An Improved System for Utilizing Low-Temperature Waste Heat of Flue Gas from Coal-Fired Power Plants

Abstract

:1. Introduction

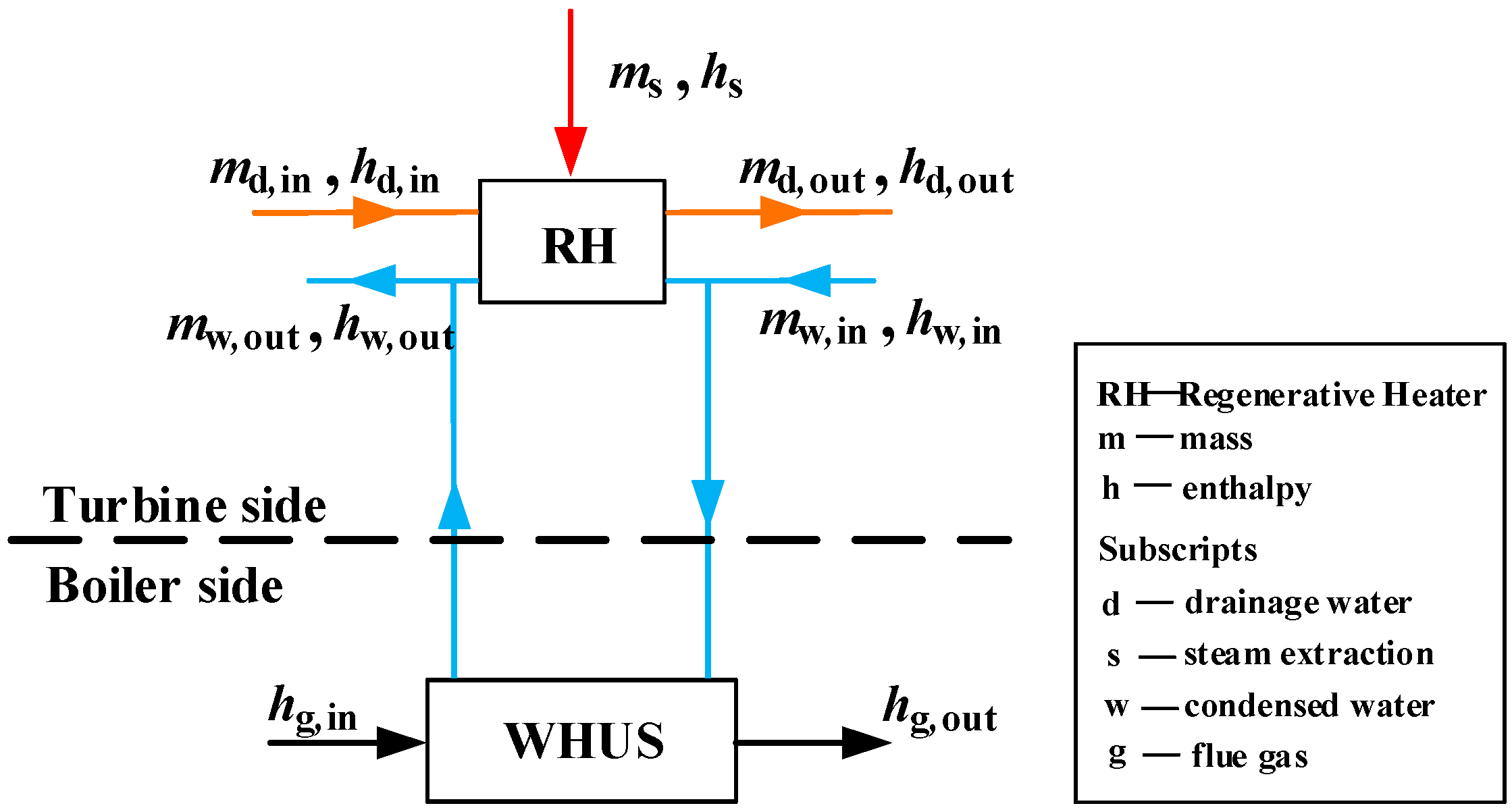

2. Waste Heat Recovery and the Evaluation Criteria

2.1. Thermodynamics of Waste Heat Recovery

2.2. Additional Work

2.3. Heat Rate Reduction

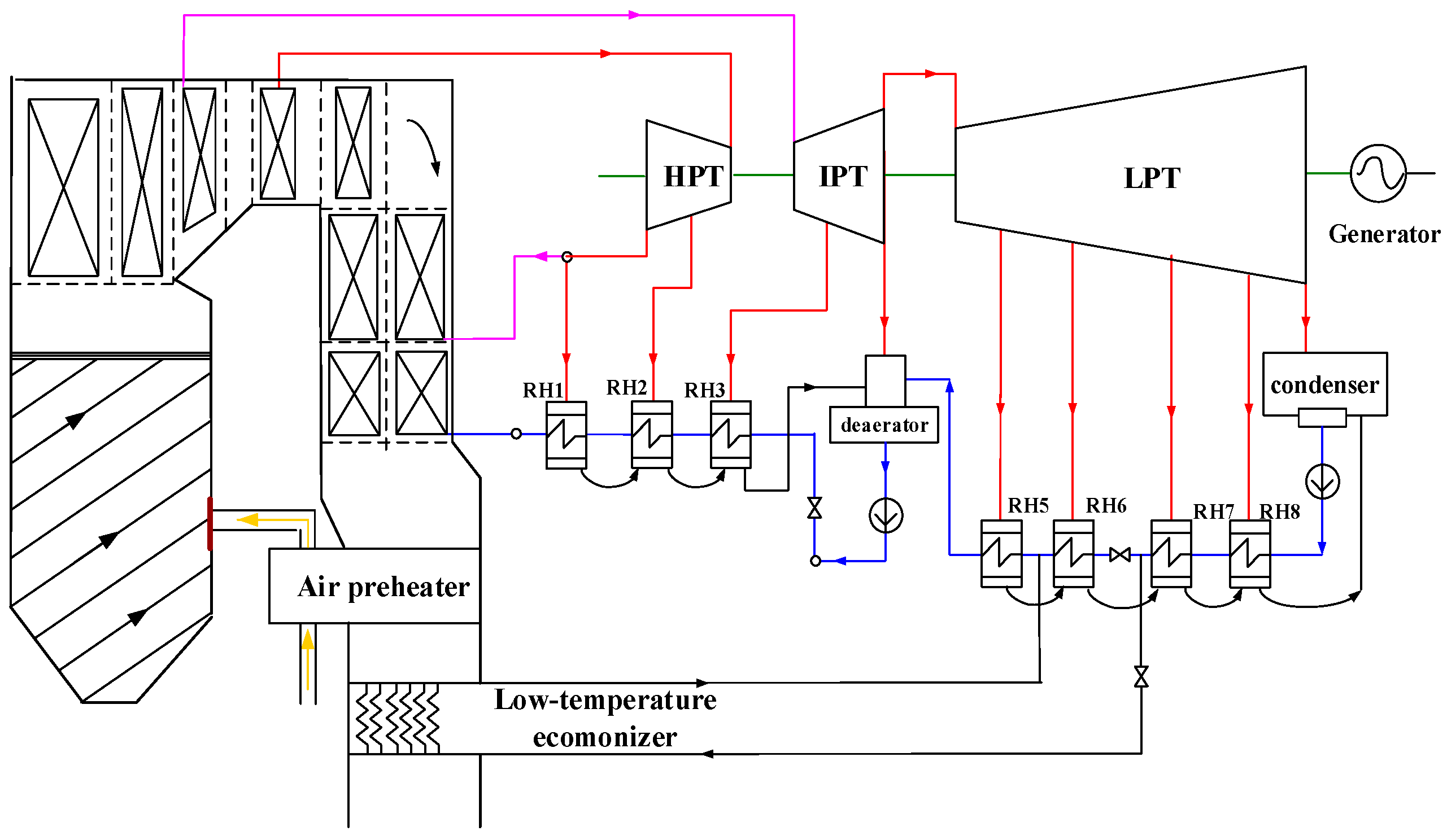

3. Description of Conventional Waste Heat Utilization Systems

3.1. Reference Coal-Fired Power Generation Unit

3.2. Conventional Waste Heat Recovery System

4. Proposal and Performance Analysis of the Improved WHUS

4.1. Description of the Improved WHUS

4.2. Thermodynamic Performance Results

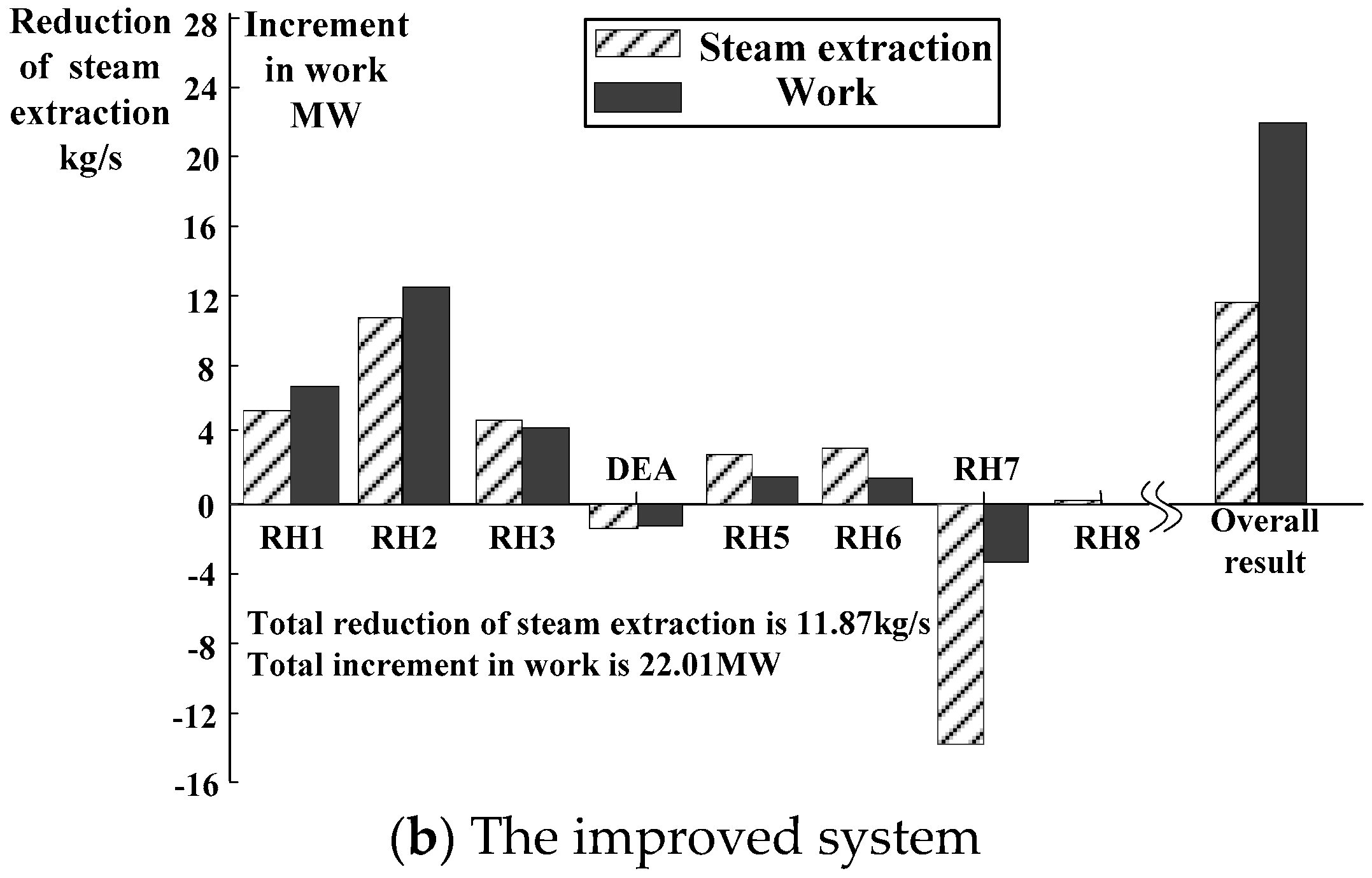

4.3. Variation in the Steam Extraction and Work Output

- In the conventional WHUS, by adopting the LTE, the flue gas with temperatures of 100–131 °C is utilized to heat the condensed water from the inlet of the RH6, as a consequence of which, the sixth-stage steam extraction has a saving of 14.06 kg/s and the power output is increased by 7.37 MW. Meanwhile, it has to be noted that the seventh and eighth-stage steam extractions show a slight increase. This can be mainly attributed to the fact that the reduction in the sixth-stage steam extraction limits the drainage water flowing into RH7 and RH8 accordingly. However, considering the variation in the seventh and eighth-stage steam extractions is relatively small, the resultant power output variation can almost be neglected. In summary, the total steam extraction of the conventional WHUS decreases by 13.12 kg/s whereas the power output increases by 7.15 MW.

- In the improved WHUS, there are obvious changes in the first, second, third, fifth and sixth-stage steam extractions. The reason is that the gas–water heat exchangers arranged in the bypass flue gas duct utilize part of the flue gas cooled from 372 °C down to 131°C to heat the feedwater of RH1–RH3 and the condensed water of RH5–RH6. As a result, the steam extractions of these regenerative heaters reduce considerably. The seventh-stage steam extraction is increased by 13.72 kg/s, which is utilized to preheat the air in the first-stage heat exchanger. Besides, the steam extraction of DEA is increased whereas the eighth-stage steam extraction is reduced; this is because the drainage water flowing into DEA and RH8 is affected by the steam extraction of the prior stage regenerative heater, which will further affect the steam extraction of DEA and RH8. Overall, in the improved WHUS, the total reduction of steam extraction is 11.87 kg/s whereas the power output increases by 22.01 MW.

- In the heat regenerative system, there is a huge working ability difference between the steam extractions from different stages of regenerative heaters. For instance, the working abilities of the first, second, third, fifth and sixth-stage steam extractions are obviously higher than that of the seventh-stage steam extraction. As can be seen from Figure 6, by saving 1 kg steam extraction of RH1, RH2 and RH3, the corresponding additional power outputs are 1.21 MW, 1.15 MW, and 0.94 MW, respectively. Whereas saving 1 kg, sixth-stage steam extraction can only improve the power output by 0.45 MW; as for RH7, the power output is only decreased by 0.25 MW if the steam extraction consumption is increased by 1 kg.

- The overall reductions in the steam extractions of the conventional WHUS and improved WHUS varied slightly (13.12 kg/s vs. 11.87 kg/s). Furthermore, the exhaust flue gas temperature of these two systems is equally set to 100 °C, which means the same amount of waste heat is recovered. Nevertheless, in the conventional WHUS, the flue gas waste heat is used to save the sixth-stage steam extraction, and the results show that its gross work output increment is 7.15 MW. However, the first, second, third, fifth and sixth-stage steam extractions are significantly reduced in the improved WHUS despite the increase in the seventh-stage steam extraction. Finally, the gross work output increment reaches 22.01 MW, which is approximately three times that of the conventional WHUS. In conclusion, with the reasonable utilization of the low-grade energy from both the boiler island and the turbine island, more high-grade steam extraction is saved in the improved WHUS, and better thermodynamic and waste heat recycling performances can be obtained, given that the same amount of waste heat is recovered in the two systems.

5. Exergy Analysis

6. Techno-Economic Analysis

6.1. Estimation of the Total Investment Cost

6.2. Economic Performance Index

7. Conclusions

- In the conventional WHUS, in order to recycle the flue gas waste heat, the LTE is adopted and arranged downstream of the air preheater in the flue gas duct. The inlet flue gas temperature of the LTE is 131 °C, which can replace part of the sixth-stage steam extraction. Combined with the engineering constraints, the heat rate of the power generation unit is only reduced by 42.56 kJ/(kWh). Furthermore, the energy-saving effects are limited.

- In the improved WHUS, the low-temperature heat from both the boiler island and the turbine island is utilized to preheat the air. In this way, the inlet air temperature of the air preheater is increased, and additionally, the saved high temperature flue gas (cooled down from 372 to 131 °C) can be introduced to the bypass flue gas duct to heat the feedwater and the condensed water. Consequently, part of the high-pressure steam extraction is saved, leading to the net power output of the improved WHUS increasing by 19.51 MW, while the heat rate is reduced by 143.35 kJ/(kWh). The energy-saving effects of the improved WHUS are remarkable.

- In the conventional WHUS, the sixth-stage steam extraction is saved, while in the improved WHUS, the first, second, third, fifth and sixth-stage steam extractions are saved. In general, the working ability of the high-pressure steam extraction is much greater than that of the low-pressure steam extraction. Therefore, the resultant energy-saving effects differ distinctly although the total amounts of steam saved by both systems are almost similar.

- For the conventional WHUS, the logarithmic mean temperature difference in the air preheating process reaches 60 °C. However, in the improved WHUS, the logarithmic mean temperature difference is less than 36 °C because the air is successively heated by low-pressure steam extraction and low-temperature flue gas. In this case, the exergy destruction of the air preheating process is reduced by 14.43 MW, which is the main reason for the decrease in the total exergy destruction of the improved WHUS. Ultimately, the exergy efficiency of the improved WHUS improves to 45.46%.

- Techno-economic analysis results show that the total investment of the improved WHUS is USD 8.536 million, which is double when compared to that of the conventional WHUS. However, the net additional power output in the improved WHUS is 19.51 MW, which is over three times that of the conventional WHUS. Consequently, the net annual revenue of the improved WHUS is up to USD 4.741 million per year, which is approximately four times that of the conventional WHUS.

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| WHUS | Waste heat recovery system |

| RH | Regenerative heater |

| LTEs | Low-temperature economizers |

| THA | The design condition |

| HPT | High-pressure turbine |

| IPT | Intermediate-pressure turbine |

| LPT | Low-pressure turbine |

| NAR | The net annual revenue |

| O&M | Operation and maintenance |

Symbols

| Outlet mass flow of water, kg/s | |

| Outlet enthalpy of water, kJ/kg | |

| Inlet mass flow of water, kg/s | |

| Inlet enthalpy of water, kJ/kg | |

| Inlet mass flow of drainage, kg/s | |

| Inlet enthalpy of drainage, kJ/kg | |

| Outlet mass flow of drainage, kg/s | |

| Outlet enthalpy of drainage, kJ/kg | |

| Inlet enthalpy of fuel gas, kJ/kg | |

| Outlet enthalpy of fuel gas, kJ/kg | |

| Recovered heat, kW | |

| amount of suppressed steam extraction, t/h | |

| Additional work output, MW | |

| Increase in auxiliary devices power, MW | |

| D | Volume flow of fuel gas, m3/s |

| Increase in flue gas resistance, kPa | |

| Induced draft fan efficiency, % | |

| Reduction of plant heat rate, kJ/kWh | |

| Net electricity output, MW | |

| Net additional power output, MW | |

| TIC | Total investment capital, million USD |

| EAI | Extra annual income, million USD |

| Size | The size parameters of equipment |

| CE | Price index factor |

| K | Region factor |

| f | Size factor |

| Iinstall | Investment cost for benchmark equipment, Million USD |

| The equivalent operation per year, h/year | |

| On-grid power tariff, USD/kWh | |

| i | Fraction interest rate per year, % |

| n | Number of years |

References

- Yuan, J.H.; Na, C.N.; Lei, Q.; Xiong, M.P.; Guo, J.S.; Hu, Z. Coal use for power generation in China. Resour. Conserv. Recy. 2016. [Google Scholar] [CrossRef]

- Gu, Y.J.; Xu, J.; Chen, D.C.; Wang, Z.; Li, Q.Q. Overall review of peak shaving for coal-fired power units in China. Renew. Sust. Energ. Rev. 2016, 54, 723–731. [Google Scholar] [CrossRef]

- Yang, Y.P.; Yang, Z.P.; Xu, G.; Wang, N.N. Situation and prospect of energy consumption for China’s thermal power generation. Proc. Chin. Soc. Electric. Eng. 2013, 33, 1–11. (In Chinese) [Google Scholar]

- Department of Energy Statistics. China Energy Statistical Yearbook 2011; China Statistics Press: Beijing, China, 2011. (In Chinese)

- Sueyoshi, T.; Goto, M.; Ueno, T. Performance analysis of US coal-fired power plants by measuring three DEA efficiencies. Energy Policy 2010, 38, 1675–1688. [Google Scholar] [CrossRef]

- Beér, J.M. High efficiency electric power generation: The environmental role. Prog. Energy Combust. Sci. 2007, 33, 107–134. [Google Scholar] [CrossRef]

- Wang, L.; Yang, Y.; Dong, C.; Yang, Z.; Xu, G.; Wu, L. Exergoeconomic Evaluation of a Modern Ultra-Supercritical Power Plant. Energies 2012, 5, 3381–3397. [Google Scholar] [CrossRef]

- Wang, L. Thermo-economic evaluation, optimization and synthesis of large-scale coal-fired power plants. Ph.D. Thesis, Technische Universität, Berlin, Germany, 25 August 2016. [Google Scholar]

- Fu, P.; Wang, N.; Wang, L.; Morosuk, T.; Yang, Y.; Tsatsaronis, G. Performance degradation diagnosis of thermal power plants: A method based on advanced exergy analysis. Energy Convers. Manage. 2016, 130, 219–229. [Google Scholar] [CrossRef]

- Wang, L.; Fu, P.; Wang, N.; Morosuk, T.; Yang, Y.; Tsatsaronis, G. Malfunction diagnosis of thermal power plants based on advanced exergy analysis: The case with multiple malfunctions occurring simultaneously. Energy Convers. Manage. 2017, 148, 1453–1467. [Google Scholar] [CrossRef]

- Wang, L.; Yang, Y.; Morosuk, T.; Tsatsaronis, G. Advanced Thermodynamic Analysis and Evaluation of a Supercritical Power Plant. Energies 2012, 5, 1850–1863. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, L.; Dong, C.; Xu, G.; Morosuk, T.; Tsatsaronis, G. Comprehensive exergy-based evaluation and parametric study of a coal-fired ultra-supercritical power plant. Appl. Energy 2013, 112, 1087–1099. [Google Scholar] [CrossRef]

- Wang, L.; Wu, L.; Xu, G.; Dong, C.; Yang, Y. Calculation and analysis of energy consumption interactions in thermal systems of large-scale coal-fired steam power generation units. Proc. Chin. Soc. Electric. Eng. 2012, 32, 9–14. (In Chinese) [Google Scholar]

- Wang, L.; Yang, Y.; Dong, C.; Xu, G. Improvement and primary application of theory of fuel specific consumption. Proc. Chin. Soc. Electric. Eng. 2012, 32, 16–21. (In Chinese) [Google Scholar]

- Wang, L.; Yang, Y.; Dong, C.; Morosuk, T.; Tsatsaronis, G. Systematic Optimization of the Design of Steam Cycles Using MINLP and Differential Evolution. ASME J. Energy Resour. Technol. 2014, 136, 031601. [Google Scholar] [CrossRef]

- Wang, L.; Yang, Y.; Dong, C.; Morozuk, T.; Tsatsaronis, G. Parametric optimization of supercritical coal-fired power plants by MINLP and differential evolution. Energy Convers. Manage. 2014, 85, 828–838. [Google Scholar] [CrossRef]

- Wang, L.; Voll, P.; Lampe, M.; Yang, Y.; Bardow, A. Superstructure-free synthesis and optimization of thermal power plants. Energy 2015, 91, 700–711. [Google Scholar] [CrossRef]

- Wang, L.; Lampe, M.; Voll, P.; Yang, Y.; Bardow, A. Multi-objective superstructure-free synthesis and optimization of thermal power plants. Energy 2016, 116, 1104–1116. [Google Scholar] [CrossRef]

- Han, X.; Yan, J.; Karellas, S.; Liu, M.; Kakaras, E.; Xiao, F. Water extraction from high moisture lignite by means of efficient integration of waste heat and water recovery technologies with flue gas pre-drying system. Appl. Therm. Eng. 2017, 110, 442–456. [Google Scholar] [CrossRef]

- Li, C.; Wang, H. Power cycles for waste heat recovery from medium to high temperature flue gas sources—From a view of thermodynamic optimization. Appl. Energy 2016, 180, 707–721. [Google Scholar] [CrossRef]

- Wang, C.J.; He, B.S.; Sun, S.Y.; Wu, Y.; Yan, N.; Yan, L.B.; Pei, X.H. Application of a low pressure economizer for waste heat recovery from the exhaust flue gas in a 600 MW power plant. Energy 2012, 48, 196–202. [Google Scholar] [CrossRef]

- Wang, C.J.; He, B.S.; Yan, L.B.; Pei, X.H.; Chen, S.N. Thermodynamic analysis of a low-pressure economizer based waste heat recovery system for a coal-fired power plant. Energy 2014, 65, 80–90. [Google Scholar] [CrossRef]

- Espatolero, S.; Cortes, C.; Romeo, L.M. Optimization of boiler cold-end and integration with the steam cycle in supercritical units. Appl. Energy 2010, 87, 1651–1660. [Google Scholar] [CrossRef]

- Chen, Q.; Finney, K.; Li, H.N.; Zhang, X.H.; Zhou, J.; Sharifi, V.; Swithenbank, J. Condensing boiler applications in the process industry. Appl. Energy 2012, 89, 30–36. [Google Scholar] [CrossRef]

- Yang, Y.; Xu, C.; Xu, G.; Han, Y.; Fang, Y.; Zhang, D. A new conceptual cold-end design of boilers for coal-fired power plants with waste heat recovery. Energ. Convers. Manage. 2015, 89, 137–146. [Google Scholar] [CrossRef]

- Xu, G.; Xu, C.; Yang, Y.; Fang, Y.; Li, Y.; Song, X. A novel flue gas waste heat recovery system for coal-fired ultra-supercritical power plants. Appl. Therm. Eng. 2014, 67, 240–249. [Google Scholar] [CrossRef]

- Wang, D.; Bao, A.; Kunc, W.; Liss, W. Coal power plant flue gas waste heat and water recovery. Appl. Energy 2012, 91, 341–348. [Google Scholar] [CrossRef]

- Strömberg, L.; Lindgren, G.; Jacoby, J.; Giering, R.; Anheden, M.; Burchhardt, U.; Altmann, H.; Kluger, F.; Stamatelopoulos, G.N. Update on Vattenfall’s 30 MWth oxyfuel pilot plant in Schwarze Pumpe. Energy Procedia 2009, 1, 581–589. [Google Scholar]

- Xu, G.; Huang, S.W.; Yang, Y.P.; Wu, Y.; Zhang, K.; Xu, C. Techno-economic analysis and optimization of the heat recovery of utility boiler flue gas. Appl. Energy 2013, 112, 907–917. [Google Scholar] [CrossRef]

- Waigaoqiao: World Class in Clean Coal. Available online: https://www.energy.siemens.com/us/pool/hq/energy-topics/living-energy/issue-2/LivingEnergy_Issue2_Cleaner_Coal_in_China.pdf (accessed on 17 August 2017).

- Jin, H.W. Design optimization of 1000 MW ultra supercritical thermal power generating unit. Zhejiang Electr. Power 2012, 7, 38–40. (In Chinese) [Google Scholar]

- Long, H.; Yan, S.; Wang, D. Integrated design technology development of ultra-supercritical unit. Electr. Power Constr. 2011, 32, 71–75. (In Chinese) [Google Scholar]

- Feng, W.Z. Development of China’s supercritical coal fired power generation unit. J. Shanghai Univ. Electr. Power 2011, 27, 417–422. (In Chinese) [Google Scholar]

- Hu, Y.P.; Zhu, B. Power Plant Boiler Handbook; China Electric Power Press: Beijing, China, 2005. (In Chinese) [Google Scholar]

- Shi, X.J.; Che, D.F.; Agnew, B.; Gao, J.M. An investigation of the performance of compact heat exchanger for latent heat recovery from exhaust flue gases. Int. J. Heat Mass Transf. 2011, 54, 606–615. [Google Scholar] [CrossRef]

- Li, Z.C. The analysis of the in-depth utilization of flue gas waste heat in power plant. Wireless Tech. 2013, 6, 84–85. (In Chinese) [Google Scholar]

- Jiang, A.Z.; Wang, G.; Shi, S.Y.; Zheng, S.H. Discussion on Calculation Formulae of Boiler’s Acid Dew-Point Temperature of Gas. Boiler Tech. 2009, 40, 11–13. (In Chinese) [Google Scholar]

| Item | Unit | RH1 | RH2 | RH3 | DEA | RH5 | RH6 | RH7 | RH8 |

|---|---|---|---|---|---|---|---|---|---|

| Temperature of steam extraction | °C | 393.0 | 351.2 | 482.6 | 380.5 | 288.6 | 192.1 | 86.1 | 63.6 |

| Pressure of steam extraction | MPa | 7.26 | 5.39 | 2.29 | 1.11 | 0.56 | 0.23 | 0.06 | 0.02 |

| Temperature of outgoing feedwater | °C | 290.0 | 268.7 | 219.4 | 183.8 | 153.3 | 122.1 | 83.3 | 60.8 |

| Pressure of outgoing feedwater | MPa | 32.70 | 32.80 | 32.90 | 1.09 | 1.29 | 1.34 | 1.39 | 1.44 |

| Temperature of incoming feedwater | °C | 268.7 | 219.4 | 189.9 | 153.3 | 122.1 | 83.3 | 60.8 | 36.2 |

| Pressure of the incoming feedwater | MPa | 32.80 | 32.90 | 33.00 | 1.29 | 1.34 | 1.39 | 1.44 | 1.53 |

| Temperature of the drainage | °C | 274.3 | 225.0 | 195.5 | — | 127.6 | 124.6 | 86.1 | 63.6 |

| Item | Unit | Conventional WHUS |

|---|---|---|

| Inlet flue gas temperature | °C | 131 |

| Outlet flue gas temperature | °C | 100 |

| Inlet condensed water temperature | °C | 83.3 |

| Outlet condensed water temperature | °C | 116 |

| Additional auxiliary power consumption | MW | 1.25 |

| Gross work output | MW | 1007.15 |

| Additional gross work output | MW | 7.15 |

| Net work output | MW | 947.83 |

| Additional net work output | MW | 5.83 |

| Reduction of heat rate | kJ/kWh | 42.56 |

| Item | Unit | High-temperature Gas–water Heat Exchanger | Low-temperature Gas–water Heat Exchanger | First-stage Heat Exchanger | Second-stage Heat Exchanger |

|---|---|---|---|---|---|

| Inlet flue gas | °C | 372 | 204.8 | — | 131 |

| Outlet flue gas | °C | 204.8 | 131 | — | 100 |

| Inlet water/steam | °C | 189.8 | 83.3 | 86.1(1*) | — |

| Outlet water/steam | °C | 290 | 153.3 | 86.1(0*) | — |

| Inlet air | °C | — | — | 25 | 60 |

| Outlet air | °C | — | — | 60 | 100 |

| Logarithmic mean temperature difference | °C | 39.44 | 49.58 | 41.15 | 35.54 |

| Area of heat exchangers | m2 | 30,847 | 12,895 | 15,061 | 29,576 |

| Item | Unit | Conventional WHUS | Improved WHUS |

|---|---|---|---|

| High-temperature gas–water heat exchanger | MW | — | 46.13 |

| Low-temperature gas–water heat exchanger | MW | — | 19.59 |

| Second-stage heat exchanger | MW | — | 34.87 |

| First-stage heat exchanger | MW | — | 30.85 |

| Low-temperature economizer | MW | 34.87 | — |

| Auxiliary power increment | MW | 1.25 | 2.28 |

| Gross work output | MW | 1007.15 | 1022.01 |

| Additional gross work output | MW | 7.15 | 22.01 |

| Net work output | MW | 947.83 | 961.51 |

| Additional net power output | MW | 5.83 | 19.51 |

| Reduction in heat rate | kJ/kWh | 42.56 | 143.35 |

| Items | Conventional WHUS | Improved WHUS | ||

|---|---|---|---|---|

| Unit | MW | % | MW | % |

| Exergy input | ||||

| Fuel input | 2248.06 | 100.00% | 2248.06 | 100.00% |

| Exergy output | ||||

| Gross power output | 1007.15 | 44.80% | 1022.01 | 45.46% |

| Exergy destruction | ||||

| exhaust flue gas | 156.48 | 6.96% | 156.48 | 6.96% |

| Boiler island | ||||

| Air preheater | 26.80 | 1.19% | 5.86 | 0.26% |

| Bypass flue gas duct | — | — | 4.39 | 0.20% |

| Low-temperature economizer | 0.86 | 0.04% | — | — |

| Second-stage heat exchanger | — | — | 3.05 | 0.14% |

| First-stage heat exchanger | — | — | 3.46 | 0.15% |

| Other equipment | 915.92 | 40.74% | 915.92 | 40.74% |

| Total exergy destruction in the boiler island | 943.58 | 41.97% | 932.68 | 41.49% |

| Turbine island | ||||

| Cylinder stator | 66.35 | 2.95% | 66.83 | 2.97% |

| Condenser | 36.38 | 1.62% | 36.37 | 1.62% |

| Regenerative system | 26.09 | 1.16% | 22.12 | 0.98% |

| Other equipment | 12.03 | 0.54% | 11.57 | 0.52% |

| Total exergy destruction in the turbine island | 140.85 | 6.27% | 136.89 | 6.09% |

| Exergy efficiency(%) | 44.80% | 45.46% | ||

| Component | Scaling Parameter | IInstall,b (MS) | Sizeb | fe | GDPd | CEd | Kd | Notes |

|---|---|---|---|---|---|---|---|---|

| Air preheater | Area | 3.82 | 3.395 × 105 m2 | 0.67 | 1 | 1 | 1 | a |

| Heater | Area | 0.693 | 1.315 × 102 m2 | 0.67 | 1 | 1 | 1 | b |

| Pump | Outlet pressure | 0.093 | 80 bar | 0.67 | 1 | 1 | 1 | c |

| Item | Unit | Conventional WHUS | Improved WHUS |

|---|---|---|---|

| Air preheater | million USD | — | 0.632 |

| High-temperature gas–water heat exchanger | million USD | — | 1.227 |

| Low-temperature gas–water heat exchanger | million USD | — | 0.684 |

| Second-stage heat exchanger | million USD | — | 3.416 |

| First-stage heat exchanger | million USD | — | 0.759 |

| Low-temperature economizer | million USD | 2.993 | — |

| Pumps | million USD | 0.093 | 0.279 |

| Pipeline | million USD | 0.154 | 0.35 |

| Engineering cost of installation | million USD | 0.525 | 1.189 |

| Total investment cost | million USD | 3.765 | 8.536 |

| Item | Unit | Conventional WHUS | Improved WHUS |

|---|---|---|---|

| Net additional power output | MW | 5.83 | 19.51 |

| Extra annual income(EAI) | million USD | 1.778 | 5.951 |

| Annualized investment capital cost(CTIC) | million USD | 0.383 | 0.869 |

| Operation & maintenance cost(CO&M) | million USD | 0.151 | 0.341 |

| Net annual revenue(NAR) | million USD | 1.244 | 4.741 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, S.; Li, C.; Tan, T.; Fu, P.; Xu, G.; Yang, Y. An Improved System for Utilizing Low-Temperature Waste Heat of Flue Gas from Coal-Fired Power Plants. Entropy 2017, 19, 423. https://doi.org/10.3390/e19080423

Huang S, Li C, Tan T, Fu P, Xu G, Yang Y. An Improved System for Utilizing Low-Temperature Waste Heat of Flue Gas from Coal-Fired Power Plants. Entropy. 2017; 19(8):423. https://doi.org/10.3390/e19080423

Chicago/Turabian StyleHuang, Shengwei, Chengzhou Li, Tianyu Tan, Peng Fu, Gang Xu, and Yongping Yang. 2017. "An Improved System for Utilizing Low-Temperature Waste Heat of Flue Gas from Coal-Fired Power Plants" Entropy 19, no. 8: 423. https://doi.org/10.3390/e19080423