Benchmark Comparison of High Voltage Discharge Separation of Photovoltaic Modules by Electrohydraulic and Electrodynamic Fragmentation

Abstract

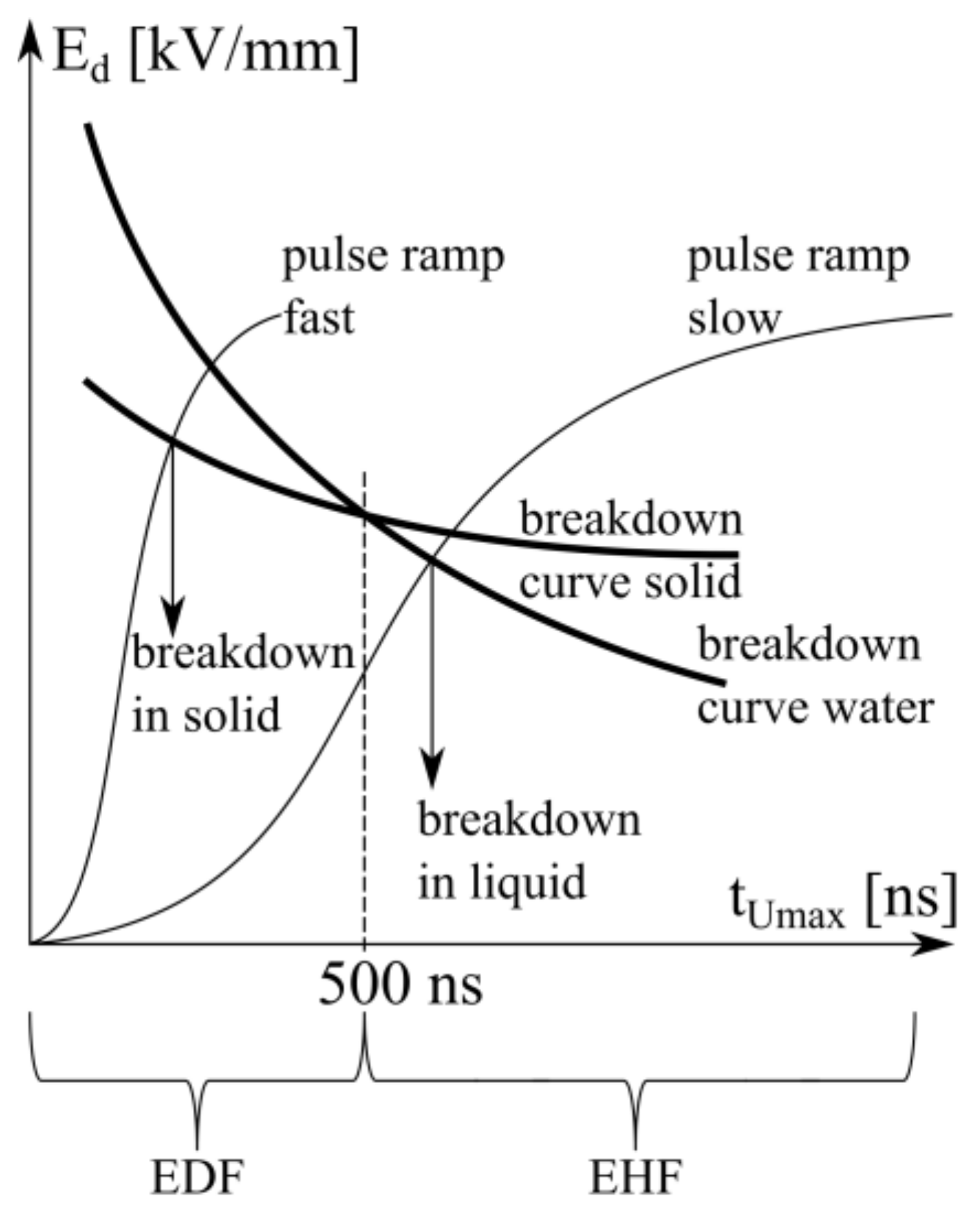

:1. Introduction

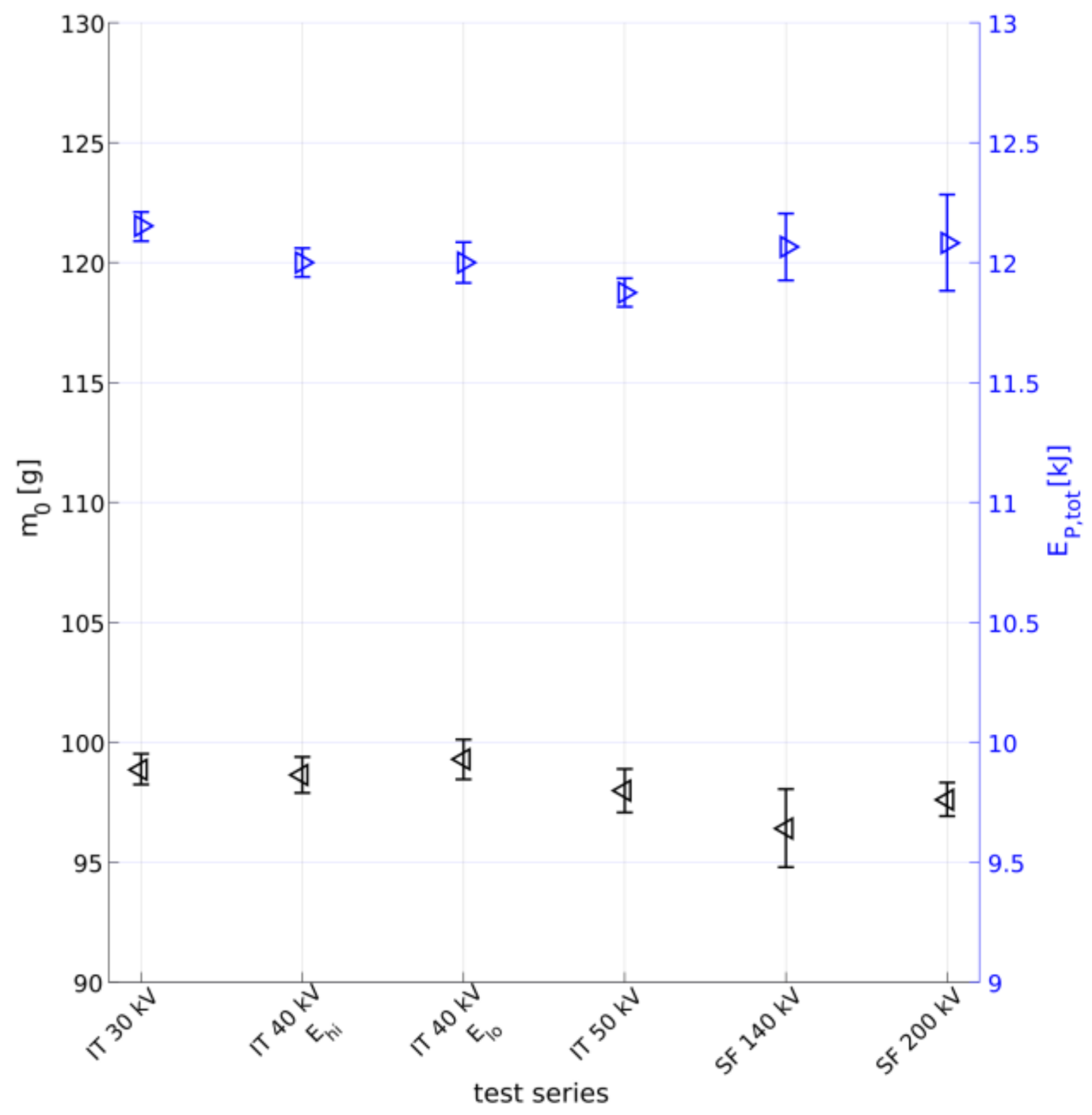

2. Materials and Methods

3. Results

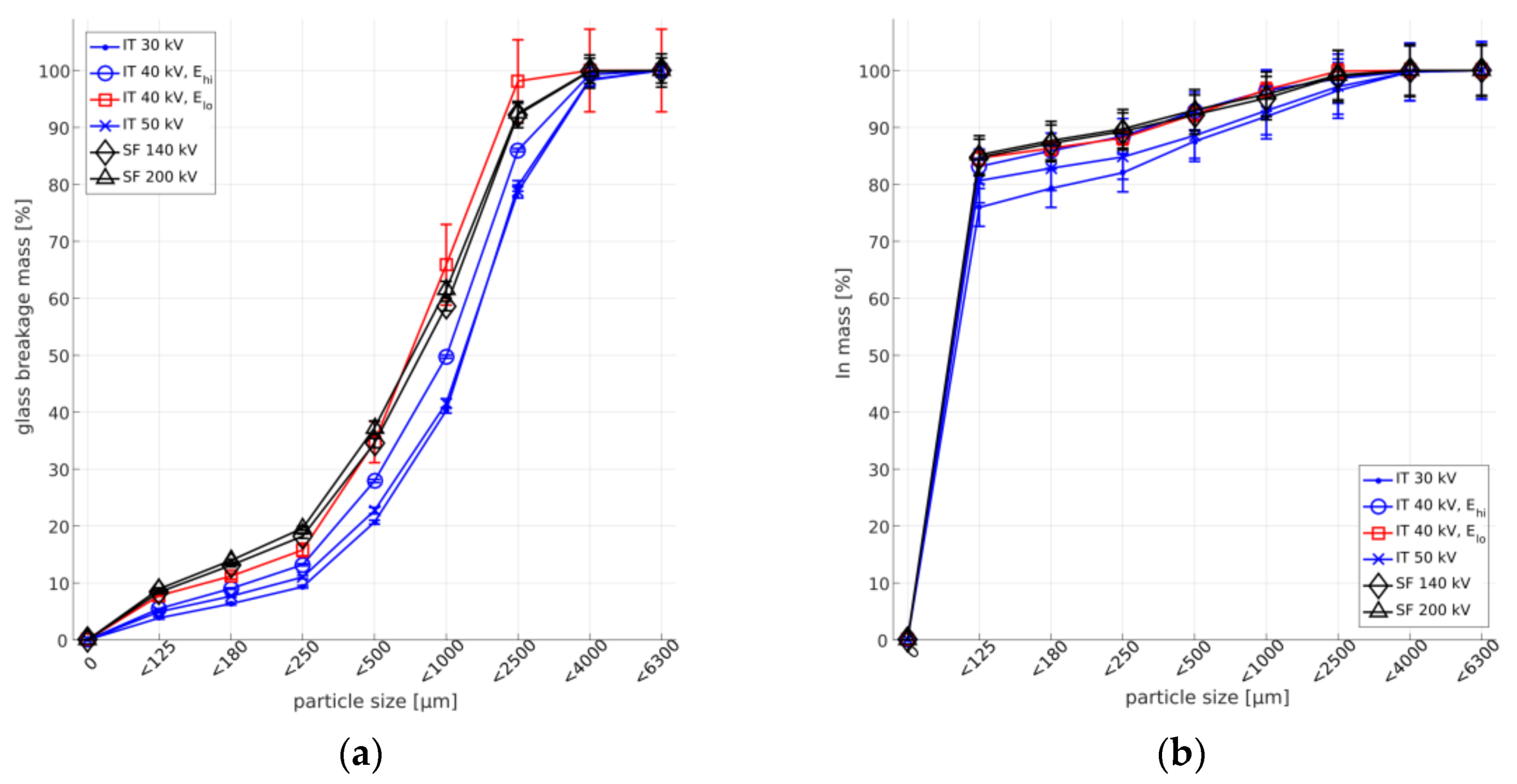

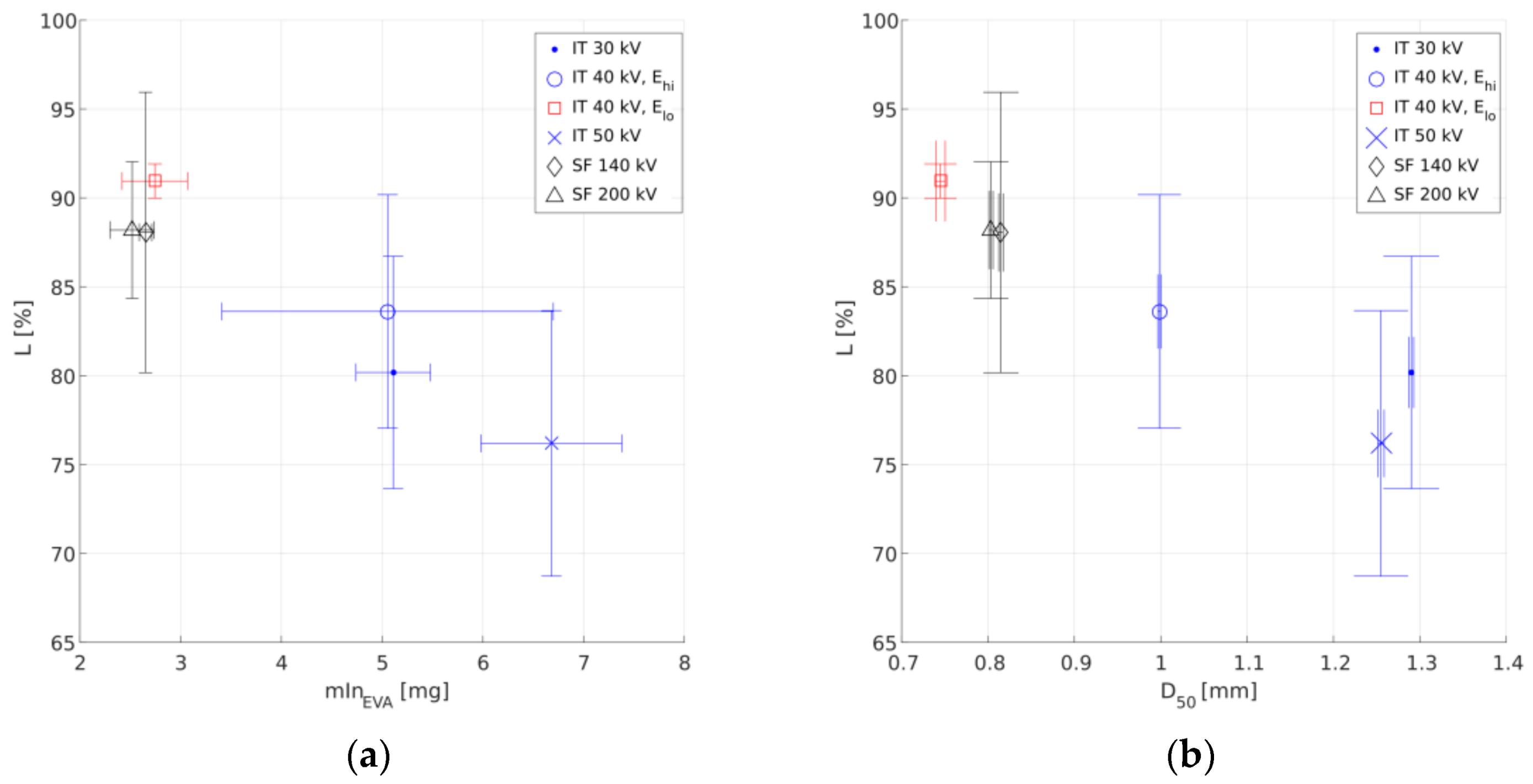

3.1. Median Particle Size

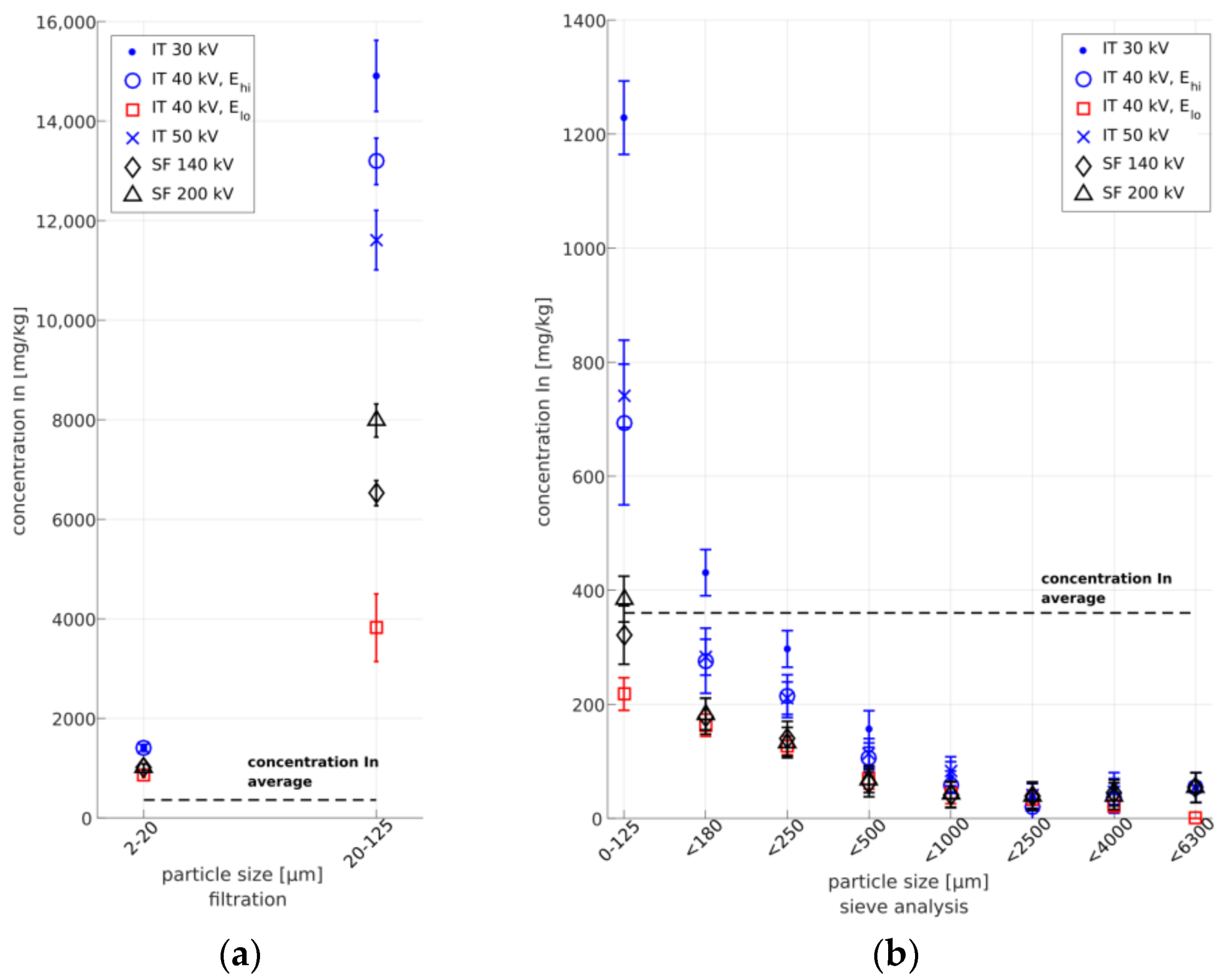

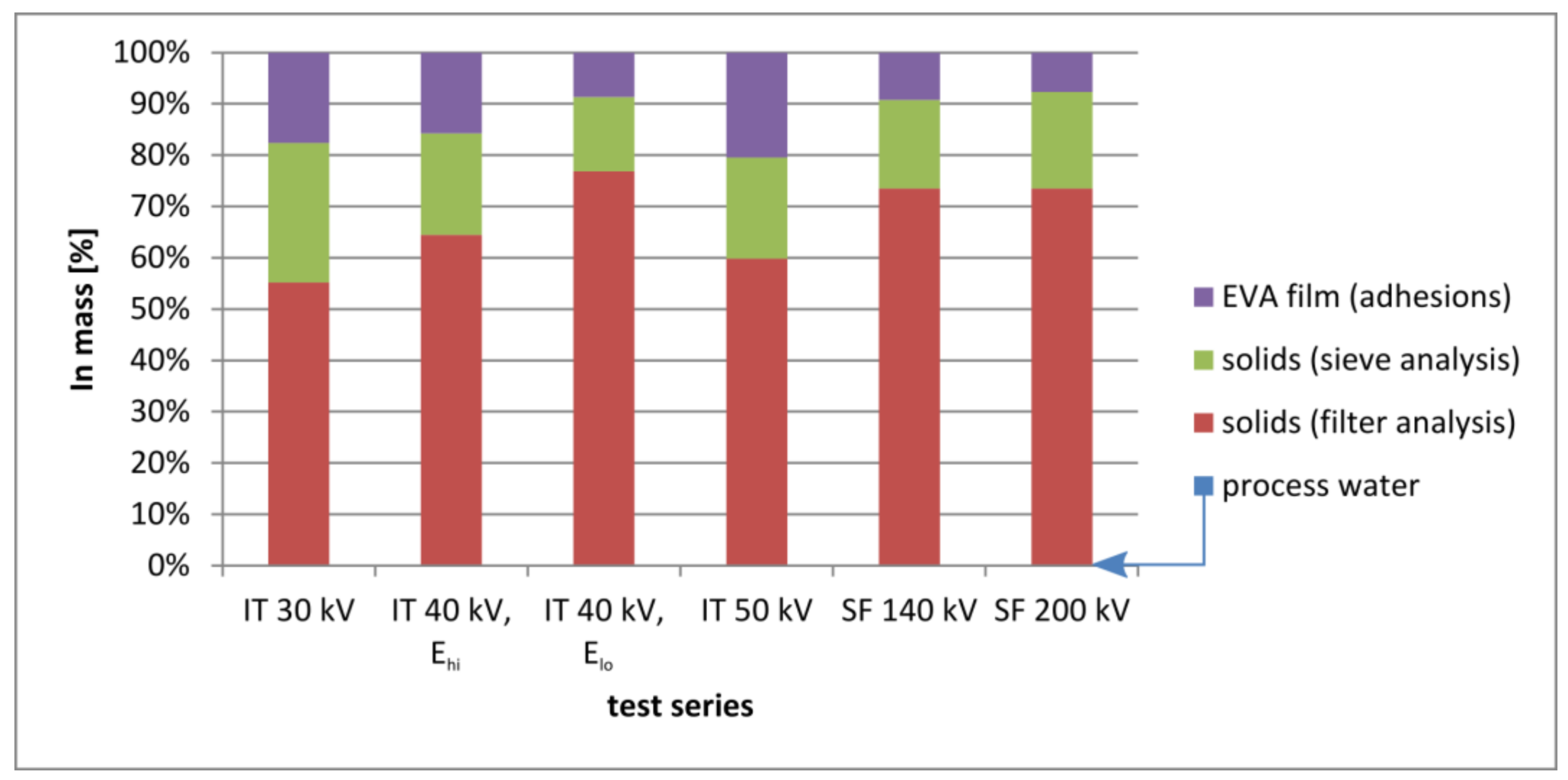

3.2. Distribution of Mass and Indium Content

3.3. Liberation

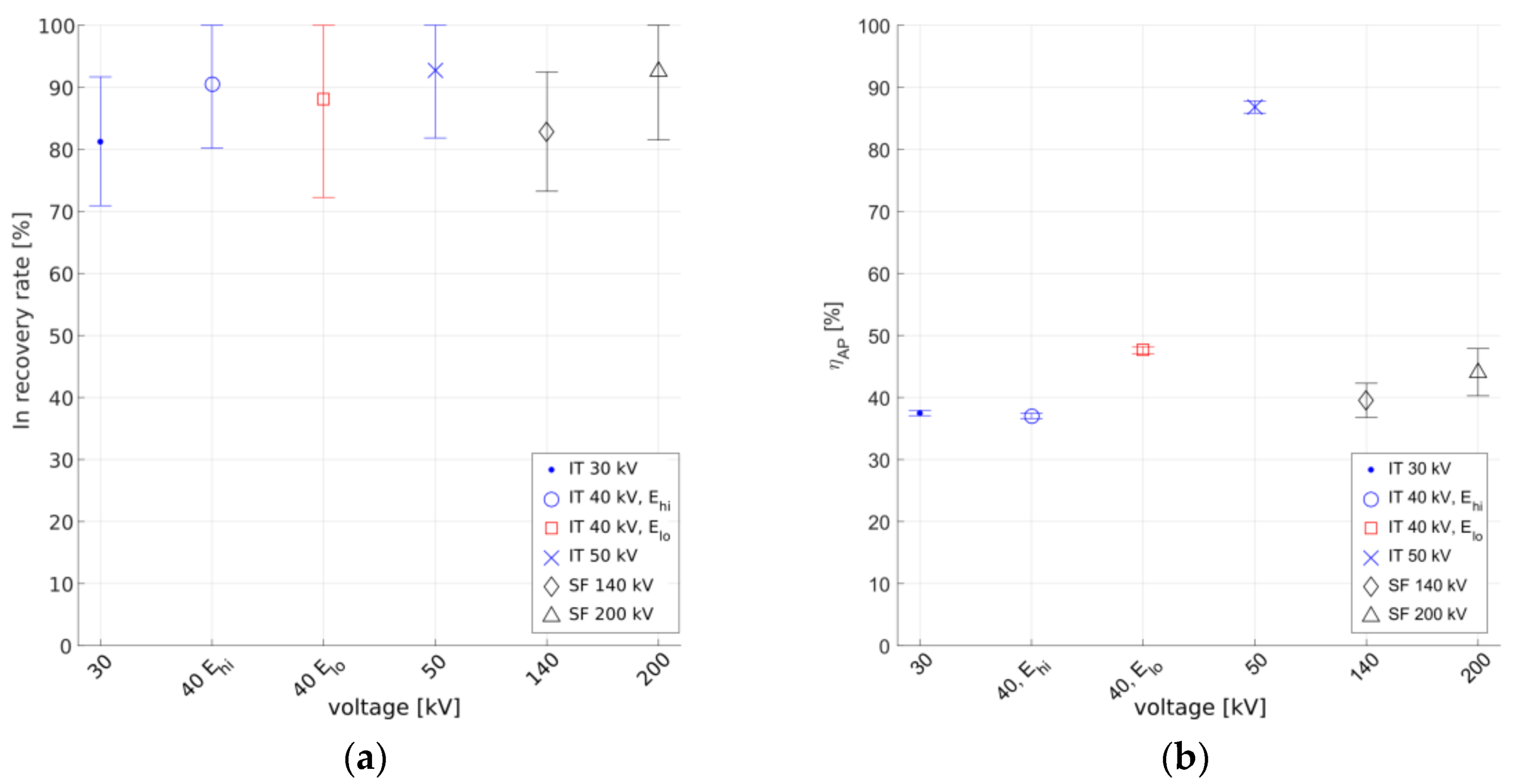

3.4. Recovery and Efficiency

4. Discussion

5. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Martens, H.; Goldmann, D. Recyclingtechnik. Fachbuch für Lehre und Praxis, 2nd ed.; Springer Vieweg: Berlin, Germany, 2016; ISBN 978-3-658-02786-5. [Google Scholar]

- European Commission (EC) Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives (Waste Framework Directive); European Commission: Strasbourg, France, 2008.

- Schug, H.; Eickenbusch, H.; Marscheider-Weidemann, F.; Zweck, A. Zukunftsmarkt Technologien zur Stofferkennung und -Trennung. Fallstudie im Auftrag des Umweltbundesamtes, UBA-Fkz. 206 14 132/05. Available online: https://www.umweltbundesamt.de/en/node/7453 (accessed on 28 March 2018).

- Weh, A.; Käppeler, J. Industrieller Einsatz des Hochspannungsimpuls-Verfahren zur Aufbereitung von Verbrennungsrückständen. In 13. Recy & DepoTech-Konferenz; Montanuniversität Leoben: Leoben, Austria, 2016; pp. 135–140. [Google Scholar]

- Lieberwirth, H. Elektroimpulszerkleinerung in Großtechnischen Zerkleinerungsmaschinen zur Aufbereitung Komplexer Erze (ELIZE), BMBF FKZ: 033R161. Available online: http://tu-freiberg.de/elize (accessed on 28 March 2018).

- Weh, A. Effiziente Metallrückgewinnung aus Kehrichtverbrennungsasche mittels Hochspannungsimpulsverfahren. In Mineralische Nebenprodukte und Abfälle; Thome-Kozmiensky, K., Ed.; TK Verlag Karl Thome-Kozmiensky: Neuruppin, Germany, 2015; Volume 2, pp. 167–191. ISBN 978-3-944310-21-3. [Google Scholar]

- Gustafsson, A.M.K. Recycling of CIGS Solar Cell Waste Materials; Chalmers University of Technology: Gothenburg, Sweden, 2014. [Google Scholar]

- Berger, W.; Simon, F.-G.; Weimann, K.; Alsema, E.A. A novel approach for the recycling of thin film photovoltaic modules. Resour. Conserv. Recycl. 2010, 54, 711–718. [Google Scholar] [CrossRef]

- Goetzberger, A.; Hebling, C.; Schock, H.-W. Photovoltaic materials, history, status and outlook. Mater. Sci. Eng. R Rep. 2003, 40, 1–46. [Google Scholar] [CrossRef]

- EPIA (European Photovoltaic Industry Association) Global Market Outlook for Photovoltaics 2013–2017. Available online: http://www.fotovoltaica.com/fv-look.pdf (accessed on 29 November 2017).

- Fischer, K.; Koch, M.; Metzger, J. Photovoltaikmodule—Umweltfreundlichkeit und Recyclingmöglichkeiten. Abschlussbericht für das Ministerium für Umwelt, Klima und Energiewirtschaft Baden Württemberg. Available online: http://www.iswa.uni-stuttgart.de/ch/img/Download_pdf/PV_Abschlussbericht_1_18072012.pdf (accessed on 29 November 2017).

- Goe, M.; Gaustad, G. Strengthening the case for recycling photovoltaics: An energy payback analysis. Appl. Energy 2014, 120, 41–48. [Google Scholar] [CrossRef]

- Sander, K.; Zangl, S.; Reichmuth, M.; Schröder, G. Stoffbezogene Anforderungen an Photovoltaik-Produkte und deren Entsorgung. Umwelt-Forschungs-Plan. FKZ 202 33 304 Endbericht. Available online: https://www.umweltbundesamt.de/sites/default/files/medien/publikation/long/2789.pdf (accessed on 29 November 2017).

- Bluhm, H.; Frey, W.; Giese, H.; Hoppe, P.; Schultheiss, C.; Strässner, R. Application of Pulsed HV Discharges to Material Fragmentation and Recycling. IEEE Trans. Dielectr. Electr. Insul. 2000, 7, 625–636. [Google Scholar] [CrossRef]

- Bluhm, H. Pulsed Power Systems, Principles and Applications, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2006; ISBN 978-3-540-34662-3. [Google Scholar]

- Schultheiss, C.; Straessner, R.; Bluhm, H.; Stemmennann, P. Concrete recycling and scraping by electrodynamic fragmentation. In Physics of Intense Light Ion Beams, Production of High Energy Density in Matter, and Pulsed Power Applications; Annual Report 1996/97, FZKA-6205; Bluhm, H., Ed.; Karlsruhe Institute of Technology: Karlsruhe, Germany, 1999; p. 218. [Google Scholar]

- Akiyama, H.; Sakai, S.; Sakugawa, T.; Namihira, T. Environmental Applications of Repetitive Pulsed Power. IEEE Trans. Dielectr. Electr. Insul. 2007, 14, 825–833. [Google Scholar] [CrossRef] [Green Version]

- Weh, A.; Monti di Sopra, F. Zerkleinerung und Aufschluss von Abfallströmen mittels gepulster Hochspannungstechnologie. In Recycling und Rohstoffe; Thome-Kozmiensky, K., Ed.; TK Verlag Karl Thome-Kozmiensky: Neuruppin, Germany, 2011; Volume 1, pp. 371–378. ISBN 978-3-935317-67-2. [Google Scholar]

- Menard, Y.; Bru, K.; Touze, S.; Lemoign, A.; Poirier, J.E.; Ruffie, G.; Bonnaudin, F.; Von Der Weid, F. Innovative process routes for a high-quality concrete recycling. Waste Manag. 2013, 33, 1561–1565. [Google Scholar] [CrossRef] [PubMed]

- Seifert, S.; Thome, V.; Karlstetter, C. Elektrodynamische Fragmentierung. Eine Technologie zur effektiven Aufbereitung von Abfallströmen. In Recycling und Rohstoffe; Thome-Kozmiensky, K., Ed.; TK Verlag Karl Thome-Kozmiensky: Neuruppin, Germany, 2014; Volume 1, pp. 431–438. ISBN 978-3-944310-10-7. [Google Scholar]

- Gehring, F.; Albrecht, S.; Homolka, S.; Leistner, P.; Thome, V.; Seifert, S. Aus Altbeton wird Beton: Ein innovativer Recyclingansatz. Bauphysik 2015, 37, 296–300. [Google Scholar] [CrossRef]

- Keller, T.; Streicher-Porte, M.; Schuler, H. Elektrodynamische Fragmentierung von Betonabbruch. In Recy & DepoTech 2016; Montanuniversität Leoben: Leoben, Austria, 2016. [Google Scholar]

- Touze, S.; Bru, K.; Menard, Y.; Weh, A.; Von der Weid, F. Electrical fragmentation applied to the recycling of concrete waste—Effect on aggregate liberation. Int. J. Miner. Process. 2017, 158, 68–75. [Google Scholar] [CrossRef]

- Touryan, K.J.; Moeny, W.M.; Aimone, C.T.; Benze, J.W. Electrohydraulic rock fracturing by pulsed power generated focused shocks. In Proceedings of the 7th Pulsed Power Conference, Monterey, CA, USA, 11–14 June 1989; IEEE: Monterey, CA, USA, 1989; pp. 69–72. [Google Scholar]

- Martino, R.; Iseli, C.; Gaydardzhiev, S.; Streicher-Porte, M.; Weh, A. Characteristics of End-of-Life Printed Wiring Boards Processed by Electrodynamic Fragmentation. Chem. Ing. Tech. 2017, 89, 152–160. [Google Scholar] [CrossRef]

- Duan, C.L.; Diao, Z.J.; Zhao, Y.M.; Huang, W. Liberation of valuable materials in waste printed circuit boards by high-voltage electrical pulses. Miner. Eng. 2015, 70, 170–177. [Google Scholar] [CrossRef]

- Weh, A. High Voltage Pulse Fragmentation Technology to Recycle Fibre-Reinforced Composites, SELFRAG CFRP Report Summary, Project ID: 323454. Available online: http://cordis.europa.eu/result/rcn/163622_en.html (accessed on 29 November 2017).

- Roux, M.; Eguemann, N.; Giger, L.; Dransfeld, C. High performance thermoplastic composite processing and recycling: from cradle to cradle. In Proceedings of the SAMPE 34th International Technical Conference, Paris, France, 11–12 March 2013; Curran Associates, Inc.: Paris, France, 2013. [Google Scholar]

- Roux, M.; Dransfeld, C.; Eguemann, N.; Giger, L. Processing and Recycling of a Thermoplastic Composite Fibre—PEEEK Aerospace part. In Proceedings of the ECCM 16, 16th European Conference on Composite Materials, Sevilla, Spain, 22–26 June 2014; ECCM: Sevilla, Spain, 2014. [Google Scholar]

- Bokelmann, K.; Hartfeil, T.; Kunkel, K.; Binnewies, M.; Gellermann, C.; Stauber, R. Neue Methoden zur Wertstoffgewinnung aus primären und sekundären Rohstoffquellen. In Recycling und Rohstoffe; Thome-Kozmiensky, K., Goldmann, D., Eds.; TK Verlag Karl Thome-Kozmiensky: Berlin, Germany, 2017; Volume 1, pp. 427–437. ISBN 978-3-944310-34-3. [Google Scholar]

- Orzol, C.; Goldmann, D.; Jäckel, H. Kohlenstofffaserrecycling, Voruntersuchungen zum elektrohydraulischen Aufschluss von kohlenstofffaserverstärktem Duroplast. In Recycling und Rohstoffe; Thome-Kozmiensky, K., Ed.; TK Verlag Karl Thome-Kozmiensky: Berlin, Germany, 2017; Volume 1, pp. 229–233. ISBN 978-3-944310-34-3. [Google Scholar]

- Swiss Equity Magazine Bei Selfrag Bleibt Kein Stein auf Dem Anderen. Available online: http://www.aasa.com/files/7713/8332/6958/SELFRAG_24_May_2011.pdf (accessed on 29 November 2017).

- ImpulsTec GmbH ImpulsTec, Industrietaugliche Schockwellenzerkleinerung. Available online: https://impulstec.com/de/unternehmen-kontakt/unternehmen (accessed on 29 November 2017).

- Tipler, P.A.; Mosca, G. Physik für Wissenschaftler und Ingenieure, 7th ed.; Wagner, J., Ed.; Springer: Berlin/Heidelberg, Germany, 2015; ISBN 978-3-642-54166-7. [Google Scholar]

| Fragmentation Method, Acronym | Plant, Acronym | Voltage Range [kV] | Pulse Rise Time [µs] | Process Volume [L] |

|---|---|---|---|---|

| Electrodynamic, EDF | SelFrag Lab S2.1, SF | 90–200 | 0.15–0.2 | 2.6 |

| Electrohydraulic, EHF | ImpulsTec EHF-100 Research System, IT | 30–50 | 0.5–2 | 0.9 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pestalozzi, F.; Eisert, S.; Woidasky, J. Benchmark Comparison of High Voltage Discharge Separation of Photovoltaic Modules by Electrohydraulic and Electrodynamic Fragmentation. Recycling 2018, 3, 13. https://doi.org/10.3390/recycling3020013

Pestalozzi F, Eisert S, Woidasky J. Benchmark Comparison of High Voltage Discharge Separation of Photovoltaic Modules by Electrohydraulic and Electrodynamic Fragmentation. Recycling. 2018; 3(2):13. https://doi.org/10.3390/recycling3020013

Chicago/Turabian StylePestalozzi, Fadri, Stefan Eisert, and Jörg Woidasky. 2018. "Benchmark Comparison of High Voltage Discharge Separation of Photovoltaic Modules by Electrohydraulic and Electrodynamic Fragmentation" Recycling 3, no. 2: 13. https://doi.org/10.3390/recycling3020013