Eco-Efficient Fiber-Reinforced Preplaced Recycled Aggregate Concrete under Impact Loading

Abstract

:1. Introduction

2. Experimental Section

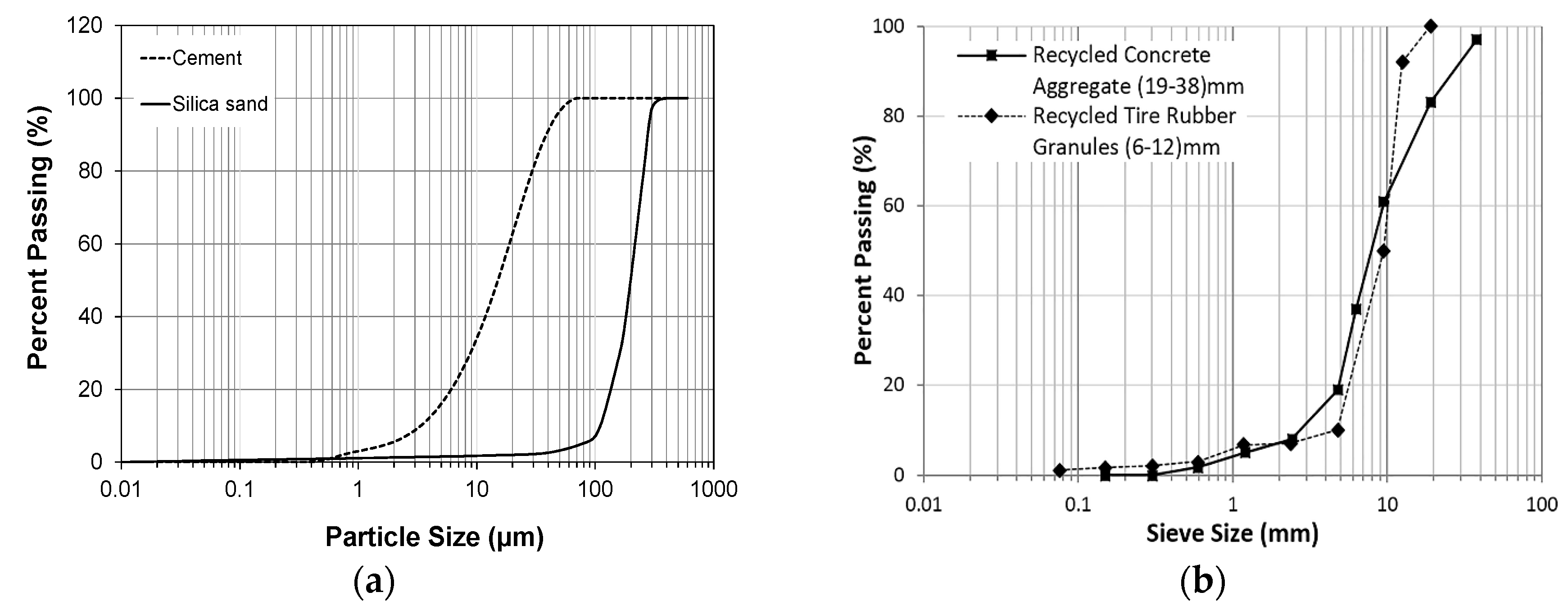

2.1. Materials and Mixture Proportions

2.2. Mixing and Specimen Preparation

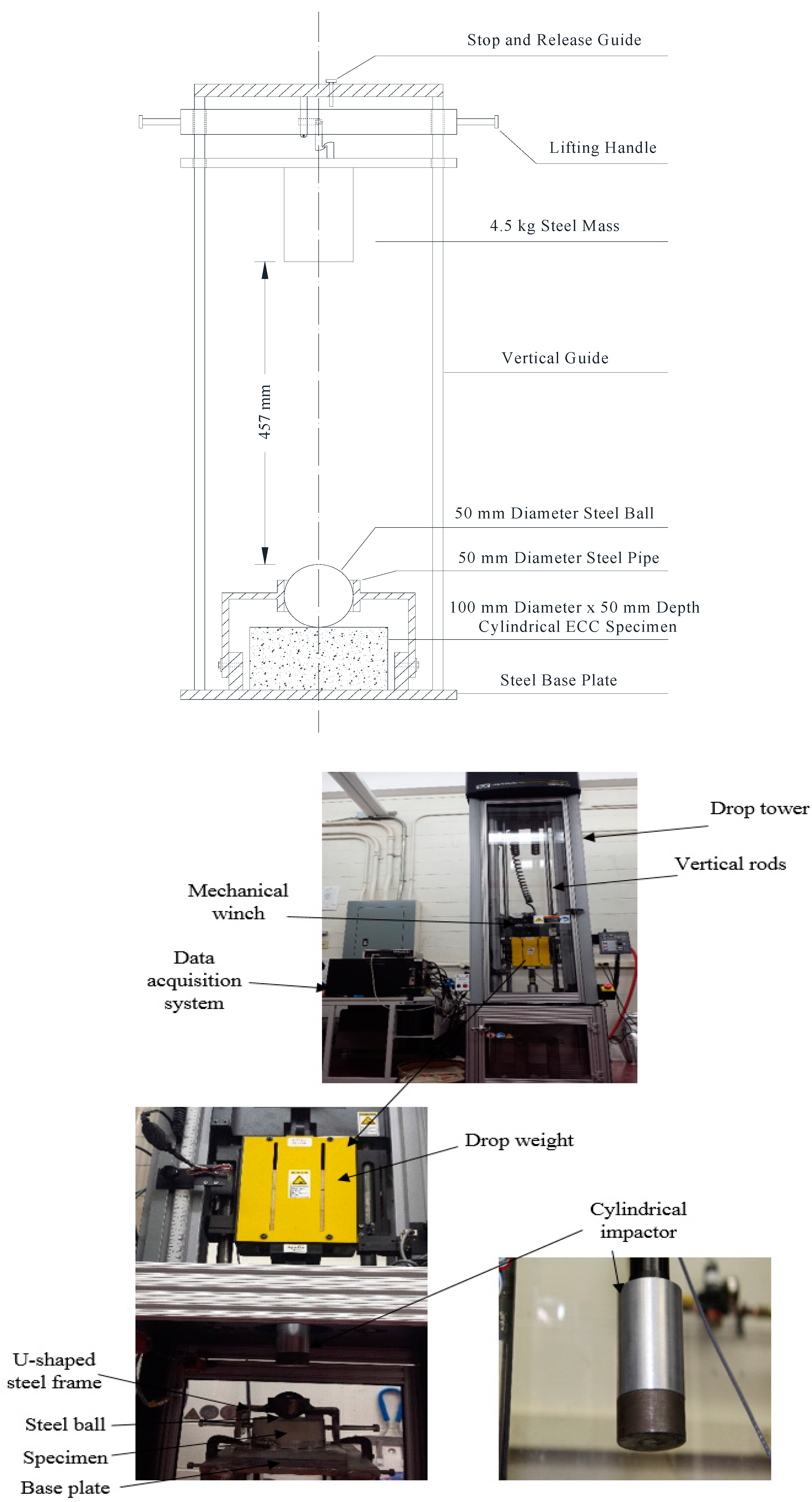

2.3. Experimental Procedures

3. Results and Discussion

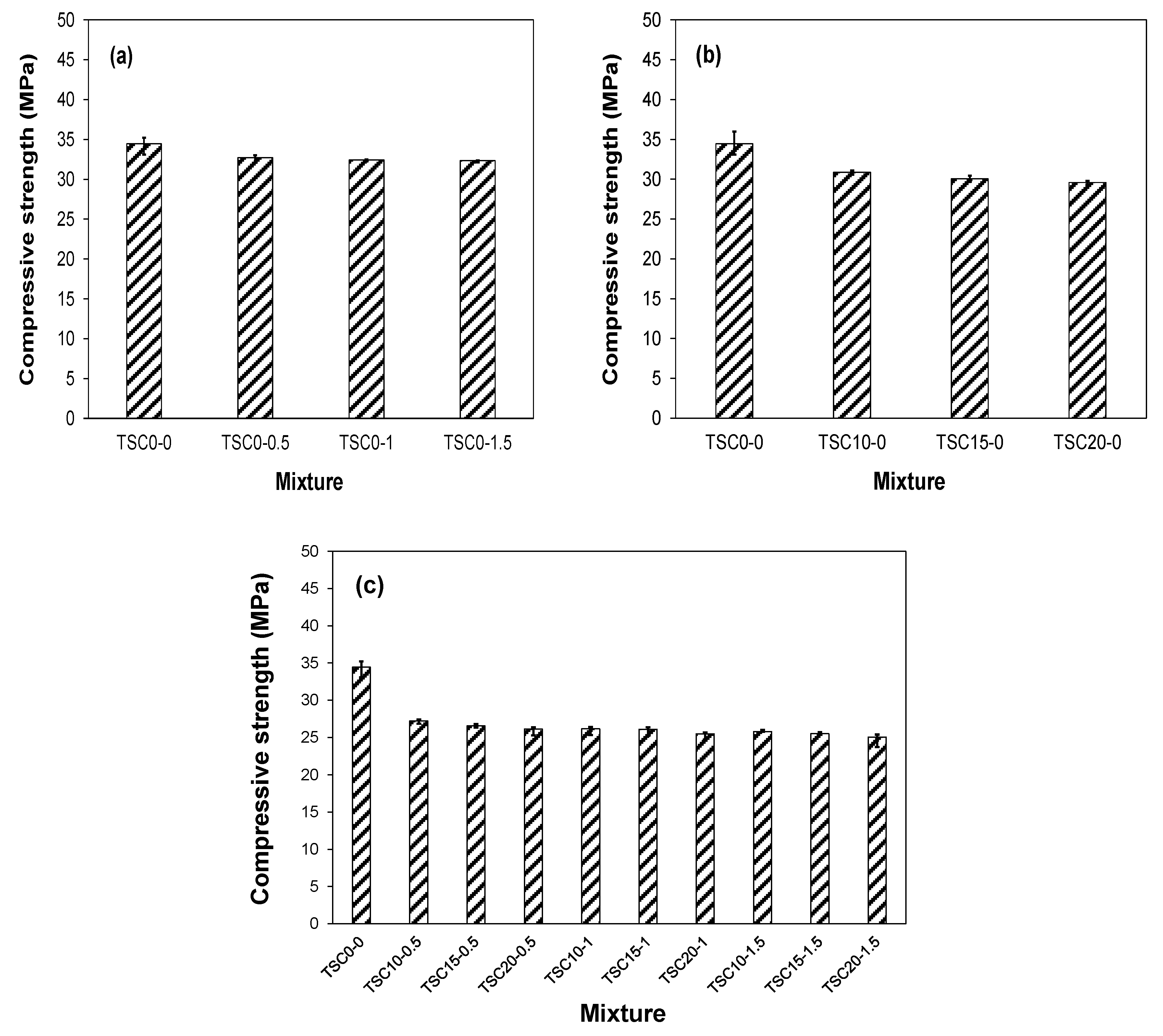

3.1. Compressive Strength

3.2. Elastic Modulus

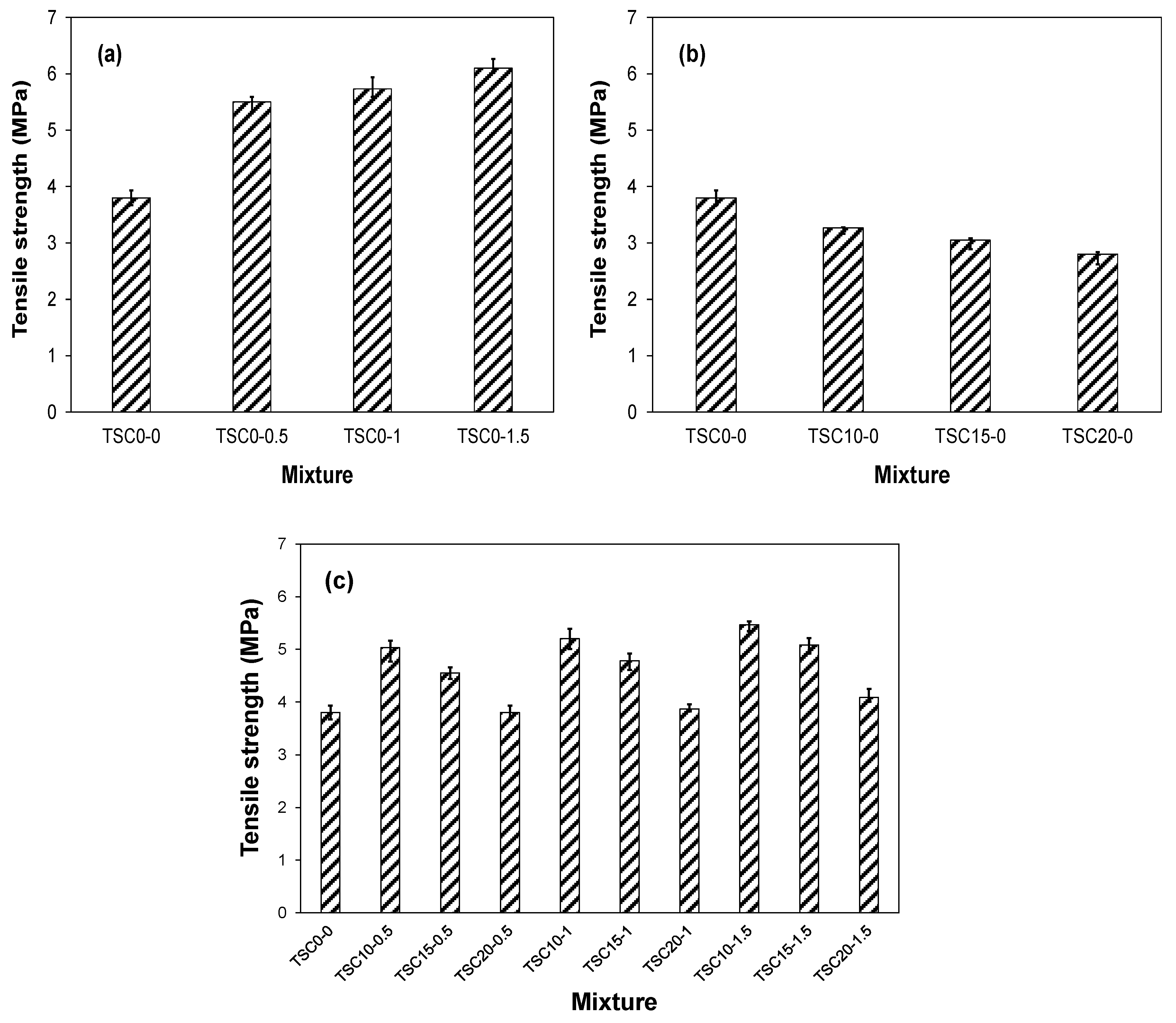

3.3. Splitting Tensile Strength

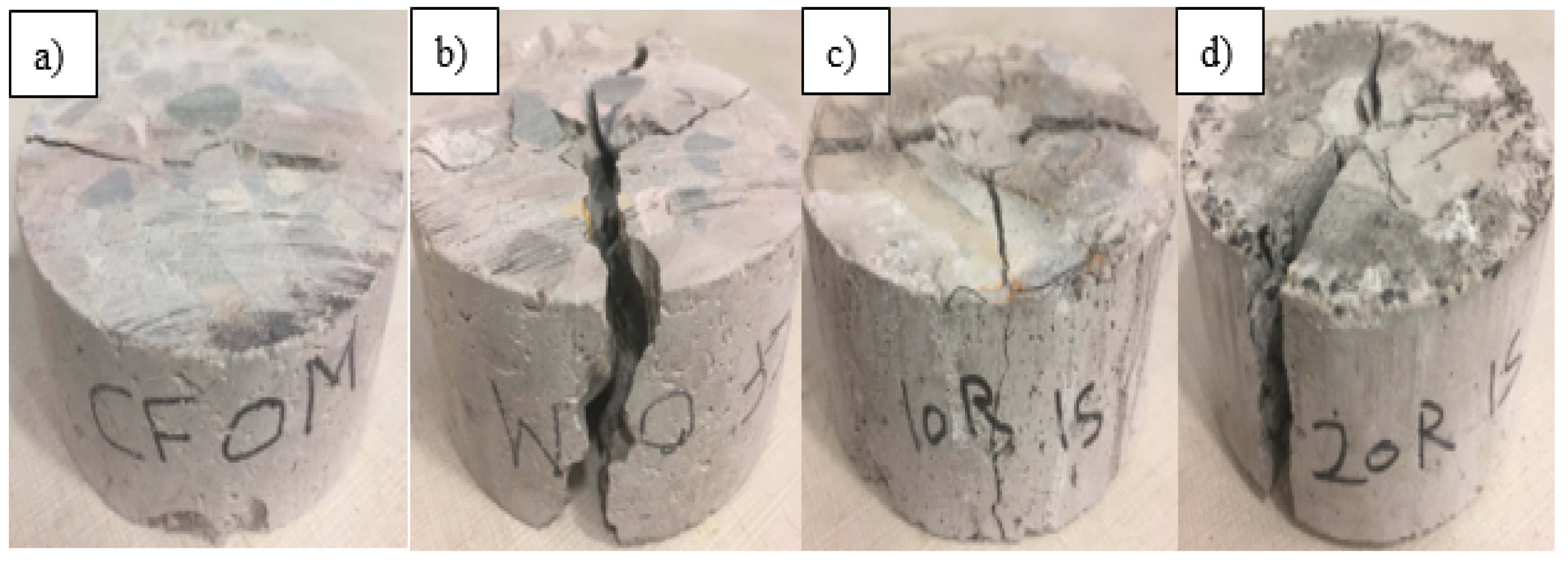

3.4. Impact Resistance

4. Statistical Analysis and Modeling

4.1. Analysis of Variance of Test Results

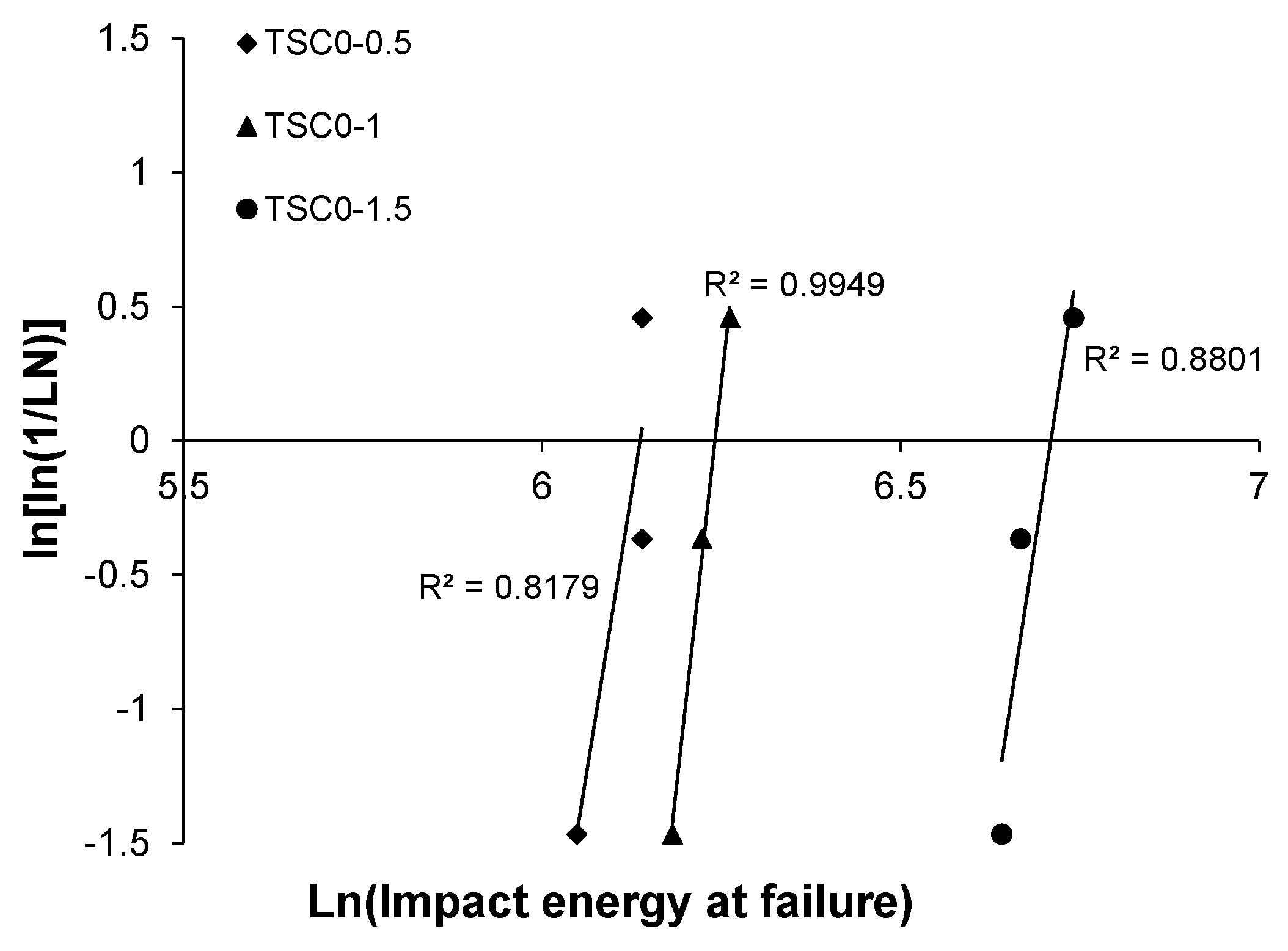

4.2. Weibull Distribution Model

5. Conclusions

- The compressive strength of TSC specimens decreased due to the tire rubber addition, while the steel wire fiber addition did not have a significant effect on the compressive strength.

- The tensile strength of the sustainable TSC specimens was significantly enhanced by up to 58% owing to the recycled steel wire fiber addition. ANOVA confirmed that incorporating recycled steel wire fiber in the TSC mixtures had a significant positive effect on the tensile capacity of the TSC. Among all of the tested specimens, TSC incorporating no tire rubber and 1.5% steel fiber achieved the highest tensile capacity.

- The behavior of TSC subjected to impact loading was enhanced by 22 to 40 times owing to the steel fiber addition. However, incorporating tire rubber in TSC decreased its impact performance.

- The Weibull distribution function achieved an adequate capability of representing the impact test data of TSC with a linear correlation between the numbers of impacts that initiated ultimate failure for all TSC specimens.

- The study pioneers a highly sustainable concrete with entirely recycled granular content, entirely recycled fibre reinforcement, and a large volume recycled binder, with a sustainable low energy mixing requirement and placement, superior tensile properties and impact resistance for the protection of civil infrastructures in the event of unexpected severe loading conditions, while valorizing waste and by-products and lowering the energy used in concrete production and placement, as well as the overall material intensity.

- A potential application of this highly eco-efficient concrete would be for pavements and sidewalks, road barriers, and protective systems for critical infrastructures against impacts.

Author Contributions

Funding

Conflicts of Interest

References

- Adhikary, S.D.; Li, B.; Fujikake, K. State-of-the-art review on low-velocity impact response of reinforced concrete beams. Mag. Concr. Res. 2016, 68, 701–723. [Google Scholar] [CrossRef]

- Alhadid, M.M.A.; Soliman, A.M.; Nehdi, M.L.; Youssef, M.A. Critical overview of blast resistance of different concrete types. Mag. Concr. Res. 2014, 66, 72–81. [Google Scholar] [CrossRef]

- Remennikov, A.; Kaewunruen, S. Impact resistance of reinforced concrete columns: Experimental studies and design considerations. In Proceedings of the 19th Australasian Conference on the Mechanics of Structures and Materials, Christchurch, New Zealand, 29 November–1 December 2006; pp. 817–824. [Google Scholar]

- Kennedy, R.P. A review of procedures for the analysis and design of concrete structures to resist missile impact effects. Nucl. Eng. Des. 1976, 37, 183–203. [Google Scholar] [CrossRef]

- Li, Q.M.; Reid, S.R.; Wen, H.M.; Telford, A.R. Local impact effects of hard missiles on concrete targets. Int. J. Impact Eng. 2005, 32, 224–284. [Google Scholar] [CrossRef]

- Luccioni, B.M.; Ambrosinia, R.D.; Danesia, R.F. Analysis of building collapse under blast loads. Eng. Struct. 2004, 26, 63–71. [Google Scholar] [CrossRef]

- Murali, G.; Santhi, A.S.; Ganesh, G.M. Impact resistance and strength reliability of fiber-reinforced concrete in bending under drop weight impact load. Int. J. Technol. 2014, 5, 111–120. [Google Scholar] [CrossRef]

- Murnal, P.B.; Chatorikar, R.N. Impact resistance of steel fiber reinforced concrete. Int. J. Res. Eng. Technol. 2015, 4, 241–246. [Google Scholar]

- Chen, Y.; May, I.M. Reinforced concrete members under drop-weight impacts. Struct. Build. 2009, 162, 45–56. [Google Scholar] [CrossRef] [Green Version]

- Hannant, D.J. Fibre reinforcement in the cement and concrete industry. Mater. Sci. Technol. 1995, 11, 853–861. [Google Scholar] [CrossRef]

- MacVicar, R.; Matuana, L.M.; Balatinecz, J.J. Aging mechanism in cellulose fiber reinforcement cement composite. Cem. Concr. Compos. 1999, 21, 189–196. [Google Scholar] [CrossRef]

- Ali, M.A.E.M.; Nehdi, M.L.; Soliman, A.M. Exploring behavior of novel hybrid-fiber reinforced engineered cementitious composite under impact loading. Mater. Des. 2017, 117, 139–149. [Google Scholar] [CrossRef]

- Mahmoud, N.; Afroughsabet, V. Combined effect of silica fume and steel fibers on the impact resistance and mechanical properties of concrete. Int. J. Impact Eng. 2010, 37, 879–886. [Google Scholar] [Green Version]

- Taner, Y.S.; Cevdet, E.E.; Findik, F. Properties of hybrid fiber reinforced concrete under repeated impact loads. Russ. J. Nondestruct. Test. 2010, 46, 538–546. [Google Scholar] [CrossRef]

- Alavi, N.A.; Hedayatian, M.; Mahmoud, N.; Afrough, S.V. An experimental and numerical study on how steel and polypropylene fibers affect the impact resistance in fiber-reinforced concrete. Int. J. Impact Eng. 2012, 46, 62–73. [Google Scholar] [CrossRef]

- Ali, M.A.E.M.; Nehdi, M.L. Innovative self-healing hybrid fiber reinforced engineered cementitious composite. Constr. Build. Mater. 2017, 150, 689–702. [Google Scholar] [CrossRef]

- Rao, B.K.; Ravindra, V.; Rajagopal, A. Experimental investigation on impact strength of steel fiber reinforced normal and self-compacting concrete. Int. J. Civ. Eng. Archit. 2012, 2, 495–505. [Google Scholar]

- Adhikary, S.D.; Li, B.; Fujikake, K. Residual resistance of impact-damaged reinforced concrete beams. Mag. Concr. Res. 2015, 67, 364–378. [Google Scholar] [CrossRef]

- Swamy, R.N.; Jojagha, A.H. Impact resistance of steel fibre reinforced lightweight concrete. Int. J. Cem. Compos. Lightweight Concr. 1982, 4, 209–220. [Google Scholar] [CrossRef]

- Yew, M.K.; Othman, I.; Yew, M.C.; Yeo, S.H.; Mahmud, H. Strength properties of hybrid nylon-steel and polypropylene-steel fibre-reinforced high strength concrete at low volume fraction. Int. J. Phys. Sci. 2011, 6, 7584–7588. [Google Scholar]

- Khalil, E.; Abd-Elmohsen, M.; Anwar, A.M. Impact resistance of rubberized Self-compacting concrete. Water Sci. 2015, 29, 45–53. [Google Scholar] [CrossRef]

- Al-Tayeb, M.M.; Abu-Bakar, B.H.; Ismail, H.; Akil, H.M. Impact resistance of concrete with partial replacements of sand and cement by waste rubber. Polym. Plast. Technol. Eng. 2012, 51, 1230–1236. [Google Scholar] [CrossRef]

- Reda-Taha, M.M.; El-Dieb, A.S.; Abdel-Wahab, M.A.; Abdel-Hameed, M.E. Mechanical, fracture, and microstructural investigations of rubber concrete. J. Mater. Civ. Eng. 2008, 20, 640–649. [Google Scholar] [CrossRef]

- Vadivel, T.S.; Thenmozhi, R.; Doddurani, M. Experimental behavior of waste tire rubber aggregate concrete under impact loading. IJST Trans. Civ. Eng. 2014, 38, 251–259. [Google Scholar]

- Abdullah, S.R.; Zainal-Abidin, W.R.W.; Shahidan, S. Strength of concrete containing rubber particle as partial cement replacement. In Proceedings of the 3rd International Conference on Civil and Environmental Engineering for Sustainability, Melaka, Malaysia, 1–2 December 2015; Volume 47, pp. 1–4. [Google Scholar]

- Yehia, S.; Helal, K.; Abusharkh, A.; Zaher, A.; Istaitiyeh, H. Strength and durability evaluation of recycled aggregate concrete. Int. J. Concr. Struct. Mater. 2015, 9, 219–239. [Google Scholar] [CrossRef]

- Nehdi, M.L.; Najjar, M.F.; Soliman, A.M.; Azabi, T.M. Novel steel fibre-reinforced preplaced aggregate concrete with superior mechanical performance. Cem. Concr. Compos. 2017, 82, 242–251. [Google Scholar] [CrossRef]

- Ismail, S.; Ramli, M. Impact resistance of recycled aggregate concrete with single and hybrid fibers. In Proceedings of the 3rd International Conference on Civil and Environmental Engineering for Sustainability, Melaka, Malaysia, 1–2 December 2015; Volume 47, pp. 1–7. [Google Scholar]

- Liu, F.; Chen, G.; Li, L.; Guo, Y. Study of impact performance of rubber reinforced concrete. Constr. Build. Mater. 2012, 36, 604–616. [Google Scholar] [CrossRef]

- ACI Committee 544. Measurement of Properties of Fiber Reinforced Concrete; 48331-3439, ACI Standard 544.2R-89 (Reapproved 2009); American Concrete Institute: Farmington Hills, MI, USA, 1999. [Google Scholar]

- Ahmad, S.; Alghamdi, S.A. A statistical approach to optimizing concrete mixture design. Sci. World J. 2014, 2014, 561539. [Google Scholar] [CrossRef]

- Soliman, A.M.; Nehdi, M.L. Effect of natural wollastonite microfibers on early age behavior of UHPC. J. Mater. Civ. Eng. 2012, 24, 816–824. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments, 8th ed.; John Wiley and Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Li, H.; Zhang, M.; Ou, J. Flexural fatigue performance of concrete containing nanoparticles for pavement. Int. J. Fatigue 2007, 29, 1292–1301. [Google Scholar] [CrossRef]

- Raif, S.; Irfan, A. Statistical analysis of bending fatigue life data using Weibull distribution in glass-fiber reinforced polyester composites. Mater. Des. 2008, 29, 1170–1181. [Google Scholar]

- Raman, B.; Rakesh, C. Fatigue-life distributions and failure probability for glass-fiber reinforced polymeric composites. Compos. Sci. Technol. 2009, 69, 1381–1387. [Google Scholar]

- Saghafi, A.; Mirhabibi, A.R.; Yari, G.H. Improved linear regression method for estimating Weibull parameters. Theor. Appl. Fract. Mech. 2009, 52, 180–182. [Google Scholar] [CrossRef]

- Rahmani, T.; Kiani, B.; Shekarchi, M.; Safari, A. Statistical and experimental analysis on the behavior of fiber reinforced concretes subjected to drop weight test. Constr. Build. Mater. 2012, 37, 360–369. [Google Scholar] [CrossRef]

- Chen, X.; Ding, Y.; Azevedo, C. Combined effect of steel fibres and steel rebars on impact resistance of high-performance concrete. J. Cent. South Univ. Technol. 2011, 18, 1677–1684. [Google Scholar] [CrossRef]

| Component (%) | Cement | Silica Sand |

|---|---|---|

| CaO | 64.35 | 0.01 |

| SiO2 | 20.08 | 99.70 |

| Al2O3 | 4.63 | 0.14 |

| Fe2O3 | 2.84 | 0.016 |

| MgO | 2.07 | 0.01 |

| SO3 | 2.85 | --- |

| K2O | --- | 0.04 |

| Na2O | --- | 0.01 |

| Loss of ignition | 2.56 | --- |

| Mixture | Cement | Silica Sand | w/cm | HRWRA | Tire Rubber (%Vf) | Steel Wires (%Vf) |

|---|---|---|---|---|---|---|

| TSC0-0 | 1.00 | 1.00 | 0.45 | 0.0004 | 0.00 | 0.00 |

| TSC0-0.5 | 1.00 | 1.00 | 0.45 | 0.0004 | 0.00 | 0.50 |

| TSC0-1 | 1.00 | 1.00 | 0.45 | 0.0004 | 0.00 | 1.00 |

| TSC0-1.5 | 1.00 | 1.00 | 0.45 | 0.0004 | 0.00 | 1.50 |

| TSC10-0 | 1.00 | 1.00 | 0.45 | 0.0004 | 10.00 | 0.00 |

| TSC15-0 | 1.00 | 1.00 | 0.45 | 0.0004 | 15.00 | 0.00 |

| TSC20-0 | 1.00 | 1.00 | 0.45 | 0.0004 | 20.00 | 0.00 |

| TSC10-0.5 | 1.00 | 1.00 | 0.45 | 0.0004 | 10.00 | 0.50 |

| TSC15-0.5 | 1.00 | 1.00 | 0.45 | 0.0004 | 15.00 | 0.50 |

| TSC20-0.5 | 1.00 | 1.00 | 0.45 | 0.0004 | 20.00 | 0.50 |

| TSC10-1 | 1.00 | 1.00 | 0.45 | 0.0004 | 10.00 | 1.00 |

| TSC15-1 | 1.00 | 1.00 | 0.45 | 0.0004 | 15.00 | 1.00 |

| TSC20-1 | 1.00 | 1.00 | 0.45 | 0.0004 | 20.00 | 1.00 |

| TSC10-1.5 | 1.00 | 1.00 | 0.45 | 0.0004 | 10.00 | 1.50 |

| TSC15-1.5 | 1.00 | 1.00 | 0.45 | 0.0004 | 15.00 | 1.50 |

| TSC20-1.5 | 1.00 | 1.00 | 0.45 | 0.0004 | 20.00 | 1.50 |

| Specimen ID | α | u | R2 |

|---|---|---|---|

| TSC0-0.5 | 16.632 | –102.06 | 0.8179 |

| TSC0-1 | 24.071 | –150.2 | 0.9949 |

| TSC0-1.5 | 17.447 | –117.1 | 0.8801 |

| TSC10-0.5 | 6.7033 | –33.594 | 0.9983 |

| TSC15-0.5 | 6.7033 | –33.594 | 0.9983 |

| TSC20-0.5 | 5.731 | –27.89 | 0.9988 |

| TSC10-1 | 10.575 | –57.553 | 0.9968 |

| TSC15-1 | 7.6731 | –39.425 | 0.9978 |

| TSC20-1 | 7.6731 | –39.425 | 0.9978 |

| TSC10-1.5 | 7.1142 | –39.266 | 0.9809 |

| TSC15-1.5 | 9.6084 | –51.415 | 0.9971 |

| TSC20-1.5 | 4.6243 | –22.566 | 0.9997 |

| Reliability Level | TSC0-0.5 | TSC0-1 | TSC0-1.5 |

|---|---|---|---|

| 0.99 | 350.647 | 424.295 | 630.411 |

| 0.90 | 403.857 | 467.803 | 721.298 |

| 0.80 | 422.496 | 482.616 | 753.000 |

| 0.70 | 434.579 | 492.112 | 773.516 |

| 0.60 | 444.067 | 499.511 | 789.607 |

| 0.50 | 452.292 | 505.885 | 803.542 |

| 0.40 | 459.945 | 511.784 | 816.499 |

| 0.30 | 467.558 | 517.623 | 829.378 |

| 0.20 | 475.790 | 523.902 | 843.291 |

| 0.10 | 486.146 | 531.756 | 860.781 |

| 0.01 | 506.835 | 547.291 | 895.667 |

| Reliability Level | TSC0-0.5 | TSC10-0.5 | TSC20-0.5 | TSC0-0.5 | TSC10-0.5 | TSC20-0.5 | TSC0-0.5 | TSC10-0.5 | TSC20-0.5 |

|---|---|---|---|---|---|---|---|---|---|

| 0.99 | 75.5889 | 75.5889 | 58.1972 | 149.5097 | 93.5563 | 93.5563 | 130.682 | 130.619 | 48.6716 |

| 0.90 | 107.324 | 107.324 | 87.6937 | 186.7112 | 127.078 | 127.078 | 181.828 | 166.807 | 80.9016 |

| 0.80 | 120.037 | 120.037 | 99.9621 | 200.4421 | 140.134 | 140.134 | 202.056 | 180.357 | 95.1556 |

| 0.70 | 128.736 | 128.736 | 108.487 | 209.5320 | 148.967 | 148.967 | 215.826 | 189.379 | 105.313 |

| 0.60 | 135.823 | 135.823 | 115.504 | 216.7714 | 156.106 | 156.106 | 227.003 | 196.593 | 113.819 |

| 0.50 | 142.15 | 142.15 | 121.822 | 223.1190 | 162.441 | 162.441 | 236.954 | 202.938 | 121.585 |

| 0.40 | 148.194 | 148.194 | 127.902 | 229.0859 | 168.458 | 168.458 | 246.434 | 208.919 | 129.149 |

| 0.30 | 154.355 | 154.355 | 134.143 | 235.0780 | 174.561 | 174.561 | 256.076 | 214.942 | 137.005 |

| 0.20 | 161.185 | 161.185 | 141.112 | 241.6197 | 181.29 | 181.29 | 266.74 | 221.534 | 145.88 |

| 0.10 | 170.031 | 170.031 | 150.212 | 249.9428 | 189.953 | 189.953 | 280.513 | 229.947 | 157.627 |

| 0.01 | 188.554 | 188.554 | 169.524 | 266.8744 | 207.911 | 207.911 | 309.219 | 247.148 | 183.117 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alfayez, S.; Ali, M.A.E.M.; Nehdi, M.L. Eco-Efficient Fiber-Reinforced Preplaced Recycled Aggregate Concrete under Impact Loading. Infrastructures 2019, 4, 37. https://doi.org/10.3390/infrastructures4020037

Alfayez S, Ali MAEM, Nehdi ML. Eco-Efficient Fiber-Reinforced Preplaced Recycled Aggregate Concrete under Impact Loading. Infrastructures. 2019; 4(2):37. https://doi.org/10.3390/infrastructures4020037

Chicago/Turabian StyleAlfayez, Saud, Mohamed A. E. M. Ali, and Moncef L. Nehdi. 2019. "Eco-Efficient Fiber-Reinforced Preplaced Recycled Aggregate Concrete under Impact Loading" Infrastructures 4, no. 2: 37. https://doi.org/10.3390/infrastructures4020037