1. Introduction

The battery is a challenging energy source for commercial electric vehicles (EV) in today’s automobile market. As there is not as much on-board energy in EVs as in internal combustion engine vehicles, estimation of the remaining driving range is a critical issue for EVs. The remaining energy of the battery pack is related to its state of charge (SoC), which can be estimated by various techniques used alone or in combination: coulomb-metric measurement, identification by observers such as Kalman filter, and comparison between the open circuit voltages (OCV) deduced from measured voltage and its OCV-SoC curve. In the context of determining the SoC from estimation of the OCV, precise determination of different OCVs for different SoCs are essential to estimate accurately the SoC of the battery at any given time. However, EVs are frequently parked for long periods (e.g., a day, a night, or a weekend), which results in a long relaxation condition for the battery. Phenomena inside the battery, such as polarization and mass transfer, have very slow dynamics and occur during hours of relaxation phase, causing voltage variations. For example,

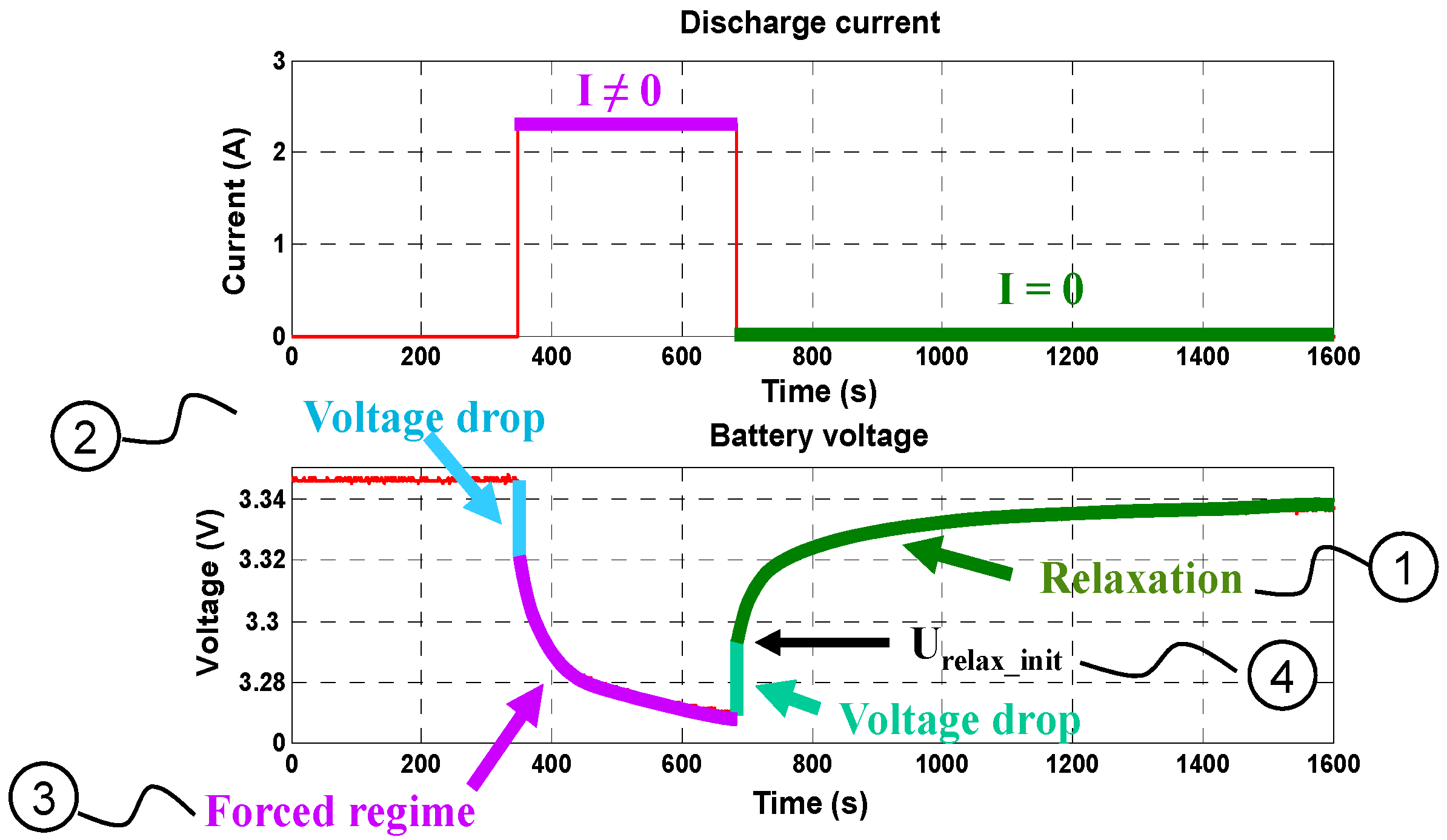

Figure 1 shows the typical voltage response of a battery following a discharge current pulse. The relaxation corresponds to the phase after a period of discharge, during which there is no current and the battery voltage tends towards a steady state.

The voltage measured at the end of the relaxation can be considered as the OCV value at this SoC.

Figure 1 also shows two other phases of the battery voltage. One is the phase of voltage drop, which occurs when the current level changes. Another one is the phase of forced regime during which the battery current is not zero.

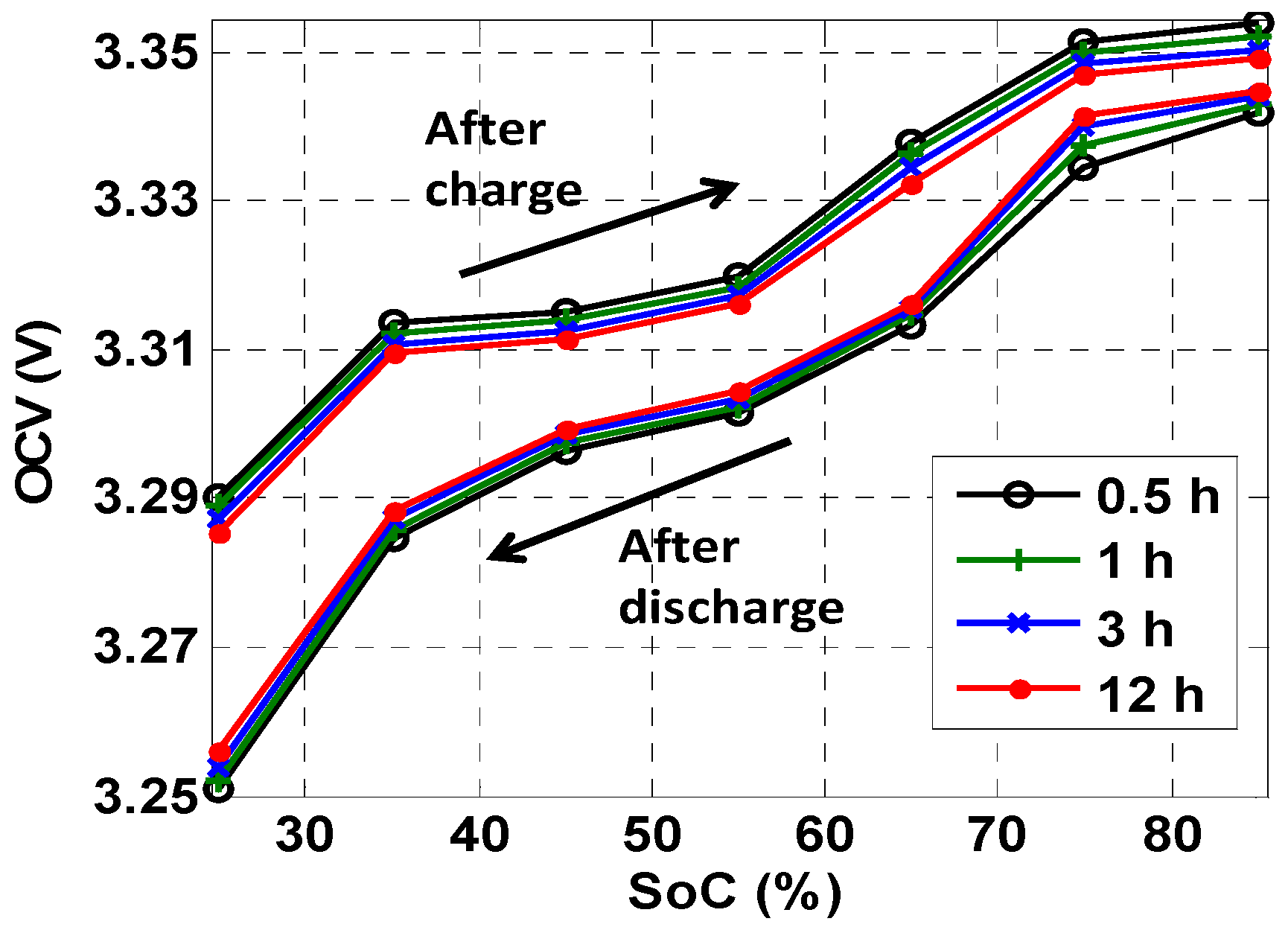

Relaxation time has a significant impact on the measured voltage, which is considered to be the OCV at the end of relaxation.

Figure 2 shows the measurement results of OCV at different SoCs and after different relaxation times of a Li-ion battery. The curves measured after discharge and charge are different. The presence of gaps between the two curves is called hysteresis. When the relaxation time increases, the value of relaxation voltage measured in discharge increases and the one in charge decreases. The longer the relaxation time, the more the measurement of the battery voltage is close to the real OCV. In fact, the battery voltage still evolves beyond a few hours. In [

1], it was stated that it may take over 24 h before the battery voltage stabilizes.

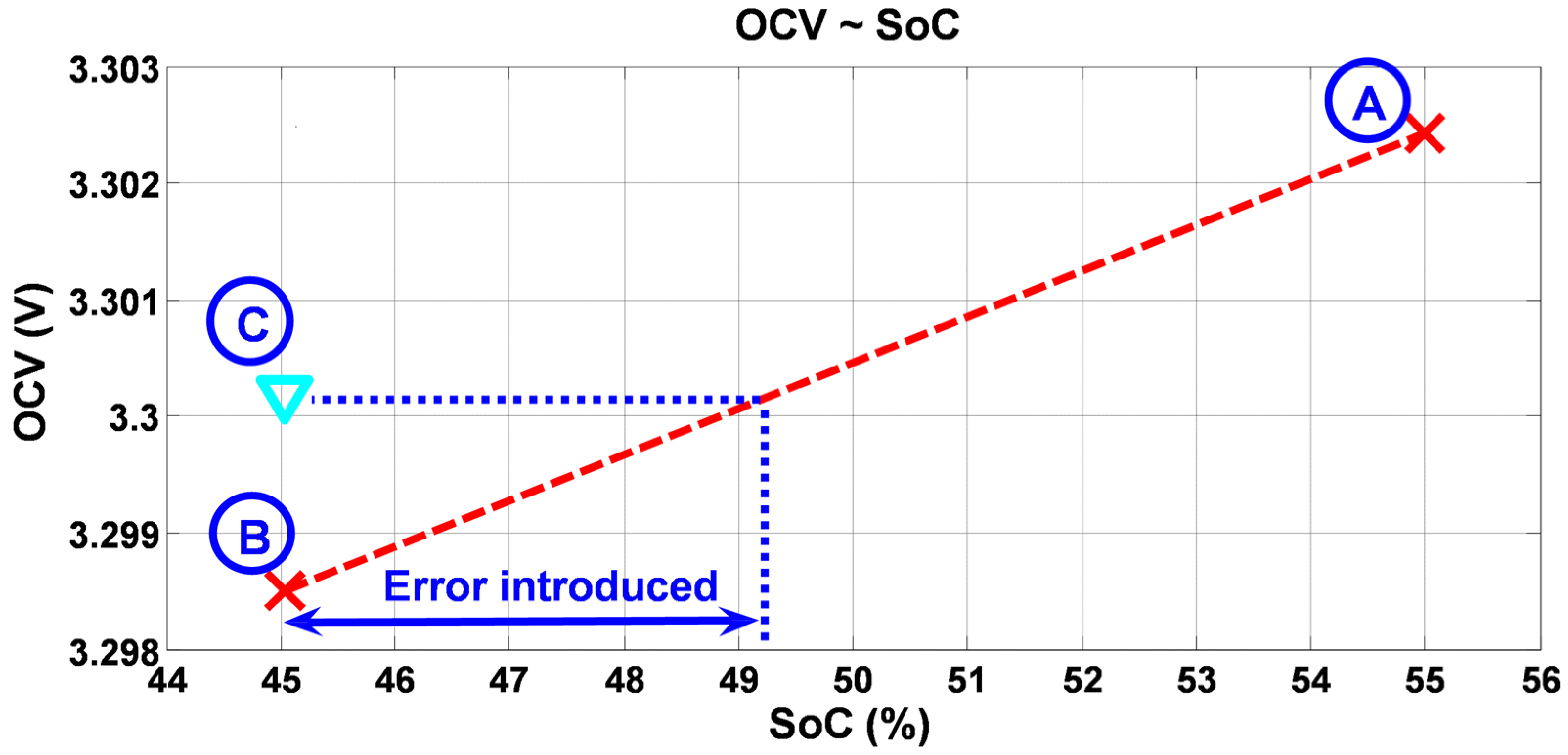

If the voltage variation during the relaxation is not taken into account in OCV estimation, error will be introduced into the estimation of SoC from the voltage. For example, as shown in

Figure 3, if the OCV-SoC curve approximated from the voltage measured after 1 h is used as the reference for estimating the SoC from the voltage measurement, the voltage increase during relaxation after discharge between 1 h and 24 h will introduce an overestimation of the SoC.

The characterization of the voltage change during long relaxation (e.g., 24 h) requires a long testing time. As the relaxation is dependent on the SoC, the measurements must be repeated at different SoCs. Yet, such extensive testing would put a heavy load on testing planning, and increase the testing costs. It is therefore interesting to reduce or adapt the measurement time of relaxation to the necessary desired precision. However, with a reduced measurement time, long-term change in voltage cannot be observed. The problem to solve is to reduce the measurement time of relaxation while maintaining the accuracy of the voltage final value.

In the literature, the problem of reducing the measurement time of relaxation has seldom been addressed. In [

2], a method of rapid testing was proposed for getting the OCV-SoC curve. However, slow variation of the voltage during the relaxation phase is not fully taken into consideration in this method. Several extrapolation methods of the battery relaxation voltage are proposed in two patents and one paper: Patents [

3,

4] used an analytical relaxation law to estimate the OCV and SoC of the battery when the battery is not in steady state. Reference [

5] used an original equivalent circuit model of relaxation with parameters varying over time. However, all these proposed methods do not use conventional electrical circuits and may be problematic for embedded implementation. In [

6], a fast extrapolation method is proposed to estimate OCV-SoC by using 6 min of relaxation; however, the error of estimation is still 4 mV apart from the OCV obtained from 5 h of relaxation. In [

7], a similar method was used with 10 min of relaxation with an error of the order of 5 mV. As we could see further in this paper, an error of 2 mV in OCV-SoC curve could cause an important error in SoC estimation.

In this paper, a new method to characterize long relaxation voltage is proposed with an error of about 1 mV. This method uses the extrapolation of conventional electric circuit response and takes into consideration the slow voltage variation during relaxation. The principle of the method, illustrated in

Figure 4, comprises: (i) a full relaxation measurement (e.g., 24 h) for a single SoC to calibrate the method; (ii) several shorter relaxations (e.g., 1 h, 5 h) measured at various considered SoCs; and (iii) an extrapolation to a longer duration (the same as in i) for each previous measurement.

This paper is organized as follows.

Section 2 gives a mathematical description of relaxation by using an electrical model.

Section 3 describes a study of the long relaxation, which reveals the possibility of extrapolating the slow voltage behavior of the relaxation from a short and partial measurement.

Section 4 gives details on the proposed extrapolation method. The validation of the proposed method through both simulations and experiments is discussed in

Section 5;

Section 6 concludes the paper.

2. Mathematical Description of Relaxation

Several types of models can be used to represent the temporal behavior of the battery (e.g., electrochemical models [

8], equivalent circuit model [

9,

10], black box model [

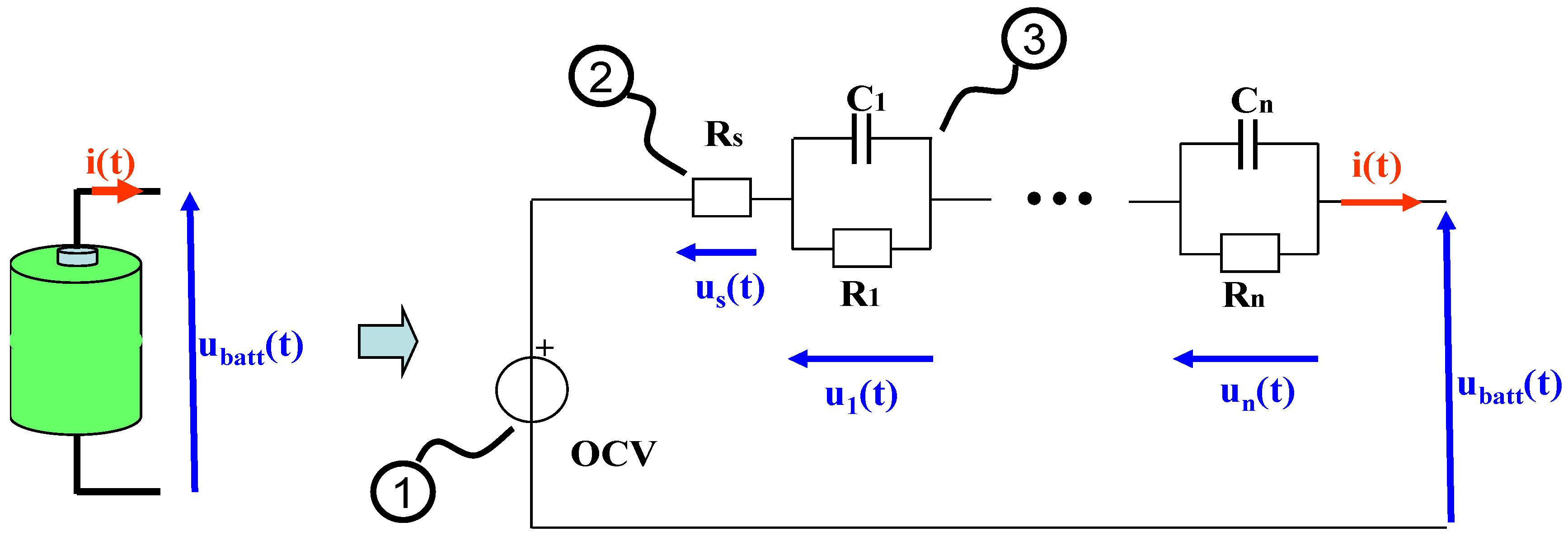

11]. In this paper, an equivalent circuit model is chosen to study the relaxation because it is simple, fast, robust, with a good compromise of accuracy/simplicity, suitable for the application of electrified vehicles, and is easily integrated into simulation software. The model used to represent the dynamic behavior of the battery is shown in

Figure 5. This model is composed of: (1) a voltage source to represent the OCV to a given SoC; (2) a resistance

Rs to represent the voltage drop; and (3) several

Ri//

Ci circuits in series to represent the forced regime and relaxation. All these parameters of the model are mainly dependent on the SoC, the temperature, the current (amplitude and direction), and the aging.

During the relaxation phase, as the current is zero, the voltage drop across the resistance

Rs is zero. However, voltage in individual

Ri//

Ci circuits is still dependent on time. By denoting

Ui_Relax the voltage drop on

Ri//

Ci at the beginning of relaxation, the voltage of the battery during relaxation can be expressed by:

where

URelax_init is the initial battery voltage at the beginning of relaxation (see (4) in

Figure 1) which can be measured directly;

t0 is the moment when the relaxation starts; and τ

i_Relax is the time constant of

Ri//

Ci circuit during relaxation with τ

1_Relax < τ

2_Relax < ··· < τ

n_Relax.

The OCV expression is given by:

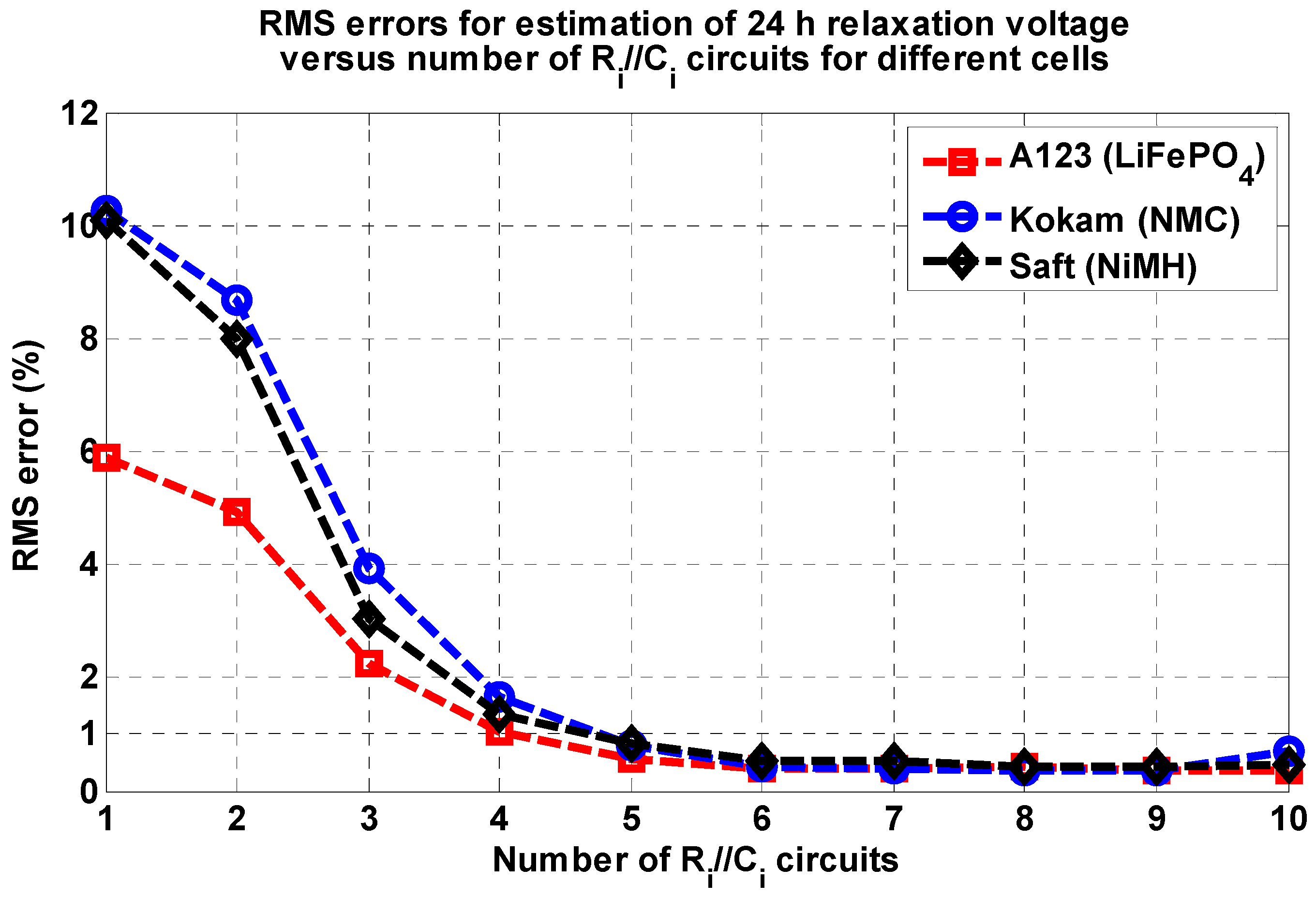

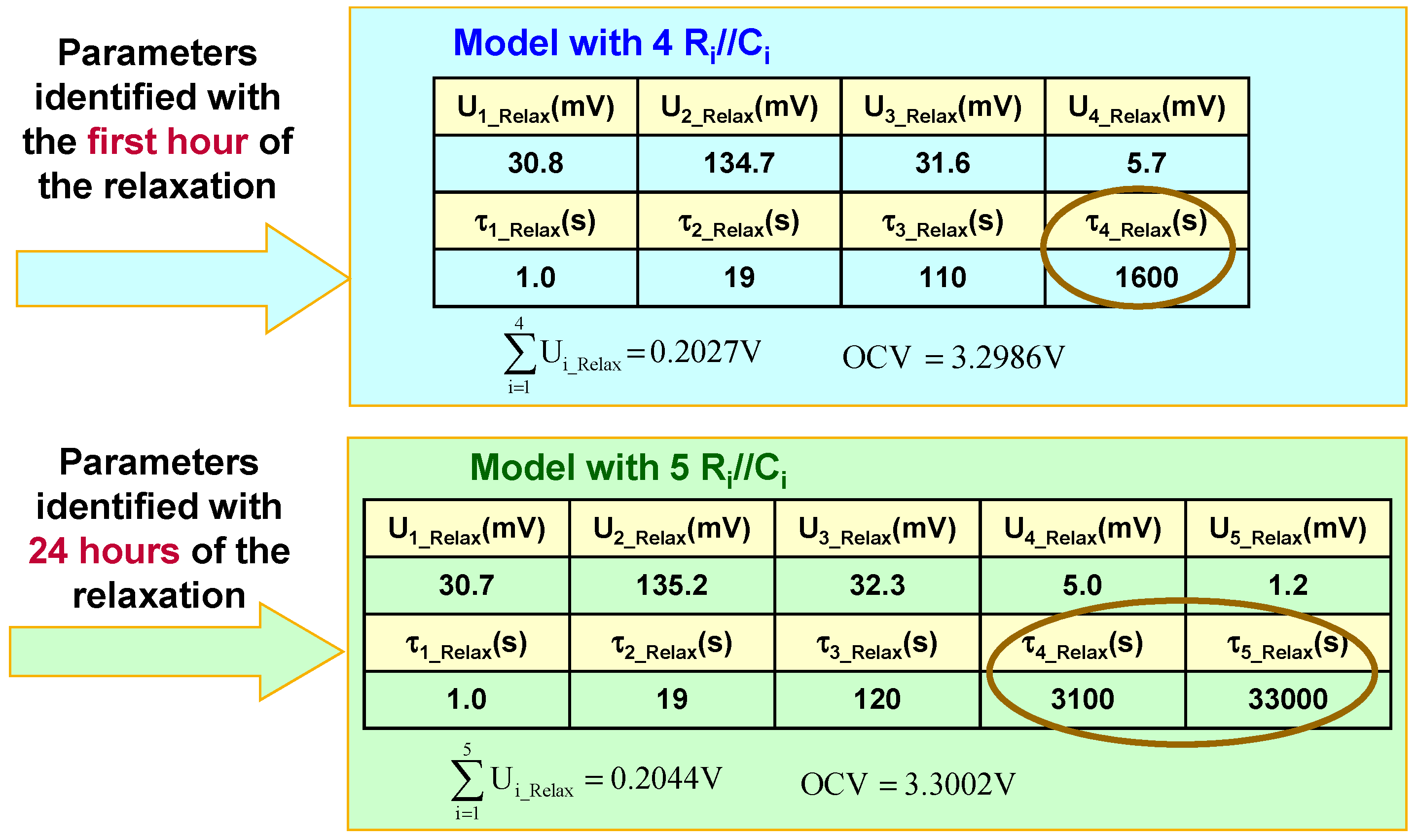

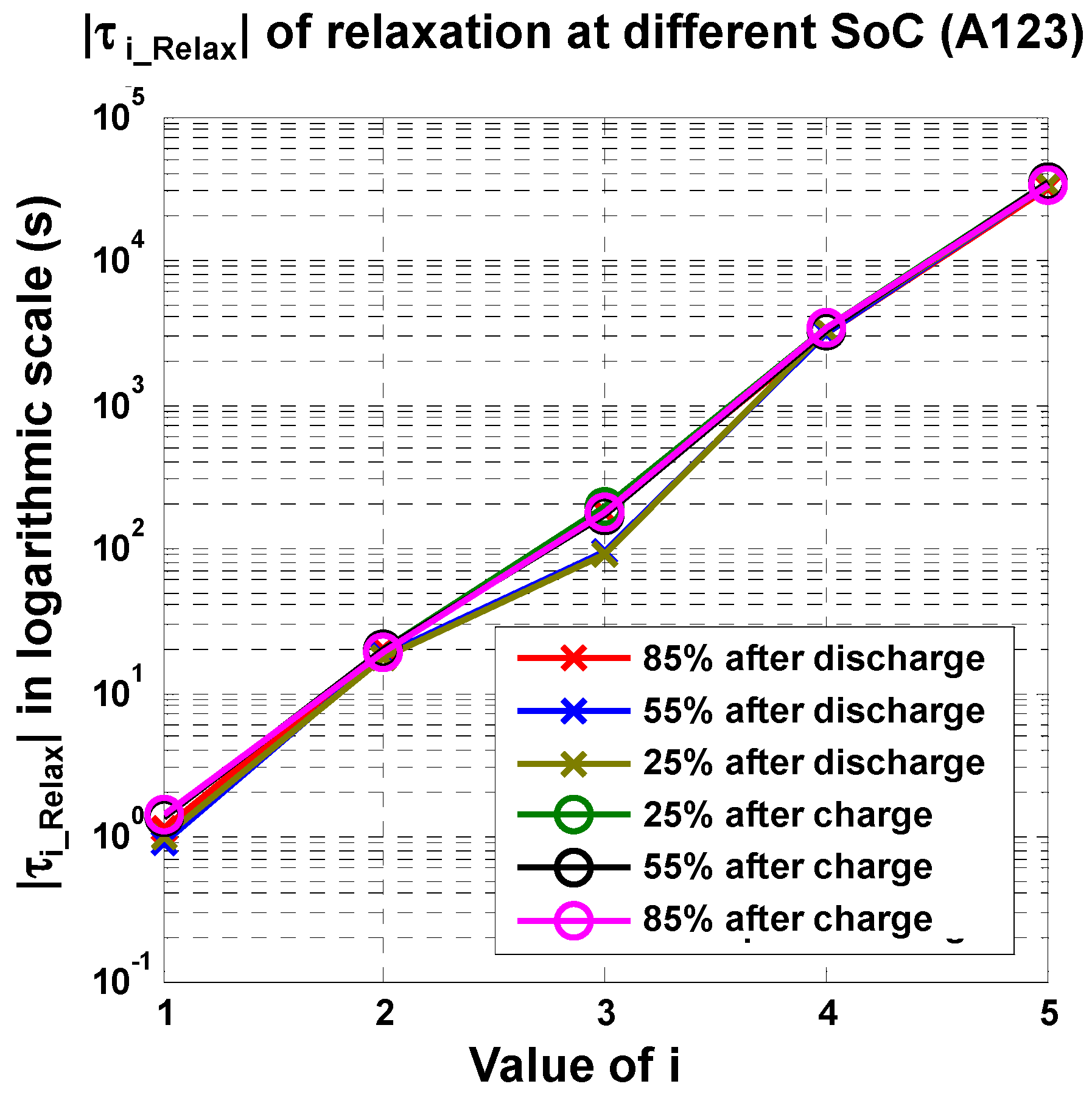

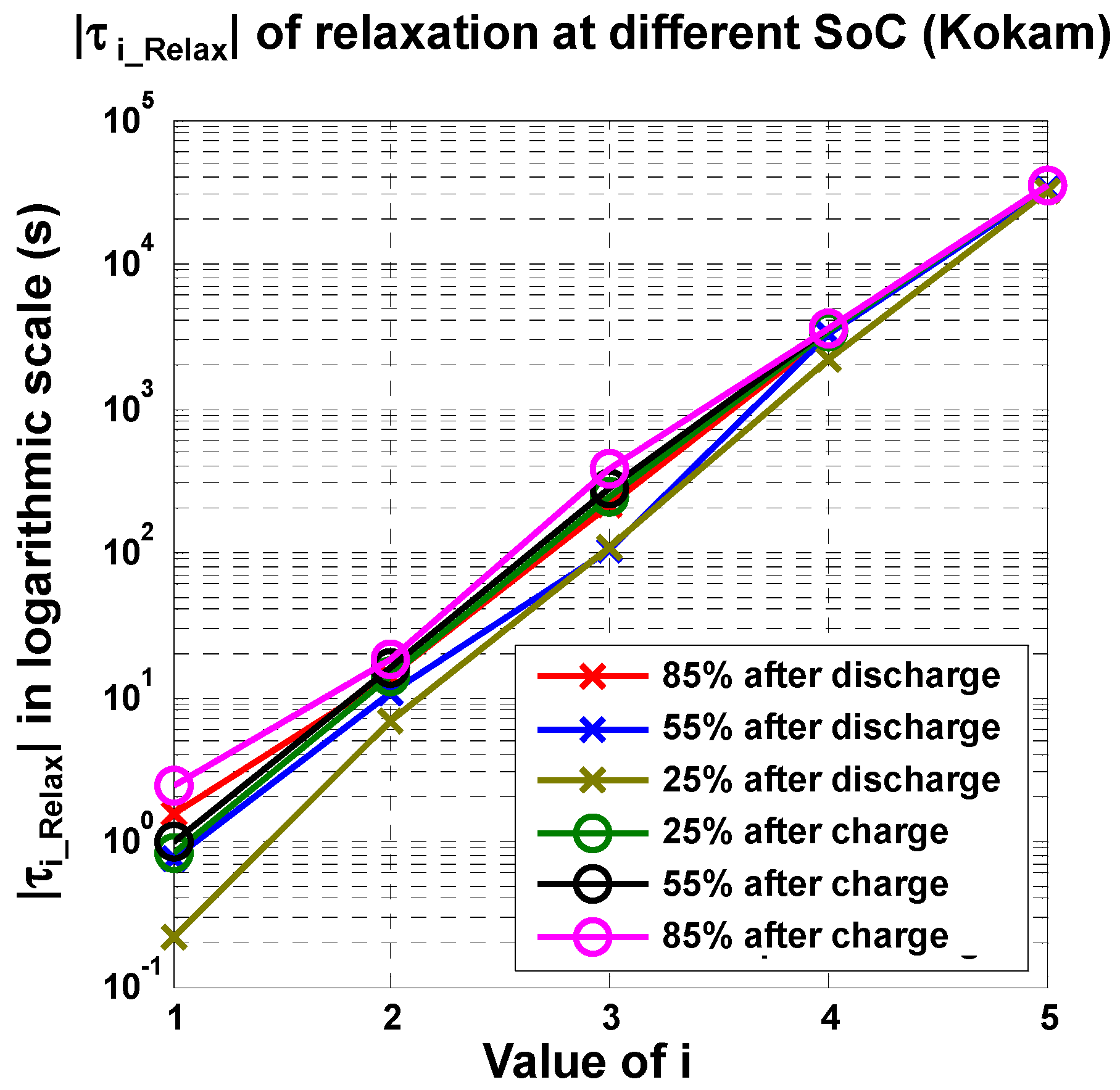

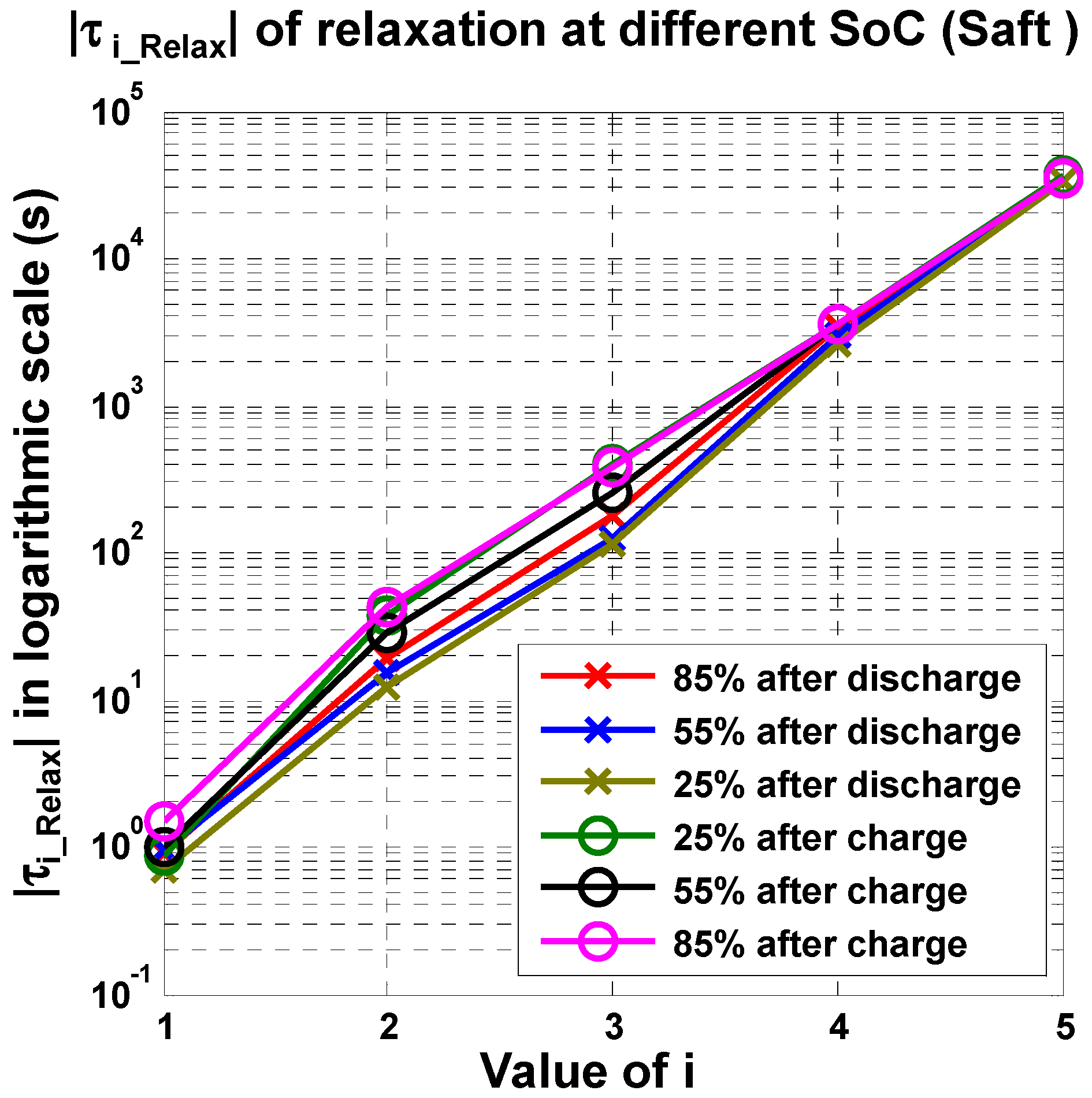

Finally, the unknown parameters to be identified for a relaxation are the number of Ri//Ci (n), the voltage drops on each circuit Ri//Ci at the beginning of relaxation (Ui_Relax), and the time constant of each circuit Ri//Ci during relaxation (τi_Relax).

In this work, the parameters of the model depend only on the SoC. All experiments presented in this paper were realized at an ambient temperature of 25 °C and with new cells.

The structure of the model in

Figure 5 is valid for both forced regime and relaxation phase. However, the values of parameters are different in each phase. The work of this paper focuses only on the relaxation phase.

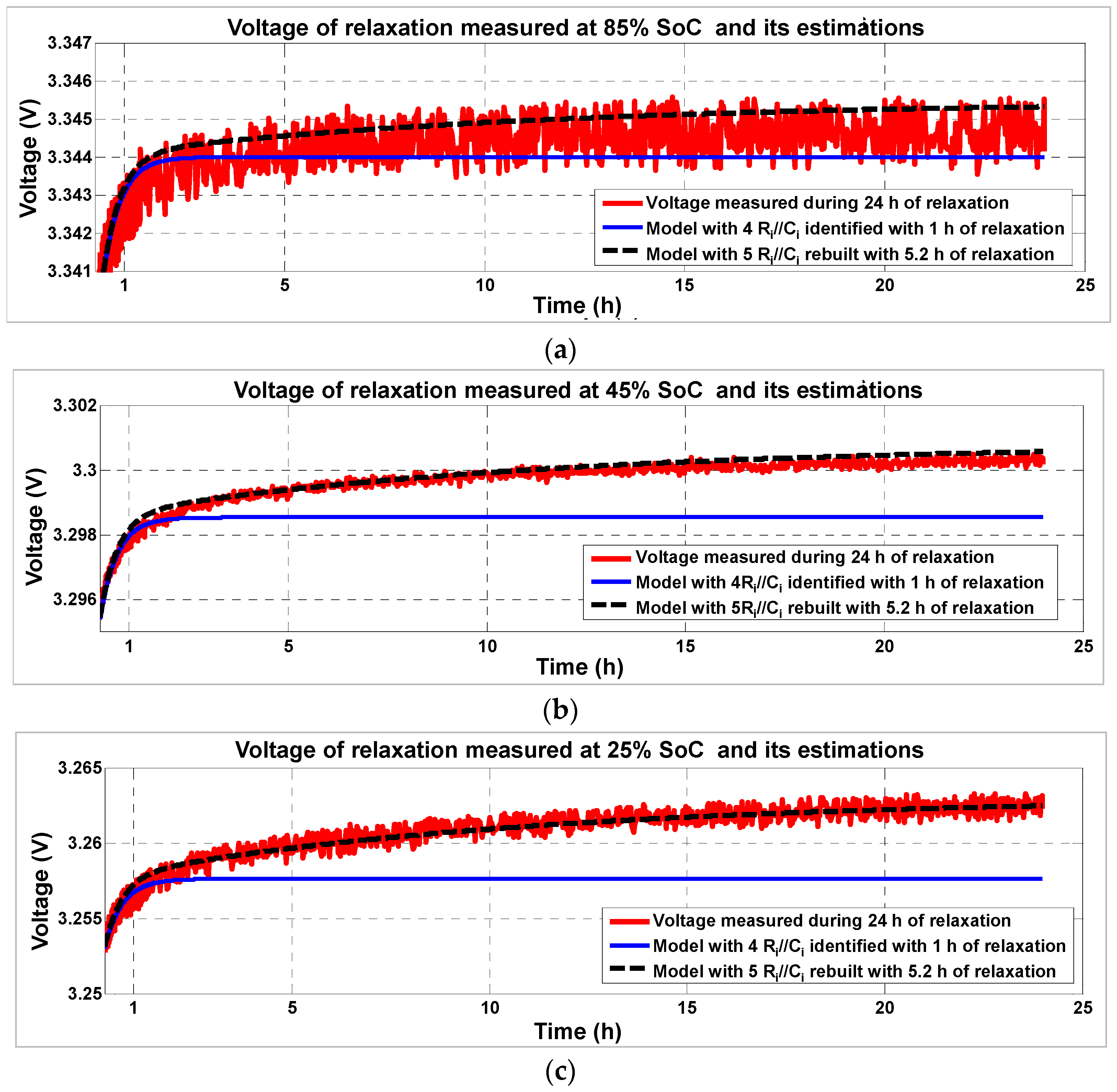

5. Validation Test

To evaluate the performance of the proposed method, a validation test was performed by using three relaxations of 24 h measured on the A123 cell. First, with the relaxation of 24 h at SoC of 45% (

Figure 11) and by choosing 0.5 mV as the acceptable accuracy, the minimum measurement duration (∆

tmin) is determined to be 5.2 h (

Figure 13). Second, with the measurements of the first 5.2 h of relaxation at SoC of 85%, 45%, and 25%, three models with five

Ri//

Ci were reconstructed. The performance of the reconstructed models to estimate relaxations of 24 h is shown in

Figure 17. The errors at the end of 24 h between the estimation of the reconstructed model and the measurement are −0.8 mV at SoC 85%, −0.2 mV at SoC 45% and 0.1 mV at SoC 25%. The result shows that the reconstructed models can accurately estimate the long relaxation during 24 h. Thus, to obtain the relaxations of 24 h at these three SoCs with the proposed method, it is only necessary to perform a measurement of 24 h of relaxation at 45% SoC and two measurements of 5.2 h at 85% and 25% SoC, in total 34.4 h of measurement. Compared to the conventional method, which requires 72 h of measurement (e.g., three measurements of 24 h for the three SoCs), the proposed method saves 37.6 h, which represents a gain of 52% in measurement time, without considering the setting of initial SoC for each test.

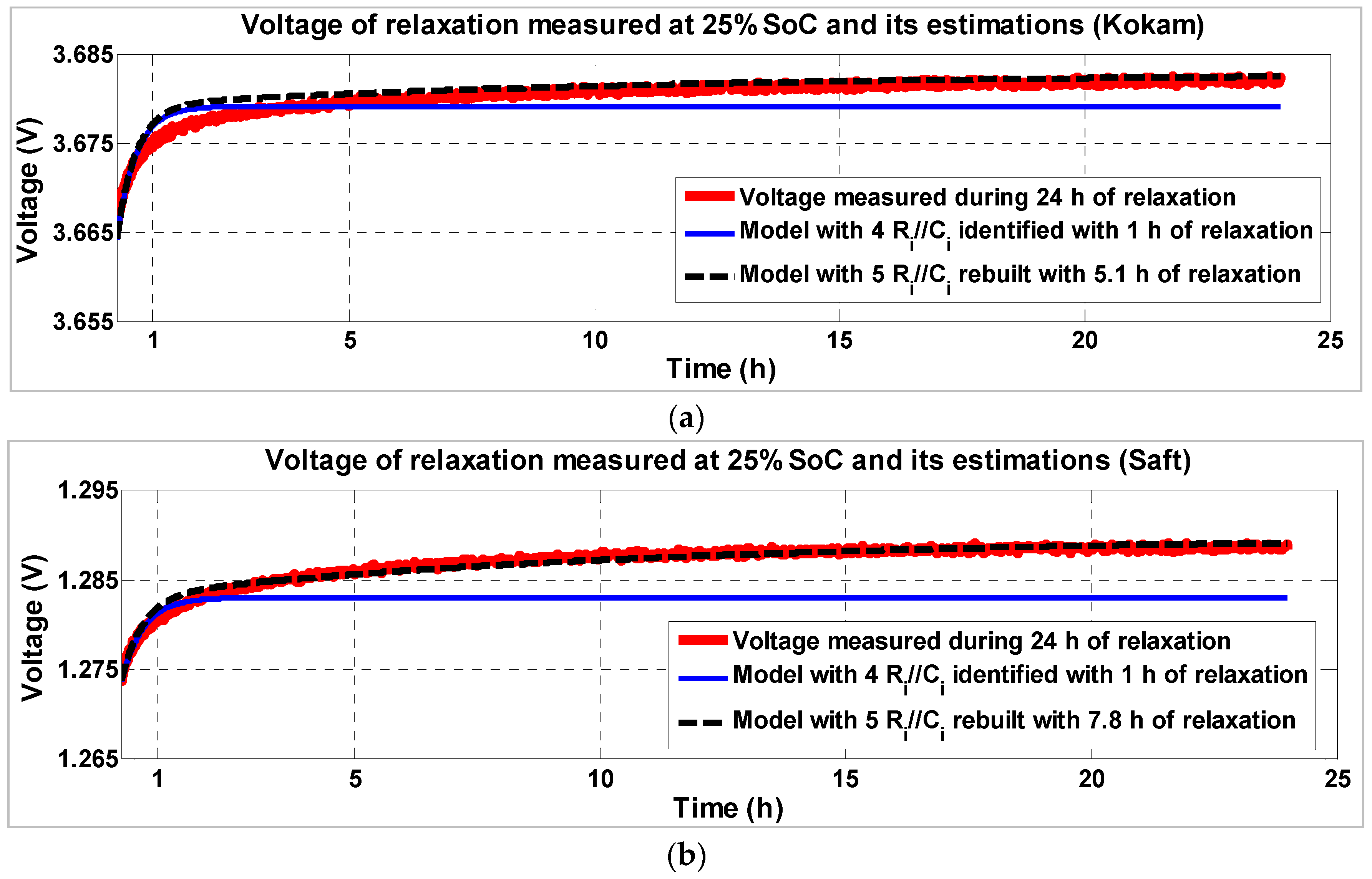

Validation tests were also conducted on two other technologies (NMC and NiMH). For example,

Figure 18 presents the result for estimation of relaxation voltage at 25% SoC for the two cells. By using the same acceptable accuracy as the A123 cell (0.5 mV), the minimum measurement duration (∆

tmin) is determined to be 5.1 h for the Kokam cell and 7.8 h for the Saft cell. The accurate estimation result in

Figure 18 shows that the proposed method is also applicable to these two technologies.

6. Conclusions

A fast characterization method to determine the full relaxation response of a battery (e.g., 24 h) has been proposed in this paper. This method allows for reconstructing an electric circuit model that is capable of correctly estimating the voltage relaxation. Only one complete measurement of the voltage relaxation at one SoC is needed to calibrate the method. For other SoCs, only a shorter measurement duration (e.g., about 5 h) is necessary. When compared with a step-by-step charging and discharging protocol (ΔSoC = 5% with 3 h of rest at each step) to determine the OCV (SoC) curve like in [

1], the present method has the following advantages: besides giving the OCV (SoC) curve it enables us to compute the variation of the output voltage during relaxation. Furthermore, if one wants to estimate 24 h of relaxation with a step-by-step protocol, it could last 40 × 24 h (20 SoC levels during charging and 20 SOC levels during discharging), which represents 40 days of experiments. With our method, only one measurement of 24 h is necessary plus 40 measurements of 5 h, which represents only nine days of works. This method could save a lot of characterization time, which is very useful when tests are required at different temperatures and aging states. When the method is applied for relaxation after charge and discharge, the OCVs obtained could also bring out the hysteresis. Furthermore, it is generic so it could easily be extended to any technology of battery and adapted to longer or shorter relaxation durations.

This method could be applied to calculate the SoC of batteries in EVs from measurements of OCV. In that case, the curve OCV (SoC) stored in the on-board computer and used to calculate the SoC is usually determined after a specified relaxation time (e.g., 24 h). The proposed model of relaxation voltage can be used to accurately predict the OCV and thus the SoC at the specified time without waiting for it. On the other hand, when the curve OCV (SoC) stored in the on-board computer is determined after a short relaxation time (e.g., 1 h), the proposed model of relaxation voltage can be used to go back in time. For example, when the vehicle has been parked for a longer time (e.g., 24 h), the value of OCV at 1 h, and thus the SoC can be determined from the measured value of OCV at 24 h.