Inexpensive Piezoelectric Elements for Nozzle Contact Detection and Build Platform Leveling in FFF 3D Printers

Abstract

:1. Introduction

- The UP! Plus 2 3D Printer [11] uses two switches to set the level and the nozzle height. To establish the errors of tilt and flatness, a microswitch mounted to a carrier is connected to the nozzle and moved to contact with the build platform at a number of positions. As the microswitch actuator is directly below the nozzle this does not introduce any significant error in X or Y positions. To set the offset in the Z direction the microswitch carrier is removed and a second switch at the back and level with the surface of the build platform is contacted by the nozzle.

- The Lulzbot Mini [12] and the Lulzbot TAZ 6 use an electrical contact method where four electrically conductive contacts at the corners of the build platform are probed by the conductive nozzle. The nozzle and contacts must be free of any insulating material such as plastic residue for this to work and in addition this method cannot find any errors in flatness of the surface.

- The Prusa i3 [13] uses an inductive probe which the manufacturer refers to as a PINDA probe to find errors in tilt and flatness of the build surface and, by probing targets in the build platform, is also able to determine errors in XY orthogonality. Some manual setting is required after determining the errors as there is no absolute detection of the nozzle height.

- The Ultimaker 3 printer [14] uses a capacitive detection method in which the electrical capacitance between the nozzle itself and the build platform is measured. The capacitance will increase as the nozzle approached the platform until the nozzle contacts the build platform at which point the measured capacitance will stop rising [15]. This method combines nozzle contact methods and proximity sensor methods and has no X, Y or Z offsets.

- The Rostock Max V3 [16] uses an accelerometer [17] to detect the deceleration which occurs when the nozzle comes into contact with the build platform. There is no X or Y offset but the necessary contact speed is higher than other nozzle contact methods and a somewhat larger Z offset is to be expected.

- The Fusion3 F400 printer [18] uses and infra red proximity sensor [19] to detect errors of tilt and flatness. As the sensor is mounted alongside the nozzle there will be offsets in X, Y and Z which will need to be compensated for in the printer software. Too much or too little reflectivity along with multiple reflections from the top and bottom surfaces of a transparent build platform can cause problems.

- Early microswitch probes were often deployed by small servos designed for use in radio controlled models. These probes had disadvantages such as poor repeatability and high mass although the method of moving a switch actuator to a point beyond the nozzle is used in several products intended for the DIY 3D printer builder. The BLTouch [20] is an example of a deployable switch sensor which uses a solenoid to extend the switch actuator.

- An example of a nozzle contact sensor using the strain gauge principle is the Delta Smart Effector [25] in which the elements constituting the strain gauge are etched into the copper clad laminate of a printed circuit board.

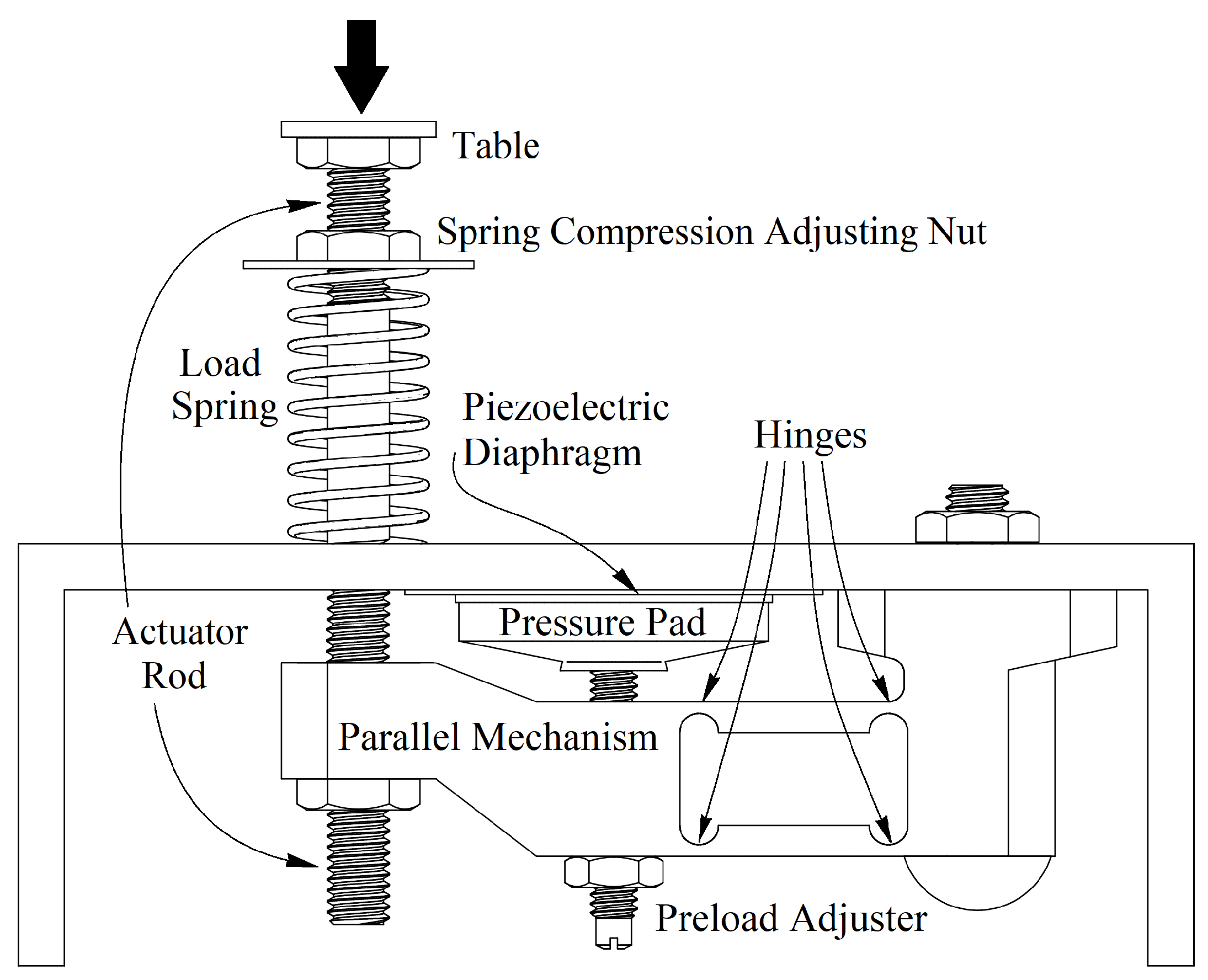

2. Materials and Methods

3. Results

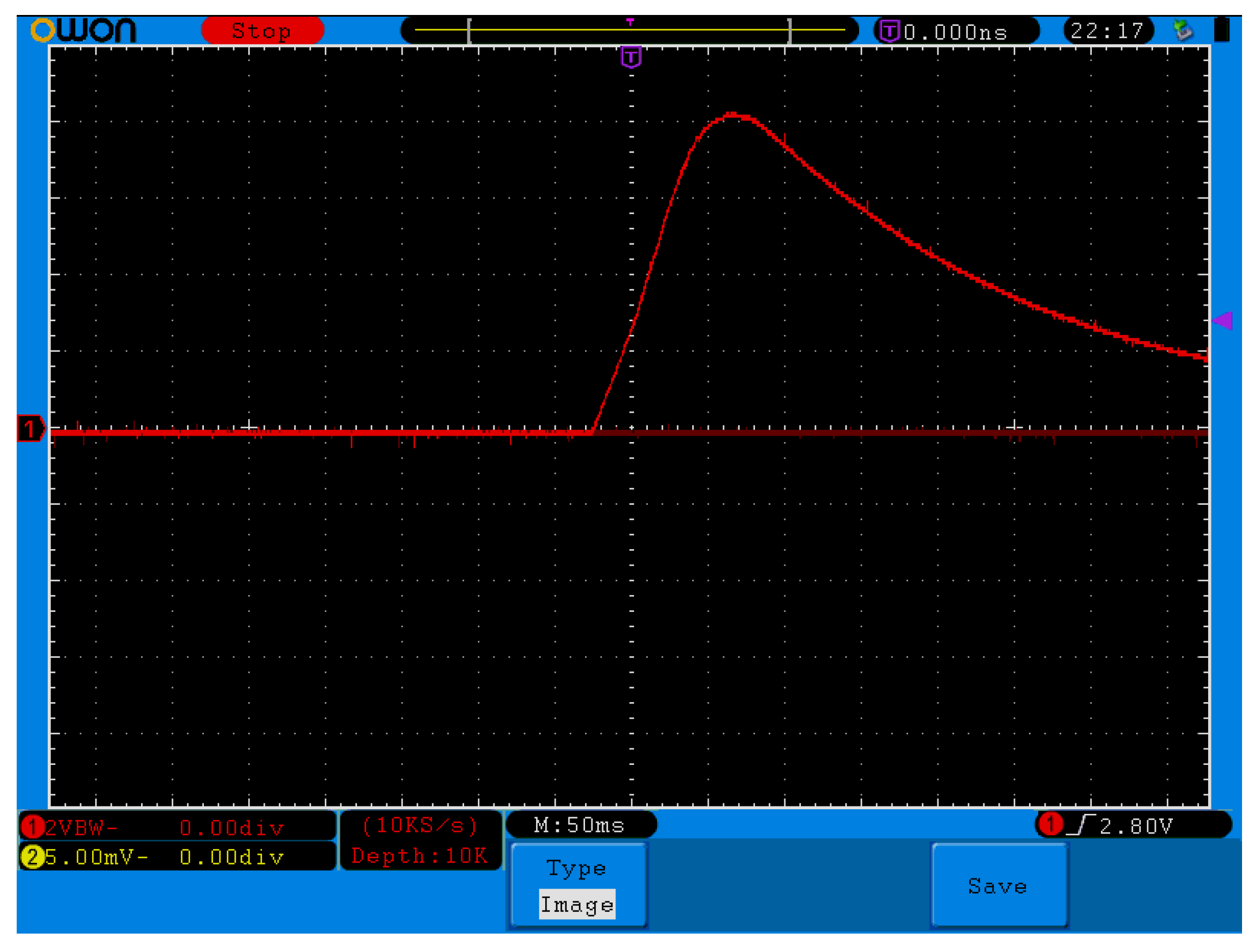

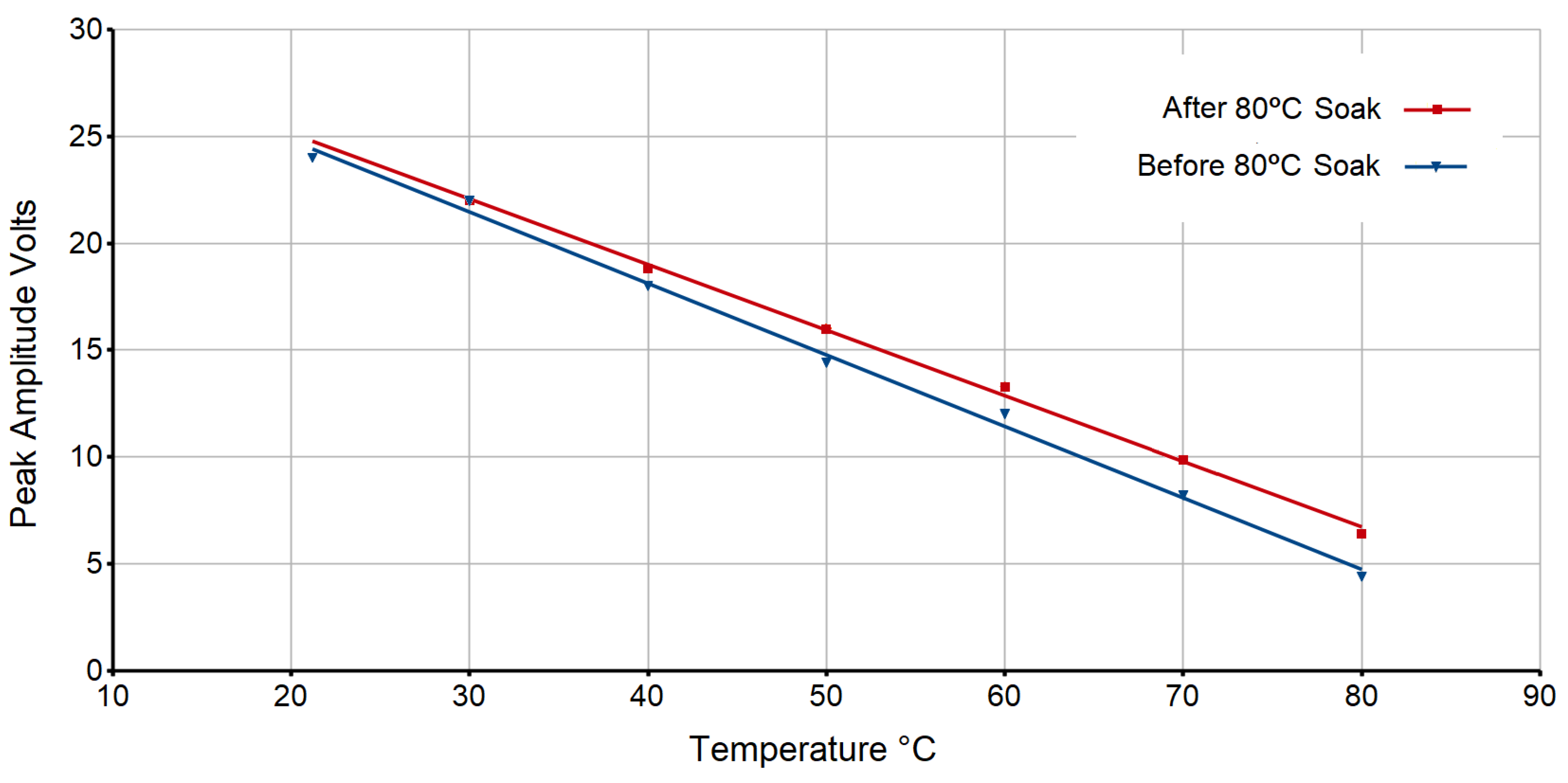

3.1. Electrical Response of Piezoelectric Diaphragms

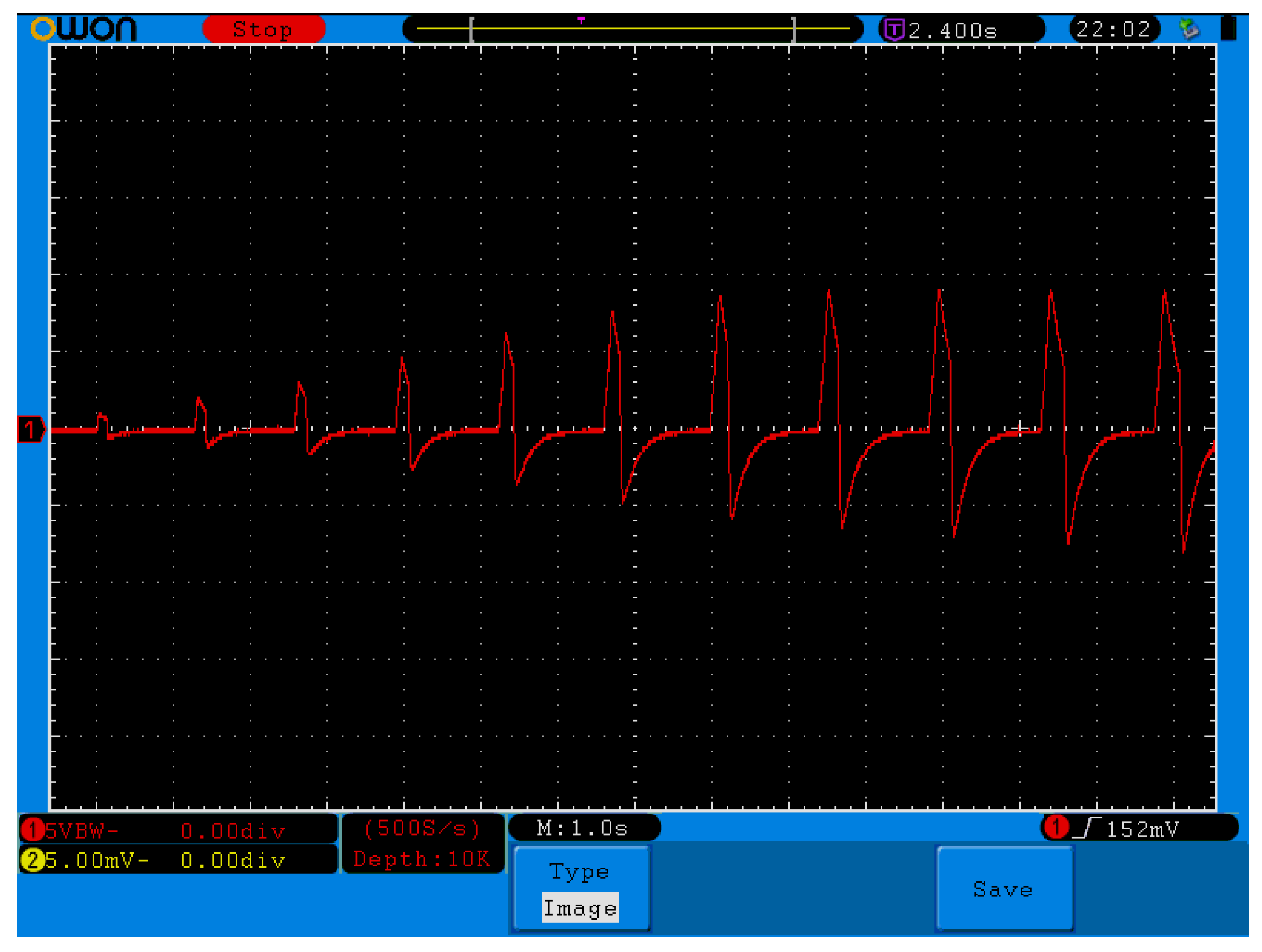

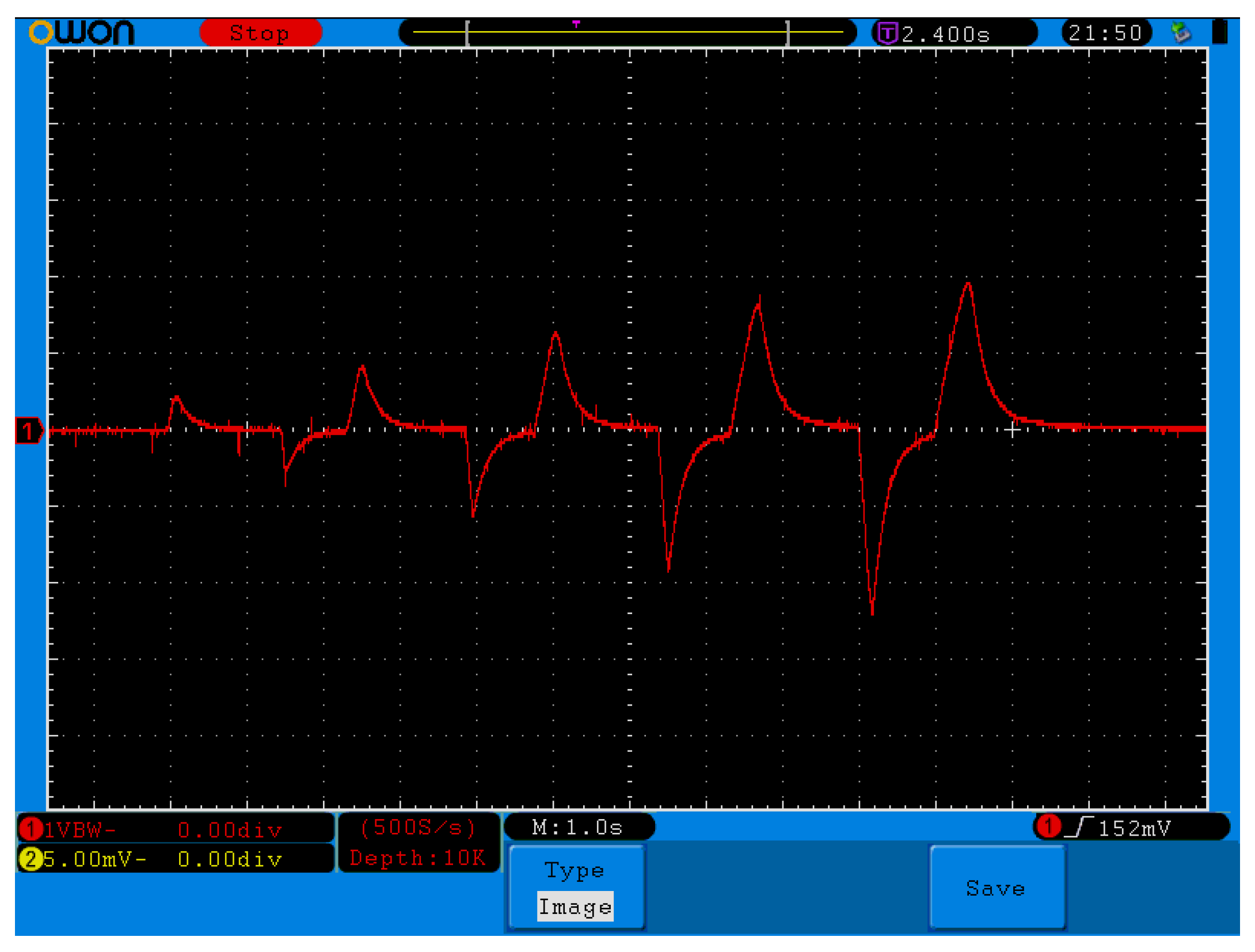

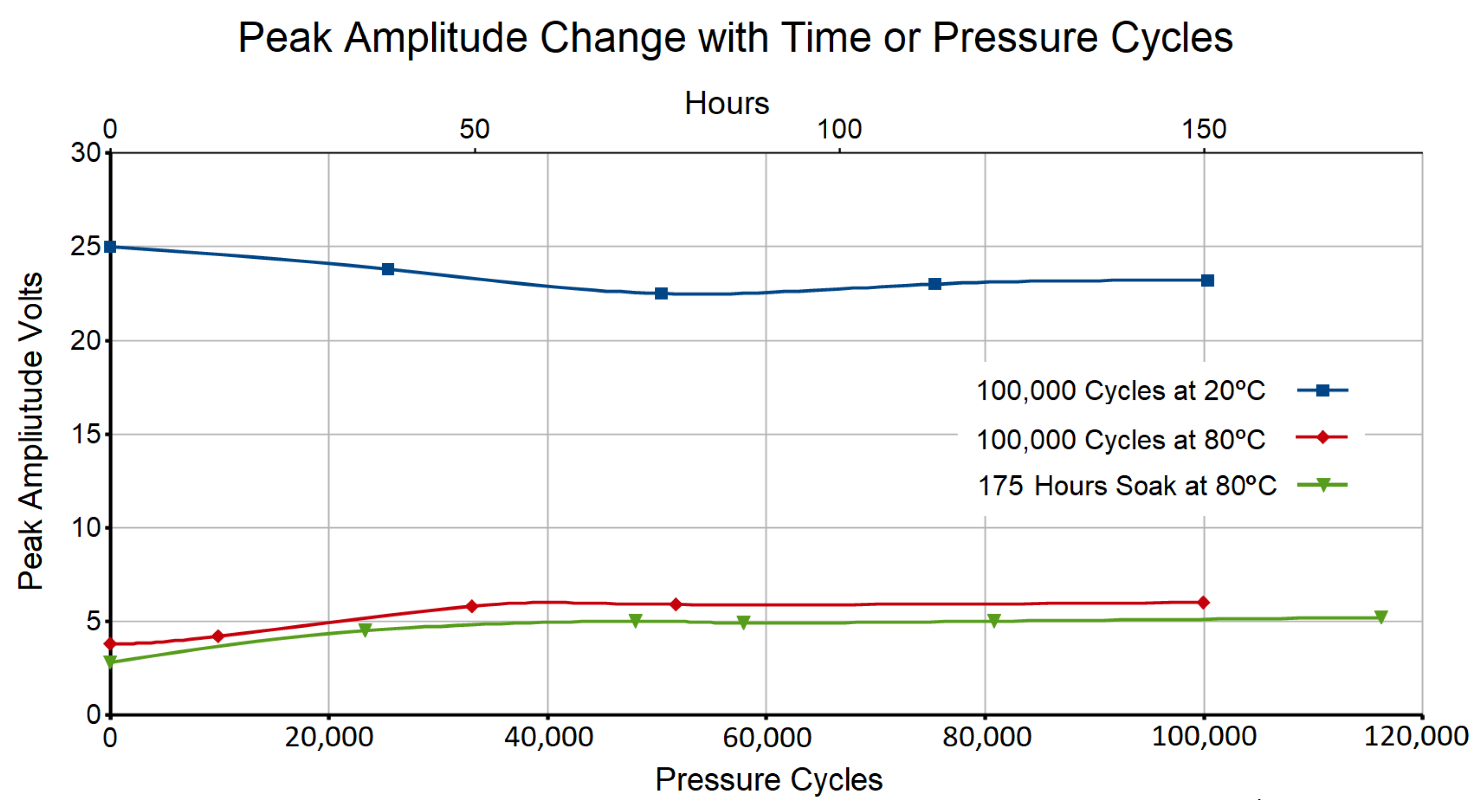

3.2. Cycling Tests to Determine Service Life

4. Discussion

4.1. Piezoelectric Sensors in RepRap Printers

4.2. Piezo Electric Nozzle Contact Sensing by Use of Drilled Piezo Ceramic Discs

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| FFF | Fused Filament Fabrication (equivalent to FDM) |

| FDM | Fused Deposition Modelling (term is protected by Stratasys Inc.) |

| ABS | Acrylonitrile Butadiene Styrene |

References

- All3DP. The Official History of the RepRap Project. 2016. Available online: https://all3dp.com/history-of-the-reprap-project/ (accessed on 17 December 2017).

- Jones, R.; Haufe, P.; Sells, E.; Iravani, P.; Olliver, V.; Palmer, C.; Bowyer, A. Reprap—The replicating rapid prototype. Robotica 2011, 29, 177–191. [Google Scholar] [CrossRef]

- RS Online Catalogue. Available online: https://uk.rs-online.com/web/p/piezo-buzzer-components/8712001/ (accessed on 10 December 2017).

- Rapidonline Catalogue. Available online: https://www.rapidonline.com/rvfm-ft-20t-6a1-uncased-piezo-transducer-35-0200 (accessed on 10 December 2017).

- Matt Freund. Cheap-Diy-Microscope-Sees-Individual-Atoms, Hackaday. Available online: https://hackaday.com/2015/01/13/cheap-diy-microscope-sees-individual-atoms/ (accessed on 10 December 2017).

- Griffey, J. The Types of 3-D Printing, Library Technology Reports. 2014. Available online: https://journals.ala.org/index.php/ltr/article/view/4796/5747 (accessed on 17 December 2017).

- Volpato, N.; Aguiomar Foggiatto, J.; Coradini Schwarz, D. The influence of support base on FDM accuracy in Z. Rapid Prototyp. J. 2014, 20, 182–191. [Google Scholar] [CrossRef]

- Steuben, J.; Van Bossuyt, D.; Turner, C. Design for fused filament fabrication additive manufacturing. In Proceedings of the ASME 2015 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, American Society of Mechanical Engineers, Boston, MA, USA, 2–5 August 2015. [Google Scholar]

- RepRapWiki Contributors. Available online: http://reprap.org/wiki/Z_probe (accessed on 17 December 2017).

- Duet3D Forum Page. Available online: https://www.duet3d.com/forum/thread.php?id=1330 (accessed on 10 December 2017).

- 3D Printing Systems. UP PLUS 2 Users Manual 2013. Available online: http://3dprintingsystems.com/UP%20Plus%202%203D%20Printer%20Manual.pdf (accessed on 8 January 2018).

- Aleph Objects Inc. Lulzbot Mini Users Manual. 2015. Available online: https://download.lulzbot.com/Mini/1.0/documentation/manual/LulzBot_Mini_manual.pdf (accessed on 9 January 2018).

- Prusa Research. 3D Printing Handbook. 2017. Available online: https://www.prusa3d.com/downloads/manual/prusa3d_manual_mk3_en.pdf?4 (accessed on 9 January 2018).

- Ultimaker. Ultimaker 3 Installation and User Manual. 2016. Available online: https://ultimaker.com/download/61355/Ultimaker (accessed on 9 January 2018).

- Inside the Ultimaker 3—Day 6—Active leveling. Available online: https://community.ultimaker.com/topic/15687-inside-the-ultimaker-3-day-6-active-leveling/ (accessed on 8 January 2018).

- Rostock Max. Available online: https://www.seemecnc.com/collections/3d-printers/products/rostock-max-v3-desktop-3d-printer-diy-kit (accessed on 9 January 2018).

- Accelerometer Sensor. Available online: https://www.seemecnc.com/products/hotend-accelerometer-probe-pcb-board-rev-5c (accessed on 9 January 2018).

- Fusion3. Fusion 3 F400 Users Manual. Available online: https://www.fusion3design.com/wp-content/uploads/2017/11/F400-User-Manual-Rev-16-11-9-17.pdf (accessed on 8 January 2018).

- F400 (Bed Leveling) Z Probe. Available online: https://store.fusion3design.com/collections/f400-s-replacement-parts/products/f400-bed-leveling-z-probe (accessed on 8 January 2018).

- BLTouch. Available online: https://www.antclabs.com/bltouch (accessed on 10 January 2018).

- Capacitive Sensor. Baomain LJC18A3-H-Z/BX. Available online: https://www.amazon.co.uk/Baomain-LJC18A3-H-Z-1-10mm-Capacitance-Proximity/dp/B015PCW2R6 (accessed on 9 January 2018).

- Hictop Inductive Sensor. Available online: https://www.hic3dprinter.com/products/hictop-3d-printer-self-leveling-upgrade-auto-leveling-sensor-bed-self-adjustment-inductive-proximity-sensor (accessed on 9 January 2018).

- Force Sensing Resistors Make for Auto Bed Levelling for 3D Printers, 3D Printing Industry. 2014. Available online: https://3dprintingindustry.com/news/force-sensing-resistors-make-auto-bed-levelling-3d-printers-24533/ (accessed on 18 December 2017).

- FSR Kit. Available online: https://www.ultibots.com/fsr-kit/ (accessed on 18 December 2017).

- Delta Smart Effector. Available online: https://www.duet3d.com/DeltaSmartEffector (accessed on 10 January 2018).

- Leggett, C. Norwegian Physicist Uses Piezo Discs to Add Auto Bed Leveling to His 3D Printer. Available online: https://3dprint.com/84479/piezo-3d-print-leveling/ (accessed on 29 July 2017).

- Piezoelectric Sound Components P37E.pdf. 2017. Available online: http://www.murata.com/~/media/webrenewal/support/library/catalog/products/sound/p37e.ashx (accessed on 2 October 2017).

- Entry in RepRap Forum Discussion. Available online: http://forums.reprap.org/read.php?1,635075,655510#msg-655510 (accessed on 2 October 2017).

- Proxxon MF70 Light Milling Machine Users Manual. Available online: http://pdf.lowes.com/operatingguides/4645489_oper.pdf (accessed on 1 October 2017).

- Mach3 Software Version R3.043.066. Available online: http://www.machsupport.com/software/mach3/ (accessed on 1 October 2017).

- Operating Manual CAL3300. 1997. Available online: http://www.advindsys.com/Manuals/CALManuals/Cal3300.pdf (accessed on 1 October 2017).

- User Manual Portable LCD Digital Storage Oscilloscope. Available online: http://owon.co.uk/wsb4318264101/down/PDS%20Series%20USER_MANUAL%20for%20UK%$20users.pdf (accessed on 2 October 2017).

- Precision Piezo Website. Available online: https://www.precisionpiezo.co.uk/shop (accessed on 18 December 2017).

- RepRap General Forum Piezoelectric Disks for Z Contact Detect and Bed Levelling. Available online: http://forums.reprap.org/read.php?1,635075 (accessed on 18 December 2017).

- RepRap General Forum Precision Piezo Z-probe Now available. Available online: http://forums.reprap.org/read.php?1,767998 (accessed on 18 December 2017).

- RepRap General Forum “Precision Piezo Bounty”. Available online: http://forums.reprap.org/read.php?1,787755 (accessed on 18 December 2017).

- Z-Probe Sensor Auto Nivelamento Impressora 3D Hotend E3d V6. Available online: https://produto.mercadolivre.com.br/MLB-857051279-z-probe-sensor-auto-nivelamento-impressora-3d-hotend-e3d-v6-_JM (accessed on 18 December 2017).

- Trianglelab Precision Piezo Z-Probe Universal Kit. Available online: https://www.aliexpress.com/store/product/trianglelab-Precision-Piezo-Z-probe-Universal-Kit-Z-probe-for-3D-printers-revolutionary-auto-bed-leveling/1654223_32832426899.html?spm=2114.12010615.0.0.48d9e4c57rbLvu (accessed on 18 December 2017).

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Simpson, M.; Khoury, S. Inexpensive Piezoelectric Elements for Nozzle Contact Detection and Build Platform Leveling in FFF 3D Printers. Inventions 2018, 3, 8. https://doi.org/10.3390/inventions3010008

Simpson M, Khoury S. Inexpensive Piezoelectric Elements for Nozzle Contact Detection and Build Platform Leveling in FFF 3D Printers. Inventions. 2018; 3(1):8. https://doi.org/10.3390/inventions3010008

Chicago/Turabian StyleSimpson, Michael, and Simon Khoury. 2018. "Inexpensive Piezoelectric Elements for Nozzle Contact Detection and Build Platform Leveling in FFF 3D Printers" Inventions 3, no. 1: 8. https://doi.org/10.3390/inventions3010008

APA StyleSimpson, M., & Khoury, S. (2018). Inexpensive Piezoelectric Elements for Nozzle Contact Detection and Build Platform Leveling in FFF 3D Printers. Inventions, 3(1), 8. https://doi.org/10.3390/inventions3010008