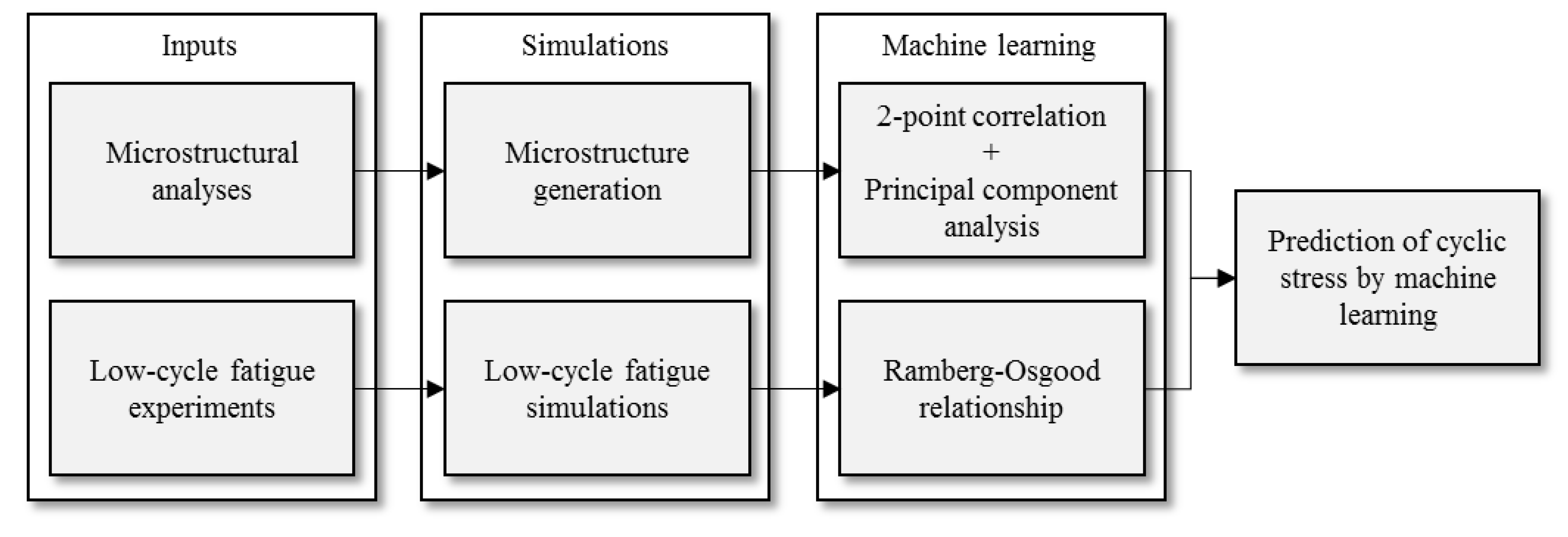

Prediction of Cyclic Stress–Strain Property of Steels by Crystal Plasticity Simulations and Machine Learning

Abstract

:1. Introduction

2. Experiments

2.1. Materials

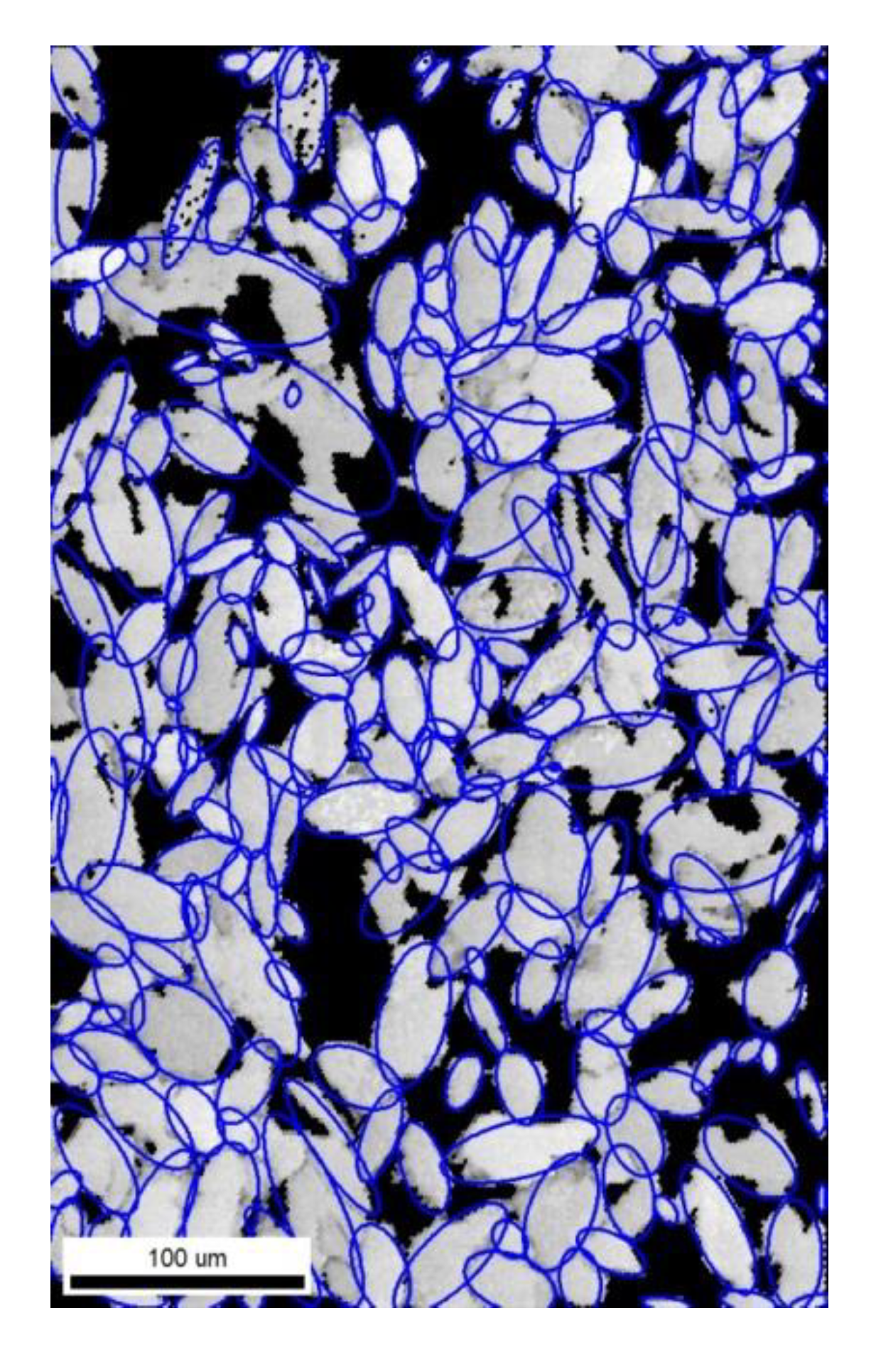

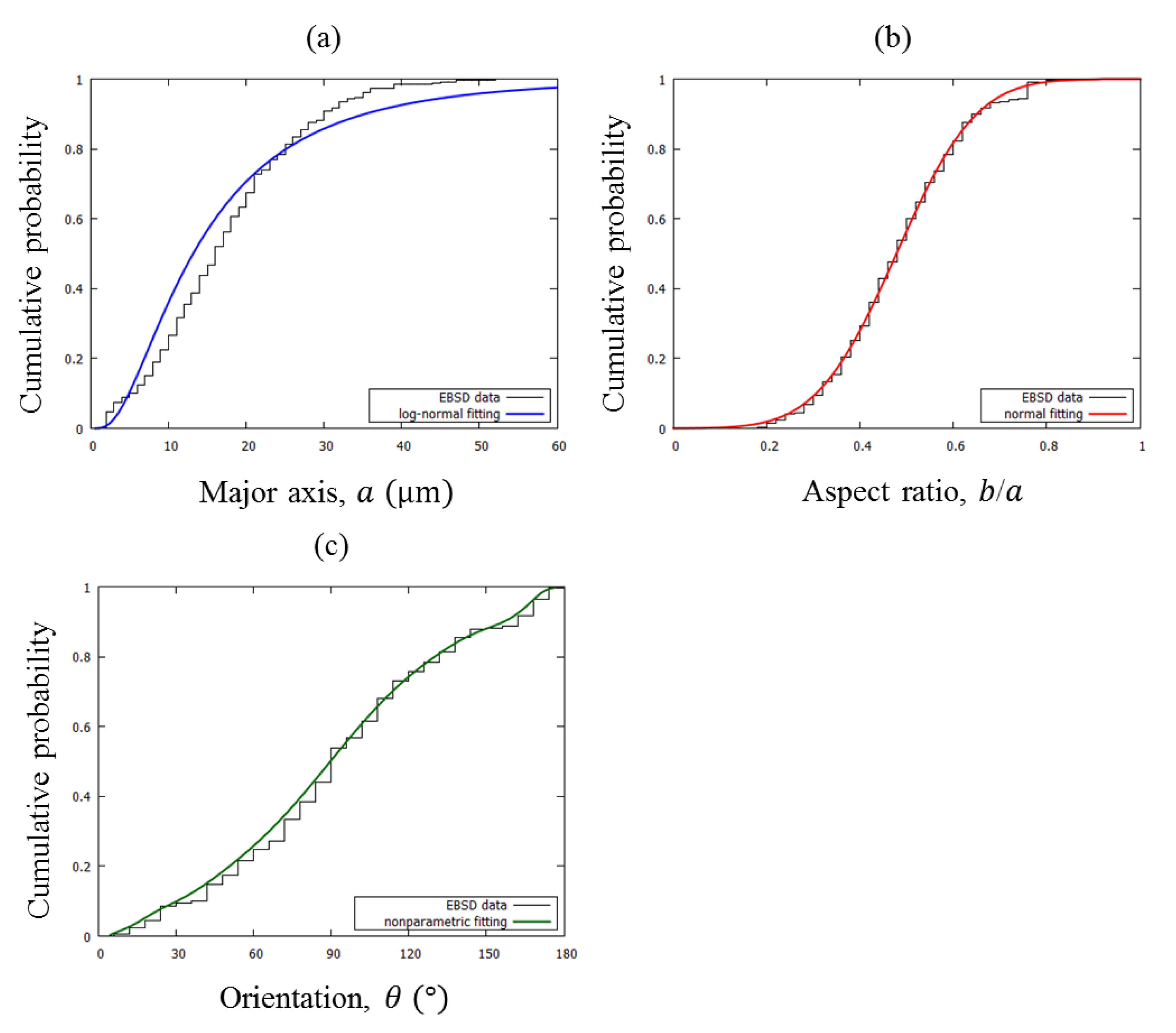

2.2. Microstructure Analysis

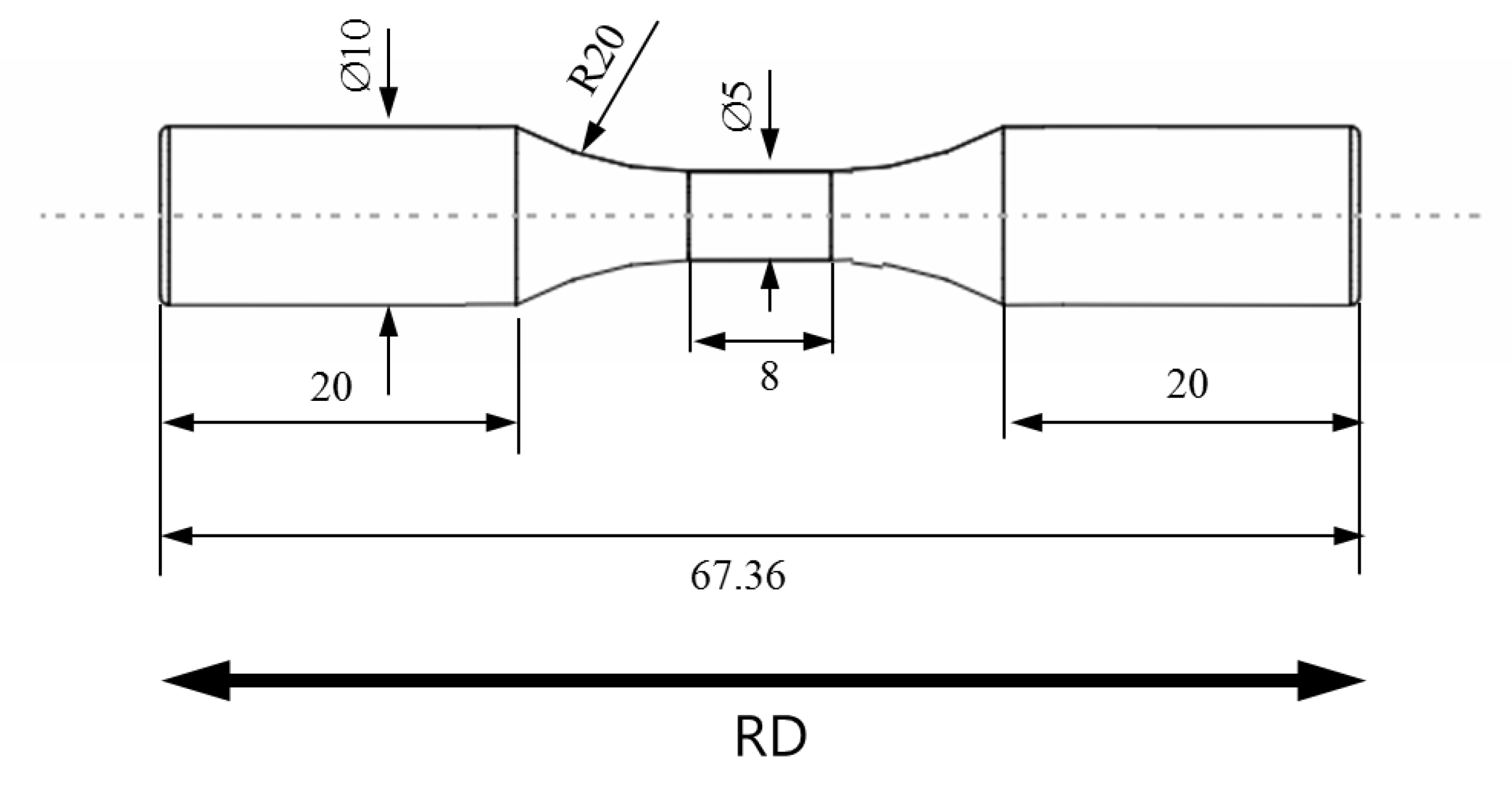

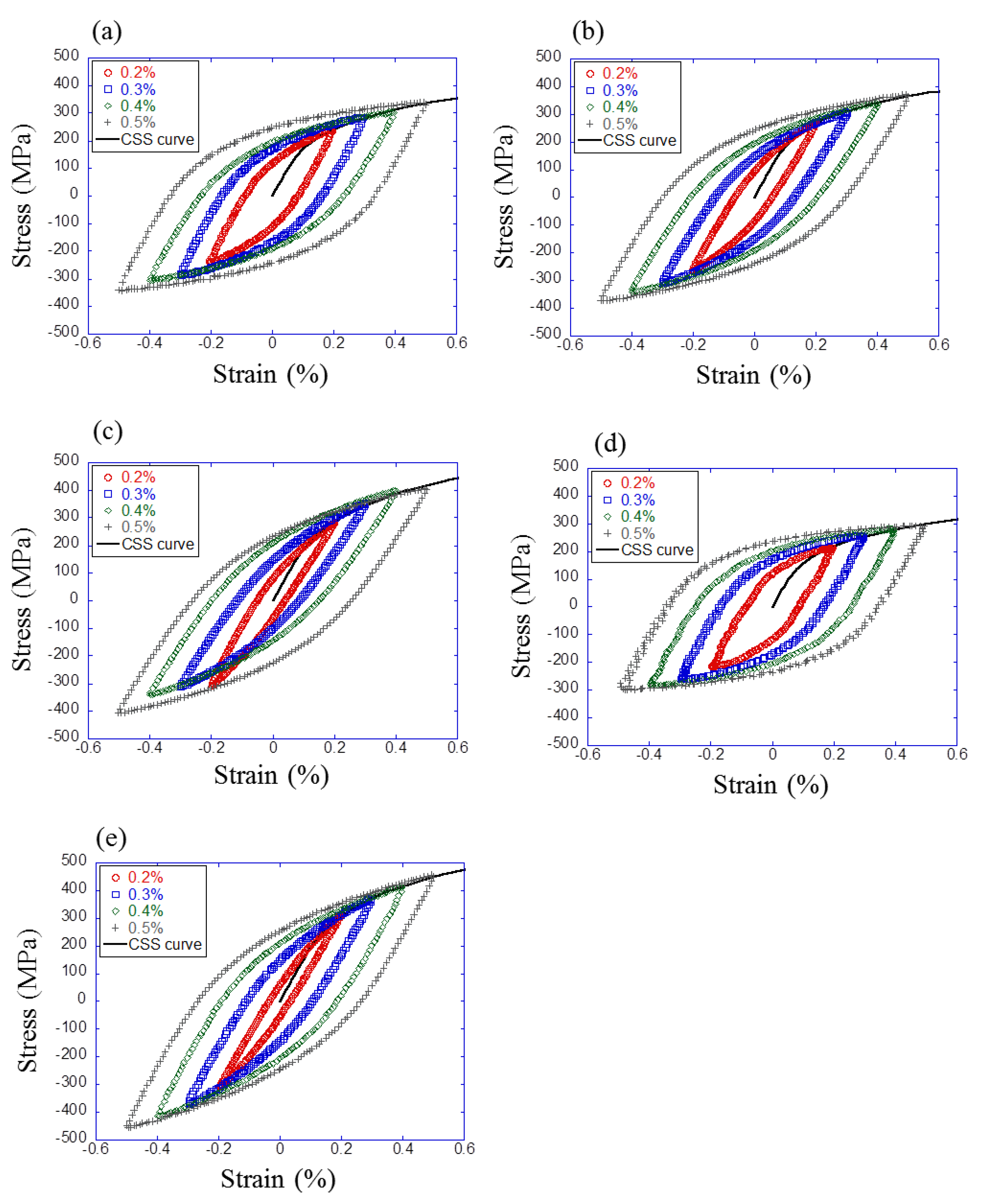

2.3. Low-Cycle Fatigue Experiments

3. Finite Element Analysis of Low-Cycle Fatigue

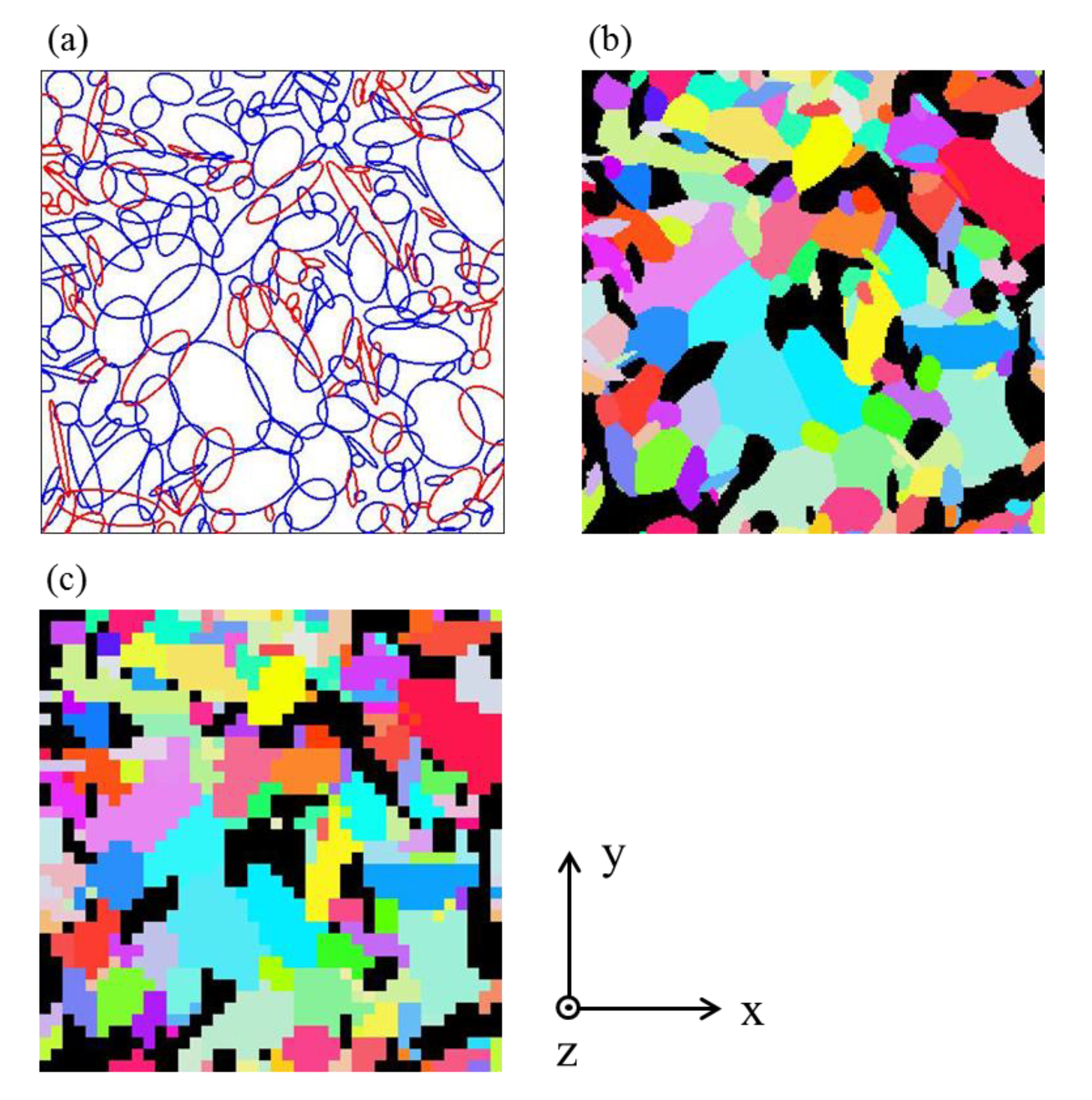

3.1. Generation of Synthetic Microstructure

3.2. Constitutive Models

3.3. Parameter Identification

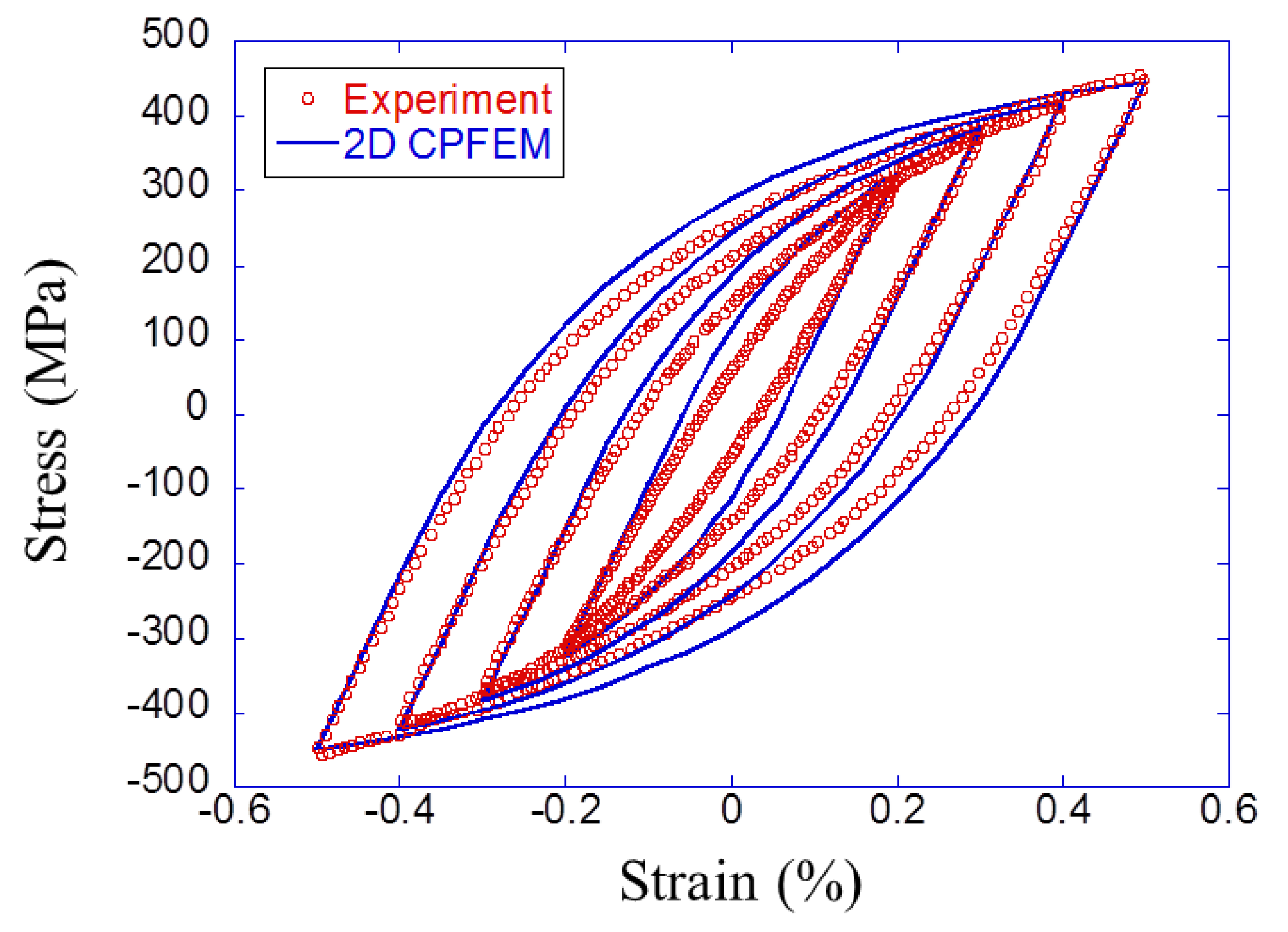

3.4. Low-Cycle Fatigue Simulations

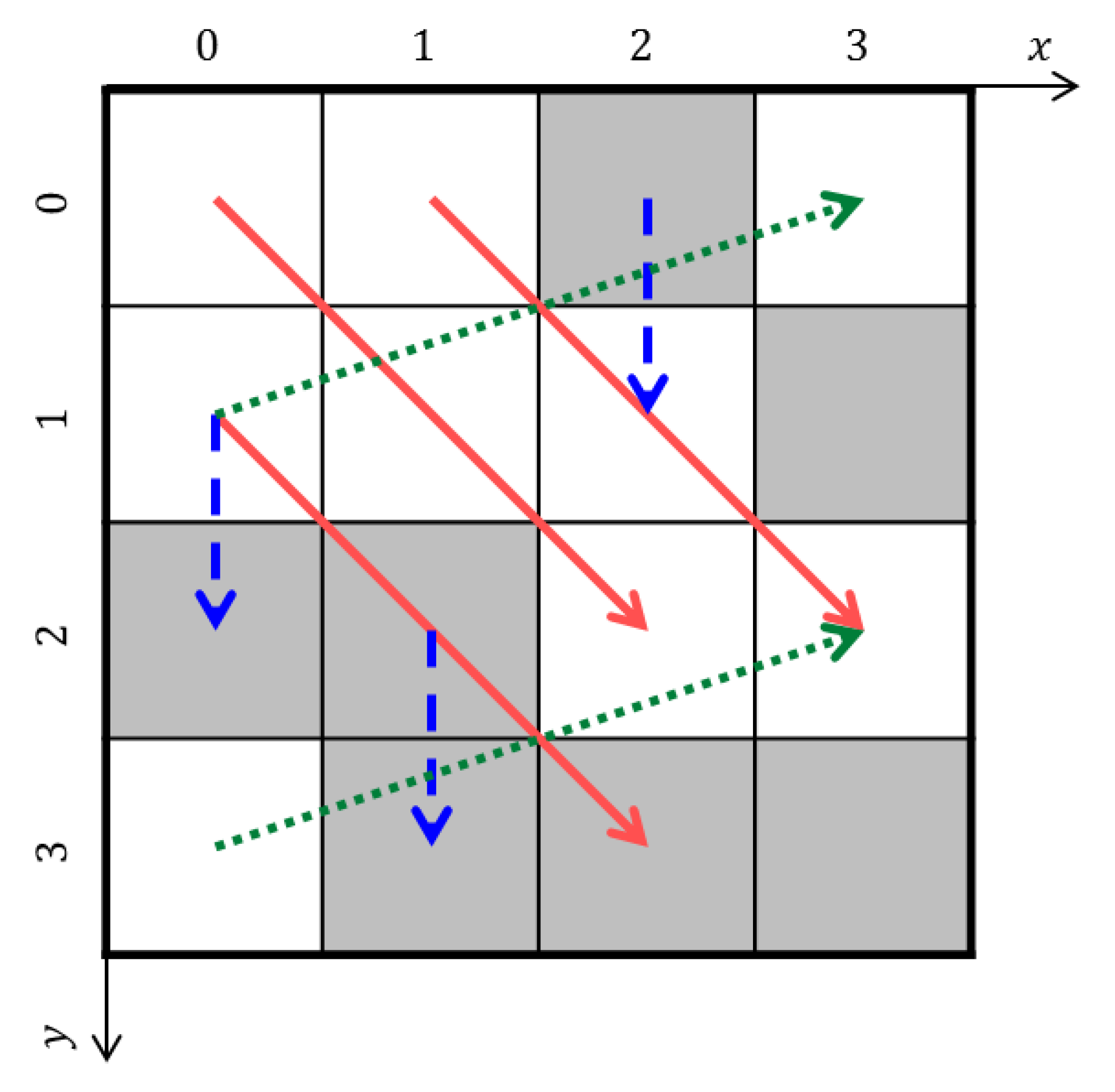

4. Microstructure Quantification by Two-Point Correlations

5. Prediction of Cyclic Stress–Strain Property by Machine Learning

5.1. Linear Regression Model

5.2. Neural Network Model

- One hidden layer with five units

- One hidden layer with ten units

- Two hidden layers with ten and five units

5.3. Microstructure-Property Dataset

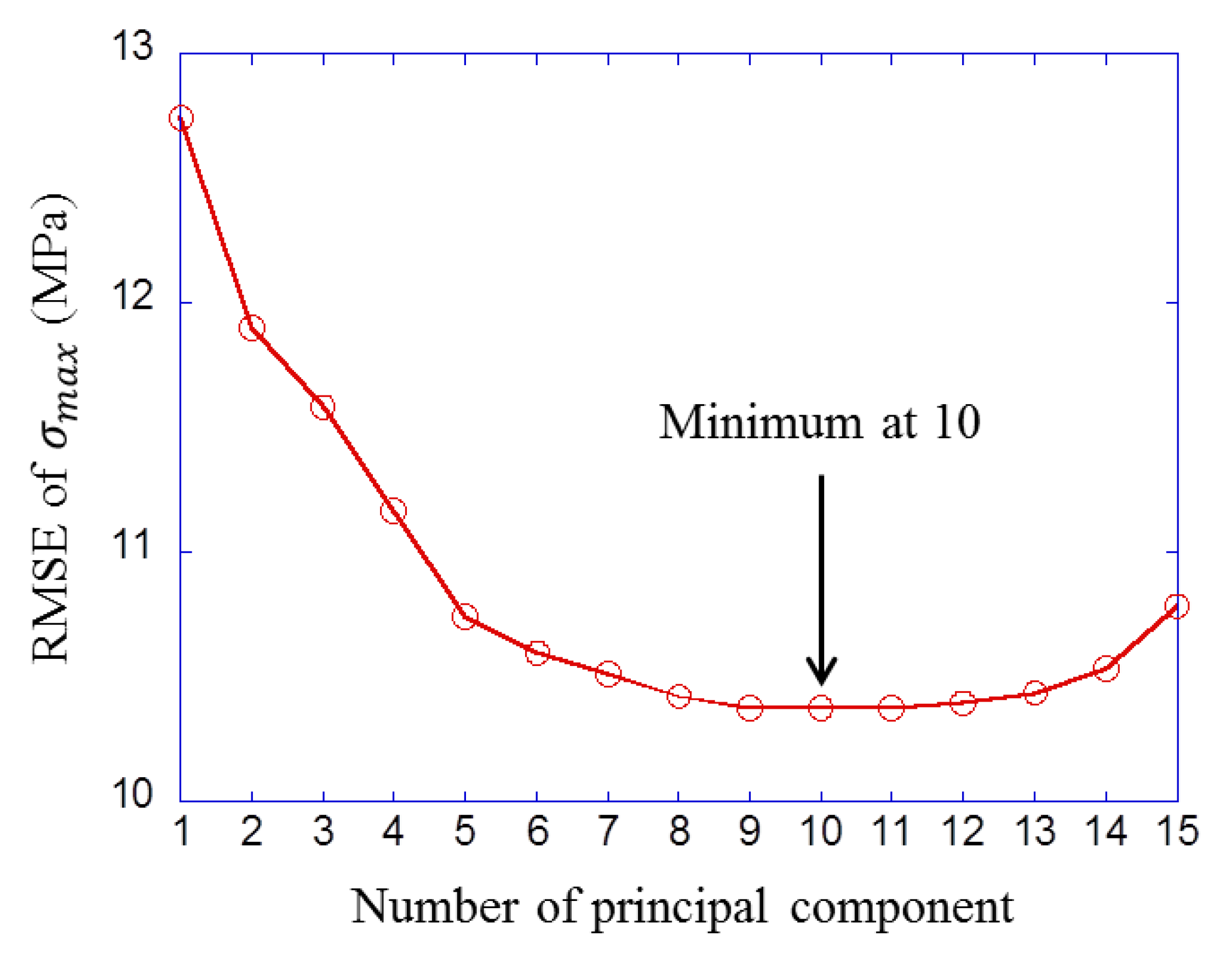

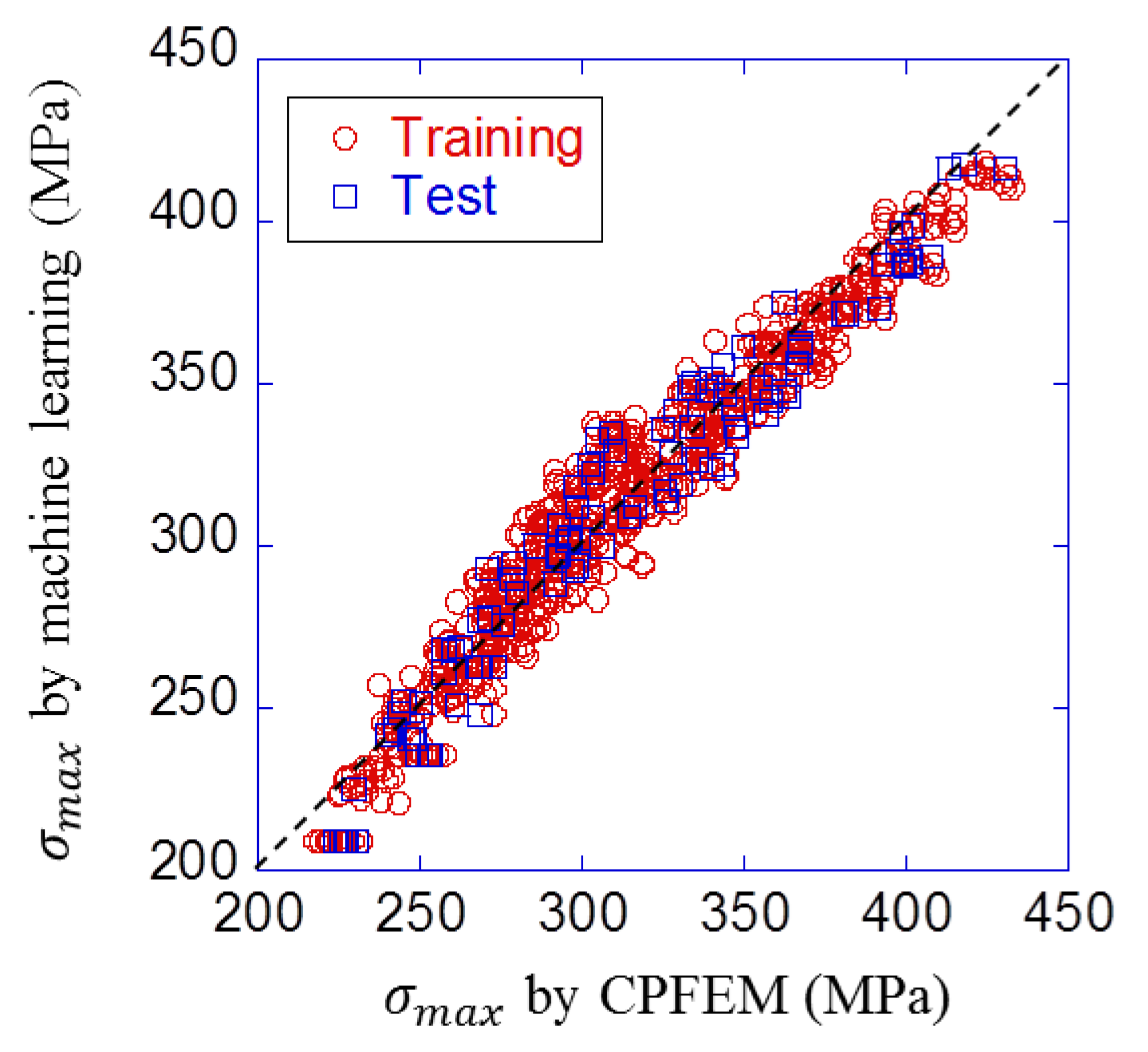

5.4. Results of Machine Learning

6. Discussion

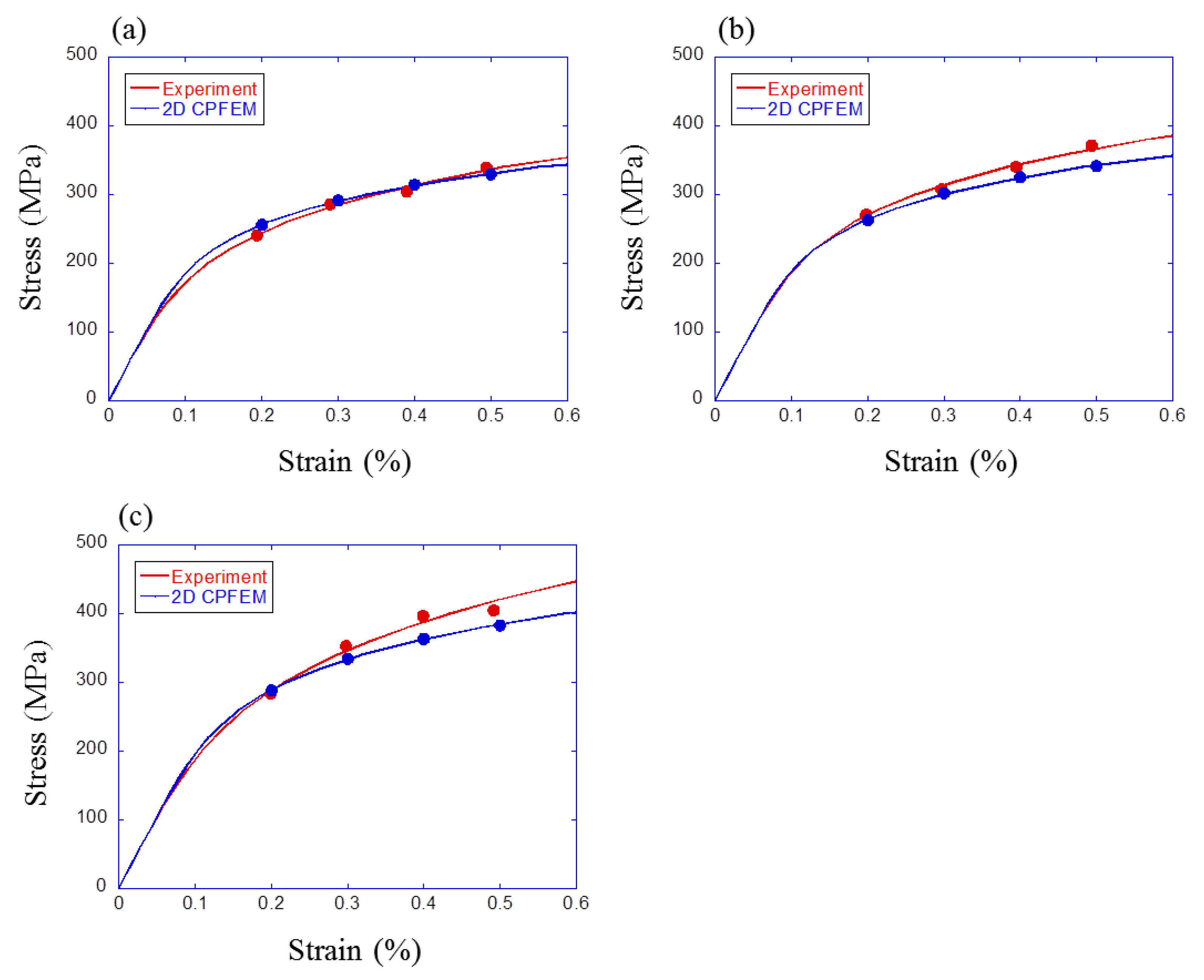

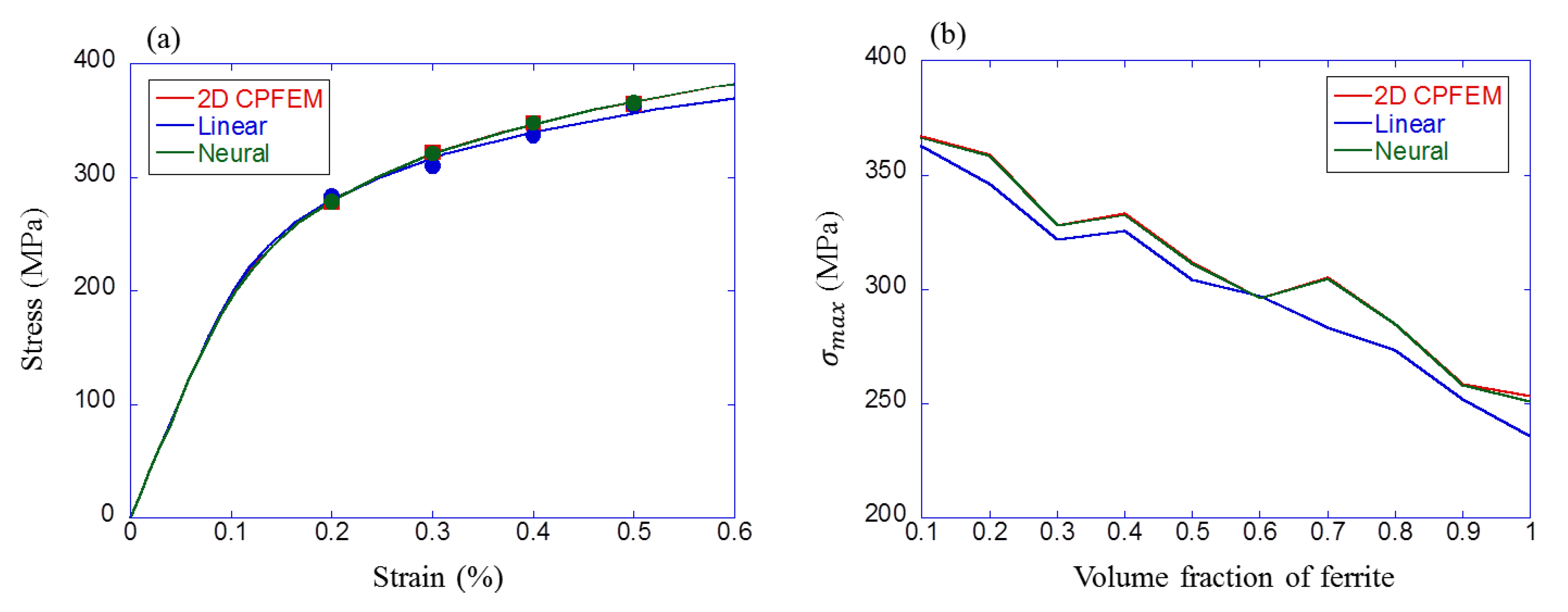

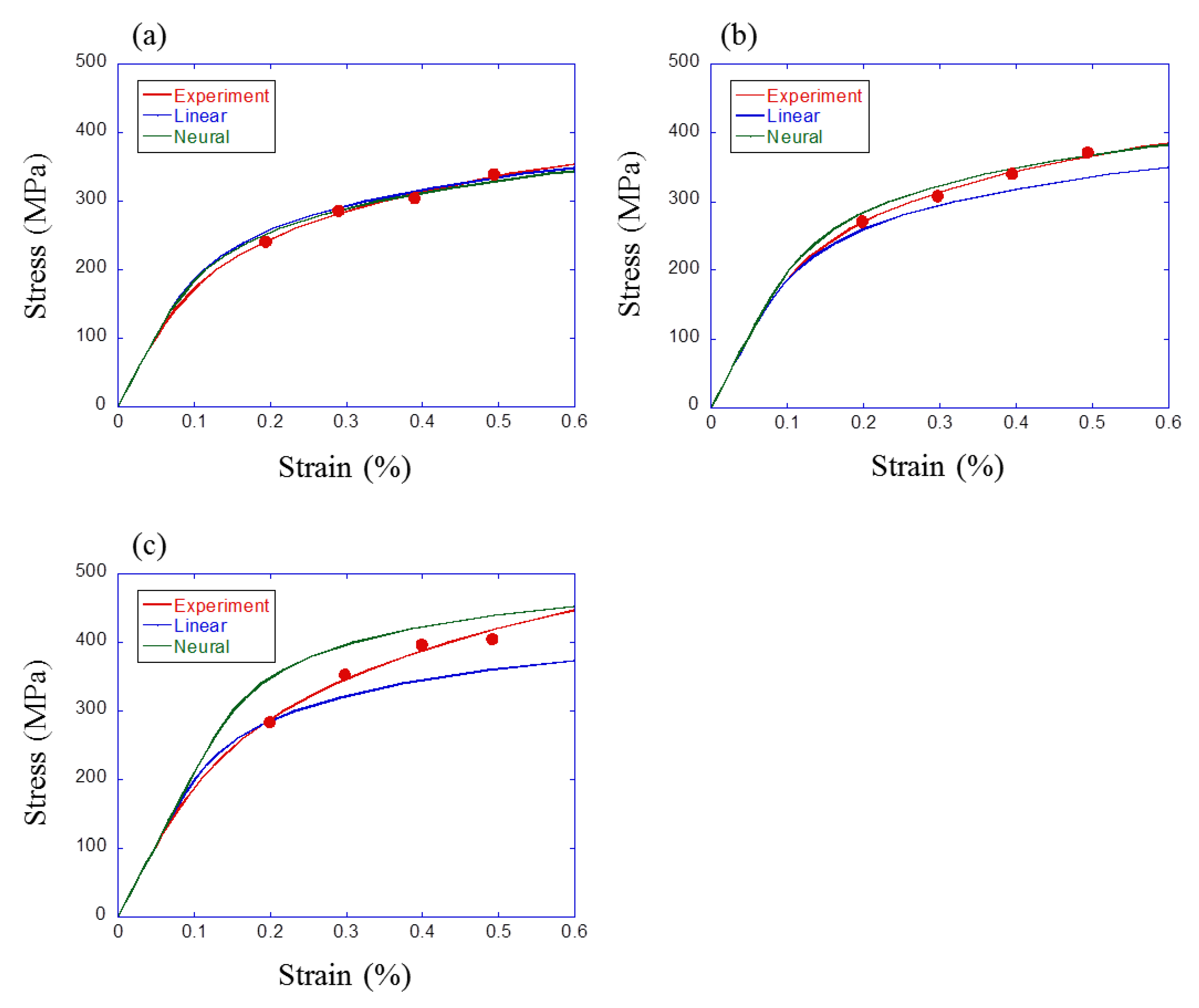

6.1. Comparison of Simulation and Experimental Results

6.2. Comparison of Machine Learning and Experimental Results

7. Conclusions

- The result of the finite element analysis showed good agreement with the experimental results. The results confirmed that the material parameters identified in this study were appropriate for fatigue analysis.

- Cyclic stress–strain property of ferrite-pearlite steel could be predicted with high accuracy by combining two-point correlation and machine learning. Also, the prediction error of the neural network model was smaller than that of the linear regression model.

- Cyclic stress–strain property predicted from the result of microstructure analysis by the model obtained by machine learning showed a good agreement with the experimental results. Thus, the prediction method proposed in this study was shown to be effective for fatigue property prediction.

Author Contributions

Funding

Conflicts of Interest

References

- Umemoto, M. Relationships between microstructure and mechanical properties in steels. Tetsu-to-Hagane 1995, 81, 157–166. [Google Scholar] [CrossRef]

- Fujii, H.; Mackay, D.J.C.; Bhadeshia, H.K.D.H. Bayesian neural network analysis of fatigue crack growth rate in nickel base superalloys. ISIJ Int. 1996, 36, 1373–1382. [Google Scholar] [CrossRef]

- Fujii, H.; Ichikawa, K. Estimation of weld properties by bayesian neural network. J. Jpn. Weld. Soc. 2001, 70, 335–339. [Google Scholar] [CrossRef]

- Malinov, S.; Sha, W.; McKeown, J.J. Modelling the correlation between processing parameters and properties in titanium alloys using artificial neural network. Comput. Mater. Sci. 2001, 21, 375–394. [Google Scholar] [CrossRef] [Green Version]

- Mukherjee, M.; Dutta, C.; Haldar, A. Prediction of hardness of the tempered martensitic rim of tmt rebars. Mater. Sci. Eng. A 2012, 543, 35–43. [Google Scholar] [CrossRef]

- Agrawal, A.; Deshpande, P.D.; Cecen, A.; Basavarsu, G.P.; Choudhary, A.N.; Kalidindi, S.R. Exploration of data science techniques to predict fatigue strength of steel from composition and processing parameters. Integr. Mater. Manuf. Innov. 2014, 3, 8. [Google Scholar] [CrossRef]

- Shiraiwa, T.; Miyazawa, Y.; Enoki, M. Prediction of fatigue strength in steels by linear regression and neural network. Mater. Trans. 2018. [Google Scholar] [CrossRef]

- Bishop, C.M. Model-based machine learning. Philos. Trans. R. Soc. A: Math.; Phys. Eng. Sci. 2013, 371, 1–17. [Google Scholar] [CrossRef]

- Olson, G.B. Computational design of hierarchically structured materials. Science 1997, 277, 1237–1242. [Google Scholar] [CrossRef]

- Briffod, F.; Shiraiwa, T.; Enoki, M. Fatigue crack initiation simulation in pure iron polycrystalline aggregate. Mater. Trans. 2016, 57, 1741–1746. [Google Scholar] [CrossRef]

- Briffod, F.; Shiraiwa, T.; Enoki, M. Microstructure modeling and crystal plasticity simulations for the evaluation of fatigue crack initiation in α-iron specimen including an elliptic defect. Mater. Sci. Eng. A 2017, 695, 165–177. [Google Scholar] [CrossRef]

- Briffod, F.; Shiraiwa, T.; Enoki, M. Numerical investigation of the influence of rolling texture and microstructure on fatigue crack initiation in bcc polycrystals. Int. J. Fatigue 2018, 107, 72–82. [Google Scholar] [CrossRef]

- Kröner, E. Statistical modelling. In Modelling Small Deformations of Polycrystals; Gittus, J., Zarka, J., Eds.; Springer: Dordrecht, The Netherlands, 1986; pp. 229–291. [Google Scholar]

- Ramberg, W.; Osgood, W.R. Description of stress-strain curves by three parameters. In National Advisory Committee for Aeronautics Technical Note, No. 902; US Government Printing Office: Washington, DC, USA, 1943; p. 902. [Google Scholar]

- Tarjus, G.; Schaaf, P.; Talbot, J. Random sequential addition: A distribution function approach. J. Stat. Phys. 1991, 63, 167–202. [Google Scholar] [CrossRef]

- St-Pierre, L.; Héripré, E.; Dexet, M.; Crépin, J.; Bertolino, G.; Bilger, N. 3d simulations of microstructure and comparison with experimental microstructure coming from o.I.M analysis. Int. J. Plast. 2008, 24, 1516–1532. [Google Scholar] [CrossRef]

- Voce, E. The relationship between stress and strain for homogeneous deformation. J. Inst. Met. 1948, 74, 537–562. [Google Scholar]

- Frederick, C.O.; Armstrong, P.J. A mathematical representation of the multiaxial bauschinger effect. Mater. High Temp. 2007, 24, 1–26. [Google Scholar] [CrossRef]

- Roters, F.; Eisenlohr, P.; Kords, C.; Tjahjanto, D.D.; Diehl, M.; Raabe, D. Damask: The düsseldorf advanced material simulation kit for studying crystal plasticity using an fe based or a spectral numerical solver. Procedia IUTAM 2012, 3, 3–10. [Google Scholar] [CrossRef]

- Rice, J.R. Inelastic constitutive relations for solids: An internal-variable theory and its application to metal plasticity. J. Mech. Phys. Solids 1971, 19, 433–455. [Google Scholar] [CrossRef]

- Hutchinson, J.W. Bounds and self-consistent estimates for creep of polycrystalline materials. Proc. R. Soc. Lond. A Math. Phys. Sci. 1976, 348, 101–127. [Google Scholar] [CrossRef]

- Peirce, D.; Asaro, R.J.; Needleman, A. An analysis of nonuniform and localized deformation in ductile single crystals. Acta Metall. 1982, 30, 1087–1119. [Google Scholar] [CrossRef]

- Peirce, D.; Asaro, R.J.; Needleman, A. Material rate dependence and localized deformation in crystalline solids. Acta Metall. 1983, 31, 1951–1976. [Google Scholar] [CrossRef]

- Needleman, A.; Asaro, R.J.; Lemonds, J.; Peirce, D. Finite element analysis of crystalline solids. Comput. Meth. Appl. Mech. Eng. 1985, 52, 689–708. [Google Scholar] [CrossRef]

- Bronkhorst, C.A.; Kalidindi, S.R.; Anand, L. Polycrystalline plasticity and the evolution of crystallographic texture in fcc metals. Philos. Trans. R. Soc. Lond. Ser. A Phys. Eng. Sci. 1992, 341, 443. [Google Scholar]

- Tasan, C.C.; Diehl, M.; Yan, D.; Zambaldi, C.; Shanthraj, P.; Roters, F.; Raabe, D. Integrated experimental–simulation analysis of stress and strain partitioning in multiphase alloys. Acta Mater. 2014, 81, 386–400. [Google Scholar] [CrossRef]

- Niezgoda, S.R.; Fullwood, D.T.; Kalidindi, S.R. Delineation of the space of 2-point correlations in a composite material system. Acta Mater. 2008, 56, 5285–5292. [Google Scholar] [CrossRef]

- Gupta, A.; Cecen, A.; Goyal, S.; Singh, A.K.; Kalidindi, S.R. Structure–property linkages using a data science approach: Application to a non-metallic inclusion/steel composite system. Acta Mater. 2015, 91, 239–254. [Google Scholar] [CrossRef]

- Cecen, A.; Fast, T.; Kalidindi, S.R. Versatile algorithms for the computation of 2-point spatial correlations in quantifying material structure. Integr. Mater. Manuf. Innov. 2016, 5, 1. [Google Scholar] [CrossRef]

- Fullwood, D.T.; Kalidindi, S.R.; Niezgoda, S.R.; Fast, A.; Hampson, N. Gradient-based microstructure reconstructions from distributions using fast fourier transforms. Mater. Sci. Eng. A 2008, 494, 68–72. [Google Scholar] [CrossRef]

- Chatterjee, S.; Hadi, A.S. Influential observations, high leverage points, and outliers in linear regression. Stat. Sci. 1986, 1, 379–393. [Google Scholar] [CrossRef]

- Bishop, C.M. Pattern Recognition and Machine Learning (Information Science and Statistics); Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Rumelhart, D.E.; Hinton, G.E.; Williams, R.J. Learning representations by back-propagating errors. Nature 1986, 323, 533. [Google Scholar] [CrossRef]

- Levenberg, K. A method for the solution of certain non-linear problems in least squares. Q. Appl. Math. 1944, 2, 164–168. [Google Scholar] [CrossRef] [Green Version]

- Marquardt, D.W. An algorithm for least-squares estimation of nonlinear parameters. J. Soc. Ind. Appl. Math. 1963, 11, 431–441. [Google Scholar] [CrossRef]

- MacKay, D.J.C. Bayesian interpolation. In Maximum Entropy and Bayesian Methods: Seattle, 1991; Smith, C.R., Erickson, G.J., Neudorfer, P.O., Eds.; Springer: Dordrecht, The Netherlands, 1992; pp. 39–66. [Google Scholar]

- Glorot, X.; Bengio, Y. Understanding the difficulty of training deep feedforward neural networks. In Proceedings of the Thirteenth International Conference on Artificial Intelligence and Statistics, Proceedings of Machine Learning Research, Chia Laguna Resort, Sardinia, Italy, 13–15 May 2010; Yee Whye, T., Mike, T., Eds.; PMLR: New York, NY, USA, 2010; pp. 249–256. [Google Scholar]

- Glorot, X.; Bordes, A.; Bengio, Y. Deep sparse rectifier neural networks. In Proceedings of the Fourteenth International Conference on Artificial Intelligence and Statistics, Fort Lauderdale, FL, USA, 11–13 April 2011; Geoffrey, G., David, D., Miroslav, D., Eds.; PMLR: New York, NY, USA, 2011; pp. 315–323. [Google Scholar]

- Lecun, Y.; Bengio, Y.; Hinton, G. Deep learning. Nature 2015, 521, 436. [Google Scholar] [CrossRef] [PubMed]

- Wu, X. On tanaka-mura’s fatigue crack nucleation model and validation. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 894–899. [Google Scholar] [CrossRef]

- Alexandre, F.; Deyber, S.; Pineau, A. Modelling the optimum grain size on the low cycle fatigue life of a ni based superalloy in the presence of two possible crack initiation sites. Scr. Mater. 2004, 50, 25–30. [Google Scholar] [CrossRef]

| Steel | C | Si | Mn | P | S | Cu | Ni | Cr | Al |

|---|---|---|---|---|---|---|---|---|---|

| S25C | 0.24 | 0.18 | 0.44 | 0.014 | 0.003 | 0.01 | 0.01 | 0.01 | 0.028 |

| S35C | 0.32 | 0.17 | 0.63 | 0.014 | 0.004 | 0.13 | 0.07 | 0.13 | 0.019 |

| S45C | 0.47 | 0.16 | 0.60 | 0.017 | 0.004 | 0.18 | 0.12 | 0.12 | 0.018 |

| K1 | 0.07 | <0.01 | 1.52 | 0.006 | 0.003 | - | - | - | 0.028 |

| Pearlite steel | 0.80 | 0.006 | 0.039 | 0.002 | 0.001 | - | - | - | - |

| Steel | K/MPa | n |

|---|---|---|

| S25C | 1233 | 0.228 |

| S35C | 1170 | 0.202 |

| S45C | 1719 | 0.242 |

| K1 | 1124 | 0.234 |

| Pearlite steel | 1626 | 0.219 |

| Elasticity | Isotropic Hardening | |||

|---|---|---|---|---|

| Kinematic hardening , | ||||

| Cubic Elasticity | Kinematic Law | |||||

|---|---|---|---|---|---|---|

| Work hardening | Kinematic hardening | |||||

| Activation Function | |||

|---|---|---|---|

| tanh | ReLU | ||

| Hidden layer condition | (i) | 4.24 | 6.23 |

| (ii) | 2.09 | 3.96 | |

| (iii) | 1.37 | 3.63 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miyazawa, Y.; Briffod, F.; Shiraiwa, T.; Enoki, M. Prediction of Cyclic Stress–Strain Property of Steels by Crystal Plasticity Simulations and Machine Learning. Materials 2019, 12, 3668. https://doi.org/10.3390/ma12223668

Miyazawa Y, Briffod F, Shiraiwa T, Enoki M. Prediction of Cyclic Stress–Strain Property of Steels by Crystal Plasticity Simulations and Machine Learning. Materials. 2019; 12(22):3668. https://doi.org/10.3390/ma12223668

Chicago/Turabian StyleMiyazawa, Yuto, Fabien Briffod, Takayuki Shiraiwa, and Manabu Enoki. 2019. "Prediction of Cyclic Stress–Strain Property of Steels by Crystal Plasticity Simulations and Machine Learning" Materials 12, no. 22: 3668. https://doi.org/10.3390/ma12223668