007, 302, 162–167. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Wang, X.Q.; Duan, Y.F.; Liu, Y.Z.; Du, S.Y. Modification of montmorillonite with poly(oxyproylene) amine hydrochlorides: Basal spacing, amount intercalated, and thermal stability. Clays Clay Miner. 2011, 59, 507–517. [Google Scholar] [CrossRef]

- Wang, J.F.; Cheng, Q.F.; Lin, L.; Chen, L.F.; Jiang, L. Understanding the relationship of performance with nanofiller content in the biomimetic layered nanocomposites. Nanoscale 2013, 5, 6356–6362. [Google Scholar] [CrossRef] [PubMed]

- Domun, N.; Hadavinia, H.; Zhang, T.; Sainsbury, T.; Liaghat, G.H.; Vahid, S. Improving the fracture toughness and the strength of epoxy using nanomaterials - a review of the current status. Nanoscale 2015, 7, 10294–10329. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.; Jin, J.; Song, M. Preparation and characterisation of covalent polymer functionalized graphene oxide. J. Mater. Chem. 2011, 21, 3455–3461. [Google Scholar] [CrossRef]

- Cano, M.; Khan, U.; Sainsbury, T.; O’Neill, A.; Wang, Z.; McGovern, I.; Maser, W.K.; Benito, A.M.; Coleman, J.N. Improving the mechanical properties of graphene oxide based materials by covalent attachment of polymer chains. Carbon 2013, 52, 363–371. [Google Scholar] [CrossRef]

- Wan, Y.J.; Tang, L.C.; Gong, L.X.; Yan, D.; Li, Y.B.; Wu, L.B.; Jiang, J.X.; Lai, G.Q. Grafting of epoxy chains onto graphene oxide for epoxy composites with improved mechanical and thermal properties. Carbon 2014, 69, 467–480. [Google Scholar] [CrossRef]

- Gârea, S.A.; Iovu, H.; Voicu, G. The influence of some new montmorillonite modifier agents on the epoxy-montmorillonite nanocomposites structure. Appl. Clay Sci. 2010, 50, 469–475. [Google Scholar] [CrossRef]

- Gârea, S.A.; Iovu, H.; Bulearca, A. New organophilic agents of montmorillonite used as reinforcing agent in epoxy nanocomposites. Polym. Test. 2008, 27, 100–113. [Google Scholar] [CrossRef]

- Blanchet, C.E.; Svergun, D.I. Small-angle X-ray scattering on biological macromolecules and nanocomposites in solution. Annu. Rev. Phys. Chem. 2013, 64, 37–54. [Google Scholar] [CrossRef] [PubMed]

- Hermes, H.E.; Frielinghuas, H.; Pyckhout-Hintzen, W.; Richter, D. Quantitative analysis of small angle neutron scattering data from montmorillonite dispersions. Polymer 2006, 47, 2147–2155. [Google Scholar] [CrossRef]

- Cooper, C.L.; Cosgrove, T.; Duijneveldt, J.S.V.; Murray, M.; Prescott, S.W. Competition between polymers for adsorption on silica: A solvent relaxation NMR and small-angle neutron scattering study. Langmuir 2013, 29, 12670–12678. [Google Scholar] [CrossRef] [PubMed]

- Yoonessi, M.; Gaier, G.R. Highly conductive multifunctional graphene polycarbonate nanocomposites. ACS Nano 2010, 4, 7211–7220. [Google Scholar] [CrossRef] [PubMed]

- Genix, A.C.; Oberdisse, J. Structure and dynamics of polymer nanocomposites studied by X-ray and neutron scattering techniques. Curr. Opin. Colloid Interface Sci. 2015, 20, 293–303. [Google Scholar] [CrossRef]

- Liu, Y.Z.; Wang, X.Q.; Chen, Y.C.; Du, S.Y. Co-intercalation of montmorillonite by poly(oxypropylene) amine hydrochlorides with different chain length. Acta Chim. Sin. 2012, 79, 911–916. [Google Scholar] [CrossRef]

- Hanley, H.J.M.; Muzny, C.D.; Ho, D.L.; Glinka, C.J.; Manias, E. A SANS study of organoclay dispersions. Int. J. Thermophys. 2001, 22, 1435–1448. [Google Scholar] [CrossRef]

- Ho, D.L.; Briber, R.M.; Glinka, C.J. Characterization of organically modified clays using scattering and microscopy techniques. Chem. Mater. 2001, 13, 1923–1931. [Google Scholar] [CrossRef]

- Nielsen, L. Models for the permeability of filled polymer systems. J. Macromol. Sci. Chem. 1967, 1, 929–942. [Google Scholar] [CrossRef]

- Bartczak, Z.; Rozanski, A.; Richert, J. Characterization of clay platelet orientation in polylactide–montmorillonite nanocomposite films by X-ray pole figures. Eur. Polym. J. 2014, 61, 274–284. [Google Scholar] [CrossRef]

- Stribeck, N. X-ray Scattering of Soft Matter; Springer: Berlin/Heidelberg, Germany, 2007; pp. 193–197. [Google Scholar]

Sample Availability: Samples of the PMSQ aerogels and the modified samples are available from the authors. |

| Sample | Modified MMT | Intercalating Sequence | Mixing Method | |

|---|---|---|---|---|

| First Modifier | Second Modifier | |||

| DGEBA/D400 | —— | —— | —— | Mechanical agitating for 30 h |

| Composite 1 | Na-MMT | —— | —— | Mechanical agitating for 30 h and ball-milling for 60 h |

| Composite 2 | T5000-D400-MMT | D400 | T5000 | |

| Composite 3 | DDA-MMT | DGEBA-D400 Adduct | —— | |

| Peak | Mn (g/mol) | Mw (g/mol) | Mw/Mn | Peak Area (%) |

|---|---|---|---|---|

| 1 | 1460 | 2022 | 1.4 | 65 |

| 2 | 368 | 407 | 1.1 | 35 |

| Sample | Radius (Å) | Platelet Thickness (Å) | Layer Thickness (Å) | No. of Platelets per Tactoid |

|---|---|---|---|---|

| Na-MMT/D2O | 925 ± 22 | 8.3 ± 0.1 | 6.3 ± 0.2 2 | 10 ± 1 |

| DDA-MMT/Ethanol | 696 ± 20 | 8.3 ± 0.1 3 | 30.1 ± 0.3 | 3 ± 2 |

| Sample | Radius (Å) | Platelet Thickness (Å) | Layer Thickness (Å) | No. of Platelets per Tactoid |

|---|---|---|---|---|

| T5000-D400-MMT/DGEBA nanocomposite | 751 ± 11 | 8.3 ± 0.1 2 | 19.1 ± 0.1 | 5 ± 1 |

| DDA-MMT/DGEBA nanocomposite | 616 ± 8 | 8.3 ± 0.1 2 | 30.8 ± 0.2 | 2 ± 1 |

| Sample | Tonset (°C) | T0.1 (°C) | T0.5 (°C) | T0.7 (°C) | Tmax (°C) |

|---|---|---|---|---|---|

| DGEBA/D400 | 308 | 343 | 366 | 379 | 360 |

| T5000-D400-MMT/DGEBA | 327 | 355 | 382 | 395 | 377 |

| DDA-MMT/DGEBA | 321 | 349 | 383 | 397 | 381 |

| Samples | DGEBA/D400 | Na-MMT/DGEBA | T5000-D400-MMT/DGEBA | DDA-MMT/DGEBA |

|---|---|---|---|---|

| N2 transmission rate (, ×10−5 ) | 4.4 ± 0.7 | 4.3 ± 0.3 | 1.7 ± 0.5 | 1.1 ± 0.3 |

| N2 transmission coefficient (, ×10−15 ) | 5.9 ± 0.8 | 5.3 ± 0.3 | 2.1 ± 0.6 | 1.2 ± 0.4 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, R.; Wang, X.; Zhang, X.; Chen, C.; Du, S. Fabrication of High Gas Barrier Epoxy Nanocomposites: An Approach Based on Layered Silicate Functionalized by a Compatible and Reactive Modifier of Epoxy-Diamine Adduct. Molecules 2018, 23, 1075. https://doi.org/10.3390/molecules23051075

Wei R, Wang X, Zhang X, Chen C, Du S. Fabrication of High Gas Barrier Epoxy Nanocomposites: An Approach Based on Layered Silicate Functionalized by a Compatible and Reactive Modifier of Epoxy-Diamine Adduct. Molecules. 2018; 23(5):1075. https://doi.org/10.3390/molecules23051075

Chicago/Turabian StyleWei, Ran, Xiaoqun Wang, Xu Zhang, Chen Chen, and Shanyi Du. 2018. "Fabrication of High Gas Barrier Epoxy Nanocomposites: An Approach Based on Layered Silicate Functionalized by a Compatible and Reactive Modifier of Epoxy-Diamine Adduct" Molecules 23, no. 5: 1075. https://doi.org/10.3390/molecules23051075