1

M2S Laboratory (Movement, Sports & Health), University Rennes 2, ENS Rennes, 35170 Bruz, France

2

MIMETIC-Analysis-Synthesis Approach for Virtual Human Simulation, INRIA Rennes Bretagne Atlantique, Campus de Beaulieu, 263 Av. Général Leclerc, 35042 Rennes, France

3

LABIOMEP Laboratory (Porto Biomechanics Laboratory), Faculty of Sport, CIFI2D, University of Porto, 4200-450 Porto, Portugal

†

These authors contributed equally to this work.

Sensors 2022, 22(15), 5786; https://doi.org/10.3390/s22155786 - 3 Aug 2022

Cited by 16 | Viewed by 6119

Abstract

This study presents a deep learning model devoted to the analysis of swimming using a single Inertial Measurement Unit (IMU) attached to the sacrum. Gyroscope and accelerometer data were collected from 35 swimmers with various expertise levels during a protocol including the four

[...] Read more.

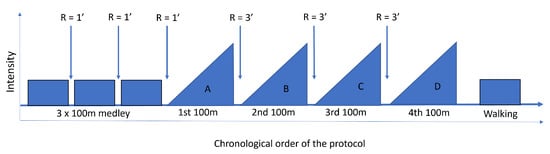

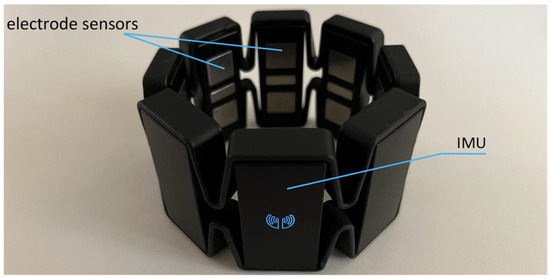

This study presents a deep learning model devoted to the analysis of swimming using a single Inertial Measurement Unit (IMU) attached to the sacrum. Gyroscope and accelerometer data were collected from 35 swimmers with various expertise levels during a protocol including the four swimming techniques. The proposed methodology took high inter- and intra-swimmer variability into account and was set up for the purpose of predicting eight swimming classes (the four swimming techniques, rest, wallpush, underwater, and turns) at four swimming velocities ranging from low to maximal. The overall F1-score of classification reached 0.96 with a temporal precision of 0.02 s. Lap times were directly computed from the classifier thanks to a high temporal precision and validated against a video gold standard. The mean absolute percentage error (MAPE) for this model against the video was 1.15%, 1%, and 4.07%, respectively, for starting lap times, middle lap times, and ending lap times. This model is a first step toward a powerful training assistant able to analyze swimmers with various levels of expertise in the context of in situ training monitoring.

Full article

(This article belongs to the Special Issue Wearables and Computer Vision for Sports Motion Analysis)

▼

Show Figures