The Effects of Pre-Fermentative Addition of Oenological Tannins on Wine Components and Sensorial Qualities of Red Wine

Abstract

:1. Introduction

2. Results and Discussion

2.1. The Influence of Oenological Tannins on Phenolic Parameters

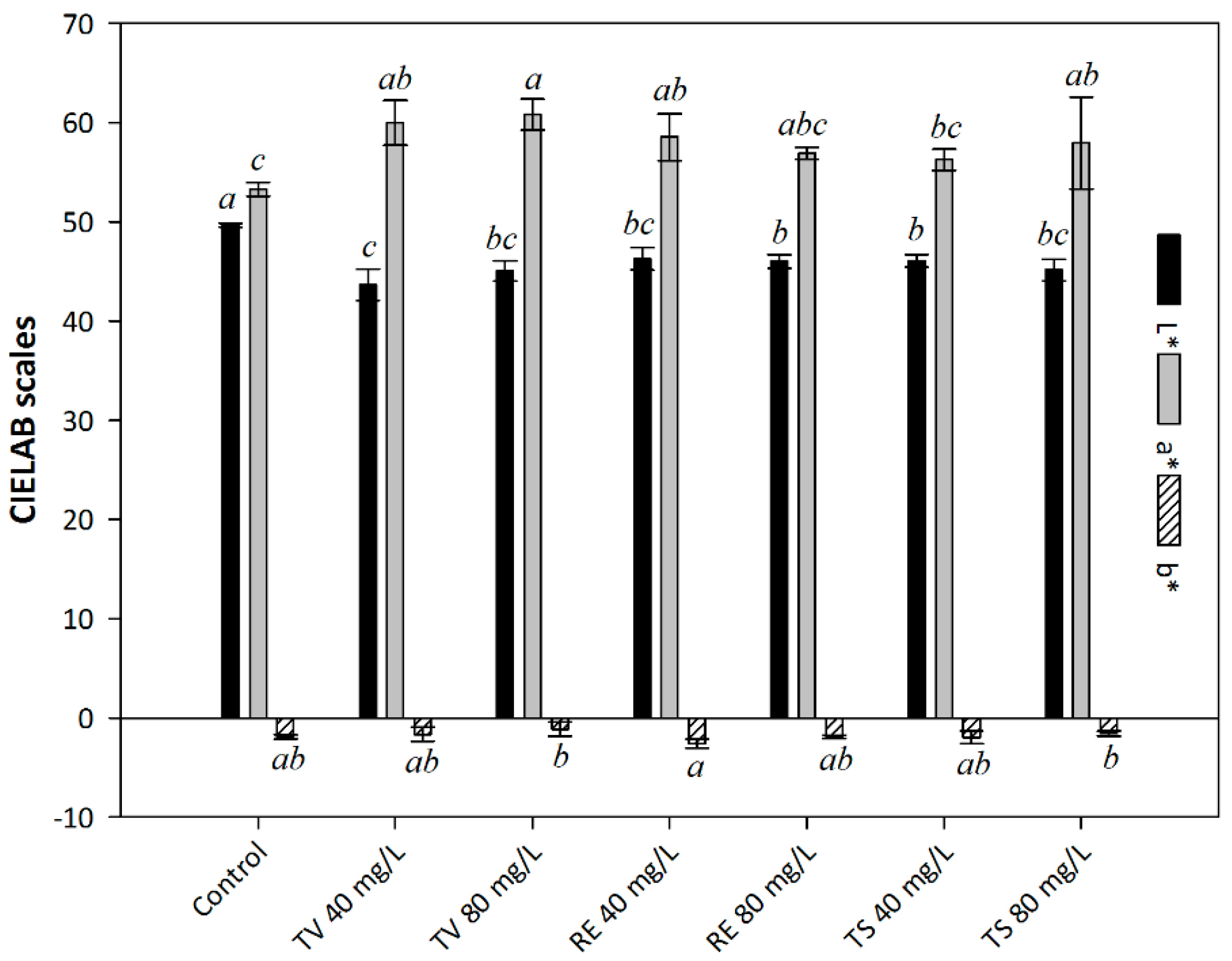

2.2. The Influence of Oenological Tannins on CIELAB Scales

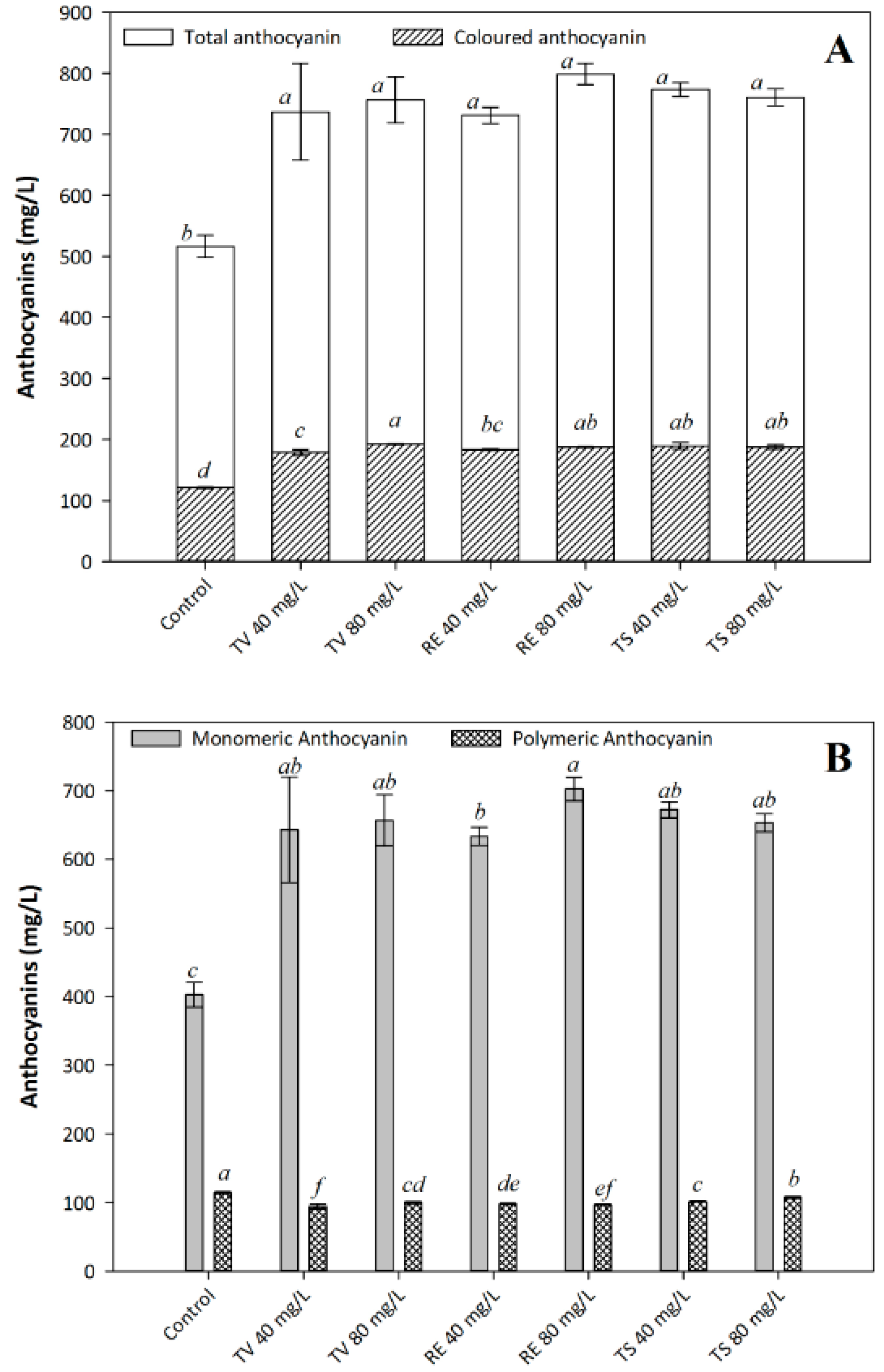

2.3. The Influence of Oenological Tannins on Wine Anthocyanins

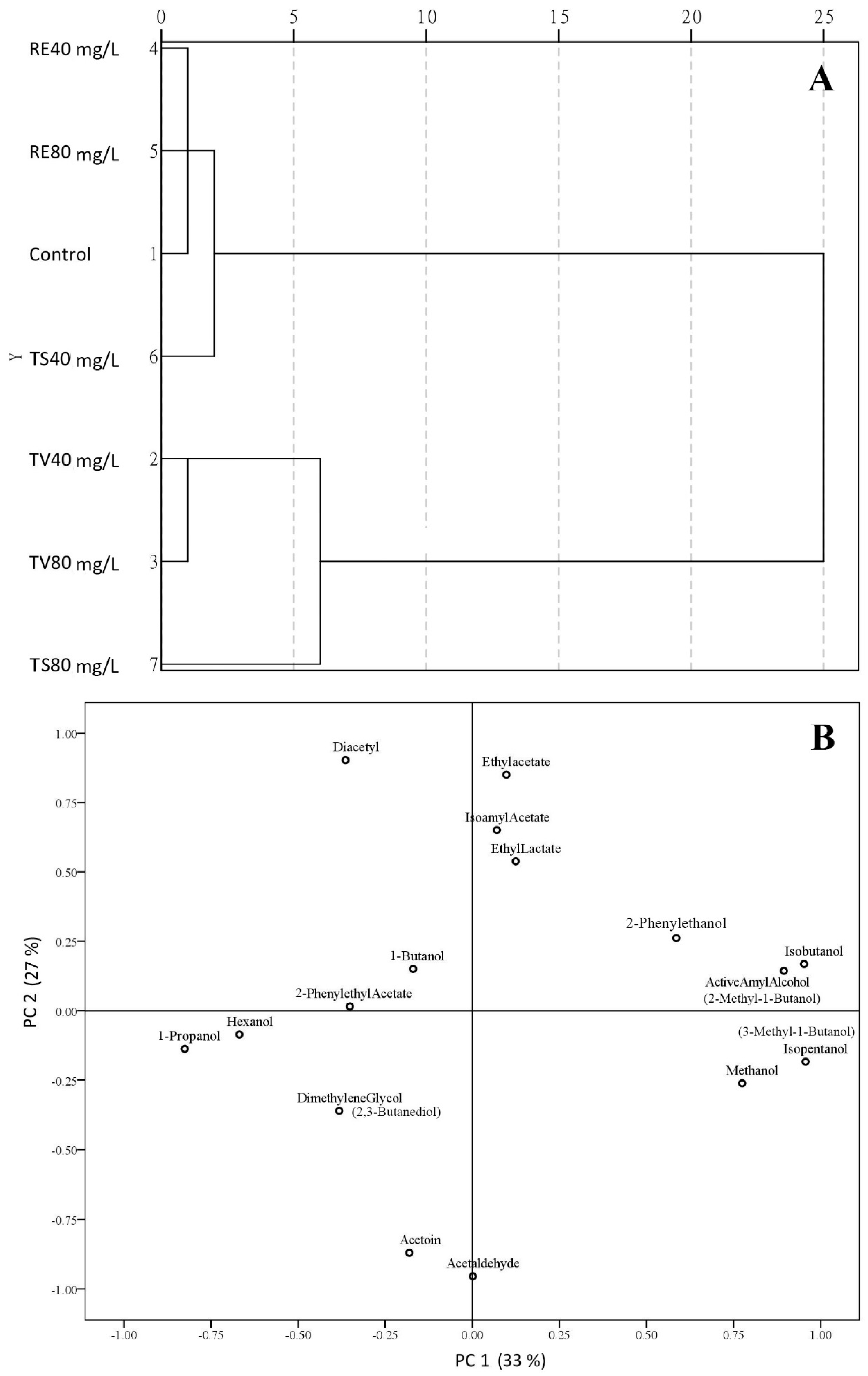

2.4. The Influence of Oenological Tannins on Volatile Compounds

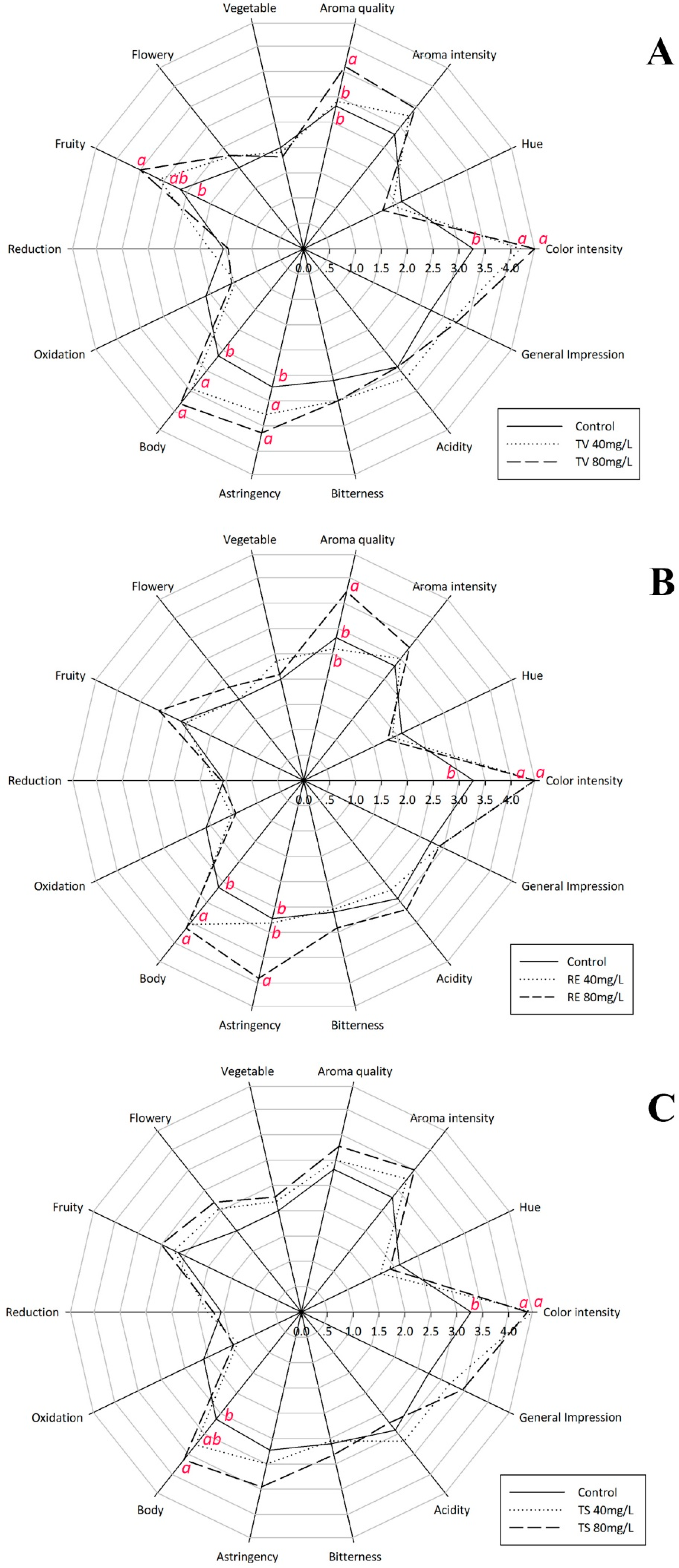

2.5. The Influence of Oenological Tannins on Sensorial Properties

3. Materials and Methods

3.1. Microorganism

3.2. Micro-Vinifications

3.3. Analytical Determinations of Physical-Chemical Parameters

3.4. Analysis of Phenolic Parameters

- Gelatine index, related to the percentage of tannins are able to combine with protein, and mainly used to detect astringent tannins in wine [23].

- PVPP index, polyvinylpolypyrrolidone is a “protein-like” fining agent with an affinity for low molecule weight phenolics, used for binding with and removing smaller phenolic such as catechins, and evaluate wine astringency and colour [24].

- HCL index, the percentage of tannins polymerized with polysaccharides and salts [8].

- Ethanol index, the percentage of tannins that can combine with polysaccharides [8].

- Vanillin index, expressed with mg/L of catechin, which is unstable carbocations that are converted into red condensation products [8].

3.5. Analysis of Wine Anthocyanin Composition and CIELAB Scale

3.6. Analysis of Volatile Compounds

3.7. Anthocyanin Analysis by HPLC/ESI-MS

3.8. Sensory Analysis

3.9. Statistics

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| AF | alcoholic fermentation |

| C3G | cyanidin-3-O-glucoside |

| C3GAc | cyanidin-3-O-(6′′-acetylglucoside) |

| C3GCm | cyanidin-3-O-(6′′-p coumaroylglucoside) |

| CA | cluster analysis |

| D3G | delphinidin-3-O-glucoside |

| M3G | malvidin-3-O-glucoside |

| M3GAc | malvidin-3-O-(6′′-acetylglucoside) |

| M3GCm | malvidin-3-O-(6′′-p-coumaroylglucoside) |

| M3GCmTI | malvidin-3-O-(6''-p-coumaroylglucoside)-trans isomer |

| M3GeC | malvidin-3-O-glucoside-ethyl-(epi)catechin |

| PCA | principal component analysis |

| Pn3G | peonidin-3-O-glucoside |

| Pn3GAc | peonidin-3-O-(6′′-acetylglucoside) |

| Pn3GCm | peonidin-3-O-(6′′-pcoumaroylglucoside) |

| Pt3G | petunidin-3-O-glucoside |

| Pt3GAc | petunidin-3-O-(6′′-acetylglucoside) |

| Pt3GCm | petunidin-3-O-(6′′-pcoumaroylglucoside) |

| PVPP | polyvinylpolypyrrolidone |

| RE | Robletan Estructura |

| TS | Tan Sutil |

| TV | Tanicol Vintage |

| Vit A + Vit B | Vitisin A + Vitisin B |

| Vit A-Ac | Vitisin A-(6′′ acetylglucoside) |

References

- Daudt, C.E.; Fogaça, A.D.O. Phenolic compounds in Merlot wines from two wine regions of Rio Grande do Sul, Brazil. Ciência E Tecnologia De Alimentos 2013, 33, 355–361. [Google Scholar] [CrossRef]

- Kai, C.; Han, S.Y.; Bo, Z.; Min, L.; Sheng, W.J. Development of lysozyme-combined antibacterial system to reduce sulfur dioxide and to stabilize Italian Riesling ice wine during aging process. Food Sci. Nutr. 2015, 3, 453–465. [Google Scholar]

- Chen, K.; Han, S.Y.; Li, M.; Sheng, W.J. Use of Lysozyme and Oligomeric Proanthocyanidin to Reduce Sulfur Dioxide and the Evolution of Volatile Compounds in Italian Riesling Ice Wine During Aging Process. J. Food Proces. Preserv. 2016. [Google Scholar] [CrossRef]

- Benito, Á.; Palomero, F.; Calderón, F.; Benito, S. Quality and Composition of Airen Wines Fermented by Sequential Inoculation of Lachancea thermotolerans and Saccharomyces cerevisiae. Food Technol. Biotechnol. 2015, 542, 135–144. [Google Scholar]

- Benito, S.; Morata, A.; Palomero, F.; González, M.C.; Suárez-Lepe, J.A. Formation of vinylphenolic pyranoanthocyanins by Saccharomyces cerevisiae and Pichia guilliermondii in red wines produced following different fermentation strategies. Food Chem. 2011, 124, 15–23. [Google Scholar] [CrossRef]

- Sonni, F.; Bastante, M.J.C.; Chinnici, F.; Natali, N.; Riponi, C. Replacement of sulfur dioxide by lysozyme and oenological tannins during fermentation: Influence on volatile composition of white wines. J. Sci. Food Agric. 2009, 89, 688–696. [Google Scholar] [CrossRef]

- Sonni, F.; Chinnici, F.; Natali, N.; Riponi, C. Pre-fermentative replacement of sulphur dioxide by lysozyme and oenological tannins: Effect on the formation and evolution of volatile compounds during the bottle storage of white wines. Food Chem. 2011, 129, 1193–1200. [Google Scholar] [CrossRef] [PubMed]

- Ribereau-Gayon, P.; Glories, Y.; Maujean, A.; Dubourdieu, D.; Ribéreau-Gayon, P.; Glories, Y.; Maujean, A.; Dubourdieu, D. The chemistry of wine stabilization and treatments. In Handbook of Enology; John Wiley & Sons Ltd.: Southern Gate, Chichester, UK, 2006; Volume 2. [Google Scholar]

- Saucier, C.; Lopes, P.; Mirabel, M.; Guerra, C.; Glories, Y. Tannin—Anthocyanin Interactions: Influence on Wine Color. Palabra Clave 2004, 2, 35–50. [Google Scholar]

- Carvalho, M.J.; Pereira, V.; Pereira, A.C.; Pinto, J.L.; Marques, J.C. Evaluation of Wine Colour Under Accelerated and Oak-Cask Ageing Using CIELab and Chemometric Approaches. Food Bioprocess Technol. 2015, 8, 2309–2318. [Google Scholar] [CrossRef]

- Clemente-Jimenez, J.M.A.; Mingorance-Cazorla, L.; Martı́Nez-Rodrı́Guez, S.; Rodrı́Guez-Vico, F. Molecular characterization and oenological properties of wine yeasts isolated during spontaneous fermentation of six varieties of grape must. Food Microbiol. 2004, 21, 149–155. [Google Scholar] [CrossRef]

- Dallas, C.; And, R.S.; Laureano, O. Products Formed in Model Wine Solutions Involving Anthocyanins, Procyanidin B2, and Acetaldehyde. J. Agric. Food Chem. 1996, 44, 2402–2407. [Google Scholar] [CrossRef]

- Boulton, R. The Copigmentation of Anthocyanins and Its Role in the Color of Red Wine: A Critical Review. Am. J. Enol. Vitic. 2001, 52, 67–87. [Google Scholar]

- Bo, Z.; Fei, H.; Zhou, P.P.; Yue, L.; Duan, C.Q. The color expression of copigmentation between malvidin-3-O-glucoside and three phenolic aldehydes in model solutions: The effects of pH and molar ratio. Food Chem. 2016, 199, 220–228. [Google Scholar]

- Morata, A.; Loira, I.; Heras, J.M.; Callejo, M.J.; Tesfaye, W.; González, C.; Suárezlepe, J.A. Yeast influence on the formation of stable pigments in red winemaking. Food Chem. 2016, 197, 686–691. [Google Scholar] [CrossRef] [PubMed]

- Mylona, A.E.; Fresno, J.M.D.; Palomero, F.; Loira, I.; Bañuelos, M.A.; Morata, A.; Calderón, F.; Benito, S.; Suárez-Lepe, J.A. Use of Schizosaccharomyces strains for Wine Fermentation—Effect on the Wine Composition and Food Safety. Int. J. Food Microbiol. 2016, 232, 63–72. [Google Scholar] [CrossRef] [PubMed]

- Morata, A.; Gómez-Cordovés, M.C.; Calderón, F.; Suárez, J.A. Effects of pH, temperature and SO2 on the formation of pyranoanthocyanins during red wine fermentation with two species of Saccharomyces. Int. J. Food Microbiol. 2006, 106, 123–129. [Google Scholar] [CrossRef] [PubMed]

- Palomero, F.; Ntanos, K.; Morata, A.; Benito, S.; Suárez-Lepe, J.A. Reduction of wine 4-ethylphenol concentration using lyophilised yeast as a bioadsorbent: Influence on anthocyanin content and chromatic variables. Eur. Food Res. Technol. 2011, 232, 971–977. [Google Scholar] [CrossRef]

- Rustioni, L.; Bedgood, D.R.; Failla, O.; Prenzler, P.D.; Robards, K. Copigmentation and anti-copigmentation in grape extracts studied by spectrophotometry and post-column-reaction HPLC. Food Chem. 2012, 132, 2194–2201. [Google Scholar] [CrossRef]

- Gregan, P.; Battaglene, T. Changes in the regulation of oenological practices to meet consumer demands in our global society. Bulletin de l' OIV 2002, 75, 502–518. [Google Scholar]

- He, F.; Liang, N.N.; Mu, L.; Pan, Q.H.; Wang, J.; Reeves, M.J.; Duan, C.Q. Anthocyanins and Their Variation in Red Wines I. Monomeric Anthocyanins and Their Color Expression. Molecules 2012, 17, 1571–1601. [Google Scholar] [CrossRef] [PubMed]

- Sarni-Manchado, P.; Fulcrand, H.; Souquet, J.M.; Cheynier, V.; Moutounet, M. Stability and Color of Unreported Wine Anthocyanin-derived Pigments. J. Food Sci. 2006, 61, 938–941. [Google Scholar] [CrossRef]

- Oberholster, A.; Carstens, L.M.; Du, T.W. Investigation of the effect of gelatine, egg albumin and cross-flow microfiltration on the phenolic composition of pinotage wine. Food Chem. 2013, 138, 1275–1281. [Google Scholar] [CrossRef] [PubMed]

- Kennedy, J.A. Wine Colour; Woodhead publishing: Oxford, UK, 2010; pp. 73–104. [Google Scholar]

- Han, F.L.; Zhang, W.N.; Pan, Q.H.; Zheng, C.R.; Chen, H.Y.; Duan, C.Q. Principal component regression analysis of the relation between CIELAB color and monomeric anthocyanins in young Cabernet Sauvignon wines. Molecules 2008, 13, 2859–2870. [Google Scholar] [CrossRef] [PubMed]

- Morata, A.; Benito, S.; Loira, I.; Palomero, F.; González, M.C.; Suárez-Lepe, J.A. Formation of pyranoanthocyanins by Schizosaccharomyces pombe during the fermentation of red must. Int. J. Food Microbiol. 2012, 159, 47–53. [Google Scholar] [CrossRef] [PubMed]

- Cowan, M.M. Plant products as antimicrobial agents. Clin. Microbiol. Rev. 1999, 12, 564–582. [Google Scholar] [PubMed]

- Bo, Z.; Rui, L.; Fei, H.; Zhou, P.P.; Duan, C.Q. Copigmentation of malvidin-3-O-glucoside with five hydroxybenzoic acids in red wine model solutions: Experimental and theoretical investigations. Food Chem. 2015, 170, 226–233. [Google Scholar]

- González-Manzano, S.; Dueñas, M.; Rivas-Gonzalo, J.C.; Escribano-Bailón, M.T.; Santos-Buelga, C. Studies on the copigmentation between anthocyanins and flavan-3-ols and their influence in the colour expression of red wine. Food Chem. 2009, 114, 649–656. [Google Scholar] [CrossRef]

- Morata, A.; Calderón, F.; González, M.C.; Gómez-Cordovés, M.C.; Suárez, J.A. Formation of the highly stable pyranoanthocyanins (Vitisins A and B) in red wines by the addition of pyruvic acid and acetaldehyde. Food Chem. 2007, 100, 1144–1152. [Google Scholar] [CrossRef]

- Benito, S.; Palomero, F.; Calderón, F.; Palmero, D.; Suárez-Lepe, J.A. Selection of appropriate Schizosaccharomyces strains for winemaking. Food Microbiol. 2014, 42, 218–224. [Google Scholar] [CrossRef] [PubMed]

- Bimpilas, A.; Panagopoulou, M.; Tsimogiannis, D.; Oreopoulou, V. Anthocyanin copigmentation and color of wine: The effect of naturally obtained hydroxycinnamic acids as cofactors. Food Chem. 2016, 197, 39–46. [Google Scholar] [CrossRef] [PubMed]

- Morata, A.; Gómez-Cordovés, M.C.; Colomo, B.; Suárez, J.A. Cell wall anthocyanin adsorption by different Saccharomyces strains during the fermentation of Vitis vinifera L. cv Graciano grapes. Eur. Food Res. Technol. 2005, 220, 341–346. [Google Scholar] [CrossRef]

- Romano, P.; Fiore, C.; Paraggio, M.; Caruso, M.; Capece, A. Function of yeast species and strains in wine flavour. Int. J. Food Microbiol. 2003, 86, 169–180. [Google Scholar] [CrossRef]

- Duarte, W.F.; Dias, D.R.; Oliveira, J.M.; Vilanova, M.; Teixeira, J.A.; Silva, J.B.A.E.; Schwan, R.F. Raspberry (Rubus idaeus L.) wine: Yeast selection, sensory evaluation and instrumental analysis of volatile and other compounds. Food Res. Int. 2010, 43, 2303–2314. [Google Scholar] [CrossRef]

- Price, G. Flash detente an exciting option for winemakers. Aust. N. Z. Grapegrow. Winemak. 2013, 595, 65–66. [Google Scholar]

- Gil-Muñoz, R.; Gómez-Plaza, E.; Martı́Nez, A.; López-Roca, J.M. Evolution of the CIELAB and other spectrophotometric parameters during wine fermentation. Influence of some pre and post fermentative factors. Food Res. Int. 1997, 30, 699–705. [Google Scholar] [CrossRef]

- Schlesier, K.; Fauhl-Hassek, C.; Forina, M.; Cotea, V.; Kocsi, E.; Schoula, R.; Jaarsveld, F.V.; Wittkowski, R. Characterisation and determination of the geographical origin of wines. Part I: Overview. Eur. Food Res. Technol. 2009, 230, 1–13. [Google Scholar] [CrossRef]

- Sample Availability: Samples of the wines and oenological tannins are available from the authors.

| Phenolic Parameters | Control | TV (40 mg/L) | TV (80 mg/L) | RE (40 mg/L) | RE (80 mg/L) | TS (40 mg/L) | TS (80 mg/L) |

|---|---|---|---|---|---|---|---|

| Total Tannins (g/L) | 2.96 ± 0.10 b | 3.11 ± 0.35 a | 3.04 ± 0.19 b | 3.65 ± 0.29 a | 3.08 ± 0.09 a,b | 3.03 ± 0.24 b | 3.02 ± 0.12 b |

| pH | 3.27 ± 0.03 | 3.40 ±0.01 | 3.33 ± 0.02 | 3.41 ± 0.01 | 3.35 ± 0.03 | 3.32 ± 0.01 | 3.43 ± 0.01 |

| Hue | 0.55 ± 0.02 a | 0.52 ± 0.02 b | 0.51 ± 0.01 b | 0.53 ± 0.01 a,b | 0.54 ± 0.01 a,b | 0.55 ± 0.01 a,b | 0.52 ± 0.04 a,b |

| Colour intensity | 2.38 ± 0.05 d | 2.77 ± 0.01 b | 2.85 ± 0.06 a | 2.71 ± 0.02 c | 2.79 ± 0.00 a,b | 2.76 ± 0.04 b,c | 2.80 ± 0.02 a,b |

| Gelatine index (%) | 66.95 ± 4.83 b,c | 65.56 ± 4.19 b,c | 74.80 ± 1.70 a,b | 64.02 ± 12.68 b,c | 87.31 ± 7.64 a | 75.52 ± 0.48 a,b | 54.08 ± 10.68 c |

| PVPP index (%) | 0.67 ± 0.09 c | 0.91 ± 0.07 a | 0.84 ± 0.06 a,b | 0.77 ± 0.13 b,c | 0.70 ± 0.04 b,c | 0.69 ± 0.03 b,c | 0.80 ± 0.13 a–c |

| HCL index (%) | 17.12 ± 6.24 c | 48.00 ± 26.29 b | 70.66 ± 21.82 a,b | 92.36 ± 4.25 a | 53.44 ± 26.35 b | 93.58 ± 4.68 a | 67.90 ± 22.45 a,b |

| Vanillin Index (g/L of Catechin) | 1.03 ± 0.06 c | 1.05 ± 0.03 c | 1.08 ± 0.04 c | 1.31 ± 0.01 a | 1.20 ± 0.08 b | 1.29 ± 0.09 a,b | 1.36 ± 0.05 a |

| Ethanol index (%) | 91.33 ± 5.23 d | 47.32 ± 17.13 a–c | 27.56 ± 18.08 a | 61.85 ± 13.59 b,c | 58.73 ± 6.65 b,c | 68.13 ± 8.04 c | 41.09 ± 13.96 a,b |

| Total Anthocyanin (mg/L) | 516.6 ± 18.36 b | 737.1 ± 79.13 a | 756.63 ± 37.29 a | 731.43 ± 13.23 a | 798.84 ± 17.46 a | 773.64 ± 11.39 a | 760.41 ± 13.93 a |

| Anthocyanins (mg/L) | [M]+ (m/z) | Fragments (m/z) | Control | TV (40 mg/L) | TV (80 mg/L) | RE (40 mg/L) | RE (80 mg/L) | TS (40 mg/L) | TS (80 mg/L) |

|---|---|---|---|---|---|---|---|---|---|

| D3G | 465 | 303 | 16.58 ± 0.69 b | 45.07 ± 2.77 a | 48.21 ± 2.38 a | 44.86 ± 3.69 a | 45.92 ± 1.44 a | 46.92 ± 4.62 a | 50.79 ± 4.71 a |

| C3G | 449 | 287 | 0.20 ± 0.04 c | 0.38 ± 0.01 b,c | 0.63 ± 0.12 b | 1.03 ± 0.12 a | 1.19 ± 0.16 a | 0.81 ± 0.06 a | 1.25 ± 0.08 a |

| Pt3G | 479 | 317 | 21.24 ± 2.34 c | 40.11 ± 6.04 b | 48.48 ± 1.62 a | 39.26 ± 1.44 b | 40.75 ± 1.21 b | 49.55 ± 0.30 a | 48.86 ± 4.10 a |

| Pn3G | 463 | 301 | 6.88 ± 2.10 b,c | 6.99 ± 1.13 b,c | 5.07 ± 0.69 c | 11.00 ± 0.20 a | 11.96 ± 0.46 a | 8.38 ± 0.44 b | 12.12 ± 0.33 a |

| M3G | 493 | 331 | 113.86 ± 4.30 b | 238.79 ± 20.62 a | 247.79 ± 9.99 a | 225.65 ± 10.83 a | 228.03 ± 6.02 a | 238.82 ± 4.26 a | 232.40 ± 13.99 a |

| Vit A + Vit B | 561/517 | 399/355 | 7.68 ± 1.70 a | 4.28 ± 0.78 b | 4.03 ± 0.37 b | 3.17 ± 0.17 b | 3.74 ± 0.11 b | 8.68 ± 0.07 a | 8.37 ± 0.68 a |

| Vit A-Ac | 603 | 399 | 4.10 ± 0.43 a | 0.77 ± 0.09 b | 0.73 ± 0.01 b,c | 0.66 ± 0.13 b,c | 0.61 ± 0.05 b,c | 0.38 ± 0.01 c,d | 0.15 ± 0.09 d |

| C3GAc | 491 | 287 | 0.99 ± 0.59 a | 0.93 ± 0.08 a | 0.97 ± 0.03 a | 0.92 ± 0.055 a | 0.85 ± 0.03 a | 0.36 ± 0.07 b | 0.86 ± 0.20 a |

| Pt3GAc | 521 | 317 | 2.38 ± 0.20 e | 8.25 ± 0.67 a | 8.16 ± 0.57 a | 5.43 ± 0.29 c | 3.31 ± 0.46 d | 2.39 ± 0.02 e | 6.72 ± 0.54 b |

| M3GeC | 809 | 3.33 ± 1.07 b | 5.21 ± 1.42 a | 6.28 ± 0.86 a | 3.25 ± 0.95 b | 4.70 ± 0.76 b | 6.38 ± 0.77 a | 0.43 ± 0.05 c | |

| Pn3GAc | 505 | 301 | 3.76 ± 0.02 e | 7.69 ± 0.65 c | 7.69 ± 0.25 c | 24.43 ± 1.06 a | 16.54 ± 1.33 b | 5.72 ± 0.49 d | 5.36 ± 0.30 d |

| M3GAc | 535 | 331 | 26.60 ± 1.65 c | 47.20 ± 3.43 b | 50.29 ± 1.64 b | 52.22 ± 5.28 b | 58.924 ± 1.50 a | 61.54 ± 1.48 a | 58.78 ± 5.38 a |

| Pt3GCm | 625 | 317 | 1.61 ± 0.18 c | 3.55 ± 1.28 b | 4.17 ± 0.29 b | ND | ND | 7.93 ± 0.33 a | 6.99 ± 0.93 a |

| Pn3GCm | 609 | 301 | ND | 0.12 ± 0.01 b | 0.13 ± 0.01 b | ND | ND | 37.82 ± 0.61 a | 36.033 ± 4.50 a |

| M3GCm | 639 | 331 | ND | 25.99 ± 2.56 | 28.68 ± 2.03 | ND | ND | ND | ND |

| C3GCm | 595 | 287 | 0.85 ± 0.21 a | ND | ND | ND | ND | 0.23 ± 0.01 b | 0.80 ± 0.09 a |

| M3GCmTI | 639 | 331 | 12.81 ± 0.30 b | ND | ND | 44.86 ± 3.69 a | 18.94 ± 2.48 b | ND | ND |

| Volatile Compounds (mg/L) | LRI § | Control | TV (40 mg/L) | TV (80 mg/L) | RE (40 mg/L) | RE (80 mg/L) | TS (40 mg/L) | TS (80 mg/L) |

|---|---|---|---|---|---|---|---|---|

| Acetaldehyde | 800 | 10.97 ± 2.65 a | 7.99 ± 0.55 c | 8.37 ± 0.10 c | 10.56 ± 0.32 b | 9.94 ± 0.39 b,c | 11.54 ± 0.77 b | 11.61 ± 0.41 b |

| Methanol | 879 | 139.10 ± 9.27 a,b | 142.53 ± 7.44 a | 137.06 ± 3.85 a,b | 132.98 ± 3.15 a,b | 129.96 ± 2.37 b | 129.81 ± 3.10 b | 130.18 ± 2.63 b |

| 1-Propanol | 1069 | 37.66 ± 2.07 a | 30.63 ± 2.36 b | 28.32 ± 0.55 b | 39.54 ± 1.46 a | 36.89 ± 0.67 a | 40.55 ± 3.87 a | 40.62 ± 0.57 a |

| Diacetyl | 1585 | 2.00 ± 0.35 e | 7.30 ± 0.38 d | 7.63 ± 0.24 d | 8.77 ± 0.34 c | 8.79 ± 0.18 c | 9.60 ± 0.43 b | 10.40 ± 0.30 a |

| Ethyl acetate | 834 | 41.87 ± 3.06 b | 54.43 ± 4.46 a | 53.38 ± 3.28 a | 49.41 ± 1.41 a | 52.31 ± 1.60 a | 53.67 ± 0.69 a | 54.83 ± 4.73 a |

| Isobutanol | 1098 | 14.27 ± 1.59 b | 19.58 ± 0.71 a | 19.95 ± 1.15 a | 13.63 ± 0.28 b,c | 13.32 ± 0.25 b,c | 13.19 ± 0.24 b,c | 12.69 ± 0.19 c |

| 1-Butanol | 1173 | 6.57 ± 2.22 | 6.35 ± 2.07 | 7.76 ± 0.55 | 6.18 ± 1.91 | 14.34 ± 12.38 | 7.40 ± 0.30 | 7.29 ± 0.30 |

| Acetoin | 1291 | 11.17 ± 1.44 a | 8.41 ± 0.45 b | 8.58 ± 0.08 b | 8.80 ± 0.01 b | 8.67 ± 0.21 b | 8.99 ± 0.15 b | 9.10 ± 0.15 b |

| Active Amyl Alcohol (2-Methyl-1-Butanol) | 1086 | 120.73 ± 31.38 b | 159.60 ± 5.48 a | 156.78 ± 5.83 a | 119.59 ± 1.60 b | 118.56 ± 1.62 b | 116.08 ± 1.04 b | 114.14 ± 3.25 b |

| Isopentanol (3-Methyl-1-Butanol) | 1208 | 37.51 ± 5.02 b | 42.42 ± 1.78 a | 42.98 ± 2.31 a | 28.47 ± 1.19 c | 28.57 ± 1.09 c | 28.36 ± 0.61 c | 26.34 ± 2.61 c |

| Ethyl lactate | 1363 | 6.17 ± 0.22 b | 6.94 ± 0.65 a,b | 8.22 ± 1.47 a | 6.61 ± 0.24 a,b | 7.07 ± 0.59 a,b | 7.65 ± 1.97 a,b | 7.11 ± 0.27 a,b |

| Dimethylene Glycol (2,3-Butanediol) | 1692 | 367.68 ± 38.62 a | 273.05 ± 53.77 b | 299.53 ± 6.71 b | 382.80 ± 19.68 a | 370.92 ± 6.43 a | 402.08 ± 22.64 a | 241.52 ± 7.36 c |

| Isoamyl acetate | 1123 | 6.79 ± 1.20 b | 9.14 ± 1.44 a,b | 8.99 ± 1.16 a,b | 9.46 ± 0.41 a | 8.72 ± 1.90 a,b | 8.19 ± 1.55 a,b | 9.34 ± 0.43 a |

| Hexanol | 1366 | 3.83 ± 0.17 a | 1.26 ± 2.19 b | 2.53 ± 2.19 a | 3.92 ± 0.33 a | 4.01 ± 0.27 a | 3.83 ± 0.06 a | 4.05 ± 0.12 a |

| 2-Phenylethanol | 1959 | 38.50 ± 8.81 b | 50.68 ± 6.54 a,b | 53.89 ± 9.58 a | 47.37 ± 2.15 a,b | 41.13 ± 7.74 a,b | 38.23 ± 8.33 b | 38.24 ± 7.78 b |

| 2-Phenylethyl acetate | 1850 | 6.18 ± 0.21 | 5.82 ± 0.33 | 5.92 ± 0.44 | 6.66 ± 1.03 | 5.98 ± 0.61 | 6.16 ± 0.55 | 6.93 ± 1.00 |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, K.; Escott, C.; Loira, I.; Del Fresno, J.M.; Morata, A.; Tesfaye, W.; Calderon, F.; Benito, S.; Suárez-Lepe, J.A. The Effects of Pre-Fermentative Addition of Oenological Tannins on Wine Components and Sensorial Qualities of Red Wine. Molecules 2016, 21, 1445. https://doi.org/10.3390/molecules21111445

Chen K, Escott C, Loira I, Del Fresno JM, Morata A, Tesfaye W, Calderon F, Benito S, Suárez-Lepe JA. The Effects of Pre-Fermentative Addition of Oenological Tannins on Wine Components and Sensorial Qualities of Red Wine. Molecules. 2016; 21(11):1445. https://doi.org/10.3390/molecules21111445

Chicago/Turabian StyleChen, Kai, Carlos Escott, Iris Loira, Juan Manuel Del Fresno, Antonio Morata, Wendu Tesfaye, Fernando Calderon, Santiago Benito, and Jose Antonio Suárez-Lepe. 2016. "The Effects of Pre-Fermentative Addition of Oenological Tannins on Wine Components and Sensorial Qualities of Red Wine" Molecules 21, no. 11: 1445. https://doi.org/10.3390/molecules21111445