1. Introduction

Today, thermoacoustic engines, coolers, and heat pumps are receiving more industrial interest. While thermoacoustic engines utilize heat to generate acoustic power, the thermoacoustic refrigerators consume the acoustic power to transfer heat from the cold reservoir. In general, there are two basic types of thermoacoustic systems: standing-wave [

1] and travelling-wave [

2] systems. Thermoacoustic systems have three distinct advantages: first, they have no moving parts and are simple in structure, have low manufacturing costs, and are highly reliable. Further, they are environmentally friendly due to the usage of inert gases as the working fluid. Additionally, heat-driven thermoacoustic devices can be driven by low quality energy sources such as waste heat and solar energy.

The main components of a thermoacoustic device are the stack/regenerators and the two heat exchangers (HXs) that are placed at both ends of the stack/regenerators in an acoustic network. Although steady flow heat exchangers are a mature technology, their design is of key importance in commercialization of thermoacoustic devices where the flow is oscillatory.

All engines and refrigerators must reject waste heat to the ambient temperature where the ambient heat sink is often available as a flowing water stream. Similarly, engines must also accept heat from a heat source at a higher temperature (i.e., burner, waste heat, solar energy, etc.).

The efficiency of thermoacoustic engines is defined as the ratio of produced acoustic power to the heat received by the system [

3]. However, irreversible dissipation of acoustic power in different components of thermoacoustic engines due to the viscous and thermal relaxation losses is the main source for performance degradation. Two highly dissipative components of thermoacoustic engines are the regenerators/stacks and the heat exchangers. These components have recently been the subject of many studies for system performance optimization. Wu et al. [

4] presented a generalized heat transfer model using a complex heat transfer exponent to optimize the performance of a thermoacoustic engine. Zhibin and Jaworski [

5] studied the role of configuration and geometrical dimensions of a regenerator on the acoustic power dissipation. The irreversibility of the porous thermoacoustic stacks in terms of entropy generation is analyzed by Tasnim et al. [

6] Chaitou and Nika [

7] considered the dependence of acoustic energy on parameters such as stack’s hydraulic radius and stack position.

As pointed out, an optimum design of TAHXs is a critical and challenging task for commercialization of thermoacoustic devices. The relationship between the acoustic energy dissipation, the heat exchanger geometry as well as the operating conditions is of significant importance. In general, while different parallel plate, finned-tube, and shell-and-tube HXs configurations are commonly used, the present knowledge of acoustic energy dissipation in TAHXs is relatively limited. It should be emphasized that designing efficient TAHXs in terms of the required heat transfer rate, in addition to low acoustic energy dissipation, remains a challenge.

Ishikawa and Hobson [

8] derived an analytical expression of the time averaged entropy generation in parallel plate HXs. Piccolo [

9,

10] developed a computational model for studying the entropy generation characteristics of TAHXs with plane fins of a standing-wave thermoacoustic device. Previous studies focused mostly on parallel plate and finned-tube HXs.

It should be pointed out that, in case of high-capacity refrigerators and engines, the thermal conductivity of solids is insufficient to carry the required heats without significant temperature differences; hence, advanced and likely complex heat exchangers have to be used to interweave the process fluid and the working gas, bringing them into intimate thermal contact. A shell-and-tube heat exchanger system is the classical approach [

11].

The present paper is focused on the shell-and-tube heat exchanger design of thermoacoustic systems and will investigate the relationship between the acoustic energy dissipation, viscous loss, thermal relaxation loss, and heat exchanger geometry. Much of the motivation behind the current work is driven by the interest as to whether there is a theoretical “optimum” of these parameters and/or the optimum of their combination for a specific operating point. Second, and more generally, the current research attempts to develop a simple but constructive methodology for comparison and evaluation of related heat exchangers at different operating conditions.

In this work, the heat exchangers are considered in the travelling-wave mode with ideal gases based on linear thermoacoustic theory. In this regard, heat exchangers with different geometries are investigated numerically and compared to each other. The dependence of the acoustic power dissipation on heat exchanger metal temperature and drive ratio for a fixed value of heat transfer rate is examined.

2. Theoretical Analysis

2.1. Thermal Modeling of Heat Exchangers

For heat transfer analysis, a local heat transfer coefficient is defined as the ratio of the heat transfer per unit area to the temperature difference between the surface and “bulk” fluid adjacent to the surface. However, in practice, a global heat transfer coefficient derived from a lumped analysis of the heat exchanger (UA-LMTD or effectiveness-NTU methods) is utilized [

12].

The surface area,

, of the heat exchanger is expressed as

where

is the heat transfer rate,

denotes the log-mean temperature and

is the overall heat transfer coefficient (W·m

−2·K

−1).

In the above equation, log-mean temperature difference model is used for thermal modeling of the shell-and-tube heat exchanger operating in the unsteady flow. The log-mean temperature difference for thermoacoustic shell-and-tube heat exchangers is formulated as follows:

where

is the gas mean temperature,

and

are the water inlet and outlet temperature, respectively.

In general, a shell-and-tube heat exchanger is considered with gas flowing through the tubes and water flowing over the tubes. The heat transfer in the heat exchanger involves the thermal resistance consisting of three parts: the resistance for heat transfer from the gas to the tube wall, the thermal resistance of the tube, and the resistance for heat transfer from the tube to the water. Therefore, the overall heat transfer coefficient is estimated based on the tube inner diameter according to

where

and

are the outside and inside tube diameters;

and

are the tube and shell-side heat transfer coefficient, respectively. Further,

is the thermal conductivity of the tube. The shell-side heat transfer coefficient for water,

, may be recalled from classical heat exchanger textbooks, such as [

12].

It should be pointed out that, for most thermoacoustic-related investigations, the heat transfer from the oscillatory gas to the heat exchanger inner surface area is mainly considered. In other words, the heat transfer across the tube wall and then further to the water is usually embedded. Thus, Equation (1) might be rewritten for heat transfer from the oscillatory gas to the tube wall as follows

where

is the temperature of the tube wall at the gas side. This temperature is noted as the HX metal temperature in DeltaEC [

13] and also as solid temperature in some TA studies [

8,

10]. Focusing on the heat transfer in oscillatory gas and employing

instead of

aids to eliminate the shell side parameters like the tube thickness, tube length and tube pitch which have a negligible influence on the acoustic energy dissipation.

The surface area,

, of a shell-and-tube heat exchanger is given as

where

is the number of tubes and

is the length of the tubes.

is calculated according to heat transfer Equation (4).

Thermoacoustic Considerations

It is important to recognize that the problem of heat transfer from an acoustically oscillating gas medium to a solid surface is fundamentally different from that addressed in most discussions of compact heat exchangers that are based on steady unidirectional flow of fluid through the tubes of the heat exchanger. Indeed, TAHXs are distinguished by an oscillatory flow with zero mean velocity and this circumstance has two important implications [

14].

The most significant difference between classical HXs and TAHXs is the acoustically oscillating gas parcels which only move a limited distance before reversing their direction of flow. The consequence of their periodic flow reversal is that one cannot arbitrarily increase the length of the heat exchange surfaces (tubes) in the direction of the flow to increase the effective surface area available for heat transfer. Thus, the optimum length, , of the heat exchanger should be of the order of the peak-to-peak displacement of the working gas acoustic displacement amplitude.

Another important aspect of TAHXs is that conventional steady flow heat transfer correlations cannot be directly applied for the estimation of the convective heat transfer coefficient, , between the gas and the solid wall of TAHXs. Different approaches are currently proposed to overcome this limitation.

Swift [

3,

15] and Garrett [

14] suggest an approximate estimation of heat transfer coefficient on the basis of a simple “boundary layer conduction heat transfer” model given as

and

for shell-and-tube heat exchangers. The thermal conductivity of the gas is denoted by

and

is the thermal penetration depth—that is, the distance through which heat will diffuse in an acoustic cycle.

Mozurkewich [

16], Peak et al. [

17], Nsofar et al. [

18] and Kamsanam et al. [

19] also developed different numerical and experimental models of

for mostly parallel plate and finned-tube TAHXs. However, for shell-and-tube TAHXs, correlations of heat transfer coefficient are still limited. In this regard, Swift’s model [

15] appears to be a sound approximation of

for oscillatory flow in shell-and-tube HXs especially when the flow in the tubes is laminar.

The tube side acoustic Reynolds number can be evaluated as follows

where

is the hydraulic diameter of the tube.

2.2. Acoustic Energy in TAHXs

According to the linear thermoacoustic theory [

1,

3], wave propagation in TAHXs is calculated using

where

and

are oscillating volume velocity and pressure, respectively.

is the cross-sectional area of gas channels in the heat exchanger.

and

are spatially averaged thermoviscous functions and are given in [

1,

3] in detail. It should be pointed out that, in this paper, thermoviscous functions for cylindrical geometry is considered for shell-and-tube TAHXs.

,

,

and

are the ratio of specific heat capacities, sound speed, correction factor for finite solid heat capacity, and mean density of the working gas, respectively.

Furthermore,

is expressed as

The time averaged acoustic power

produced in a length

of the channel is given in complex notation in the general form as

Here, the tilde, “~”, indicates a complex conjugation. Subscript 2 indicates the second order quantity and Re denotes the real part of the complex number.

Substituting Equations (10) and (11) into Equation (13), one obtain as [

3]:

In the above equation, the viscous resistance per unit length of the channel,

, the thermal relaxation conductance per unit length of the channel,

, and the complex gain/attenuation constant for the volume flow rate,

, are defined as follows:

and

Here, , and are the Prandtl number, mean pressure, and mean temperature of the working gas, respectively.

On the right hand side of Equation (14), regardless of the temperature gradient along the length of the channel, the first two terms represent viscous and thermal-relaxation dissipation, which always consume acoustic power. The third term denotes the acoustic power produced (or consumed) by the channel due to the axial temperature gradient depending on the magnitude and direction of the axial temperature gradient.

In TAHXs, it is mostly assumed that the length of the heat exchanger is short; therefore, remains constant and there is no axial temperature gradient (), so the third term vanishes. Therefore, it will be more convenient to refer to as a “net” time averaged acoustic power dissipated per unit length of the heat exchanger due to viscous and thermal relaxation loss (the first two terms of the RHS of Equation (14)).

To calculate the acoustic power dissipated in the heat exchanger,

is integrated over the length of the heat exchanger. Thus,

is written as

where

and

represent viscous and thermal dissipation of acoustic power in the heat exchanger, respectively.

For shell-and-tube heat exchangers, replacing

with

in Equations (18) and (19), one may rewrite

and

as follows

3. Results and Discussion

In this paper, is used as an evaluation index for TAHXs. However, it is also important to understand both and which provide an estimation of the total dissipation if integrated together. Therefore, for shell-and-tube heat exchangers, both and , are numerically determined. The normalized tube diameter, , is used for the analysis. All calculations are performed for helium as the working fluid ( = 2/3, = 5/3).

According to Equations (1) and (21), the knowledge of heat transfer rate (

), gas mean temperature (

), TAHX metal temperature (

), and

(which is equal to

in this paper) are required for numerical analysis. The gas mean temperature is determined in the design process of thermoacoustic systems. For example, in Backhaus and Swift’s travelling-wave engine [

2], the heat load of the ambient heat exchanger is 1614 W, the

of the heat exchanger is 20 mm, and the gas mean temperature is 319 K at the middle of HX. The operating frequency is 84 Hz with helium at a mean pressure of 3.1 MPa as the working gas. In addition, the HX material is stainless steel. Parameters of the TAHX and the working conditions are presented in

Table 1. In this paper, for the purpose of comparison of the proposed model, the experimental results of the shell-and-tube HX of Backhaus and Swift’s thermoacoustic Stirling heat engine (TASHE) [

2] is considered.

In the following sections, the analysis of acoustic energy in shell-and-tube HXs is presented. The TAHXs are considered with a fixed value of heat load. Further, the impact of the geometry configuration (), the TAHX metal temperature (), and the drive ratio (DR) on the acoustic energy dissipation is examined. The optimum value of as a function of the drive ratio at various is determined. Changes on the acoustic energy dissipation due to the geometry is investigated for different values of . The effect of on the heat exchanger geometry as well as the acoustic energy dissipation is assessed. Moreover, the impact of the drive ratio as an important design parameter is discussed.

The validation of the model is performed by comparing the numerical predictions of the present model with the experimental results of TASHE’s shell-and-tube HX [

2]. The results are shown in

Table 2. As illustrated, regarding the design conditions presented in

Table 1, the proposed model can design a shell-and-tube HX and predict the acoustic power dissipated in the HX with good accuracy compared to the shell-and-tube HX of TASHE [

2].

3.1. Variation of Acoustic Energy Dissipation due to Geometry Configuration

The impact of the geometry on acoustic energy dissipation, both viscous and thermal losses, is examined. It should be pointed out that at any of interest, heat exchangers with different configurations (different tube diameters and tube numbers) are designed with maintaining the surface area as constant. Moreover, each configuration can transfer the specified heat load, at the designed with different value of dissipation of acoustic energy.

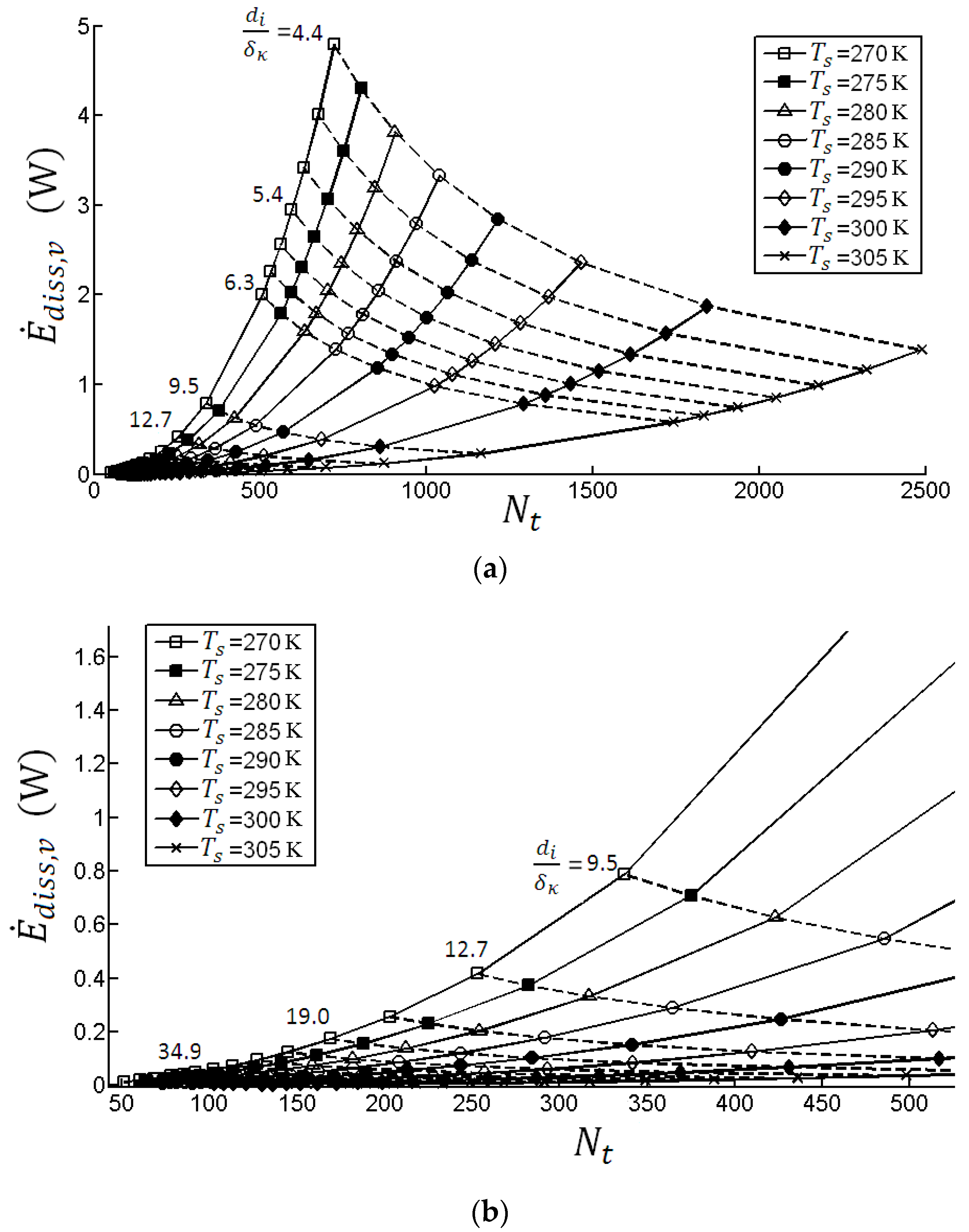

Figure 1 shows

for the designed shell-and-tube heat exchanger as a function of number of tubes at various

, ranging from 270 K to 305 K, for normalized tube diameters

. It can be seen by inspection that, for a fixed

, viscous dissipation decreases with increasing

and requiring less number of tubes.

One may state that at any , the growth of viscous dissipation for heat exchangers with more narrow tubes is associated with the increase of the cross-sectional area of the gas channels in the heat exchanger () while the heat transfer area () is kept constant for the specified heat load. Indeed, when the tube diameter decreases in the heat exchanger, the number of the tubes has to be increased to keep the surface area unchanged. However, this triggers a decrease of the which further leads to an increase of the viscous resistance. This is in agreement with Equation (21).

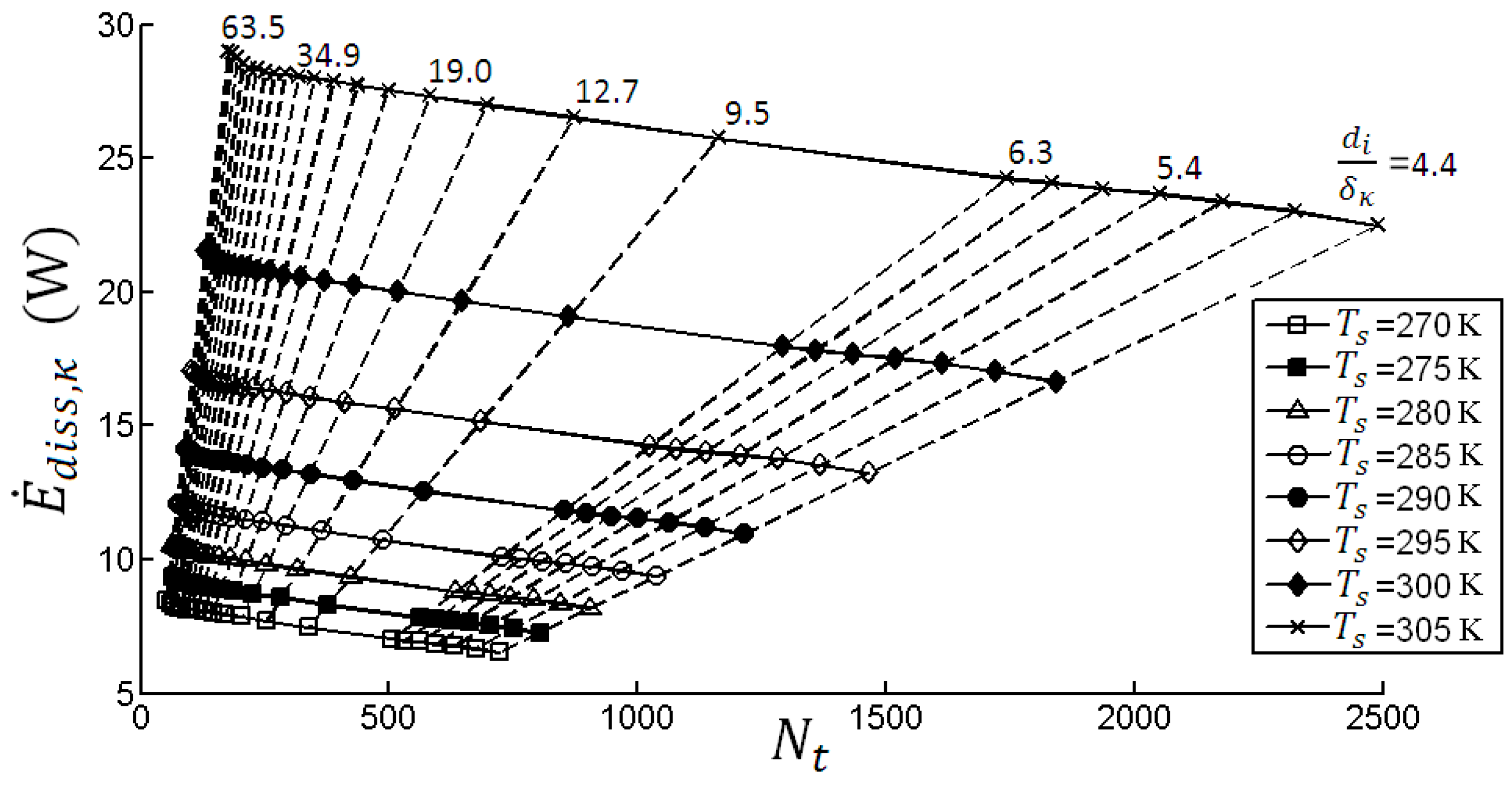

A simulation on

analogous to that of

in

Figure 1 is performed. The results are demonstrated in

Figure 2. It is evident that

has a different behavior than

. At constant

, an increase of normalized tube diameter

has an increasing impact on the thermal dissipation of acoustic power.

Considering the different behaviors of

and

, while viscous dissipation decreases with increasing

, thermal relaxation dissipation decreases. A further investigation is made on the impact of the geometric parameters of HXs on the total acoustic energy dissipation.

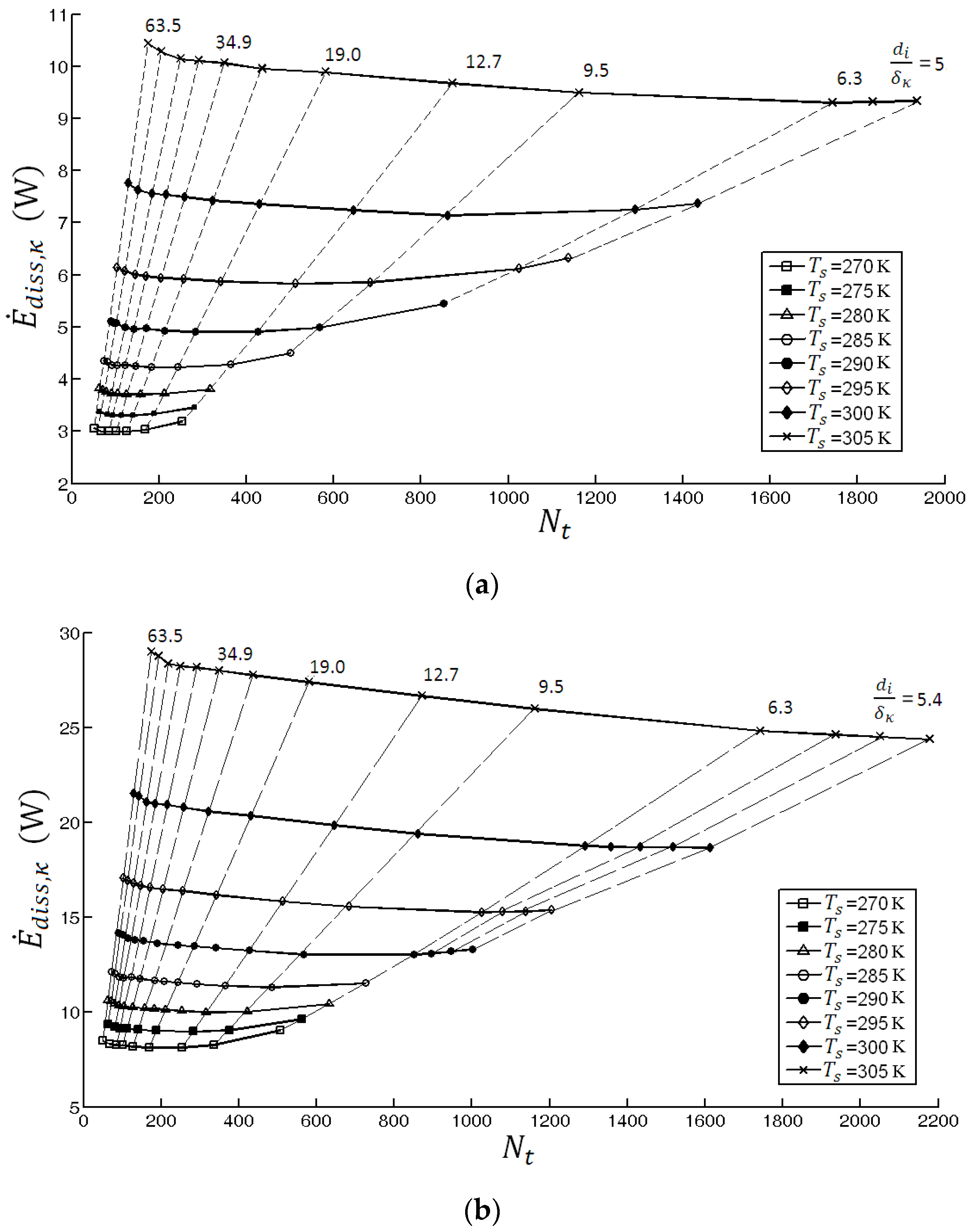

Figure 3 illustrates the total acoustic energy dissipation

—that is, the combined

and

—as a function of number of tubes at various

for normalized tube diameter

.

A close inspection of the results presented in

Figure 3b indicates the existence of a configuration for which the total dissipation,

, becomes a minimum,

. The corresponding normalized tube diameters

is referred to

. In fact, the strong dependence of acoustic energy dissipation on both the number and diameter of the tubes suggests that minimization in acoustic energy dissipation can constitute an effective design criteria to choose the optimal configuration of TAHXs for the given conditions. The optimal TAHXs configuration in correspondence with different operating conditions is presented in

Table 3 and

Table 4. In fact,

Table 3 and

Table 4 are illustrating the shell-and-tube HXs with minimum acoustic energy dissipation

at different

values for drive ratios DR = 0.06 and DR = 0.1, respectively.

Furthermore, it should be mentioned that the weight of viscous and thermal relaxation losses on the total acoustic energy dissipation is different; thermal relaxation plays the dominant role especially at higher

values. A close inspection of

Figure 3b reveals that at high

values the thermal dissipation of acoustic power is much more than the viscous dissipation; thus, an optimum configuration for which

becomes a minimum is not available.

Moreover, considering that is related to the total time averaged acoustic power dissipation of the heat exchanger, one may state that both the HX metal temperature as well as the drive ratio significantly influence the acoustic power dissipation of shell-and-tube HXs in the travelling-wave engines. The dependence of acoustic energy dissipation on HX metal temperature and the drive ratio are discussed in the following sections.

3.2. The Influence of on Acoustic Energy Dissipation

The influence of

on acoustic energy dissipation is further examined. While the viscous dissipation decreases with

, the thermal relaxation dissipation increases as shown in

Figure 1 and

Figure 2, respectively. As it can be seen in

Figure 3a,b, the strong dependence of total acoustic energy dissipation on

is caused essentially by the thermal relaxation term. The results show that by increasing the

, larger surface area is needed for heat transfer and consequently the thermal dissipation of acoustic power increases.

Further, it can be seen that both viscous and thermal relaxation dissipations do not vary linearly proportional to . As the temperature difference between the gas and the metal decreases, the acoustic energy dissipation increases progressively.

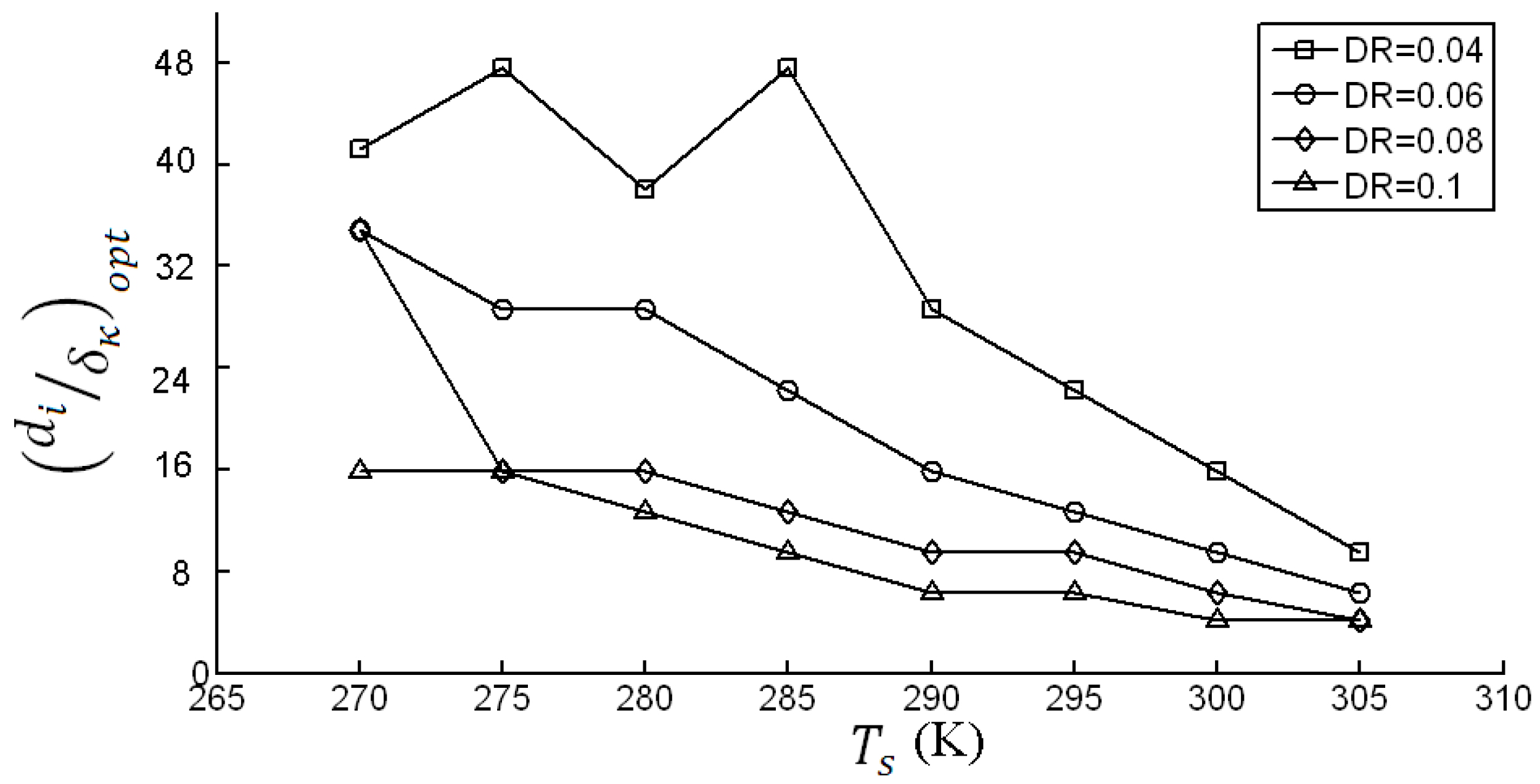

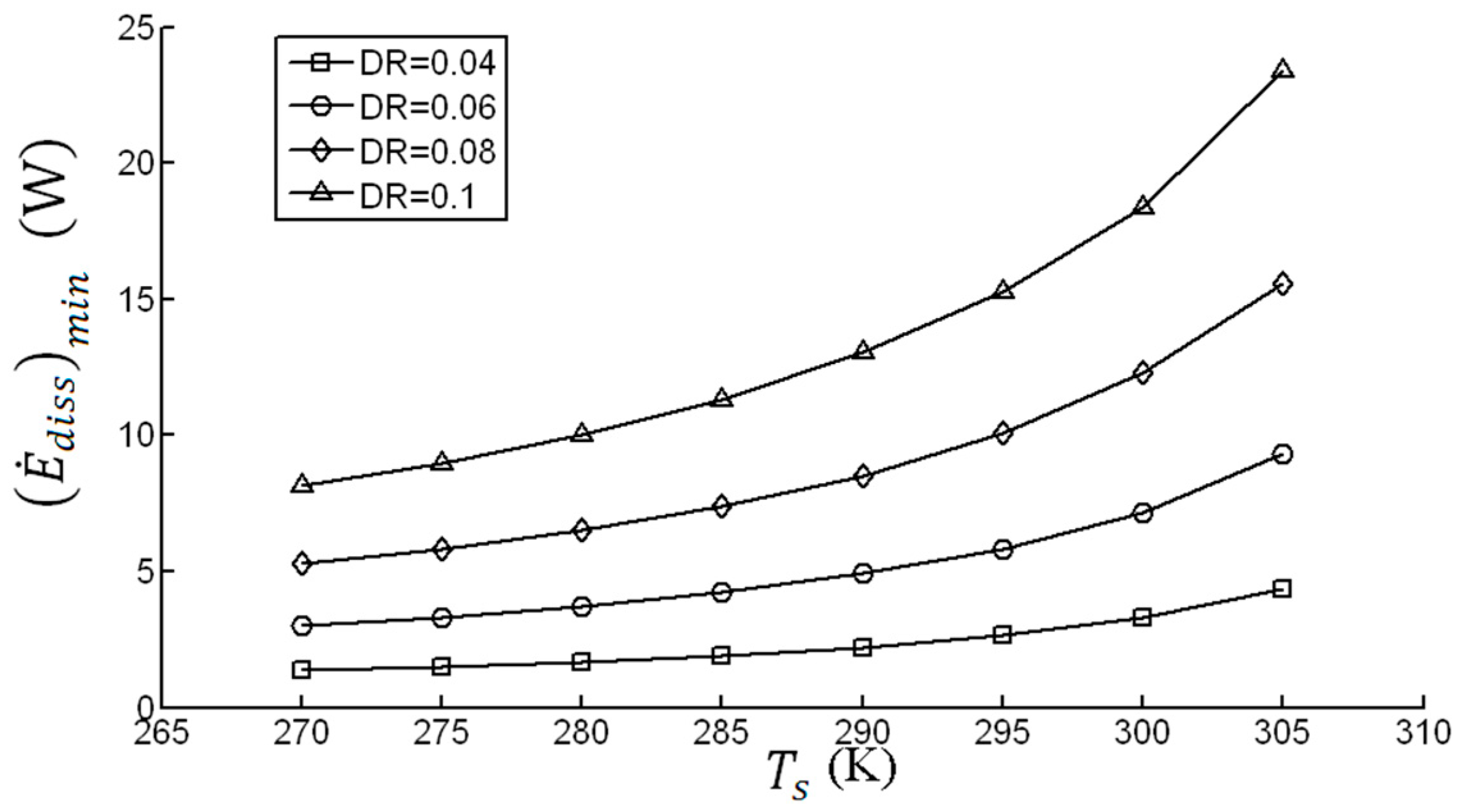

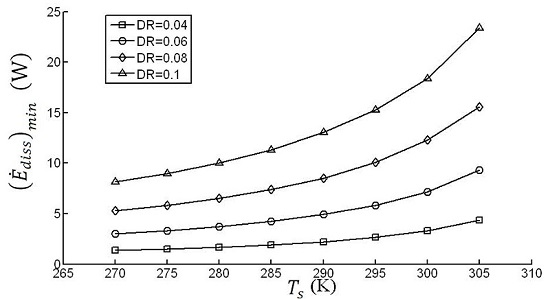

The design strategy, developed in the previous section and which is based on acoustic energy dissipation minimization, is applied to the model TAHX under study at different operating conditions. At various drive ratios and

, the optimal configuration and its corresponding

is determined,

Figure 4. It can be seen that an increase of

has a minor effect on

at lower drive ratios; however, it has a major effect at larger drive ratios. To be exact, for a TAHX metal temperature of

K, an increase of the drive ratio from 0.04 to 0.1 will increase six-fold the total dissipation.

The variation of

with

at different drive ratios is shown in

Figure 5. It is evident that

slightly decreases as

increases. This decrease in

has a lower magnitude at larger drive ratios. One may recall that as the TAHX metal temperature increases, the corresponding

decreases—that is, the optimum diameter of the tube decreases. Theoretically, it is possible to obtain an optimum combination between the

of the tube and TAHX metal temperature for a minimum acoustic power dissipation.

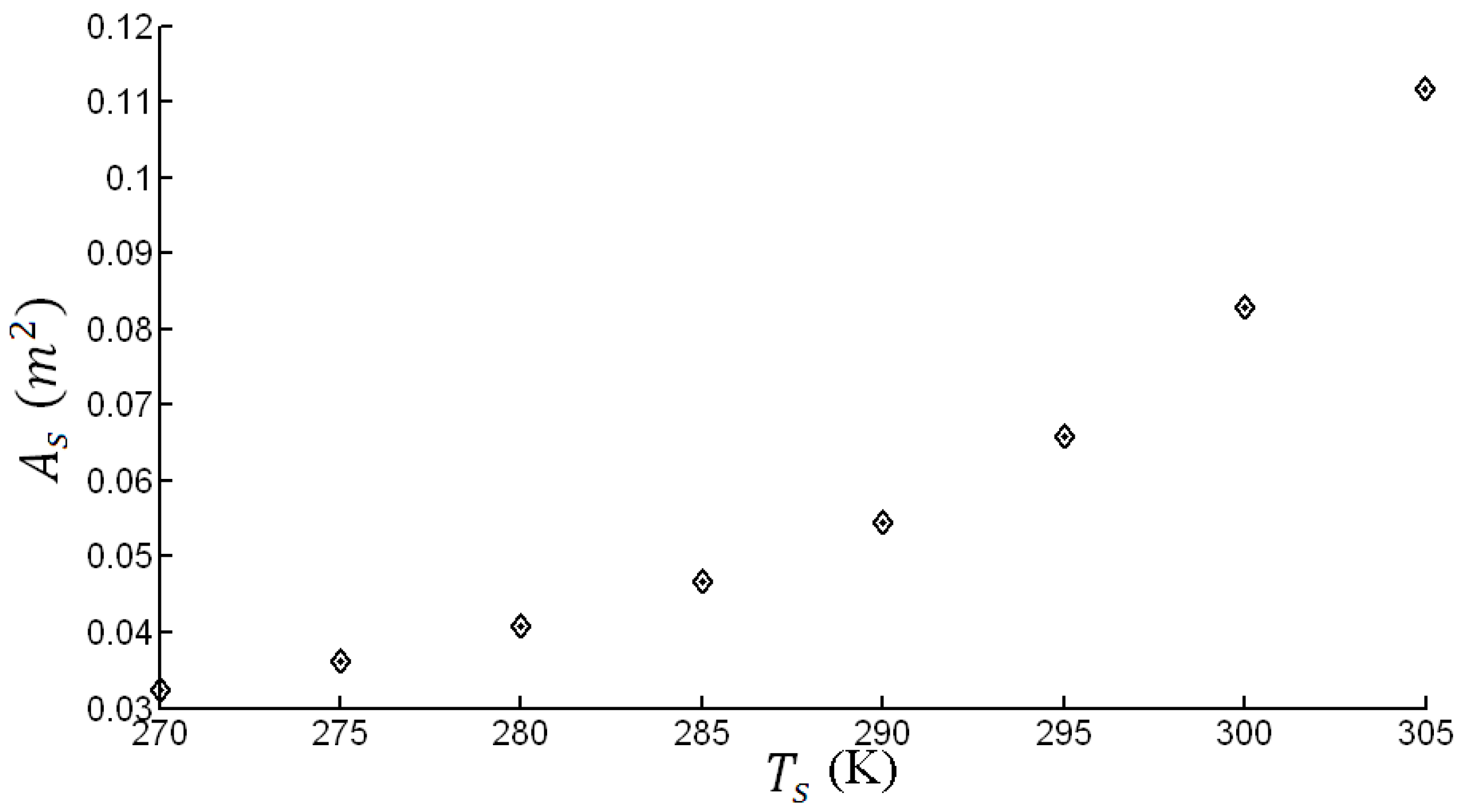

The variation of the heat exchanger surface area

versus

is plotted in

Figure 6. It is evident that

is proportional to

and hence the acoustic power dissipated in the HX and so

is nearly in proportion to

. This result is in good agreement with the analysis in

Section 2.1—that is, the thermal relaxation dissipation, which has the biggest impact in total dissipation in the HX, is proportional to

.

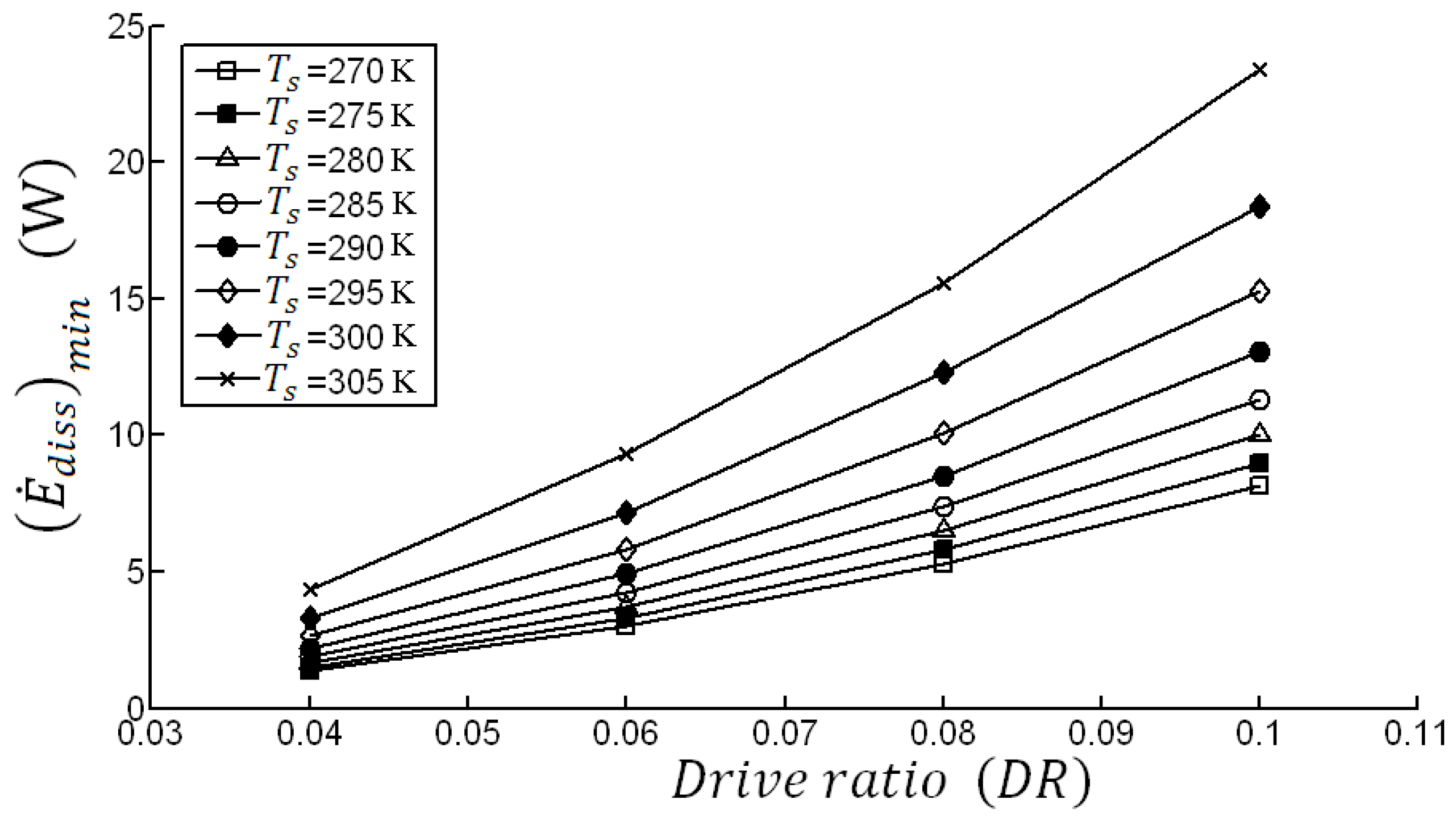

3.3. The Influence of Drive Ratio (DR) on Acoustic Energy Dissipation

Further investigation is made on the impact of the drive ratio on the total acoustic energy dissipation,

Figure 3a,b. A comparison between these figures reveals the strong dependency of the total acoustic energy dissipation on the drive ratio. Further, considering the drive ratio as an operating condition, analysis of the influence of drive ratio on the optimal TAHX configuration indicates the increase of the minimum energy dissipation

with the drive ratio. This fact is clearly supported by the rearrangement of the previous results illustrated in

Figure 7.

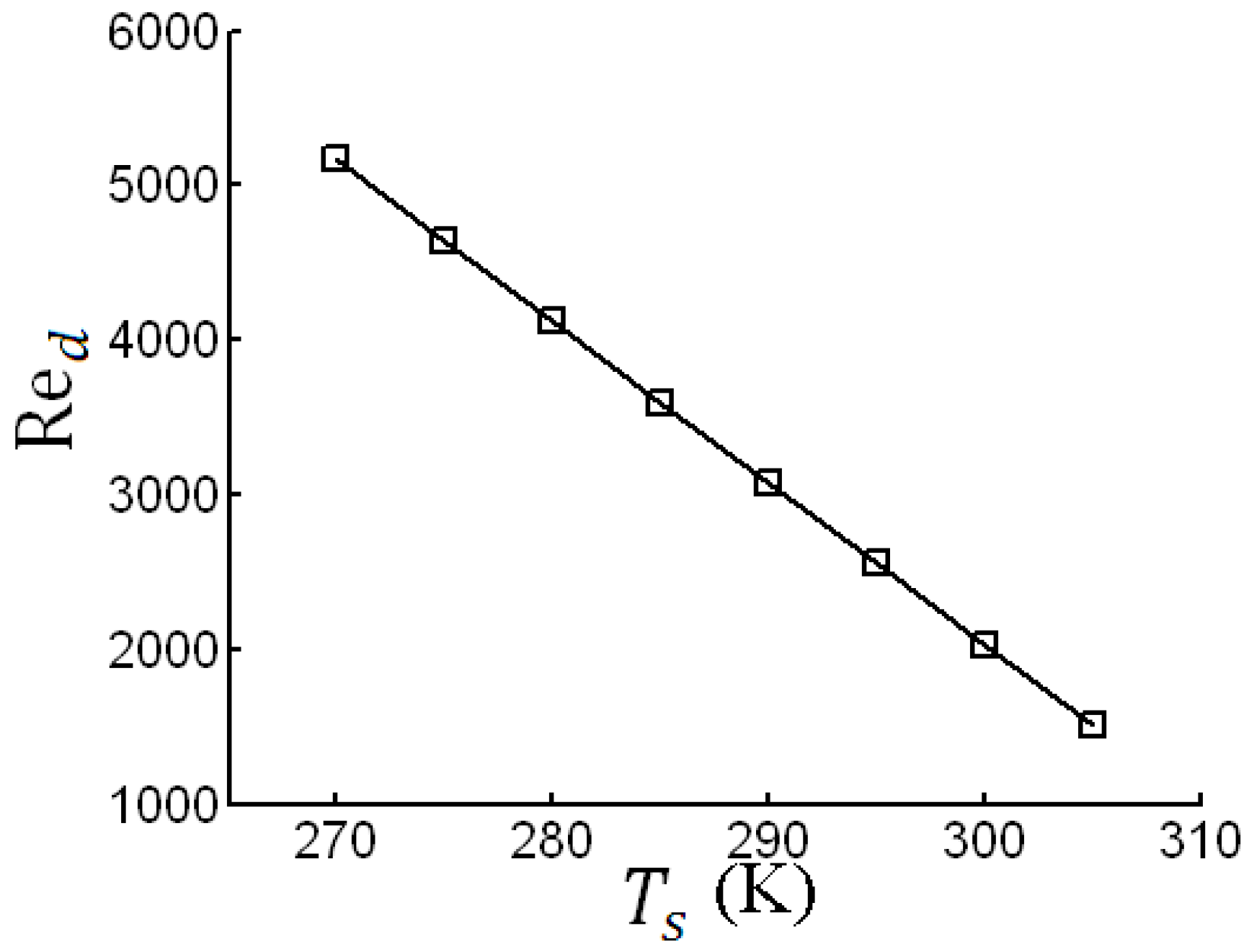

Finally, the variation of Reynolds number with TAHX metal temperatures

is provided in

Figure 8. As mentioned previously, one may specify the values for

,

, and

to determine

, the surface area of the HX. However, different HX configurations (

,

) might be designed to provide the same

. Moreover, since the volume velocity of the gas entering the HX is constant for all the possible configurations, the volume velocity in each tube as well as

changes. Nevertheless,

remains constant at each

and decreasing the temperature difference between the oscillating gas and the heat exchanger will result in a larger heat transfer area as shown in

Figure 6. Further, the increment of heat transfer surface area is provided by increasing the number of tubes, consequently leading to a decrease of

in correspondence with

.

4. Conclusions

Today, thermoacoustic engines, coolers, and heat pumps are gaining more interest for commercialization. While thermoacoustic engines utilize heat to generate acoustic power, the thermoacoustic refrigerators consume the acoustic power to transfer heat from the cold reservoir. A key parameter in making thermoacoustic devices more competitive with classical products is the optimum design of the heat exchangers. Hence, a deeper knowledge of heat exchangers is required so that the gas mean temperature does not change along the flow oscillation and dissipate acoustic energy in the form of viscous and thermal relaxation while transferring the specified heat load.

This research is motivated by developing a simple but constructive methodology for comparison and evaluation of related heat exchangers with respect to acoustic energy dissipation, viscous loss, thermal relaxation loss, tube dimension, and drive ratio. In this paper, the performance of shell-and-tube TAHXs in the travelling-wave mode with ideal gases is investigated through a numerical model based on the classical linear thermoacoustic theory.

The results indicate that, at equal operating conditions, viscous dissipation and thermal relaxation dissipation have opposing behaviors. While decreases with , increases. Consequently, an optimum value of exists, denoted as , at which the total acoustic dissipation becomes a minimum, . The impact of the heat exchanger metal temperature on is also investigated. It is determined that, in general, increases with . Further, are obtained to be decreasing with metal temperature . In fact, heat transfer with minimum acoustic energy dissipation at lower temperature defects leads to . For example, at a drive ratio of 0.06 and metal temperature of 285, the minimum dissipation occurs around ; whereas at and higher, the minimum dissipation appears at relatively lower . The relation between the acoustic energy dissipation and the drive ratio for various is also presented. It is shown that the acoustic energy dissipation increases with the drive ratio. The growth rate, however, was lower for smaller values of .

The proposed model is able to put in evidence the strong dependence of the acoustic energy dissipation on both the diameter and the number of tubes and the existence of minima in correspondence with tube diameter normalized by thermal penetration depth. The different weight of the viscous and thermal losses affecting the HXs behavior is also highlighted with the second one dominating. Also important for design purposes is that acoustic energy dissipation minimization criterion can be effectively employed for the optimization of the configuration of the shell-and-tube TAHXs.