1. Introduction

The U.S. market for hemp grain and fiber, a sustainable crop [

1] with several applications [

2], is expected to increase at a rate of 17.1% from 2023 to 2030, with an expected value of USD 16.75 billion [

3]. Since its legalization in the 2014 and 2018 U.S. Farm bills, interest in growing and utilizing industrial hemp has been expanding. Different varieties of hemp are cultivated for CBD (cannabidiol) oil, grain, or fiber, while some varieties can produce both fiber and grain. CBD oil is the highest-value product produced from the hemp flower and is commonly used for treating physical as well as mental illnesses [

4]. In 2022, 3082 megagrams (Mg) of floral hemp was produced in the U.S., with an estimated value of USD 179 million [

4]. However, the CBD hemp market has been saturated due to high producer participation [

4]. There is a need to increase the production of multiple varieties of hemp for different uses.

Hemp is a temperate crop that can be grown for fiber and grain in many U.S. states [

5]. In 2022, hemp grain production was highest in Midwestern states (1383 ha), followed by Northwestern states (396 ha) [

4]. Hemp fiber production was also most concentrated in the Midwest, mainly Missouri (526 ha) and South Dakota (324 ha), followed by Montana (255 ha), Virginia (194 ha), North Carolina (170 ha), Kentucky (73 ha) and Oregon (40 ha) [

4]. In 2022, the total hemp grain production was 1104 Mg, worth USD 3.6 million, while hemp fiber production was 9545 Mg, worth USD 28.3 million [

4]. Due to the market saturation of hemp grown for CBD, there is increasing interest in growing hemp in rotation with other major grains such as corn, soybean, and other oilseed crops that are used for grain and fiber. Hemp grain and fiber have high-value applications in food and textile industries [

6]. Hemp grain is sold as a dietary supplement, due to its nutritional benefits [

7]. Similarly, there are several applications of hemp fiber, including construction and building materials, textiles, and paper [

8,

9]. In addition, to encourage more producers to grow hemp for grain and fiber, new federal laws are being written that reduce the THC content restrictions for grain and fiber hemp varieties [

10].

Current research on hemp is focused on establishing agronomy for hemp production methods and other best management practices for hemp harvest and storage for different hemp varieties [

11,

12,

13,

14,

15]. These practices include determining optimal growing degree day requirements, field preparation, seeding rates, row spacing, nutrients requirements, harvest timing, and potential yield [

12,

13,

14,

15,

16,

17,

18]. These studies have found that early-maturing varieties are better for fiber production while late maturing varieties are better for seed production [

17,

18]. However, grain loss due to seed shatter is a major concern for grain production, thus the optimal harvest timing is at a seed maturity of ~70% and a grain moisture between 22 and 30% [

12,

17]. In addition, research on herbicides and pesticides for hemp is ongoing.

A few studies have evaluated the economic viability of hemp production. One study considered intercropping fiber hemp with loblolly pine for 6 years during its establishment in the Southwestern U.S. It estimated that such a system could produce 25% higher overall returns for the farm compared to monocropping of loblolly pine [

19]. Another study in the Czech Republic evaluated the economics of using the residual biomass from CBD hemp production for energy or biochar and found that the cost of biochar or direct use of hemp biomass for energy would be less than other biomass grown solely for bioenergy [

20]. However, this study allocated the cost of field production completely to the flowers, and only considered the costs associated with collecting and processing the residual biomass. One study, which evaluated the economic viability of industrial hemp production in Turkey, estimated the hemp stalk production costs for hemp fiber alone and a dual purpose (fiber and grain) at USD 0.29 kg

−1 and USD 0.41 kg

−1, respectively [

21].

These economic analyses have mostly been conducted using linear programming, directly using costs and prices from the literature. However, a comprehensive systems analysis using process modeling has not been conducted for the Midwestern U.S., where hemp grain and fiber production is increasing [

4]. Thus, the main objective of this study is to determine the technical feasibility and costs of hemp grain and fiber production, harvest and post-harvest logistics, and processing for the Midwestern U.S. This study incorporates current agronomic and best management practices and state-of-the-art technology for harvest and post-harvest logistics and processing.

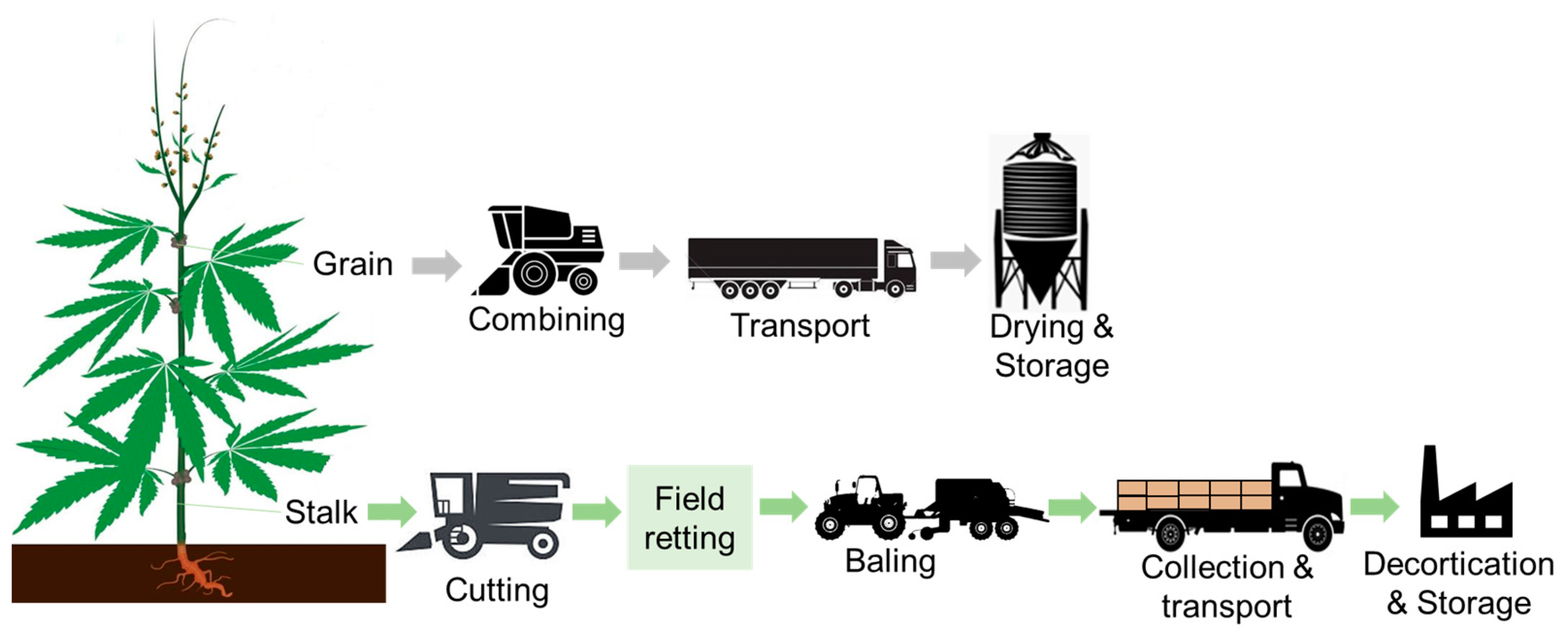

3. Results and Discussion

3.1. Feedstock Production and Fertilizer Requirement

The grain and fiber produced from the 162 ha farm had an IQR of 128–141 and 487–647 t/year, respectively. Hemp grain yields were lower than hemp fiber yields. However, hemp grain is considered a superfood and could be used for higher-value applications than processed hemp fiber, which could make hemp grain more attractive for farmers. With the implementation of the best management practices, hemp grain and fiber yields are likely to increase in the future.

Hemp grain required 206–284 kg Mg

−1 of urea for nitrogen, 57–109 kg Mg

−1 of DAP for phosphorus, and 49–85 kg Mg

−1 of potash for potassium. For hemp fiber, 62–87 kg Mg

−1 of urea, 22–34 kg Mg

−1 of DAP, and 30–55 kg Mg

−1 of potash were required. For comparison, the fertilizer requirement for hemp production is higher than that of the major row crops in the U.S. (corn: 60 kg Mg

−1 of urea, 12 kg Mg

−1 of DAP and 28 kg Mg

−1 of potash [

79]; soybean: 14 kg Mg

−1 of DAP and 23 kg Mg

−1 of potash [

80]) due to the lower hemp grain and fiber yields (Mg ha

−1).

3.2. Machinery, Fuel and Labor Requirements for Field Operations

For the modeled 162 ha farm size, for both hemp grain and fiber production, one of each piece of equipment for different operations was enough to fulfill the machinery needs. However, for smaller farms, i.e., 49 ha [

25], which is the current median hemp farm size in the U.S., it would not be economic for a farmer to own all the equipment; thus, hiring custom operators would be the most viable option.

Machinery hour, fuel, and labor requirements are summarized in

Table 6. Machinery hour requirements for the seeding of grain and fiber hemp were similar, as the productivity of the grain drill was assumed to be the same. The slightly higher number of hours required for fiber hemp is due to the higher number of trips required for refilling the grain drill during planting as the seeding rate for fiber is higher. A similar trend was observed for fertilization because of the higher fertilizer requirements for fiber hemp per hectare.

Combine harvesting was considered for grain while mowing, windrowing, and baling were considered for fiber stalk harvesting. The number of grain harvesting, collection, and transportation hours was high because a small plot combine was considered for harvesting grain hemp, while the grain cart would transport the grain to the field edge for storage. Due to the small width of the plot combine, the number of harvesting hours was high. If a large combine was considered, the field productivity of the combine would be much higher than the plot combine considered here. However, since the scale of operation considered in this analysis was small, a plot combine was considered to be suitable. Fiber harvest hours were also high compared to other field operations because of the multiple operations required, including mowing, windrowing, and baling, which increased the total number of harvesting hours. The collection and transportation of the hemp stalk bales were considered to be performed using an efficient bale collector and stacker, and thus had lower machinery hour requirements. The fuel use for grain and fiber production and harvesting and labor hour requirements followed a similar trend to machinery hour requirements.

3.3. Hemp Fiber Stalk Processing Resource Requirements

Hemp stalk processing requirements were estimated in terms of energy, labor, and equipment requirements. One decorticator (454 kg h

−1) and one stationary baling unit (4–6 bales h

−1) with the rated processing capacities would be sufficient to process the amount of hemp stalks produced from the 162 ha farm considered in this analysis. The total number of equipment hours required for processing was estimated to be in the IQR of 1084–1437 h year

−1, which is equivalent to 3.6–4.8 months per year, with the decorticator and stationary baling unit working simultaneously. This type of facility would be similar to cotton gins in the U.S., which typically operate for 1–2 months of the year, and remain idle for the rest of the year [

81]. Having an on-farm processing unit to process the hemp stalk could provide employment for farm workers beyond the harvest period, which would be beneficial for the rural economy. It was assumed that one full-time worker would be able to complete the processing tasks, as the decorticator and stationary baling units considered are fully automated. The worker would be required to monitor the processing equipment and move the materials. All processing was considered to be performed using electricity and the energy requirements for hemp stalk processing for the farm size considered were estimated to be in the IQR of 12,075–16,010 kWh year

−1.

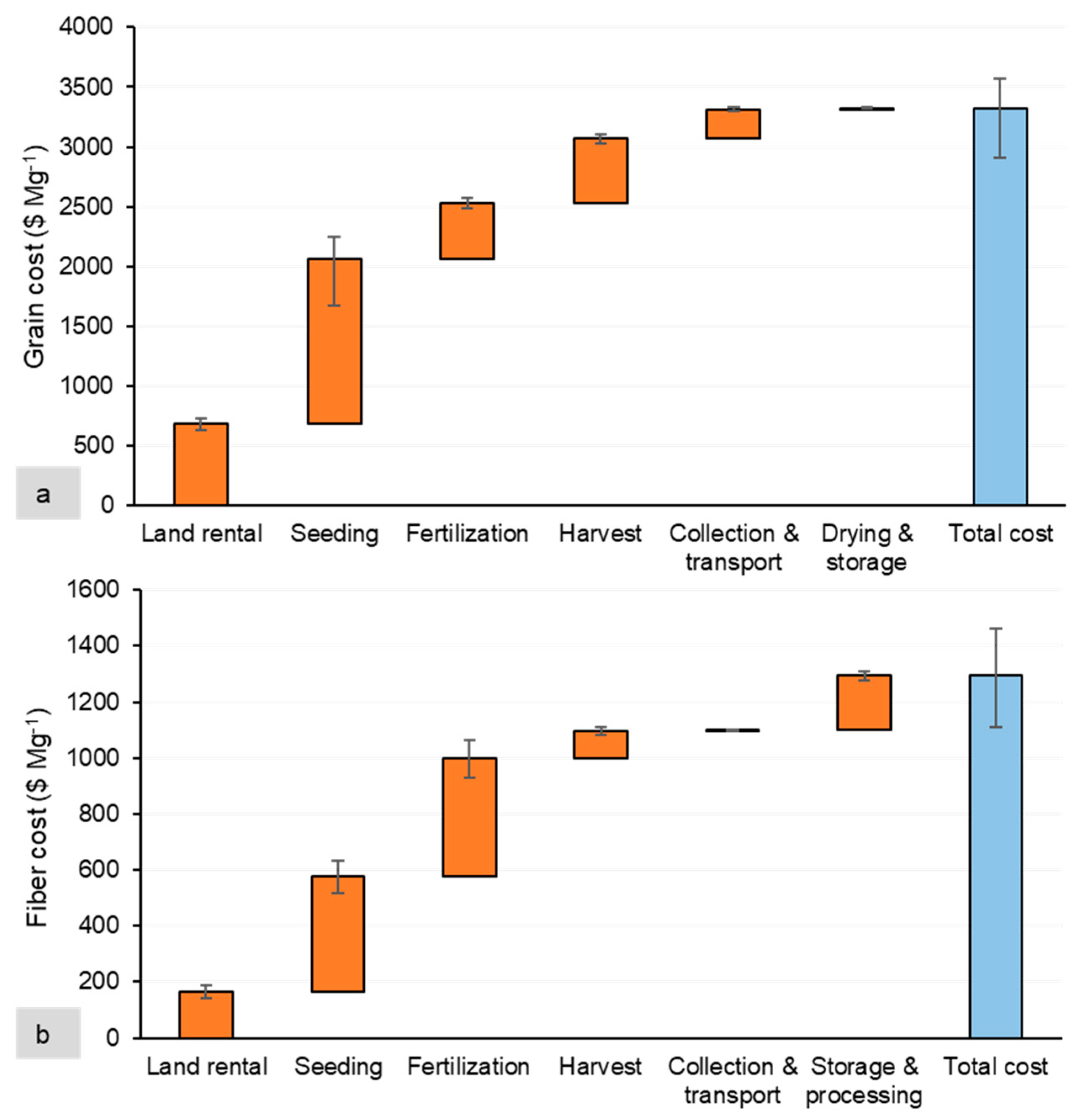

3.4. Hemp Grain and Fiber Production Cost

The total cost of hemp grain production, harvesting, post-harvest logistics, and drying and storage was estimated to be in the IQR of USD 2913–3573 Mg

−1 (

Figure 2a). The total cost of hemp fiber production, harvest, post-harvest logistics, and processing was estimated to be in the IQR of USD 1155–1505 Mg

−1 (

Figure 2b). Hemp fiber production and processing costs were lower than grain costs because of the lower fertilizer requirements and higher fiber yields. For grain hemp, the cost of consumables, i.e., seeds and fertilizers, contributed 50% of the total production cost, followed by equipment (23%), land rental (21%), labor (4%), and fuel (2%). Similarly, for fiber hemp, consumables, i.e., seeds and fertilizers, contributed 59% of the total production cost, followed by equipment (20%), land rental (12%), labor (7%), and fuel/energy (1%). The cost of the seeds contributed 94% and 95% of the total seeding cost for grain and fiber hemp, respectively, due to the current low hemp seed production, as the crop is in its infancy. With the increase in hemp seed production and price stabilization, it is likely that the cost of hemp seeds will be reduced, thus reducing the overall cost of production. Fertilization operations followed a similar trend as fertilizer prices have increased drastically since 2020 [

82] due to rising inflation, and hemp grain and fiber have higher fertilizer requirements, while producing lower yields compared to conventional crops such as corn (14 Mg ha

−1) and soybean (4.7 Mg ha

−1).

For harvest and post-harvest logistics, equipment cost was the highest contributor for both grain and fiber hemp. This was due to the use of capital-intensive farm equipment, which has high productivity but is fully automated with low labor requirements. For grain hemp, the harvest cost alone contributed to 16% of the total cost due to the high cost of the combine. For fiber hemp, harvest and post-harvest logistics had a lower contribution of 11% because of the use of existing equipment, which is less expensive and efficient for biomass cutting and baling.

The contribution of grain hemp drying and storage to the total cost was low because grain drying and storage are already commercially available. It was assumed that the cost of grain hemp drying and storage would be same as that for commercial facilities. For fiber hemp processing, facility-related costs contributed 63% of the total cost, followed by labor (36%) and energy (1%). The contribution of facilities and labor was significant because of the small size of the processing plant and the high cost of the processing equipment. As hemp stalk processing equipment is in its infancy, only a few companies manufacture the processing equipment, and the related costs are high. Because the amount of material for a 162 ha farm requires only 3.6–4.8 months for processing, the excess equipment capacity would allow the processing of additional material in this facility. Thus, if more material is processed, the facility and labor needs will not increase in the same proportion due to economy of scale, which can help reduce the total processing costs. However, collecting more material will result in a larger collection radius around the processing plant, increasing the transport distance between the field and the plant, which can increase the post-harvest logistics cost.

3.5. Income from Hemp Grain and Fiber

Based on the current market prices of hemp grain and fiber, the average net income for the 162 ha farm considered was estimated to be USD 325,212 year

−1 (IQR: USD 62,671–551,136 year

−1) for hemp grain and USD 1,162,115 year

−1 (IQR: USD 874,421–1,412,350 year

−1) for hemp fiber, respectively. For the same farm size, corn and soybean would have generated a net income of USD 53,200–200,000 year

−1 and USD 46,400–128,400 year

−1, respectively, considering high corn and soybean yields of 14 and 4.7 Mg ha

−1 and higher-than-average prices of USD 262 Mg

−1 and USD 530 Mg

−1, respectively [

83]. The higher estimated income for hemp grain is due to its market price (USD 3.32 kg

−1) [

5], which is 13 and 6 times higher than that of corn (USD 0.26 kg

−1) [

83] and soybean (USD 0.52 kg

−1), respectively [

83]. Similarly, the price of hemp fiber (USD 3.3 kg

−1) [

5] is two times higher than other natural fibers such as cotton (USD 1.87 kg

−1) [

84].

Despite the potential to produce a higher income for the farmers, the resource (seeds, fertilizers) requirements for the production of hemp grain and fiber are high compared to existing crops, as hemp is new to farmers in the U.S. Due to the newness of hemp products and markets, prices are volatile, thus there is risk that the income generated could be lower. Similar to the decrease in CBD biomass prices over the last few years [

85], it is likely that hemp grain and fiber prices will decrease as their production increases. Thus, the results from this analysis would be applicable for the current state of technology and for the current costs and prices, which are likely to change in the future as hemp markets develop, and thus market volatility is the main limitation of this study. In addition, the environmental impacts of hemp grain and fiber production and processing need to be evaluated and compared to existing ones. However, this study can provide direction to farmers and processors that are interested in hemp but are hesitant due to unknown associated costs.

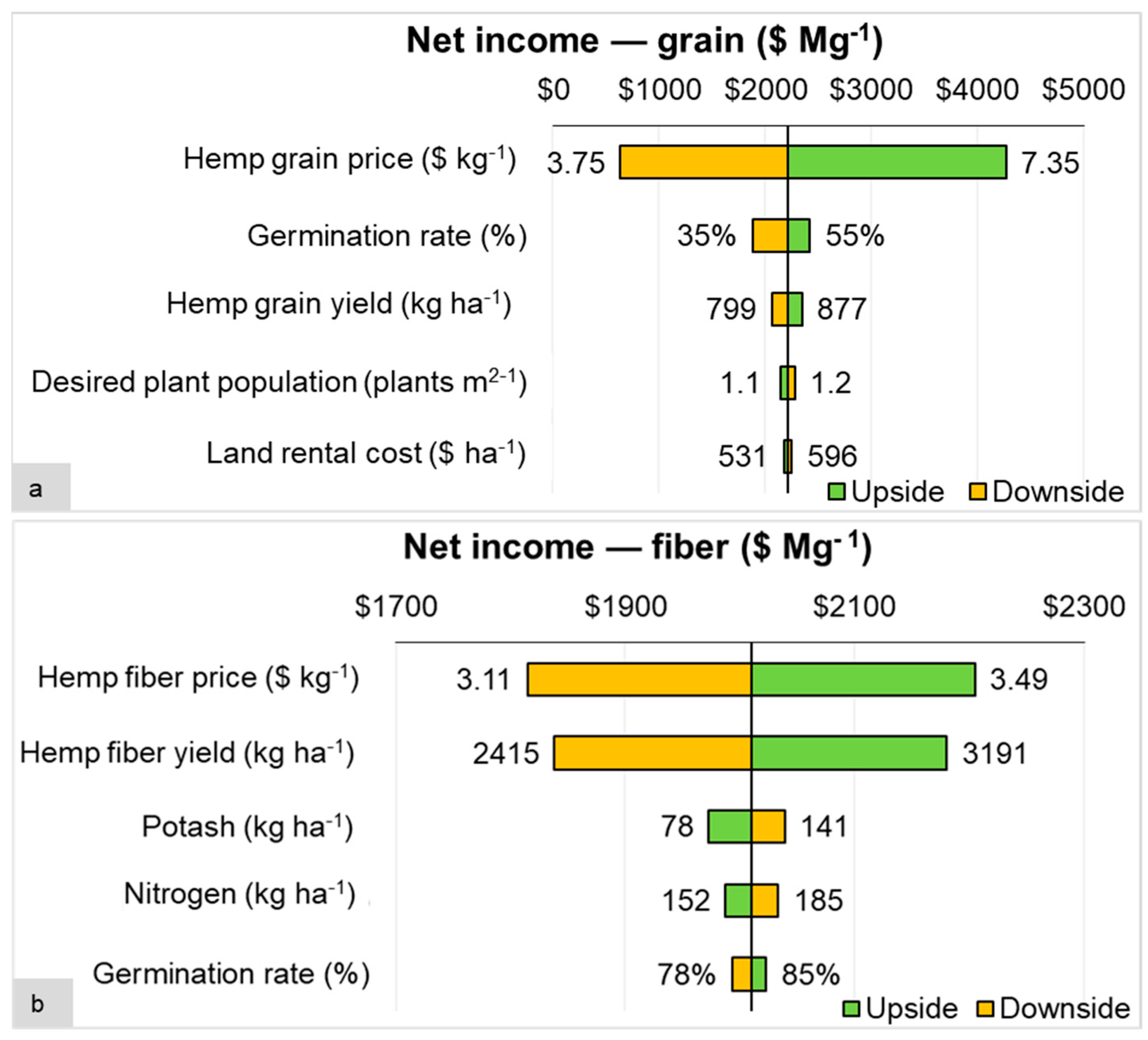

3.6. Sensitivity Analysis

Sensitivity analysis was conducted to identify the parameters that were most influential on the net income. The price of hemp grain and fiber were the most influential parameters as there is currently high variability in their price due to the volatile market (

Figure 3). Other influential parameters were associated with seeding and fertilization, including the germination rate, plant population, and fertilizer application rate, as these operations were among the highest contributors to the production cost, which would negatively influence the net income obtained. In addition, hemp grain and fiber yields also had a high influence on the net income, as the yield can directly increase/decrease the net income. For grain hemp, land rental cost was also one of the most influential parameters as it contributed more than 20% of the cost. Farmers and processors, as well as other researchers, can use this sensitivity analysis as a starting point, which identifies the major hotspots within the system in the current context. This will provide direction for future research as the system needs to be optimized for the field production of both grain and fiber hemp and the processing of the fiber stalks.

4. Conclusions

The techno-economics of hemp grain and fiber production and processing for an average U.S. farm size of 162 ha was evaluated. The total cost of hemp grain and fiber production, harvest, post-harvest logistics, and processing was estimated to be USD 2913–3573 Mg−1 and USD 1155–1505 Mg−1, respectively. Seed and fertilizer costs were the largest contributor to the field production cost, while facility and labor costs were the highest contributors to processing costs. This analysis showed that hemp grain and fiber had high resource requirements but, with the current state of technology, could produce higher net income compared to conventional crops. However, due to the high price fluctuations, hemp production for grain and fiber also showed risks when considering low market product prices. In conclusion, under current conditions, hemp grain and fiber can provide U.S. farmers with a viable alternative crop that can be grown in rotation with existing crops such as corn, soybean and cotton.