Upcycling Polymers and Natural Fibers Waste—Properties of a Potential Building Material

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Composite and Specimen Preparation

2.3. Methods

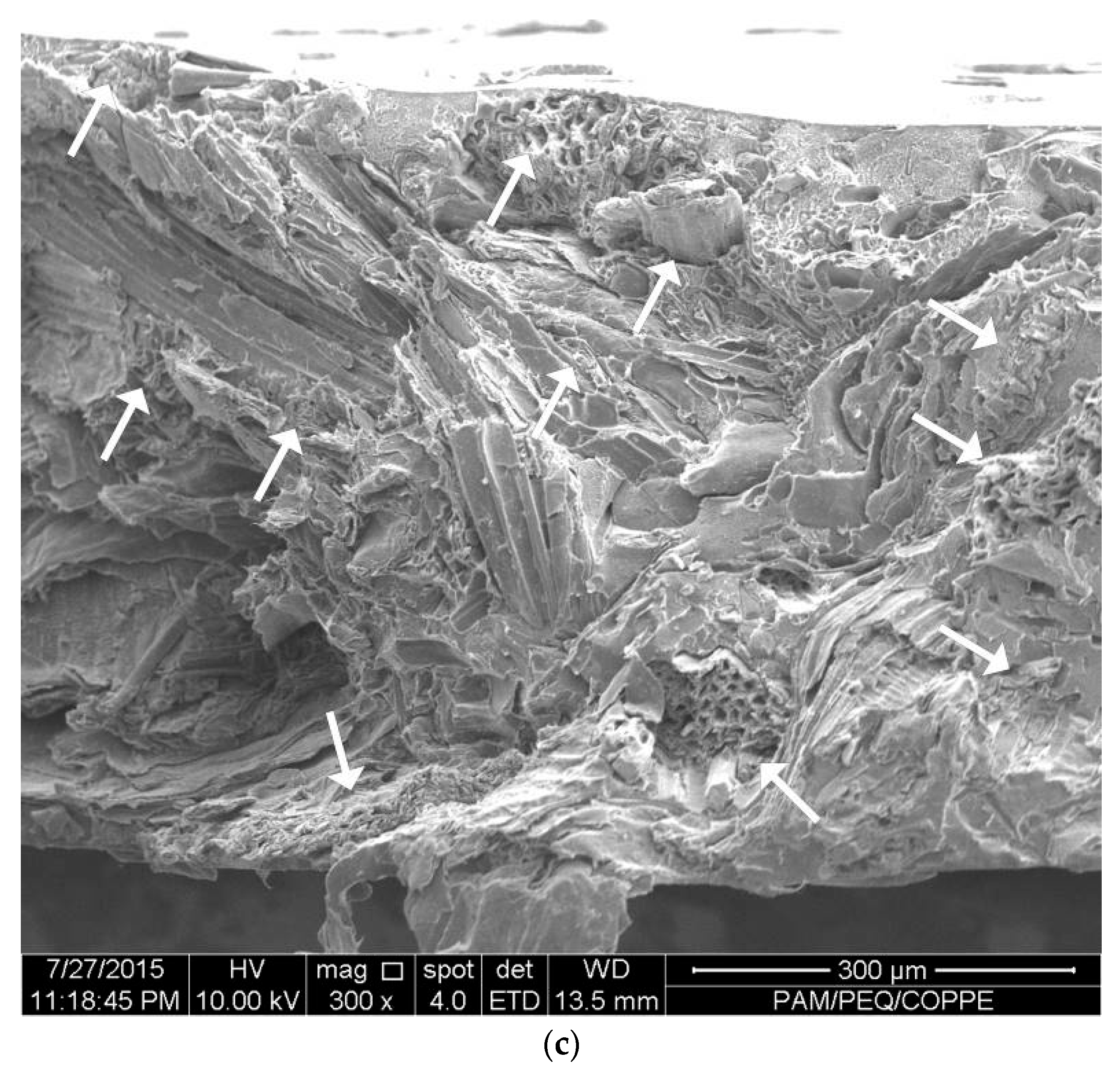

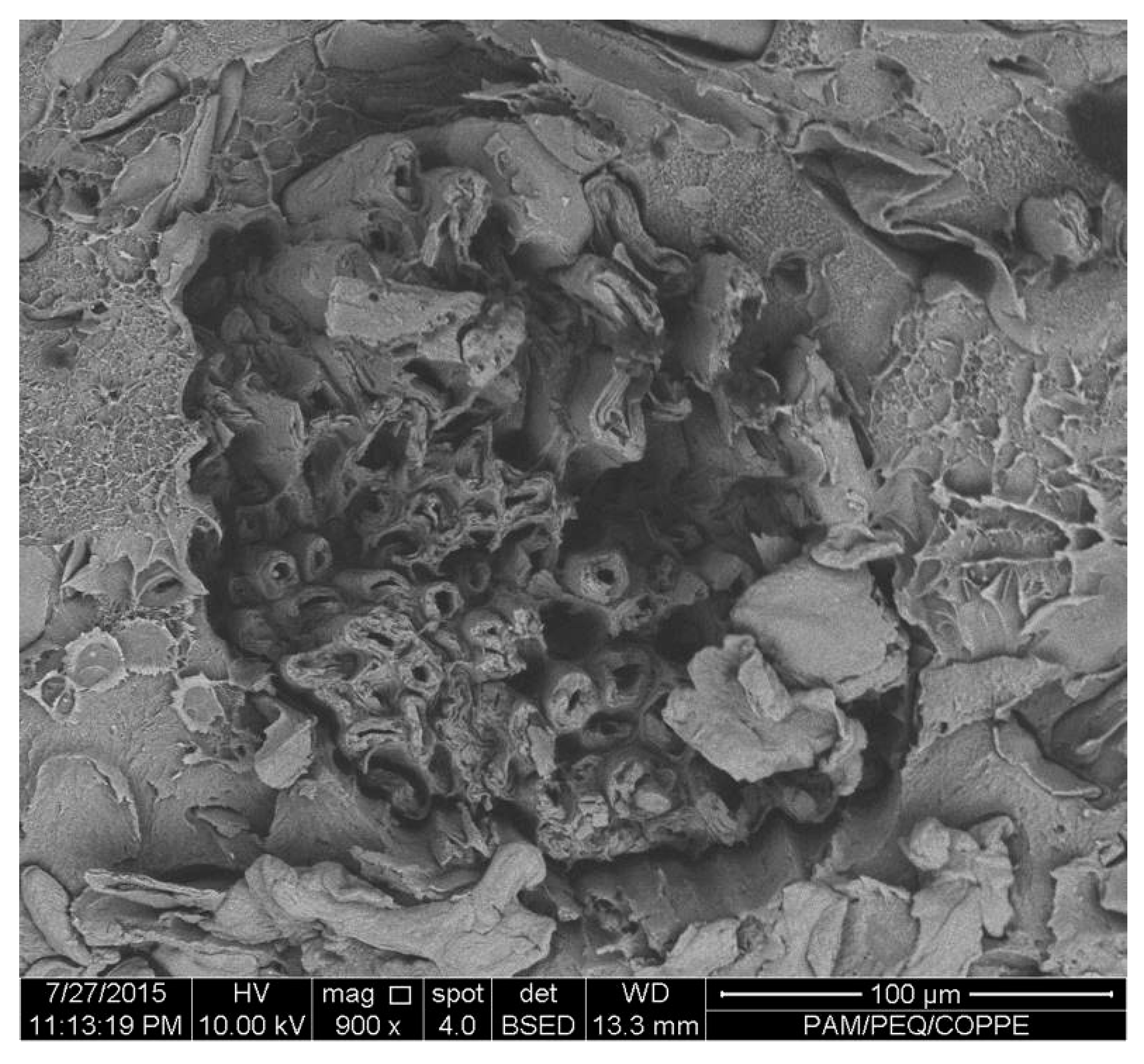

2.3.1. Scanning Electron Microscopy (SEM)

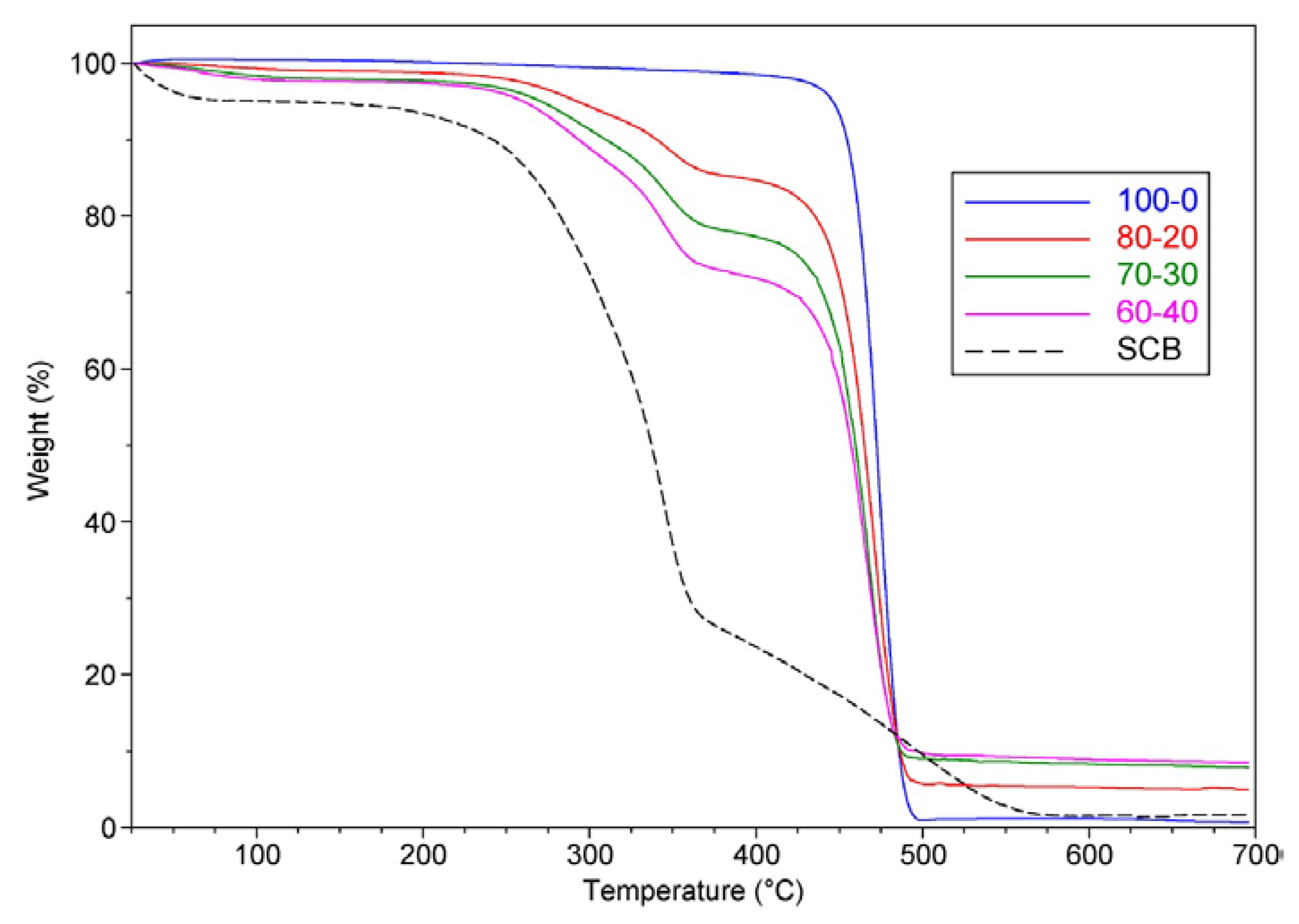

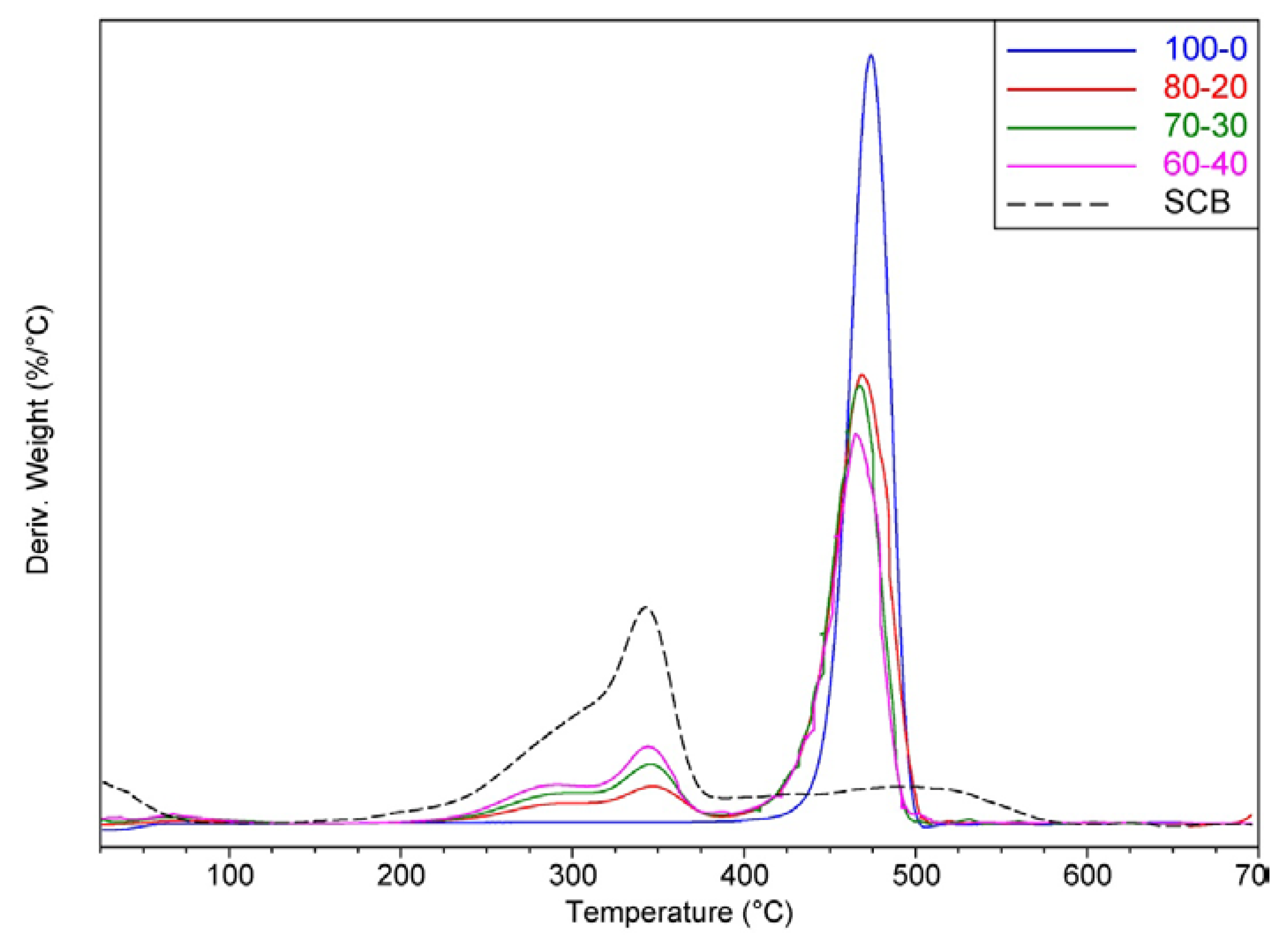

2.3.2. Thermogravimetry/Derivative Thermogravimetry (TG/DTG)

2.3.3. Differential Scanning Calorimetry (DSC)

2.3.4. Compressive Strength

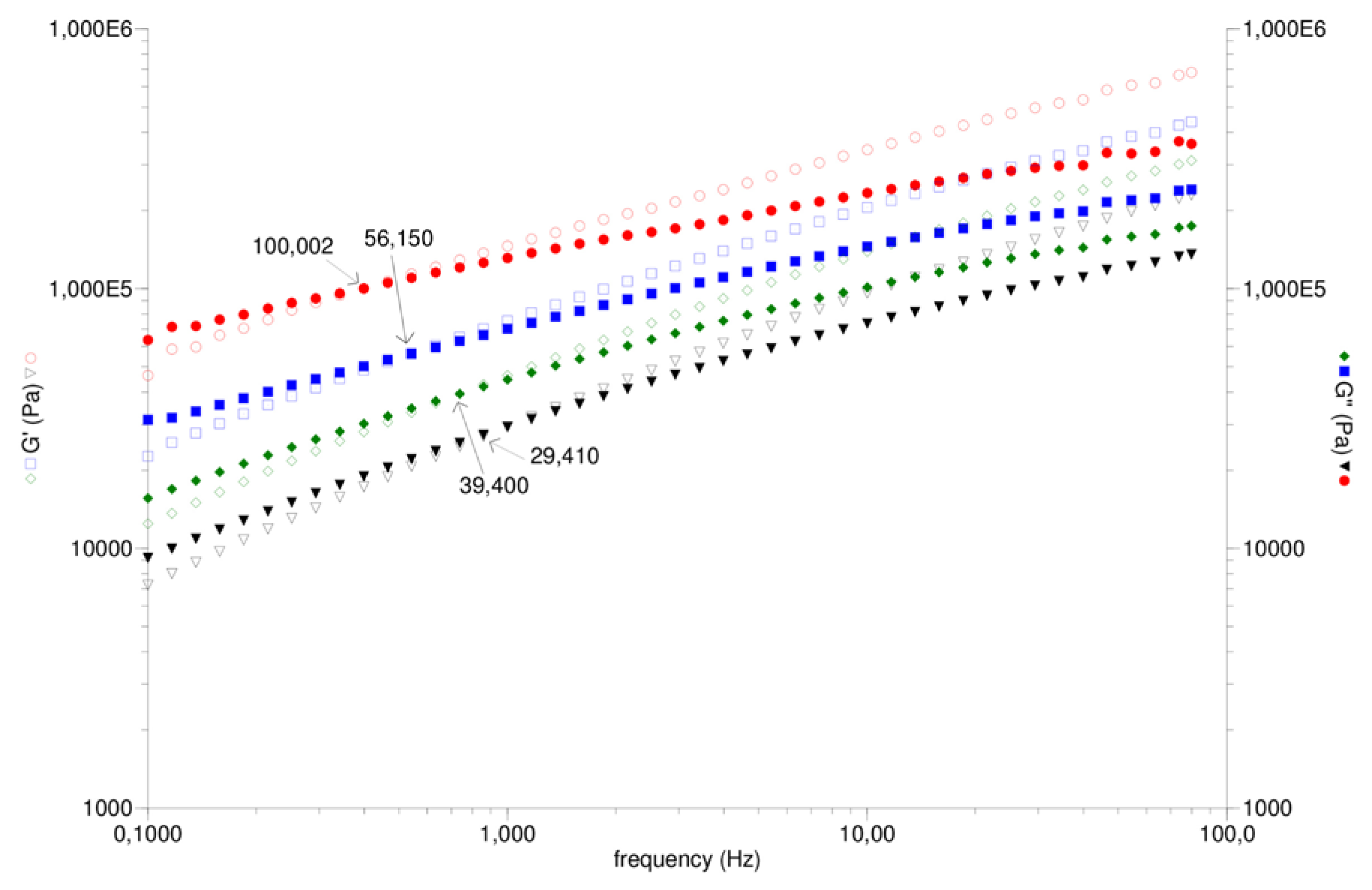

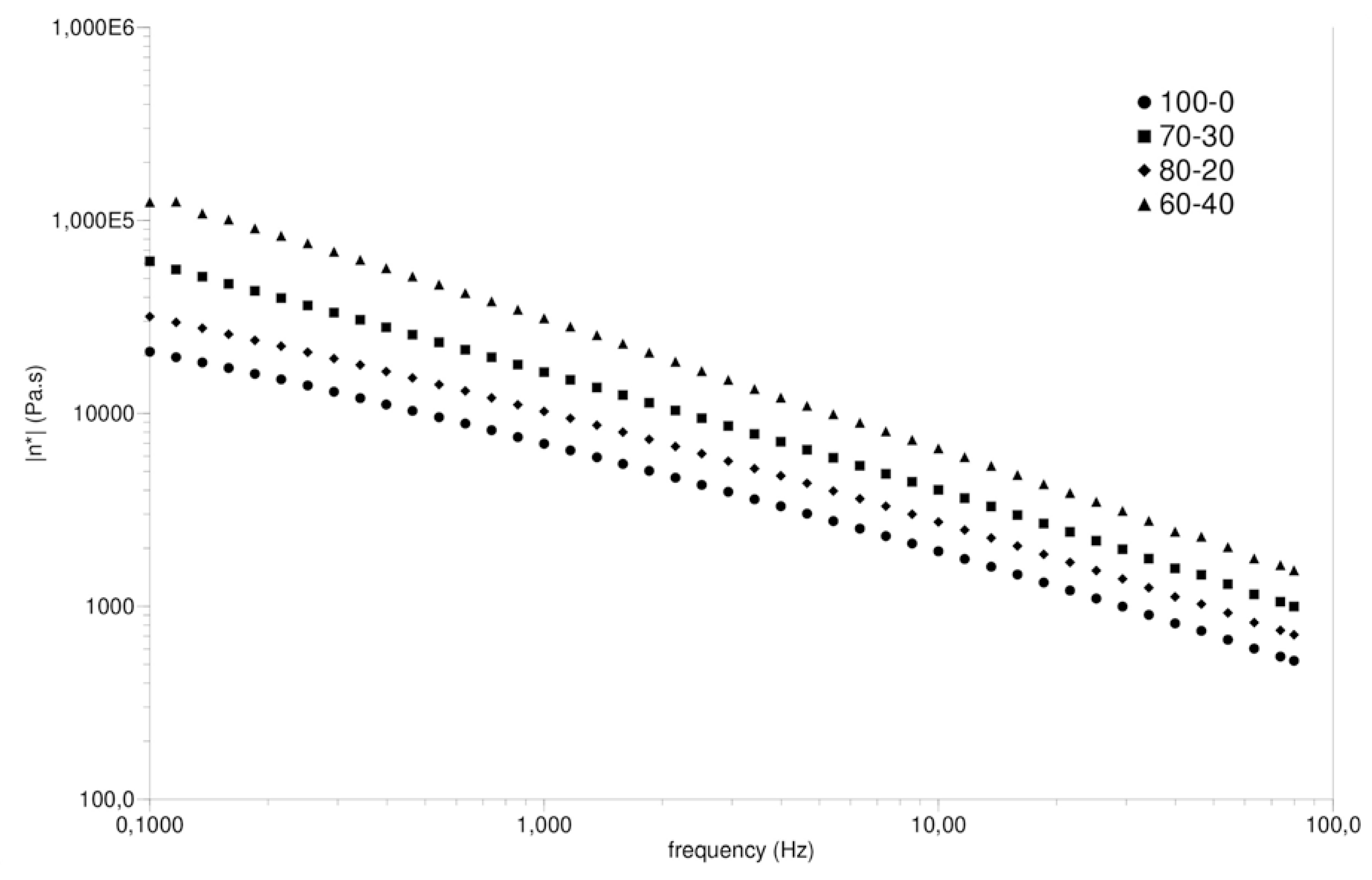

2.3.5. Rheological Measurements

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lima, A.C.; Monteiro, S.N.; Satyanarayana, K.G. Recycled polyethylene composites reinforced with jute fabric from sackcloth: Part i-preparation and preliminary assessment. J. Polym. Environ. 2012, 20, 245–253. [Google Scholar] [CrossRef]

- Yu, L.; Dean, K.; Li, L. Polymer blends and composites from renewable resources. Prog. Polym. Sci. 2006, 31, 576–602. [Google Scholar] [CrossRef]

- Brown, L.R. Eco-Economy: Building an Economy for the Earth; W.W. Norton & Company: New York, NY, USA, 2001. [Google Scholar]

- Brown, L.R. Plan B 4.0: Mobilizing to Save Civilization (Substantially Revised); W.W. Norton & Company: New York, NY, USA, 2009. [Google Scholar]

- Mohanty, A.; Misra, M.; Drzal, L. Sustainable bio-composites from renewable resources: Opportunities and challenges in the green materials world. J. Polym. Environ. 2002, 10, 19–26. [Google Scholar] [CrossRef]

- Solow, R.M. The economics of resources or the resources of economics. Am. Econ. Rev. 1974, 64, 1–14. [Google Scholar]

- Martins, A.F.; Suarez, J.C.M.; Mano, E.B. Recycled polyolefin products with higher performance than the corresponding virgin materials. Polímeros 1999, 9, 27–32. [Google Scholar] [CrossRef]

- Santi, C.R.; Correa, A.C.; Manrich, S. Films of post-consumer polypropylene composites for the support layer in synthetic paper. Polímeros 2006, 16, 123–128. [Google Scholar] [CrossRef]

- Braungart, M. Upcycle to eliminate waste: The chemist recasts materials in an endless loop. Nature 2013, 494, 174–175. [Google Scholar] [CrossRef]

- McDonough, W.; Braungart, M.; Clinton, B. The Upcycle: Beyond Sustainability—Designing for Abundance; Macmillan: New York, NY, USA, 2013. [Google Scholar]

- Da Silva Hipolito, I.; da Silva Hipolito, R.; de Almeida Lopes, G. Polímeros na construção civil. In Proceedings of the Simpósio de Excelencia em Gestão e Tecnologia, Resende, Brazil, 23–25 October 2013.

- Antink, R.; Garrigan, C.; Bonetti, M.; Westaway, R. Greening the Supply Chain; DTI/1753/PA; UNEP-SBCI: Paris, France, 2012; p. 88. [Google Scholar]

- Lauriano, L.A. Como anda a Gestão da Sustentabilidade no Setor da Construção? Avaiable online: http://acervo.ci.fdc.org.br/AcervoDigital/Relat%C3%B3rios%20de%20Pesquisa/Relat%C3%B3rios%20de%20pesquisa%202013/RP1301.pdf (accessed on 29 April 2016).

- Roodman, D.M.; Lenssen, N.; Peterson, J.A. A Building Revolution: How Ecology and Health Concerns are Transforming Construction; Worldwatch Institute: Washington, DC, USA, 1995. [Google Scholar]

- Conroy, A.; Halliwell, S.; Reynolds, T. Composite recycling in the construction industry. Compos. A Appl. Sci. Manuf. 2006, 37, 1216–1222. [Google Scholar] [CrossRef]

- Piva, A.M.; Wiebeck, H. Reciclagem do Plástico: Como Fazer da Reciclagem um Negócio Lucrativo; Artliber: São Paulo, Brazil, 2004; p. 111. [Google Scholar]

- Mendes, L.C.; Cestari, S.P. Printability of HDPE/natural fiber composites with high content of cellulosic industrial waste. Mater. Sci. Appl. 2011, 2, 1331–1339. [Google Scholar] [CrossRef]

- Cestari, S.P.; Mendes, L.C. Thermal properties and morphology of high-density polyethylene filled with coffee dregs. J. Therm. Anal. Calorim. 2013, 114, 1–4. [Google Scholar]

- Cestari, S.P.; Mendes, L.C.; Altstadt, V.; Mano, E.B.; Silva, D.F.D.; Keller, J.-H. Crystallization kinetics of recycled high density polyethylene and coffee dregs composites. Polym. Polym. Compos. 2014, 22, 541–550. [Google Scholar]

- Cestari, S.P.; Mendes, L.C.; Silva, D.F.D.; Chimanowsky, J.P., Jr.; Altstädt, V.; Demchuk, V.; Lang, A.; Leonhardt, R.G.; Keller, J.-H. Properties of recycled high density polyethylene and coffee dregs composites. Polímeros 2013, 23, 733–737. [Google Scholar] [CrossRef]

- Bozorg-Haddad, A.; Iskander, M.; Chen, Y. Compressive strength and creep of recycled HDPE used to manufacture polymeric piling. Constr. Build. Mater. 2012, 26, 505–515. [Google Scholar] [CrossRef]

- ASTM-D695. D695. In Standard Test Method for Compressive Properties of Rigid Plastics; American Society for Testing and Materials: Philadelphia, PA, USA, 2010. [Google Scholar]

- Acha, B.; Marcovich, N.; Reboredo, M. Lignin in jute fabric–polypropylene composites. J. Appl. Polym. Sci. 2009, 113, 1480–1487. [Google Scholar] [CrossRef]

- Redighieri, K.I.; Costa, D.A. Propriedades mecânicas e absorção de água dos compósitos de pebdrec e partículas de madeira de reflorestamento. Rev. Univ. Rural Sér. Ciênc. Exatas Terra 2006, 25, 28–35. [Google Scholar]

- Pandey, A.; Soccol, C.R.; Nigam, P.; Soccol, V.T. Biotechnological potential of agro-industrial residues. I: Sugarcane bagasse. Bioresour. Technol. 2000, 74, 69–80. [Google Scholar] [CrossRef]

- Guimarães, J.; Frollini, E.; Da Silva, C.; Wypych, F.; Satyanarayana, K. Characterization of banana, sugarcane bagasse and sponge gourd fibers of brazil. Ind. Crops Prod. 2009, 30, 407–415. [Google Scholar] [CrossRef]

- Ramos, F.; Mendes, L. Recycled high-density polyethylene/gypsum composites: Evaluation of the microscopic, thermal, flammability, and mechanical properties. Green Chem. Lett. Rev. 2014, 7, 199–208. [Google Scholar] [CrossRef]

- Apostolov, A.A.; Evstatiev, M.; Denchev, Z.; Friedrich, K.; Fakirov, S. Effect of composition on transcrystallization with reorientation of polypropylene in drawn PET/PP blend. J. Mater. Sci. 2007, 42, 1245–1250. [Google Scholar] [CrossRef]

- Na, B.; Guo, M.; Yang, J.; Tan, H.; Zhang, Q.; Fu, Q. Crystal morphology and transcrystallization mechanism of isotactic polypropylene induced by fibres: Interface nucleation versus bulk nucleation. Polym. Int. 2006, 55, 441–448. [Google Scholar] [CrossRef]

- NBR-6136. Blocos Vazados de Concreto Simples para Alvenaria—Requisitos. Avaiable online: http://www.construpac.com.br/pdf/nbr6136.pdf (accessed on 29 April 2016).

- Kealy, T. Rheological analysis of the degradation of HDPE during consecutive processing steps and for different processing conditions. J. Appl. Polym. Sci. 2009, 112, 639–648. [Google Scholar] [CrossRef]

- Lozano, K.; Yang, S.; Zeng, Q. Rheological analysis of vapor—Grown carbon nanofiber—Reinforced polyethylene composites. J. Appl. Polym. Sci. 2004, 93, 155–162. [Google Scholar] [CrossRef]

| Material | Tonset (°C) | Tfinal (°C) | Tmax (°C) | Residue (%) |

|---|---|---|---|---|

| 100–0 | 459 | 500 | 475 | 1 |

| 80–20 | 299/451 | 500 | 348/471 | 5 |

| 70–30 | 256/332/449 | 500 | 347/467 | 8 |

| 60–40 | 254/333/448 | 500 | 291/346/468 | 9 |

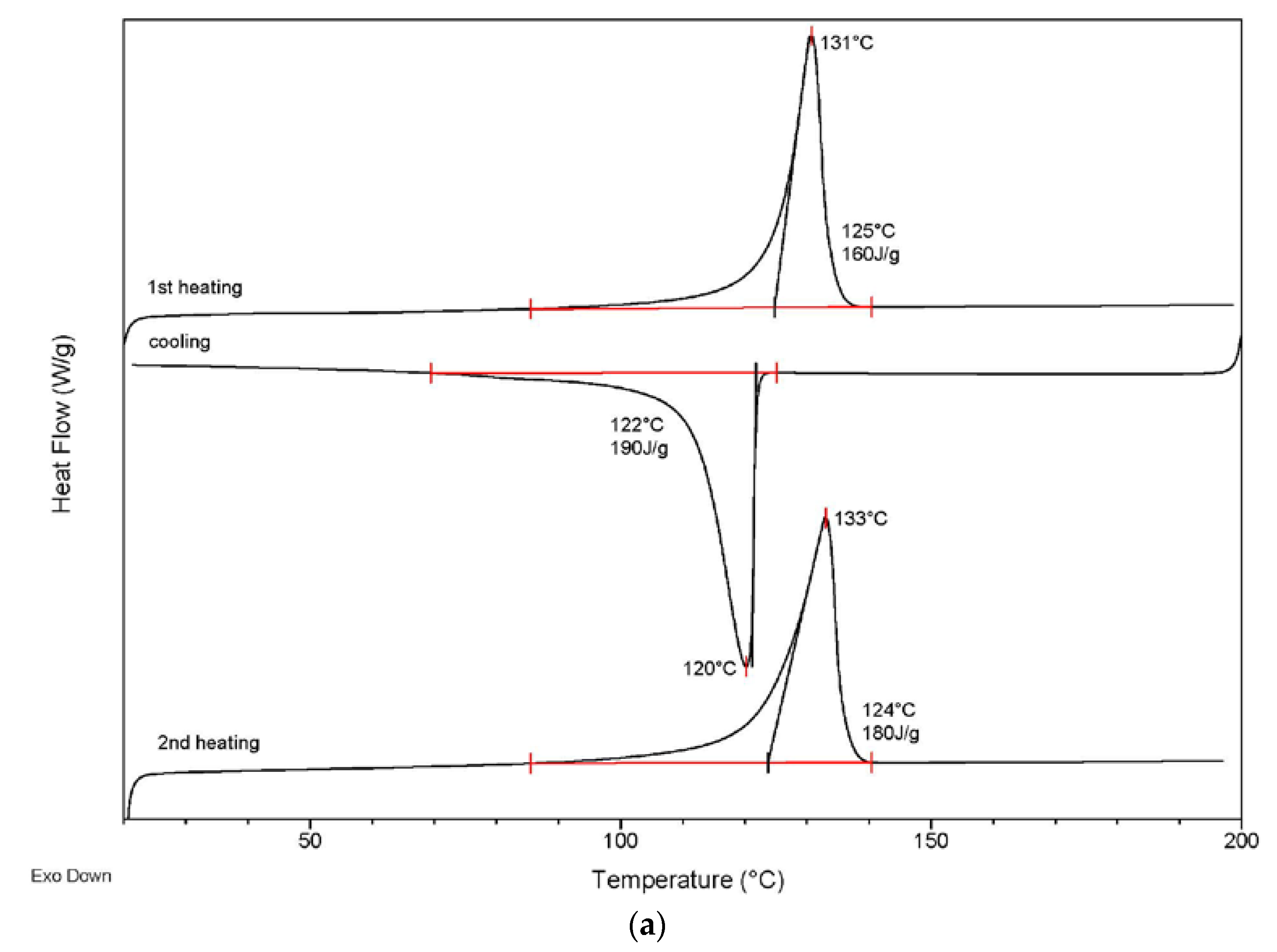

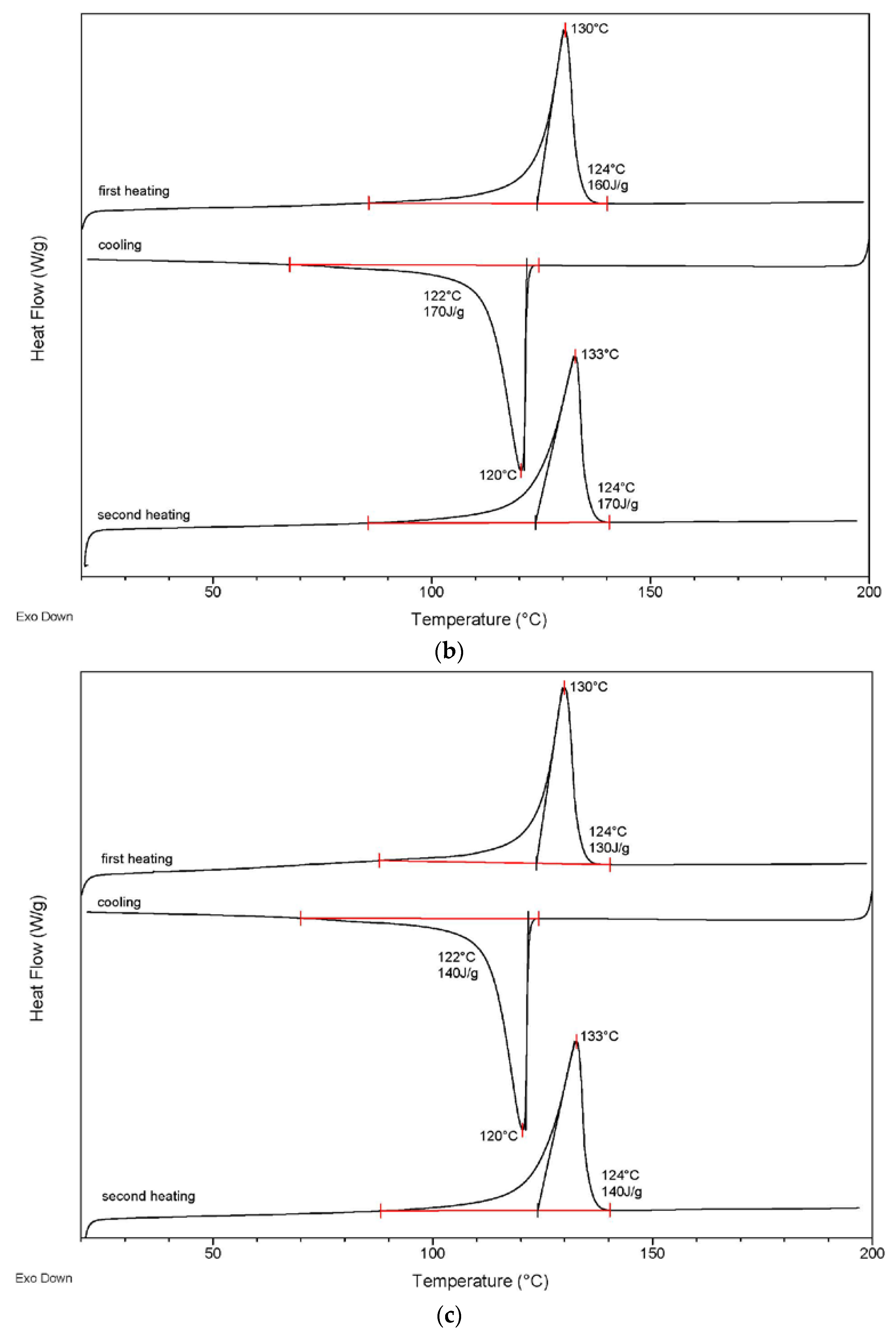

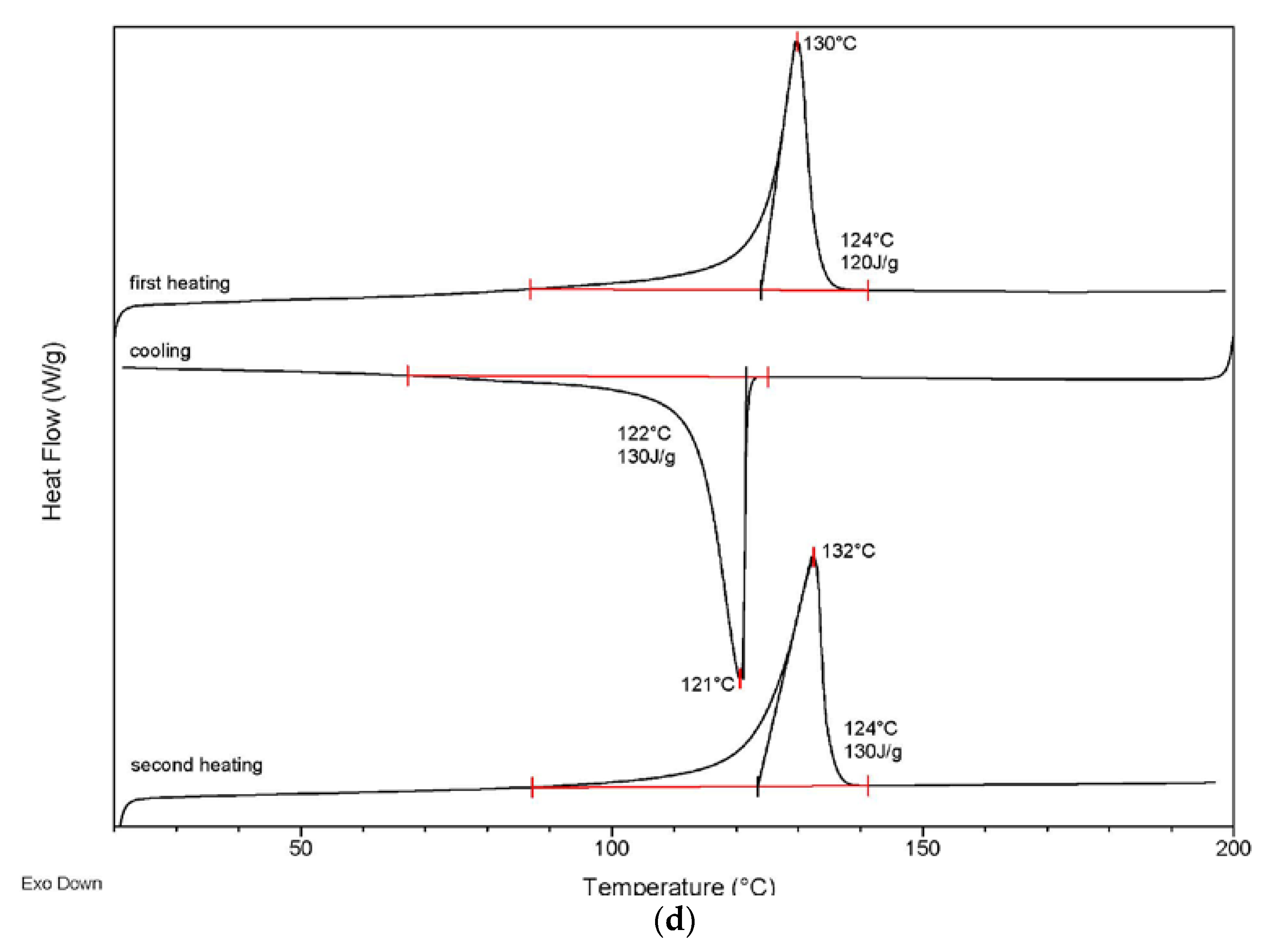

| Material | Tm (°C) | ΔHm (°C) | Tc (°C) | Xc (%) |

|---|---|---|---|---|

| 100–0 | 133 | 180 | 120 | 62 |

| 80–20 | 133 | 170 | 120 | 73 |

| 70–30 | 133 | 140 | 120 | 69 |

| 60–40 | 132 | 130 | 121 | 75 |

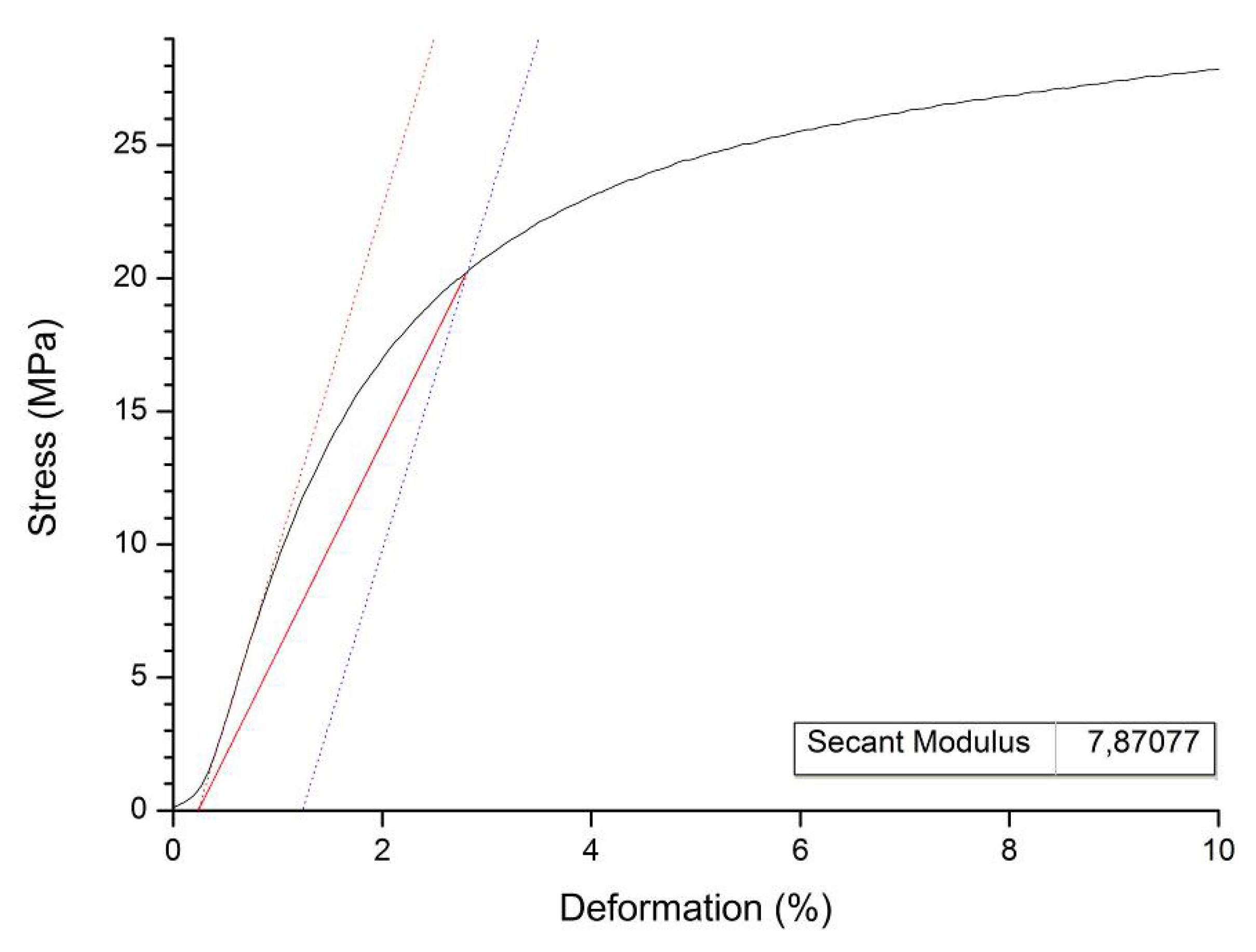

| Composite | Ecs (MPa) |

|---|---|

| 100–0 | 5.39 |

| 80–20 | 7.87 |

| 70–30 | 7.36 |

| 60–40 | 8.80 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cestari, S.P.; Mendes, L.C.; Altstädt, V.; Lopes, L.M.A. Upcycling Polymers and Natural Fibers Waste—Properties of a Potential Building Material. Recycling 2016, 1, 205-218. https://doi.org/10.3390/recycling1010205

Cestari SP, Mendes LC, Altstädt V, Lopes LMA. Upcycling Polymers and Natural Fibers Waste—Properties of a Potential Building Material. Recycling. 2016; 1(1):205-218. https://doi.org/10.3390/recycling1010205

Chicago/Turabian StyleCestari, Sibele P., Luis C. Mendes, Volker Altstädt, and Léa M. A. Lopes. 2016. "Upcycling Polymers and Natural Fibers Waste—Properties of a Potential Building Material" Recycling 1, no. 1: 205-218. https://doi.org/10.3390/recycling1010205

APA StyleCestari, S. P., Mendes, L. C., Altstädt, V., & Lopes, L. M. A. (2016). Upcycling Polymers and Natural Fibers Waste—Properties of a Potential Building Material. Recycling, 1(1), 205-218. https://doi.org/10.3390/recycling1010205