The Addition of Charcoal Fines Can Increase the Photodegradation Resistance of Polymeric Biocomposites †

Abstract

:1. Introduction

2. Materials and Methods

Data Analysis

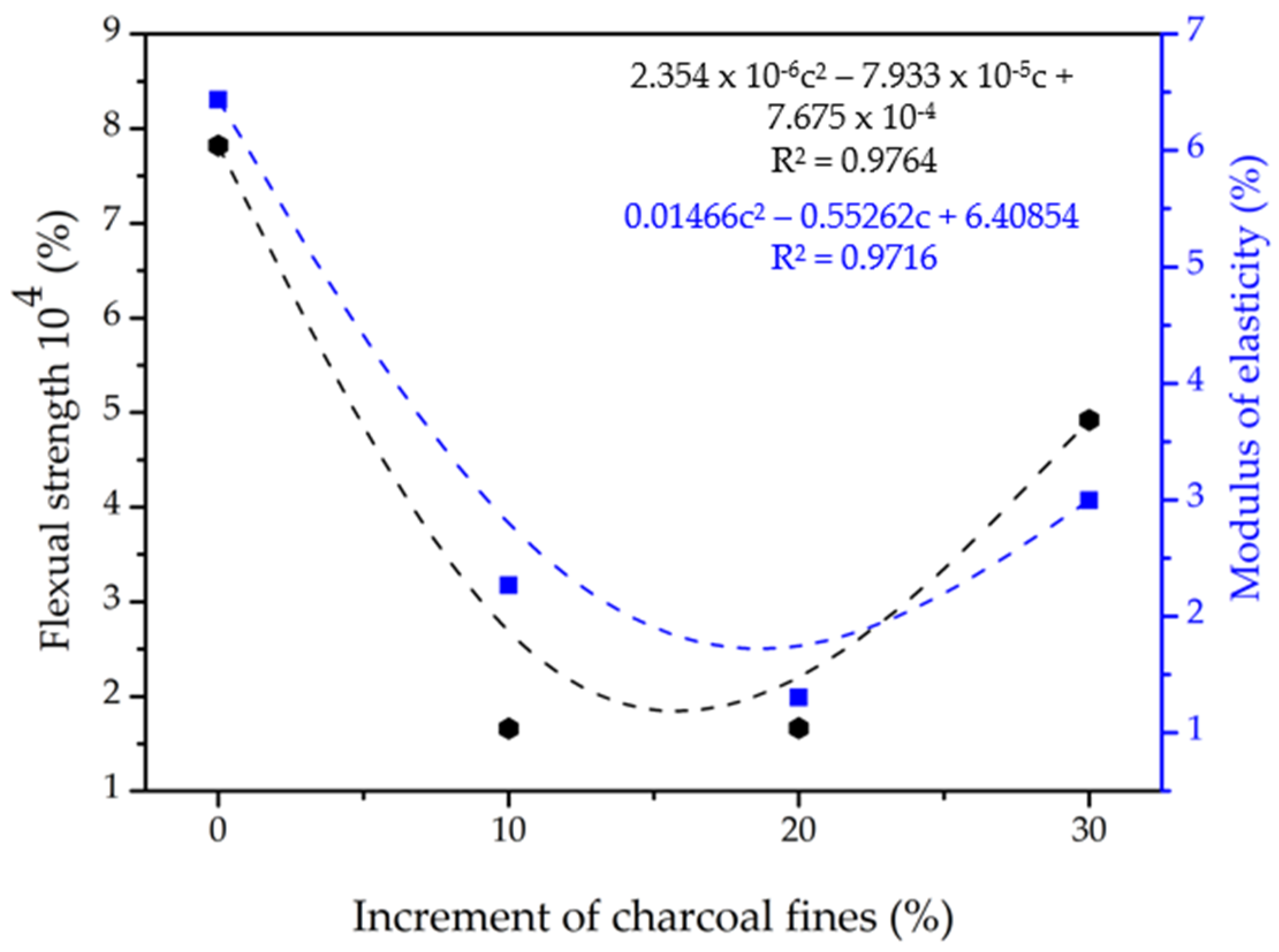

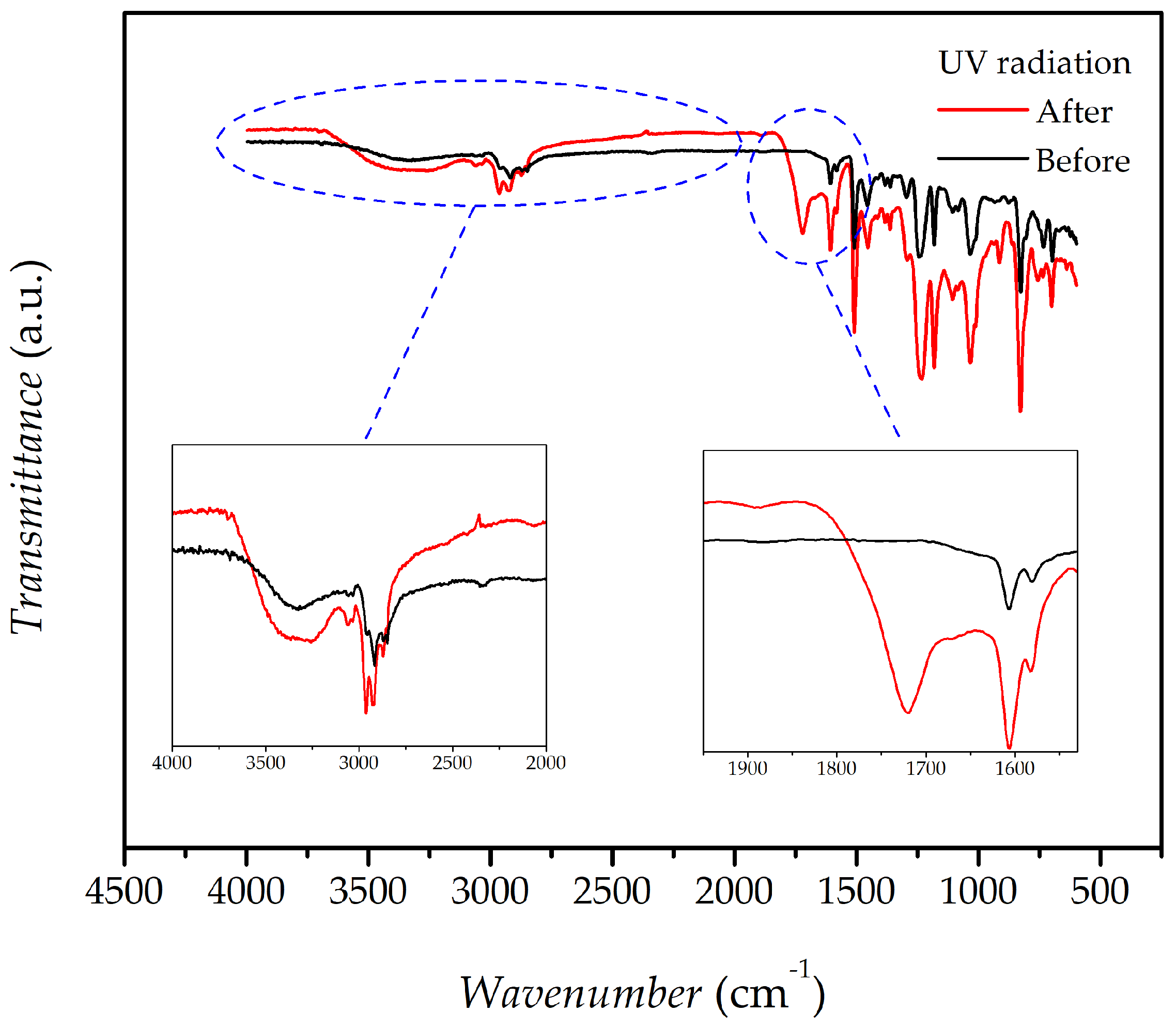

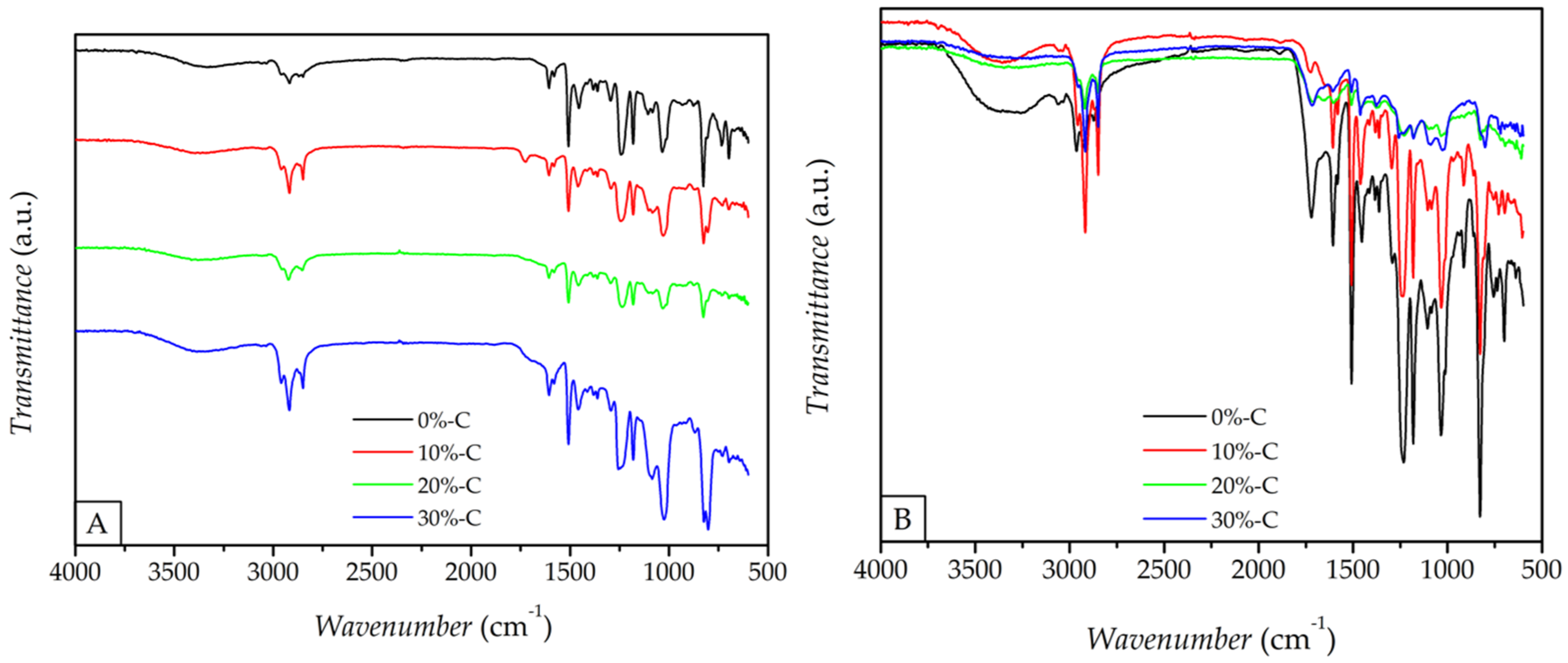

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Polok-Rubiniec, M.; Włodarczyk-Fligier, A. Polypropylene matrix composite with charcoal filler. J. Achiev. Mater. Manuf. Eng. 2020, 2, 60–66. [Google Scholar] [CrossRef]

- Nazarpour-Fard, H.; Rad-Moghadam, K.; Shirini, F.; Hosain Beheshty, M.; Hosein Asghari, G. Reinforcement of epoxy resin/carbon fiber composites by carboxylated carbon nanotubes: A dynamic mechanical study. Polimery 2018, 63, 253–263. [Google Scholar] [CrossRef]

- Akaluzia, R.O.; Edoziuno, F.O.; Adediran, A.A.; Odoni, B.U.; Edibo, S.; Olayanju, T.M.A. Evaluation of the effect of reinforcement particle sizes on the impact and hardness properties of hardwood charcoal particulate-polyester resin composites. Mater. Today Proc. 2021, 38, 570–577. [Google Scholar] [CrossRef]

- Jagadeesh, V.; Venkatasubbaiah, K.; Lakshumu Naidu, A. Experimental study on mechanical behavior of natural hybrid composites filled with ground nut shell ash. Mech. Mech. Eng. 2019, 23, 218–227. [Google Scholar] [CrossRef]

- Reddy, S.; Xu, X.; Guo, T.; Zhu, R.; He, L.; Ramakrishana, S. Allotropic carbon (graphene oxide and reduced graphene oxide) based biomaterials for neural regeneration. Curr. Opin. Biomed. Eng. 2018, 6, 120–129. [Google Scholar] [CrossRef]

- Das, S.C.; Ashek-E-Khoda, S.; Sayeed, M.A.; Paul, D.; Dhar, S.A.; Grammatikos, S.A. On the use of wood charcoal filler to improve the properties of natural fiber reinforced polymer composites. Mater. Today Proc. 2021, 44, 926–929. [Google Scholar] [CrossRef]

- Huang, J.; Mao, C.; Zhu, Y.; Jiang, W.; Yang, X. Control of carbon nanotubes at the interface of a co-continuous immiscible polymer blend to fabricate conductive composites with ultralow percolation thresholds. Carbon N. Y. 2014, 73, 267–274. [Google Scholar] [CrossRef]

- American Society for Testing Materials—ASTM. D 7264M-15; Standard Test Method for Flexural Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2021.

- Maity, P.; Kasisomayajula, S.; Parameswaran, V.; Basu, S.; Gupta, N. Improvement in surface degradation properties of polymer composites due to pre-processed nanometric alumina fillers. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 63–72. [Google Scholar] [CrossRef]

- Nikafshar, S.; Zabihi, O.; Ahmadi, M.; Mirmohseni, A.; Taseidifar, M.; Naebe, M. The Effects of UV Light on the Chemical and Mechanical Properties of a Transparent Epoxy-Diamine System in the Presence of an Organic UV Absorber. Materials 2017, 10, 180. [Google Scholar] [CrossRef] [PubMed]

- Islam, M.T.; Das, S.C.; Saha, J.; Paul, D.; Islam, M.T.; Rahman, M.; Khan, M.A. Effect of Coconut Shell Powder as Filler on the Mechanical Properties of Coir-polyester Composites. Chem. Mater. Eng. 2017, 5, 75–82. [Google Scholar] [CrossRef]

- Xanthos, M. Functional Fillers for Plastics, 1st ed.; Wiley-VCH Verlag GmbH: Weinheim, Germany, 2005; pp. 5–19. [Google Scholar]

- Dahal, R.K.; Acharya, B.; Saha, G.; Bissessur, R.; Dutta, A.; Farooque, A. Biochar as a filler in glassfiber reinforced composites: Experimental study of thermal and mechanical properties. Compos. Part B Eng. 2019, 175, 107169. [Google Scholar] [CrossRef]

- Yui, H.; Wu, G.; Sano, H.; Sumita, M.; Kino, K. Morphology and electrical conductivity of injection-molded polypropylene/carbon black composites with addition of high-density polyethylene. Polymer 2006, 47, 3599–3608. [Google Scholar] [CrossRef]

- Peña, J.M.; Allen, N.S.; Edge, M.; Liauw, C.M.; Valange, B. Studies of synergism between carbon black and stabilisers in LDPE photodegradation. Polym. Degrad. Stab. 2001, 72, 259–270. [Google Scholar] [CrossRef]

- Ghasemi-Kahrizsangi, A.; Neshati, J.; Shariatpanahi, H.; Akbarinezhad, E. Improving the UV degradation resistance of epoxy coatings using modified carbon black nanoparticles. Prog. Org. Coatings 2015, 85, 199–207. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Delatorre, F.M.; Pereira, A.K.S.; da Silva, Á.M.; de Souza, E.C.; Oliveira, M.P.; Profeti, D.; Profeti, L.P.R.; Dias Júnior, A.F. The Addition of Charcoal Fines Can Increase the Photodegradation Resistance of Polymeric Biocomposites. Environ. Sci. Proc. 2022, 13, 8. https://doi.org/10.3390/IECF2021-10812

Delatorre FM, Pereira AKS, da Silva ÁM, de Souza EC, Oliveira MP, Profeti D, Profeti LPR, Dias Júnior AF. The Addition of Charcoal Fines Can Increase the Photodegradation Resistance of Polymeric Biocomposites. Environmental Sciences Proceedings. 2022; 13(1):8. https://doi.org/10.3390/IECF2021-10812

Chicago/Turabian StyleDelatorre, Fabíola Martins, Allana Katiussya Silva Pereira, Álison Moreira da Silva, Elias Costa de Souza, Michel Picanço Oliveira, Demetrius Profeti, Luciene Paula Roberto Profeti, and Ananias Francisco Dias Júnior. 2022. "The Addition of Charcoal Fines Can Increase the Photodegradation Resistance of Polymeric Biocomposites" Environmental Sciences Proceedings 13, no. 1: 8. https://doi.org/10.3390/IECF2021-10812