“7M”Advantage of Abrasive Waterjet for Machining Advanced Materials

Abstract

:1. Introduction

2. Facilities and Devices

2.1. JetMachining Centers

2.2. AWJ Nozzles

2.3. Vacuum Assist

2.4. Accessories for 3D Machining

- A Tilt-A-Jet (TAJ) is for compensating the natural taper on AWJ-cut edges resulting from the spread of the jet after it exits the nozzle (https://www.omax.com/accessories/tilt-a-jet). Figure 4b illustrates a photograph of the TAJ. It is a 3-axis device with a programmable tilt up to ±9° for the maximum tilt angle around the vertical axis. During machining, the TAJ dynamically tilts the nozzle along the tool path to eliminate the taper on the part automatically, while leaving twice the taper on the scrap.

- An A-Jet (articulate jet) is a software-controlled multi-axis cutting head that greatly expands the versatility of the OMAX JetMachining Center. With a cutting range from 0° to 60°, the A-Jet can easily cut beveled edges, angled sides, and countersinks (https://www.omax.com/accessories/a-jet).

- A submersible Rotary Axis is for machining 3D features in tube, pipe, and bar stock (https://www.omax.com/accessories/rotary-axis).

2.5. Machineability and Pierceability

3. Samples of AWJ-Machined Parts

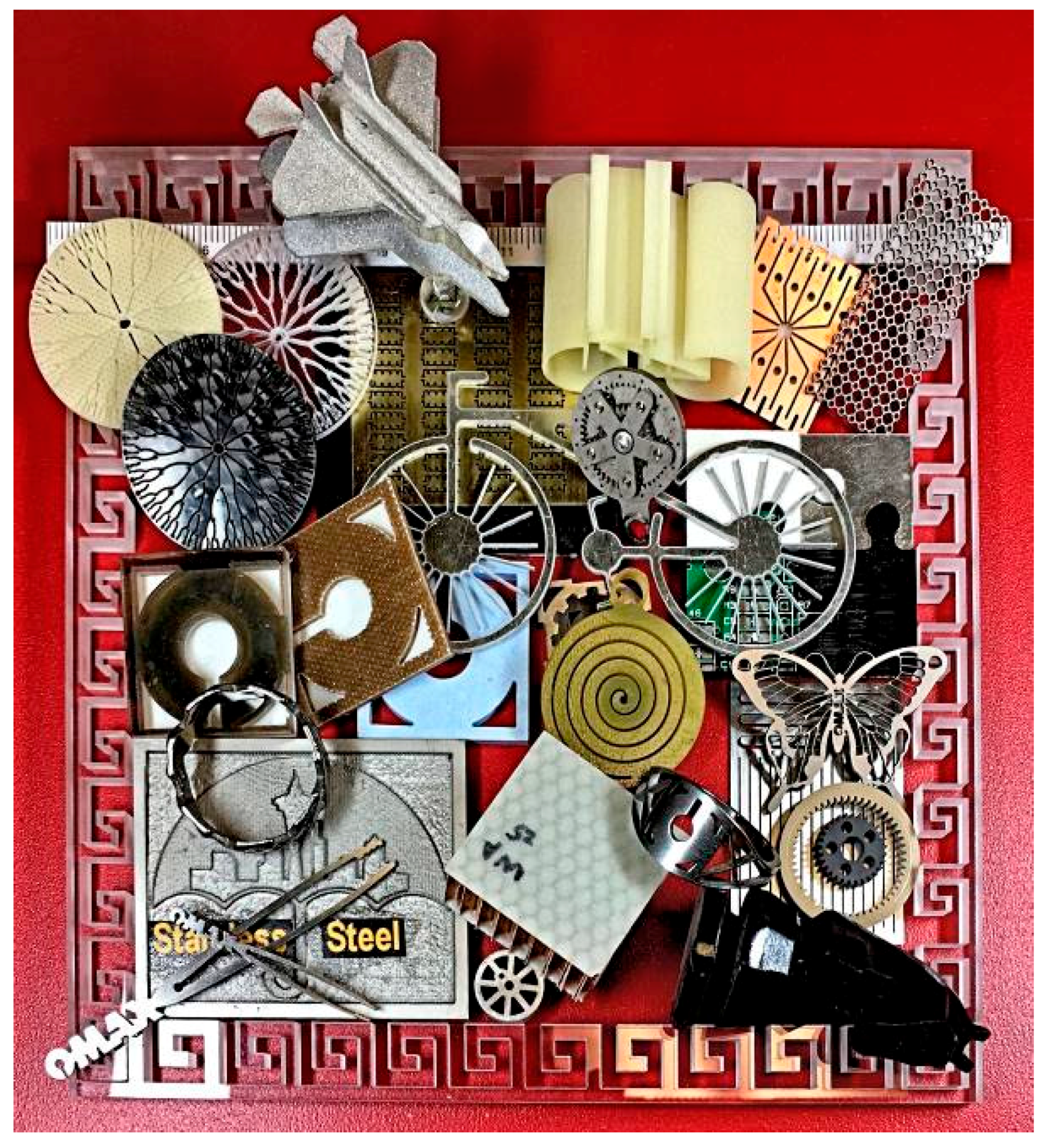

3.1. Material Independence

3.2. Part Size and Thickness

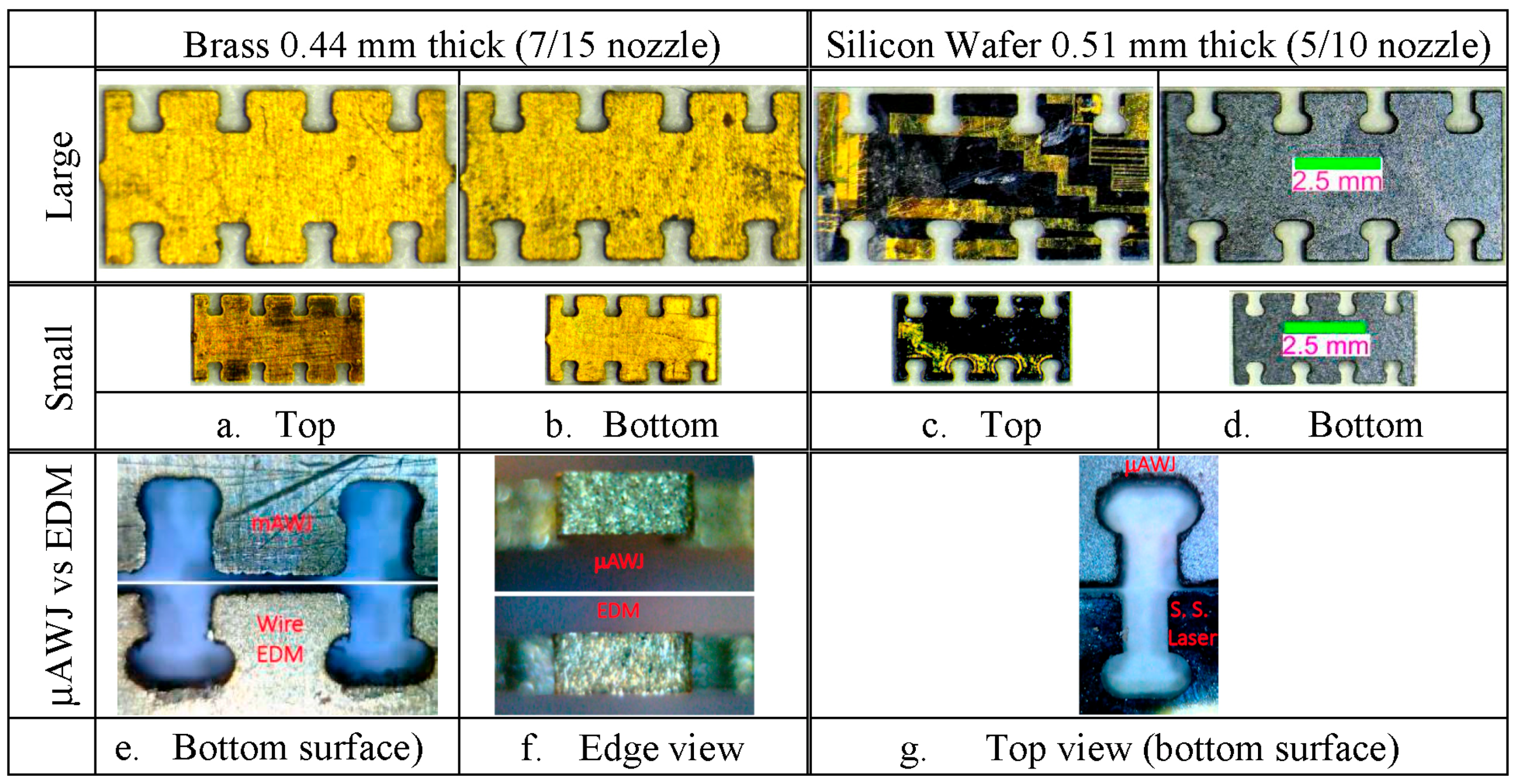

3.3. Delicate and Difficult Materials

3.4. Multimode Machining

3.5. Taper-Free Parts

3.6. AWJ Hole Drilling

3.7. Etching and Milling

3.8. 3D Machining

- No accessory—fighter plane (cut at three different orientations)

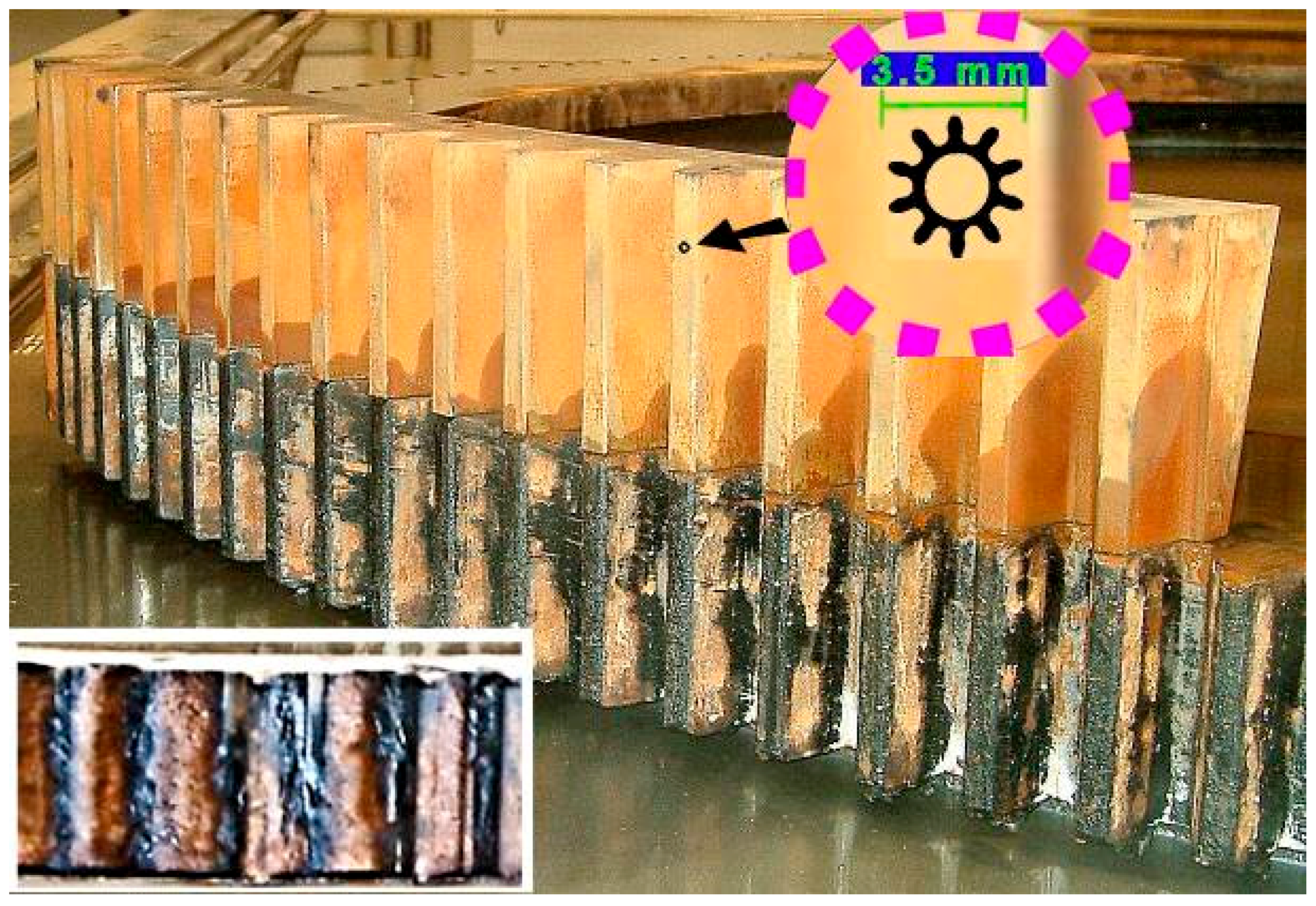

- Rotary Axis—space Needle, carbon fiber ring, titanium mesh cage, interlocking necklace, carbon fiber tube, 25 mm OD stainless steel tube, and steel gear

- A-Jet—honeycombs and blisk

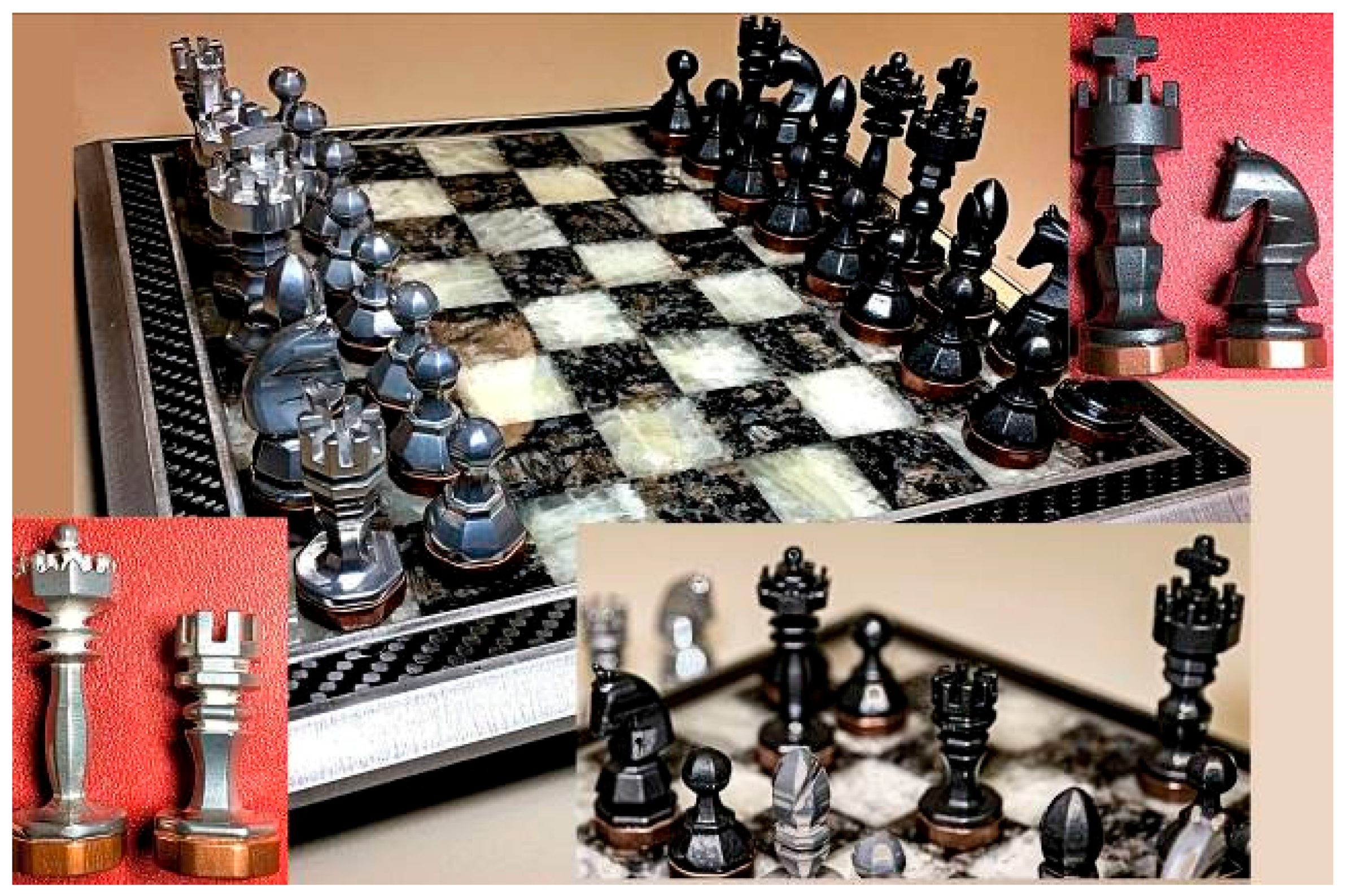

- Combined Rotary Axis and A-Jet—chess pieces, steel pipe joint, and brass tube.

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Rasmussen, B. Market Trend: This Industry is Ready to Explode. Zoltek: Industry News. March 2008. Available online: http://www.compositesworld.com/columns/market-trends-this-industry-is-ready-to-explode (accessed on 5 September 2017).

- Zelinski, P., Sr. (Ed.) Machining at Mach 3. MMSOnline.com. February 2009. Available online: http://www.mmsonline.com/articles/machining-at-mach-3 (accessed on 5 September 2017).

- Mrazova, M. Advanced composite materials of the future in aerospace industry. INCAS Bull. 2013, 5, 139–150. [Google Scholar] [CrossRef]

- Liu, H.-T.; Schubert, E.; McNiel, D.; Soo, K. Applications of Abrasive-Waterjets for Precision Machining of Composites. In Proceedings of the SAMPE 2010 Conference and Exhibition, Seattle, WA, USA, 17–20 May 2010. [Google Scholar]

- Liu, H.-T. Machining Honeycomb Composites with Ultrahigh-Pressure Abrasive Waterjets. In Proceedings of the 18th International Conference on Water Jetting, Gdansk, Poland, 13–15 September 2006. [Google Scholar]

- Liu, H.-T. Abrasive-waterjet machining of most materials from macro to micro scales. In Proceedings of the TechConnect World Innovation Conference and Expo, Washington, DC, USA, 14–17 June 2015. [Google Scholar]

- Liu, H.-T. Precision machining of advanced materials with abrasive waterjets. IOP Conf. Ser Mater. Sci. Eng. 2017. [Google Scholar] [CrossRef]

- Edelstein, A.S.; Cammarata, R.C. (Eds.) Nanomaterials: Synthesis, Properties, and Applications; Taylor & Francis: New York, NY, USA, 1996; p. 593. [Google Scholar]

- Black, S. Abrasive machining methods for composites. High Perform. Compos. 2004, 12, 32–37. [Google Scholar]

- Hashish, M. When Abrasive Waterjets Shine. The Fabricator.com. 14 September 2004. Available online: http://www.thefabricator.com/WaterjetCutting/WaterjetCutting_Article.cfm?ID=955 (accessed on 5 September 2017).

- Liu, H.-T.; Fang, S.; Hibbard, C. Enhancement of Ultrahigh-Pressure Technology with LN2 Cryogenic Jets. In Proceedings of the 10th American Waterjet Conference, Houston, TX, USA, 14–17 August 1999. [Google Scholar]

- Liu, H.-T. Flash Vaporizing Water Jet and Piercing with Flash Vaporization. U.S. Patent 7,815,490, 19 October 2010. [Google Scholar]

- Liu, H.-T. Versatility of micro abrasive waterjet technology for machining nanomaterials. In Dekker Encyclopedia of Nanoscience and Nanotechnology, 3rd ed.; Taylor and Francis: New York, NY, USA, 2017. [Google Scholar]

- Liu, H.-T.; Schubert, E. Micro Abrasive-Waterjet Technology (Chapter Title). In Micromachining Techniques for Fabrication of Micro and Nano Structures; Mojtaba, K., Ed.; INTECH Open Access Publisher: Rijeka, Croatia, 2012; pp. 205–234. ISBN 978-953-307-906-6. Available online: http://cdn.intechweb.org/pdfs/27087.pdf (accessed on 5 September 2017).

- Shanmugam, D.K.; Nguyen, T.; Wang, J. A study of delamination on rapite/epoxy composites in abrasive waterjet machining. Compos Part A Appl. Sci. Manuf. 2008, 39, 923–929. [Google Scholar] [CrossRef]

- Ravi-Chandar, K.; Satapathy, S. Mechanical Properties of G-10 Glass-Epoxy Composites; Institute for Advanced Technology, The University of Texas at Austin: Austin, TX, USA, 2007; p. 10, IAT.R 0466; Available online: http://www.dtic.mil/dtic/tr/fulltext/u2/a470630.pdf (accessed on 5 September 2017).

- Liu, H.-T.; Olsen, J.H. Application of AWJ for 3D Machining. In Proceedings of the WJTA-ICMA Conference and Expo, Houston, TX, USA, 9–11 September 2013. [Google Scholar]

- Khalajhedayati, A.; Pan, Z.; Rupert, T.J. Manipulating the interfacial structure of nanomaterials to achieve a unique combination of strength and ductility. Nat. Commun. 2016, 7, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.-T. Roles of taper compensation in AWJ precision machining. In Proceedings of the International Conference on Water Jetting, Seattle, WA, USA, 16–18 November 2016. [Google Scholar]

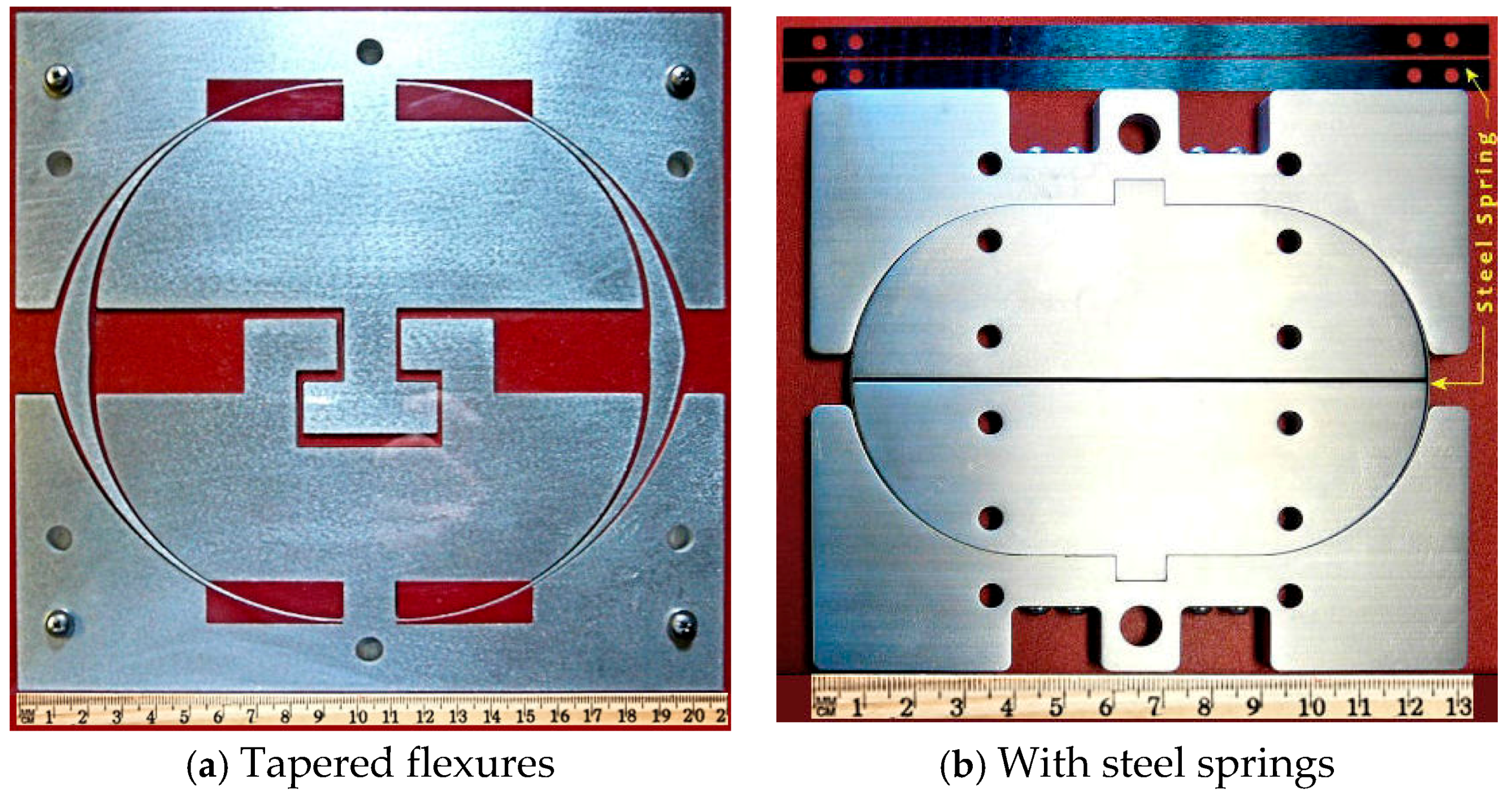

- Kluger, J.M.; Sapsis, T.P.; Slocum, A.H. High-resolution and large force-range load cell by means of nonlinear cantilever beams. Precis. Eng. 2016, 43, 241–256. [Google Scholar] [CrossRef]

- Kluger, J.M.; Sapsis, T.P.; Slocum, A.H. Ring-based stiffening flexure applied as a load cell with high resolution and large force range. ASME J. Mech. Des. 2017, 139, 103501. [Google Scholar] [CrossRef]

- Liu, H.-T. Hole drilling with abrasive fluidjets. Int. J. Adv. Manuf. Technol. 2007, 32, 942–957. [Google Scholar] [CrossRef]

- Liu, H.-T.; Miles, P.; Hibbard, C.; Cooksey, N. Measurements of water-droplet and abrasive speeds in waterjets and abrasive waterjets. In Proceedings of the 10th American Waterjet Conference, Houston, TX, USA, 14–17 August 1999. [Google Scholar]

- Liu, H.-T.; Hovanski, Y.; Caldwell, D.D.; Williford, R.E. Low-Cost Manufacturing of Flow Channels with Multi-Nozzle Abrasive-Waterjets: A Feasibility Investigation. In Proceedings of the 19th International Conference on Water Jetting, Nottingham, UK, 15–17 October 2008. [Google Scholar]

- Liu, H.-T. Near-Net Shaping of Optical Surfaces with Abrasive Suspension Jets. In Proceedings of the 14th International Conference on Jetting Technology, Brugge, Belgium, 21–23 September 1998; pp. 285–294. [Google Scholar]

| Material/Configuration | Mask | Pressure (MPa) | Traversing Speed (m/s) | Number of Pass | Abrasive (mesh) | RMS (mm) |

|---|---|---|---|---|---|---|

| Stainless Steel_flat (Figure 16a) | No | 138 | ~0.013 | Single | Garnet (80) | 0.061 |

| Stainless Steel_Concave (Figure 16d) | No | 138 | ~0.013 | Single | Garnet (80) | 0.062 |

| Lexan/DDA (Figure 17a) | Yes | 345 | 31.42 | Multiple | No | 0.051 |

| Stainless Steel/DDA (Figure 17b) | Yes | 345 | 31.42 | Multiple | Garnet (120) | 0.020 |

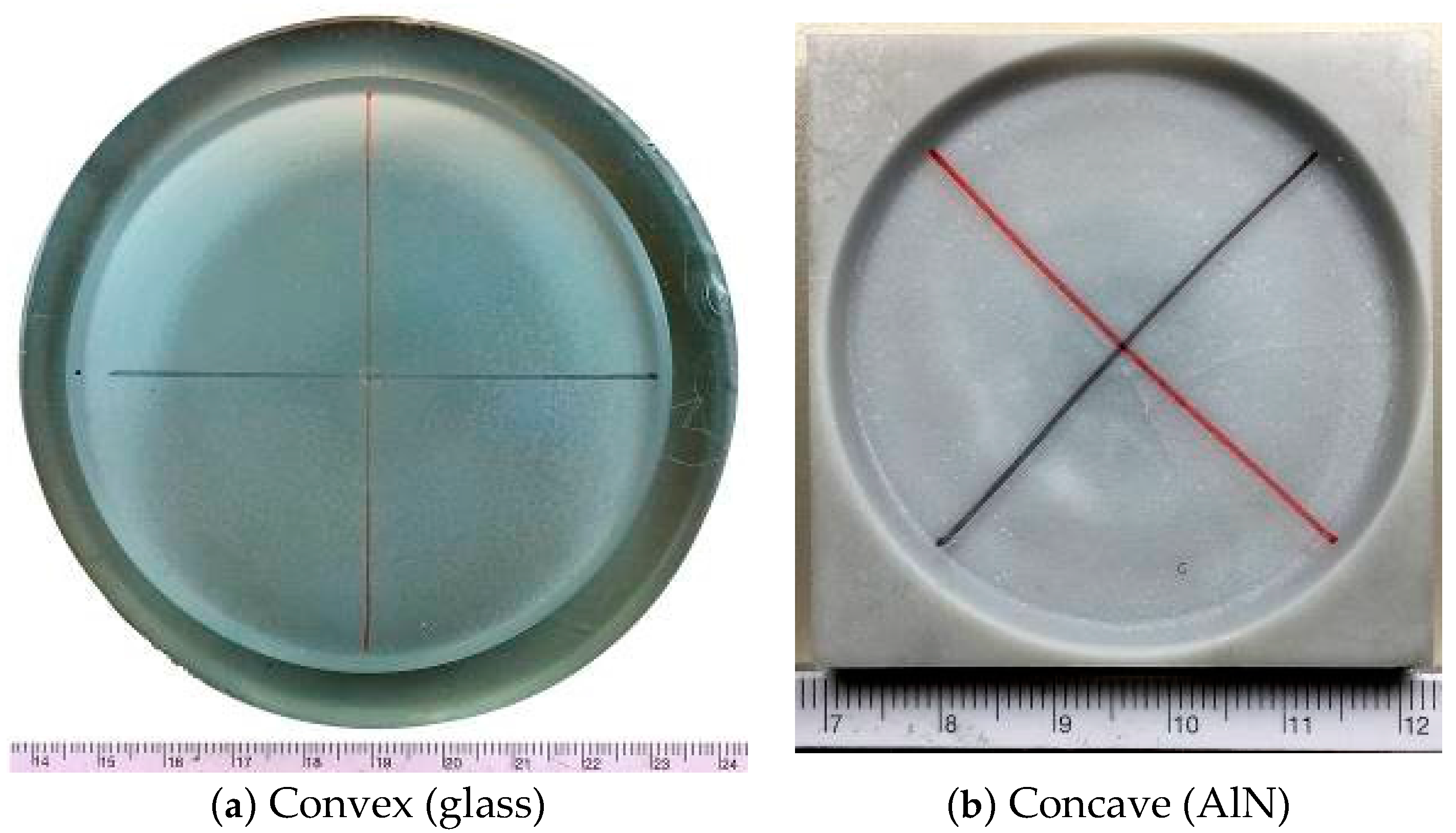

| Glass Convex/ASJ (Figure 18a) | No | 52–69 | 13.09 | Multiple | Garnet (~320) | 0.008 |

| Aluminum Nitrite (AlN)/ASJ (Figure 18b) | No | 52–69 | 13.09 | Multiple | Garnet mixed with Al2O3 (~320) | 0.006 |

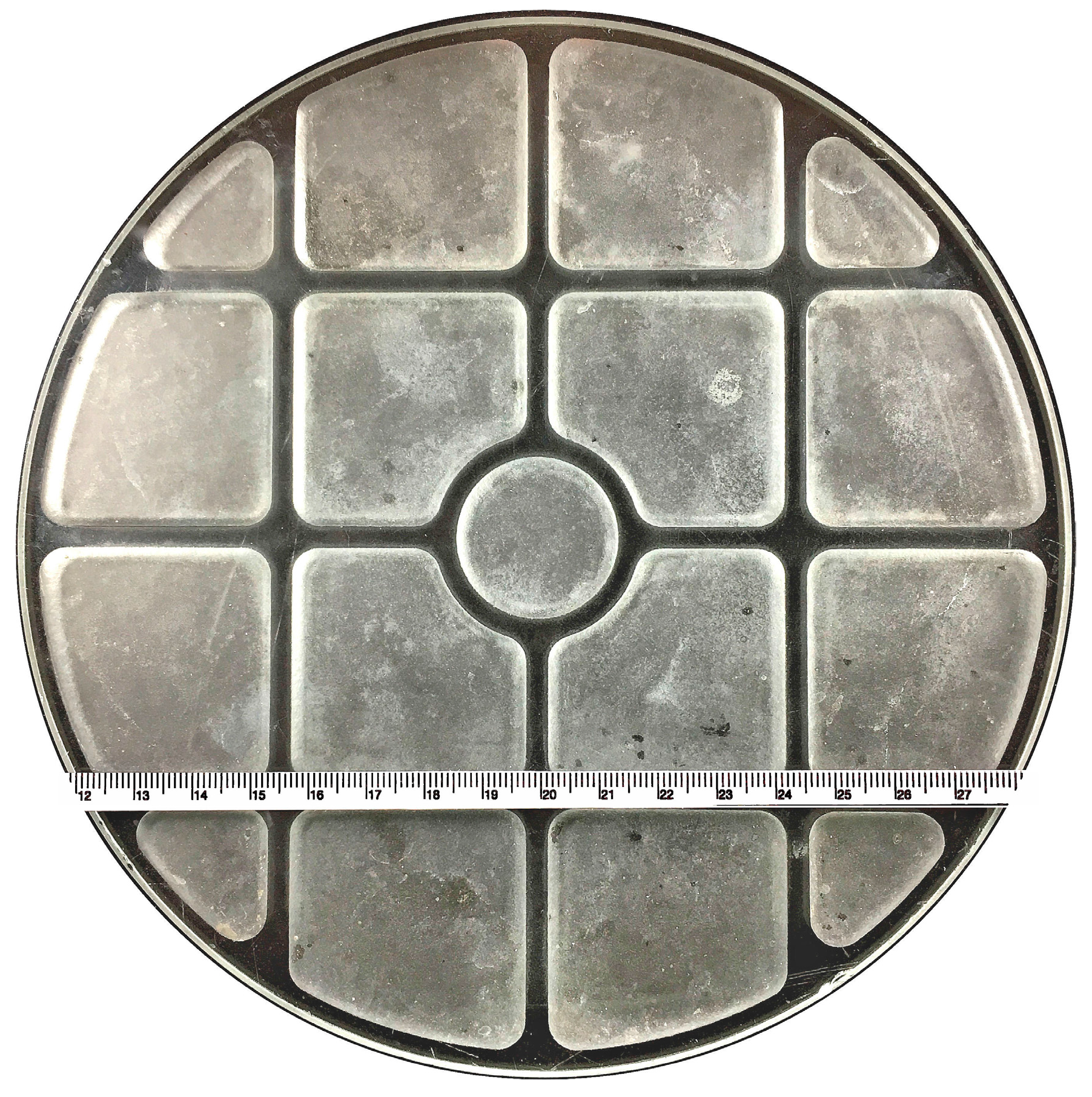

| Glass/Pocket (Figure 19) | Yes | 138 | 8.50 | Multiple | Garnet (220) | 0.015 |

© 2017 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.-T. “7M”Advantage of Abrasive Waterjet for Machining Advanced Materials. J. Manuf. Mater. Process. 2017, 1, 11. https://doi.org/10.3390/jmmp1010011

Liu H-T. “7M”Advantage of Abrasive Waterjet for Machining Advanced Materials. Journal of Manufacturing and Materials Processing. 2017; 1(1):11. https://doi.org/10.3390/jmmp1010011

Chicago/Turabian StyleLiu, (Peter) H.-T. 2017. "“7M”Advantage of Abrasive Waterjet for Machining Advanced Materials" Journal of Manufacturing and Materials Processing 1, no. 1: 11. https://doi.org/10.3390/jmmp1010011