Sensing of the Engine Cylinder Valves Motion †

Abstract

:1. Introduction

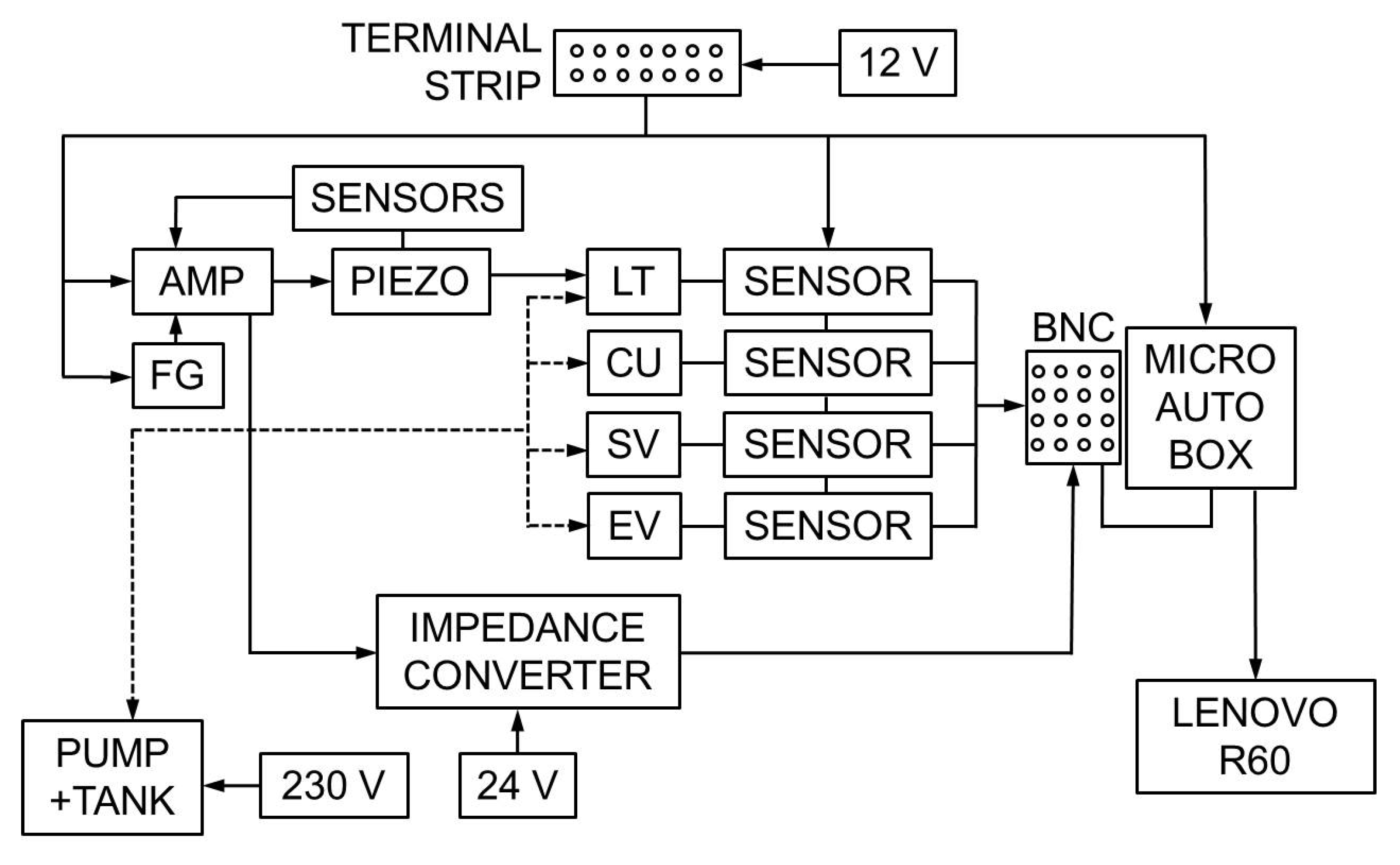

2. Peripheral Electric and Electronic Devices

2.1. Block Diagram of the Redesigned FVVT Sytem

- AMP = piezo amplifier

- FG = function generator

- LT = lever transmission

- CU = control unit

- SV = servo valve

- EV = engine valve body

- control piston in the control unit

- servo piston within the servo valve

- engine valves

2.2. Displacement Sensors

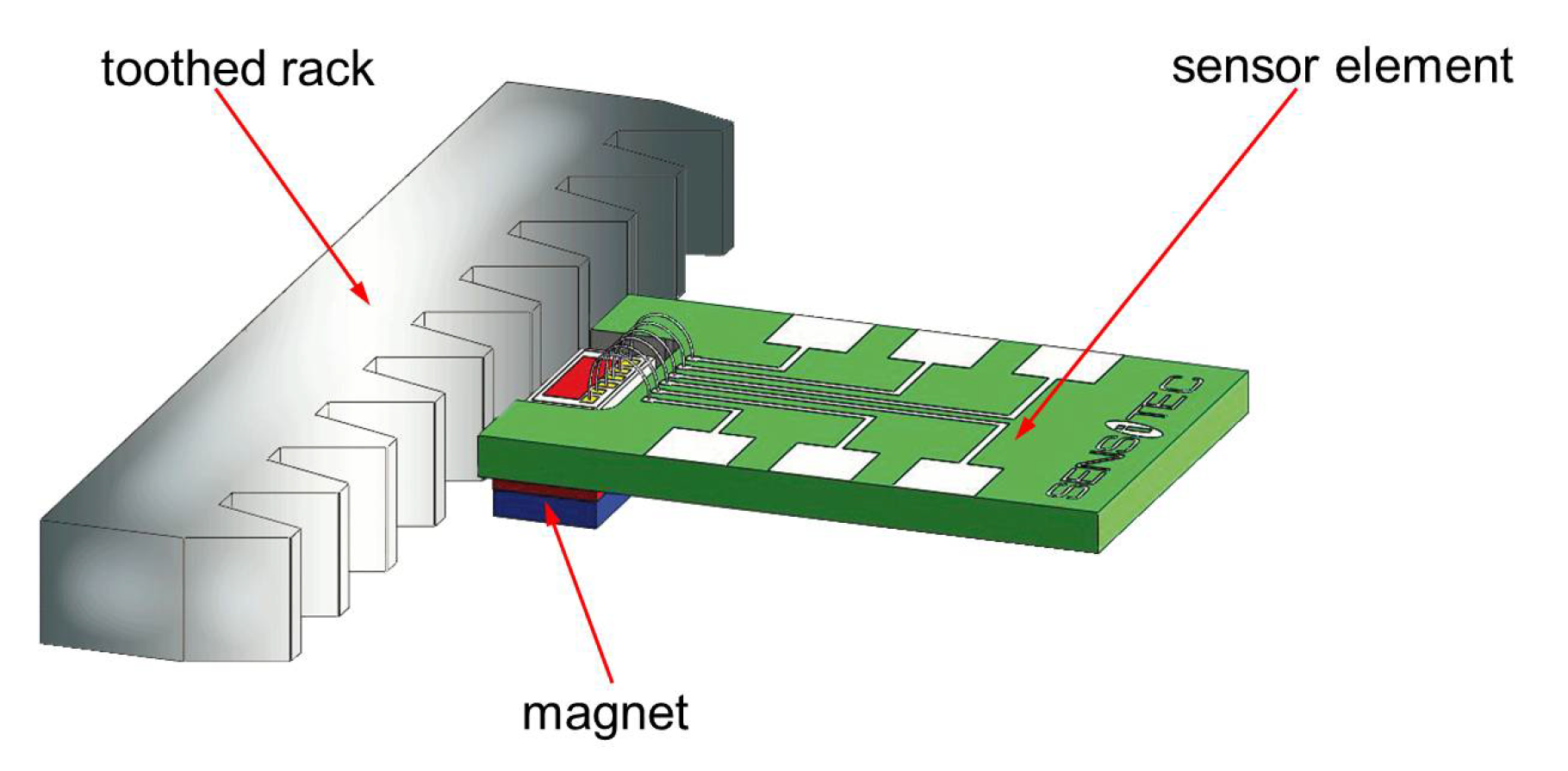

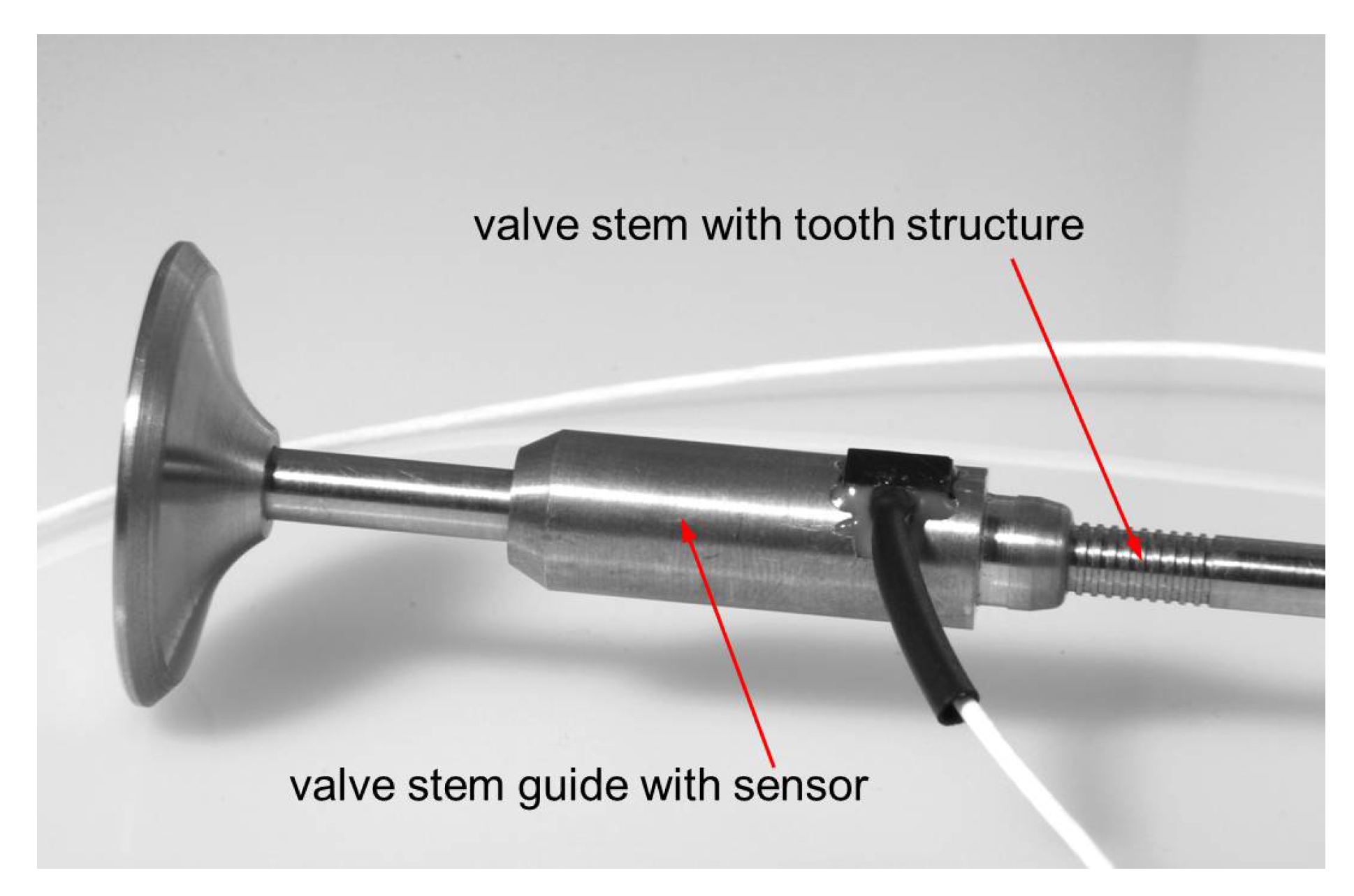

2.2.1. Sensitec GLM7xxASB-Ax

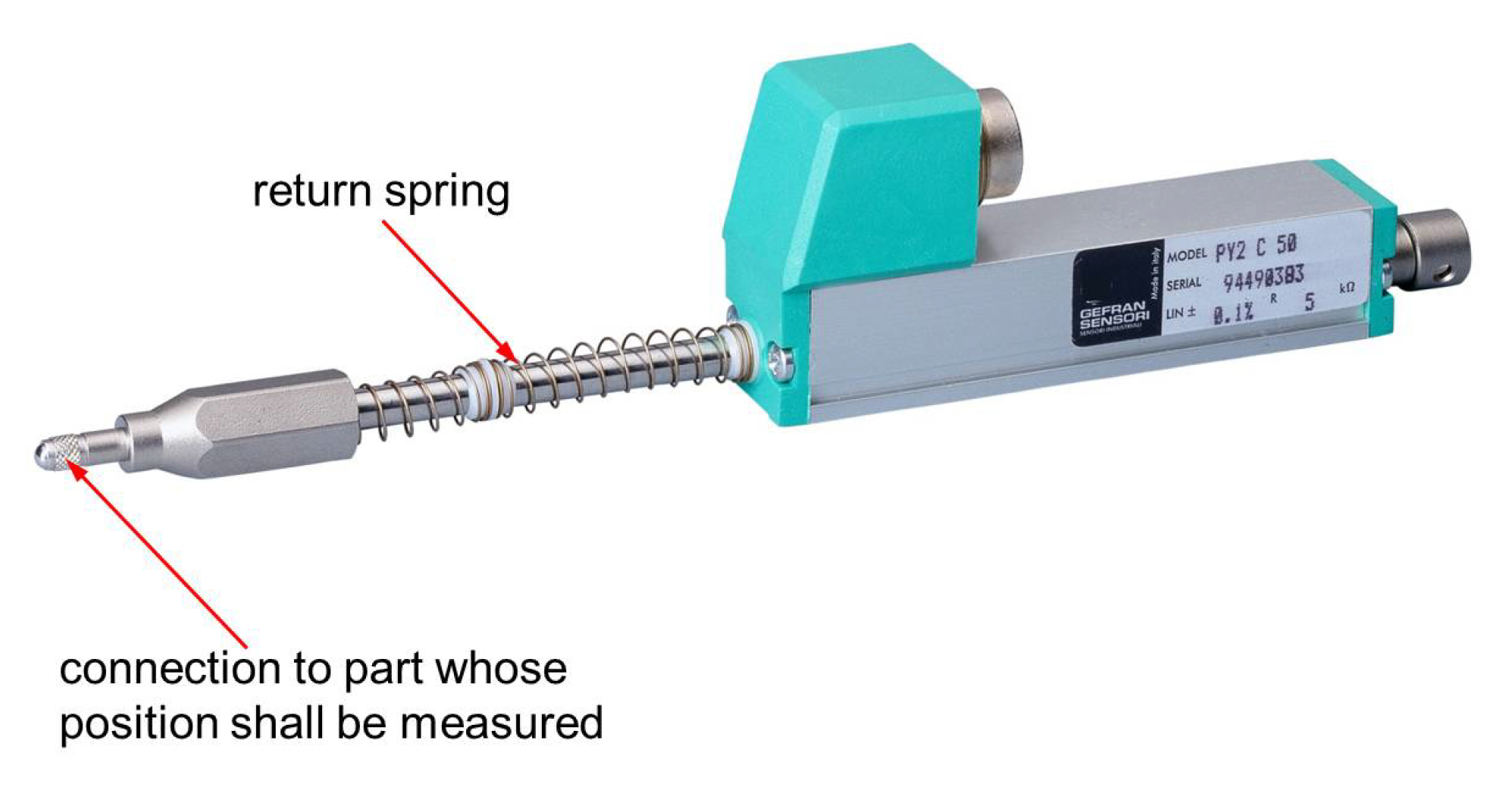

2.2.2. Gefran PY2C25

2.2.3. Cost-Benefit Analysis

2.3. Pressure Transducer

2.4. Piezo Amplifier

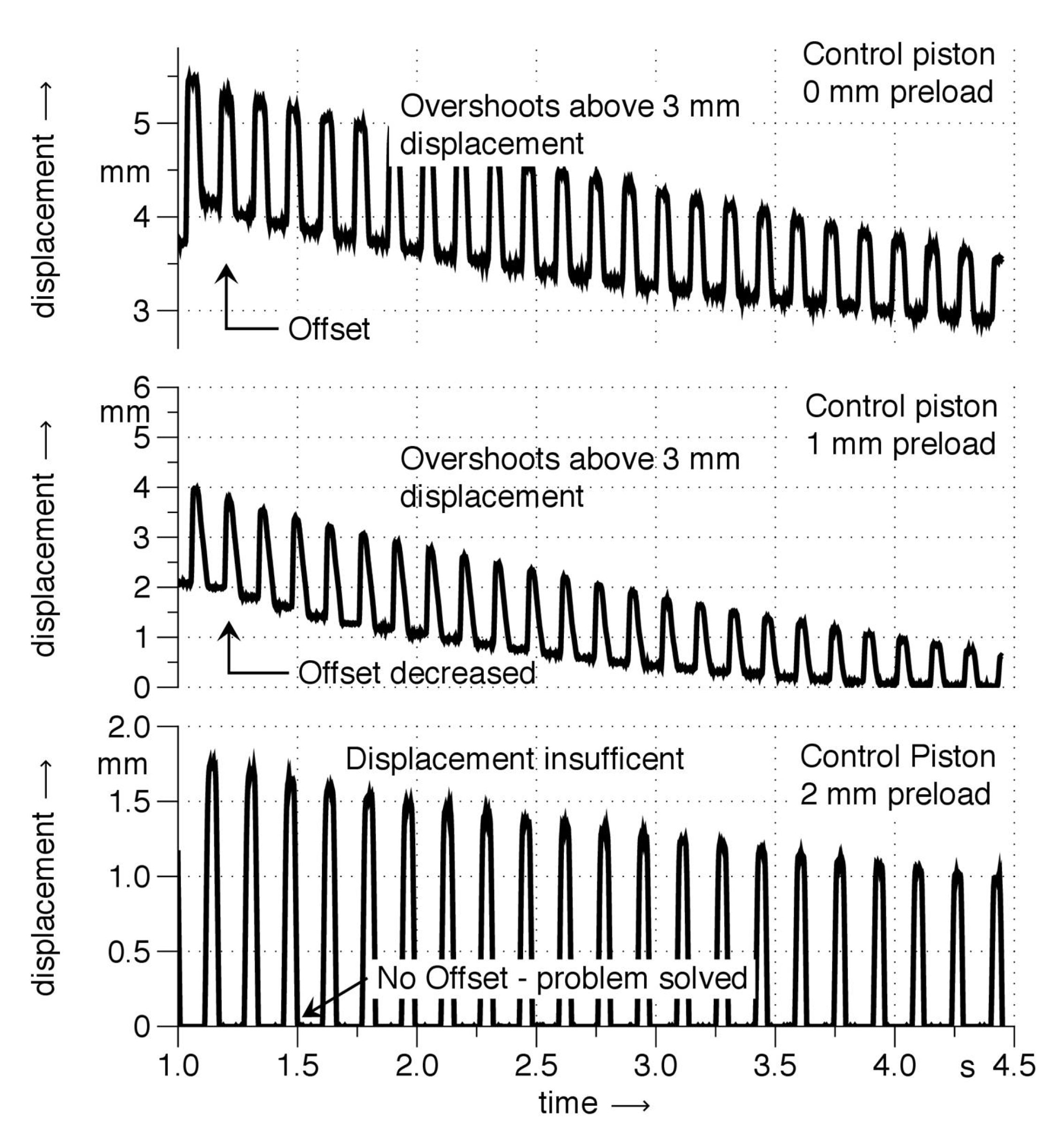

2.5. Development Control System and Some Measurements

References

- Sensitec. Products, Length-And-Path, Details about the Technical Principles of the Length and Position Measurement. 2014. Available online: http://www.sensitec.com/ (accessed on 27 April 2017).

- Sensitec. Technology, MR Sensor Technology. 2014. Available online: http://www.sensitec.com/ (accessed on 27 April 2017).

- Deng, C.; Kang, Y.; Li, E.; Zhang, Y.; Cheng, J.; Ge, T. A new model of the signal generation mechanism on magnetostrictive position sensor. Measurement 2014, 47, 591–597. [Google Scholar] [CrossRef]

- MTS Sensor Technologie GmbH & Co. KG. Die Temposonics® Positionsmessung—Magnetostriktiv! 2014. Available online: http://www.mtssensor.de/Magnetostriktion.26.0.html (accessed on 27 April 2017).

- Gefran SPA. PY2 Rectilinear Displacement Transducer. 2014. Available online: http://www.gefran.com/en/product_categories/38-\rectilinear-displacement-transducers%28rc1%29/products/73-py2-rectilinear-displacement-transducer#certifications (accessed on 27 April 2017).

- Physik Instrumente (PI). PICA High-Power Piezo Driver/Servo Controller: High Energy Efficiency through Energy Recovery; PDF Catalogue Datasheet; Physik Instrumente GmbH & Co. KG: Karlsruhe/Palmbach, Germany, 2012. [Google Scholar]

- dSPACE. Exklusive Angebote für Hochschulen: dSPACE ACE Kit; Product Brochure; dSPACE Digital Signal Processing and Control Engineering GmbH: Paderborn, Germany, 2014. [Google Scholar]

| Criterion | Weighting | Sensitec GLM700 | Gefran PY2C25 | ||

|---|---|---|---|---|---|

| Fulfillment | FxW | Fulfillment | FxW | ||

| Cost | 4 | 1 | 4 | 8 | 32 |

| Dynamic performance | 3 | 10 | 30 | 8 | 24 |

| Precision | 3 | 10 | 30 | 10 | 30 |

| Sensor wear | 2 | 10 | 20 | 10 | 20 |

| Package | 2 | 10 | 20 | 5 | 10 |

| Installation | 4 | 1 | 4 | 8 | 32 |

| Total | 108 | 148 | |||

| Ranking | 2 | 1 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Behre, L.; Mercorelli, P. Sensing of the Engine Cylinder Valves Motion. Proceedings 2017, 1, 26. https://doi.org/10.3390/ecsa-3-E013

Behre L, Mercorelli P. Sensing of the Engine Cylinder Valves Motion. Proceedings. 2017; 1(2):26. https://doi.org/10.3390/ecsa-3-E013

Chicago/Turabian StyleBehre, Leander, and Paolo Mercorelli. 2017. "Sensing of the Engine Cylinder Valves Motion" Proceedings 1, no. 2: 26. https://doi.org/10.3390/ecsa-3-E013