Dynamic Process Behavior in Laser Chemical Micro Machining of Metals

Abstract

:1. Introduction

2. Methodology

2.1. Experimental

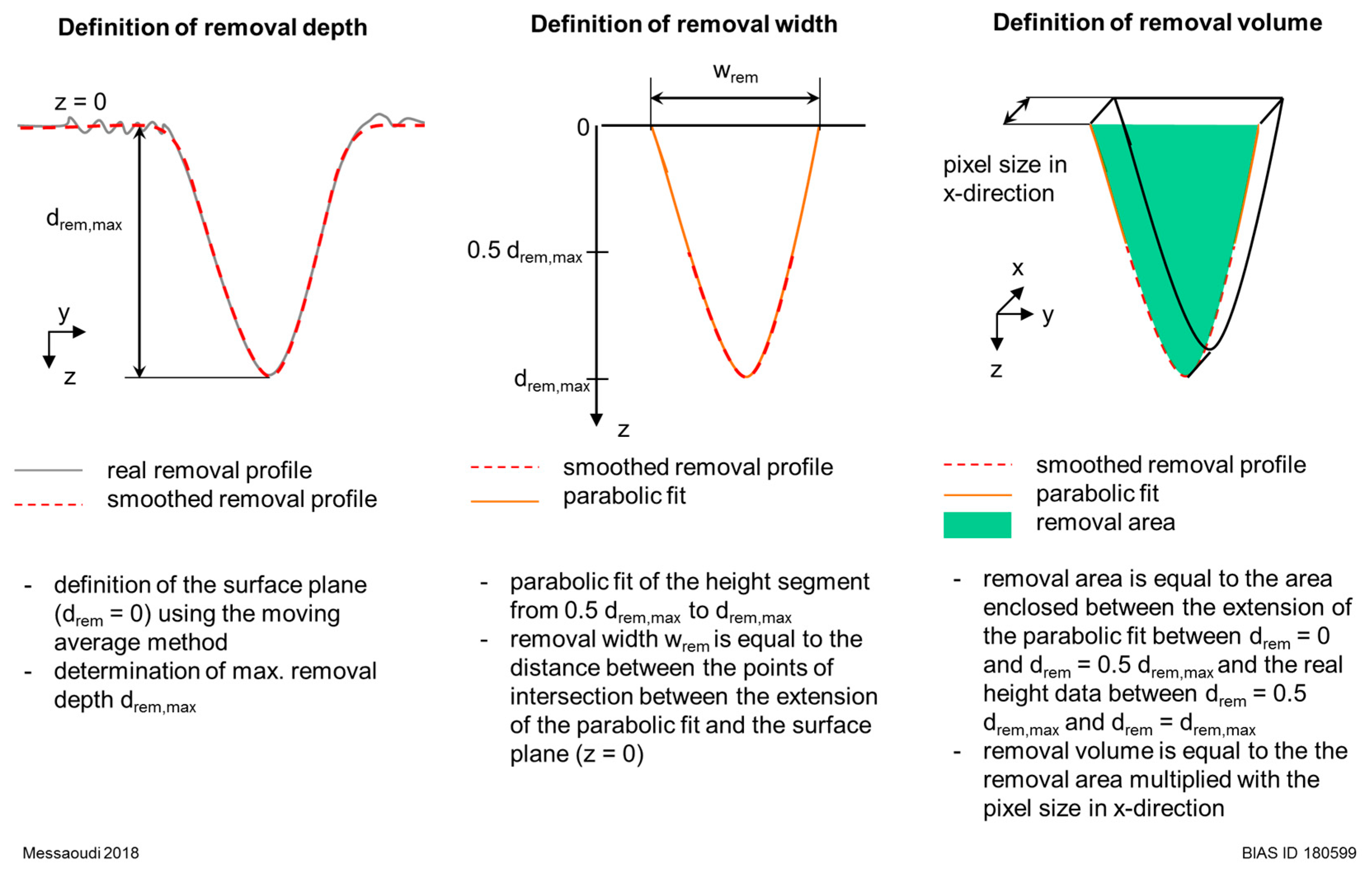

2.2. Definition of the Removal Geometry

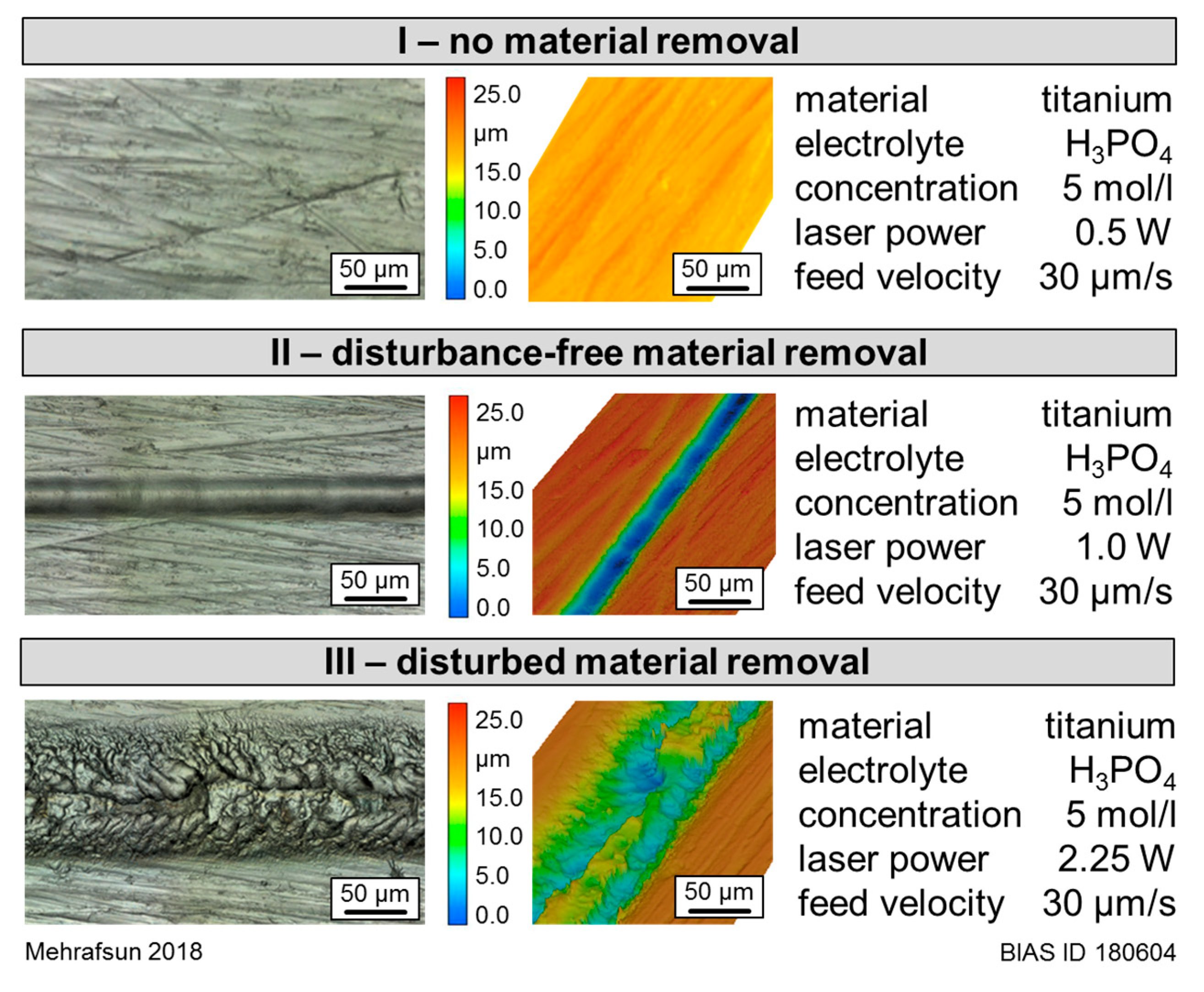

2.3. Categorization of the Removal Quality

- category I: no material removal;

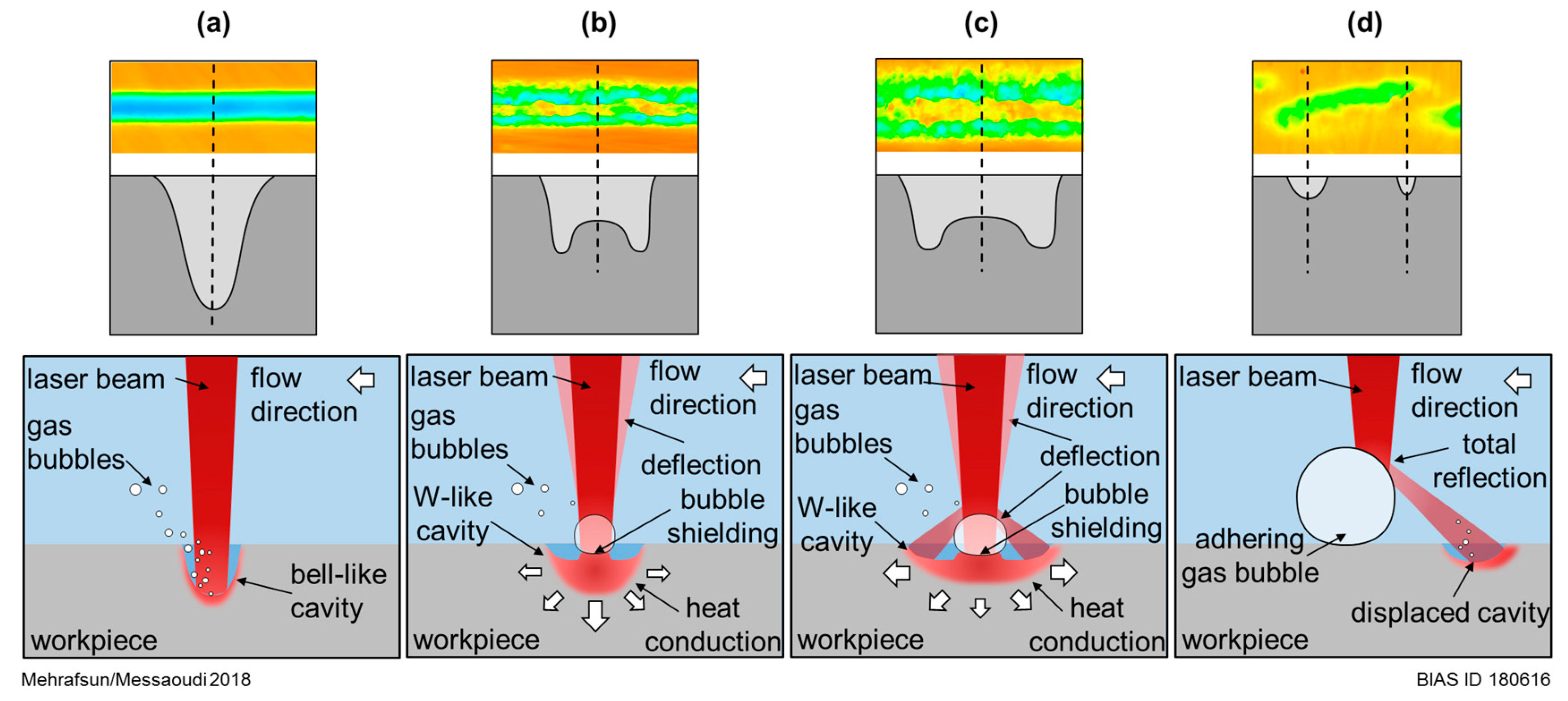

- category II: a disturbance-free removal characterized with a bell-like profile;

- category III: a disturbed material removal characterized with a non-bell-like profile, such as a W-like one.

3. Results

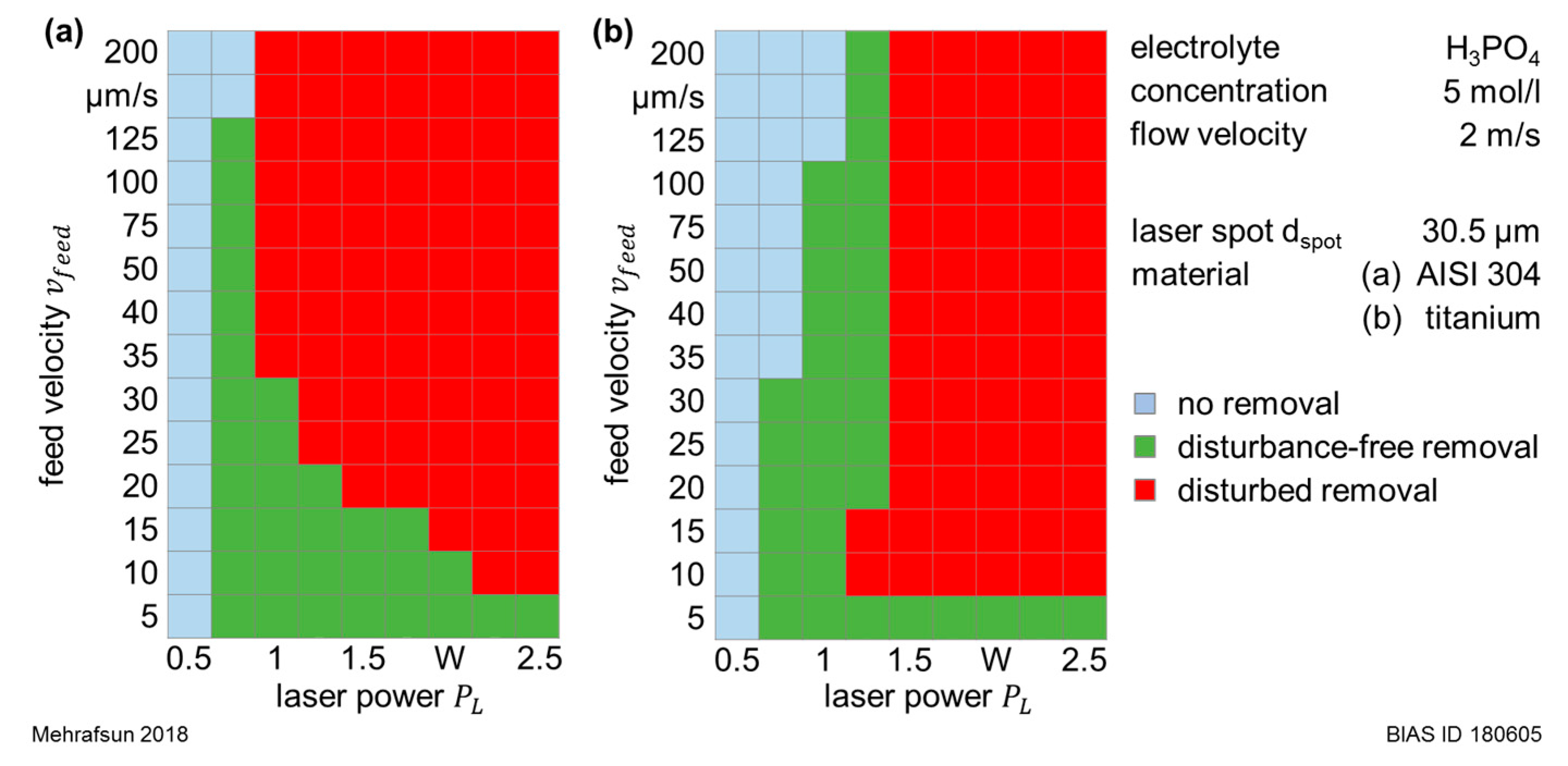

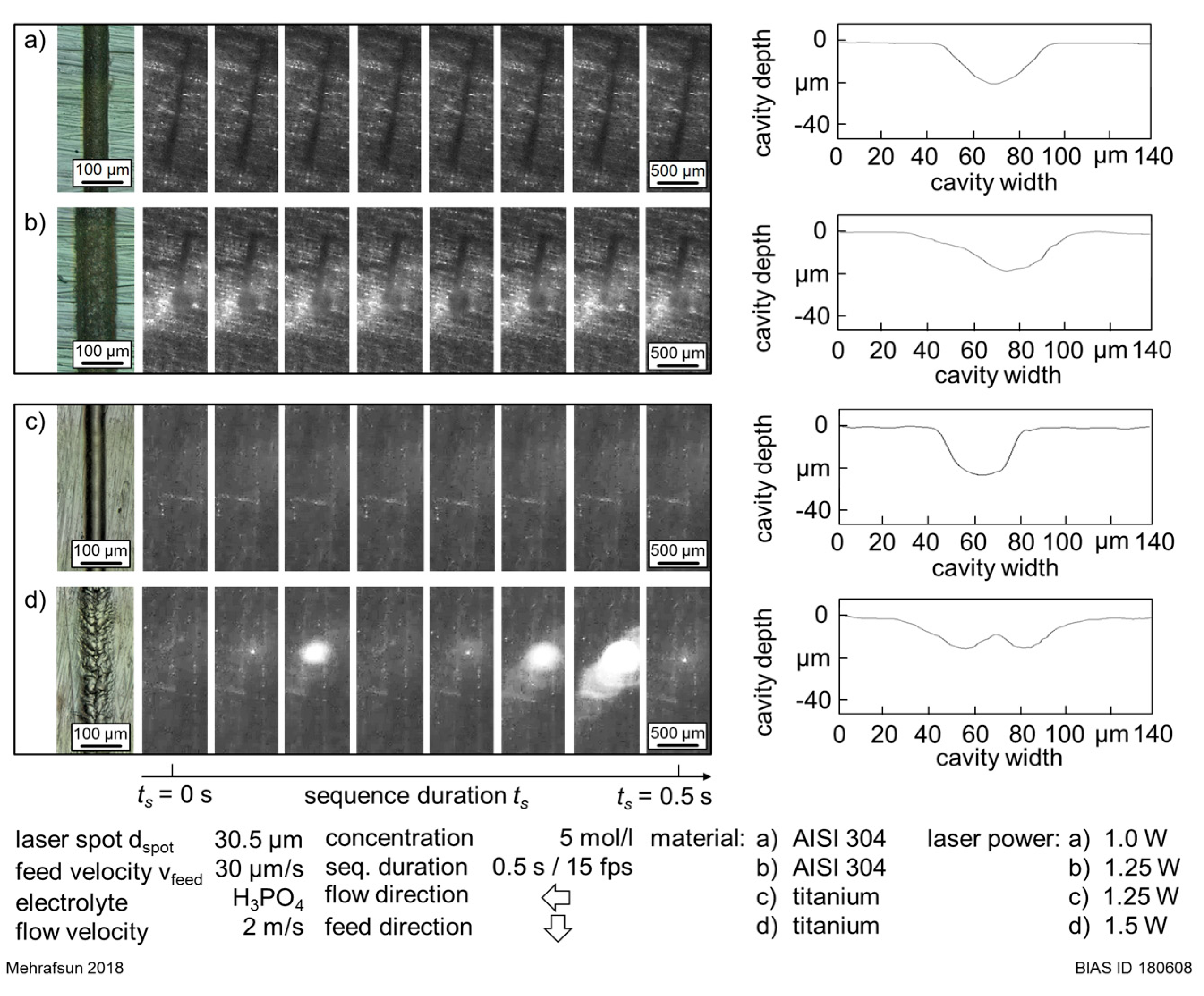

3.1. Influence of the Material on the Removal Characteristics

3.1.1. Resulting Process Windows

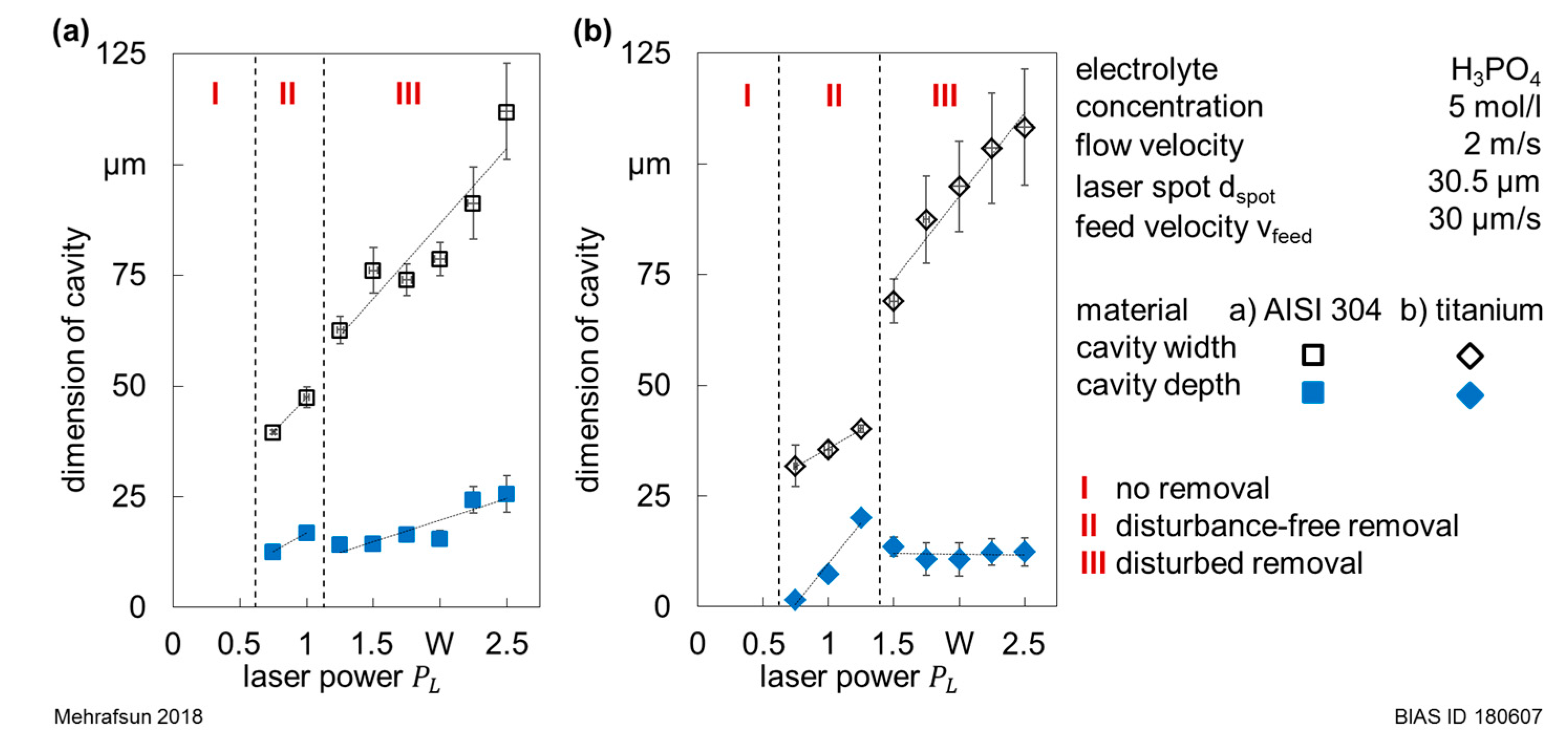

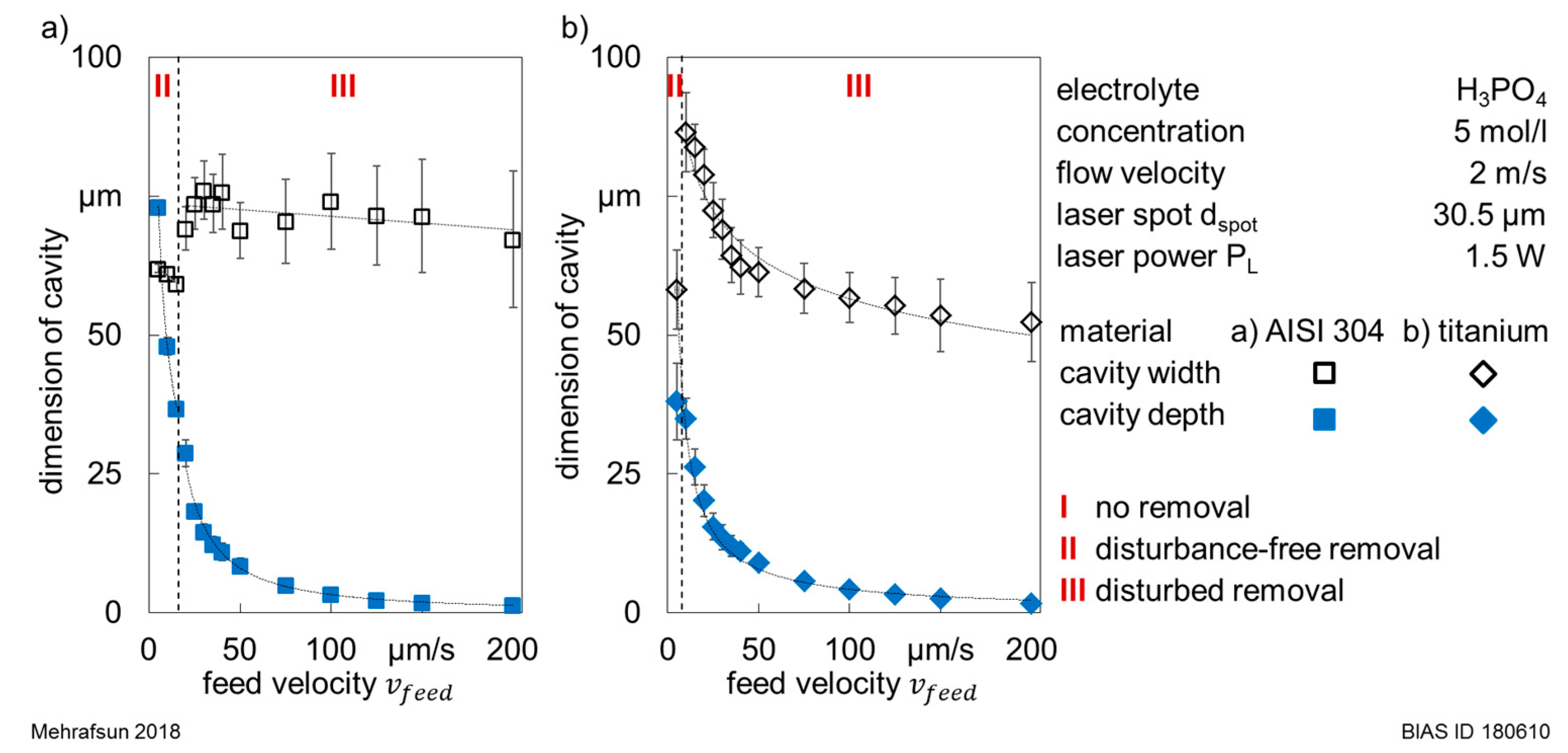

3.1.2. Influence of Laser Power on Removal Characteristics

3.1.3. Influence of Feed Velocity on Removal Characteristics

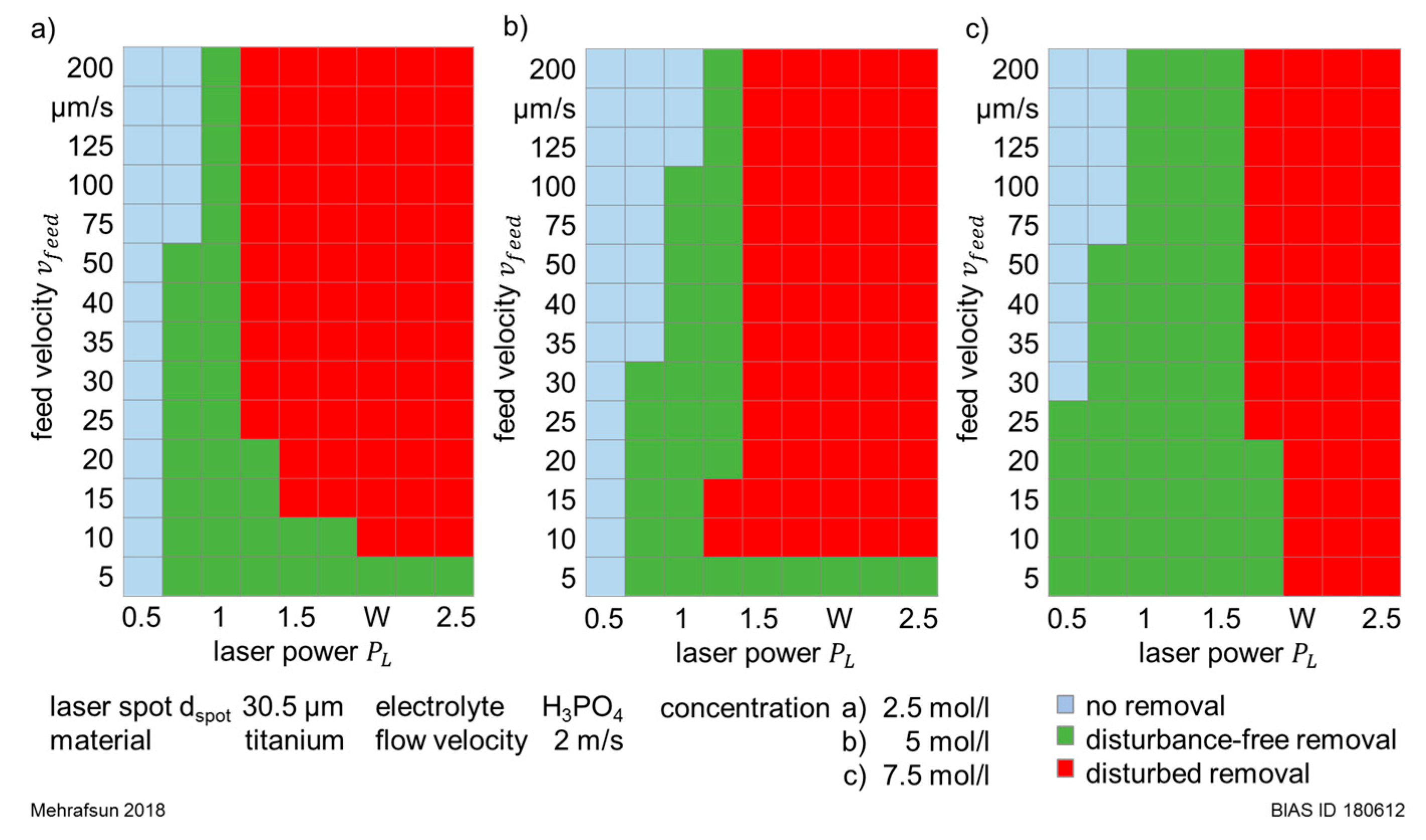

3.2. Influence of Electrolyte Concentration on Removal Characteristics

3.2.1. Resulting Process Windows

3.2.2. Influence of Laser Power on Removal Characteristics

3.2.3. Influence of Feed Velocity on Removal Characteristics

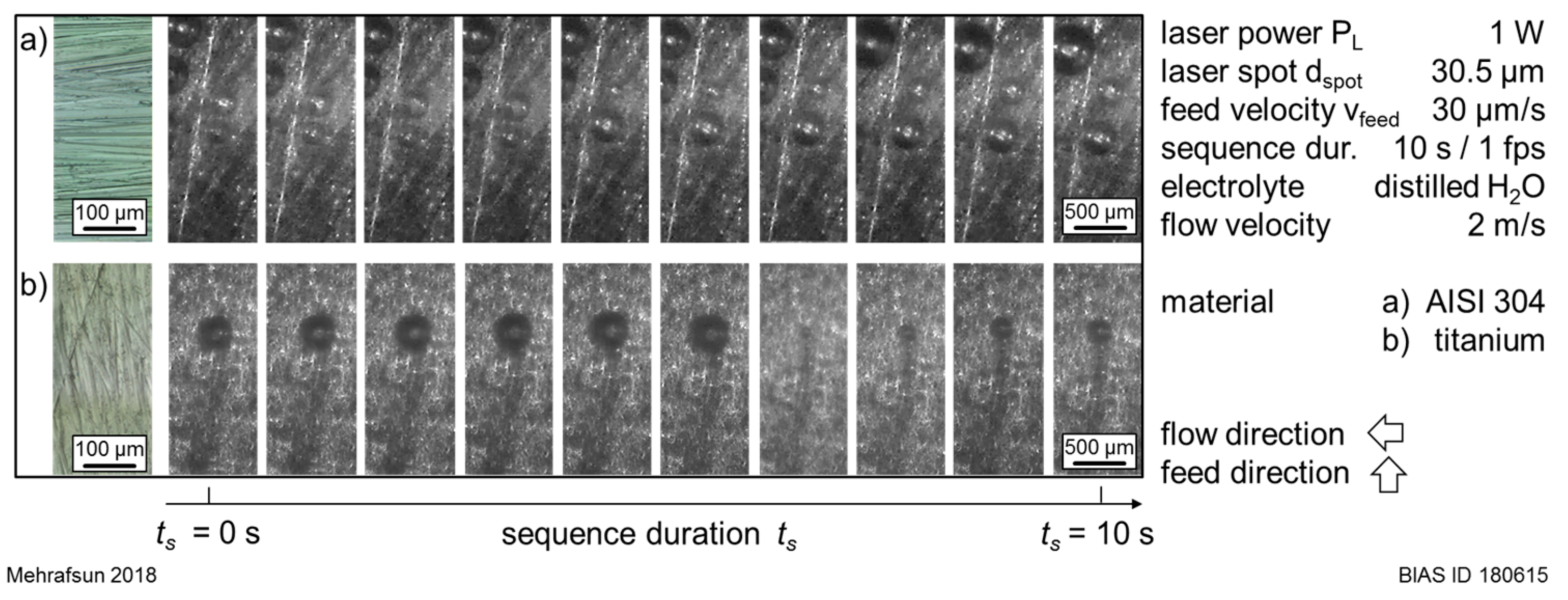

3.3. Laser-Induced Electrolyte Boiling

4. Discussion

4.1. Disturbance of Material Removal by Gas Formation

4.2. Influence of Material

4.3. Influence of Electrolyte Concentration

5. Conclusions

- The occurrence of removal disturbances was caused by adhering gas bubbles. On the one hand, these bubbles inhibited the material dissolution reaction and supported a simultaneous deposition of metallic salts and oxides. Moreover, the gas bubbles influenced the location and amount of laser energy by deflection and total reflection and led to a broadening or a dislocation of the removal area.

- Due to the lower tendency of gas bubble adherence, the LCM of stainless steel was much more pronounced and less affected by disturbances compared with titanium.

- The disturbance-free removal took place over a larger process window when the electrolyte concentration was increased. Here, the interrelation between viscosity, electrochemical potential and the electrolyte hydrodynamics was supposed to determine the bubble adherence behavior and the chemical reactivity. However, this is still to be investigated more in detail.

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hsu, T.-R. Miniaturisation—A paradigm shift in advanced manufacturing and education. In Proceedings of the IEEE/ASME International Conference on Advanced Manufacturing Technologies and Education in the 21st Century, Chia-Yi, Taiwan, 10–15 August 2002. [Google Scholar]

- Bauerle, D. Laser Processing and Chemistry, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar] [CrossRef]

- Wulfsberg, J.P.; Hilpert, S.E.; Ostendorf, A.; Samm, K. Fundamentals of Laser Assisted Micro Forming. In Proceeding of the 1st Colloquium od DFG Priority Program Process Scaling 2003; Vollertsen, F., Hollmann, F., Eds.; BIAS Verlag: Bremen, Germany, 2003; pp. 89–98. ISBN 3-933762-14-6. [Google Scholar]

- Li, L.; Achara, C. Chemical assisted laser machining for the minimization of recast and heat-affected zone. CIRP Ann. 2004, 53, 175–178. [Google Scholar] [CrossRef]

- Stephen, A.; Vollertsen, F. Mechanisms and Processing Limits in Laser Thermochemical Machining. CIRP Ann. 2010, 59, 251–254. [Google Scholar] [CrossRef]

- Nowak, R.; Metev, S. Thermochemical Laser Etching of Stainless Steel and Titanium in Liquids. Appl. Phys. A 1996, 63, 133–138. [Google Scholar] [CrossRef]

- Messaoudi, H.; Hauser, O.; Matson, A.; Mehrafsun, S.; Vollertsen, F. Fertigungsqualität laserchemisch hergestellter Mikroumformwerkzeuge. In Proceedings of the Fachbeiträge 8. Kolloquium Mikroproduktion, Bremen, Germany, 27–28 November 2017; Vollertsen, F., Hopmann, C., Schulze, V., Wulfsberg, J., Eds.; BIAS Verlag: Bremen, Germany, 2017; pp. 171–178, ISBN 978-3-933762-56-6. [Google Scholar]

- Mehrafsun, S.; Stephen, A.; Vollertsen, F. Comparison of laser-thermal and laser-chemical machining. In Proceedings of the 3rd International Conference on nano Manufacturing (nanoMan2012), Tokyo, Japan, 25–27 July 2012; Fang, F., Kuriyagawa, T., Eds.; Wako: Saitama, Japan, 2012; pp. 251–254. [Google Scholar]

- Stephen, A.; Lilienkamp, T.; Metev, S.; Sepold, G. Laser-Assisted Micro-machining of Large-Area 3D Metallic Microparts. In Proceedings of the 1st International Conference of the European Society for Precision Engineering and Nanotechnology, Bremen, Germany, 31 May–4 June 1999; McKeown, P., Corbett, J., Eds.; Shaker Verlag: Aachen, Germany, 1999; pp. 20–23. [Google Scholar]

- Messaoudi, H.; Böhmermann, F.; Mikulewitsch, M.; von Freyberg, A.; Fischer, A.; Riemer, O.; Vollertsen, F. Chances and Limitations in the Application of Laser Chemical Machining for the Manufacture of Micro Forming Dies. In Proceedings of the 5th International Conference on New Forming Technology (ICNFT 2018), Bremen, Germany, 19–21 September 2018; pp. 1–8, in press. [Google Scholar]

- Robert, C.; Messaoudi, H.; Riemer, O.; Brinksmeier, E.; Vollertsen, F. Modifikation der Oberflächenfeingestalt monokristalliner Diamanten. In Proceedings of the Fachbeiträge 8. Kolloquium Mikroproduktion, Bremen, Germany, 27–28 November 2017; Vollertsen, F., Hopmann, C., Schulze, V., Wulfsberg, J., Eds.; BIAS Verlag: Bremen, Germany, 2017; pp. 187–194, ISBN 978-3-933762-56-6. [Google Scholar]

- Eckert, S.; Köhnsen, A.; Vollertsen, F. Surface finish using laser-thermochemical machining. In Lasers in Manufacturing (LIM 2017); Available online: https://www.wlt.de/lim/Proceedings2017/Data/PDF/Contribution195_final.pdf (accessed on 18 July 2018).

- De Silva, A.K.M.; Pajak, P.T.; McGeough, J.A.; Harrison, D.K. Thermal effects in laser assisted jet electrochemical machining. CIRP Ann. Manuf. Technol. 2011, 60, 243–246. [Google Scholar] [CrossRef]

- Mora, A.; Haase, M.; Rabbow, T.J. Discrete Model for laser driven etching and microstructuring of metallic surfaces. Phys. Rev. E 2005, 72, 060101. [Google Scholar] [CrossRef] [PubMed]

- Rabbow, T.J.; Plath, P.J.; Mora, A.; Haase, M. Selforganized Structure Formation in Organized Microstructuring by Laser-Jet-Etching. Int. J. Bifurc. Chaos 2017, 27, 1750001. [Google Scholar] [CrossRef]

- Mehrafsun, S.; Vollertsen, F. Disturbance of material removal in laser-chemical machining by emerging gas. Ann. CIRP 2013, 62, 195–198. [Google Scholar] [CrossRef]

- Messaoudi, H.; Eckert, S.; Vollertsen, F. Thermal Analysis of Laser Chemical Machining: Part I: Static Irradiation. Mater. Sci. Appl. 2017, 8, 685–707. [Google Scholar] [CrossRef]

- Eckert, S.; Messaoudi, H.; Mehrafsun, S.; Vollersten, F. Laser-thermochemical induced micro-structures on titanium. J. Mater. Sci. Surf. Eng. 2017, 5, 685–691. [Google Scholar] [CrossRef]

- Faghri, A.; Zhang, Y.; Howell, J.R. Advanced Heat and Mass Transfer; Global Digital Press: Columbia, MO, USA, 2010; pp. 665–734. [Google Scholar]

- Buhlert, M. Elektropolieren und Elektrostrukturieren von Edelstahl, Messing und Aluminium: Untersuchung des Transpassiven Abtragsprozesses Einschließlich Unerwünschter Nebeneffekte; Fortschrittberichte VDI, Reihe 2(553); VDI Verlag GmbH: Düsseldorf, Germany, 2000. [Google Scholar]

- Buhlert, M. Removal Process. In Electropolishing, 1st ed.; Eugen, G., Leuze Verlag, K.G., Eds.; Leuze Verlag: Bad Saulgau, Germany, 2015; pp. 13–48. [Google Scholar]

- Lazic, V.; Jovicevic, S.; Carpanese, M. Laser induced bubbles inside liquids: Transient optical properties and effects on beam propagation. Appl. Phys. Lett. 2012, 101, 054101. [Google Scholar] [CrossRef]

- Mehrafsun, S.; Zhang, P.; Vollertsen, F.; Goch, G. Laser-chemical Precision Machining of Micro Forming Tools at low Laser Powers, Laser-based Micro- and Nanopackaging and Assembly VI. Proc. SPIE 2012, 8244, 82440K. [Google Scholar]

- Messaoudi, H.; Panhale, S.D.; Thiemicke, F. Influence of the electrolyte streaming on thermal impact and removal characteristics during laser chemical machining of metals. To be published.

- Mehrafsun, S.; Messaoudi, H.; Vollertsen, F. Influence of material and surface roughness on gas bubble formation and adhesion in laser-chemical machining. In Proceedings of the 5th International Conference on Nanomanufacturing (nanoMan 2016), Macau, China, 15–17 August 2016; pp. 1–8. [Google Scholar]

- Qiang, H.; Chen, J.; Han, B.; Shen, Z.-H.; Lu, J.; Ni, X.-W. Study of underwater laser propulsion using different target materials. Opt. Express 2014, 22, 17532–17545. [Google Scholar] [CrossRef] [PubMed]

- Bobe, U. Die Reinigbarkeit technischer Oberflachen im immergierten System. Ph.D. Thesis, Technische Universitat München, München, Germany, 2008. [Google Scholar]

- Messaoudi, H.; Mehrafsun, S.; Vollertsen, F. Influence of the etchant on material removal geometry in laser chemical machining. In Proceedings of the 4th International Conference on Nanomanufacturing (nanoMan 2014), Bremen, Germany, 8–10 July 2014; Fang, F., Brinksmeier, E., Riemer, O., Eds.; Institut für Werkstofftechnik: Bremen, Germany, 2014. [Google Scholar]

- Schnurmann, R. Größe von Gasblasen in Flüssigkeiten. Colloid Polym. Sci. 1937, 80, 148–151. [Google Scholar] [CrossRef]

| Parameter | Unit | Value | |

|---|---|---|---|

| laser beam (continuous wave) | wavelength λ | nm | 1080 |

| focus spot diameter dspot | µm | 30.5 | |

| focal position Δz | µm | 0 | |

| feed velocity vfeed | µm/s | 10 … 200 | |

| laser power PL | W | 0.5 … 2.5 | |

| phosphoric acid (H3PO4) | concentration | mol/L | 2.5, 5, 7.5 |

| boiling temperature TBoiling | °C | 104 | |

| layer height | mm | 2 | |

| transmission coefficient τE | - | 0.98 | |

| flow speed vflow | m/s | 2 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mehrafsun, S.; Messaoudi, H. Dynamic Process Behavior in Laser Chemical Micro Machining of Metals. J. Manuf. Mater. Process. 2018, 2, 54. https://doi.org/10.3390/jmmp2030054

Mehrafsun S, Messaoudi H. Dynamic Process Behavior in Laser Chemical Micro Machining of Metals. Journal of Manufacturing and Materials Processing. 2018; 2(3):54. https://doi.org/10.3390/jmmp2030054

Chicago/Turabian StyleMehrafsun, Salar, and Hamza Messaoudi. 2018. "Dynamic Process Behavior in Laser Chemical Micro Machining of Metals" Journal of Manufacturing and Materials Processing 2, no. 3: 54. https://doi.org/10.3390/jmmp2030054