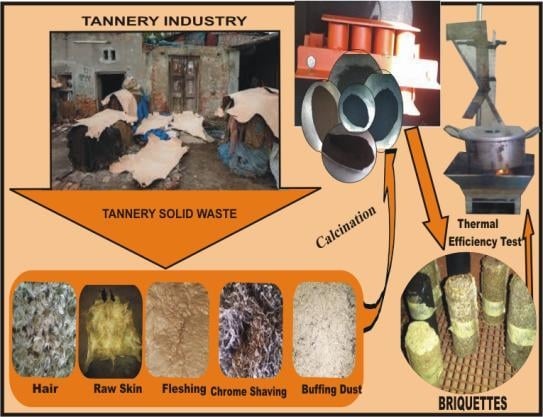

Production and Characterization of Biomass Briquettes from Tannery Solid Waste

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Collection

2.3. Sample Pre-Treatment

- Sorting: The feedstock was carefully sorted manually to remove impurities such as pieces of wood, bone, metal and any other unwanted materials.

- Drying: Hair, pre-fleshing and lime fleshing wastes from the beam house/pre-tanning unit were air dried to reduce the moisture content (up to 90% dryness) and then they were evenly mixed and oven dried at 50 °C. Chrome shavings and buffing dust from tanned leather wastes were oven dried at 105 °C in accordance with the methods described by Ozgunay et al. [19]. The local starch used as binder was air dried at room temperature for 48 h.

- Size Reduction: The biomass was then reduced in size by milling until it could pass through a screen or reaches a suitably small and uniform size (1 mm). The hair waste being very light was reduced to 0.5 mm.

- Calcination: Exactly 500 g of each of the dried samples were put in a crucible and placed in an oven at a temperature of 450 °C for 30 min. The calcined samples were then transferred into a silver plate to reduce the temperature and avoid further combustion.

- Maceration: The waste was macerated to provide uniform consistency (slurry). Maceration of the carbonized Calcined Hair (HR), Fleshing (FL), Chrome Shavings (CS) and Buffing Dust (BD) samples were done by mixing equal amounts of each “sample” with “cassava starch binder” and “water” at the ratio of 4:5:1 [19]. The non-carbonized feed was macerated by mixing varying amounts of each sample with the binder and water at the same ratio. The starch was mixed with hot water to form slurry before adding the feeds so as to facilitate flow of lignin present in the biomass, which acts as a natural binder to increase adhesion between intermolecular particles. Total volume of water used was 120 cm3.

2.4. Preliminary Analysis

2.4.1. Proximate Analysis of the Pretreated Sample

- (a)

- Percentage volatile matter: The percentage volatile matter (PVM) was determined using the standard method CEN/TS 15148. Two grams of briquette sample was pulverized and oven dried at 105 °C until its weight was constant. The sample was then heated at 550 °C for 10 min and weighed after cooling. The PVM was calculated using:where PVM is the percentage volatile matter, A is the weight of the oven-dried sample and B is the weight of the sample after 10 min in the furnace at 550 °C.

- (b)

- Percentage moisture content on dry basis: The percentage moisture content (PMC) was determined using standard CEN/TS 14774. Three grams of briquette sample was oven dried at 105 ± 2 °C until a constant mass was obtained. The change in weight (D) after 16–24 h was then used to determine the sample’s PMC using:where PMC is the percentage moisture content, D is change in weight, and E is the initial weight before drying.

- (c)

- Percentage ash content: The percentage ash content (PAC) was determined using standard CEN/TS 14775. Two grams of the briquette was heated in a furnace at 450 °C for 1 h and weighed after cooling to get the weight of the ash (C). The PAC was determined using:where PAC is the percentage ash content, C is the weight after cooling, and A is the weight of the oven-dried sample

- (d)

- Percentage fixed carbon: The percentage fixed carbon (PFC) was computed by subtracting the sum of PVM, PAC and PMC from 100.Fixed Carbon = 100% − (PVM + PAC + PMC),

2.4.2. Ultimate Analysis of the Raw Sample

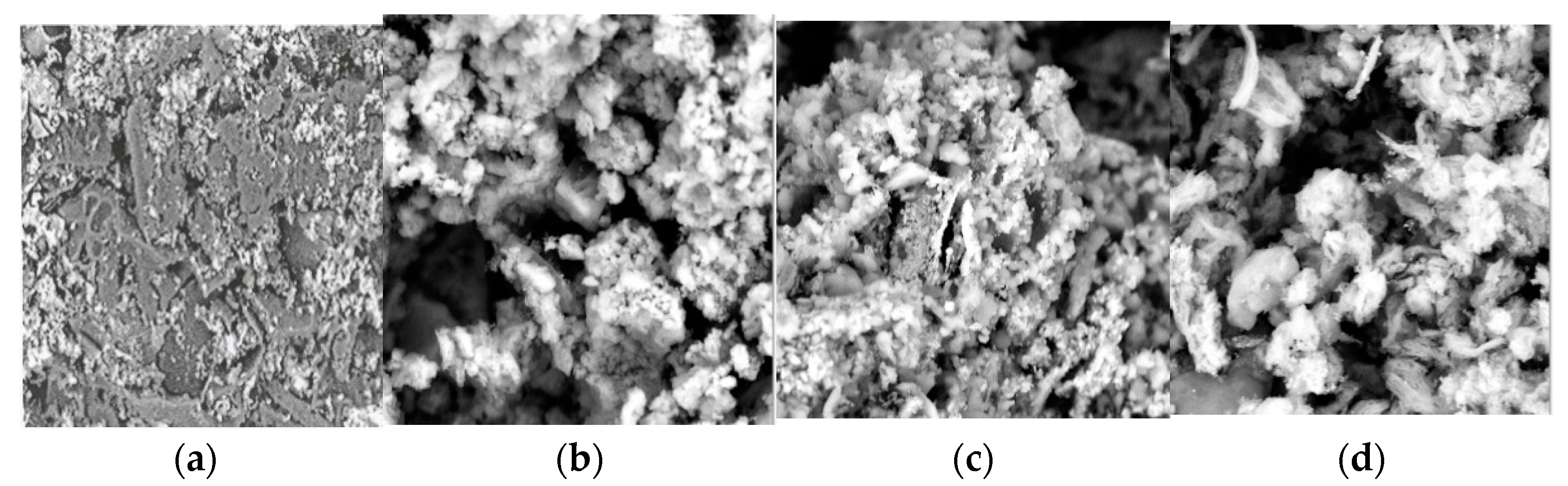

2.5. Scanning Electron Microscopy (SEM) Analysis

2.6. Briquetting of Pretreated Sample

2.7. Characterization of Briquette

2.8. Calorific Value

2.9. Durability

2.10. Density

2.11. Determination of Compressive Strength

2.12. Proximate and Thermal Analysis of Briquette

2.12.1. Proximate Analysis of Briquette

2.12.2. Energy Evaluation Analysis

2.12.3. Thermal Fuel Efficiency (TFE) Test

2.12.4. Burning Rate

2.12.5. Ignition Time

2.13. Statistical Analysis

3. Results and Discussion

3.1. Ultimate Analysis of Pretreated Waste Sample

3.2. Proximate Analysis

3.2.1. pH of Pretreated Waste Samples

3.2.2. Moisture Content

3.2.3. Volatile Matter

3.2.4. Ash Content

3.2.5. Fixed Carbon

3.2.6. Calorific Value

3.2.7. Compressive Strength

3.2.8. Durability

3.2.9. Bulk Density

3.2.10. Ignition Time

3.2.11. Water Boiling Time

3.2.12. Burning Rate

3.2.13. Thermal Efficiency

3.2.14. Potential Uses of TSW-Derived Briquettes

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Atta, A.Y.; Aminu, M.; Yusuf, N.; Gano, Z.S.; Ahmed, O.U.; Fasanya, O.O. Potentials of waste to energy in Nigeria. J. Appl. Sci. Res. 2016, 12, 1–6. [Google Scholar]

- Adetunji, A.R.; Isadare, D.A.; Akinluwade, K.J.; Adewoye, O.O. Waste-to-wealth applications of cassava—A review study of industrial and agricultural applications. Adv. Res. 2015, 4, 212–229. [Google Scholar] [CrossRef]

- Sthiannopkao, S.; Wong, M.H. Handling e-waste in developed and developing countries: Initiatives, practices, and consequences. Sci. Total Environ. 2013, 463, 1147–1153. [Google Scholar] [CrossRef] [PubMed]

- Masilamani, D.; Srinivasan, V.; Ramachandran, R.K.; Gopinath, A.; Madhan, B.; Saravanan, P. Sustainable packaging materials from tannery trimming solid waste: A new paradigm in wealth from waste approaches. J. Clean. Prod. 2017, 164, 885–891. [Google Scholar] [CrossRef]

- Hu, J.; Xiao, Z.; Zhou, R.; Deng, W.; Wang, M.; Ma, S. Ecological utilization of leather tannery waste with circular economy model. J. Clean. Prod. 2011, 19, 221–228. [Google Scholar] [CrossRef]

- Ravindran, B.; Wong, J.W.; Selvam, A.; Thirunavukarasu, K.; Sekaran, G. Microbial biodegradation of proteinaceous tannery solid waste and production of a novel value added product—Metalloprotease. Bioresour. Technol. 2016, 217, 150–156. [Google Scholar] [CrossRef] [PubMed]

- Okolo, N.V.; Olowolafe, E.A.; Akawu, I.; Okoduwa, S.I.R. Effects of industrial effluents on soil resources in Challawa industrial area, Kano, Nigeria. J. Glob. Ecol. Environ. 2016, 5, 1–10. [Google Scholar]

- Jini, R.; Bijinu, B.; Baskaran, V.; Bhaskar, N. Utilization of solid wastes from tanneries as possible protein source for feed applications: Acute and sub-acute toxicological studies to assess safety of products prepared from delimed tannery fleshings. Waste Biomass Valoriz. 2016, 7, 439–446. [Google Scholar] [CrossRef]

- Juel, M.A.I.; Mizan, A.; Ahmed, T. Sustainable use of tannery sludge in brick manufacturing in Bangladesh. Waste Manag. 2017, 60, 259–269. [Google Scholar] [CrossRef] [PubMed]

- İşler, A.; Sundu, S.; Tüter, M.; Karaosmanoğlu, F. Transesterification reaction of the fat originated from solid waste of the leather industry. Waste Manag. 2010, 30, 2631–2635. [Google Scholar] [CrossRef] [PubMed]

- Lazaroiu, G.; Pană, C.; Mihaescu, L.; Cernat, A.; Negurescu, N.; Mocanu, R.; Negreanu, G. Solutions for energy recovery of animal waste from leather industry. Energy Convers. Manag. 2017. [Google Scholar] [CrossRef]

- Souza, E.A.; Silva, L.A. Energy recovery from tannery sludge wastewaters through photocatalytic hydrogen production. J. Environ. Chem. Eng. 2016, 4, 2114–2120. [Google Scholar] [CrossRef]

- Romallosa, A.R.D.; Kraft, E. Feasibility of biomass briquette production from municipal wastestreams by integrating the informal sector in the Philippine. Resources 2017, 6, 12. [Google Scholar] [CrossRef]

- Garrido, M.A.; Conesa, J.A.; Garcia, M.D. Characterization and production of fuel briquettes made from biomass and plastic wastes. Energies 2017, 10, 850. [Google Scholar] [CrossRef]

- Lubwama, M.; Yiga, V.A. Development of groundnut shells and bagasse briquettes as sustainable fuel sources for domestic cooking applications in Uganda. Renew. Energy 2017, 111, 532–542. [Google Scholar] [CrossRef]

- Merete, W.; Haddis, A.; Alemayehu, E.; Ambelu, A. The potential of coffee husk and pulp as an alternative source of environmentally friendly energy. East Afr. J. Sci. 2014, 8, 29–36. [Google Scholar]

- Rahaman, S.A.; Salam, P.A. Characterization of cold densified rice straw briquettes and the potential use of sawdust as binder. Fuel Process. Technol. 2017, 158, 9–19. [Google Scholar] [CrossRef]

- Nwabue, F.I.; Unah, U.; Itumoh, E.J. Production and characterisation of smokeless bio-coal briquettes incorporating plastic waste materials. Environ. Technol. Innov. 2017. [Google Scholar] [CrossRef]

- Ozgunay, H.; Colak, S.; Mutlu, M.M.; Akyuz, F. Characterization of leather industry wastes. Polish J. Environ. Stud. 2007, 16, 867–873. [Google Scholar]

- Wessapan, T.; Somsuk, N.; Borirak, T. Design and Development of a Compact Screw-Press Biomass Briquetting Machine for Productivity Improvement and Cost Reduction. In Proceedings of the First TSME International Conference on Mechanical Engineering, Ubon Ratchathani, Thailand, 20–22 October 2010. [Google Scholar]

- Panwar, N.L.; Rathore, N.S. Design and performance evaluation of a 5 kW producer gas stove. Biomass Bioenergy 2008, 32, 1349–1352. [Google Scholar] [CrossRef]

- Jibrin, Y.; Ibrahim, Y.V.; Sadiq, U.; Agbo, S.A.; Iliyasu, U. Core power prediction for Nigeria research reactor-1 (NIRR-1) using measurements of dose-rate and temperature. Progress Nucl. Energy 2016, 91, 256–264. [Google Scholar] [CrossRef]

- Moses, I.A.; Sonloye, S.A.; Ewa, I.O.B. Instrumental Neutron Activation Analysis (Inaa) of high ranking nigerian coals from Enugu and Okaba. Int. J. Sci. Res. Innov. Technol. 2015, 2, 60–69. [Google Scholar]

- Ndirika, V.I.O. Development and performance, evaluation of a baking oven using charcoal as source of energy. Nigeria J. Renew. Energy 1998, 12, 83–91. [Google Scholar]

- Onuegbu, T.U.; Ekpunobi, U.E.; Ogbu, I.M.; Ekeoma, M.O.; Obumselu, F.O. Comparative studies of ignition time and water boiling test of coal and biomass briquettes blend. IJRRAS 2011, 7, 153–159. [Google Scholar]

- Karunanithy, C.; Wang, Y.; Muthukumarappan, K.; Pugalendhi, S. Physiochemical characterization of briquettes made from different feedstocks. Biotechnol. Res. Int. 2012, 2012, 12. [Google Scholar] [CrossRef] [PubMed]

- Grover, P.D.; Mishra, S.K. International Workshop on Biomass Briquetting; FAO: New Delhi, India, 1995. [Google Scholar]

- Chin, O.C.; Siddiqui, K.M. Characteristics of some biomass briquettes prepared under modest die pressures. Biomass Bioenergy 2000, 18, 223–228. [Google Scholar] [CrossRef]

- Zubairu, A.; Gana, S.A. Production and characterization of briquette charcoal by carbonization of agro-waste. Energy Power 2014, 4, 41–47. [Google Scholar]

- Wang, Q.; Han, K.; Gao, J.; Li, H.; Lu, C. The pyrolysis of biomass briquettes: Effect of pyrolysis temperature and phosphorus additives on the quality and combustion of bio-char briquettes. Fuel 2017, 199, 488–496. [Google Scholar] [CrossRef]

- Chukwu, M.; Folayan, C.O.; Pam, G.Y.; Obada, D.O. Characterization of some Nigerian coals for power generation. J. Combust. 2016, 2016, 11. [Google Scholar] [CrossRef]

- Tumuru, J.S.; Sokhansanji, S.; Lim, C.J.; Bi, T.; Lau, A.; Melin, S.; Sowlati, T.; Oveisi, E. Quality of wood pellet produced in British Columbia for export. Appl. Eng. Agric. 2010, 26, 1013–1020. [Google Scholar] [CrossRef]

- Adapa, P.K.; Schoe, G.J.; Tabil, L.G.; Sokhanasanj, S.; Crerar, B. Pelleting of Fractionated Alfalfa Products; American Society of Associated Executives (ASAE): Washington, DC, USA, 2003; pp. 104–115. [Google Scholar]

- Chitedze, J.; Monzerezi, M.; Kalenga-Saka, J.D.; Steenkamp, J. Binding effect of cassava starch on the compression and mechanical properties of ibruprofen tablets. J. Appl. Pharm. Sci. 2012, 2, 31–37. [Google Scholar] [CrossRef]

- Lela, B.; Barišić, M.; Nižetić, S. Cardboard/sawdust briquettes as biomass fuel: Physical–mechanical and thermal characteristics. Waste Manag. 2016, 47, 236–245. [Google Scholar] [CrossRef] [PubMed]

- Brand, M.A.; Jacinto, R.C.; Antunes, R.; da-Cunha, A.B. Production of briquettes as a tool to optimize the use of waste from rice cultivation and industrial processing. Renew. Energy 2017, 111, 116–123. [Google Scholar] [CrossRef]

- Prasityousil, J.; Muenjina, A. Properties of solid fuel briquettes produced from rejected material of municipal waste composting. Procedia Environ. Sci. 2013, 17, 603–610. [Google Scholar] [CrossRef]

- Shuma, R.; Madyira, D.M. Production of loose biomass briquettes from agricultural and forestry residues. Procedia Manuf. 2017, 7, 98–105. [Google Scholar] [CrossRef]

- Oyelaran, O.A.; Balogun, O.; Ambali, A.O.; Abidoye, J.K. Characterization of briquette produced from tannery solid waste. J. Mater. Eng. Struct. 2017, 4, 79–86. [Google Scholar]

- Ward, B.J.; Yacob, T.W.; Montoya, L.D. Evaluation of solid fuel char briquettes from human waste. Environ. Sci. Technol. 2014, 48, 9852–9858. [Google Scholar] [CrossRef] [PubMed]

- Chatziaras, N.; Psomopoulos, C.S.; Themelis, N.J. Use of waste derived fuels in cement industry: A review. Manag. Environ. Q. Int. J. 2016, 27, 178–193. [Google Scholar] [CrossRef]

- Citrasari, N.; Pinatih, T.A.; Kuncoro, E.P.; Soegianto, A.; Salamun; Irawan, B. Potency of bio-charcoal briquette from leather cassava tubers and industrial sludge. AIP Conf. Proc. 2017, 1854, 020007. [Google Scholar]

- Onuegbu, T.U.; Ogbu, I.M.; Ejikeme, C. Comparative analyses of densities and calorific values of wood and briquettes samples prepared at moderate pressure and ambient temperature. Int. J. Plant Anim. Environ. Serv. 2011, 2, 40–45. [Google Scholar]

- Kaliyan, N.; Morey, R.V. Densification characteristics of corn cobs. Fuel Process. Technol. 2010, 91, 559–565. [Google Scholar] [CrossRef]

- Richards, S.R. Physical testing of fuel briquettes. Fuel Process. Technol. 1990, 25, 89–100. [Google Scholar] [CrossRef]

- Olorunnisola, A. Production of fuel briquettes from waste paper and coconut husk admixtures. Agric. Eng. Int. CIGR E J. 2007, 9, 1–11. [Google Scholar]

- Audu, E.B. Fuel Wood Consumption and desertification in Nigeria. Int. J. Sci. Technol. 2013, 3, 1–5. [Google Scholar]

- Nlom, J.H.; Karimov, A.A. Modeling fuel choice among households in Northern Cameroon. Sustainability 2015, 7, 9989–9999. [Google Scholar] [CrossRef]

- FAO (Food and Agriculture Organization). Global Forest Resources Assessment 2015. In How Are the World’s Forests Changing? Food and Agriculture Organization of the United Nations: Rome, Italy, 2016; pp. 1–54. [Google Scholar]

- Saad, S.; Bugaje, I.M. Biomass consumption in Nigeria: Trends and policy issues. J. Agric. Sustain. 2016, 9, 127–157. [Google Scholar]

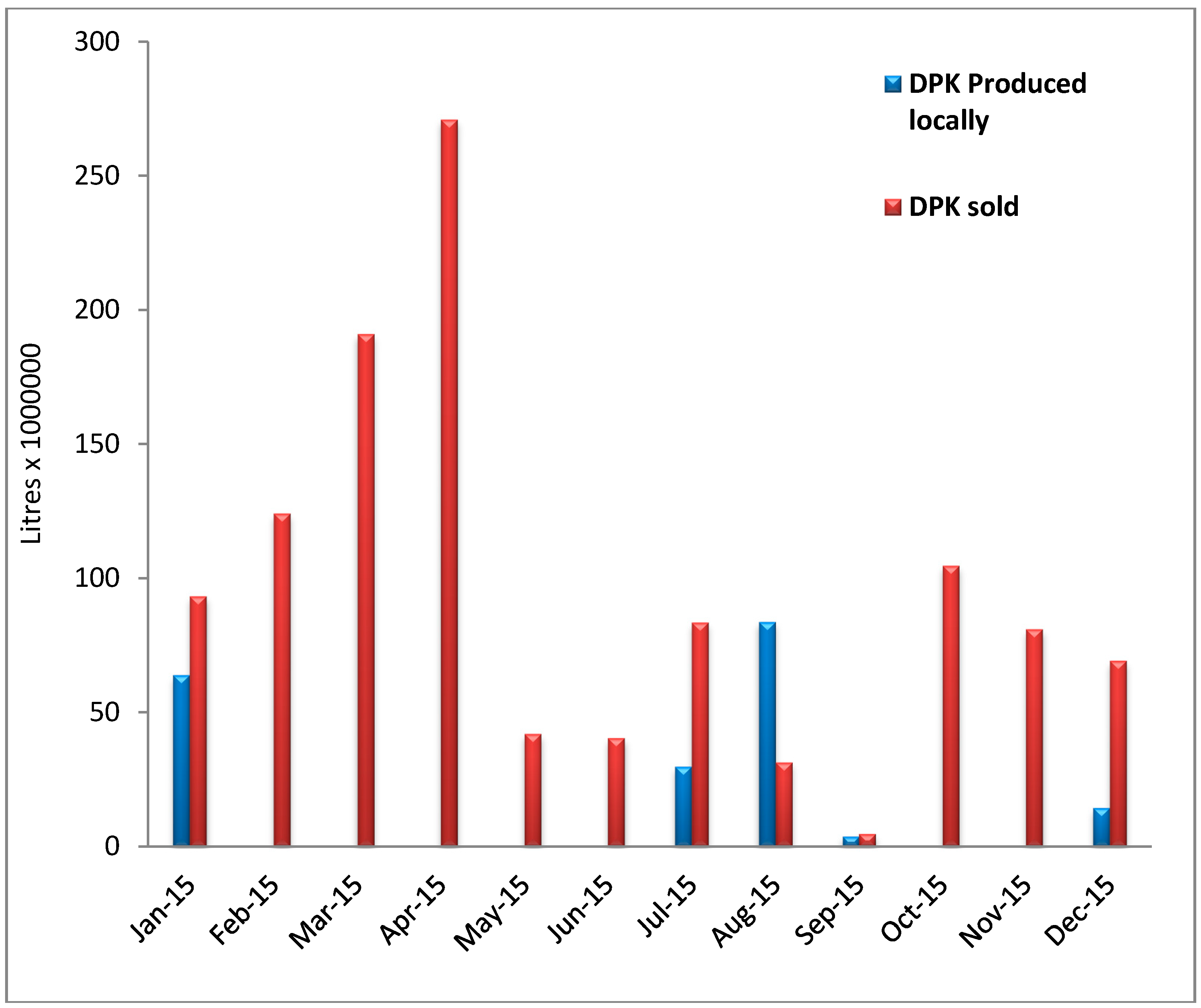

- Adelaja, A.O.; Ojolo, S.J. Future projections for domestic consumption of dual purpose kerosene in Nigeria. Int. J. Energy Technol. Policy 2013, 9, 224–237. [Google Scholar] [CrossRef]

- NNPC (Nigerian National Petroleum Corporation). December 2015 Financial and Operartions Report; NNPC Group, Ed.; NNPC: Abuja, Nigeria, 2016. [Google Scholar]

- Desalu, O.O.; Ojo, O.O.; Ariyibi, E.K.; Kolawole, T.F.; Ogunleye, A.I. A community survey of the pattern and determinants of household sources of energy for cooking in rural and urban south western, Nigeria. Pan Afr. Med. J. 2012, 12, 1–12. [Google Scholar]

- Kuti, O.A.; Adegoke, C.O. Comparative Performance of composite sawdust briquette with kerosene fuel under domestic cooking conditions. AU JT 2008, 12, 57–61. [Google Scholar]

- NNPC. January 2016 Financial and Operations Report. In Financial and Operations Report; NNPC Group: Abuja, Nigeria, 2016. [Google Scholar]

| Element | HR (mg/kg) | FL (mg/kg) | CS (mg/kg) | BD (mg/kg) |

|---|---|---|---|---|

| Mg | BDL | 6770.00 ± 528.00 | BDL | BDL |

| Al | 122.00 ± 9.00 | 15,190.00 ± 198.00 | 2129.00 ± 134.00 | 9612.00 ± 87.00 |

| Cl | 2007.00 ± 32.00 | 4118.00 ± 58.00 | 68,580.00 ± 274.00 | 1612.00 ± 34.00 |

| Ca | 3055.00 ± 238.00 | 372,300.00 ± 3351.00 | 31,440.00 ± 1321.00 | 650.00 ± 126.00 |

| V | BDL | 13.40 ± 1.30 | 60.60 ± 3.40 | 8.70 ± 0.70 |

| Mn | 4.70 ± 0.10 | 157.00 ± 1.00 | NA | 5.80 ± 0.10 |

| Na | 2413 ± 10 | 5820.00 ± 12.00 | 6562.00 ± 7.00 | 3054.00 ± 9.00 |

| Sr | BDL | 383.00 ± 21.00 | NA | BDL |

| K | 663 ± 114 | 1259.00 ± 180.00 | BDL | BDL |

| La | BDL | 1.50 ± 0.10 | BDL | 7.10 ± 0.20 |

| Sm | BDL | 0.16 ± 0.02 | 0.22 ± 0.05 | 0.94 ± 0.04 |

| Sc | 0.09 ± 0.01 | 0.51 ± 0.02 | 0.43 ± 0.02 | 1.15 ± 0.02 |

| Cr | 19.9 ± 0.3 | 46.70 ± 0.50 | 4909.00 ± 5.00 | 4441.00 ± 4.00 |

| Fe | 387 ± 40 | 4153.00 ± 75.00 | 903.00 ± 57.00 | 836.00 ± 50.00 |

| Co | BDL | 0.23 ± 0.02 | 0.08 ± 0.02 | 0.16 ± 0.02 |

| Zn | 82 ± 5 | 187.00 ± 6.00 | 33.00 ± 4.00 | 29.00 ± 3.00 |

| Br | 1.8 ± 0.2 | 1.10 ± 0.20 | 9.40 ± 0.30 | 0.90 ± 0.10 |

| Rb | 6 ± 2 | 6.50 ± 1.50 | BDL | 4.70 ± 1.40 |

| Sb | BDL | BDL | 0.03 ±0.01 | BDL |

| Ba | BDL | 56.00 ± 13.00 | BDL | BDL |

| Eu | BDL | BDL | BDL | 0.21 ± 0.04 |

| Yb | BDL | 0.34 ± 0.06 | BDL | BDL |

| Th | BDL | 0.12 ± 0.01 | 0.21 ± 0.04 | 0.16 ± 0.03 |

| Briquette ID | HR (g) | FL (g) | CS (g) | BD (g) | ST (g) |

|---|---|---|---|---|---|

| 1 | 10 | 10 | 10 | 10 | 60 |

| 2 | 15 | 10 | 5 | 10 | 60 |

| 3 | 5 | 15 | 15 | 5 | 60 |

| 4 | 15 | 25 | 5 | 5 | 50 |

| 5 | 20 | 50 | 15 | 15 | 0 |

| 6 | 10 | 10 | 10 | 10 | 60 |

| SAMPLES | pH | MC (wt. %) | VM (wt. %) | AC (wt. %) | FC (wt. %) | CV (MJ/kg) |

|---|---|---|---|---|---|---|

| HR | 9.57 | 4.98 | 9.70 | 2.78 | 82.54 | 9.08 |

| FL | 11.60 | 6.75 | 14.50 | 3.45 | 75.96 | 14.57 |

| CS | 4.13 | 5.90 | 10.09 | 2.53 | 81.48 | 10.69 |

| BD | 5.37 | 1.02 | 9.41 | 2.35 | 87.22 | 11.78 |

| Briquette ID | MC (wt. %) | VM (wt. %) | AC (wt. %) | FC (wt. %) | CV (MJ/kg) |

|---|---|---|---|---|---|

| 1 | 0.68 | 2.17 | 3.06 | 94.09 | 20.14 |

| 2 | 0.53 | 2.27 | 3.14 | 92.38 | 19.82 |

| 3 | 0.95 | 2.76 | 3.9 | 93.23 | 18.63 |

| 4 | 1.08 | 1.84 | 2.93 | 94.13 | 22.14 |

| 5 | 1.26 | 2.14 | 3.37 | 93.22 | 24.1 |

| 6 | 0.38 | 1.9 | 3.11 | 94.61 | 21.46 |

| Briquette ID | Weight of Briquette (g) | Bulk Density (kg/cm³) | Compressive Strength (kN/cm²) | Durability Test (wt. %) |

|---|---|---|---|---|

| 1 | 72.08 ± 0.07 f | 0.70 ± 0.03 c | 0.22 ± 0.02 d | 99.23 |

| 2 | 66.01 ± 0.05 a | 0.65 ± 0.01 b | 0.17 ± 0.01 c | 99.77 |

| 3 | 68.50 ± 0.14 c | 0.67 ± 0.01 b | 0.19 ± 0.01 c | 99.27 |

| 4 | 69.50 ± 0.31 d | 0.64 ± 0.01 b | 0.12 ± 0.01 b | 98.94 |

| 5 | 66.74 ± 0.25 b | 0.60 ± 0.02 a | 0.11 ± 0.01 b | 98.12 |

| 6 | 71.25 ± 0.28 e | 0.71 ± 0.02 c | 0.06 ± 0.01 a | 98.68 |

| Waste Composed Briquette | Calorific Value (MJ/kg) | Source |

|---|---|---|

| Cardboard and Saw dust | 16.94 | [35] |

| Rice Husk | 17.04 | [36] |

| Rice Straw | 17.98 | [36] |

| 90%Rice Straw + 10% Rice Husk Ash | 17.01 | [36] |

| Groundnut shells and bagasse | 22.5 | [15] |

| Waste compost | 22.42 | [37] |

| Sugar cane leaves (cow dung binder) | 19.11 | [38] |

| Waste Plastic and Coal | 19.27 | [18] |

| Buffing Dust of Total Solid Wastes | 20.17 | [39] |

| Human Waste | 25.1 | [40] |

| Used Tire | 23.02 | [41] |

| Industrial Plastic | 18.21 | [41] |

| Waste Oil | 14.65 | [41] |

| Paper and saw dust | 16.68 | [13] |

| Leather and Sludge | 7.68 | [42] |

| Elephant grass blended with 50% coal | 18.53 | [43] |

| Gmelina Arborea | 18.6 | [43] |

| Sample | Weight of Briquette (g) | Volume of Water (I) | Ignition Time (min) | Water Boiling Time (min) | Burning Rate (g/min) | Thermal Efficiency (%) |

|---|---|---|---|---|---|---|

| 1 | 150 | 100 | 15.33 ± 0.71 d | 29.35 ± 0.21 b | 0.13 ± 0.02 a | 21.09 |

| 2 | 150 | 100 | 15.07 ± 0.38 d | 32.18 ± 0.31 d | 0.12 ± 0.01 a | 20.23 |

| 3 | 150 | 100 | 17.00 ± 0.26 e | 32.18 ± 0.31 d | 0.16 ± 0.01 b | 20.71 |

| 4 | 150 | 100 | 12.10 ± 0.46 b | 31.00 ± 0.52 c | 0.18 ± 0.02 b | 20.78 |

| 5 | 150 | 100 | 13.40 ± 0.75 c | 29.32 ± 0.40 b | 0.17 ± 0.01 b | 23.13 |

| 6 | 150 | 100 | 9.23 ± 0.45 a | 28.20 ± 0.23 a | 0.13 ± 0.01 a | 26.38 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Onukak, I.E.; Mohammed-Dabo, I.A.; Ameh, A.O.; Okoduwa, S.I.R.; Fasanya, O.O. Production and Characterization of Biomass Briquettes from Tannery Solid Waste. Recycling 2017, 2, 17. https://doi.org/10.3390/recycling2040017

Onukak IE, Mohammed-Dabo IA, Ameh AO, Okoduwa SIR, Fasanya OO. Production and Characterization of Biomass Briquettes from Tannery Solid Waste. Recycling. 2017; 2(4):17. https://doi.org/10.3390/recycling2040017

Chicago/Turabian StyleOnukak, Imeh E., Ibrahim A. Mohammed-Dabo, Alewo O. Ameh, Stanley I.R. Okoduwa, and Opeoluwa O. Fasanya. 2017. "Production and Characterization of Biomass Briquettes from Tannery Solid Waste" Recycling 2, no. 4: 17. https://doi.org/10.3390/recycling2040017