Wear of Carbide Plates with Diamond-like and Micro-Nano Polycrystalline Diamond Coatings during Interrupted Cutting of Composite Alloy Al/SiC

Abstract

:1. Introduction

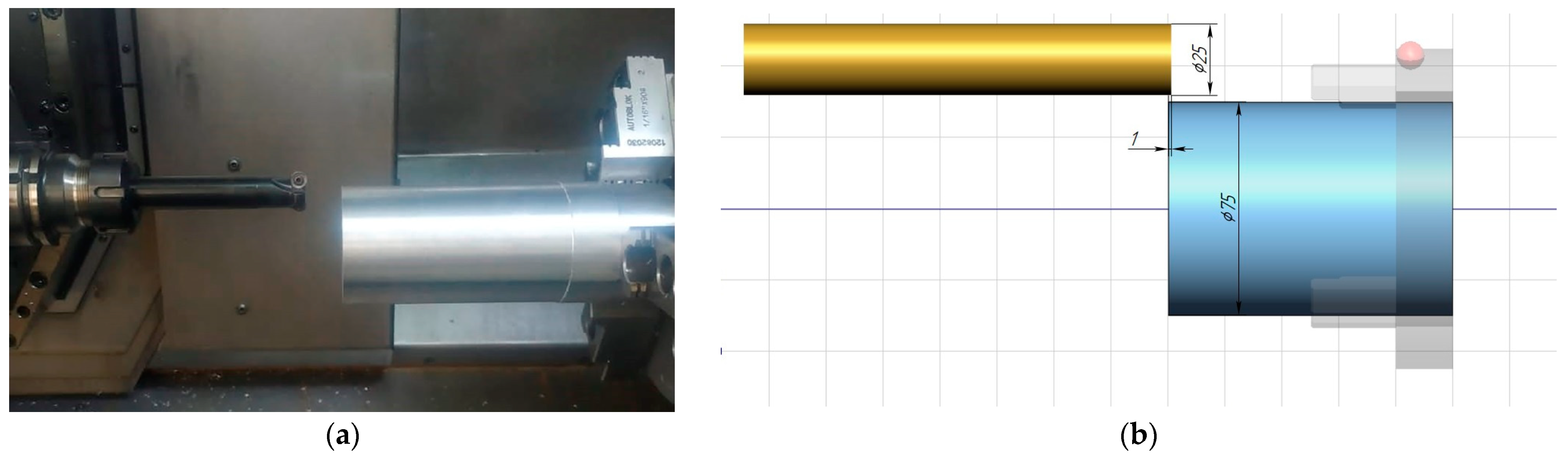

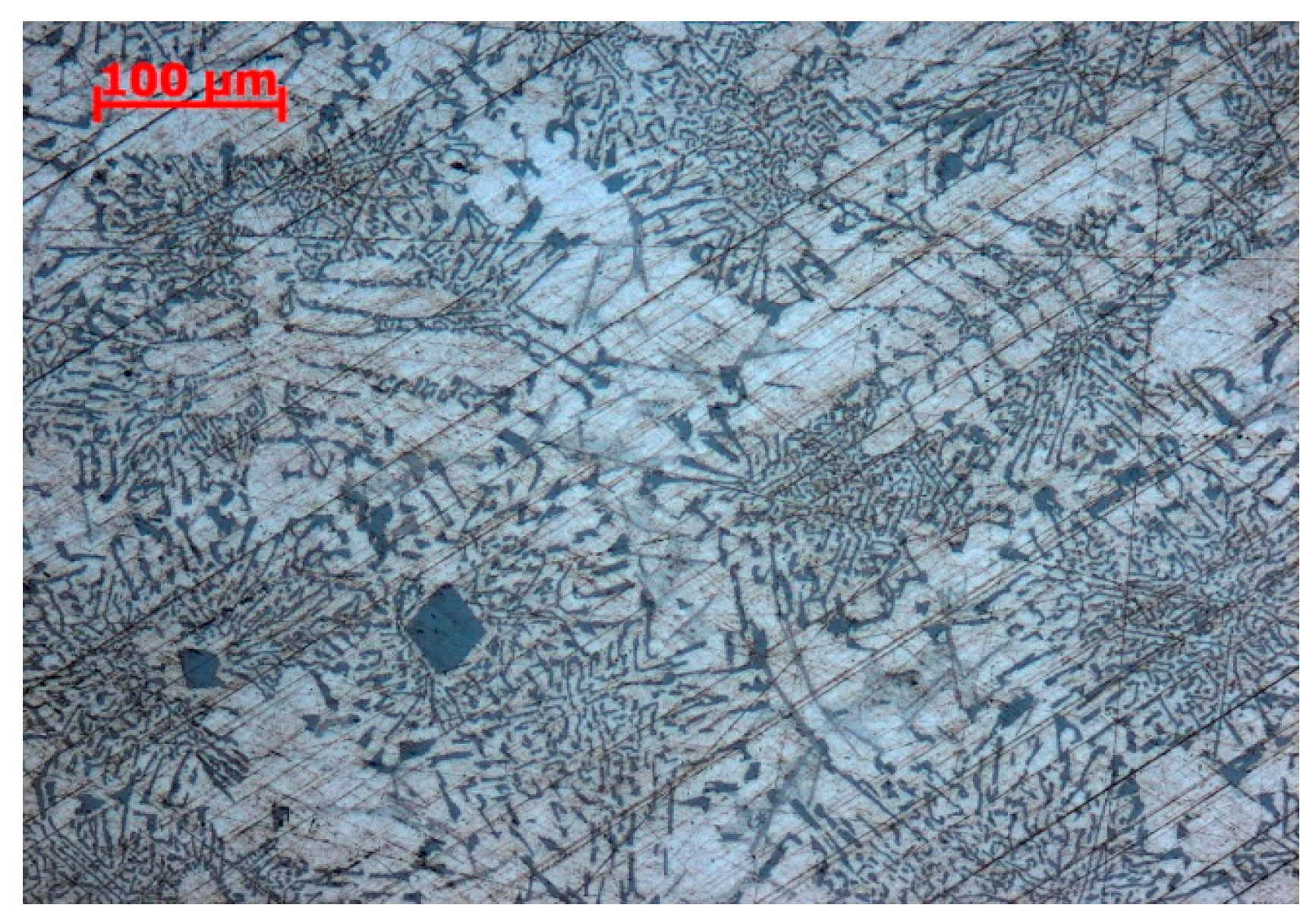

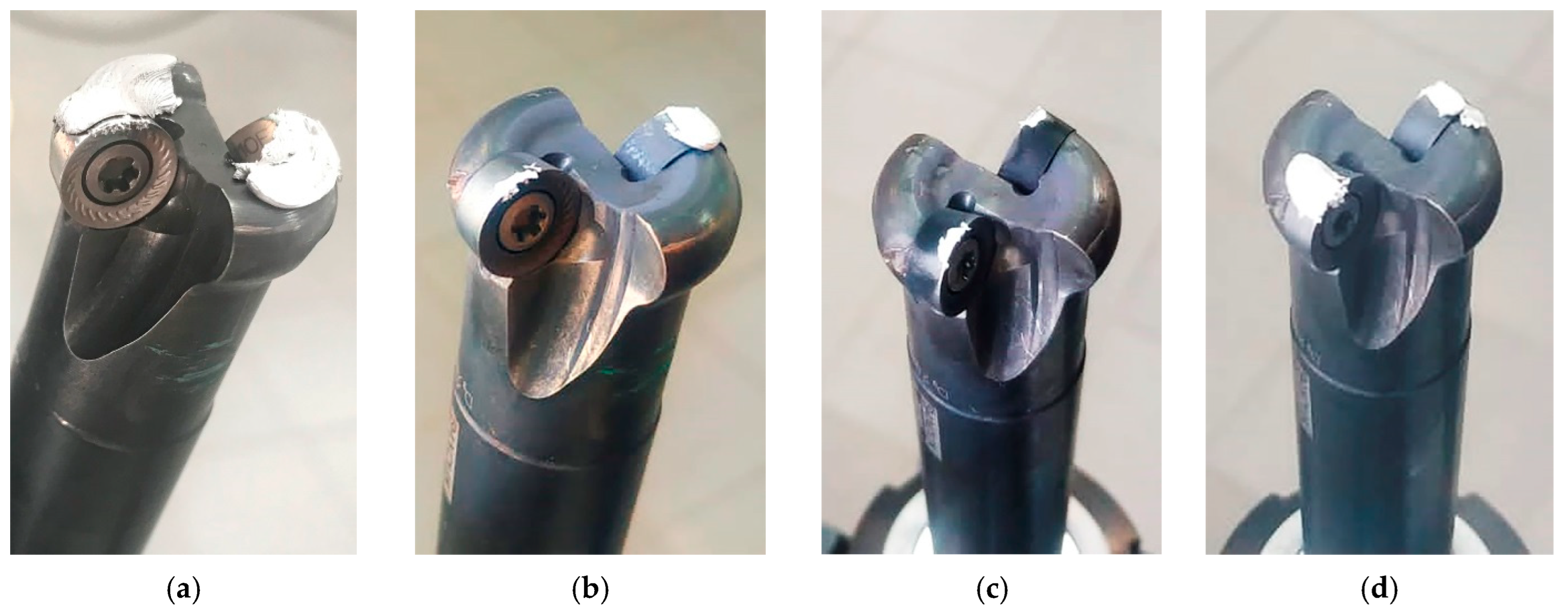

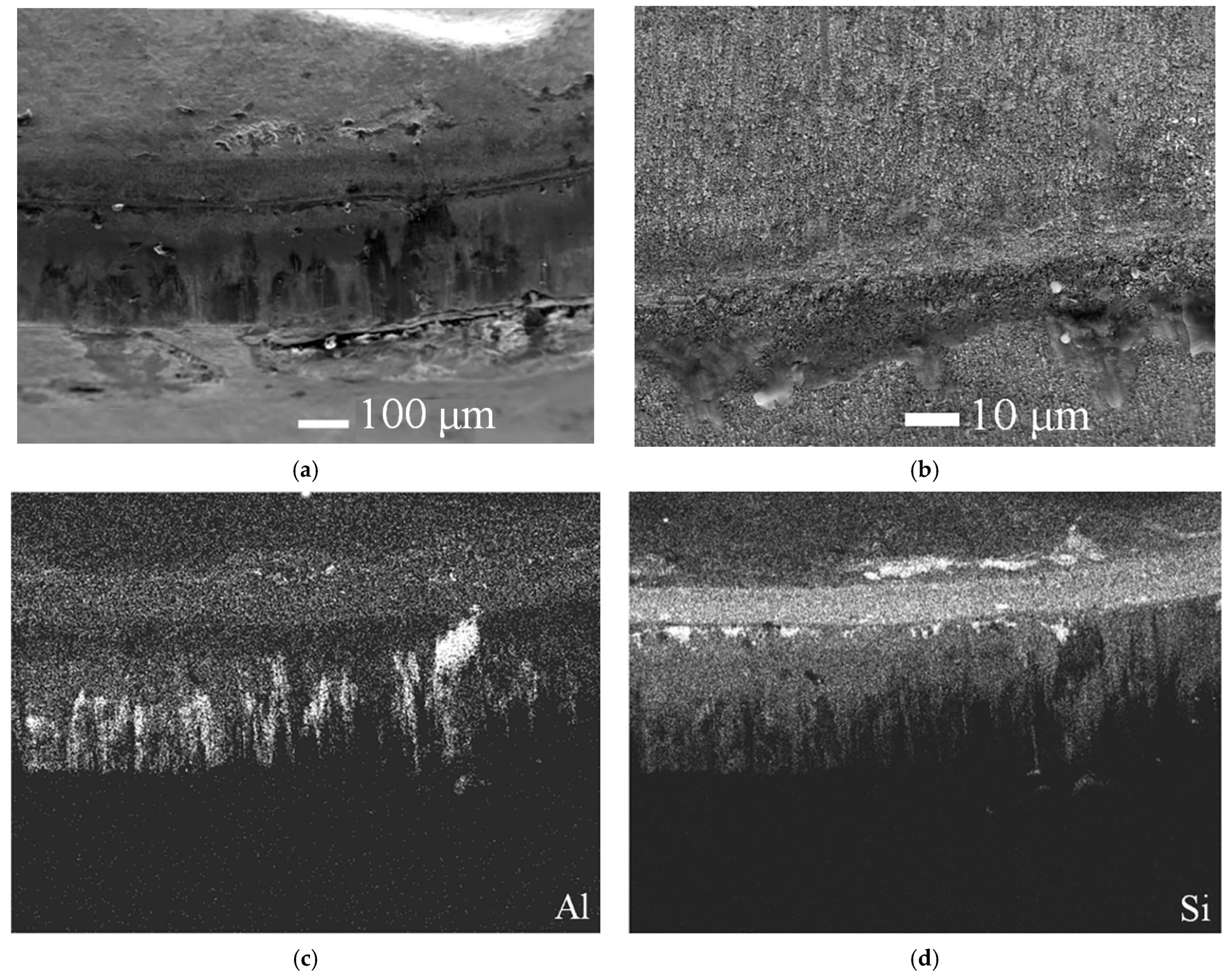

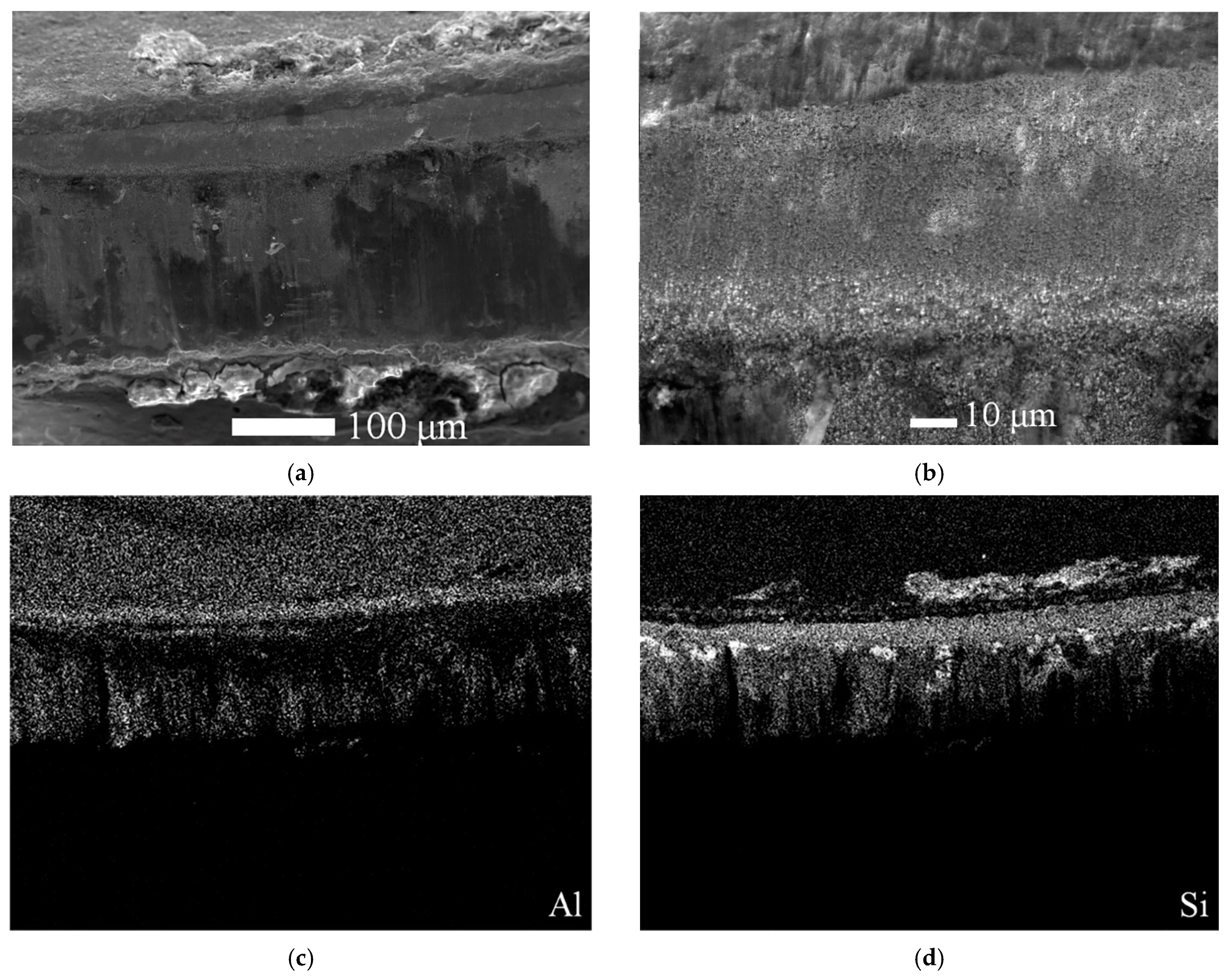

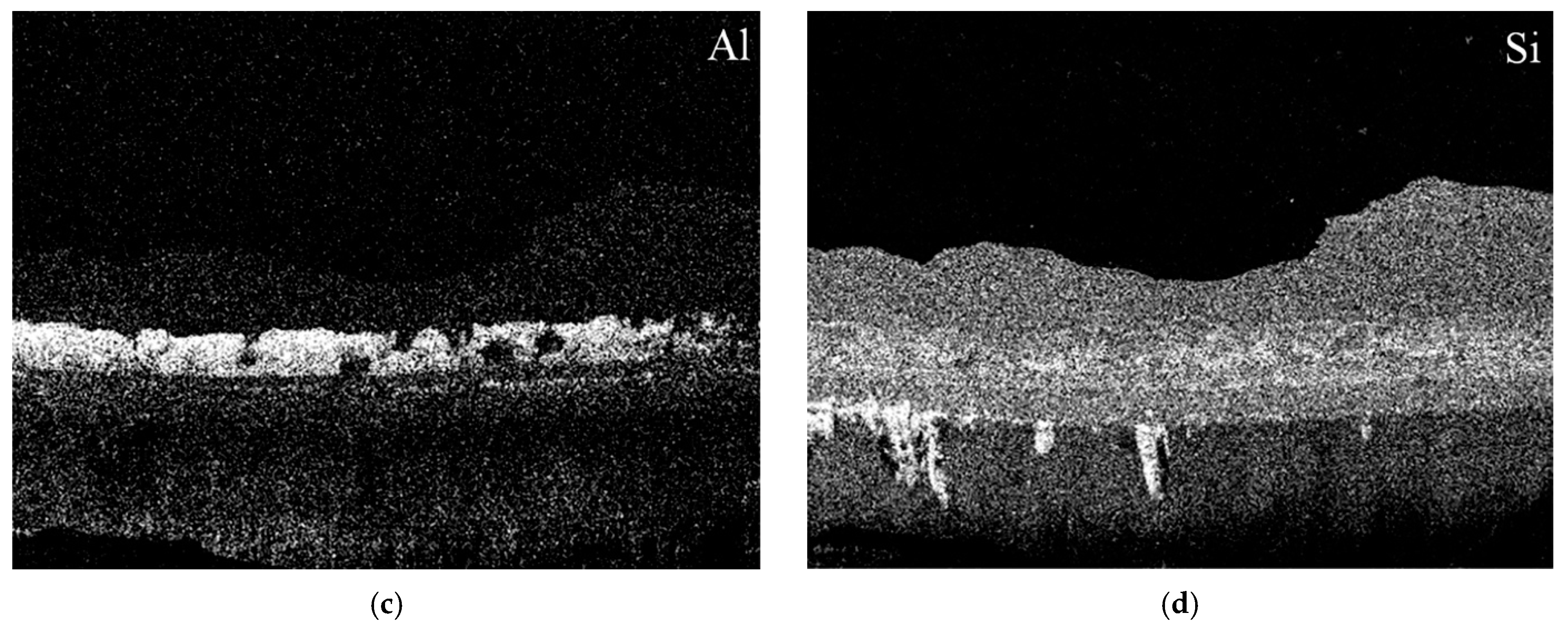

2. Materials and Methods

2.1. Cutting Tools and Machined Material

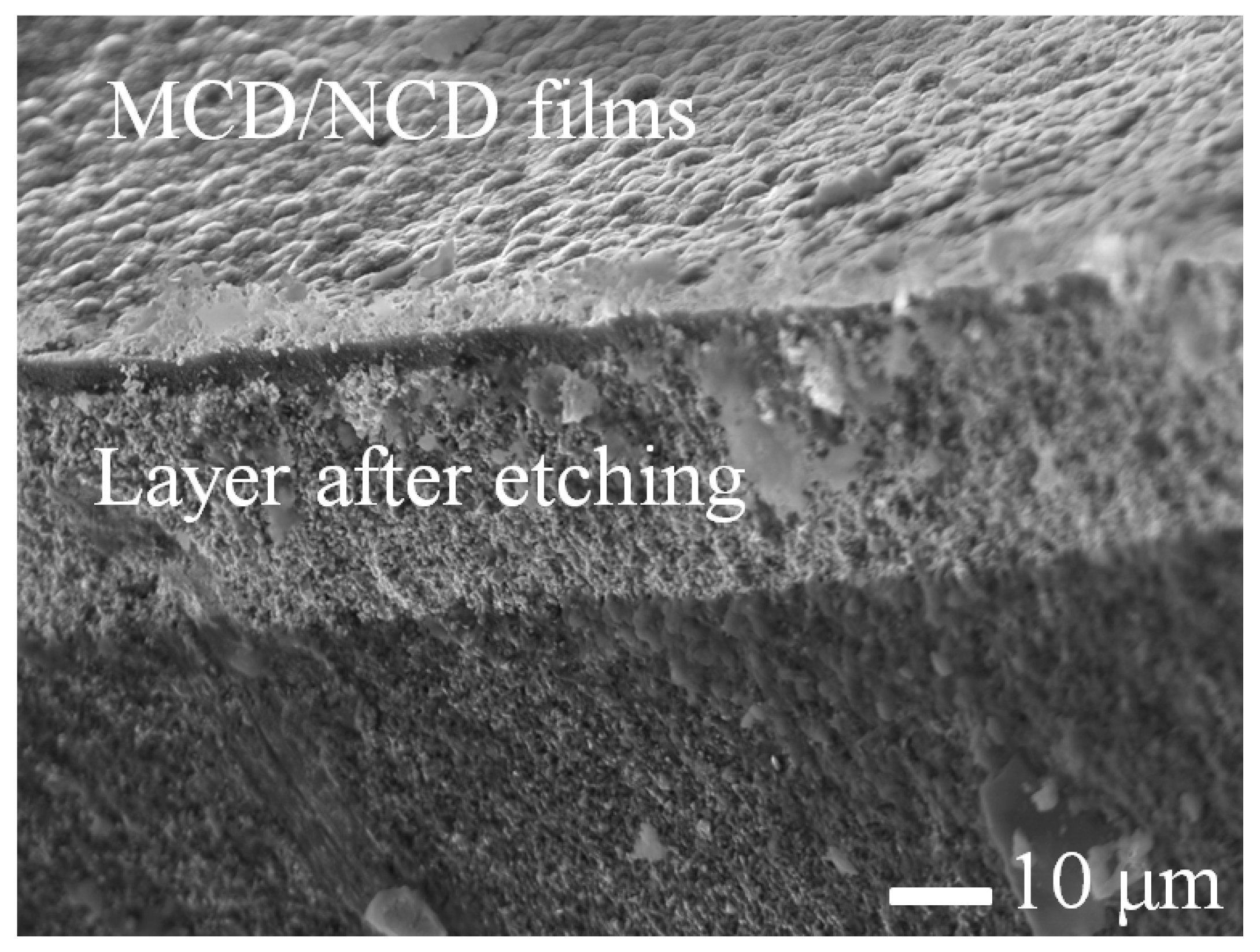

2.2. Tool Coatings

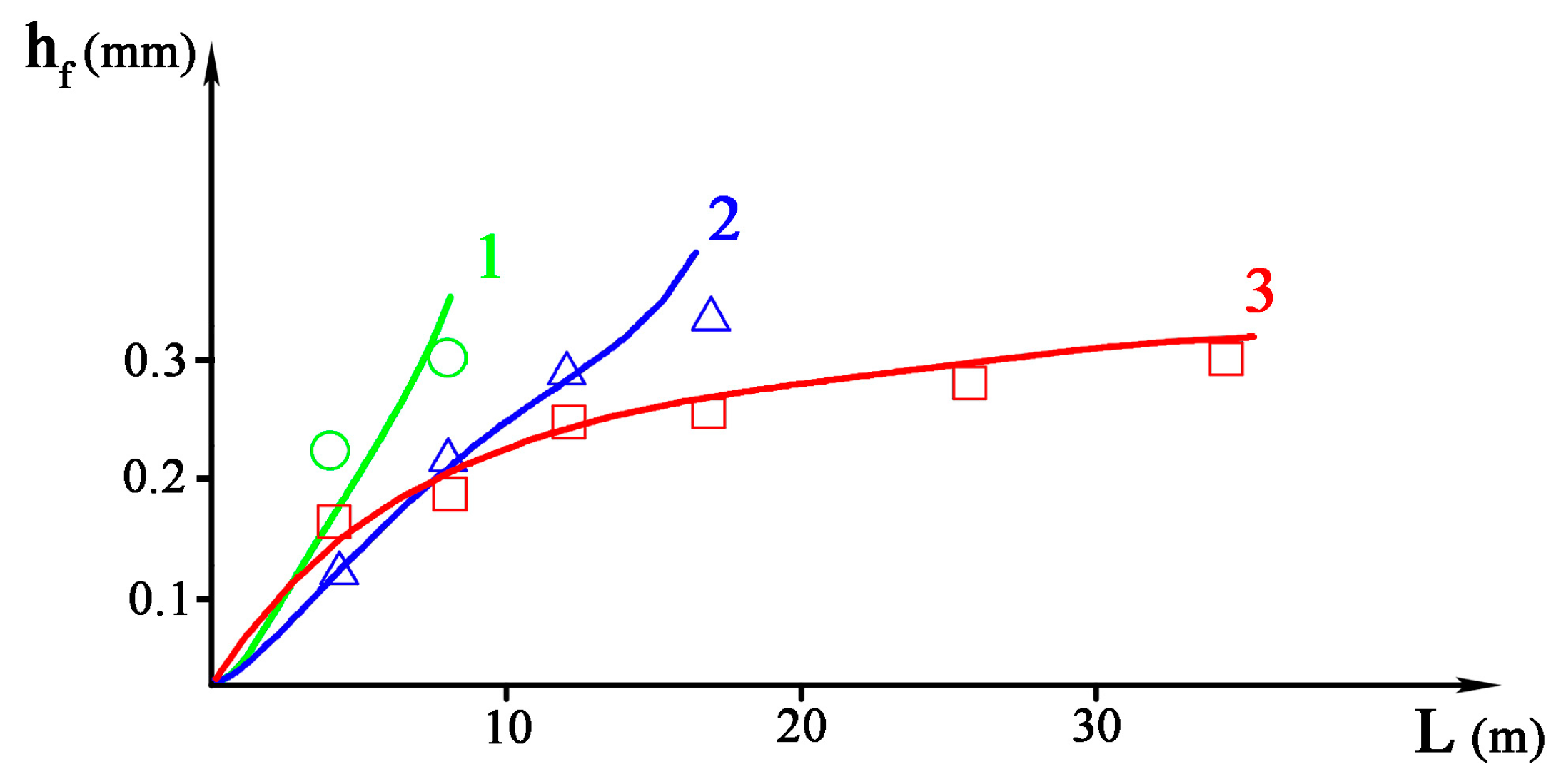

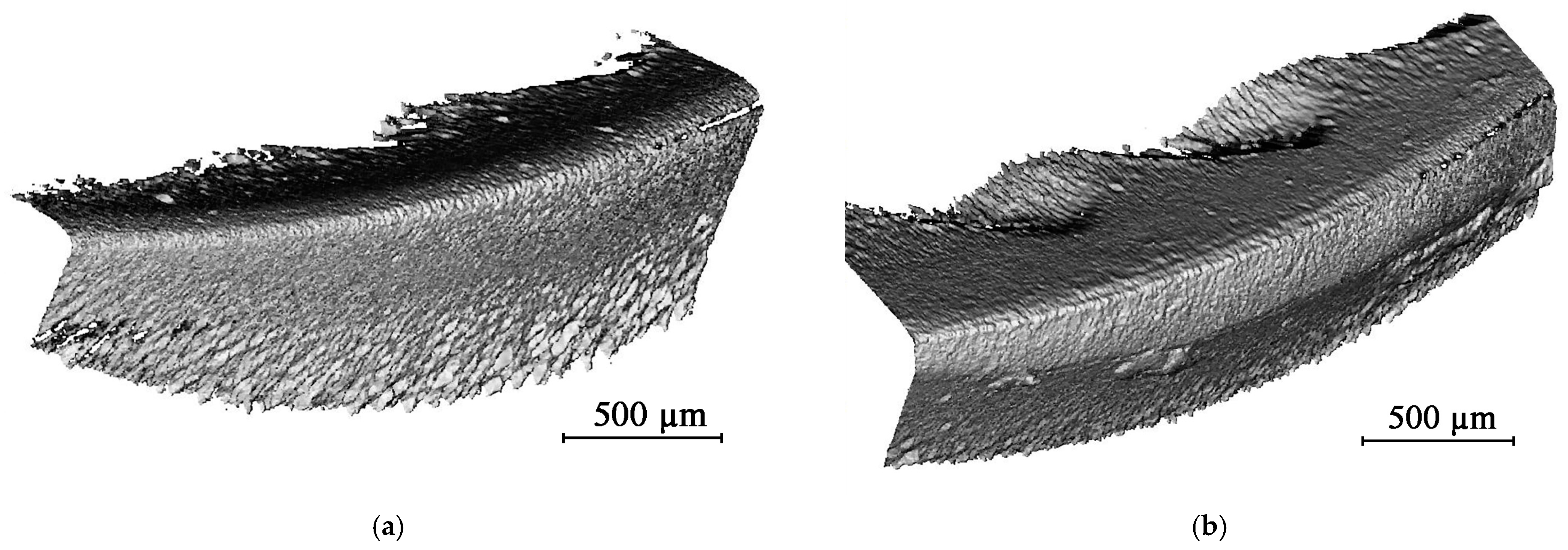

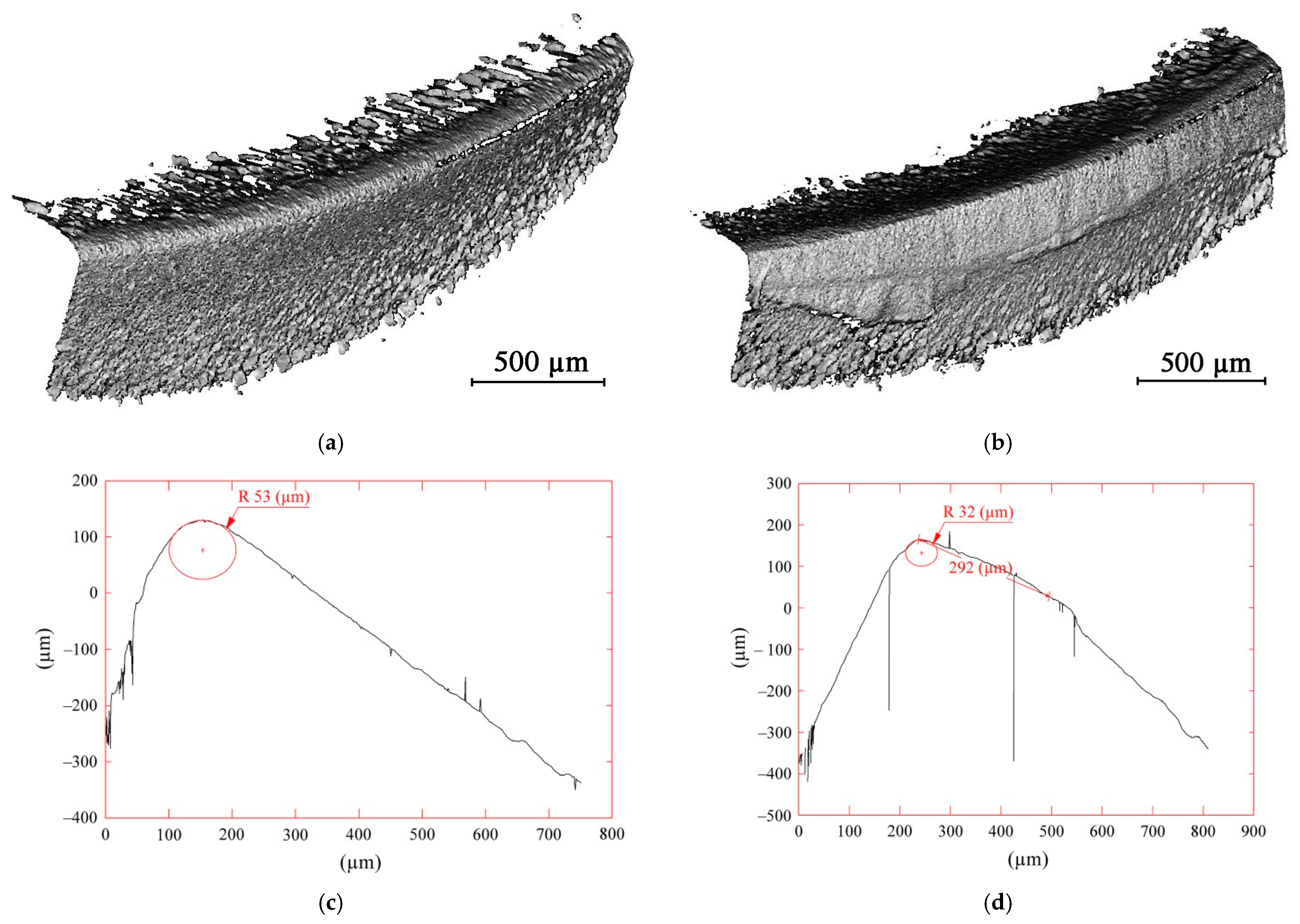

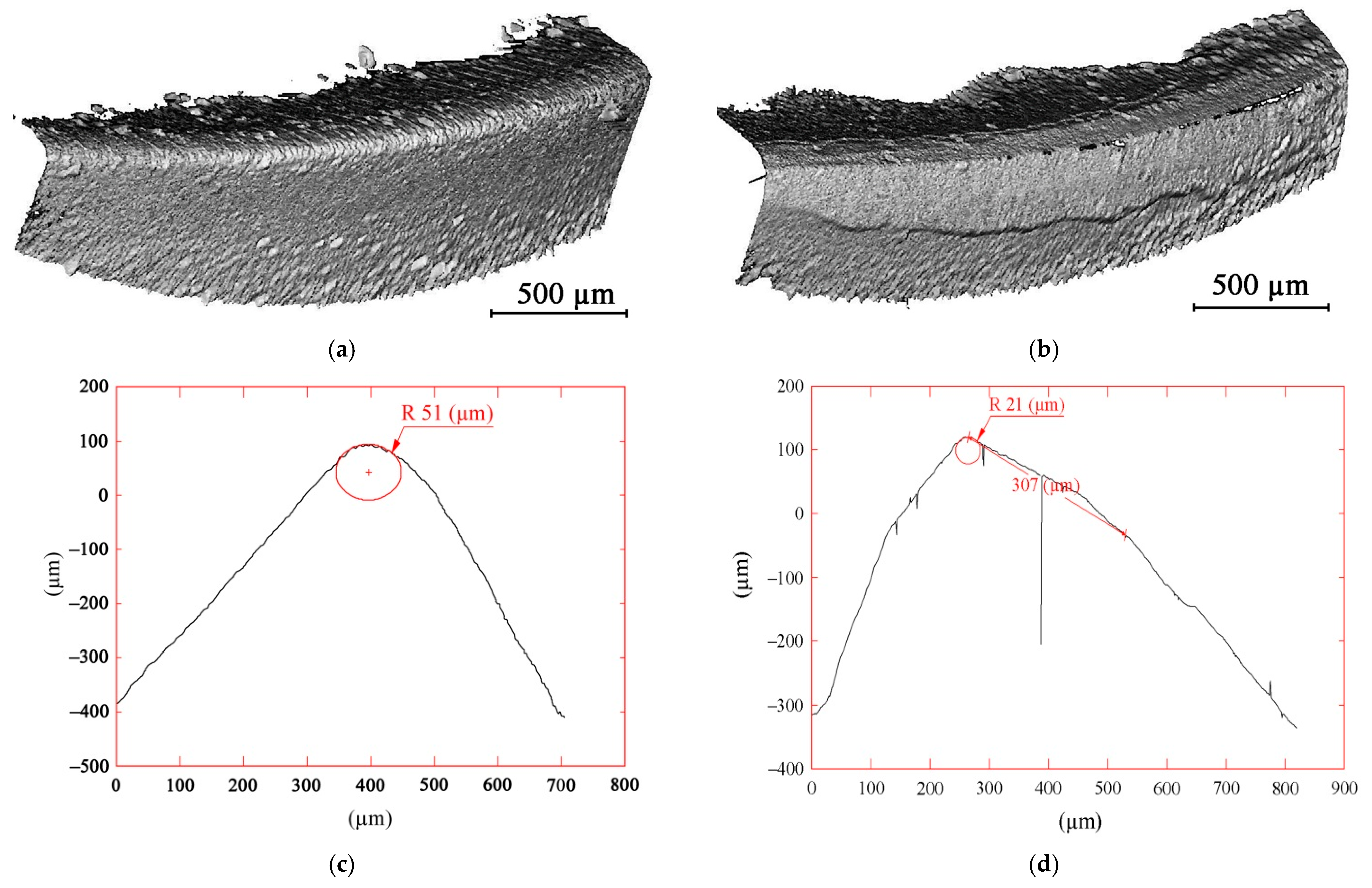

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kathiravan, S.; Thanigaivelan, R.; Suresh, P. Fabrication, microstructure, and machinability of aluminum metal-matrix composites. Mater. Sci. 2022, 40, 112–124. [Google Scholar] [CrossRef]

- Sambathkumar, M.; Gukendran, R.; Mohanraj, T.; Karupannasamy, D.K.; Natarajan, N.; Christopher, D.S. A Systematic Review on the Mechanical, Tribological, and Corrosion Properties of Al 7075 Metal Matrix Composites Fabricated through Stir Casting Process. Adv. Mater. Sci. Eng. 2023, 1, 5442809. [Google Scholar] [CrossRef]

- Nturanabo, F.; Masu, L.; Kirabira, J.B. Novel Application of Aluminium Metal Matrix Composites. In Aluminum Alloys and Composites; Cooke, K.O., Ed.; IntechOpen: London, UK, 2019. [Google Scholar] [CrossRef]

- Vijayakumar, S.; Soundarrajan, M.; Palanisamy, P.; Pasupathi, K. Studies on Mechanical Properties of Al-SiC Metal Matrix Composite. Int. J. Mater. Sci. Eng. 2016, 2, 1–5. Available online: https://www.researchgate.net/publication/310954061 (accessed on 5 December 2023).

- Poornesh, M.; Harish, N.; Kiran, A. Mechanical and Tribological Properties of Centrifugally Cast Al-Si-SiC Composites. Am. J. Mater. Sci. 2016, 6, 31–35. [Google Scholar]

- Singh, R.K.; Khan, M.M.; Telang, A. Effects of SiCp Reinforcement on the Abrasive Wear Properties of Al-Si Alloy. Int. J. Eng. Technol. 2016, 8, 1679–1686. [Google Scholar] [CrossRef]

- Santos, M.C., Jr.; Machado, A.; Sales, W.F.; Barrozo, M.; Emmanuel, O.; Ezugwu, E.O. Machining of aluminum alloys: A review. Int. J. Adv. Manuf. Technol. 2016, 86, 3067–3080. [Google Scholar] [CrossRef]

- Repeto, D.; Fernández-Vidal, S.R.; Mayuet, P.F.; Salguero, J.; Batista, M. On the Machinability of an Al-63%SiC Metal Matrix Composite. Materials 2020, 13, 1186. [Google Scholar] [CrossRef] [PubMed]

- Kohli, A.; Bain, H.S.; Jain, S.; Priyadarshi, D. Machinability and Wear of Aluminium Based Metal Matrix Composites by MQL—A Review. Mat. Sci. Res. India 2017, 14, 194–203. [Google Scholar] [CrossRef]

- Sougavabar, M.A.; Niknam, S.A.; Davoodi, B. Study of tool flank wear and surface quality in milling of Al520-MMCs reinforced with SiC and Sn particles. J. Sci. Technol. Compos. 2023, 9, 1970–1975. [Google Scholar]

- Lin, J.; Jia, R.; Zhou, Y.; Gu, Y. PCD tool wear in cutting SiCp/6005Al composites. Diam. Abras. Eng. 2023, 43, 322–331. [Google Scholar] [CrossRef]

- Calatoru, V.D.; Balazinski, M.; Mayer, R.; Paris, H.; L’Esperance, G. Diffusion wear mechanism during high-speed machining of 7475-T7351 aluminum alloy with carbide end mills. Wear 2008, 265, 1793–1800. [Google Scholar] [CrossRef]

- Chang, H.; Li, S.; Shi, R. Design and manufacturing technology of high-speed milling cutter for aluminum alloy. Procedia Eng. 2017, 174, 630–637. [Google Scholar] [CrossRef]

- Ghoreishi, R.; Roohi, A.H.; Ghadikolaei, A.D. Evaluation of tool wear in high-speed face milling of Al/SiC metal matrix composites. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 146. [Google Scholar] [CrossRef]

- Chen, J.-P.; Gu, L.; He, G.-J. A review on conventional and nonconventional machining of SiC particle-reinforced aluminum matrix composites. Adv. Manuf. 2020, 8, 279–315. [Google Scholar] [CrossRef]

- Grabowski, A.; Nowak, M.; Śleziona, J. Laser cutting of an AlSi alloy/SiCp composites: Theory and experiments. J. Achiev. Mater. Manuf. Eng. 2006, 17, 61–64. Available online: https://www.researchgate.net/publication/42107256 (accessed on 5 December 2023).

- Mohan, R.R.; Venkatraman, R.; Raghuraman, S.; Kumar, P.M.; Rinawa, M.L.; Subbiah, R.; Arulmurugan, B.; Rajkumar, S. Processing of Aluminium-Silicon Alloy with Metal Carbide as Reinforcement through Powder-Based Additive Manufacturing: A Critical Study. Scanning 2022, 2022, 5610333. [Google Scholar] [CrossRef]

- Huang, B.; Zhang, E.-G.; Zhou, Q.; Lin, R.-C.; Du, H.-M. Research on the Performance of Diamond-Like Carbon Coatings on Cutting Aluminum Alloy: Cutting Experiments and First-Principles Calculations. Coatings 2021, 11, 63. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Volosova, M.A.; Vereschaka, A.A.; Sitnikov, N.N.; Milovich, F.; Bublikov, J.I.; Fyodorov, S.V.; Seleznev, A.E. Properties of (Cr,Al,Si)N-(DLC-Si) composite coatings deposited on a cutting ceramic substrate. Ceram. Int. 2020, 46, 18241–18255. [Google Scholar] [CrossRef]

- Ashkinazi, E.; Fedorov, S.; Khomich, A.; Rogalin, V.; Bolshakov, A.; Sovyk, D.; Grigoriev, S.; Konov, V. Technology Features of Diamond Coating Deposition on a Carbide Tool. C 2022, 8, 77. [Google Scholar] [CrossRef]

- Polini, R. Chemically vapor deposited diamond coatings on cemented tungsten carbides: Substrate pretreatments, adhesion and cutting performance. Thin Solid Film. 2006, 515, 4–13. [Google Scholar] [CrossRef]

- Lu, F.; Hao, T.; Bai, X.; Fu, Z. Research on the innovative pretreatment to improve the adhesion and performance of diamond coatings. Fuller. Nanotub. Carbon Nanostructures 2022, 30, 1002–1010. [Google Scholar] [CrossRef]

- Martinez-Martinez, D.; De Hosson, J. On the deposition and properties of DLC protective coatings on elastomers: A critical review. Surf. Coat. Technol. 2014, 258, 677–690. [Google Scholar] [CrossRef]

- Hofmann, D.; Kunkel, S.; Bewilogua, K.; Wittorf, R. From DLC to Si-DLC based layer systems with optimized properties for tribological applications. Surf. Coat. Technol. 2013, 215, 357–363. [Google Scholar] [CrossRef]

- Kuznetsova, T.; Lapitskaya, V.; Khabarava, A.; Trukhan, R.; Chizhik, S.; Torskaya, E.; Fedorov, S.; Aizikovich, S.; Sadyrin, E.; Warcholinski, B. Features of wear of DLC-Si coating under microcontact conditions during the formation of secondary structures. Compos. Struct. 2023, 316, 117039. [Google Scholar] [CrossRef]

- Lukaszkowicz, K.; Sondor, J.; Balin, K.; Kubacki, J.M. Characteristics of CrAlSiN + DLC coating deposited by lateral rotating cathode arc PVD and PACVD process. Appl. Surf. Sci. 2014, 312, 126–133. [Google Scholar] [CrossRef]

- Vereschaka, A.; Grigoriev, S.; Tabakov, V.; Migranov, M.; Sitnikov, N.; Milovich, F.; Andreev, N. Influence of the Nanostructure of Ti-TiN-(Ti,Al,Cr)N Multilayer Composite Coating on Tribological Properties and Cutting Tool Life. Tribol. Int. 2020, 150, 106388. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Milovich, F.; Tabakov, V.; Sitnikov, N.; Andreev, N.; Sviridova, T.; Bublikov, J. Investigation of multicomponent nanolayer coatings based on nitrides of Cr, Mo, Zr, Nb, and Al. Surf. Coat. Technol. 2020, 401, 126258. [Google Scholar] [CrossRef]

- Polcar, T.; Cavaleiro, A. High temperature properties of CrAlN, CrAlSiN and AlCrSiN coatings—Structure and oxidation. Mater. Chem. Phys. 2011, 129, 195–201. [Google Scholar] [CrossRef]

- Ding, X.-Z.; Zeng, X.T.; Liu, Y.C. Structure and properties of CrAlSiN Nanocomposite coatings deposited by lateral rotating cathode arc. Thin Solid Film. 2011, 519, 1894–1900. [Google Scholar] [CrossRef]

- Ashkinazi, E.E.; Yurov, V.Y.; Sedov, V.S.; Bolshakov, A.P.; Rogalin, V.E.; Antonova, I.A.; Ralchenko, V.G.; Konov, V.I. Nondestructive diagnostics of diamond coatings of hard alloy cutters. AIP Conf. Proc. 2019, 2176, 040001. [Google Scholar] [CrossRef]

- Sedov, V.; Martyanov, A.; Altakhov, A.; Popovich, A.; Shevchenko, M.; Savin, S.; Zavedeev, E.; Zanaveskin, M.; Sinogeykin, A.; Ralchenko, V.; et al. Effect of substrate holder design on stress and uniformity of large area polycrystalline diamond films grown by microwave plasma-assisted CVD. Coatings 2020, 10, 939. [Google Scholar] [CrossRef]

- Sedov, V.; Martyanov, A.; Ashkinazi, E.; Tiazhelov, I.; Savin, S.; Sovyk, D.; Mandal, S.; Fedorov, S.; Grigoriev, S.; Ralchenko, V. Effect of diamond seeds size on the adhesion of CVD diamond coatings on WC-Co instrument. Surf. Interfaces 2023, 38, 102861. [Google Scholar] [CrossRef]

- Sedov, V.; Martyanov, A.; Savin, S.; Zavedeev, E.; Kudryavtsev, O.; Bland, H.; Mandal, S.; Williams, O.; Ralchenko, V.; Konov, V. CVD synthesis of multi-layered polycrystalline diamond films with reduced roughness using time-limited injections of N2 gas. Diam. Relat. Mater. 2021, 114, 108333. [Google Scholar] [CrossRef]

- Zolkin, A.; Semerikova, A.; Chepkasov, S.; Khomyakov, M. Characteristics of the Raman spectra of diamond-like carbon films. Influence of methods of synthesis. Mater. Today Proc. 2017, 4, 11480–11485. [Google Scholar] [CrossRef]

- Robertson, J. Diamond-like Amorphous Carbon. Mater. Sci. Eng. R 2002, 37, 129–281. [Google Scholar] [CrossRef]

- Nistor, L.C.; Van Landuyt, J.; Ralchenko, V.G.; Obraztsova, E.D.; Smolin, A.A. Nanocrystalline diamond films: Transmission electron microscopy and Raman spectroscopy characterization. Diam. Relat. Mater. 1997, 6, 159–168. [Google Scholar] [CrossRef]

- Meng, X.; Lin, Y.; Mi, S. The Research of Tool Wear Mechanism for High-Speed Milling ADC12 Aluminum Alloy Considering the Cutting Force Effect. Materials 2021, 14, 1054. [Google Scholar] [CrossRef]

- Han, X.; Xu, D.; Liao, Z.; Li, H.N. On understanding the specific cutting mechanisms governing the workpiece surface integrity in metal matrix composites machining. J. Mater. Process. Technol. 2020, 288, 116875. [Google Scholar] [CrossRef]

- Larsen-Basse, J. Binder extrusion in sliding wear of WC-Co alloys. Wear 1985, 105, 247–256. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Volosova, M.A.; Fedorov, S.V.; Mosyanov, M.A. Influence of DLC Coatings Deposited by PECVD Technology on the Wear Resistance of Carbide End Mills and Surface Roughness of AlCuMg2 and 41Cr4 Workpieces. Coatings 2020, 10, 1038. [Google Scholar] [CrossRef]

- Ashkinazi, E.E.; Tsygankov, P.A.; Sedov, V.S.; Vinogradov, D.V.; Kozlova, M.V.; Popovich, A.F.; Dravin, V.A.; Ralchenko, V.G. Microwave plasma CVD deposition of micro- and nanocrystalline diamond coatings on hard alloy substrates. In Proceedings of the 12th International Conference “Interaction of Radiation with Solids”, Minsk, Belarus, 19–22 September 2017; pp. 425–427. [Google Scholar]

- Gershman, I.; Mironov, A.; Fox Rabinovich, G.; Muravyeva, T.; Shkalei, I.; Shcherbakova, O.; Torskaya, E.; Fedorov, S.; Endrino, J.L. Secondary Structures on the Friction Surface of Diamond-like Coating. Coatings 2022, 12, 1685. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Diameter | 24.886 mm |

| Number of teeth | 2 |

| End teeth runout | 0.0013 mm |

| Insert radius | 5.0398 mm |

| Spiral angle (spiral left) | 13.971° |

| The rake angle is 1 mm from the top | 3.209° |

| The flank angle is 1 mm from the top | 18.805° |

| Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Bi |

| 13.49 | 1.032 | 4.228 | 0.021 | 0.506 | 0.024 | 0.012 | 0.012 | 0.036 | 0.033 |

| Ga | Li | Na | P | Pb | Sn | V | Zr | Sb | Al |

| 0.017 | 0.013 | 0.016 | 0.005 | 0.128 | 0.020 | 0.049 | 0.019 | 0.009 | Base |

| Diamond-like Coating | Polycrystalline Diamond Coating | |

|---|---|---|

| Type | A 1 µm thickness amorphous carbon film a-C:H:Si is grown on a 2.6 µm intermediate nitride ncAlTiCrN/Si3N4 layer. | A 6 µm thickness 12-layer diamond coating with alternating crystals with micro- and nanostructure (MCD/NCD). |

| Technique | The plasma-enhanced chemical vapor deposition using acetylene (C2H2) and tetramethyl silane (Si(CH3)4) on Platit π311 + DLC installation. | The microwave (2.45 GHz) plasma CVD reactor ARDIS-100 uses a methane/hydrogen gas mixture with periodic nitrogen injection. |

| Structure | The surface microstructure of DLC-Si coatings is globular. The diameter of the globules does not exceed 2 µm, but droplets with a diameter of 3–5 µm were formed due to the deposition technique. | Microcrystalline diamond layers consist mainly of grains with a size of 1–2 µm. However, the size of individual crystallites can reach 10 µm. Nanocrystalline particles consist primarily in randomly oriented grains with a size of no more than 500 nm. |

| Properties | HIT25 = 25.4 GPa | HIT25 = 28.5 GPa |

| EIT = 328 GPa | EIT = 719 GPa | |

| HV = 2318 Vickers | HV = 2601 Vickers |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ashkinazi, E.E.; Fedorov, S.V.; Martyanov, A.K.; Sedov, V.S.; Khmelnitsky, R.A.; Ralchenko, V.G.; Ryzhkov, S.G.; Khomich, A.A.; Mosyanov, M.A.; Grigoriev, S.N.; et al. Wear of Carbide Plates with Diamond-like and Micro-Nano Polycrystalline Diamond Coatings during Interrupted Cutting of Composite Alloy Al/SiC. J. Manuf. Mater. Process. 2023, 7, 224. https://doi.org/10.3390/jmmp7060224

Ashkinazi EE, Fedorov SV, Martyanov AK, Sedov VS, Khmelnitsky RA, Ralchenko VG, Ryzhkov SG, Khomich AA, Mosyanov MA, Grigoriev SN, et al. Wear of Carbide Plates with Diamond-like and Micro-Nano Polycrystalline Diamond Coatings during Interrupted Cutting of Composite Alloy Al/SiC. Journal of Manufacturing and Materials Processing. 2023; 7(6):224. https://doi.org/10.3390/jmmp7060224

Chicago/Turabian StyleAshkinazi, Evgeny E., Sergey V. Fedorov, Artem K. Martyanov, Vadim S. Sedov, Roman A. Khmelnitsky, Victor G. Ralchenko, Stanislav G. Ryzhkov, Andrey A. Khomich, Mikhail A. Mosyanov, Sergey N. Grigoriev, and et al. 2023. "Wear of Carbide Plates with Diamond-like and Micro-Nano Polycrystalline Diamond Coatings during Interrupted Cutting of Composite Alloy Al/SiC" Journal of Manufacturing and Materials Processing 7, no. 6: 224. https://doi.org/10.3390/jmmp7060224