A Solvent-Free Surface Suspension Melt Technique for Making Biodegradable PCL Membrane Scaffolds for Tissue Engineering Applications

Abstract

:1. Introduction

2. Results and Discussion

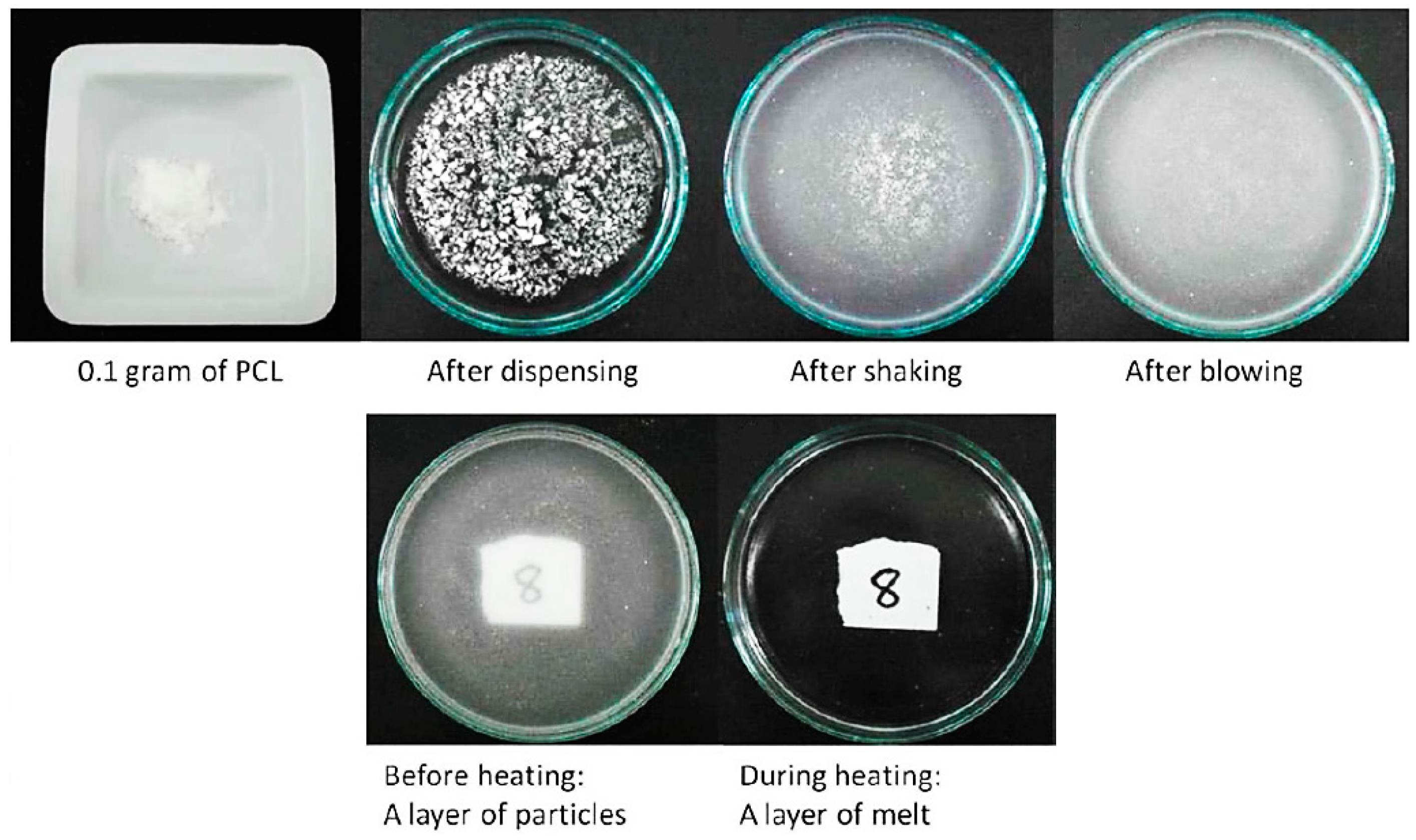

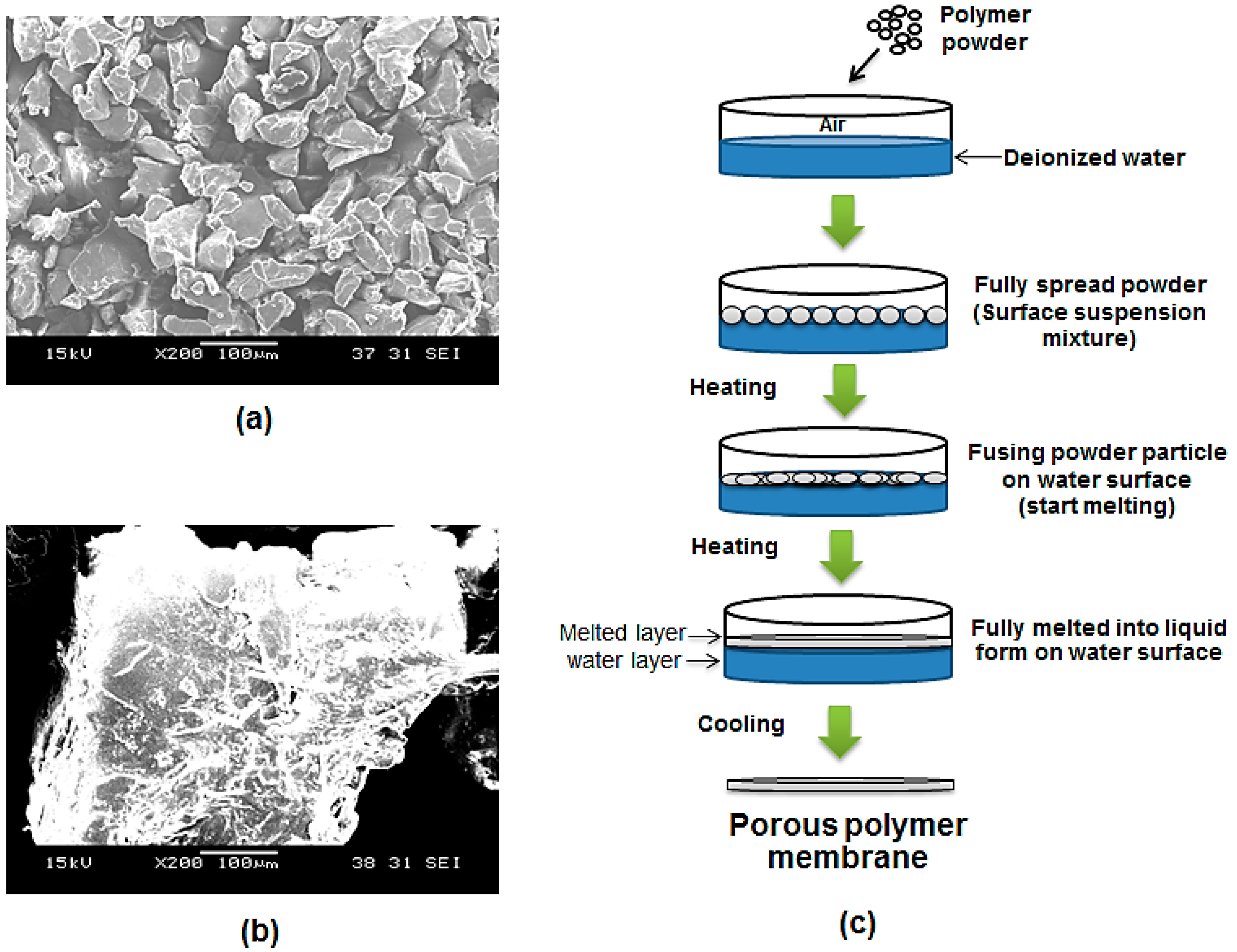

2.1. Formation of a Layer of PCL Particles

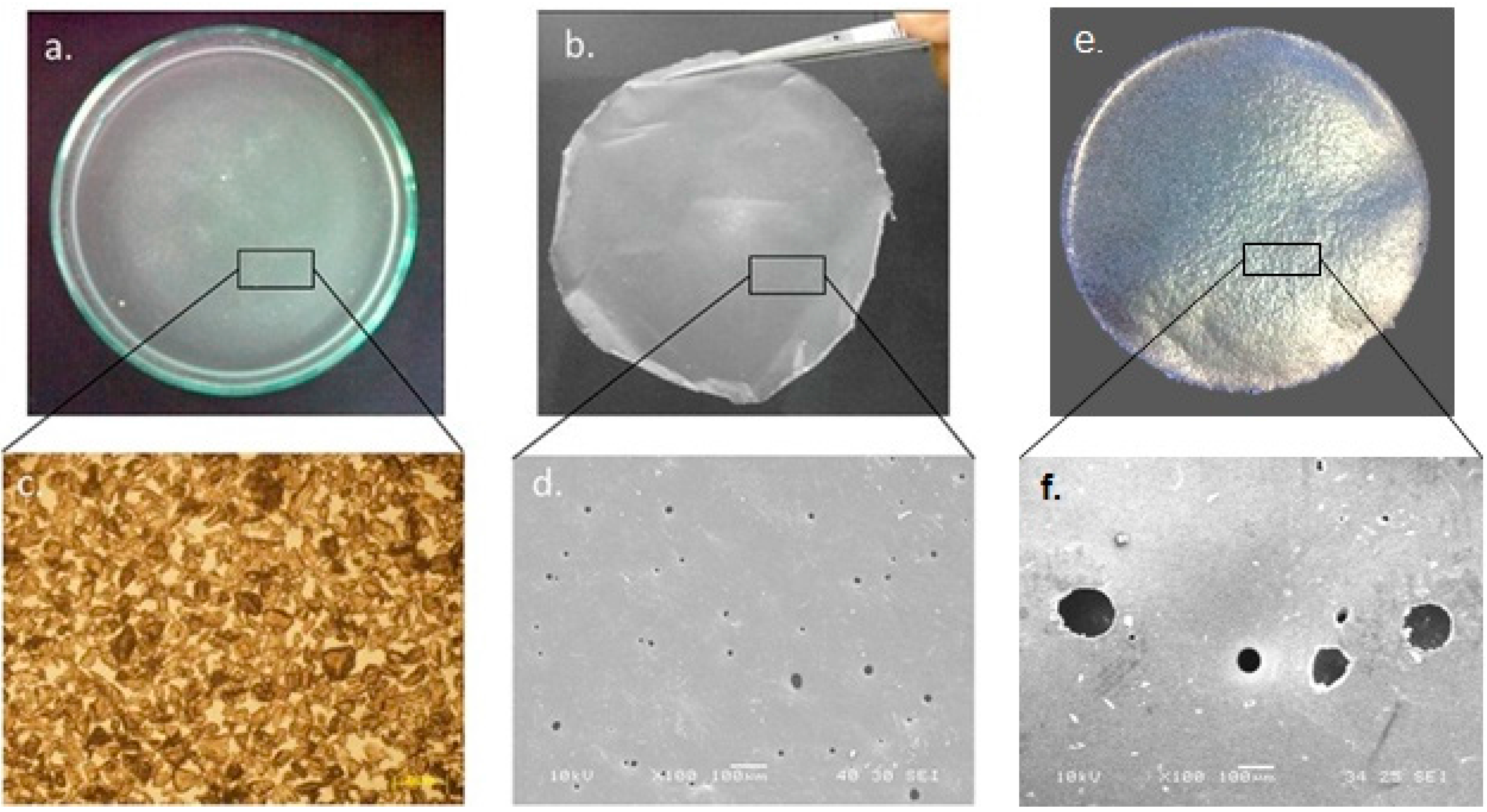

2.2. Fabrication of a Membrane from a Layer of PCL Particles

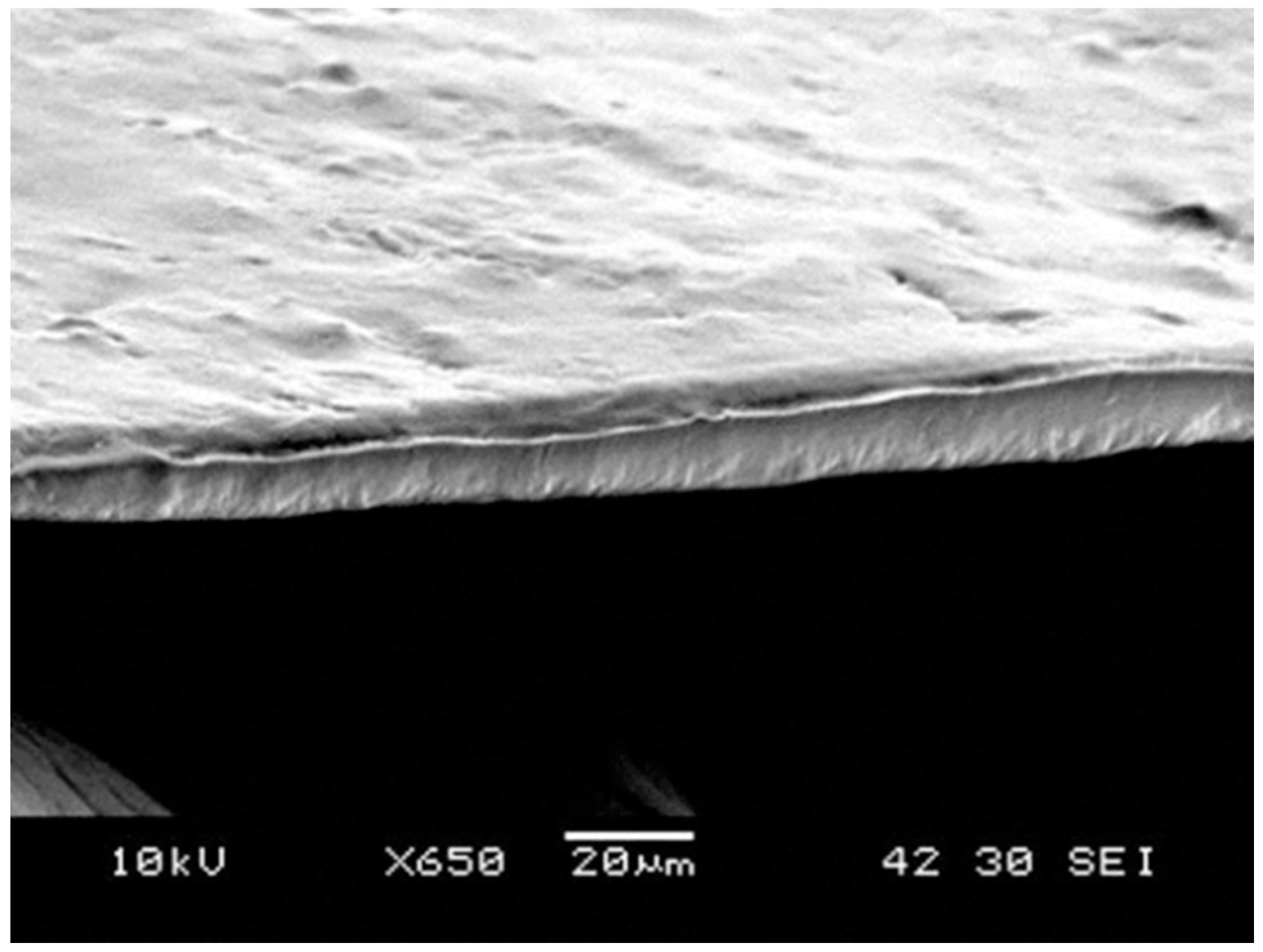

2.3. Membrane Surface Characteristics and Mechanical Strength

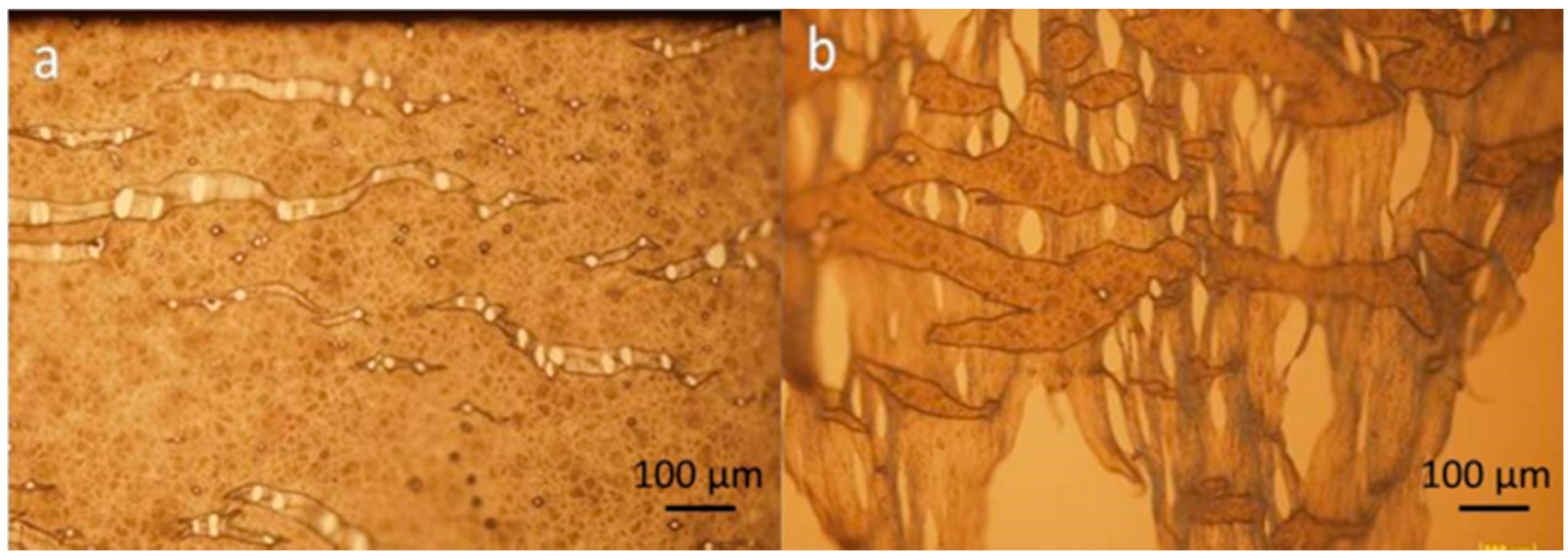

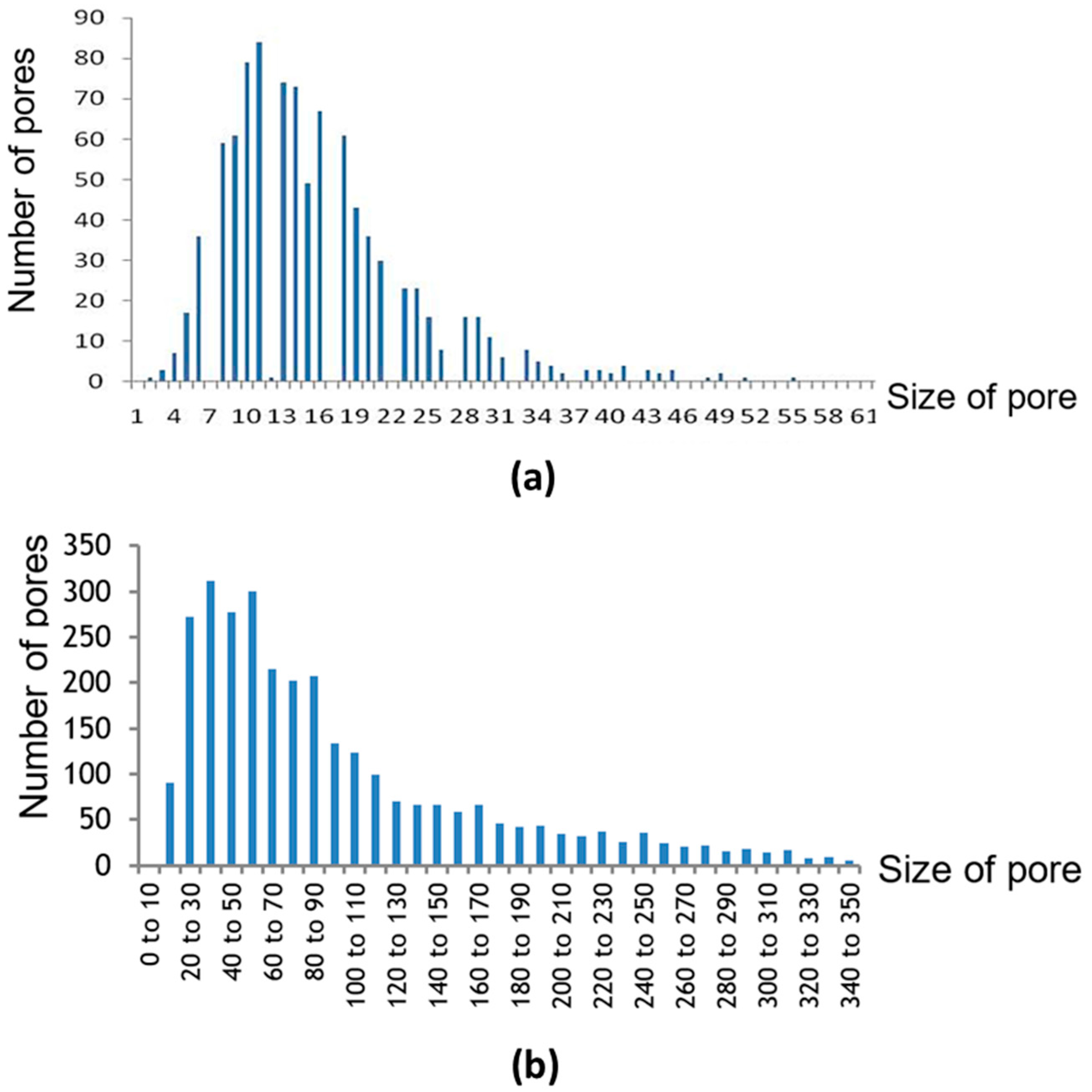

2.4. Distribution of Pore Size

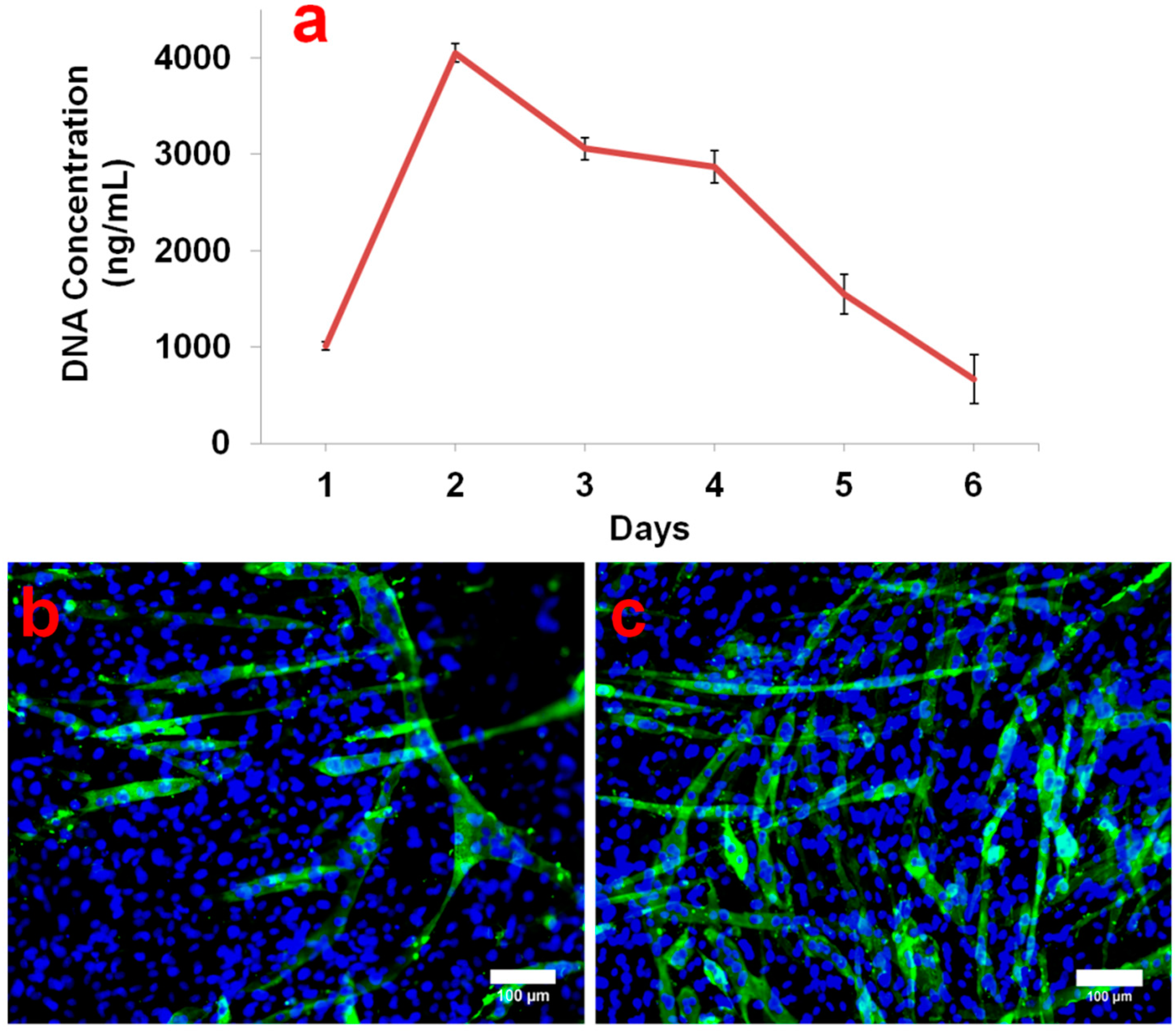

2.5. In Vitro Cell Compatibility Study

3. Experimental Section

3.1. Polycaprolactone Membrane Fabrication

3.2. Membrane Characterization

3.2.1. Membrane Morphology

3.2.2. Thickness Measurement

3.2.3. Pore Size Measurement

3.2.4. Surface Roughness Measurement

3.2.5. Mechanical Tests

3.3. In Vitro Evaluation of Membranes for Cell Compatibility

3.3.1. Cell Culture

3.3.2. Immunocytochemistry and Microscopy

3.3.3. Cell Proliferation Assay

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Suntornnond, R.; An, J.; Yeong, W.Y.; Chua, C.K. Biodegradable polymeric films and membranes processing and forming for tissue engineering. Macromol. Mater. Eng. 2015, 300, 858–877. [Google Scholar] [CrossRef]

- Xu, C.Y.; Inai, R.; Kotaki, M.; Ramakrishna, S. Aligned biodegradable nanofibrous structure: A potential scaffold for blood vessel engineering. Biomaterials 2004, 25, 877–886. [Google Scholar] [CrossRef]

- Zong, X.; Bien, H.; Chung, C.-Y.; Yin, L.; Fang, D.; Hsiao, B.S.; Chu, B.; Entcheva, E. Electrospun fine-textured scaffolds for heart tissue constructs. Biomaterials 2005, 26, 5330–5338. [Google Scholar] [CrossRef] [PubMed]

- Riboldi, S.A.; Sampaolesi, M.; Neuenschwander, P.; Cossu, G.; Mantero, S. Electrospun degradable polyesterurethane membranes: Potential scaffolds for skeletal muscle tissue engineering. Biomaterials 2005, 26, 4606–4615. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tiaw, K.S.; Teoh, S.H.; Chen, R.; Hong, M.H. Processing methods of ultrathin poly(ε-caprolactone) films for tissue engineering applications. Biomacromolecules 2007, 8, 807–816. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Shi, G.; Bei, J.; Wang, S.; Cao, Y.; Shang, Q.; Yang, G.; Wang, W. Fabrication and surface modification of macroporous poly(l-lactic acid) and poly(l-lactic-co-glycolic acid) (70/30) cell scaffolds for human skin fibroblast cell culture. J. Biomed. Mater. Res. 2002, 62, 438–446. [Google Scholar] [CrossRef] [PubMed]

- Diban, N.; Stamatialis, D.F. Functional Polymer Scaffolds for Blood Vessel Tissue Engineering. Macromol. Symp. 2011, 309–310, 93–99. [Google Scholar] [CrossRef]

- Magerl, A.; Goedel, W.A. Porous polymer membranes via selectively wetted surfaces. Langmuir 2012, 28, 5622–5632. [Google Scholar] [CrossRef] [PubMed]

- Yan, F.; Goedel, W.A. Polymer membranes with two-dimensionally arranged pores derived from monolayers of silica particles. Chem. Mater. 2004, 16, 1622–1626. [Google Scholar] [CrossRef]

- Htay, A.S.; Teoh, S.H.; Hutmacher, D.W. Development of perforated microthin poly(ε-caprolactone) films as matrices for membrane tissue engineering. J. Biomater. Sci. Polym. Ed. 2004, 15, 683–700. [Google Scholar] [CrossRef] [PubMed]

- Penel-Pierron, L.; Seguela, R.; Lefebvre, J.M.; Miri, V.; Depecker, C.; Jutigny, M.; Pabiot, J. Structural and mechanical behavior of nylon-6 films. Ii. Uniaxial and biaxial drawing. J. Polym. Sci., Part B Polym. Phys. 2001, 39, 1224–1236. [Google Scholar] [CrossRef]

- Tong, H.-W.; Wang, M. Electrospinning of poly(hydroxybutyrate-co-hydroxyvalerate) fibrous scaffolds for tissue engineering applications: Effects of electrospinning parameters and solution properties. J. Macromol. Sci. Phys. 2011, 50, 1535–1558. [Google Scholar] [CrossRef]

- Pham, Q.P.; Sharma, U.; Mikos, A.G. Electrospinning of polymeric nanofibers for tissue engineering applications: A review. TiEng 2006, 12, 1197–1211. [Google Scholar]

- Cheng, Z.; Teoh, S.H. Surface modification of ultra thin poly (ε-caprolactone) films using acrylic acid and collagen. Biomaterials 2004, 25, 1991–2001. [Google Scholar] [CrossRef] [PubMed]

- Tiaw, K.S.; Goh, S.W.; Hong, M.; Wang, Z.; Lan, B.; Teoh, S.H. Laser surface modification of poly(ε-caprolactone) (pcl) membrane for tissue engineering applications. Biomaterials 2005, 26, 763–769. [Google Scholar] [CrossRef] [PubMed]

- Nandakumar, A.; Yang, L.; Habibovic, P.; van Blitterswijk, C. Calcium phosphate coated electrospun fiber matrices as scaffolds for bone tissue engineering. Langmuir 2009, 26, 7380–7387. [Google Scholar] [CrossRef] [PubMed]

- Leong, W.S.; Wu, S.C.; Ng, K.; Tan, L.P. Electrospun 3D multi-scale fibrous scaffold for enhanced human dermal fibroblast infiltration. Inter. J. Bioprint. 2016, 2. [Google Scholar] [CrossRef]

- Sharma, S.; Mohanty, S.; Gupta, D.; Jassal, M.; Agrawal, A.K.; Tandon, R. Cellular response of limbal epithelial cells on electrospun poly-ε-caprolactone nanofibrous scaffolds for ocular surface bioengineering: A preliminary in vitro study. Mol. Vis. 2011, 17, 2898–2910. [Google Scholar] [PubMed]

- Ren, J.; Liu, W.; Zhu, J.; Gu, S. Preparation and characterization of electrospun, biodegradable membranes. J. Appl. Polym. Sci. 2008, 109, 3390–3397. [Google Scholar] [CrossRef]

- Zulfakar, S.S.; White, J.D.; Ross, T.; Tamplin, M.L. Cultured c2c12 cell lines as a model for assessment of bacterial attachment to bovine primary muscle cells. Meat Sci. 2013, 94, 215–219. [Google Scholar] [CrossRef] [PubMed]

- Fishman, J.M.; Tyraskis, A.; Maghsoudlou, P.; Urbani, L.; Totonelli, G.; Birchall, M.; de Coppi, P. Skeletal muscle tissue engineering: Which cell to use? TiEng 2013, 19, 503–515. [Google Scholar] [CrossRef] [PubMed]

- Rossi, F.; Charlton, C.A.; Blau, H.M. Monitoring protein–protein interactions in intact eukaryotic cells by β-galactosidase complementation. Proc. Natl. Acad. Sci. USA 1997, 94, 8405–8410. [Google Scholar] [CrossRef] [PubMed]

- Robey, T.E.; Saiget, M.K.; Reinecke, H.; Murry, C.E. Systems approaches to preventing transplanted cell death in cardiac repair. J. Mol. Cell. Cardiol. 2008, 45, 567–581. [Google Scholar] [CrossRef] [PubMed]

- Andrés, V.; Walsh, K. Myogenin expression, cell cycle withdrawal, and phenotypic differentiation are temporally separable events that precede cell fusion upon myogenesis. J. Cell Biol. 1996, 132, 657–666. [Google Scholar] [CrossRef] [PubMed]

- Moran, J.L.; Li, Y.; Hill, A.A.; Mounts, W.M.; Miller, C.P. Gene expression changes during mouse skeletal myoblast differentiation revealed by transcriptional profiling. Physiol. Genomics 2002, 10, 103–111. [Google Scholar] [CrossRef] [PubMed]

- Yung, K.C.; Mei, S.M.; Yue, T.M. A study of the heat-affected zone in the UV yag laser drilling of gfrp materials. J. Mater. Process. Technol. 2002, 122, 278–285. [Google Scholar] [CrossRef]

- Stępak, B.; Antończak, A.J.; Bartkowiak-Jowsa, M.; Filipiak, J.; Pezowicz, C.; Abramski, K.M. Fabrication of a polymer-based biodegradable stent using a co2 laser. Arch. Civil Mech. Eng. 2014, 14, 317–326. [Google Scholar] [CrossRef]

- Narayanan, G.; Gupta, B.S.; Tonelli, A.E. Enhanced mechanical properties of poly (ε-caprolactone) nanofibers produced by the addition of non-stoichiometric inclusion complexes of poly (ε-caprolactone) and α-cyclodextrin. Polymer 2015, 76, 321–330. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, S.; Ye, S.; Feng, J. A feasible route to balance the mechanical properties of epoxy thermosets by reinforcing a pcl-ppc-pcl toughened system with reduced graphene oxide. Compos. Sci. Technol. 2016, 125, 108–113. [Google Scholar] [CrossRef]

- Kiatpanichgij, S.; Afzulpurkar, N.; Kim, T.-W. Three-dimensional model reconstruction from industrial computed tomography-scanned data for reverse engineering. Virtual Phys. Prototyp. 2014, 9, 97–114. [Google Scholar] [CrossRef]

- Chua, C.K.; Yeong, W.Y. Bioprinting: Principles and Applications; World Scientific Publishing Company Incorporated: Seoul, Korea, 2014. [Google Scholar]

- An, J.; Chua, C.K.; Mironov, V. A perspective on 4d bioprinting. Int. J. Bioprint. 2016, 2. [Google Scholar] [CrossRef]

- Dean, D.; Mott, E.; Luo, X.; Busso, M.; Wang, M.O.; Vorwald, C.; Siblani, A.; Fisher, J.P. Multiple initiators and dyes for continuous digital light processing (cdlp) additive manufacture of resorbable bone tissue engineering scaffolds. Virtual Phys. Prototyp. 2014, 9, 3–9. [Google Scholar] [CrossRef]

- Lee, J.M.; Yeong, W.Y. A preliminary model of time-pressure dispensing system for bioprinting based on printing and material parameters: This paper reports a method to predict and control the width of hydrogel filament for bioprinting applications. Virtual Phys. Prototyp. 2015, 10, 3–8. [Google Scholar] [CrossRef]

- Vaezi, M.; Yang, S. Extrusion-based additive manufacturing of peek for biomedical applications. Virtual Phys. Prototyp. 2015, 10, 123–135. [Google Scholar] [CrossRef]

- Jardini, A.L.; Larosa, M.A.; de Carvalho Zavaglia, C.A.; Bernardes, L.F.; Lambert, C.S.; Kharmandayan, P.; Calderoni, D.; Maciel Filho, R. Customised titanium implant fabricated in additive manufacturing for craniomaxillofacial surgery. Virtual Phys. Prototyp. 2014, 9, 115–125. [Google Scholar] [CrossRef]

- Khoo, Z.X.; Teoh, J.E.M.; Liu, Y.; Chua, C.K.; Yang, S.; An, J.; Leong, K.F.; Yeong, W.Y. 3d printing of smart materials: A review on recent progresses in 4d printing. Virtual Phys. Prototyp. 2015, 10, 103–122. [Google Scholar] [CrossRef]

- An, J.; Chua, C.K.; Leong, K.F. Biodegradable double-layer cell carriers for tissue engineering. In Proceedings of the 1st International Symposium on Bioengineering (ISOB 2011), Singapore, 19 January 2011.

- An, J.; Chua, C.K.; Leong, K.F. A novel membrane formation method: Inspiration from duckweeds. In Proceedings of the 4th International Conference PMI 2010, Ghent, Belgium, 15–17 September 2010.

- Sample Availability: Samples of the compounds are available from the authors.

| Method | Processing and Membrane Morphology | |||||

|---|---|---|---|---|---|---|

| Fabrication Duration | Organic Solvent Involving | Pore Structure | Texture | Thickness | Reference | |

| Solvent (solution) casting | Hours to Days | Yes | Insufficient pores; Require post-processing | Flat Solid | Depends on concentration | [10] |

| Biaxial-drawing | Hours | Depends on film preparation | Insufficient pores; Require post-processing | Flat Solid | Ultra-thin | [5,11] |

| Electrospinning | Hours | Yes | Micro-nano pores | Random fibers structure | Dense ultra-thin | [12,13] |

| Parameter | Membrane Properties | |

|---|---|---|

| From 100 µm Powder | From 500 µm Powder | |

| Thickness | 27.3 ± 2.8 µm | 134.9 ± 3.6 µm |

| Roughness | 3.4 ± 2.9 µm | 5.5 ± 3.0 µm |

| Stiffness | 2.40 ± 0.40 N/mm | 0.15 ± 0.02 N/mm |

| Ultimate tensile load | 1.6 ± 0.3 N | 10.1 ± 2.5 N |

| Powder Size | Sample | 1 | 2 | 3 |

|---|---|---|---|---|

| 100 µm | Number of pores measured | 949 | 885 | 1000 |

| Average (µm) | 16.2 ± 9.2 | 16.7± 10.9 | 16.2 ± 6.3 | |

| Max size (µm) | 95 | 80 | 46.1 | |

| Min size (µm) | 2 | 3 | 6 | |

| 500 µm | Number of pores measured | 996 | 1016 | 1000 |

| Average (µm) | 151.7 ± 70.7 | 61.2 ± 30.5 | 73.3 ± 26.2 | |

| Max size (µm) | 350 | 288 | 347 | |

| Min size (µm) | 14 | 11 | 14 |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suntornnond, R.; An, J.; Tijore, A.; Leong, K.F.; Chua, C.K.; Tan, L.P. A Solvent-Free Surface Suspension Melt Technique for Making Biodegradable PCL Membrane Scaffolds for Tissue Engineering Applications. Molecules 2016, 21, 386. https://doi.org/10.3390/molecules21030386

Suntornnond R, An J, Tijore A, Leong KF, Chua CK, Tan LP. A Solvent-Free Surface Suspension Melt Technique for Making Biodegradable PCL Membrane Scaffolds for Tissue Engineering Applications. Molecules. 2016; 21(3):386. https://doi.org/10.3390/molecules21030386

Chicago/Turabian StyleSuntornnond, Ratima, Jia An, Ajay Tijore, Kah Fai Leong, Chee Kai Chua, and Lay Poh Tan. 2016. "A Solvent-Free Surface Suspension Melt Technique for Making Biodegradable PCL Membrane Scaffolds for Tissue Engineering Applications" Molecules 21, no. 3: 386. https://doi.org/10.3390/molecules21030386