Strength Development and Durability of Concrete Containing Recycled Roof Tile Aggregate

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials Used

2.2. Mix Proportion of Concrete

2.3. Test Methods

3. Results

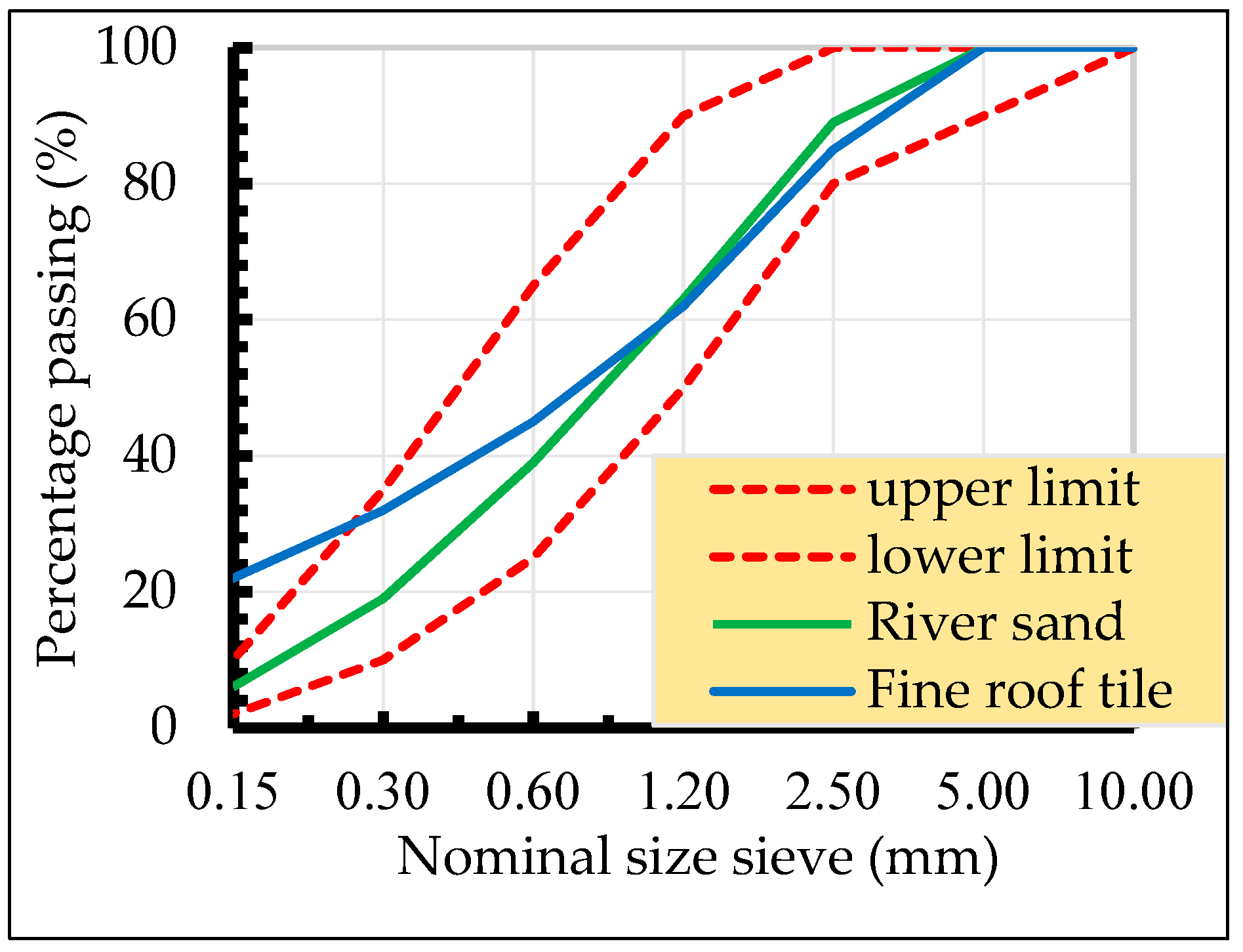

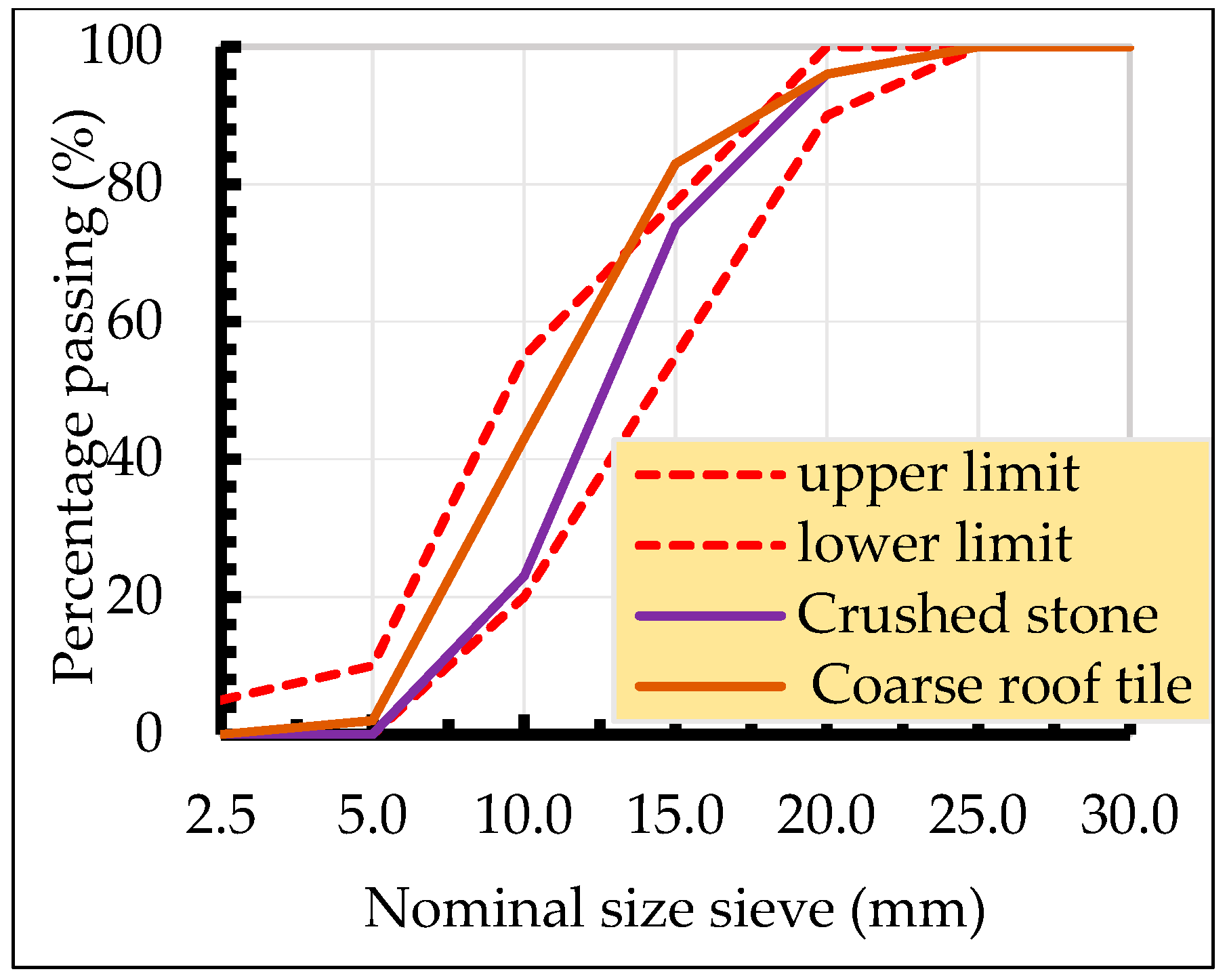

3.1. Properties of Aggregate

3.2. Fresh Properties

3.3. Hardened Properties of Concrete

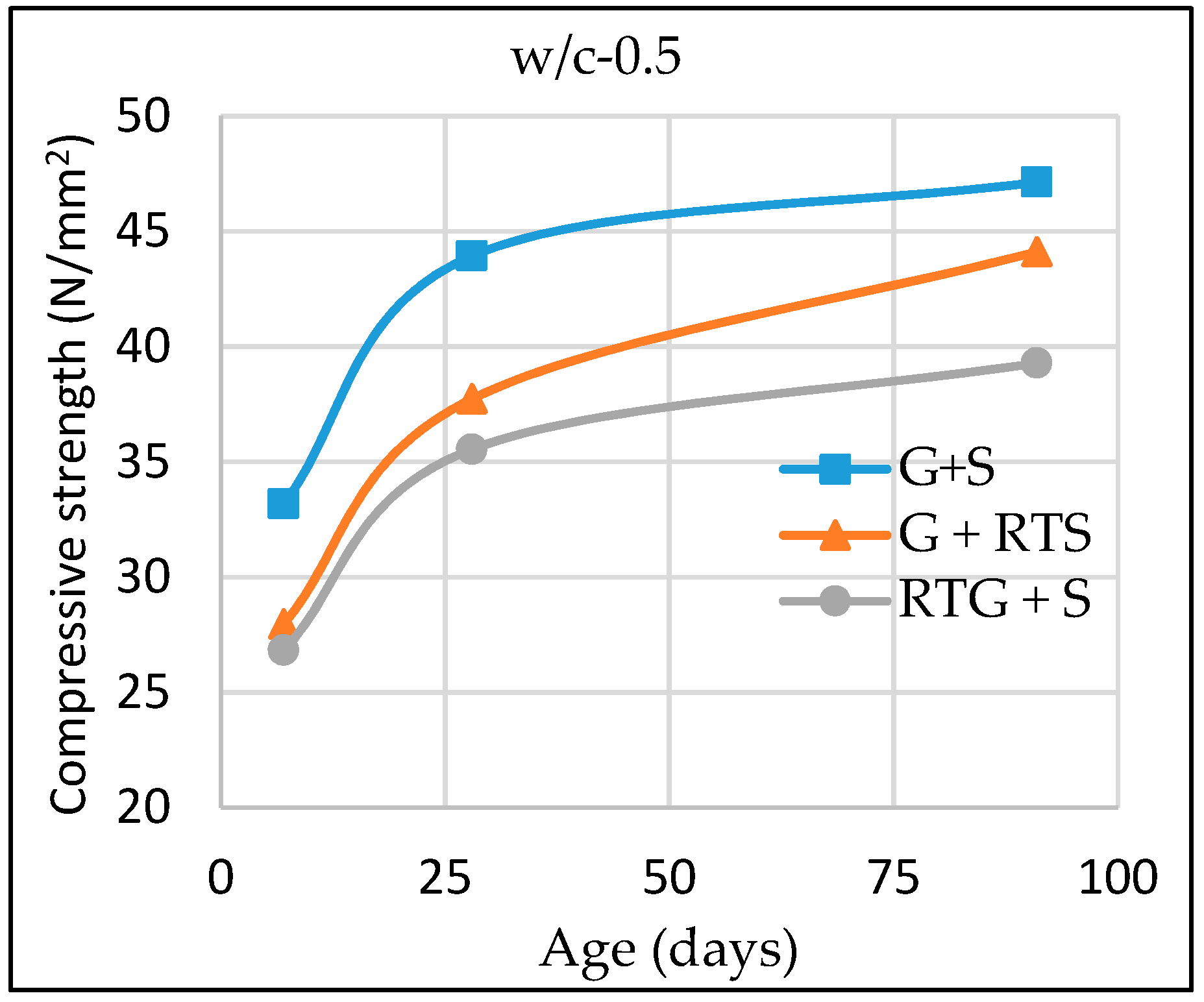

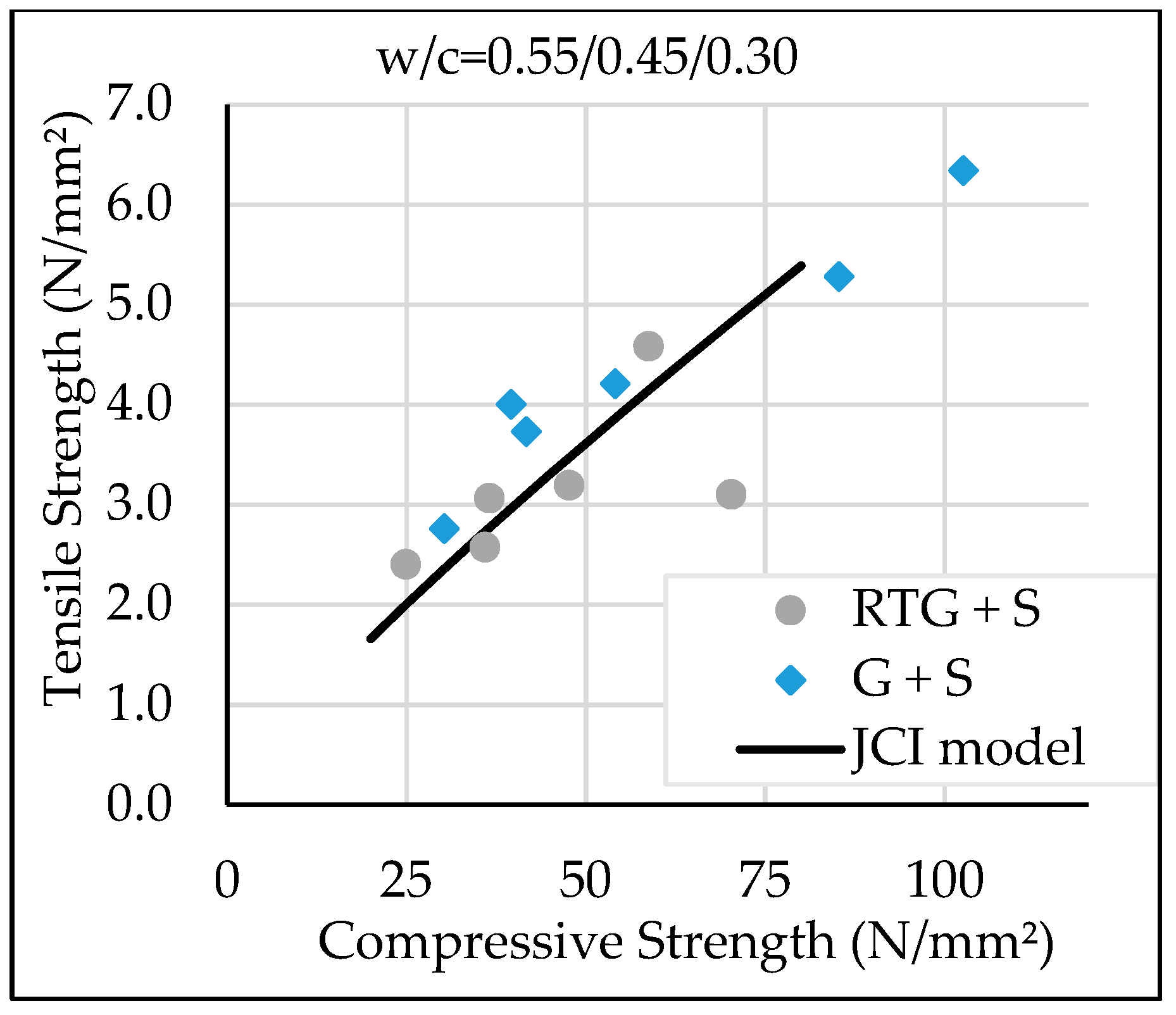

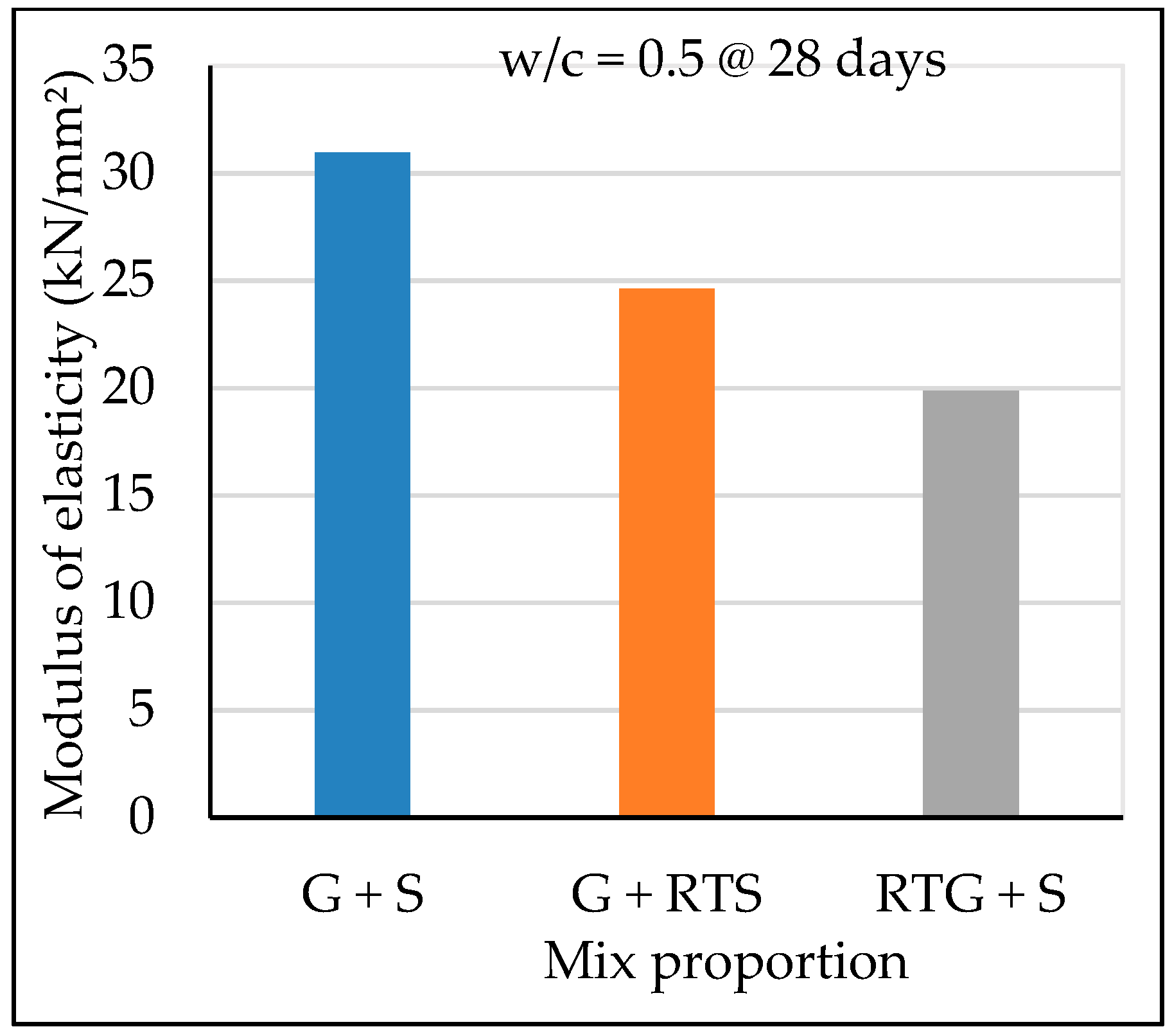

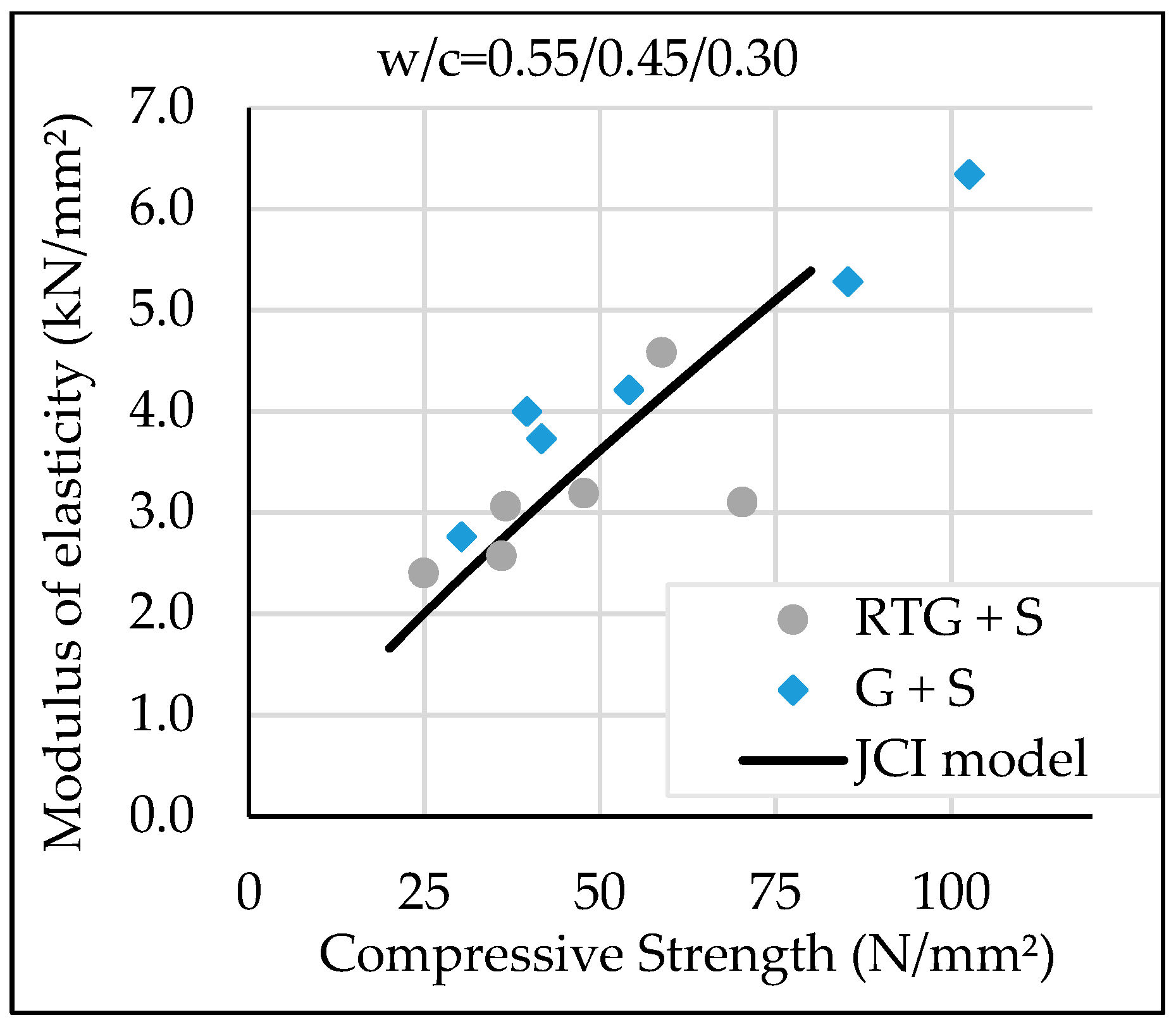

3.3.1. Mechanical Properties

- Ec (t): Modulus of elasticity of concrete at age t (N/mm2);

- ft (t): Splitting tensile strength of concrete at age t (N/mm2);

- fc’(t): Compressive strength of concrete at age t (N/mm2);

- t: age of concrete (days).

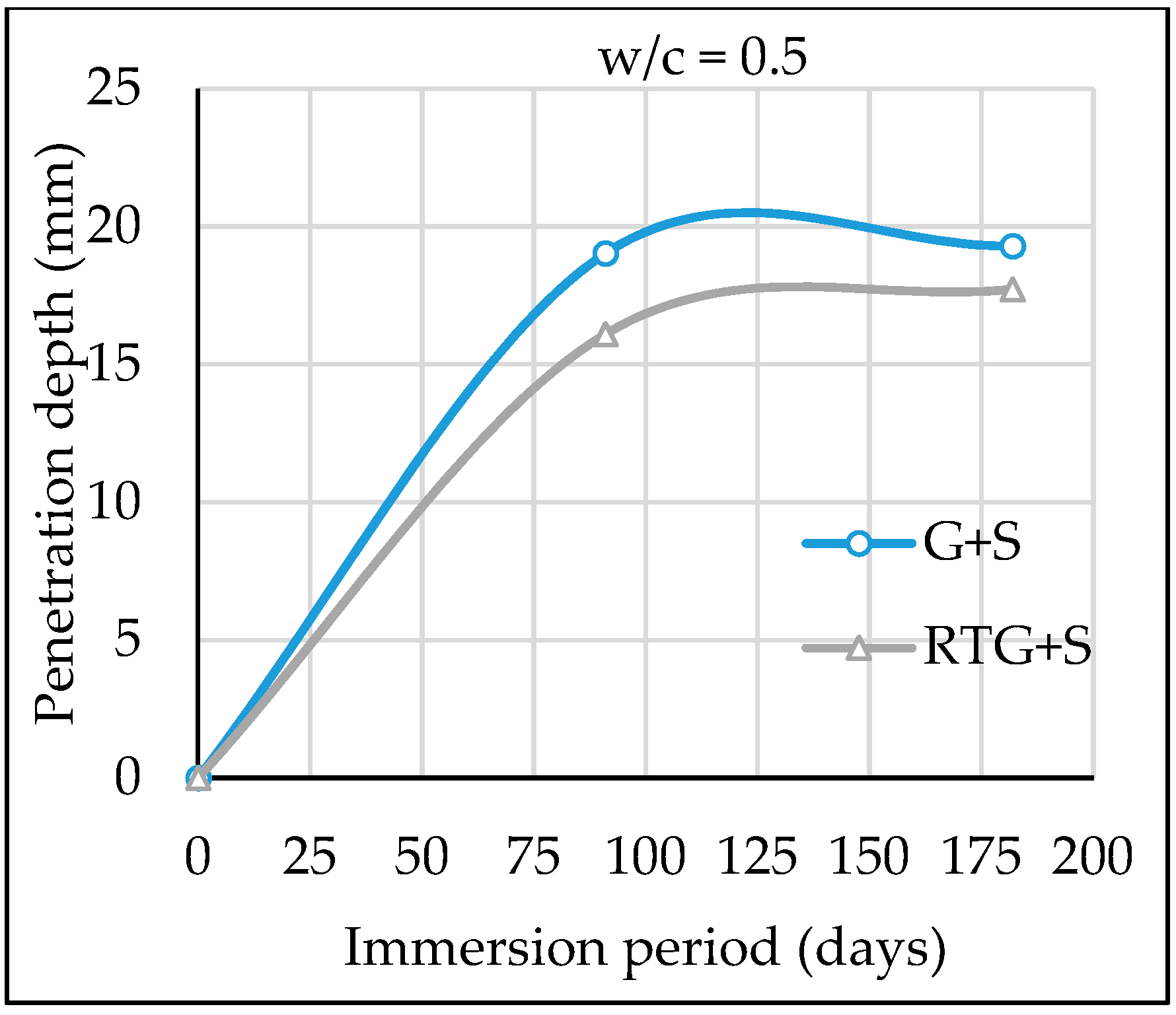

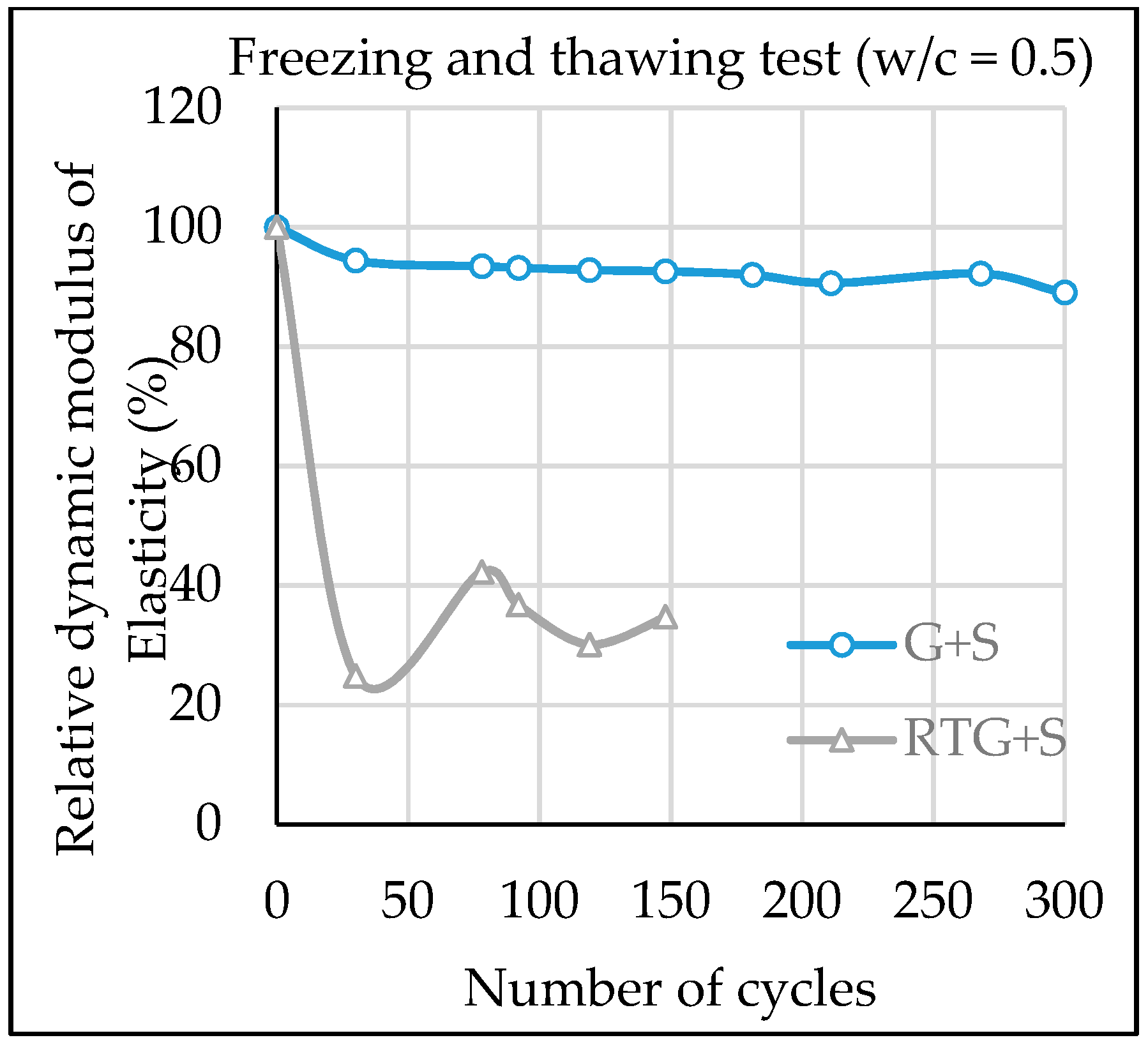

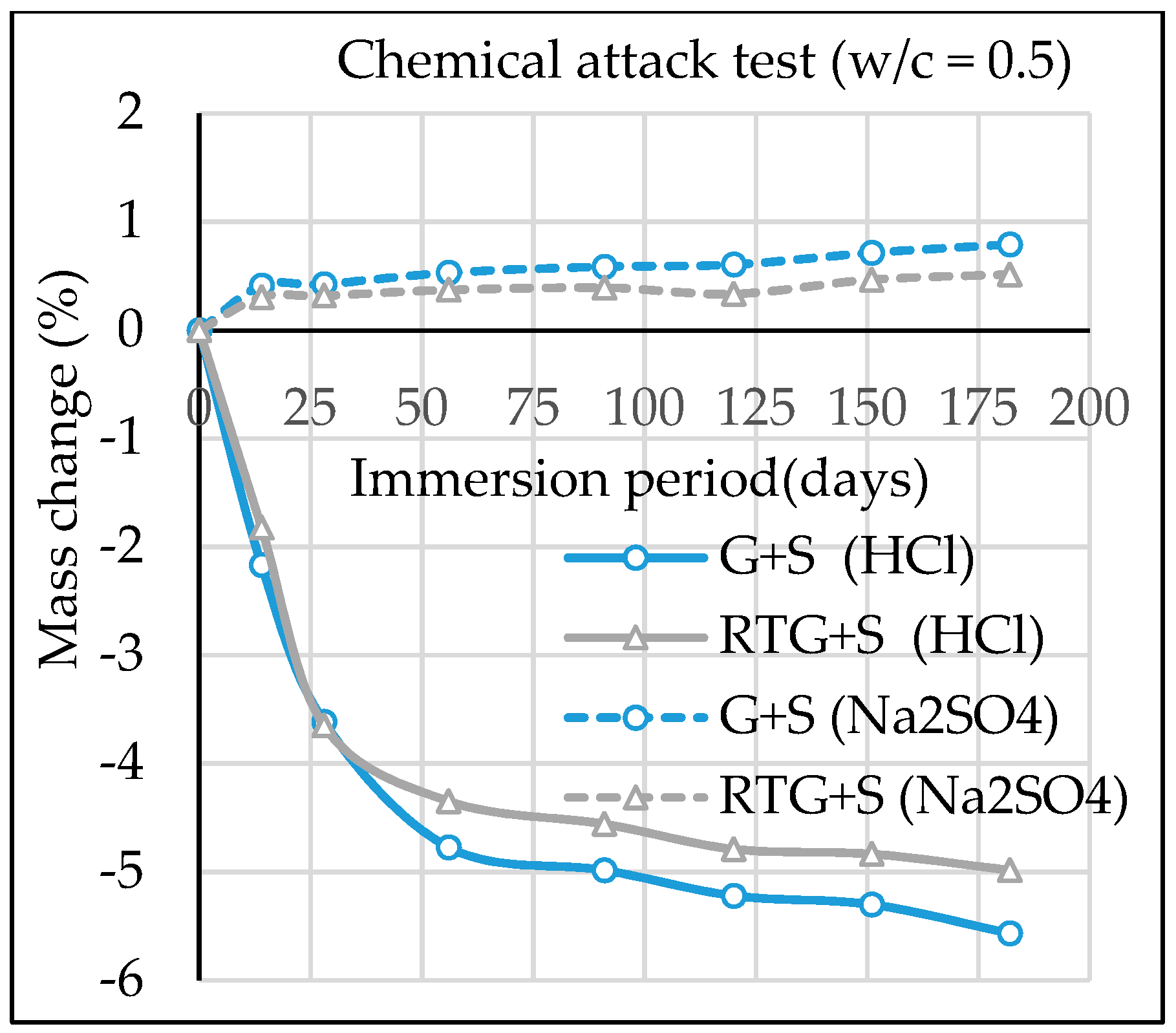

3.3.2. Durability

4. Discussions

5. Conclusions

- ♦

- Results of water absorption, specific gravity, crushing value and abrasion value show that recycled roof tile has inferior physical properties than normal crushed stone aggregate.

- ♦

- The compressive strength, splitting tensile strength, drying shrinkage and modulus of elasticity of concrete containing recycled roof tile aggregate becomes a concern when it is used for high strength.

- ♦

- The JCI model equation is not recommended for prediction of modulus of elasticity for concrete containing recycled roof tile aggregate. A modified equation of the JCI can be used to predict modulus of elasticity for concrete containing recycled roof tile and this equation was used in this study.

- ♦

- Test data shows poor performance of concrete containing recycled roof tile against freezing and thawing as compared to normal aggregate concrete. No adverse effect of recycled roof tile aggregate against carbonation, acid attack, and chloride penetration.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Etxeberria, M.; Vegas, I. Effect of Fine Ceramic recycled aggregate (RA) and mixed fine RA on hardened properties of concrete. Mag. Concr. Res. 2014, 67, 645–655. [Google Scholar] [CrossRef]

- Shafii, F. Achieving Sustainable Construction. In Proceedings of the 6th Asia-Pacific Structural Engineering and Construction Conference (APSEC 2006), Kuala Lumpur, Malaysia, 5–6 September 2006. [Google Scholar]

- Andrés, J.; César, M.; Guerra, M.I.; Julia, M.M.; Aguado, P.J.; Sánchez de Rojas, M.I.; Frías, M.; Rodríguez, O. Re-use of ceramic wastes in construction. Cera. Mater. 2010, 10, 197–214. [Google Scholar]

- Giridhar, V.; Rao, H.S.; Kumar, P.S.P. Influence of ceramic waste aggregate properties on strength of ceramic waste aggregate concrete. IJRET 2015, 4, 15–24. [Google Scholar]

- Kumar, R. Influence of recycled coarse aggregate derived from construction and demolition waste (CDW) on abrasion resistance of pavement concrete. Constr. Build. Mater. 2017, 142, 248–255. [Google Scholar] [CrossRef]

- Bui, P.T.; Ogawa, Y.; Nakarai, K.; Sato, R. Internal curing of Class-F fly-ash concrete using high-volume roof-tile waste aggregate. Mater. Struc. 2017, 50, 4. [Google Scholar] [CrossRef]

- Tobita, H.; Uehara, T.; Umehara, H.; Yutake, H. Study on applicability of disposed roof tile as aggregate for concrete. Proc. Jpn. Concr. Inst. 2006, 28, 1577–1582. (In Japanese) [Google Scholar]

- Sugiyama, M. The Compressive Strength of Concrete Containing Tile Chips, Crushed Scallop Shells, or Crushed Roofing Tiles. In Proceedings of the International RILEM Conference on the Use of Recycled Materials in Buildings and Structures, Barcelona, Spain, 8 November 2004; pp. 658–664. [Google Scholar]

- Japanese Standards Association. JIS R 5210: Portland Cement; Japanese Standards Association: Tokyo, Japan, 2009. [Google Scholar]

- Japanese Standards Association. JIS A 6204: Chemical Admixtures for Concrete; Japanese Standards Association: Tokyo, Japan, 2011. [Google Scholar]

- Japanese Standards Association. JIS A 1102: Method of Test for Sieve Analysis of Aggregates; Japanese Standards Association: Tokyo, Japan, 2014. [Google Scholar]

- Japanese Society of Civil Engineers. JSCE G 572: Determination Method of Apparent Diffusion Coefficient of Chloride Ion in Concrete by Immersion; Japanese Society of Civil Engineers: Tokyo, Japan, 2003. [Google Scholar]

- Japan Testing Center for Construction Materials. JSTM C 7401: Method of Test for Chemical Resistance of Concrete in Aggressive Solution; Japan Testing Center for Construction Materials: Tokyo, Japan, 1999. [Google Scholar]

- Japanese Standards Association. JIS A 1148: Method of Test for Resistance of Concrete to Freezing and Thawing; Japanese Standards Association: Tokyo, Japan, 2010. [Google Scholar]

- Japanese Standards Association. JIS A 1110: Methods of Test for Density and Water Absorption of Coarse Aggregates; Japanese Standards Association: Tokyo, Japan, 2006. [Google Scholar]

- Japanese Standards Association. JIS A 1104: Methods of Test for Bulk Density of Aggregates and Solid Content in Aggregates; Japanese Standards Association: Tokyo, Japan, 2006. [Google Scholar]

- Japanese Industrial Standards Association. JIS A 1121: Test for Resistance to Abrasion of Coarse Aggregate by Use of the Los Angeles Machine; Japanese Industrial Standards Association: Tokyo, Japan, 2007. [Google Scholar]

- British Standards Institution. BS 812.110: Methods of determination of aggregate crushing value (ACV). 1990. Available online: http://saliergeotechnical.co.uk/British%20Standards%20NEW/BS%20EN%20812/BS%20812-110%201990.pdf (accessed on 29 June 1990).

- Japan Concrete Institute. Guidelines for Control of Cracking of Mass Concrete; Japan Concrete Institute: Tokyo, Japan, 2016. [Google Scholar]

- Neville, A.M. Properties of Concrete, 4th ed.; John Wiley & Sons, Inc.: New York, NY, USA, 1996. [Google Scholar]

- Midorikawa, T.; Nemoto, Y.; Ohno, H. Study on Utilization of Disposed Roof Tile as Material for Concrete. In Proceedings of the 64 the Annual Meeting of Japan Society of Civil Engineers, Fukuoka, Japan, 2 September 2009; pp. 717–718. (In Japanese). [Google Scholar]

- Japan Society of Civil Engineers. Standard Specification for Concrete Structures- Design. 2007. Available online: http://www.jsce.or.jp/committee/concrete/e/Standard_specification/JGC15_Design_1.0.pdf (accessed on December 2010).

- Muragishi, Y.; Ogawa, Y.; Kawai, K.; Sato, R. Effect of internal curing by disposed roof tile coarse aggregate in fly ash concrete subjected to steam curing. Proc. Jpn. Concr. Inst. 2014, 36, 670–675. [Google Scholar]

- Hill, J.; Byars, E.A.; Sharp, J.H.; Lynsdale, C.J.; Cripps, J.C.; Zhou, Q. An experimental study of combined acid and sulfate attack of concrete. Cem. Concr. Compos. 2003, 25, 997–1003. [Google Scholar] [CrossRef]

- Amano, Y.; Uehara, T.; Umehara, H.; Takenaga, Y. Utilization of Waste Sansyu Roof Tiles for Concrete. Concr. Resear. Tech. 2010, 2, 1–11. [Google Scholar]

| Mix | w/c (%) | s/a (%) | Air Content (%) | Slump (Slump Flow) (cm) | Unit Content (kg/m³) | Unit Content (mL/m3) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| W | C | S | G | SP | AEWR | AE | |||||

| G+S | 50 | 47 | 5.7 | 16.0 | 175 | 350 | 815 | 936 | - | 3500 | 3.5 |

| G+RTS | 36 | 5.5 | 12.0 | 190 | 380 | 522 | 1086 | - | 3800 | 38.0 | |

| RTG+S | 47 | 6.5 | 20.0 | 180 | 360 | 805 | 795 | - | 3600 | 3.6 | |

| RTG+S | 30 | 43 | 1.1 | (71.0 × 68.0) | 170 | 567 | 675 | 784 | 8400 | - | 3.8 |

| 45 | 46 | 5.4 | 21.0 | 180 | 400 | 773 | 794 | - | 4000 | 1.6 | |

| 55 | 48 | 5.4 | 20.0 | 180 | 327 | 835 | 793 | - | 3600 | 3.6 | |

| Aggregate Type | Sample | Specific Gravity (g/cm3) | Water Absorption (%) | Bulk Density (kg/m3) | Fineness Modulus | Abrasion Value (%) | Crushing Value (%) |

|---|---|---|---|---|---|---|---|

| Fine aggregate | River sand (S) | 2.59 | 2.55 | 1735 | 2.82 | N/A | N/A |

| Roof tile (RTS) | 2.29 | 9.85 | 1340 | 2.55 | N/A | N/A | |

| Coarse aggregate | Crushed stone (G) | 2.64 | 0.76 | 1615 | - | 11.1 | 9.7 |

| Roof tile (RTG) | 2.25 | 9.94 | 1300 | - | 33.5 | 28.4 | |

| Test methods | JIS A 1110 [15] | JIS A 1104 [16] | JIS A 1102 [11] | JIS A 1121 [17] | BS 812 [18] | ||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ceesay, A.B.; Miyazawa, S. Strength Development and Durability of Concrete Containing Recycled Roof Tile Aggregate. Recycling 2019, 4, 29. https://doi.org/10.3390/recycling4030029

Ceesay AB, Miyazawa S. Strength Development and Durability of Concrete Containing Recycled Roof Tile Aggregate. Recycling. 2019; 4(3):29. https://doi.org/10.3390/recycling4030029

Chicago/Turabian StyleCeesay, Alhagie Bakary, and Shingo Miyazawa. 2019. "Strength Development and Durability of Concrete Containing Recycled Roof Tile Aggregate" Recycling 4, no. 3: 29. https://doi.org/10.3390/recycling4030029