Biofuels and Their Co-Products as Livestock Feed: Global Economic and Environmental Implications

Abstract

:1. Introduction

2. Results and Discussion

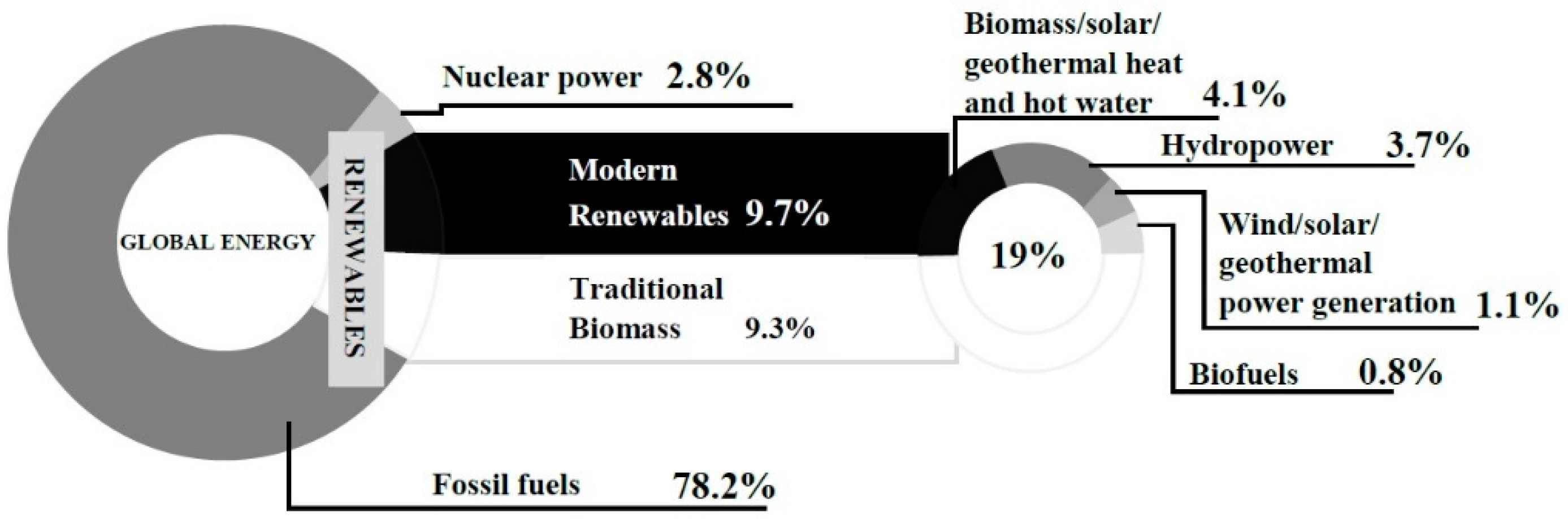

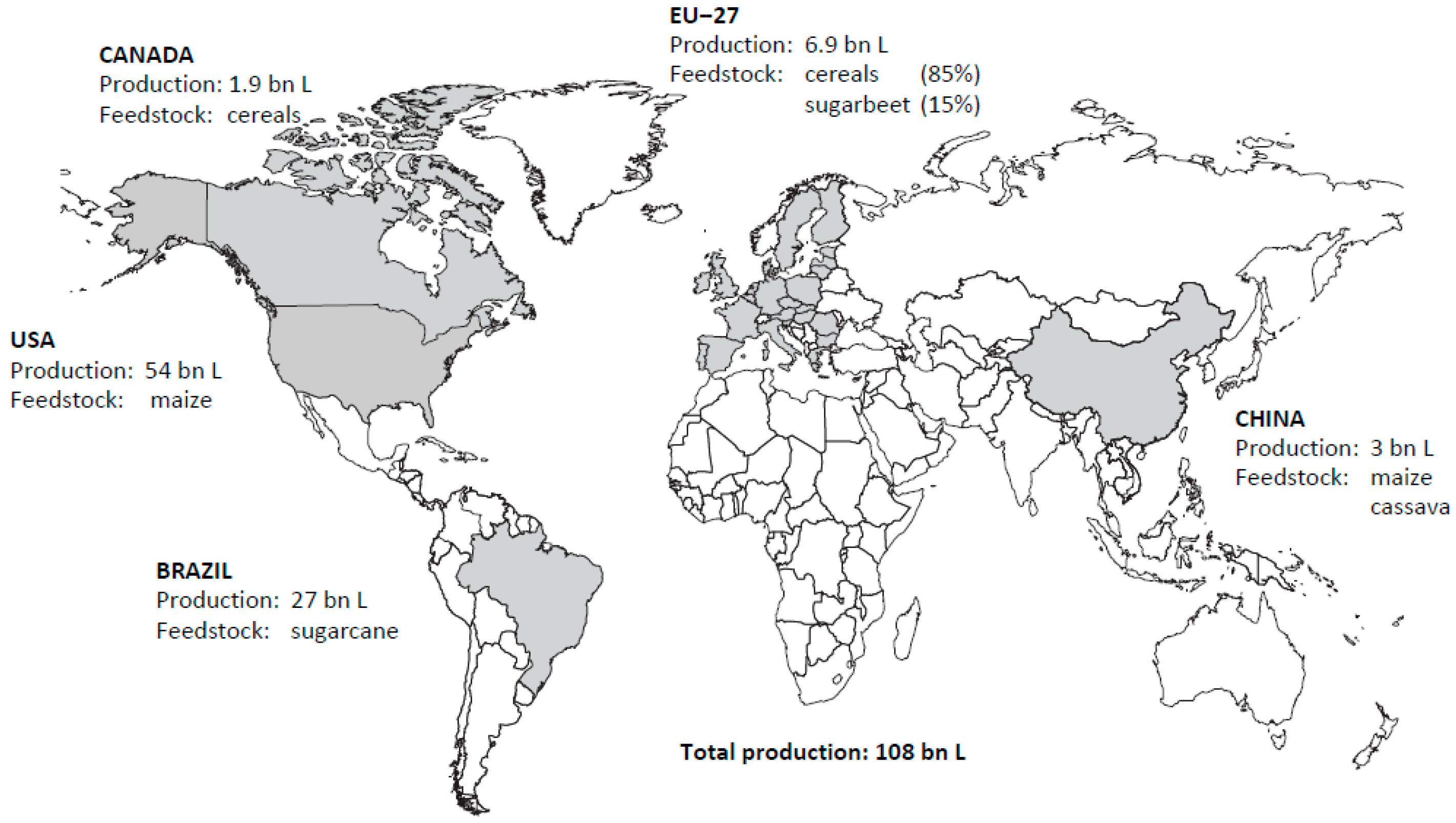

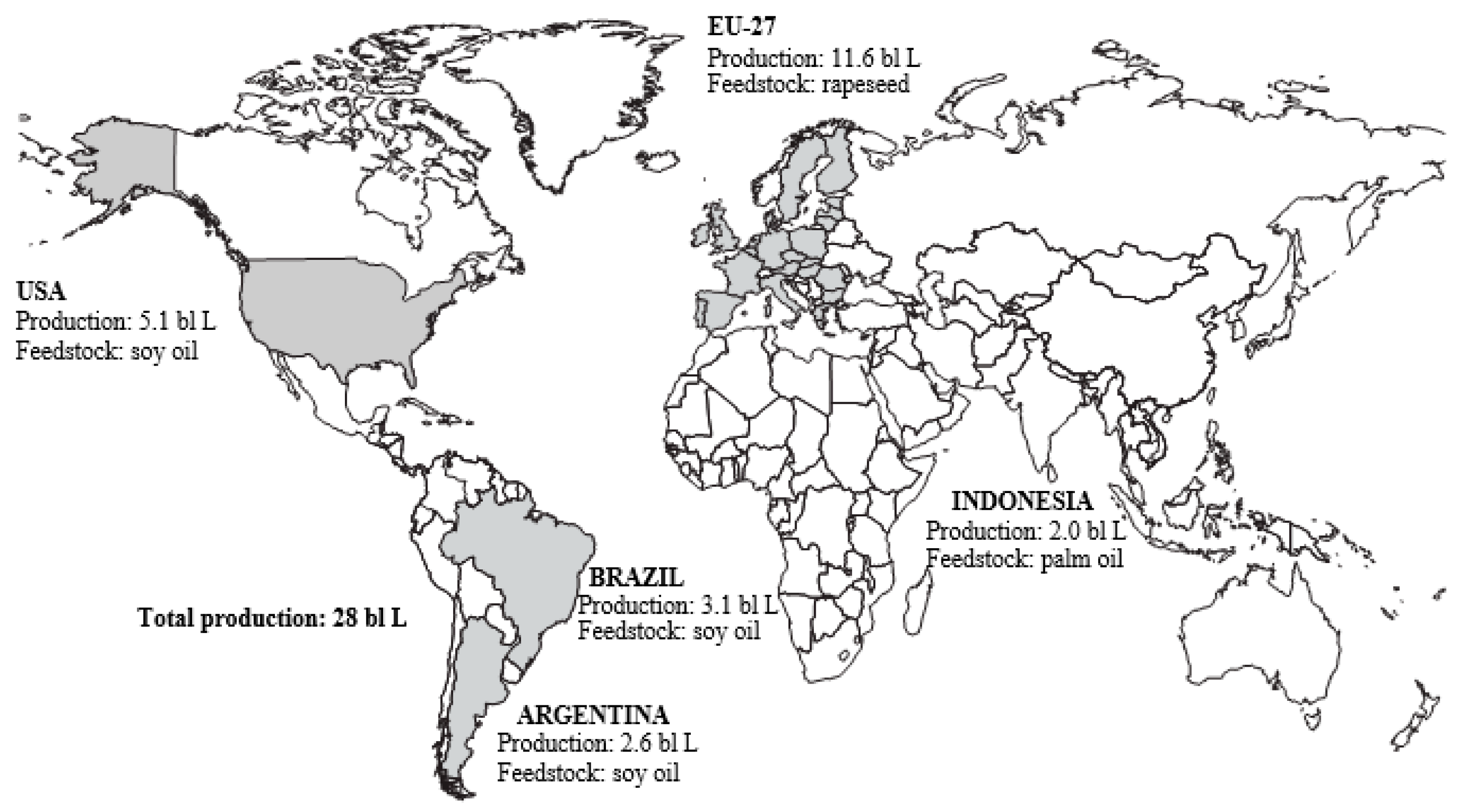

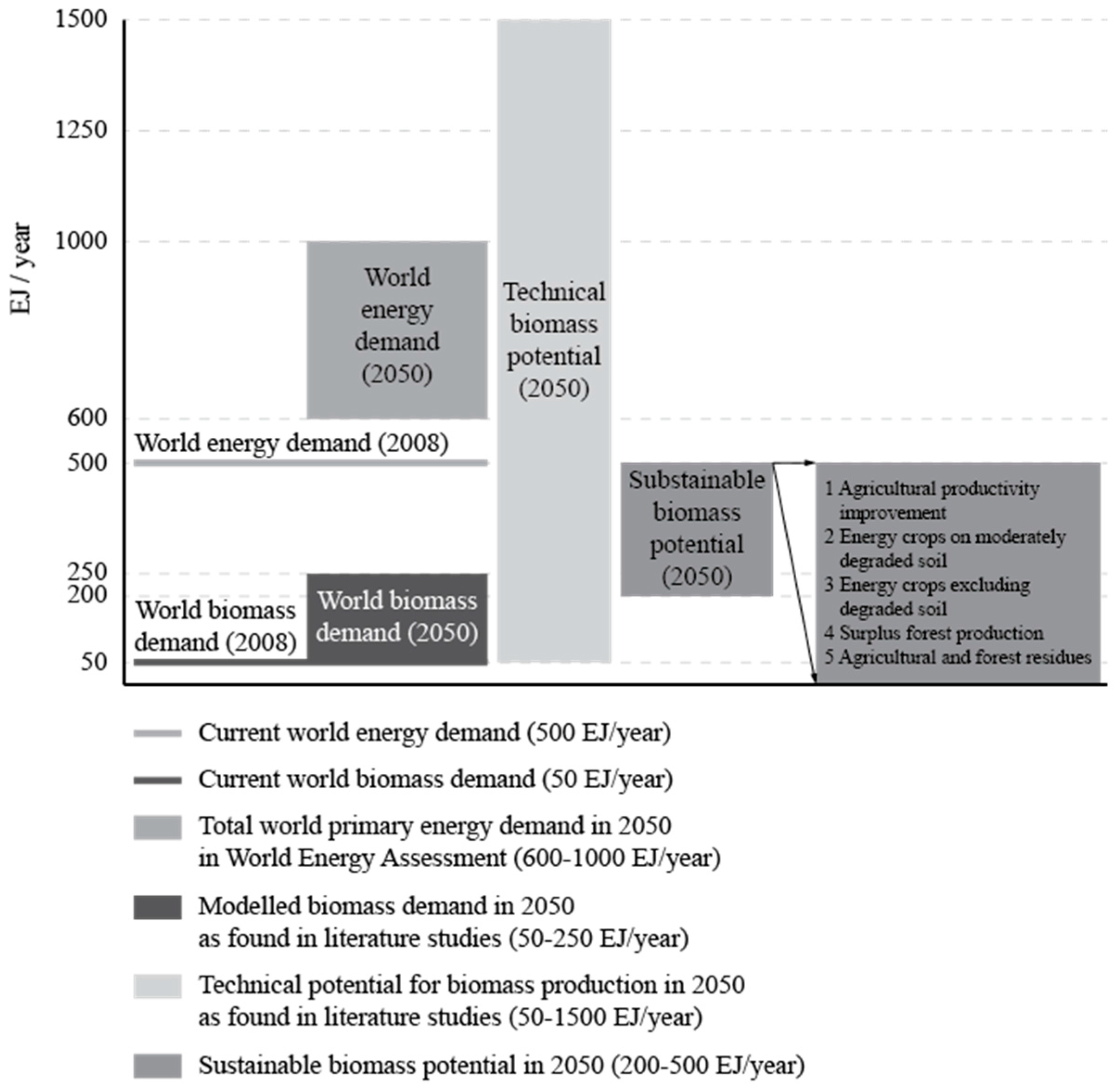

2.1. Bioenergy Potential

2.2. Competition between Conventional and Advanced Biofuels

2.2.1. Giant Reed for Biofuels

2.2.2. Algae for Biofuels

2.3. Feedstocks and Co-Products of Biofuel Production

Animal Feed Produced from the Ethanol and Biodiesel Industry

2.4. Attributes of Co-Products of Biofuels Production

2.4.1. Economic Implications

2.4.2. Environmental Implications

Land Use Change and GHG Emission

Algae as Animal Feed

New Market Opportunities for Biofuel Co-Products

3. Materials and Methods

- Co-products of biofuels as livestock feed: biofuel’s co-products refer to co-products that are generated during the process and used as animal feed

- Economic, environmental and land use implications of biofuel’s co-products. When co-products are used credits can be attributed to the biofuel production chain including economic viability, GHG emission savings and avoided land use. Impact on land use and GHG emissions are the main focuses the existing studies paid attention to.

- Advanced biofuels: future production is influenced by the competition between conventional and advanced biofuels based on food crops and lignocellulosic feedstocks.

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| CO2 | carbon dioxide |

| DDG | dried distillers’ grains |

| DDGS | dried distillers’ grains with solubles |

| dLUC | direct land use change |

| FAO | Food and Agriculture Organization of the United Nations |

| DME | dimethyl ether |

| GHG | greenhouse gas |

| ILUC | indirect land use change |

| OECD | Organisation for Economic Cooperation and Development |

| RED | renewable energy directive |

| RFS | renewable fuel standard |

| WDG | Wet distillers’ grain |

| CGF | corn gluten feed |

References

- Popp, J.; Lakner, Z.; Harangi-Rakos, M.; Fari, M. The effect of bioenergy expansion: Food, energy, and environment. Renew. Sustain. Energy Rev. 2014, 32, 559–578. [Google Scholar] [CrossRef]

- International Energy Agency. The Renewable Energy 2013. Medium-Term Market Report. A Growing Role for Renewables in the Energy Mix; International Energy Agency: Paris, France, 2013; p. 13. [Google Scholar]

- World Bioenergy Association. Global Bioenergy Statistics 2014; WBA: Stockholm, Sweden, 2014. [Google Scholar]

- United States Department of Agriculture. Agricultural Projections to 2024; Interagency Agricultural Projections Committee: Washington, DC, USA, 2015; p. 91.

- OECD/FAO. Agricultural Outlook; 2015; Avaliable online: http://dx.doi.org/10.1787/data-00736-en (assessed on 10 December 2015).

- International Energy Agency. World Energy Outlook 2015; International Energy Agency: Paris, France, 2015; p. 200. [Google Scholar]

- Licht, F.O. World Ethanol and Biofuels Report; Agra Informa: London, UK, 2013. [Google Scholar]

- Elobeid, A.E.; Carriquiry, M.A.; Fabiosa, J.F. Land-use change and greenhouse gas emissions in the fapri-card model system: Addressing bias and uncertainty. Clim. Chang. Econ. 2012, 3. [Google Scholar] [CrossRef]

- Khanna, M.; Zilberman, D. Modeling the land-use and greenhouse-gas implications of biofuels. Clim. Chang. Econ. 2012, 3. [Google Scholar] [CrossRef]

- Witzke, P.; Banse, M.; Gömann, H.; Heckelei, T.; Breuer, T.; Mann, S.; Kempen, M.; Adenäuer, M.; Zintl, A. Modelling of Energy-Crops in Agricultural Sector Models—A Review of Existing Methodologies; Joint Research Centre—Institute for Prospective Technological Studies Luxembourg: Ispra, Italy, 2008; p. 59. [Google Scholar]

- Golub, A.A.; Hertel, T.W. Modeling land-use change impacts of biofuels in the gtap-bio framework. Clim. Chang. Econ. 2012, 3. [Google Scholar] [CrossRef]

- Beach, R.H.; Zhang, Y.W.; McCarl, B.A. Modeling bioenergy, land use, and ghg emissions with fasomghg: Model overview and analysis of storage cost implications. Clim. Chang. Econ. 2012, 3. [Google Scholar] [CrossRef]

- Makkar, H.P.S. Biofuel Co-Products as Livestock Feed—Opportunities and Challenges; FAO: Rome, Italy, 2012; p. 533. [Google Scholar]

- International Energy Agency. World Energy Outlook 2012; International Energy Agency: Paris, France, 2012; p. 690. [Google Scholar]

- Smeets, E.M.W.; Faaij, A.P.C.; Lewandowski, I.M.; Turkenburg, W.C. A bottom-up assessment and review of global bio-energy potentials to 2050. Prog. Energy Combust. 2007, 33, 56–106. [Google Scholar] [CrossRef]

- International Energy Agency. A Sustainable and Reliable Energy Source Main Report; International Energy Agency: Paris, France, 2009; p. 108. [Google Scholar]

- Dornburg, V.; van Vuuren, D.; van de Ven, G.; Langeveld, H.; Meeusen, M.; Banse, M.; van Oorschot, M.; Ros, J.; van den Born, G.J.; Aiking, H.; et al. Bioenergy revisited: Key factors in global potentials of bioenergy. Energy Environ. Sci. 2010, 3, 258–267. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change. Special Report on Renewable Energy Sources and Climate Change Mitigation; Cambridge University Press: Cambridge, UK, 2011; p. 246. [Google Scholar]

- Haberl, H.; Beringer, T.; Bhattacharya, S.C.; Erb, K.H.; Hoogwijk, M. The global technical potential of bio-energy in 2050 considering sustainability constraints. Curr. Opin. Environ. Sustain. 2010, 2, 394–403. [Google Scholar] [CrossRef] [PubMed]

- Global Energy Assessment. Global Energy Assessment—Toward a Sustainable Future; Cambridge University Press: Cambridge, UK, 2012; p. 113. [Google Scholar]

- Haberl, H.; Erb, K.H.; Krausmann, F.; Gaube, V.; Bondeau, A.; Plutzar, C.; Gingrich, S.; Lucht, W.; Fischer-Kowalski, M. Quantifying and mapping the human appropriation of net primary production in earth’s terrestrial ecosystems. PNAS 2007, 104, 12942–12945. [Google Scholar] [CrossRef] [PubMed]

- Larcher, W. Physiological Plant Ecology: Ecophysiology and Stress Physiology of Functional Groups; Springer Science & Business Media: Berlin, Germany, 2003; p. 513. [Google Scholar]

- Saugier, B.; Roy, J.; Mooney, H.A. Estimations of global terrestrial productivity: Converging toward a single number. In Terrestrial Global Productivity; Academic Press: San Diego, CA, USA, 2001; pp. 543–557. [Google Scholar]

- Food and Agriculture Organization. Faostat Database; Economic and Social Development Department: Rome, Italy, 2011. [Google Scholar]

- International Energy Agency. Energy Technology Perspectives 2010. Scenarios & Strategies to 2050; International Energy Agency: Paris, France, 2010; p. 706. [Google Scholar]

- Paulová, L.; Melzoch, K.; Rychtera, M.; Patáková, P. Production of 2nd generation of liquid biofuels. In Liquid, Gaseous and Solid Biofuels: Conversion Techniques; Fang, Z., Ed.; InTech Open Access Publisher: Rijeka, Croatia, 2013; pp. 47–78. [Google Scholar]

- Alshaal, T.; Domokos-Szabolcsy, E.; Marton, L.; Czako, M.; Katai, J.; Balogh, P.; Elhawat, N.; El-Ramady, H.; Fari, M. Phytoremediation of bauxite-derived red mud by giant reed. Environ. Chem. Lett. 2013, 11, 295–302. [Google Scholar] [CrossRef]

- El-Ramady, H.R.; Abdalla, N.; Alshaal, T.; Fári, M.; Prokisch, J.; Pilon-Smits, E.A.H.; Domokos-Szabolcsy, É. Selenium phytoremediation by giant reed. In Hydrogen Production and Remediation of Carbon and Pollutants; Lichtfouse, E., Schwarzbauer, J., Robert, D., Eds.; Springer International Publishing: Cham, Switzerland, 2015; pp. 133–198. [Google Scholar]

- Pandey, V.C.; Bajpai, O.; Singh, N. Energy crops in sustainable phytoremediation. Renew. Sustain. Energy Rev. 2016, 54, 58–73. [Google Scholar] [CrossRef]

- Jones, M.B.; Finnan, J.; Hodkinson, T.R. Morphological and physiological traits for higher biomass production in perennial rhizomatous grasses grown on marginal land. Glob. Chang. Biol. Bioenergy 2015, 7, 375–385. [Google Scholar] [CrossRef]

- Ge, X.M.; Xu, F.Q.; Vasco-Correa, J.; Li, Y.B. Giant reed: A competitive energy crop in comparison with miscanthus. Renew. Sustain. Energy Rev. 2016, 54, 350–362. [Google Scholar] [CrossRef]

- Giessow, J.; Casanova, J.; Leclerc, R.; MacArthur, R.; Fleming, G.; Giessow, J. Arundo donax (Giant Reed): Distribution and Impact Report; State Water Resources Control Board California Invasive Plant Council (Cal-IPC): California, CA, USA, 2011; pp. 1–240. [Google Scholar]

- Maceda-Veiga, A.; Basas, H.; Lanzaco, G.; Sala, M.; Sostoa, A.; Serra, A. Impacts of the invader giant reed (Arundo donax) on riparian habitats and ground arthropod communities. Biol. Invasions 2016, 18, 731–749. [Google Scholar] [CrossRef]

- Nackley, L.L.; Kim, S.-H. A salt on the bioenergy and biological invasions debate: Salinity tolerance of the invasive biomass feedstock Arundo donax. GCB Bioenergy 2015, 7, 752–762. [Google Scholar] [CrossRef]

- International Energy Agency. Renewable Energy. Medium-Term Market Report 2015. Market Analysis and Forecasts to 2020; International Energy Agency: Paris, France, 2015; p. 14. [Google Scholar]

- Kretschmer, B.; Allen, B.; Kieve, D.; Smith, C. The Sustainability of Advanced Biofuels in the EU: Assessing the Sustainability of Wastes, Residues and Other Feedstocks Set out in the European Commission’s Proposal on indirect Land Use Change (ILUC); Institute for European Environmental Policy (IEEP): London, UK, 2013; p. 37. [Google Scholar]

- Renewable Energy Policy Network for the 21st Century. Renewables 2015, Global Status Report; Paris, France, 2015; p. 251. [Google Scholar]

- Searchinger, T.; Heimlich, R. Avoiding Bioenergy Competition for Food Crops and Land; World Resources Institute: Washington, DC, USA, 2015; p. 44. [Google Scholar]

- Wang, M.; Dunn, J.B. Comments on Avoiding Bioenergy Competition for Food Crops and Land by Searchinger and Heimlich; Argonne National Laboratory: Argonne, IL, USA, 2015; pp. 1–9.

- Lynd, L.R.; Larson, E.; Greene, N.; Laser, M.; Sheehan, J.; Dale, B.E.; McLaughlin, S.; Wang, M. The role of biomass in america’s energy future: Framing the analysis. Biofuels Bioprod. Biorefin. 2009, 3, 113–123. [Google Scholar] [CrossRef]

- Cai, X.M.; Zhang, X.A.; Wang, D.B. Land availability for biofuel production. Environ. Sci. Technol. 2011, 45, 334–339. [Google Scholar] [CrossRef] [PubMed]

- Perlack, R.D.; Eaton, L.M.; Turhollow, A.F., Jr.; Langholtz, M.H.; Brandt, C.C.; Downing, M.E.; Graham, R.L.; Wright, L.L.; Kavkewitz, J.M.; Shamey, A.M. Us Billion-Ton Update: Biomass Supply for a Bioenergy and Bioproducts Industry; U.S. Department of Energy: Oak Ridge, Tennessee, TN, USA, 2011; p. 227.

- Werling, B.P.; Dickson, T.L.; Isaacs, R.; Gaines, H.; Gratton, C.; Gross, K.L.; Liere, H.; Malmstrom, C.M.; Meehan, T.D.; Ruan, L.L.; et al. Perennial grasslands enhance biodiversity and multiple ecosystem services in bioenergy landscapes. PNAS 2014, 111, 1652–1657. [Google Scholar] [CrossRef] [PubMed]

- Stolarski, M.J.; Krzyzaniak, M.; Luczyski, M.; Zaluski, D.; Szczukowski, S.; Tworkowski, J.; Golaszewski, J. Lignocellulosic biomass from short rotation woody crops as a feedstock for second-generation bioethanol production. Ind. Crop Prod. 2015, 75, 66–75. [Google Scholar] [CrossRef]

- Allwright, M.R.; Taylor, G. Molecular breeding for improved second generation bioenergy crops. Trends Plant Sci. 2016, 21, 43–54. [Google Scholar] [CrossRef] [PubMed]

- Triana, F.; Nassi o Di Nasso, N.; Ragaglini, G.; Roncucci, N.; Bonari, E. Evapotranspiration, crop coefficient and water use efficiency of giant reed (Arundo donax L.) and miscanthus (Miscanthus × giganteus greef et deu.) in a mediterranean environment. GCB Bioenergy 2015, 7, 811–819. [Google Scholar] [CrossRef]

- Testa, R.; Foderà, M.; Di Trapani, A.M.; Tudisca, S.; Sgroi, F. Giant reed as energy crop for southern italy: An economic feasibility study. Renew. Sustain. Energy Rev. 2016, 58, 558–564. [Google Scholar] [CrossRef]

- Alshaal, T.; Domokos-Szabolcsy, E.; Marton, L.; Czako, M.; Katai, J.; Balogh, P.; Elhawat, N.; El-Ramady, H.; Gerocs, A.; Fari, M. Restoring soil ecosystems and biomass production of Arundo donax L. Under microbial communities-depleted soil. Bioenergy Res. 2014, 7, 268–278. [Google Scholar] [CrossRef]

- Alshaal, T.; Elhawat, N.; Domokos-Szabolcsy, É.; Kátai, J.; Márton, L.; Czakó, M.; El-Ramady, H.; Fári, M.G. Giant reed (Arundo donax L.): A green technology for clean environment. In Phytoremediation; Ansari, A.A., Gill, S.S., Gill, R., Lanza, G.R., Newman, L., Eds.; Springer International Publishing: Cham, Switzerland, 2014; Volume 1, pp. 3–20. [Google Scholar]

- Elhawat, N.; Alshaal, T.; Domokos-Szabolcsy, E.; El-Ramady, H.; Marton, L.; Czako, M.; Katai, J.; Balogh, P.; Sztrik, A.; Molnar, M.; et al. Phytoaccumulation potentials of two biotechnologically propagated ecotypes of arundo donax in copper-contaminated synthetic wastewater. Environ. Sci. Pollut. Res. 2014, 21, 7773–7780. [Google Scholar] [CrossRef] [PubMed]

- Elhawat, N.; Alshaal, T.; Domokos-Szabolcsy, E.; El-Ramady, H.; Antal, G.; Marton, L.; Czako, M.; Balogh, P.; Fari, M. Copper uptake efficiency and its distribution within bioenergy grass giant reed. Bull. Environ. Contam. Toxicol. 2015, 95, 452–458. [Google Scholar] [CrossRef] [PubMed]

- Rabemanolontsoa, H.; Saka, S. Comparative study on chemical composition of various biomass species. RSC Adv. 2013, 3, 3946–3956. [Google Scholar] [CrossRef]

- Franscisco, L.; Carlos, G.J.; Antonie, P.; Javier, F.M.; Minerva, A.M.Z.; Gil, G. Chemical and energetic characterization of species with a high-biomass production: Fractionation of their components. Environ. Prog. Sustain. 2010, 29, 499–509. [Google Scholar] [CrossRef]

- Shatalov, A.A.; Pereira, H. Xylose production from giant reed (Arundo donax L.): Modeling and optimization of dilute acid hydrolysis. Carbohyd. Polym. 2012, 87, 210–217. [Google Scholar] [CrossRef]

- Komolwanich, T.; Tatijarern, P.; Prasertwasu, S.; Khumsupan, D.; Chaisuwan, T.; Luengnaruemitchai, A.; Wongkasemjit, S. Comparative potentiality of kans grass (Saccharum spontaneum) and giant reed (Arundo donax) as lignocellulosic feedstocks for the release of monomeric sugars by microwave/chemical pretreatment. Cellulose 2014, 21, 1327–1340. [Google Scholar] [CrossRef]

- Corno, L.; Pilu, R.; Adani, F. Arundo donax L.: A non-food crop for bioenergy and bio-compound production. Biotechnol. Adv. 2014, 32, 1535–1549. [Google Scholar] [CrossRef] [PubMed]

- Silva, C.F.L.E.; Schirmer, M.A.; Maeda, R.N.; Barcelos, C.A.; Pereira, N. Potential of giant reed (Arundo donax L.) for second generation ethanol production. Electron. J. Biotechnol. 2015, 18, 10–15. [Google Scholar] [CrossRef]

- Darzins, A.; Pienkos, P.; Edye, L. Current Status and Potential for Algal Biofuels Production; National Renewable Energy Laboratory: Golden, CO, USA, 2010; pp. 1–131.

- International Energy Agency. Algae—The Future for Bioenergy? Summary and Conclusions from the Iea Bioenergy Exco64 Workshop; International Energy Agency: Paris, France, 2010; p. 16. [Google Scholar]

- Sikes, K.; McGill, R.; van Walwijk, M. Algae as a Feedstock for Biofuels: An Assessment of the State of Technology and Opportunities.Final Report; IEA-Advanced Motor Fuels Agreement, Annex 34, Subtask 2 USA; 2011; pp. 1–23. [Google Scholar]

- Diltz, R.; Pullammanappallil, P. Biofuels from algae. In Liquid, Gaseous and Solid Biofuels: Conversion Techniques; Fang, Z., Ed.; InTech Open Access Publisher: Rijeka, Croatia, 2013; pp. 431–449. [Google Scholar]

- Ndimba, B.K.; Ndimba, R.J.; Johnson, T.S.; Waditee-Sirisattha, R.; Baba, M.; Sirisattha, S.; Shiraiwa, Y.; Agrawal, G.K.; Rakwal, R. Biofuels as a sustainable energy source: An update of the applications of proteomics in bioenergy crops and algae. J. Proteom. 2013, 93, 234–244. [Google Scholar] [CrossRef] [PubMed]

- Huntley, M.E.; Johnson, Z.I.; Brown, S.L.; Sills, D.L.; Gerber, L.; Archibald, I.; Machesky, S.C.; Granados, J.; Beal, C.; Greene, C.H. Demonstrated large-scale production of marine microalgae for fuels and feed. Algal Res. 2015, 10, 249–265. [Google Scholar] [CrossRef]

- Zhou, W.G.; Chen, P.; Min, M.; Ma, X.C.; Wang, J.H.; Griffith, R.; Hussain, F.; Peng, P.; Xie, Q.L.; Li, Y.; et al. Environment-enhancing algal biofuel production using wastewaters. Renew. Sustain. Energy Rev. 2014, 36, 256–269. [Google Scholar] [CrossRef]

- Kligerman, D.C.; Bouwer, E.J. Prospects for biodiesel production from algae-based wastewater treatment in brazil: A review. Renew. Sustain. Energy Rev. 2015, 52, 1834–1846. [Google Scholar] [CrossRef]

- Hoh, D.; Watson, S.; Kan, E. Algal biofilm reactors for integrated wastewater treatment and biofuel production: A review. Chem. Eng. J. 2016, 287, 466–473. [Google Scholar] [CrossRef]

- Gnansounou, E.; Raman, J.K. Life cycle assessment of algae biodiesel and its co-products. Appl. Energy 2016, 161, 300–308. [Google Scholar] [CrossRef]

- High Level Panel of Experts on Food Security and Nutrition. Biofuels and Food Security; HLPE: Rome, Italy, 2013; pp. 1–131. [Google Scholar]

- Association, R.F. Fueling a Nation Feeding the World. The role of the U.S. Ethanol Industry in Food and Feed Production; Washington, DC, USA, 2014; pp. 1–11. [Google Scholar]

- Wisner, R. November monthly renewable energy report. Distillers grains balance sheet. Agricultural Marketing Resource Center: Ames, Iowa, IA, USA, 2015. [Google Scholar]

- European Commission. Directive 2009/28/ec of the european parliament and of the council of 23 April 2009 on the promotion of the use of energy from renewable sources and amending and subsequently repealing directives 2001/77/ec and 2003/30/ec, (oj l 140/16). In Directive 2009/28/EC; European Commission: Brussels, Belgium, 2009; pp. 16–62. [Google Scholar]

- Organization for Economic Cooperation and Development. Biofuel Support Policies: An Economic Assessment; OECD Publishing: Paris, France, 2008. [Google Scholar]

- Huang, H.X.; Khanna, M.; Onal, H.; Chen, X.G. Stacking low carbon policies on the renewable fuels standard: Economic and greenhouse gas implications. Energy Policy 2013, 56, 5–15. [Google Scholar] [CrossRef]

- Lynd, L.R.; Sow, M.; Chimphango, A.F.A.; Cortez, L.A.B.; Cruz, C.H.B.; Elmissiry, M.; Laser, M.; Mayaki, I.A.; Moraes, M.A.F.D.; Nogueira, L.A.H.; et al. Bioenergy and african transformation. Biotechnol. Biofuels 2015, 8, 18. [Google Scholar] [CrossRef] [PubMed]

- Dale, B.E.; Anderson, J.E.; Brown, R.C.; Csonka, S.; Dale, V.H.; Herwick, G.; Jackson, R.D.; Jordan, N.; Kaffka, S.; Kline, K.L.; et al. Take a closer look: Biofuels can support environmental, economic and social goals. Environ. Sci. Technol. 2014, 48, 7200–7203. [Google Scholar] [CrossRef] [PubMed]

- Trostle, R.; Marti, D.; Rosen, S.; Westcott, P. Why Have Food Commodity Prices Risen Again; Economic Research Service: Washington, DC, USA, 2011; pp. 1–29. [Google Scholar]

- Zhang, W.; Yu, E.A.; Rozelle, S.; Yang, J.; Msangi, S. The impact of biofuel growth on agriculture: Why is the range of estimates so wide? Food Policy 2013, 38, 227–239. [Google Scholar] [CrossRef]

- De Gorter, H.; Drabik, D. Policy update: The effect of biofuel policies on food grain commodity prices. Biofuels 2012, 3, 21–24. [Google Scholar] [CrossRef]

- De Gorter, H.; Drabik, D. Policy update: Biofuel policies and grain crop price volatility. Biofuels 2012, 3, 111–113. [Google Scholar] [CrossRef]

- De Gorter, H.; Drabik, D.; Just, D.R. Biofuel policies and food grain commodity prices 2006–2012: All boom and no bust? AgBioForum 2013, 16, 1–13. [Google Scholar]

- Durham, C.; Davies, G.; Bhattacharyya, T. Can Biofuels Policy Work for Food Security? An Analytical Paper for Discussion; UK Department for Environment, Food and Rural Affairs (DEFRA): Devon, UK, 2012; pp. 1–29.

- Hamelinck, C. Biofuels and Food Security. Risks and Opportunities; ECOFYS: Utrecht, The Netherlands, 2013; pp. 1–23. [Google Scholar]

- Taheripour, F.; Hertel, T.W.; Tyner, W.E.; Beckman, J.F.; Birur, D.K. Biofuels and their by-products: Global economic and environmental implications. Biomass Bioenergy 2010, 34, 278–289. [Google Scholar] [CrossRef]

- Irwin, S.; Good, D. Ethanol production profits: The risk from lower prices of distillers grains. Farmdoc Dly. 2015, 5, 46. [Google Scholar]

- European Commission. Directive 2009/30/ec of the european parliament and of the council of 23 April 2009 amending directive 98/70/ec as regards the specification of petrol, diesel and gas-oil and introducing a mechanism to monitor and reduce greenhouse gas emissions and amending council directive 1999/32/ec as regards the specification of fuel used by inland waterway vessels and repealing directive 93/12/eec. In Directive 2009/30/EC; European Commission: Brussels, Belgium, 2009; pp. 88–113. [Google Scholar]

- OECD/FAO. Agricultural Outlook 2009–2018; Paris, France, 2009; pp. 1–95. [Google Scholar]

- Searchinger, T.; Heimlich, R.; Houghton, R.A.; Dong, F.X.; Elobeid, A.; Fabiosa, J.; Tokgoz, S.; Hayes, D.; Yu, T.H. Use of us croplands for biofuels increases greenhouse gases through emissions from land-use change. Science 2008, 319, 1238–1240. [Google Scholar] [CrossRef] [PubMed]

- Fargione, J.; Hill, J.; Tilman, D.; Polasky, S.; Hawthorne, P. Land clearing and the biofuel carbon debt. Science 2008, 319, 1235–1238. [Google Scholar] [CrossRef] [PubMed]

- Melillo, J.M.; Reilly, J.M.; Kicklighter, D.W.; Gurgel, A.C.; Cronin, T.W.; Paltsev, S.; Felzer, B.S.; Wang, X.D.; Sokolov, A.P.; Schlosser, C.A. Indirect emissions from biofuels: How important? Science 2009, 326, 1397–1399. [Google Scholar] [CrossRef] [PubMed]

- Fritsche, U.R.; Wiegmann, K. Indirect Land Use Change and Biofuels; Directorate General For Internal Policies, Policy Department A: Economic and Scientific Policy Environment, Public Health and Food Safety: Brussels, Belgium, 2011. [Google Scholar]

- Dunn, J.B.; Mueller, S.; Kwon, H.Y.; Wang, M.Q. Land-use change and greenhouse gas emissions from corn and cellulosic ethanol. Biotechnol. Biofuels 2013, 6. [Google Scholar] [CrossRef] [PubMed]

- Babcock, B.A.; Iqbal, Z. Using Recent Land Use Changes to Validate Land Use Change Models; Center for Agricultural and Rural Development: Ames, IA, USA, 2014; pp. 1–34. [Google Scholar]

- Van den Bos, A.; Hamelinck, C. Greenhouse Gas Impact of Marginal Fossil Fuel Use; ECOFYS: Utrecht, The Netherlands, 2014; pp. 1–29. [Google Scholar]

- Wang, M.J.; Dunn, B.; Mueller, S.; Qin, Z.; Tyner, W.; Goodwin, B. Comments on Ethanol’s Broken Promise by the Environmental Working Group (May 2014); Argonne National Laboratory: Argonne, IL, USA, 2014; pp. 1–13.

- Taheripour, F.; Tyner, W.E. Biofuels and land use change: Applying recent evidence to model estimates. Appl. Sci. 2013, 3, 14–38. [Google Scholar] [CrossRef]

- Macedo, M.N.; DeFries, R.S.; Morton, D.C.; Stickler, C.M.; Galford, G.L.; Shimabukuro, Y.E. Decoupling of deforestation and soy production in the southern amazon during the late 2000s. PNAS 2012, 109, 1341–1346. [Google Scholar] [CrossRef] [PubMed]

- Hertel, T.W.; Golub, A.A.; Jones, A.D.; O’Hare, M.; Plevin, R.J.; Kammen, D.M. Effects of us maize ethanol on global land use and greenhouse gas emissions: Estimating market-mediated responses. Bioscience 2010, 60, 223–231. [Google Scholar] [CrossRef]

- Mosnier, A.; Havlik, P.; Valin, H.; Baker, J.; Murray, B.; Feng, S.; Obersteiner, M.; McCarl, B.A.; Rose, S.K.; Schneider, U.A. Alternative us biofuel mandates and global ghg emissions: The role of land use change, crop management and yield growth. Energy Policy 2013, 57, 602–614. [Google Scholar] [CrossRef]

- National Research Council. Renewable Fuel Standard: Potential Economic and Environmental Effects of U.S. Biofuel Policy; The National Academies Press: Washington, DC, USA, 2011; p. 250. [Google Scholar]

- Langeveld, J.W.A.; Dixon, J.; van Keulen, H.; Quist-Wessel, P.M.F. Analyzing the effect of biofuel expansion on land use in major producing countries: Evidence of increased multiple cropping. Biofuel Bioprod. Biorefin. 2014, 8, 49–58. [Google Scholar] [CrossRef]

- International Energy Agency. Technology Roadmap Biofuels for Transport; International Energy Agency: Paris, France, 2011; p. 52. [Google Scholar]

- Croezen, H.; Brouwer, F. Estimating Indirect Land Use Impacts from by-Products Utilization; CE Delft: Delft, The Netherlands, 2008; pp. 1–31. [Google Scholar]

- Becker, E.W. Micro-algae as a source of protein. Biotechnol. Adv. 2007, 25, 207–210. [Google Scholar] [CrossRef] [PubMed]

- Spolaore, P.; Joannis-Cassan, C.; Duran, E.; Isambert, A. Commercial applications of microalgae. J. Biosci. Bioeng. 2006, 101, 87–96. [Google Scholar] [CrossRef] [PubMed]

- Gouveia, L.; Batista, A.P.; Sousa, I.; Raymundo, A.; Bandarra, N.M. Microalgae in novel food products. In Food Chemistry Research Developments; Papadoupoulos, K., Ed.; Nova Science Publishers: New York, NY, USA, 2008; pp. 75–112. [Google Scholar]

- Yap, T.N.; Wu, J.F.; Pond, W.G.; Krook, L. Feasibility of feeding spirulina-maxima, arthrospira-platensis or chlorella sp to pigs weaned to a dry diet at 4 to 8 days of age. Nutr. Rep. Int. 1982, 25, 543–552. [Google Scholar]

- Henman, D.; Australia, R. Evaluation of Algal Meal as an Energy and Protein Source in Pig Diets 4a-102. Report Prepared for the Co-Operative Research Centre for High Integrity Australian Pork; Australian Government’s Cooperative Research Centres: Corowa, New South Wales, Australia, 2012; pp. 1–12. [Google Scholar]

- Kovač, D.J.; Simeunović, J.B.; Babić, O.B.; Mišan, A.Č.; Milovanović, I.L. Algae in food and feed. Food Feed Res. 2013, 40, 21–32. [Google Scholar]

- Milledge, J.J. Commercial application of microalgae other than as biofuels: A brief review. Rev. Environ. Sci. Biotechnol. 2011, 10, 31–41. [Google Scholar] [CrossRef]

- Nelson, K.A.; Motavalli, P.P.; Smoot, R.L. Utility of dried distillers grain as a fertilizer source for corn. J. Agric. Sci. 2009, 1, 3–12. [Google Scholar] [CrossRef]

- Abe, S.S.; Hashimoto, S.; Umezane, T.; Yamaguchi, T.; Yamamoto, S.; Yamada, S.; Endo, T.; Nakata, N. Agronomic and environmental performance of rapeseed oilcake in the lowland rice farming of japan. Commun. Soil Sci. Plant Anal. 2010, 41, 1944–1958. [Google Scholar] [CrossRef]

- Snyder, A.J.; Johnson-Maynard, J.L.; Morra, M.J. Nitrogen mineralization in soil incubated with n-15-labeled brassicaceae seed meals. Appl. Soil Ecol. 2010, 46, 73–80. [Google Scholar] [CrossRef]

- Vivekanandhan, S.; Mohanty, A.; Misra, M.; Zarrinbakhsh, N. Coproducts of biofuel industries in value-added biomaterials uses: A move towards a sustainable bioeconomy. In Liquid, Gaseous and Solid Biofuels: Conversion Techniques; Fang, Z., Ed.; InTech Open Access Publisher: Rijeka, Croatia, 2013; pp. 491–541. [Google Scholar]

- De Corato, U.; Pane, C.; Bruno, G.L.; Cancellara, F.A.; Zaccardelli, M. Co-products from a biofuel production chain in crop disease management: A review. Crop Prot. 2015, 68, 12–26. [Google Scholar] [CrossRef]

| Studies Referring to 2050 | Low Range | High Range |

|---|---|---|

| Smeets et al. [15] | 215 | 1272 |

| IEA Bioenergy [16] | 50 | 1500 |

| Dornburg et al. [17] | 200 | 500 |

| IPPC [18] | 50 | 500 |

| Haberl et al. [19] | 160 | 270 |

| Global Energy Assessment [20] | 80 | 140 |

| Hemi-Cellulose (%) | Cellulose (%) | Lignin (%) | Ashes (%) | References |

|---|---|---|---|---|

| 24.2 | 41.6 | 24.9 | 3.2 | [52] |

| 34.8 | 20.9 | 23.0 | n.d. | [53] |

| 25.61 ± 0.07 | 33.85 ± 0.06 | 24.02 ± 0.04 | 5.04 ± 0.03 | [54] |

| 24.4 ± 0.52 | 39.1 ± 0.25 | 19.2 ± 3.25 | 4.2 ± 0.67 | [55] |

| 14.5 | 39.6 | 24.3 | 5.3 | [56] |

| 35.27 ± 2.80 | 31.10 ± 1.03 | 18.49 ± 0.10 | n.d. | [57] |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Popp, J.; Harangi-Rákos, M.; Gabnai, Z.; Balogh, P.; Antal, G.; Bai, A. Biofuels and Their Co-Products as Livestock Feed: Global Economic and Environmental Implications. Molecules 2016, 21, 285. https://doi.org/10.3390/molecules21030285

Popp J, Harangi-Rákos M, Gabnai Z, Balogh P, Antal G, Bai A. Biofuels and Their Co-Products as Livestock Feed: Global Economic and Environmental Implications. Molecules. 2016; 21(3):285. https://doi.org/10.3390/molecules21030285

Chicago/Turabian StylePopp, József, Mónika Harangi-Rákos, Zoltán Gabnai, Péter Balogh, Gabriella Antal, and Attila Bai. 2016. "Biofuels and Their Co-Products as Livestock Feed: Global Economic and Environmental Implications" Molecules 21, no. 3: 285. https://doi.org/10.3390/molecules21030285

APA StylePopp, J., Harangi-Rákos, M., Gabnai, Z., Balogh, P., Antal, G., & Bai, A. (2016). Biofuels and Their Co-Products as Livestock Feed: Global Economic and Environmental Implications. Molecules, 21(3), 285. https://doi.org/10.3390/molecules21030285