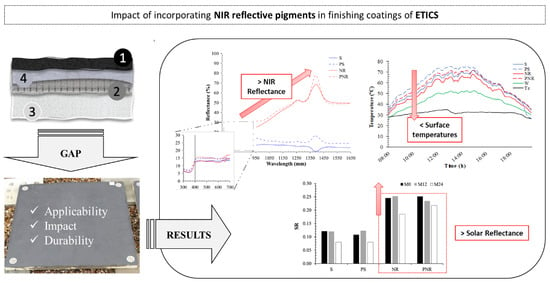

Impact of Incorporating NIR Reflective Pigments in Finishing Coatings of ETICS

Abstract

:1. Introduction

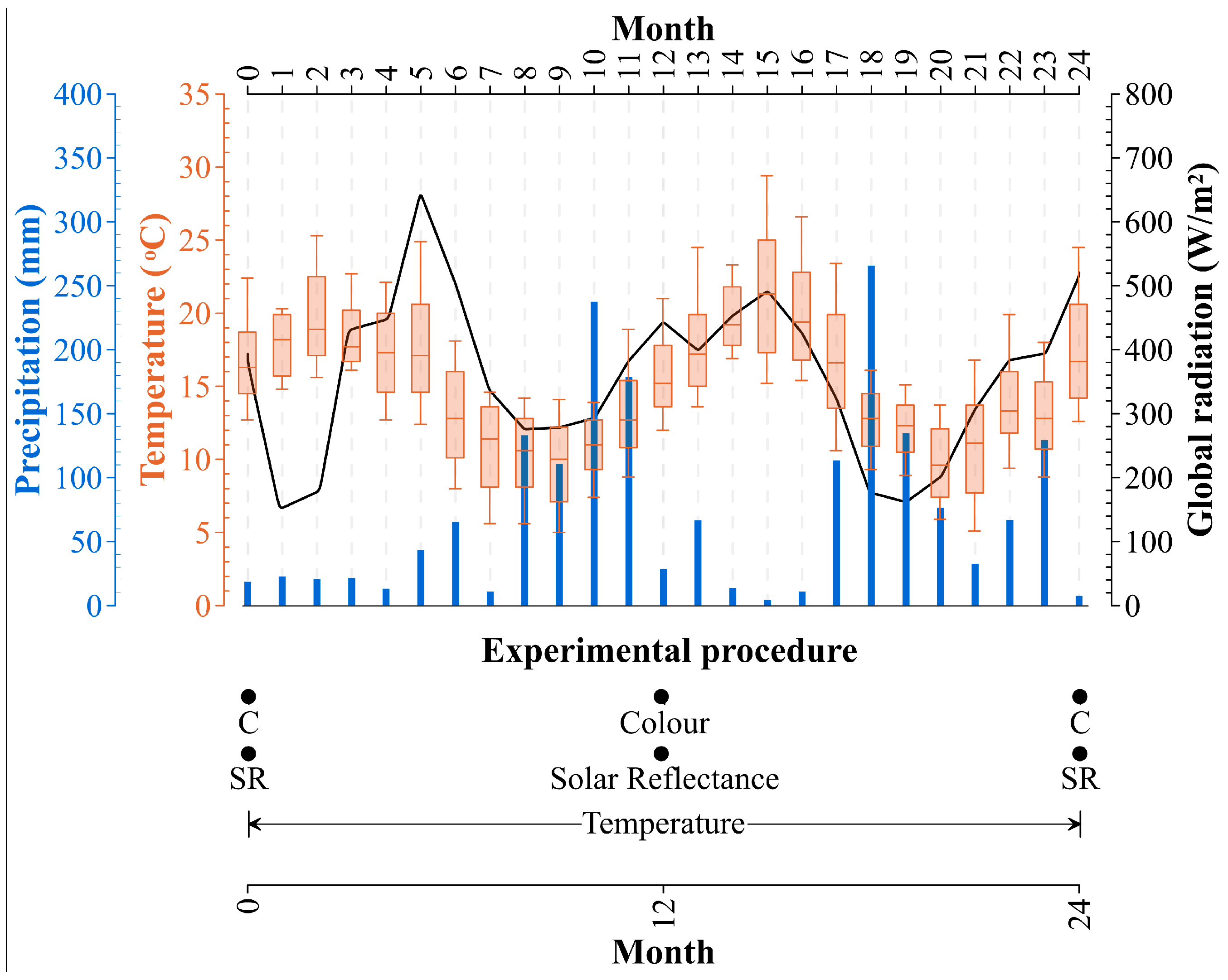

2. Methodology

2.1. Experimental Procedure

2.2. Materials

3. Results and Discussion

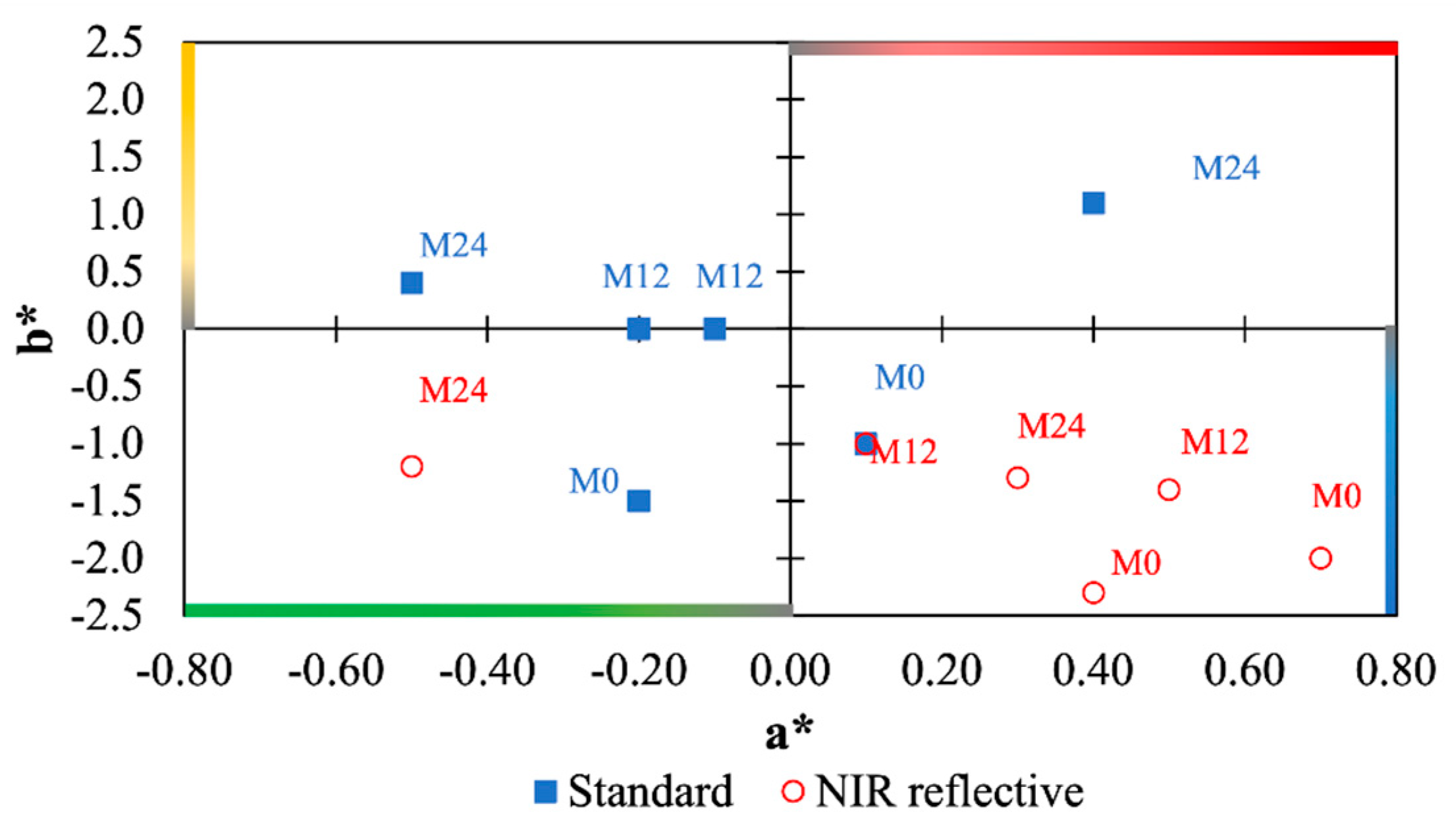

3.1. Colour

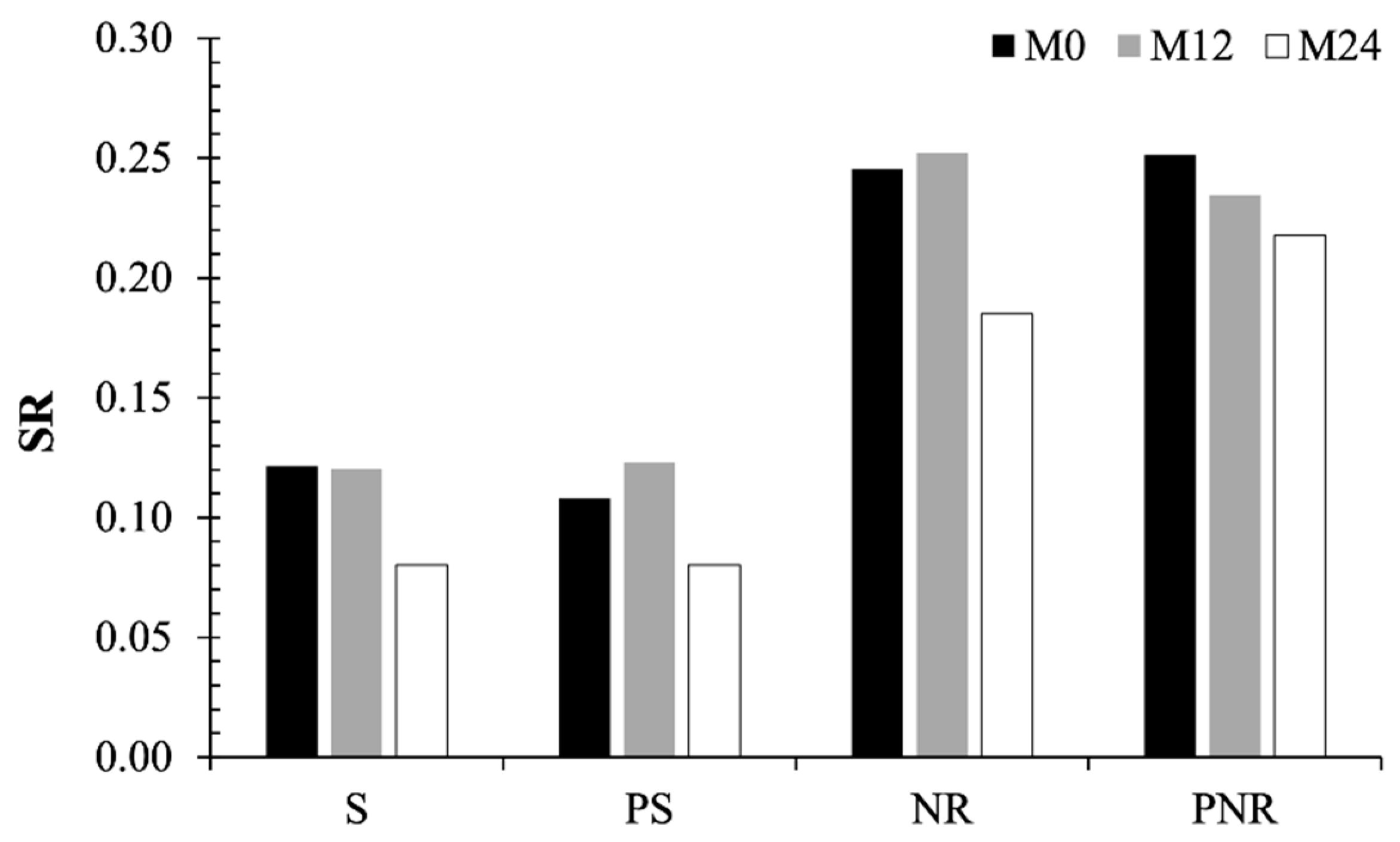

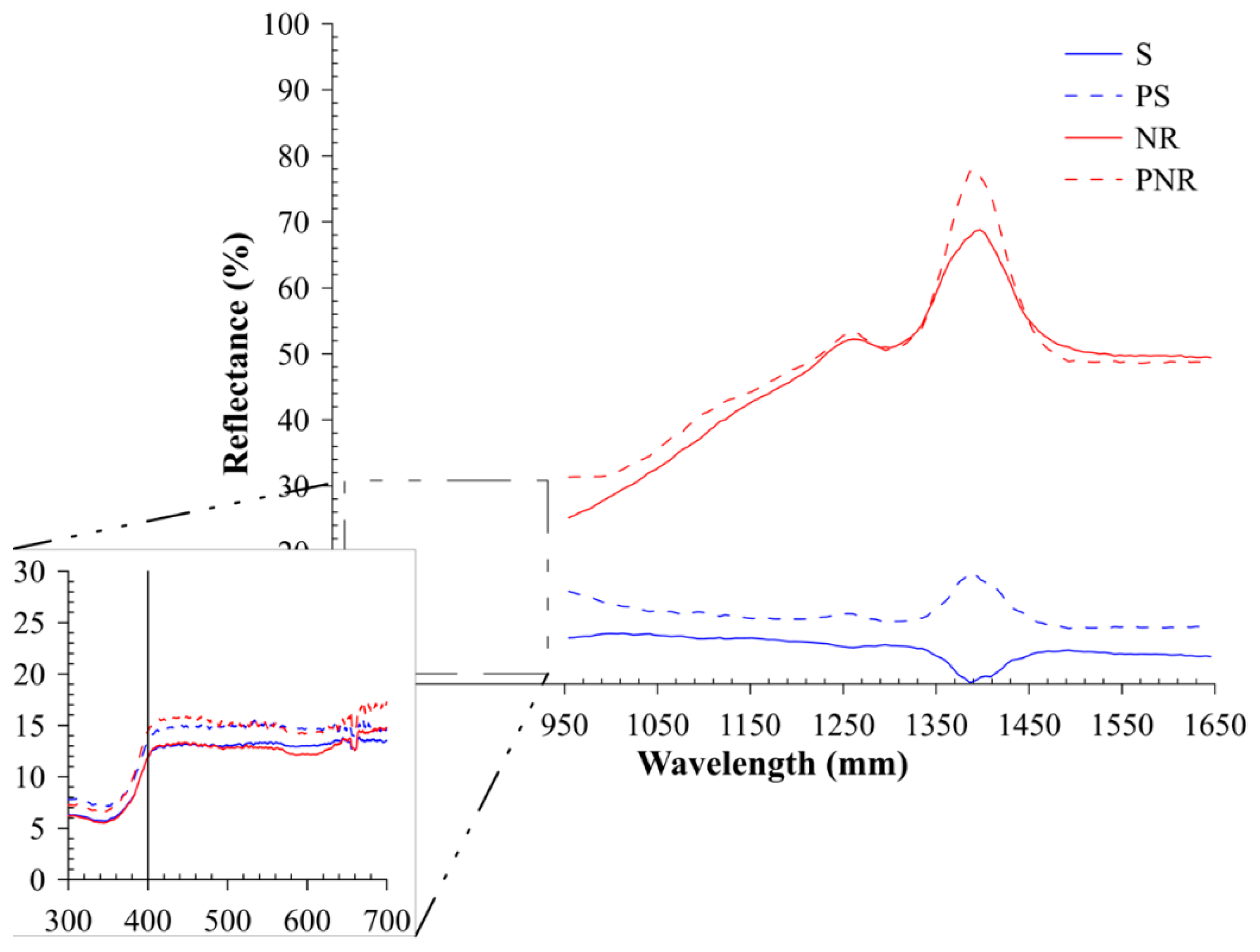

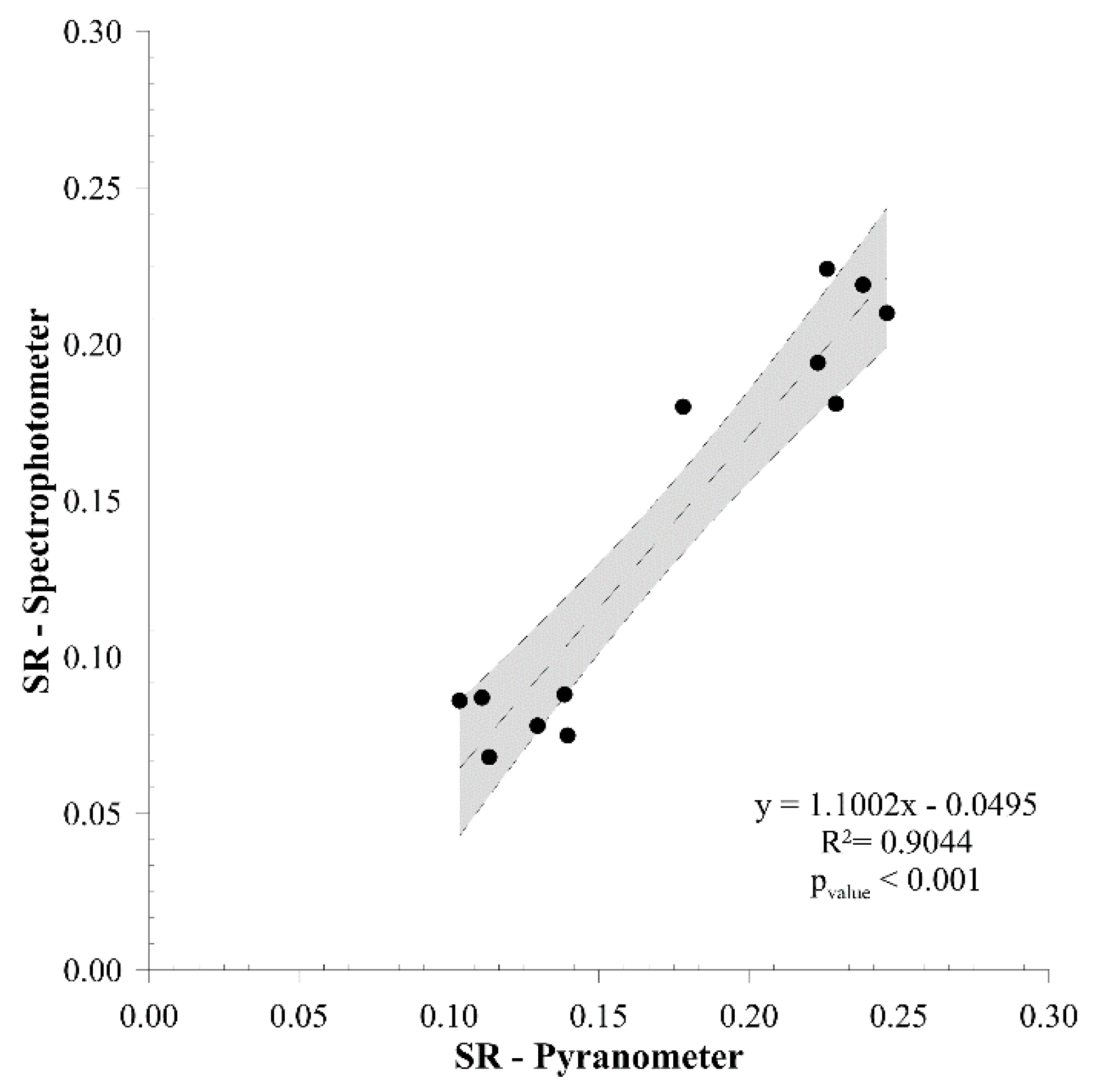

3.2. Solar Reflectance

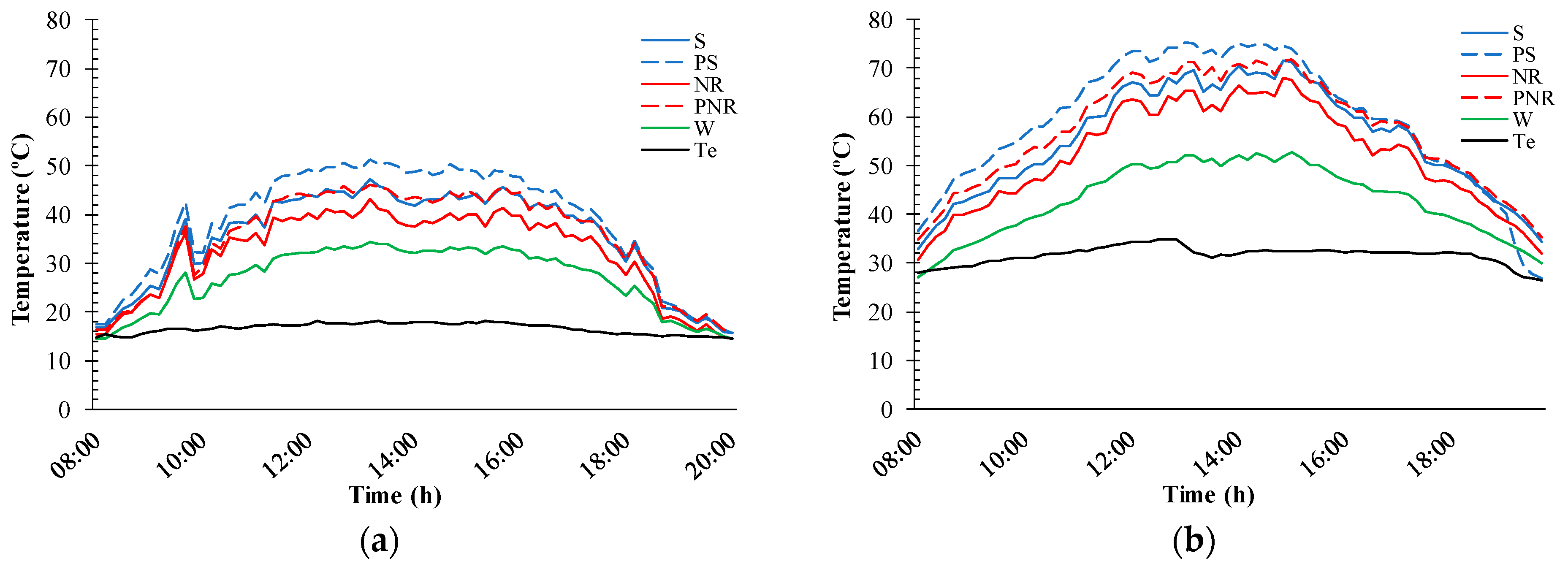

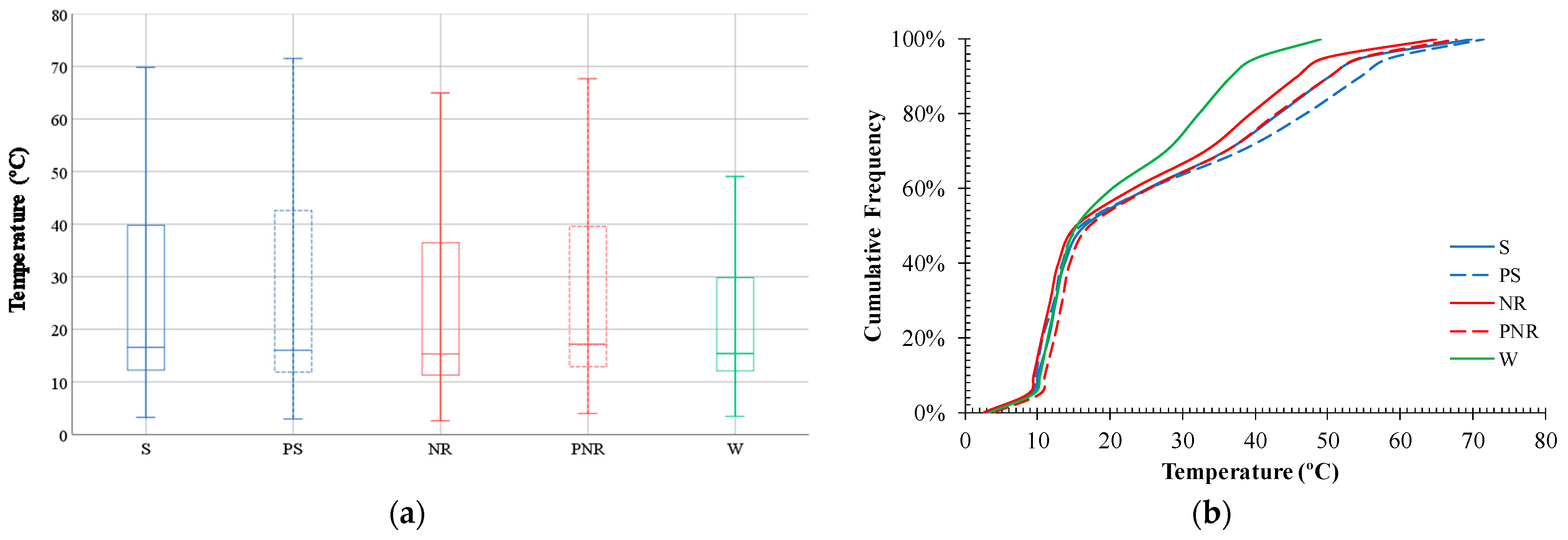

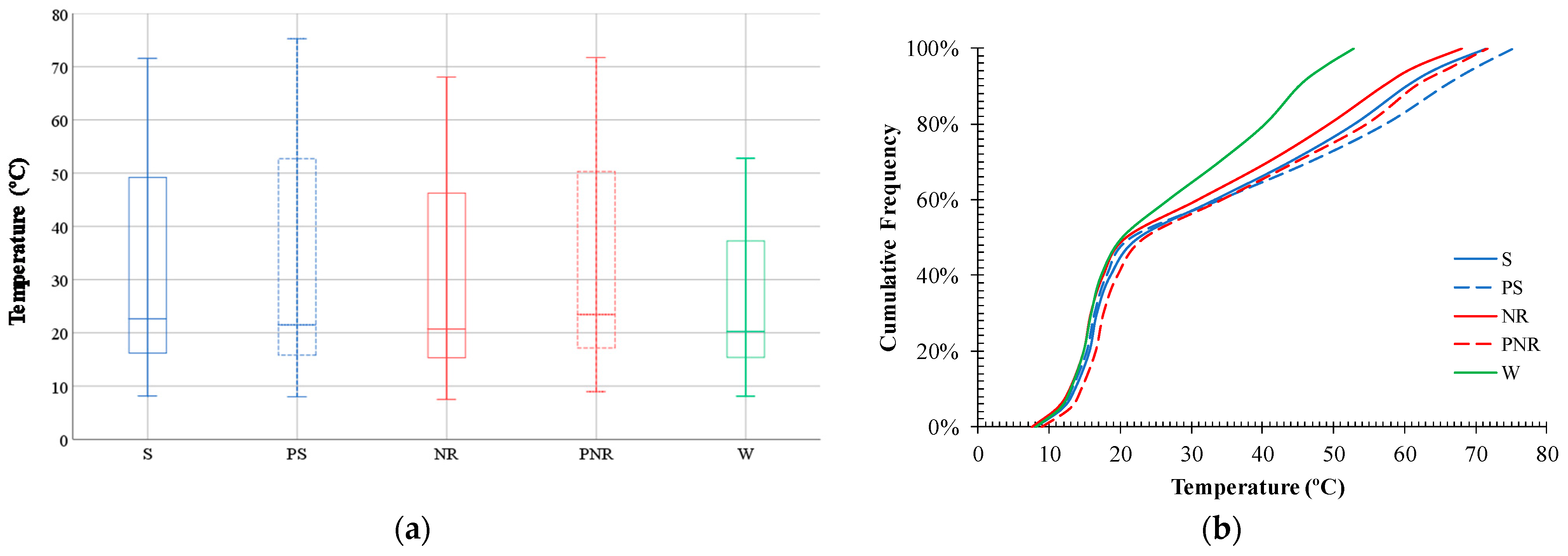

3.3. Surface Temperature

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kisilewicz, T.; Fedorczak-Cisak, M.; Barkanyi, T. Active thermal insulation as an element limiting heat loss through external walls. Energy Build. 2019, 205, 109541. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F. Eco-efficient construction and building materials research under the EU Framework Programme Horizon 2020. Constr. Build. Mater. 2014, 51, 151–162. [Google Scholar] [CrossRef] [Green Version]

- Pedroso, M.; Flores-Colen, I.; Silvestre, J.; Gomes, M.; Silva, L.; Ilharco, L. Physical, mechanical, and microstructural characterisation of an innovative thermal insulating render incorporating silica aerogel. Energy Build. 2020, 211, 109793. [Google Scholar] [CrossRef]

- Vale, H.; Melo, H.; Soares, A.; Flores-Colen, I.; Gomes, M.G. Performance of Industrial Thermal Insulation Renders. In Proceedings of the 9th International Masonry Conference, Guimarães, Portugal, 7–9 July 2014; Lourenço, P.B., Haseltine, B.A., Vasconcelos, G., Eds.; International Masonry Society: Whyteleafe, UK, 2014. [Google Scholar]

- Künzel, H.; Künzel, H.; Sedlbauer, K. Long-term performance of External Thermal Insulation Systems (ETICS). Architectura 2006, 5, 11–24. [Google Scholar]

- Barreira, E.; de Freitas, V.P. Experimental study of the hygrothermal behaviour of External Thermal Insulation Composite Systems (ETICS). Build. Environ. 2013, 63, 31–39. [Google Scholar] [CrossRef]

- D’Orazio, M.; Cursio, G.; Graziani, L.; Aquilanti, L.; Osimani, A.; Clementi, F.; Yéprémian, C.; Lariccia, V.; Amoroso, S. Effects of water absorption and surface roughness on the bioreceptivity of ETICS compared to clay bricks. Build. Environ. 2014, 77, 20–28. [Google Scholar] [CrossRef]

- Nilica, R.; Harmuth, H. Mechanical and fracture mechanical characterization of building materials used for external thermal insulation composite systems. Cem. Concr. Res. 2005, 35, 1641–1645. [Google Scholar] [CrossRef]

- Daniotti, B.; Cecconi, F.R.; Paolini, R.; Galliano, R. Durability Evaluation of External Thermal Insulation Composite Systems: Frequency Assessment of Thermal Shocks. In Proceedings of the CIB World Building Congress 2013, Brisbane, QLD, Australia, 5–9 May 2013; Queensland University of Technology (QUT), Ed.; [Google Scholar]

- Kvande, T.; Bakken, N.; Bergheim, E.; Thue, J.V. Durability of ETICS with Rendering in Norway—Experimental and Field Investigations. Buildings 2018, 8, 93. [Google Scholar] [CrossRef] [Green Version]

- Daniotti, B.; Cecconi, F.R. CIB W080: WG3 Test Methods for Service Life Prediction; CIB Report: Publication 331; Politecnico di Milano: Milan, Italy, 2010; ISBN 978-90-6363-062-1. [Google Scholar]

- Spagnolo, S.L.; Daniotti, B. Performance over Time and Durability Assessment of External Thermal Insulation Systems with Artificial Stone Cladding; Research for Development; Springer: Berlin/Heideberg, Germany, 2019; pp. 277–287. [Google Scholar]

- EOTA. ETAG 004, Guideline for European Technical Approval of External Thermal Insulation Composite Systems with Rendering; European Organisation for Technical Approvals: Brussels, Belgium, 2013. [Google Scholar]

- EOTA. EAD 040083-00-0404, External Thermal Insulation Composite Systems (ETICS) with Rendering; European Organisation for Technical Approvals: Brussels, Belgium, 2019. [Google Scholar]

- EAE. European Guideline for the Application of ETICS; European Association for External Thermal Insulation Composite Systems: Baden-Baden, Germany, 2011. [Google Scholar]

- Daniotti, B.; Cecconi, F.R.; Paolini, R.; Galliano, R.; Ferrer, J.; Battaglia, L. Durability evaluation of ETICS: Analysis of failures case studies and heat and moisture transfer simulations to assess the frequency of critical events. In Proceedings of the 4th Portuguese Conference on Mortars & ETICS, Coimbra, Portugal, 29–30 March 2012. [Google Scholar]

- ASTM. Standard Tabels for Reference Solar Spectral Irradiances: Direct Normal and Hemispherical on 37° Tilted Surface; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- ASTM. ASTM E1918-06 (2015): Standard Test Method for Measuring Solar Reflectance of Horizontal and Low-Sloped Surfaces in the Field; American Society for Testing and Materials: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Santamouris, M. Heat Island Research in Europe: The State of the Art. Adv. Build. Energy Res. 2007, 1, 123–150. [Google Scholar] [CrossRef]

- Pisello, A.L. State of the art on the development of cool coatings for buildings and cities. Sol. Energy 2017, 144, 660–680. [Google Scholar] [CrossRef]

- Mohelnikova, J. Materials for reflective coatings of window glass applications. Constr. Build. Mater. 2009, 23, 1993–1998. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Jalali, S. Nanotechnology: Advantages and drawbacks in the field of construction and building materials. Constr. Build. Mater. 2011, 25, 582–590. [Google Scholar] [CrossRef] [Green Version]

- Borsoi, G.; Parracha, J.; Caiado, P.; Flores-Colen, I.; Dionísio, A.; Veiga, R. Assessing Water Resistance and Surface Properties of ETICS. In Proceedings of the XV International Conference on Durability of Building Materials and Components (DBMC 2020), Barcelona, Spain, 20–23 October 2020; Serrat, C., Casas, J.R., Gibert, V., Eds.; [Google Scholar]

- Levinson, R.; Berdahl, P.; Akbari, H. Solar spectral optical properties of pigments—Part II: Survey of common colorants. Sol. Energy Mater. Sol. Cells 2005, 89, 351–389. [Google Scholar] [CrossRef]

- Baneshi, M.; Maruyama, S.; Komiya, A. The Effects of Using Some Common White Pigments on Thermal and Aesthetic Performances of Pigmented Coatings. J. Therm. Sci. Technol. 2009, 4, 131–145. [Google Scholar] [CrossRef] [Green Version]

- Baneshi, M.; Gonome, H.; Komiya, A.; Maruyama, S. The effect of particles size distribution on aesthetic and thermal per-formances of polydisperse TiO2 pigmented coatings: Comparison between numerical and experimental results. J. Quant. Spectrosc. Radiat. Transf. 2012, 113, 594–606. [Google Scholar] [CrossRef]

- Piri, N. Application of Multi Flux Model to Predict Optical Performance of Titanium Dioxide Nanopigments. Int. J. Nanosci. Nanotechnol. 2019, 15, 27–36. [Google Scholar]

- Kinoshita, S.; Yoshida, A. Investigating performance prediction and optimization of spectral solar reflectance of cool painted layers. Energy Build. 2016, 114, 214–220. [Google Scholar] [CrossRef]

- Jose, S.; Joshy, D.; Narendranath, S.B.; Periyat, P. Recent advances in infrared reflective inorganic pigments. Sol. Energy Mater. Sol. Cells 2019, 194, 7–27. [Google Scholar] [CrossRef]

- Xiang, B.; Yin, X.; Zhang, J. A novel cool material: ASA (acrylonitrile-styrene-acrylate) matrix composites with solar reflective inorganic particles. Compos. Sci. Technol. 2017, 145, 149–156. [Google Scholar] [CrossRef]

- Xiang, B.; Zhang, J. Effects of content and surface hydrophobic modification of BaTiO3 on the cooling properties of ASA (acrylonitrile-styrene-acrylate copolymer). Appl. Surf. Sci. 2018, 427, 654–661. [Google Scholar] [CrossRef]

- Song, J.; Qin, J.; Qu, J.; Song, Z.; Zhang, W.; Xue, X.; Shi, Y.; Zhang, T.; Ji, W.; Zhang, R.; et al. The effects of particle size distribution on the optical properties of titanium dioxide rutile pigments and their applications in cool non-white coatings. Sol. Energy Mater. Sol. Cells 2014, 130, 42–50. [Google Scholar] [CrossRef]

- Xie, N.; Li, H.; Abdelhady, A.; Harvey, J. Laboratorial investigation on optical and thermal properties of cool pavement nano-coatings for urban heat island mitigation. Build. Environ. 2019, 147, 231–240. [Google Scholar] [CrossRef]

- Zhou, A.; Yu, Z.; Chow, C.L.; Lau, D. Enhanced solar spectral reflectance of thermal coatings through inorganic additives. Energy Build. 2017, 138, 641–647. [Google Scholar] [CrossRef]

- Uemoto, K.L.; Sato, N.M.; John, V.M. Estimating thermal performance of cool colored paints. Energy Build. 2010, 42, 17–22. [Google Scholar] [CrossRef]

- Daniotti, B.; Diamanti, M.V.; Luongo, N.; Massari, S.; Pedeferri, M.P.; Spagnolo, S.L. Characterization of durability and photocatalytic properties of TiO2 cement-based materials. In Materials for Energy, Efficiency and Sustainability: TechConnect Briefs 2018; TechConnect Briefs: Washington, DC, USA, 2018; Volume 2, pp. 203–206. ISBN 978-0-9975117-9-6. [Google Scholar]

- Borsoi, G.; Esteves, C.; Flores-Colen, I.; Veiga, R. Effect of Hygrothermal Aging on Hydrophobic Treatments Applied to Building Exterior Claddings. Coatings 2020, 10, 363. [Google Scholar] [CrossRef] [Green Version]

- Piri, N.; Shams-Nateri, A.; Mokhtari, J. Solar spectral performance of nanopigments. Sol. Energy Mater. Sol. Cells 2017, 162, 72–82. [Google Scholar] [CrossRef]

- Daniotti, B.; Spagnolo, S.L. Service life prediction for buildings’ design to plan a sustainable building maintenance. In Proceedings of the Portugal SB 2007—Sustainable Construction, Materials and Practices: Challenge of the Industry for the New Millennium, Lisbon, Portugal, 12–14 September 2007; pp. 515–521. [Google Scholar]

- Grynning, S.; Gradeci, K.; Gaarder, J.E.; Time, B.; Lohne, J.; Kvande, T. Climate Adaptation in Maintenance Operation and Management of Buildings. Buildings 2020, 10, 107. [Google Scholar] [CrossRef]

- Stagrum, A.E.; Andenæs, E.; Kvande, T.; Lohne, J. Climate Change Adaptation Measures for Buildings—A Scoping Review. Sustainabiliy 2020, 12, 1721. [Google Scholar] [CrossRef] [Green Version]

- Berdahl, P.; Akbari, H.; Levinson, R.; Miller, W.A. Weathering of roofing materials—An overview. Constr. Build. Mater. 2008, 22, 423–433. [Google Scholar] [CrossRef] [Green Version]

- Susca, T. Enhancement of life cycle assessment (LCA) methodology to include the effect of surface albedo on climate change: Comparing black and white roofs. Environ. Pollut. 2012, 163, 48–54. [Google Scholar] [CrossRef] [PubMed]

- Sleiman, M.; Chen, S.; Gilbert, H.E.; Kirchstetter, T.W.; Berdahl, P.; Bibian, E.; Bruckman, L.S.; Cremona, D.; French, R.H.; Gordon, D.A.; et al. Soiling of building envelope surfaces and its effect on solar reflectance—Part III: Interlaboratory study of an accelerated aging method for roofing materials. Sol. Energy Mater. Sol. Cells 2015, 143, 581–590. [Google Scholar] [CrossRef] [Green Version]

- Ferrari, C.; Touchaei, A.G.; Sleiman, M.; Libbra, A.; Muscio, A.; Siligardi, C.; Akbari, H. Effect of aging processes on solar reflectivity of clay roof tiles. Adv. Build. Energy Res. 2014, 8, 28–40. [Google Scholar] [CrossRef]

- ASTM. Standard Practice for Laboratory Soiling and Weathering of Roofing Materials to Simulate Effects of Natural Exposure on Solar Reflectance and Thermal Emittance; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- Akbari, H.; Levinson, R.; Stern, S. Procedure for measuring the solar reflectance of flat or curved roofing assemblies. Sol. Energy 2008, 82, 648–655. [Google Scholar] [CrossRef] [Green Version]

- Levinson, R.; Akbari, H.; Berdahl, P. Measuring solar reflectance—Part II: Review of practical methods. Sol. Energy 2010, 84, 1745–1759. [Google Scholar] [CrossRef] [Green Version]

- Levinson, R.; Egolf, M.; Chen, S.; Berdahl, P. Experimental comparison of pyranometer, reflectometer, and spectropho-tometer methods for the measurement of roofing product albedo. Sol. Energy 2020, 206, 826–847. [Google Scholar] [CrossRef]

- Hukseflux, T.S. Pyranometer Products. Available online: http://www.hukseflux.com/product_group/pyranometer (accessed on 22 April 2016).

- ISO. ISO 9060:2018—Solar Energy—Specification and Classification of Instruments for Measuring Hemispherical Solar and Direct Solar Radiation; International Organization for Standardization: Geneva, Switzerland, 2018. [Google Scholar]

- ASTM. Standard Test Method for Solar Absorptance, Reflectance, and Transmittance of Materials Using Integrating Spheres; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- ISO. EN ISO/CIE 11644: Colorimetry Part 3: CIE Tristimulus Values; CIE International Commission on Illumination: Geneva, Switzerland, 2019. [Google Scholar]

- Hanson, A.R. 1—What is colour? In Colour Design, 2nd ed.; Best, J., Ed.; Woodhead Publishing: Cambridge, UK, 2012; pp. 3–21. [Google Scholar]

- Sattar, S. Characterizing Color with Reflectance. J. Chem. Educ. 2019, 96, 1124–1128. [Google Scholar] [CrossRef]

- Sharma, G.; Wu, W.; Dalal, E.N. The CIEDE2000 color-difference formula: Implementation notes, supplementary test data, and mathematical observations. Color Res. Appl. 2004, 30, 21–30. [Google Scholar] [CrossRef]

- Brainard, D.H. Color Appearance and Color Difference Specification. Sci. Color 2003, 191–216. [Google Scholar] [CrossRef]

- Weatherall, I.L.; Coombs, B.D. Skin Color Measurements in Terms of CIELAB Color Space Values. J. Investig. Dermatol. 1992, 99, 468–473. [Google Scholar] [CrossRef] [Green Version]

- Revel, G.M.; Martarelli, M.; Emiliani, M.; Gozalbo, A.; Orts, M.J.; Bengochea, M.Á.; Delgado, L.G.; Gaki, A.; Katsiapi, A.; Taxiarchou, M.; et al. Cool products for building envelope—Part I: Development and lab scale testing. Sol. Energy 2014, 105, 770–779. [Google Scholar] [CrossRef]

- Coser, E.; Moritz, V.F.; Krenzinger, A.; Ferreira, C.A. Development of paints with infrared radiation reflective properties. Polímeros 2015, 25, 305–310. [Google Scholar] [CrossRef] [Green Version]

- Rossi, S.; Lindmark, H.; Fedel, M. Colored Paints Containing NIR-Reflective Pigments Exposed to Accelerated Ultraviolet Radiation Aging with Possible Application as Roof Coatings. Coatings 2020, 10, 1135. [Google Scholar] [CrossRef]

- Cozza, E.; Alloisio, M.; Comite, A.; Di Tanna, G.; Vicini, S. NIR-reflecting properties of new paints for energy-efficient buildings. Sol. Energy 2015, 116, 108–116. [Google Scholar] [CrossRef]

- Mokrzycki, W.; Tatol, M. Color difference Delta E—A survey. Mach. Graph. Vis. 2011, 20, 383–411. [Google Scholar]

- Ihara, T.; Jelle, B.P.; Gao, T.; Gustavsen, A. Accelerated aging of treated aluminum for use as a cool colored material for facades. Energy Build. 2016, 112, 184–197. [Google Scholar] [CrossRef]

- Paolini, R.; Zani, A.; Poli, T.; Antretter, F.; Zinzi, M. Natural aging of cool walls: Impact on solar reflectance, sensitivity to thermal shocks and building energy needs. Energy Build. 2017, 153, 287–296. [Google Scholar] [CrossRef]

- Pisello, A.L.; Fortunati, E.; Fabiani, C.; Mattioli, S.; Dominici, F.; Torre, L.; Cabeza, L.F.; Cotana, F. PCM for improving pol-yurethane-based cool roof membranes durability. Sol. Energy Mater. Sol. Cells 2017, 160, 34–42. [Google Scholar] [CrossRef]

- Gobakis, K.; Kolokotsa, D.; Maravelaki-Kalaitzaki, N.; Perdikatsis, V.; Santamouris, M. Development and analysis of ad-vanced inorganic coatings for buildings and urban structures. Energy Build. 2015, 89, 196–205. [Google Scholar] [CrossRef]

- Santamouris, M. Cooling the cities—A review of reflective and green roof mitigation technologies to fight heat island and improve comfort in urban environments. Sol. Energy 2014, 103, 682–703. [Google Scholar] [CrossRef]

- Rosso, F.; Pisello, A.L.; Jin, W.; Ghandehari, M.; Cotana, F.; Ferrero, M. Cool Marble Building Envelopes: The Effect of Aging on Energy Performance and Aesthetics. Sustainability 2016, 8, 753. [Google Scholar] [CrossRef] [Green Version]

- Vox, G.; Maneta, A.; Schettini, E. Evaluation of the radiometric properties of roofing materials for livestock buildings and their effect on the surface temperature. Biosyst. Eng. 2016, 144, 26–37. [Google Scholar] [CrossRef]

- Gonome, H.; Baneshi, M.; Okajima, J.; Komiya, A.; Maruyama, S. Controlling the radiative properties of cool black-color coatings pigmented with CuO submicron particles. J. Quant. Spectrosc. Radiat. Transf. 2014, 132, 90–98. [Google Scholar] [CrossRef]

- Ganguly, A.; Chowdhury, D.; Neogi, S. Performance of Building Roofs on Energy Efficiency—A Review. Energy Procedia 2016, 90, 200–208. [Google Scholar] [CrossRef]

- Zinzi, M.; Carnielo, E.; Rossi, G. Directional and angular response of construction materials solar properties: Characteri-sation and assessment. Sol. Energy 2015, 115, 52–67. [Google Scholar] [CrossRef]

- Meola, C.; Boccardi, S.; Carlomagno, G.M. (Eds.) Infrared Thermography in the Evaluation of Aerospace Composite Materials. In Infrared Thermography in the Evaluation of Aerospace Composite Materials; Woodhead Publishing: Cambridge, UK, 2017; pp. 57–83. [Google Scholar]

- Krimpalis, S.; Karamanis, D. A novel approach to measuring the solar reflectance of conventional and innovative building components. Energy Build. 2015, 97, 137–145. [Google Scholar] [CrossRef]

- Li, H.; Harvey, J.; Kendall, A. Field measurement of albedo for different land cover materials and effects on thermal performance. Build. Environ. 2013, 59, 536–546. [Google Scholar] [CrossRef]

| Specimen | Primer | NIR Finishing Coating | Description |

|---|---|---|---|

| S | Standard black (reference) | ||

| PS | ● | Standard black with primer | |

| NR | ● | NIR Black | |

| PNR | ● | ● | NIR Black with primer |

| W | White (reference) |

| Initial Colour | Specimen | Month | CIELab Coordinates ** | ||

|---|---|---|---|---|---|

| L* | a* | b* | |||

| S | 0 | 34.0 ± 0.17 | −0.2 ± 0.10 | −1.5 ± 0.25 | |

| 12 | 33.9 ± 0.10 | −0.1 ± 0.10 | 0.0 ± 0.10 | ||

| 24 | 35.9 ± 0.45 | −0.5 ± 0.10 | 0.4 ± 0.50 | ||

| PS | 0 | 33.4 ± 0.36 | 0.1 ± 0.15 | −1.0 ± 0.53 | |

| 12 | 33.3 ± 0.71 | −0.2 ± 0.06 | 0.0 ± 0.06 | ||

| 24 | 34.5 ± 0.12 | 0.4 ± 0.31 | 1.1 ± 0.15 | ||

| NR | 0 | 34.8 ± 0.62 | 0.4 ± 0.06 | −2.3 ± 0.36 | |

| 12 | 34.7 ± 0.84 | 0.1 ± 0.15 | −1.0 ± 0.67 | ||

| 24 | 36.3 ± 0.21 | −0.5 ± 0.17 | −1.2 ± 0.06 | ||

| PNR | 0 | 34.1 ± 0.60 | 0.7 ± 0.10 | −2.0 ± 0.31 | |

| 12 | 33.5 ± 0.21 | 0.5 ± 0.15 | −1.4 ± 0.30 | ||

| 24 | 35.5 ± 0.06 | 0.3 ± 0.10 | −1.3 ± 0.26 | ||

| Specimen | SR (-) * | ||

|---|---|---|---|

| Month 0 | Month 12 | Month 24 | |

| S | 0.12 ± 0.007 | 0.12 ± 0.009 | 0.08 ± 0.011 |

| PS | 0.11 ± 0.002 | 0.12 ± 0.008 | 0.08 ± 0.007 |

| NR | 0.25 ± 0.003 | 0.25 ± 0.006 | 0.19 ± 0.008 |

| PNR | 0.25 ± 0.006 | 0.23 ± 0.010 | 0.22 ± 0.007 |

| W | 0.62 ± 0.003 | 0.61 ± 0.008 | 0.47 ± 0.009 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramos, N.M.M.; Maia, J.; Souza, A.R.; Almeida, R.M.S.F.; Silva, L. Impact of Incorporating NIR Reflective Pigments in Finishing Coatings of ETICS. Infrastructures 2021, 6, 79. https://doi.org/10.3390/infrastructures6060079

Ramos NMM, Maia J, Souza AR, Almeida RMSF, Silva L. Impact of Incorporating NIR Reflective Pigments in Finishing Coatings of ETICS. Infrastructures. 2021; 6(6):79. https://doi.org/10.3390/infrastructures6060079

Chicago/Turabian StyleRamos, Nuno M. M., Joana Maia, Andrea R. Souza, Ricardo M. S. F. Almeida, and Luís Silva. 2021. "Impact of Incorporating NIR Reflective Pigments in Finishing Coatings of ETICS" Infrastructures 6, no. 6: 79. https://doi.org/10.3390/infrastructures6060079