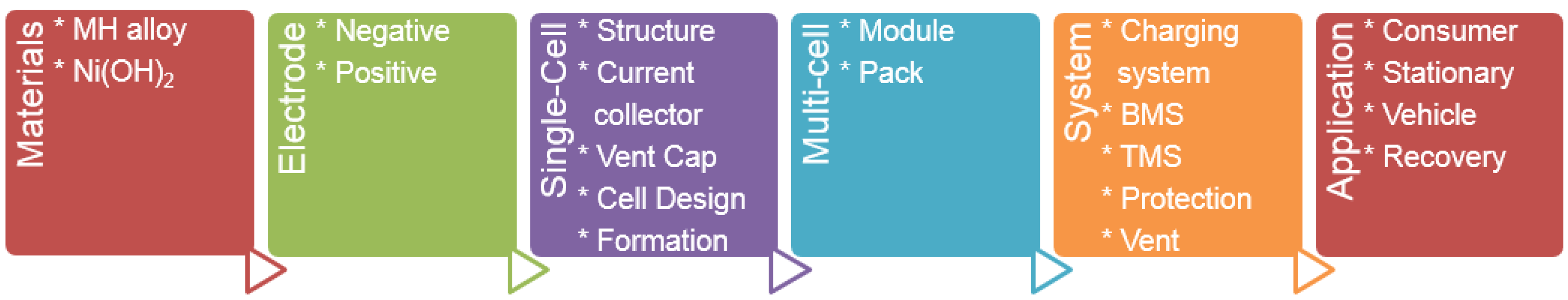

Reviews on the U.S. Patents Regarding Nickel/Metal Hydride Batteries

Abstract

:1. Introduction

2. Results

2.1. Active Materials

2.1.1. Metal Hydride Alloys in the Negative Electrode

2.1.2. Nickel Hydroxide in the Positive Electrode

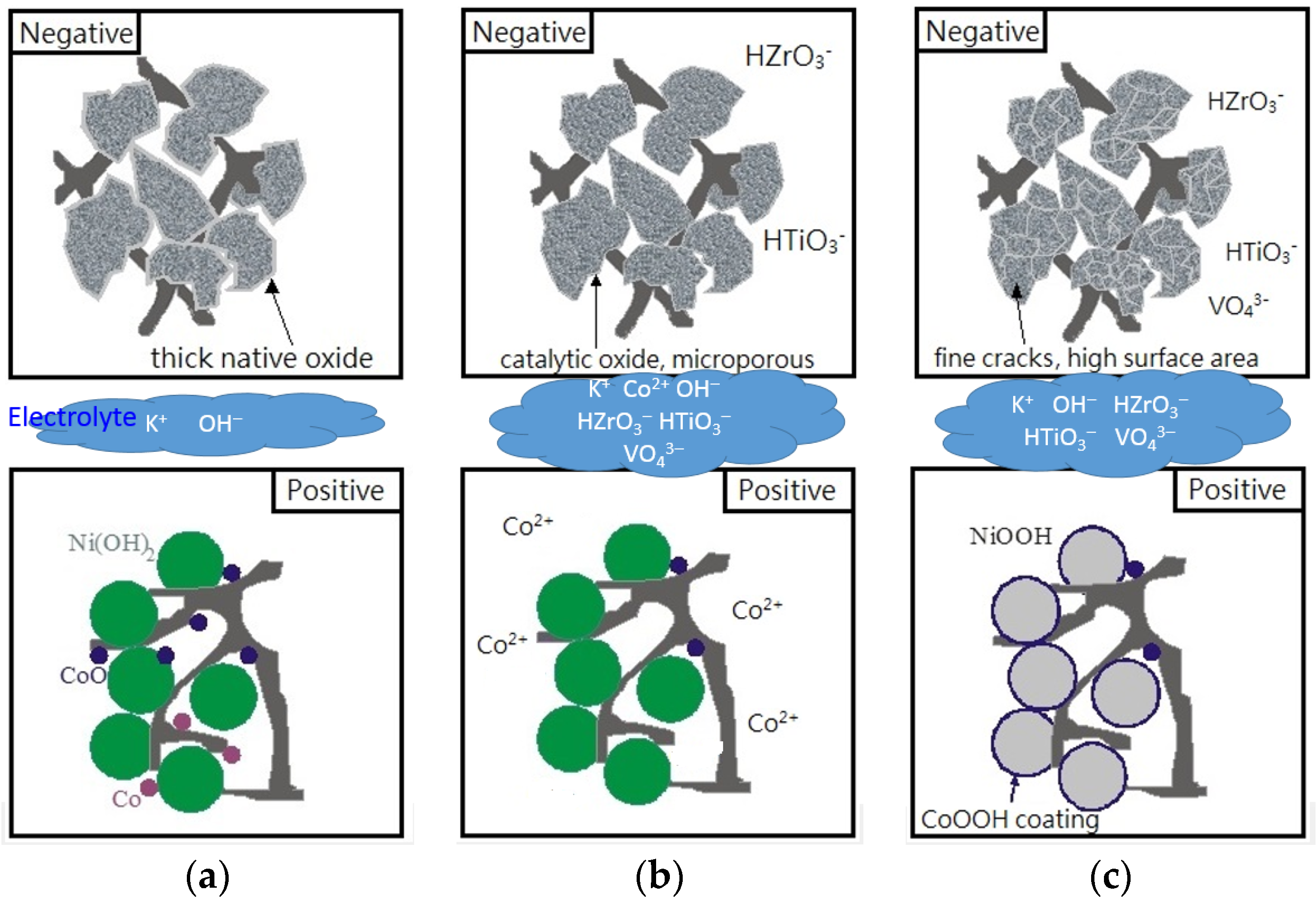

2.2. Electrode Fabrication

2.2.1. Negative Electrode (Anode)

2.2.2. Positive Electrode (Cathode)

2.3. Cell Assembly

2.3.1. Cell Construction

2.3.2. Current Collector

2.3.3. Other Components

2.3.4. Cell Design

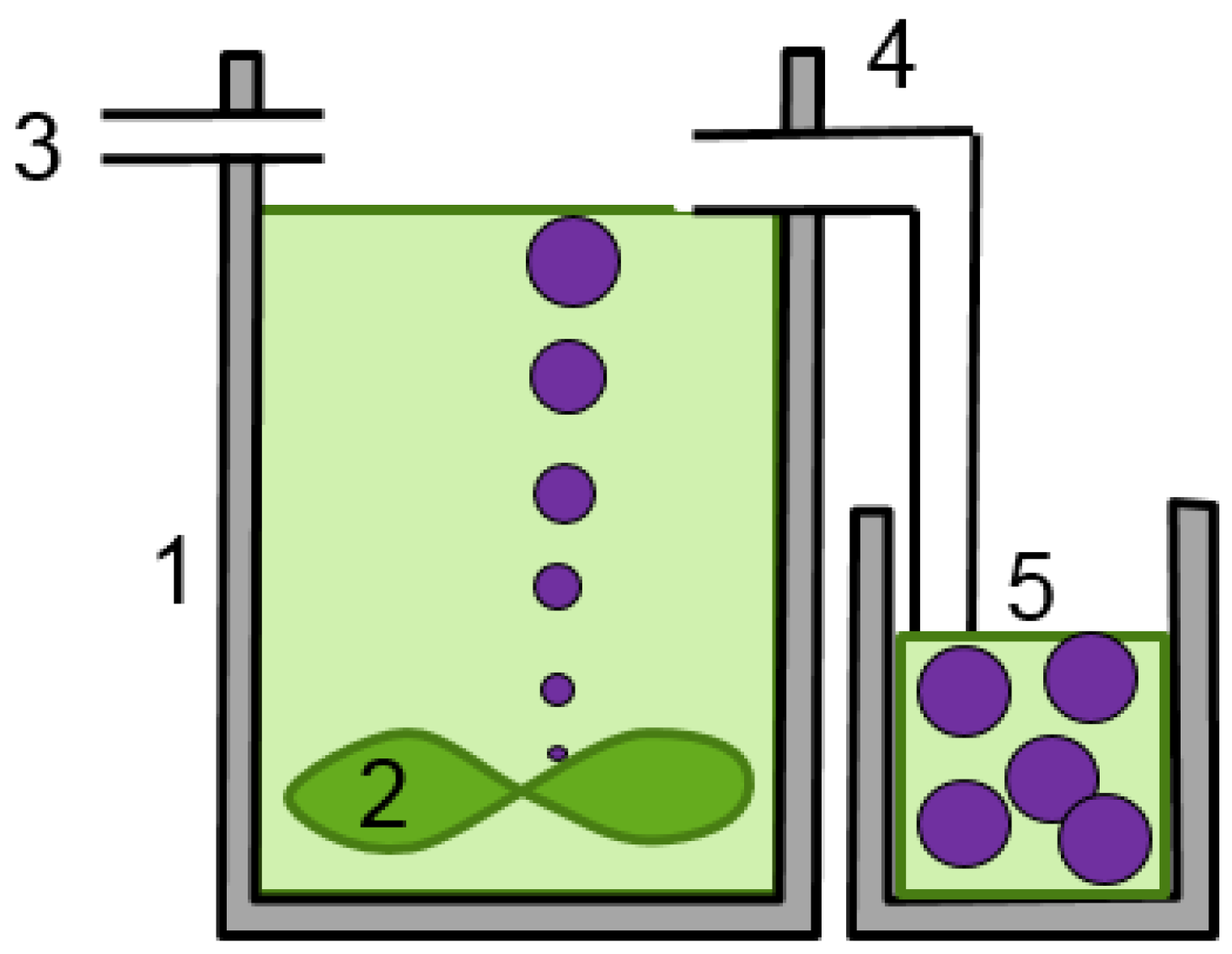

2.3.5. Formation Process

2.4. Multi-Cell Construction

2.4.1. Module Assembly

2.4.2. Pack Assembly

2.5. System Integration

2.5.1. Charging System

2.5.2. Battery Management System

2.5.3. Protection System

2.5.4. Thermal Management System

2.6. Others

2.6.1. Application

2.6.2. Revivification and Recycling

3. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| Ni/MH | Nickel/metal hydride |

| MH | Metal hydride |

| OBC | Ovonic Battery Company |

| FCC | Face-centered-cubic |

| 1C/1C | 1C charge and discharge rates |

| DOD | Depth of discharge |

| BCC | Body-centered-cubic |

| NPPS | Ni-plated perforated steel |

| ECD | Energy conversion devices |

| SS | Stainless steel |

| EV | Electric vehicle |

| HEV | Hybrid electric vehicle |

| OCR | Overcharge reservoir |

| ODR | Overdischarge reservoir |

| N/P | Negative-to-positive ratio |

| SOC | State of charge |

| BMS | Battery management system |

| TMS | Thermal management system |

| ΔT | Temperature change |

| −ΔV | Negative voltage change |

| dV/dt | Voltage change with time |

| dT/dt | Temperature change with time |

| Vt | Terminal voltage |

| SOH | State of health |

| UPS | Uninterrupted power supply |

References

- Sakai, T. Secondary Battery with Hydrogen Storage Alloys. In Hydrogen Storage Alloys—Fundamentals and Frontier Technology; Tamura, H., Ed.; NTS Inc.: Tokyo, Japan, 1998; p. 411. [Google Scholar]

- Osumi, Y. Suiso Kyuzou Goukin; Agune Co. Ltd.: Tokyo, Japan, 1999; pp. 473–507. [Google Scholar]

- Kleperis, J.; Wójcik, G.; Czerwinski, A.; Skowronski, J.; Kopczyk, M.; Beltowska-Brzezinska, M. Electrochemical behavior of metal hydride. J. Solid State Electrochem. 2001, 5, 229–249. [Google Scholar] [CrossRef]

- Feng, F.; Geng, M.; Northwood, D.O. Electrochemical behaviour of intermetallic-based metal hydrides used in Ni/metal hydride (MH) batteries: A review. Int. J. Hydrog. Energy 2001, 26, 725–734. [Google Scholar] [CrossRef]

- Hong, K. The development of hydrogen storage electrode alloys for nickel hydride batteries. J. Power Sources 2001, 96, 85–89. [Google Scholar] [CrossRef]

- Cuevas, F.; Joubert, J.M.; Latroche, M.; Percheron-Guégan, A. Intermetallic compounds as negative electrodes of Ni/MH batteries. Appl. Phys. A 2001, 72, 225–238. [Google Scholar] [CrossRef]

- Petrii, O.A.; Levin, E.E. Hydrogen-accumulating materials in electrochemical systems. Russ. J. Gen. Chem. 2007, 77, 790–796. [Google Scholar] [CrossRef]

- Zhao, X.; Ma, L. Recent progress in hydrogen storage alloys for nickel/metal hydride secondary batteries. Int. J. Hydrog. Energy 2009, 34, 4788–4796. [Google Scholar] [CrossRef]

- Liu, Y.; Pan, H.; Gao, M.; Wang, Q. Advanced hydrogen storage alloys for Ni/MH rechargeable batteries. J. Mater. Chem. 2011, 21, 4743–4755. [Google Scholar] [CrossRef]

- Young, K.; Nei, J. The current status of hydrogen storage alloy development for electrochemical applications. Materials 2013, 6, 4574–4608. [Google Scholar] [CrossRef]

- Young, K. Electrochemical Applications of Metal Hydrides. In Compendium of Hydrogen Energy; Barbir, F., Basile, A., Veziroğlu, T.N., Eds.; Woodhead Publishing Ltd.: Cambridge, UK, 2015; Volume 3, pp. 289–304. [Google Scholar]

- Oliva, P.; Leonardi, J.; Laurent, J.F.; Delmas, C.; Braconnier, J.J.; Figlarz, M.; Fievet, F.; Guibert, A.C. Review of the structure and the electrochemistry of nickel hydroxide and oxy-hydroxides. J. Power Sources 1982, 8, 229–255. [Google Scholar] [CrossRef]

- Barton, R.T.; Mitchell, P.J.; Hampson, N.A. The electrotechnology of the nickel positive electrode: A review of the recent literature. Surf. Coat. Technol. 1986, 28, 1–9. [Google Scholar] [CrossRef]

- Yuan, A.; Zhang, J.; Cao, C. Research progress of nickel hydroxide electrodes. Chin. J. Power Sources 2001, 25, 53–59. [Google Scholar]

- Vidotti, M.; Torresi, R.; Torresi, S.I. Nickel hydroxide modified electrodes: A review study concerning its structural and electrochemical properties aiming the application in electrocatalysis, electrochromism and secondary batteries. Quim. Nova 2010, 33, 2176–2186. [Google Scholar] [CrossRef]

- Hall, D.S.; Lockwood, D.J.; Bock, C.; McDougall, B.R. Nickel hydroxides and related materials: A review of their structures, synthesis and properties. Proceed. R. Soc. A Math. Phys. Eng. Sci. 2015, 471. [Google Scholar] [CrossRef] [PubMed]

- Ouchi, T.; Young, K.; Moghe, D. Reviews on the Japanese patent applications regarding nickel/metal hydride batteries. Batteries 2016, 2. [Google Scholar] [CrossRef]

- Beccu, K. Electrical Accumulator with a Metal Hydride Serving as the Cathodic Reactive Material Arranged in Suspension in the Electrolyte. U.S. Patent 3,520,728, 14 July 1970. [Google Scholar]

- Beccu, K. Accumulator Electrode with Capacity for Strong Hydrogen and Method of Manufacturing Said Electrode. U.S. Patent 3,669,745, 13 June 1972. [Google Scholar]

- Ikoma, M.; Kawano, H.; Matsumoto, I.; Yanagihara, N. Sealed Storage Battery and Method for Making Its Electrode. U.S. Patent 4,837,119, 6 June 1989. [Google Scholar]

- Ikoma, M.; Kawano, H.; Takahashi, O.; Matsumoto, I.; Ikeyama, M. Alkaline Storage Battery Using Hydrogen Absorbing Alloy. U.S. Patent 4,925,748, 15 May 1990. [Google Scholar]

- Ikoma, M.; Kawano, H.; Ito, Y.; Matsumoto, I. Sealed Type Nickel-Hydride Battery and Production Process Thereof. U.S. Patent 4,935,318, 19 June 1990. [Google Scholar]

- Hasebe, H.; Takeno, K.; Mitsuyasu, K.; Sato, Y.; Takahashi, H.; Hayashida, H.; Sawatari, I.; Ishiwa, K.; Hata, K.; Yoshida, K.; et al. Nickel-Metal Hydride Secondary Cell. U.S. Patent 5,032,475, 16 July 1991. [Google Scholar]

- Yamano, M.; Sakai, T.; Furukawa, N.; Murakami, S.; Matsumoto, T. Metal/Hydrogen Alkaline Storage Battery. U.S. Patent 4,636,445, 13 January 1987. [Google Scholar]

- Nakahori, S.; Honda, H. Method of Manufacturing Nickel Hydroxide Electrode for Alkaline Storage Cell. U.S. Patent 4,844,948, 4 July 1989. [Google Scholar]

- Oshitani, M.; Hasegawa, K.; Yufu, H. Alkaline Battery with a Nickel Electrode. U.S. Patent 4,985,318, 15 January 1991. [Google Scholar]

- Willems, J.J.G.; Buschow, K.H.J. From permanent magnets to rechargeable hydride electrodes. J. Less Comm. Met. 1987, 129, 13–30. [Google Scholar] [CrossRef]

- Born Guegen, A.P.; Achard, J.C.; Loriers, J.; Bonnemay, M.; Bronoёl, G.; Sarradin, J.; Schlapbach, L. Electrode Materials Based on Lanthanum and Nickel, and Electrochemical Uses of Such Materials. U.S. Patent 4,107,405, 15 August 1978. [Google Scholar]

- Willems, J.J.G.S.A.; van Beek, J.R.G.C.M.; Buschow, K.H.J. Electrochemical Cell Comprising Stable Hydride-Forming Material. U.S. Patent 4,487,817, 11 December 1984. [Google Scholar]

- Osumi, Y.; Suzuki, H.; Kato, A.; Nakane, M.; Miyake, Y. Alloy for Occlusion of Hydrogen. U.S. Patent 4,147,536, 3 April 1979. [Google Scholar]

- Osumi, Y.; Suzuki, H.; Kato, A.; Oguro, K.; Nakane, N. Alloy for Occlusion of Hydrogen. U.S. Patent 4,396,576, 2 August 1983. [Google Scholar]

- Kanda, M.; Sato, Y. Hermetically Sealed Metallic Oxide-Hydrogen Battery Using Hydrogen Storage Alloy. U.S. Patent 4,605,603, 12 August 1986. [Google Scholar]

- Mori, H.; Hasegawa, K.; Watada, M.; Oshitani, M. Metal Hydride Electrode. U.S. Patent 5,393,616, 28 February 1995. [Google Scholar]

- Hasebe, H.; Inada, S.; Isozaki, Y.; Inaba, T.; Sawa, T.; Horie, H.; Yagi, N.; Shizu, H.; Kanazawa, Y. Hydrogen-absorbing Alloy for Battery, Method of Manufacturing the Same, and Secondary Nickel-Metal Hydride Battery. U.S. Patent 5,843,372, 1 December 1998. [Google Scholar]

- Hirosawa, T.; Ikemachi, T. Hydrogen Storage Alloy Electrode and Manufacturing Method of the Same. U.S. Patent 5,766,792, 16 June 1998. [Google Scholar]

- Hazama, T. Hydrogen Absorbing Electrode for Use in Nickel-Metal Hydride Secondary Batteries. U.S. Patent 5,284,619, 8 February 1994. [Google Scholar]

- Lichtenberg, F. Alloys for Use as Active Material for the Negative Electrode of an Alkaline, Rechargeable Nickel-Metal Hydride Battery, and Process for Its Production. U.S. Patent 5,738,958, 14 April 1998. [Google Scholar]

- Ohyama, H.; Nakatsuji, K.; Kikuyama, S.; Dansui, Y. Negative Electrode Material for Nickel-Metal Hydride Battery and Treatment Method Thereof, and Nickel-Metal Hydride Battery. U.S. Patent 8,202,650, 19 June 2012. [Google Scholar]

- Kojima, Y.; Ikeda, H.; Furukawa, S.; Sugiyama, K.; Kobayashi, N. Hydrogen-Absorbing Alloy and Electrode for Nickel-Metal Hydride Secondary Batteries. U.S. Patent 8,377,374, 19 February 2013. [Google Scholar]

- Young, K.; Fetcenko, M.A.; Huang, B.; Chao, B. NdNi5 Alloys for Hydrogen Storage and Ni-MH Batteries. U.S. Patent 8,968,644, 3 March 2015. [Google Scholar]

- Ito, S.; Sakamoto, H. Nickel-Metal Hydride Battery. U.S. Patent 8,119,284, 21 February 2012. [Google Scholar]

- Lv, H. High-Temperature Ni-MH Battery and a Method for Making the Same. U.S. Patent 6,689,514, 10 February 2004. [Google Scholar]

- Fetcenko, M.A.; Young, K.; Ovshinsky, S.R.; Ouchi, T. Hydrogen Storage Alloys Having Improved Cycle Life and low Temperature Operating Characteristics. U.S. Patent 7,393,500, 1 July 2008. [Google Scholar]

- Gamo, T.; Moriwaki, Y.; Yamashita, T.; Fukuda, M. Method of Making a Hydrogen Storage Alloy and Product. U.S. Patent 4,144,103, 13 March 1979. [Google Scholar]

- Sapru, K.; Hong, K.; Fetcenko, M.A.; Venkatesan, S. Hydrogen Storage Materials and Methods of Sizing and Preparing the Same for Electrochemical Applications. U.S. Patent 4,551,400, 5 November 1985. [Google Scholar]

- Venkatesan, S.; Reichman, B.; Fetcenko, M.A. Enhanced Charge Retention Electrochemical Hydrogen Storage Alloys and an Enhanced Charge Retention Electrochemical Cell. U.S. Patent 4,728,586, 1 March 1988. [Google Scholar]

- Fetcenko, M.A.; Ovshinsky, S.R. Catalytic Hydrogen Storage Electrode Materials for Use in Electrochemical Cells and Electrochemical Cells Incorporating the Materials. U.S. Patent 5,104,617, 14 April 1992. [Google Scholar]

- Fetcenko, M.A.; Ovshinsky, S.R. Metastable Hydrogen Storage Alloy Material. U.S. Patent 5,135,589, 4 August 1992. [Google Scholar]

- Fetcenko, M.A.; Ovshinsky, S.R.; Kajita, K. Electrode Alloy Having Decreased Hydrogen Overpressure and/or Low Self-Discharge. U.S. Patent 5,238,756, 24 August 1993. [Google Scholar]

- Fetcenko, M.A.; Ovshinsky, S.R. Metal Hydride Cells Having Improved Cycle Life and Charge Retention. U.S. Patent 5,330,861, 19 July 1994. [Google Scholar]

- Ovshinsky, S.R.; Fetcenko, M.A. Electrochemical Hydrogen Storage Alloys and Batteries fabricated from These Alloys Having Significantly Improved Capacity. U.S. Patent 5,407,761, 18 April 1995. [Google Scholar]

- Fetcenko, M.A.; Ovshinsky, S.R.; Chao, B.S.; Reichman, B. Electrochemical Hydrogen Storage Alloys for Nickel Metal Hydride Batteries. U.S. Patent 5,536,591, 16 July 1996. [Google Scholar]

- Ovshinsky, S.R.; Fetcenko, M.A.; Im, J.S.; Young, K.; Chao, B.S.; Reichman, B. Hydrogen Storage Materials Having a High Density of Non-Conventional Useable Hydrogen Storing Sites. U.S. Patent 5,840,440, 24 November 1998. [Google Scholar]

- Fetcenko, M.A.; Young, K.; Ovshinsky, S.R.; Reichman, B.; Koch, J.; Mays, W. Modified Electrochemical Hydrogen Storage Alloy Having Increased Capacity, Rate Capability and Catalytic Activity. U.S. Patent 6,270,719, 7 August 2001. [Google Scholar]

- Fetcenko, M.A.; Young, K.; Fierro, C. Hydrogen Storage Battery and Methods for Making. U.S. Patent 6,593,024, 15 July 2003. [Google Scholar]

- Seri, H.; Yamamura, Y.; Tsuji, Y.; Moriwaki, Y.; Iwaki, T. Hydrogen Storage Alloy Electrodes. U.S. Patent 5,468,309, 21 November 1995. [Google Scholar]

- Tsuji, Y.; Yamamoto, O.; Yamamura, Y.; Seri, H.; Toyoguchi, Y. Hydrogen Storage Alloy and Electrode Therefrom. U.S. Patent 5,753,054, 19 May 1998. [Google Scholar]

- Izumi, Y.; Moriwaki, Y.; Yamashita, K.; Tokuhiro, T. Nickel-Metal Hydride Storage Battery and Alloy for Configuring Negative Electrode of the Same. U.S. Patent 5,962,156, 5 October 1999. [Google Scholar]

- Knosp, B.; Bouet, J.; Jordy, C.; Mimoun, M.; Gicquel, D. Hydridable Material for the Negative Electrode in a Nickel-Metal Hydride Storage Battery. U.S. Patent 5,626,987, 6 May 1997. [Google Scholar]

- Iba, H.; Akiba, E. Hydrogen-Absorbing Alloy. U.S. Patent 5,968,291, 19 October 1999. [Google Scholar]

- Iba, H.; Akiba, E. Hydrogen-Absorbing Alloy and Process for Preparing the Same. U.S. Patent 6,153,032, 28 November 2000. [Google Scholar]

- Nichimura, K.; Yano, M.; Nakamura, H.; Hamasaki, K.; Tokuda, M.; Itoh, Y. Nickel-Metal Hydride Storage Battery. U.S. Patent 6,632,567, 14 October 2003. [Google Scholar]

- Tsukahara, M.; Takahashi, K.; Mishima, T.; Isomura, A.; Sakai, T.; Miyamura, H.; Uehara, I. Hydrogen-Occluding Alloy and Hydrogen-Occluding Alloy Electrode. U.S. Patent 5,690,799, 25 November 1997. [Google Scholar]

- Tsukahara, M.; Takahashi, K.; Mishima, T.; Isomura, A.; Sakai, T.; Miyamura, H.; Uehara, I. Hydrogen-Occluding Alloy and Hydrogen-Occluding Alloy Electrode. U.S. Patent 5,776,626, 7 July 1998. [Google Scholar]

- Ovishinsky, S.R.; Fetcenko, M.A. Electrochemical Hydrogen Storage Alloys and Batteries Fabricated from Mg Containing Base Alloy. U.S. Patent 5,506,069 A, 9 April 1996. [Google Scholar]

- Ovishinsky, S.R.; Fetcenko, M.A.; Reichman, B.; Young, K.; Chao, B.; Im, J. Electrochemical Hydrogen Storage Alloys and Batteries Fabricated from Mg Containing Base Alloys. U.S. Patent 5,616,432 A, 1 April 1997. [Google Scholar]

- Fetcenki, M.A.; Young, K.; Ouchi, T.; Reinhout, M.; Ovshinsky, S.R. Mg-Ni Hydrogen Storage Composite Having High Storage Capacity and Excellent Room Temperature Kinetics. U.S. Patent 7,211,541, 1 May 2007. [Google Scholar]

- Ovshinsky, S.R.; Fetcenko, M.A.; Im, J.; Chao, B.; Reichman, B.; Young, K. Electrochemical Hydrogen Storage Alloys and Batteries Containing Heterogeneous Powder Particles. U.S. Patent 5,554,456, 10 September 1996. [Google Scholar]

- Ting, J.; Habel, U.; Peretti, M.W.; Eisen, W.B.; Young, R.; Chao, B.; Huang, B. Electrochemical Hydrogen Storage Alloys for Nickel Metal Hydride Batteries, Fuel Cells and Methods of Manufacturing Same. U.S. Patent 6,500,583, 31 December 2002. [Google Scholar]

- Komori, K.; Matsuda, H.; Toyoguchi, Y. Active Material for Hydrogen Storage Alloy Electrode and Method for Producing the Same. U.S. Patent 6,444,361, 3 September 2002. [Google Scholar]

- Arvidsson, J.; Carlström, R.; Hallén, H.; Löfgren, S. Powder Composition and Process for the Preparation Thereof. U.S. Patent 6,245,165, 12 June 2001. [Google Scholar]

- Hayashida, H.; Kitayama, H.; Yamamoto, M.; Inada, S.; Sakai, I.; Kono, T.; Yoshida, H.; Inaba, T.; Kanda, M. Nickel-Hydrogen Secondary Battery. U.S. Patent 6,200,705, 13 March 2001. [Google Scholar]

- Kakeya, T.; Kanemoto, M.; Kuzuhara, M.; Ozaki, T.; Watada, M.; Sakai, T. Hydrogen Storage Alloy, Hydrogen Storage Alloy Electrode, Secondary Battery, and Method for Producing Hydrogen Storage Alloy. U.S. Patent 8,343,660, 1 January 2013. [Google Scholar]

- Ozaki, T.; Sakai, T.; Kanemoto, M.; Kakeya, T.; Kuzuhara, M.; Watada, M. Hydrogen Absorbing Alloy, Production Method Thereof, and Secondary Battery. U.S. Patent 8,343,659, 1 January 2013. [Google Scholar]

- Kono, T.; Sakai, I.; Yoshida, H.; Inaba, T.; Yamamoto, M.; Takeno, S. Hydrogen-Absorbing Alloy, Electrode and Secondary Battery. U.S. Patent 6,214,492, 10 April 2001. [Google Scholar]

- Hayashida, H.; Yamamoto, M.; Kitayama, H.; Inada, S.; Sakai, I.; Kono, T.; Yoshida, H.; Inaba, T.; Kanda, M. Nickel-Hydrogen Secondary Battery. U.S. Patent 6,248,475, 19 June 2001. [Google Scholar]

- Hasebe, H.; Sori, N.; Arai, T. Nickel-Metal Hydride Secondary Cell, and Method of Manufacturing the Same, Hydrogen Absorbing Alloy Particles for Cell, Method of Manufacturing the Same. U.S. Patent 5,219,678, 15 June 1993. [Google Scholar]

- Inaba, T.; Sawa, T.; Inada, S.; Kawashima, F.; Sato, N.; Sakamoto, T.; Okamura, M.; Arai, T.; Hashimoto, K. Hydrogen-Absorbing Alloy for Battery and Secondary Nickel-Metal Hydride Battery. U.S. Patent 5,753,386, 19 May 1998. [Google Scholar]

- Ovshinsky, S.R.; Young, R.T.; Chao, B. Hydrogen Storage Alloys and Methods and Improved Nickel Metal Hydride Electrodes and Batteries Using Same. U.S. Patent 6,210,498, 3 April 2001. [Google Scholar]

- Chen, Y.; Cai, Y.; Yu, D.; Dai, X. Method and an Equipment for Producing Rapid Condensation Hydrogen Storage Alloy Powder. U.S. Patent 6,174,345, 16 January 2001. [Google Scholar]

- Yamamoto, K.; Miyake, Y.; Okada, C.; Kitazume, N. Method for Production of Rare Earth Metal-Nickel Hydrogen Occlusive Alloy Ingot. U.S. Patent 5,680,896, 28 October 1997. [Google Scholar]

- Sun, B.; Chen, X. Vacuum Induction Melting and Strip Casting Equipment for Rare Earth Permanent Magnetic Alloy. U.S. Patent 20140352909 A1, 4 December 2014. [Google Scholar]

- Shinya, N.; Sugahara, H.; Ishii, M. Process for Producing Hydrogen Absorbing Alloy Powder and Hydrogen Absorbing Alloy Electrode. U.S. Patent 6,284,066, 4 September 2001. [Google Scholar]

- Sapru, K.; Reichman, B.; Reger, A.; Ovshinsky, S.R. Rechargeable Battery and Electrode Used Therein. U.S. Patent 4,623,597, 18 November 1986. [Google Scholar]

- Ovshinsky, S.R.; Fetcenko, M.A. Electrochemical Hydrogen Storage Alloys and Batteries Fabricated These Alloys Having Significantly Improved Performance Characteristics. U.S. Patent 5,277,999, 11 January 1994. [Google Scholar]

- Fetcenko, M.A.; Young, K.; Ovshinsky, S.R.; Reichman, B.; Koch, J.; Mays, W. Modified Electrochemical Hydrogen Storage Alloy Having Increased Capacity, Rate Capability and Catalytic Activity. U.S. Patent 6,740,448, 25 May 2004. [Google Scholar]

- Fetcenko, M.A.; Ovshinsky, S.R.; Young, K.; Reichman, B.; Ouchi, T.; Koch, J.; Mays, W. Hydrogen Storage Alloys Having a High Porosity Surface Layer. U.S. Patent 6,830,725, 14 December 2004. [Google Scholar]

- Young, K.; Reichman, B.; Fetcenko, M.A. Metal Hydride Alloy with Catalyst Particles and Channels. U.S. Patent 8,877,378, 4 November 2014. [Google Scholar]

- Wikipedia. Nickel-Iron Battery. Available online: https://en.wikipedia.org/wiki/Nickel-iron_battery (accessed on 9 February 2016).

- Edison, T.A. Reversible Galvanic Battery. U.S. Patent 678722 A, 16 July 1901. [Google Scholar]

- Edison, T.A. Reversible Galvanic Battery. U.S. Patent 692507, 4 February 1902. [Google Scholar]

- Gutjahr, M.A.; Schmid, R.; Beccu, K.D. Method of Manufacturing Positive Nickel Hydroxide Electrodes. U.S. Patent 3,877,987 A, 15 April 1975. [Google Scholar]

- Gutjahr, M.A.; Schmid, R.; Beccu, K.D. Method of Manufacturing Positive Nickel Hydroxide Electrodes. U.S. Patent 3,926,671 A, 16 December 1975. [Google Scholar]

- Fritts, D.H.; Leonard, J.F. Method of Nickel Electrode Production. U.S. Patent 4,399,005, 16 August 1983. [Google Scholar]

- Fritts, D.H.; Leonard, J.F. Method for Fabricating Battery Plaque and Low Shear Nickel Electrode. U.S. Patent 4,628,593, 16 December 1986. [Google Scholar]

- Fetcenko, M.; Koch, J. Nickel-Metal Hydride Batteries. In Linden’s Handbook of Batteries, 4th ed.; Reddy, T.B., Ed.; McGraw-Hill: New York, NY, USA, 2011; p. 229. [Google Scholar]

- Ovshinsky, S.R.; Fetcenko, M.A.; Venkatesan, S.; Holland, A. Compositionally and Structurally Disordered Multiphase Nickel Hydroxide Positive Electrode for Alkaline Rechargeable Electrochemical Cells. U.S. Patent 5,344,728, 6 September 1994. [Google Scholar]

- Ovshinsky, S.R.; Fetcenko, M.A.; Venkatesan, S.; Holland, A. Compositionally and Structurally Disordered Multiphase Nickel Hydroxide Positive Electrode Containing Modifiers. U.S. Patent 5,948,564, 7 September 1999. [Google Scholar]

- Oshitani, M.; Yufu, H. Nickel Electrode for Alkaline Battery and Battery Using Said Nickel Electrode. U.S. Patent 4,844,999, 4 July 1989. [Google Scholar]

- Fierro, C.; Fetcenko, M.A.; Young, K.; Ovshinsky, S.R.; Sommers, B.; Harrison, C. Nickel Hydroxide Positive Electrode Material Exhibiting Improved Conductivity and Engineered Activation Energy. U.S. Patent 6,228,535, 8 May 2001. [Google Scholar]

- Watada, M.; Oshitani, M.; Onishi, M. Nickel Electrode for Alkaline Battery. U.S. Patent 5,366,831, 22 November 1994. [Google Scholar]

- Ohta, K.; Matsuda, H.; Ikoma, M.; Morishita, N.; Toyoguchi, Y. Nickel Positive Electrode for Alkaline Storage Battery and Sealed Nickel-Hydrogen Storage Battery Using Nickel Positive Electrode. U.S. Patent 5,571,636, 5 November 1996. [Google Scholar]

- Yamawaki, A.; Nakahori, S.; Tadokoro, M.; Hamamatsu, T.; Baba, Y. Nickel Electrode Active Material; a Nickel Electrode and a Nickel Alkali Storage Cell Using Such Nickel Electrode Active Material; and Production Methods of Such Material, Electrode, and Cell. U.S. Patent 5,629,111, 13 May 1997. [Google Scholar]

- Ovshinsky, S.R.; Fetcenko, M.A.; Venkatesan, S.; Holland, A. Compositionally and Structurally Disordered Multiphase Nickel Hydroxide Positive Electrode for Alkaline Rechargeable Electrochemical Cells. U.S. Patent 5,637,423, 10 June 1997. [Google Scholar]

- Ikoma, M.; Akutsu, N.; Enokido, M.; Yoshii, F.; Kaiya, H.; Tsuda, S. Nickel Hydroxide Active Material Powder and Nickel Positive Electrode and Alkali Storage Battery Using Them. U.S. Patent 5,700,596, 23 December 1997. [Google Scholar]

- Matsuda, H.; Okada, Y.; Ohta, K.; Toyoguchi, Y. Active Material and Positive Electrode for Alkaline Storage Battery. U.S. Patent 5,773,169, 30 June 1998. [Google Scholar]

- Joo, K.; Choi, J.; Choi, K.; Kim, G.; Lee, S. Active Material for Nickel Electrode and Nickel Electrode Having the Same. U.S. Patent 5,789,113, 4 August 1998. [Google Scholar]

- Corrigan, D.; Fierro, C.; Martin, F.J.; Ovshinsky, S.R.; Xu, L. Nickel Battery Electrode Having Multiple Composition Nickel Hydroxide Active Materials. U.S. Patent 5,861,225, 19 January 1999. [Google Scholar]

- Okada, Y.; Ohta, K.; Matsuda, H.; Toyoguchi, Y. Nickel Hydroxide Positive Electrode Active Material Having a Surface Layer Containing a Solid Solution Nickel Hydroxide With Manganese Incorporated Therein. U.S. Patent 6,066,416, 23 May 2000. [Google Scholar]

- Dansui, Y.; Kato, F.; Suzuki, K.; Yuasa, K. Nickel/Metal Hydride Storage Battery. U.S. Patent 6,074,785, 13 June 2000. [Google Scholar]

- Fierro, C.; Fetcenko, M.A.; Young, K.; Ovshinsky, S.R.; Sommers, B.; Harrison, C. Nickel Hydroxide Positive Electrode Material Exhibiting Improved Conductivity and Engineered Activation Energy. U.S. Patent 6,447,953, 10 September 2002. [Google Scholar]

- Jackovitz, J.F.; Pantier, E.A. Alkali Slurry Ozonation to Produce a High Capacity Nickel Battery Material. U.S. Patent 4,481,128, 6 November 1984. [Google Scholar]

- Ovshinsky, S.R.; Corrigan, D.; Venkatesan, S.; Young, R.; Fierro, C.; Fetcenko, M.A. Chemically and Compositionally Modified Solid Solution Disordered Multiphase Nickel Hydroxide Positive Electrode for Alkaline Rechargeable Electrochemical Cells. U.S. Patent 5,348,822, 20 September 1994. [Google Scholar]

- Ovshinsky, S.R.; Young, R.T. Nickel Metal Hydride Battery Containing a Modified Disordered Multiphase Nickel Aluminum Based Positive Electrode. U.S. Patent 5,567,549, 22 October 1996. [Google Scholar]

- Young, R.; Ovshinsky, S.R.; Xu, L. Beta to Gamma Phase Cycleable Electrochemically Active Nickel Hydroxide Material. U.S. Patent 5,905,003, 18 May 1999. [Google Scholar]

- Ovshinsky, S.R.; Young, R.T.; Xu, L.; Kumar, S. Active Nickel Hydroxide Material Having Controlled Water Content. U.S. Patent 6,019,955, 1 February 2000. [Google Scholar]

- Singh, D.B. Gamma NiOOH Nickel Electrodes. U.S. Patent 6,020,088, 1 February 2000. [Google Scholar]

- Aladjov, B. Battery-Grade Nickel Hydroxide and Method for Its Preparation. U.S. Patent 5,788,943, 4 August 1998. [Google Scholar]

- Olbrich, A.; Meese-Marktscheffel, J.; Stoller, V.; Erb, M.; Albrecht, S.; Gille, G.; Maikowske, G.; Schrumpf, F.; Schmoll, J.; Jahn, M. Nickel Hydroxide and Method for Producing Same. U.S. Patent 7,563,431, 21 July 2009. [Google Scholar]

- Kato, F.; Tanigawa, F.; Dansui, Y.; Yuasa, K. Positive Electrode Material for Alkaline Storage Battery, Method of Producing the Same, and Alkaline Storage Battery Using the Same. U.S. Patent 6,083,642, 4 July 2000. [Google Scholar]

- Junichi, I.; Yuri, K.; Tetsushi, M.; Toyoshi, I. Nickel Hydroxide Particles Having an α- or β-Cobalt Hydroxide Coating Layer for Use in Alkali Batteries and a Process for Producing the Nickel Hydroxide. U.S. Patent 6,040,007, 21 March 2000. [Google Scholar]

- Fetcenko, M.A.; Fierro, C.; Ovshinsky, S.R.; Sommers, B.; Reichman, B.; Young, K.; Mays, W. Composite Positive Electrode Material and Method for Making Same. U.S. Patent 6,177,213, 23 January 2001. [Google Scholar]

- Fetcenko, M.A.; Fierro, C.; Ovshinsky, S.R.; Sommers, B.; Reichman, B.; Young, K.; Mays, W. Composite Positive Electrode Material and Method for Making Same. U.S. Patent 6,348,285, 19 February 2002. [Google Scholar]

- Fetcenko, M.A.; Fierro, C.; Ovshinsky, S.R.; Sommers, B.; Reichman, B.; Young, K.; Mays, W. Composite Positive Electrode Material and Method for Making Same. U.S. Patent 6,548,209, 15 April 2003. [Google Scholar]

- Fetcenko, M.A.; Fierro, C.; Ovshinsky, S.R.; Sommers, B.; Reichman, B.; Young, K.; Mays, W. Composite Positive Electrode Material and Method for Making Same. U.S. Patent 6,569,566, 27 May 2003. [Google Scholar]

- Fierro, C.; Fetcenko, M.A.; Young, K.; Ovshinsky, S.R.; Sommers, B.; Harrison, C. Nickel Hydroxide Electrode Material With Improved Microstructure and Method for Making the Same. U.S. Patent 7,294,434, 13 November 2007. [Google Scholar]

- Ovshinsky, S.R.; Fetcenko, M.A.; Fierro, C.; Gifford, P.R.; Corrigan, D.A.; Benson, P.; Martin, F.J. Enhanced Nickel Hydroxide Positive Electrode Materials for Alkaline Rechargeable Electrochemical Cells. U.S. Patent 5,523,182, 4 June 1996. [Google Scholar]

- Fierro, C.; Fetcenko, M.A.; Ovshinsky, S.R.; Corrigan, D.A.; Sommers, B.; Zallen, A. Nickel Hydroxide Electrode Material and Method for Making the Same. U.S. Patent 6,416,903, 9 July 2002. [Google Scholar]

- Tokuda, M.; Ogasawara, T.; Yano, M.; Fujitani, S. Nickel Hydroxide Electrode for Alkaline Storage Battery and Alkaline Storage Battery. U.S. Patent 6,835,498, 28 December 2004. [Google Scholar]

- Wolff, M.; Nuss, M.A.; Fetcenko, M.A.; Lijoi, A.L. Method for the Continuous Fabrication of Hydrogen Storage Alloy Negative Electrodes. U.S. Patent 4,820,481, 11 April 1989. [Google Scholar]

- Wang, Y.; Li, W.; Sun, L.; Wang, S.; Wang, W.; Li, C.; Wang, J. Electrode of Charging Battery and Method and Equipment for Making Electrode. CN Patent 1,085,896, 29 May 2002. [Google Scholar]

- Hasebe, H.; Takeno, K.; Sato, Y.; Takahashi, H.; Hayashida, H.; Mitsuyasu, K.; Swatari, I. Nickel-Metal Hydride Secondary Cell. U.S. Patent 5,053,292, 1 October 1991. [Google Scholar]

- Yun, K.S.; Cho, B.W.; Cho, W.I.; Paik, C.H. Fabrication Method for Paste-Type Metal Hydride Electrode. U.S. Patent 5,682,592, 28 October 1997. [Google Scholar]

- Venkatesan, S.; Reichman, B.; Ovshinsky, S.R.; Prasad, B.; Corrigan, D.A. High Power Nickel-Metal Hydride Batteries and High Power Electrodes for Use Therein. U.S. Patent 5,856,047, 5 January 1999. [Google Scholar]

- Reichman, B.; Venkatesan, S.; Ovshinsky, S.R.; Fetcenko, M.A. Nickel-Metal Hydride Batteries Having High Power Electrodes and Low-Resistance Electrode Connections. U.S. Patent 5,851,698, 22 December 1998. [Google Scholar]

- Towsley, F.E. Method for Making Electrodes for Nickel-Metal Hydride Batteries. U.S. Patent 6,881,234, 19 April 2005. [Google Scholar]

- James, D.; Allison, D.B., II; Kelley, J.J.; Doe, J.B. Electrical Energy Devices. U.S. Patent 6,451,485, 17 September 2002. [Google Scholar]

- Moriwaki, Y.; Karanaka, S.; Iwasaki, M.; Yamasaki, Y.; Maeda, A. Hydrogen Storage Alloy Electrode, Battery Including the Same and Method for Producing the Both. U.S. Patent 6,610,445, 26 August 2003. [Google Scholar]

- Nakayama, S. Negative Electrode and Nickel-Metal Hydride Storage Battery Using the Same. U.S. Patent 7,534,529, 19 May 2009. [Google Scholar]

- Magari, Y.; Tanaka, T.; Akita, H.; Shinyama, K.; Funahashi, A.; Nohma, T. Nickel-Metal Hydride Storage Battery. U.S. Patent 6,924,062, 2 August 2005. [Google Scholar]

- Akita, H.; Tanaka, T.; Magari, Y.; Shinyama, K.; Funahashi, A.; Nohma, T. Nickel-Metal Hydride Storage Battery. U.S. Patent 6,926,998, 9 August 2005. [Google Scholar]

- Frye, B.; Pensabene, S.; Puglisi, V. Electrode Structure for Nickel Metal Hydride Cells. U.S. Patent 5,478,594, 26 December 1995. [Google Scholar]

- Kawase, H.; Morishita, S.; Towata, S.; Suzuki, K.; Abe, K. Sealed. U.S. Patent 5,948,563, 7 September 1999. [Google Scholar]

- Matsuura, Y.; Maeda, R.; Shinyama, K.; Tanaka, T.; Nohma, T.; Yonezu, I. Hydrogen Absorbing Alloy Electrode and Nickel-Metal Hydride Battery. U.S. Patent 6,475,671, 5 November 2002. [Google Scholar]

- Kuribayashi, Y.; Sugahara, H.; Ishii, M.; Shima, S. Hydrogen Absorbing Alloy Powder and Electrodes Formed of the Hydrogen Absorbing Alloy Powder. U.S. Patent 6,235,130, 22 May 2001. [Google Scholar]

- Ovshinsky, S.R.; Aladjov, B.; Venkatesan, S.; Dhar, S.K.; Hopper, T.; Fok, K. Method of Activating Hydrogen Storage Alloy Electrode. U.S. Patent 6,605,375, 12 August 2003. [Google Scholar]

- Young, K.; Fetcenko, M.A.; Ovshinsky, S.R. Hydrogen Storage Powder and Process for Preparing the Same. U.S. Patent 6,461,766, 8 October 2002. [Google Scholar]

- Noréus, D.; Zhou, Y. Method for Improving the Properties of Alloy Powders for NiMH Batteries. U.S. Patent 7,056,397, 6 June 2006. [Google Scholar]

- Okawa, T.; Murakami, T.; Aoki, K.; Usui, H. Nickel Metal Hydride Rechargeable Battery and Method for Manufacturing Negative Electrode Thereof. U.S. Patent 8,389,159, 5 March 2013. [Google Scholar]

- Matsuura, Y.; Nogami, M.; Maeda, R.; Shinyama, K.; Yonezu, I.; Nishio, K. Metal Hydride Alkaline Storage Cell and Manufacturing Method Thereof. U.S. Patent 6,852,447, 8 February 2005. [Google Scholar]

- Köhler, U.; Chen, G.; Lindner, J. Gastight, Sealed Metal Oxide/metal Hydride Storage Battery. U.S. Patent 5,639,569, 17 June 1997. [Google Scholar]

- Ferrando, W. Suspension Method of Impregnating Active Material into Composite Nickel Plaque. U.S. Patent 4,574,096, 4 March 1986. [Google Scholar]

- Amiel, O.; Belkhir, I.; Freluche, J.; Pineau, N.; Dupuy, C.; Babin, S. Non-Sintered Electrode With Three-Dimensional Support for a Secondary Electrochemical Cell Having an Alkaline Electrolyte. U.S. Patent 6,656,640, 2 December 2003. [Google Scholar]

- Pensabene, S.F.; Royalty, R.L. Electrode Having a Conductive Contact Area and Method of Making the Same. U.S. Patent 5,196,281, 23 March 1993. [Google Scholar]

- Babjak, J.; Ettel, V.A.; Paserin, V. Method of Forming Nickel Foam. U.S. Patent 4,957,543, 18 September 1990. [Google Scholar]

- Kawano, H.; Hayashi, T.; Matsumoto, I. Non-Sintered Type Nickel Electrode. U.S. Patent 5,824,435, 20 October 1998. [Google Scholar]

- Ohnishi, M.; Watada, M.; Oshitani, M. Nickel Electrode and Alkaline Battery Using the Same. U.S. Patent 5,200,282, 6 April 1993. [Google Scholar]

- Kobayashi, T. Nickel Electrode Plate for an Alkaline Storage Battery. U.S. Patent 5,677,088, 14 October 1997. [Google Scholar]

- Harada, K.; Ishii, M.; Watanabe, K.; Yamanaka, S. Process for Preparing Metallic Porous Body, Electrode Substrate for Battery and Process for Preparing the Same. U.S. Patent 5,640,669, 17 June 1997. [Google Scholar]

- Venkatesan, S.; Aladjov, B.; Fok, K.; Hopper, T.; Ovshinsky, S.R. Nickel Hydroxide Paste with Molasses Binder. U.S. Patent 6,818,348, 16 November 2004. [Google Scholar]

- Ovshinsky, S.R.; Aladjov, B.; Tekkanat, B.; Venkatesan, S.; Dhar, S.K. Active Electrode Composition With Conductive Polymeric Binder. U.S. Patent 7,238,446, 3 July 2007. [Google Scholar]

- Lee, W.W. Cobalt Treatment of Nickel Composite Electrode Surfaces. U.S. Patent 4,595,463, 17 June 1986. [Google Scholar]

- Geng, M.; Phillips, J.; Mohanta, S. Nickel Hydroxide Electrode for Rechargeable Batteries. U.S. Patent 8,048,566, 1 November 2011. [Google Scholar]

- Hyashi, K.; Tomioka, K.; Morishita, N.; Ikeyama, M.; Ikoma, M. Nickel Positive Electrode for Alkaline Rechargeable Batteries and Nickel Metal Hydride Cells. U.S. Patent 5,968,684, 19 October 1999. [Google Scholar]

- Seyama, Y.; Sasaki, H.; Murata, T. Positive Active Material for Alkaline Battery and Electrode Using the Same. U.S. Patent 6,251,538, 26 June 2001. [Google Scholar]

- Maeda, T.; Shinyama, K.; Matsuura, Y.; Nogami, M.; Yonezu, I.; Nishio, K. Nickel-Hydrogen Storage Battery. U.S. Patent 6,472,101, 29 October 2002. [Google Scholar]

- Miyamoto, K.; Bando, N. Active Material for Positive Electrode for Alkaline Secondary Cell and Method for Producing the Same, and Alkaline Secondary Cell Using the Active Material for Positive Electrode and Method for Producing the Same. U.S. Patent 6,528,209, 4 March 2003. [Google Scholar]

- Seyama, Y.; Sasaki, H.; Murata, T. Positive Active Material for Alkaline Battery and Electrode Using the Same. U.S. Patent 6,558,842, 6 May 2003. [Google Scholar]

- Sakamoto, H.; Ohkawa, K.; Yuasa, S. Alkali Battery Positive Electrode Active Material, Alkali Battery Positive Electrode, Alkali Battery, and Method for Manufacturing Alkali Battery Positive Electrode Active Material. Patent WO2006011430 A1, 2 February 2006. [Google Scholar]

- Pensabene, S.F.; Puglisi, V.J. Positive Nickel Electrode for Nickel Metal Hydride Cells. U.S. Patent 5,466,546, 14 November 1995. [Google Scholar]

- Nakayama, S.; Yuasa, K.; Kaiya, H. Nickel Positive Electrode Plate and Alkaline Storage Battery. U.S. Patent 6,803,148, 12 October 2004. [Google Scholar]

- Nakayama, S.; Yuasa, K.; Kaiya, H. Nickel Positive Electrode Plate and Alkaline Storage Battery. U.S. Patent 7,364,818, 29 April 2008. [Google Scholar]

- Bauerlein, P. Ni/Metal Hydride Secondary Element. U.S. Patent 6,881,519, 19 April 2005. [Google Scholar]

- Ovshinsky, S.R.; Corrigon, D.A.; Benson, P.; Fierro, C.A. Nickel Metal Hydride Battery Containing a Modified Disordered Multiphase Nickel Hydroxide Positive Electrode. U.S. Patent 5,569,563, 29 October 1996. [Google Scholar]

- Dansui, Y.; Suzuki, T.; Kasahara, H.; Yao, T. Nickel-Metal Hydride Secondary Battery Comprising a Compound Silicate. U.S. Patent 6,461,767, 8 October 2002. [Google Scholar]

- Maeda, A.; Kimiya, H.; Moriwaki, Y.; Matsumoto, I. Alkaline Storage Battery. U.S. Patent 6,338,917, 15 January 2002. [Google Scholar]

- Dansui, Y.; Suzuki, T.; Kasahara, H. Method of Preparing a Nickel Positive Electrode Active Material. U.S. Patent 7,147,676, 12 December 2006. [Google Scholar]

- Hayashi, K.; Tomioka, K.; Morishita, N.; Ikoma, M. Nickel Positive Electrode and Alkaline Storage Battery Using the Same. U.S. Patent 6,027,834, 22 February 2000. [Google Scholar]

- Klein, M. Method for Preparing Conductive Electrochemically Active Material. U.S. Patent 5,585,142, 17 December 1996. [Google Scholar]

- Klein, M. Method for Fabricating a Battery Electrode. U.S. Patent 5,611,823, 18 March 1997. [Google Scholar]

- Young, K.; Ng, K.Y.S.; Bendersky, L.A. A technical report of the robust affordable next generation energy storage system-BASF program. Batteries 2016, 2. [Google Scholar] [CrossRef]

- Yoshinaka, T.; Yamamoto, S.; Inagaki, T.; Nakamura, Y.; Tanigawa, F.; Kaiya, H.; Takeshima, H. Sealed Cylindrical Nickel-Metal Hydride Storage Battery. U.S. Patent 6,805,995, 19 October 2004. [Google Scholar]

- Ovshinsky, S.R.; Fetcenko, M.A.; Holland, A.; Dean, K.; Fillmore, D. Optimized Cell Pack for Large Sealed Nickel-Metal Hydride Batteries. U.S. Patent 5,558,950, 24 September 1996. [Google Scholar]

- Ovshinsky, S.R.; Corrigan, D.A.; Venkatesan, S.; Dhar, S.K.; Holland, A.; Fillmore, D.; Higley, L.; Gow, P.; Himmler, R.; Karditsas, N.; et al. Mechanical and Thermal Improvements in Metal Hydride Batteries, Battery Modules and Battery Packs. U.S. Patent 5,879,831, 9 March 1999. [Google Scholar]

- Kozawa, H.; Kojima, K.; Ono, T.; Yanagawa, H.; Kitazume, H.; Taguchi, K. Rectangular Nickel-Metal Hydride Secondary Cell. U.S. Patent 5,372,897, 13 December 1994. [Google Scholar]

- Kozawa, H.; Kojima, K.; Ono, T.; Yanagawa, H.; Kitazume, H.; Taguchi, K. Method of Making a Rectangular Nickel-Metal Hydride Secondary Cell. U.S. Patent 5,490,867, 13 February 1996. [Google Scholar]

- Kozawa, H.; Kojima, K.; Ono, T.; Yanagawa, H.; Kitazume, H.; Taguchi, K. Method of Manufacturing a Nickel-Metal Hydride Secondary Cell. U.S. Patent 5,537,733, 23 July 1996. [Google Scholar]

- Yuasa, S.; Morishita, N.; Taniguchi, A.; Ikoma, M. Rectangular Alkaline Storage Battery and Battery Module and Battery Pack Using the Same. U.S. Patent 20020022179 A1, 21 February 2002. [Google Scholar]

- Kawasaki Heavy Industries. Bipolar 3D Design Is the Secret to the High Capacity and Rapid Charge/Discharge of the GIGACELL. Available online: https://global.kawasaki.com/en/energy/solutions/battery_energy/about_gigacell/structure.html (accessed on 9 February 2016).

- Kato, F.; Tanigawa, F.; Yuasa, K. Nickel-Metal Hydride Storage Battery and Assembly of the Same. U.S. Patent 6,958,200, 25 October 2005. [Google Scholar]

- Sasaki, E.W.; Owens, B.B.; Passerini, S. Rechargeable Battery. U.S. Patent 6,265,100, 24 July 2001. [Google Scholar]

- Klein, M. Method of Making Electrodes for Bipolar Electrochemical Battery. U.S. Patent 5,478,363, 26 December 1995. [Google Scholar]

- Klein, M. Bipolar Electrochemical Battery of Stacked Wafer Cells. U.S. Patent 5,393,617, 28 February 1995. [Google Scholar]

- Mrotek, E.N.; Kao, W. Bipolar Battery and Method of Making Same. U.S. Patent 5,688,615, 18 November 1997. [Google Scholar]

- Fredriksson, L.; Puester, N. Bipolar Battery and Biplate Assembly. U.S. Patent 7,097,937, 29 August 2006. [Google Scholar]

- Fredriksson, L.; Puester, N.H. Bipolar Battery and a Method for Manufacturing a Bipolar Battery. U.S. Patent 7,258,949, 21 August 2007. [Google Scholar]

- Fredriksson, L.; Puester, N. Bipolar Battery and a Biplate Assembly. U.S. Patent 7,767,337, 3 August 2010. [Google Scholar]

- Puester, N.H.; Hock, D.; Fredriksson, L. Method for Manufacturing a Bipolar Battery with a Gasket. U.S. Patent 8,470,469, 25 June 2013. [Google Scholar]

- Benczur-Uermoessy, G. Gastight Prismatic Nickel-Metal Hydride Cell. U.S. Patent 7,205,065, 17 April 2007. [Google Scholar]

- Corrigan, D.A.; Gow, P.; Higley, L.R.; Muller, M.D.; Osgood, A.; Ovshinsky, S.R.; Payne, J.; Puttaiah, R. Monoblock Battery Assembly. U.S. Patent 6,255,015, 3 July 2001. [Google Scholar]

- Lyman, P.C. Battery. U.S. Patent 5,567,544, 22 October 1996. [Google Scholar]

- Park, Y. Secondary Battery. U.S. Patent 2013/0149579 A1, 13 June 2013. [Google Scholar]

- Fuhr, J.D.; Dougherty, T.J.; Dinkelman, J.P. Battery Cell. U.S. Patent 8,609,278, 17 December 2013. [Google Scholar]

- Hirano, F. Cylindrical Storage Battery. U.S. Patent 6,703,158, 9 March 2004. [Google Scholar]

- Hashimoto, T. Negative Electrode Current Collector, Negative Electrode Using the Same, and Non-Aqueous Electrolytic Secondary Cell. U.S. Patent 7,150,942, 19 December 2006. [Google Scholar]

- Nakamaru, H. Current Collector. U.S. Patent D522,965, 13 June 2006. [Google Scholar]

- Kometani, S.; Nagase, T.; Masuda, Y.; Asanuma, H.; Enishi, E.; Kondo, T. Collector Used for an Alkali Storage Battery. U.S. Patent 6,979,514, 27 December 2005. [Google Scholar]

- Mori, H.; Sakamoto, K.; Bandou, T.; Okabe, K. Nickel Metal-Hydride Battery. U.S. Patent 7,867,655, 11 January 2011. [Google Scholar]

- Fuhr, J.D.; Bowen, G.K.; Dinkleman, J.P.; Dougherty, T.J.; Tsutsui, W.; Bonin, C. Current Collector for An Electromechanical Cell. U.S. Patent 8,679,678, 25 March 2014. [Google Scholar]

- Shinohara, W.; Yamamoto, Y.; Hosokawa, H.; Yamauchi, Y. Method of Manufacturing Sealed Battery and Sealed Battery. U.S. Patent 6,843,811, 18 January 2005. [Google Scholar]

- Ling, P.T.P.; Ng, S.O.A. Prismatic Battery Cells, Batteries with Prismatic Battery Cells and Methods of Making Same. U.S. Patent 20060040176 A1, 23 February 2006. [Google Scholar]

- Dean, K.; Holland, A.; Ovshinsky, H.C.; Fetcenko, M.; Venkatesan, S.; Dhar, S. Hydrogen Containment Cover Assembly for Sealing the Cell Can of a Rechargeable Electrochemical Hydrogen Storage Cell. U.S. Patent 5,171,647, 15 December 1992. [Google Scholar]

- Pate, P.E. Electrochemical Cell Safety Vent. U.S. Patent 6,080,505, 27 June 2000. [Google Scholar]

- Sugita, N. Sealed Battery with Less Electrolyte Leakage. U.S. Patent 6,838,207, 4 January 2005. [Google Scholar]

- Komori, K.; Matsuura, T.; Hamada, S.; Eto, T.; Nakamura, Y. Nickel Metal Hydride Storage Battery With a Safety Valve for Relieving Excess Gas Pressure in the Battery When the Safety Valve Is Open, the Safety Valve Having a Hydrogen-Permeable Value Member for Allowing Hydrogen-Gas Leakage Therethrough When the Safety Valve Is Closed. U.S. Patent 7,758,994, 20 July 2010. [Google Scholar]

- Hamada, S.; Matsuura, T.; Eto, T.; Miyamoto, H. Nickel-Metal Hydride Storage Battery. U.S. Patent 7,807,282, 5 October 2010. [Google Scholar]

- Fuhr, J.D.; Trester, D.; Houchin-Miller, G.; Bonin, C.; Pacheco, A.C. Battery Module with Sealed Vent Chamber. U.S. Patent 8,999,538, 7 April 2015. [Google Scholar]

- Fuhr, J.D.; Tsutsui, W.; Houchin-Miller, G.P.; Bonin, C.M. Vent for Electrochemical Cell. U.S. Patent 8,945,740, 3 February 2015. [Google Scholar]

- Tyler, M.; Fuhr, J. Device for Aiding in the Fracture of a Vent of an Electrochemical Cell. U.S. Patent 9,105,902, 11 August 2015. [Google Scholar]

- Komori, K.; Ogata, Y.; Adachi, A.; Maekawa, K.; Fujioka, N. Nickel Metal Hydride Storage Battery. U.S. Patent 7,452,629, 18 November 2008. [Google Scholar]

- Hamada, S.; Eto, T. Sealed Rechargeable Battery and Battery Module. U.S. Patent 7,393,611, 1 July 2008. [Google Scholar]

- Kung, J.K. Battery Separator for Nickel/Metal Hydride Batteries. U.S. Patent 5,298,348, 29 March 1994. [Google Scholar]

- Senyarich, S.; Viaud, P. Storage Cell Having an Alkaline Electrolyte, in Particular a Storage Cell of Nickel-Cadmium or Nickel Metal Hydride. U.S. Patent 5,939,222, 17 August 1999. [Google Scholar]

- Whear, J.K.; Yaritz, J.G. Nonwoven Separator for a Nickel-Metal Hydride Battery. U.S. Patent 6,537,696, 25 March 2003. [Google Scholar]

- Tsukiashi, M.; Teraoka, H.; Hata, K.; Tajima, M. Battery Separator and Manufacturing Method Thereof, and Alkali Secondary Battery Having the Separator Incorporated Therein. U.S. Patent 6,623,809, 23 September 2003. [Google Scholar]

- Harada, Y.; Tanaka, T.; Magari, Y.; Shinyama, K.; Nohma, T.; Yonezu, I. Separator for Nickel-Metal Hydride Storage Battery and Nickel-Metal Hydride Storage Battery. U.S. Patent 7,052,800, 30 May 2006. [Google Scholar]

- Harada, Y.; Tanaka, T.; Shinyama, K.; Nohma, T.; Yonezu, I. Separator for Alkaline Secondary Battery, Method for Preparing the Same Alkaline Secondary Battery. U.S. Patent 6,790,562, 14 September 2004. [Google Scholar]

- Tsuji, Y.; Nakai, H.; Muraoka, Y. Nickel-Metal Hydride Storage Battery. U.S. Patent 7,435,511, 14 October 2008. [Google Scholar]

- Lim, H.S.; Arora, P. Separator Media for Electrochemical Cells. U.S. Patent 20140134498 A1, 15 May 2014. [Google Scholar]

- Sato, N.; Komori, K.; Morishita, N. Separator for Alkaline Storage Battery and Alkaline Storage Battery Using the Same. U.S. Patent 6,933,079, 23 August 2005. [Google Scholar]

- Young, K.; Yasuoka, S. Capacity degradation mechanisms in nickel/metal hydride batteries. Batteries 2016, 2. [Google Scholar] [CrossRef]

- Joshi, A.V.; Gordon, J.H.; Bhavaraju, S. Nickel-Metal Hydride Battery Using Alkali Ion Conducting Separator. U.S. Patent 8,012,621, 6 September 2011. [Google Scholar]

- Joshi, A.V.; Gordon, J.H.; Bhavaraju, S. Nickel-Metal Hydride/Hydrogen Hybrid Battery Using Alkali Ion Conducting Separator. U.S. Patent 9,209,445, 8 December 2015. [Google Scholar]

- Alkordi, M.H.; Eddaoudi, M. Electrode Separator. U.S. Patent 20130280611 A1, 24 October 2013. [Google Scholar]

- Yan, S.; Young, K.; Ng, K.Y.S. Effects of salt additives to the KOH electrolyte used in Ni/MH batteries. Batteries 2015, 1, 54–73. [Google Scholar] [CrossRef]

- Young, K.; Nei, J.; Rotarov, D. Studies in various hydroxides used as electrolyte in Ni/MH batteries. Batteries 2016. to be submitted for publication. [Google Scholar]

- Kitayama, H.; Hayashida, H.; Yamamoto, M.; Bando, N.; Miyamoto, K.; Suzuki, H. Nickel-Metal Hydride Secondary Battery. U.S. Patent 6,399,247, 4 June 2002. [Google Scholar]

- Anani, A.A.; Reichert, V.R.; Massaroni, K.M. Metal Hydride Electrochemical Cell Having a Polymer Electrolyte. U.S. Patent 5,541,019, 30 July 1996. [Google Scholar]

- Iwakura, C.; Furukawa, N.; Izumi, Y.; Moriwaki, Y. Nickel-Metal Hydride Storage Battery and Production Method Thereof. U.S. Patent 7,022,434, 4 April 2006. [Google Scholar]

- Ovshinsky, S.R.; Young, R. Solid State Battery Using a Hydrogenated Silicon Nitride Electrolyte. U.S. Patent 5,552,242, 3 September 1996. [Google Scholar]

- Nakamura, Y. Power Storage Device. U.S. Patent 7,803,486, 28 September 2010. [Google Scholar]

- Young, K.; Fetcenko, M.A. Low Cost, High Power, High Energy Density, Solid-State, Bipolar Metal Hydride Batteries. U.S. Patent 8,974,948, 10 March 2015. [Google Scholar]

- Van Deutekom, H.J.H. Rechargeable Electrochemical Cell. U.S. Patent 4,214,043, 22 July 1980. [Google Scholar]

- Van Deutekom, H.J.H. Rechargeable Electrochemical Cell. U.S. Patent 4,312,928, 26 January 1982. [Google Scholar]

- Ikezoe, M. Sealed Nickel-Metal Hydride Storage Cells and Hybrid Electric Having the Storage Cells. U.S. Patent 7,353,894, 8 April 2008. [Google Scholar]

- Takee, M.; Tadokoro, M.; Ise, T.; Yamawaki, A. Nickel-Metal Hydride Storage Cell Having a High Capacity and an Excellent Cycle Characteristic and Manufacturing. U.S. Patent 6,368,748, 9 April 2002. [Google Scholar]

- Berlureau, T.; Liska, J. Sealed Nickel-Metal Hydride Storage Cell. U.S. Patent 6,444,349, 3 September 2002. [Google Scholar]

- Onishi, M.; Fukunaga, H.; Isogai, M.; Nagai, R. Nickel Metal-Hydride Cell. U.S. Patent 6,593,031, 15 July 2003. [Google Scholar]

- Young, K.; Fierro, C.; Reichman, B.; Fetcenko, M.A.; Koch, J.; Zallen, A. Nickel Metal Hydride Battery Design. U.S. Patent 7,261,970, 28 August 2007. [Google Scholar]

- Hasebe, H.; Tsuruta, S.; Yoshida, H.; Yamamoto, M.; Kanno, K.; Ishitsuka, K.; Komiyama, K.; Oppata, H. Alkaline Secondary Battery Manufacturing Method, Alkaline Secondary Battery Positive Electrode, Alkaline Secondary Battery, and a Method of Manufacturing an Initially Charged Alkaline Secondary Battery. U.S. Patent 5,708,349, 13 January 1998. [Google Scholar]

- Nanamoto, K.; Umehara, Y. Method for Manufacturing Nickel-Metal-Hydride Battery. U.S. Patent 5,814,108, 29 September 1998. [Google Scholar]

- Singh, D.B. Method of Forming CoOOH and NiOOH in a NiMH Electrochemical Cell and An Electrochemical Cell Formed Thereby. U.S. Patent 6,270,535, 7 August 2001. [Google Scholar]

- Onishi, M.; Tomioka, K.; Fujioka, N.; Ikoma, M. Method for Producing a Nickel Metal-Hydride Storage Battery. U.S. Patent 6,669,742, 30 December 2003. [Google Scholar]

- Morishita, N.; Ito, S.; Seri, H. Nickel-Metal Hydride Rechargeable Battery. U.S. Patent 7,560,188, 14 July 2009. [Google Scholar]

- Toyota Prius Battery. Available online: http://www.toyotapriusbattery.com (accessed on 9 February 2016).

- Ovshinsky, S.R.; Corrigan, D.A.; Venkatesan, S.; Dhar, S.K.; Holland, A.; Fillmore, D.; Higley, L.; Gow, P.; Himmler, R.; Karditsas, N.; et al. Mechanical and Thermal Improvements in Metal Hydride Batteries, Battery Modules and Battery Packs. U.S. Patent 6,372,377, 16 April 2002. [Google Scholar]

- Ovshinsky, S.R.; Corrigan, D.A.; Venkatesan, S.; Dhar, S.K.; Holland, A.; Fillmore, D.; Higley, L.; Gow, P.; Himmler, R.; Karditsas, N.; et al. Mechanical and Thermal Improvements in Metal Hydride Batteries, Battery Modules and Battery Packs. U.S. Patent 6,878,485, 12 April 2005. [Google Scholar]

- Morishita, N.; Hamada, S.; Matsuda, H.; Ikoma, M. Cell and Module Battery of Sealed Nickel-Metal Hydride Storage. U.S. Patent 5,747,186, 5 May 1998. [Google Scholar]

- Hamada, S.; Kasahara, H.; Ito, S.; Ando, H.; Eto, T. Nickel-Metal Hydride Secondary Battery Module and Secondary Battery Module Manufacturing Method. U.S. Patent 8,785,014, 22 July 2014. [Google Scholar]

- Hamada, S.; Inoue, H.; Fujioka, N.; Ikoma, M. Battery Module. U.S. Patent 6,551,741, 22 April 2003. [Google Scholar]

- Muis, P. Interconnectors for a Battery Assembly. U.S. Patent 8,541,130, 24 September 2013. [Google Scholar]

- Yang, J.H. Battery Module of High Cooling Efficiency. U.S. Patent 7,955,726, 7 June 2011. [Google Scholar]

- Houchin-Miller, G.P.; Pacheco, A.C.; Wiegmann, M.; Joswig, R.; Hoh, M.; Balk, M.; Obasih, K. Battery System with Heat Exchanger. U.S. Patent 8,603,660, 10 December 2013. [Google Scholar]

- Houchin-Miller, G.P.; Pacheco, A.C.; Wiegmann, M.; Joswig, R.; Hoh, M.; Balk, M.; Obasih, K. Battery System with Heat Exchanger. U.S. Patent 9,225,045, 29 December 2015. [Google Scholar]

- Gadawski, T.J.; Payne, J. Battery Module and Method for Cooling the Battery Module. U.S. Patent 8,399,118 B2, 19 March 2013. [Google Scholar]

- Koetting, W.; Payne, J. Battery Module and Method for Cooling the Battery Module. U.S. Patent 8,399,119 B2, 19 March 2013. [Google Scholar]

- Shinyashiki, Y.; Fujiwara, M.; Maeda, H.; Funahashi, A. Method for Compressing Individual Cells in Battery Module. U.S. Patent 8,309,247, 13 November 2012. [Google Scholar]

- Chamberlain, C.P.; Lamb, D.; Lauby, W.J.; Voorheis, H.T. Compact, Shock Resistant Battery Pack. U.S. Patent 5,466,545, 14 November 1995. [Google Scholar]

- Wheeler, D.K.; Moores, R.G., Jr.; Walter, R.T. Battery Pack for Cordless Device. U.S. Patent 7,273,676, 25 September 2007. [Google Scholar]

- Adams, P.; Ellis, R.; Newton, J. Battery Pack Control Circuit for Handheld Battery Operated Device. U.S. Patent 8,548,633, 1 October 2013. [Google Scholar]

- Pyo, K.R. Battery Pack and Manufacturing Method for the Same. U.S. Patent 8,835,045, 16 September 2014. [Google Scholar]

- Shih, C.; Chang, C.; Yeh, S.; Liu, L.; Wu, S. Battery Pack. U.S. Patent 20130171492 A1, 4 July 2013. [Google Scholar]

- Mita, Y. Battery Module and Temperature-Controlling Apparatus for Battery. U.S. Patent 5,456,994, 10 October 1995. [Google Scholar]

- Inui, K.; Nakanishi, T. Battery Pack. U.S. Patent 6,504,342, 7 January 2003. [Google Scholar]

- Ogata, Y.; Hamada, S. Battery Pack Cooling Structure. U.S. Patent 6,709,783, 23 March 2004. [Google Scholar]

- Inui, K.; Etoh, T. Fluid-Cooled Battery Pack System. U.S. Patent 6,953,638, 11 October 2005. [Google Scholar]

- Ovshinsky, S.R.; Corrigan, D.A.; Venkatesan, S.; Dhar, S.K.; Holland, A.; Fillmore, D.; Higley, L.; Gow, P.; Himmler, R.; Karditsas, N.; et al. Mechanical and Thermal Improvements in Metal Hydride Batteries, Battery Modules and Battery Packs. U.S. Patent 7,217,473, 15 May 2007. [Google Scholar]

- Fuhr, J.D.; Houchin-Miller, G.P.; Swoyer, J.L.; Pacheco, A.C.; Zhang, X.; Obashih, K.M. Prismatic Electrochemical Cell. U.S. Patent 20130216872 A1, 22 August 2013. [Google Scholar]

- Yuen, T.K. Battery Charging Circuit for Charging NiMH and NiCd Batteries. U.S. Patent 5,489,836, 6 February 1996. [Google Scholar]

- Feldstein, R.S. NiCd/NiMH Battery Charger. U.S. Patent 5,523,668, 4 June 1996. [Google Scholar]

- McClure, M.S. Battery Monitoring and Charging Control Unit. U.S. Patent 5,563,496, 8 October 1996. [Google Scholar]

- Seong, H.; Im, S. Battery Charging Circuit with Charging Rate Control. U.S. Patent 5,698,963, 16 December 1997. [Google Scholar]

- Im, S.; Seoung, H.; Choi, B. Fast-Charging Device for Rechargeable Batteries. U.S. Patent 5,717,311, 10 February 1998. [Google Scholar]

- Cheon, K. Dual Battery Charging Device for Charging Nickel Metal-Hydride and Lithium-Ion Batteries. U.S. Patent 5,744,937, 28 April 1998. [Google Scholar]

- Gaza, B.S. Microcontrolled Battery Charger. U.S. Patent 5,764,030, 9 June 1998. [Google Scholar]

- Yeon, S. Charge Mode Control in a Battery Charger. U.S. Patent 5,821,736, 13 October 1998. [Google Scholar]

- Gaza, B.S. Microcontrolled Battery Charger. U.S. Patent 5,998,966, 7 December 1999. [Google Scholar]

- Yuen, T.K. Battery Charger. U.S. Patent 6,208,148, 27 March 2001. [Google Scholar]

- Tsenter, B. Battery Charger and Method of Charging Nickel Based Batteries. U.S. Patent 6,313,605, 6 November 2001. [Google Scholar]

- Gignac, R.G. Temperature/Voltage Controlled Battery Charging Circuit. U.S. Patent 6,707,273, 16 March 2004. [Google Scholar]

- Santana, G.L., Jr. Battery, Battery Charger, Electrical System and Method of Charging a Battery. U.S. Patent 6,924,620, 2 August 2005. [Google Scholar]

- Morgan, R. Rechargeable Batteries. U.S. Patent 7,459,882, 2 December 2008. [Google Scholar]

- Ishikawa, Y.; Okabayashi, H.; Sakai, M.; Kobayashi, M. Charging Apparatus. U.S. Patent 20130285600 A1, 31 October 2013. [Google Scholar]

- Guang, H.T.; Hua, L.W.; Wentink, R.F. Multiple Cell Battery Charger Configured With a Parallel Topology. U.S. Patent 8,860,372, 14 October 2014. [Google Scholar]

- Geodken, T.J. Battery Charger Having Variable-Magnitude Charging Current Source. U.S. Patent 5,166,596, 24 November 1992. [Google Scholar]

- Dias, D.R.; Mumper, E.W. Battery Charger Systems and Methods. U.S. Patent 5,488,284, 30 January 1996. [Google Scholar]

- Kamke, J.E. Apparatus and Method for Maintaining the Charge of a Battery. U.S. Patent 5,493,198, 20 February 1996. [Google Scholar]

- Hanselmann, D.; Mayer, B.; Nutz, K.; Weller, S. Charging Method for Storage Batteries. U.S. Patent 5,537,023, 16 July 1996. [Google Scholar]

- Takeda, T. Control Method and Control Apparatus for Secondary Battery Charging in Constant Current Charging Method. U.S. Patent 5,627,451, 6 May 1997. [Google Scholar]

- Sage, G.E. Pulse-Charge Battery Charger. U.S. Patent 5,633,574, 27 May 1997. [Google Scholar]

- Im, S.; Seoung, H.; Choi, B. Method and Apparatus for Detecting a Full-Charge Condition While Charging a Battery. U.S. Patent 5,691,624, 25 November 1997. [Google Scholar]

- Podrazhansky, Y.M.; Tsenter, B. Control and Termination of a Battery Charging Process. U.S. Patent 5,694,023, 2 December 1997. [Google Scholar]

- Kuno, H. Battery Charger and Method for Completing Charging at Designated Time. U.S. Patent 5,736,834, 7 April 1998. [Google Scholar]

- Lane, R.W. Method and Apparatus for Charging Batteries. U.S. Patent 5,739,672, 14 April 1998. [Google Scholar]

- Wieczorek, R. Method for Charging a Rechargeable Battery. U.S. Patent 5,773,956, 30 June 1998. [Google Scholar]

- Kwan, H.; Chen, Y.; Chu, C.; Chen, S.; Wang, C. Automatic Battery Charging System Using Lowest Charge Current Detection. U.S. Patent 5,844,398, 1 December 1998. [Google Scholar]

- Paryani, A.; Sando, Y. Refreshing Charge Control Method and Apparatus to Extend the Life of Batteries. U.S. Patent 6,011,380, 4 January 2000. [Google Scholar]

- Freiman, J.F. Temperature Compensated Voltage Limited Fast Charge of Nickel Cadmium and Nickel Metal Hydride Battery Packs. U.S. Patent 6,020,722, 1 February 2000. [Google Scholar]

- Hardie, J.O. Battery Charger. U.S. Patent 6,211,655, 3 April 2001. [Google Scholar]

- Pavlovic, V.S. Method and Apparatus for Charging Batteries Utilizing Heterogeneous Reaction Kinetics. U.S. Patent 6,495,992, 17 December 2002. [Google Scholar]

- Patino, J.; Fiske, J.D. Battery Charging Algorithm. U.S. Patent 6,731,096, 4 May 2004. [Google Scholar]

- Patino, J. Method and System for Battery State of Charge Estimation by Using Measured Changes in Voltage. U.S. Patent 7,098,666, 29 August 2006. [Google Scholar]

- Hoff, C.M.; Nelson, J.E. Controlling Re-Charge of a Nickel Metal-Hydride (NiMH) or Nickel Cadmium (NiCd) Battery. U.S. Patent 7,129,676 B2, 31 October 2006. [Google Scholar]

- Meng, C.; Daou, Y. Systems and Methods for Temperature-Dependent Battery Charging. U.S. Patent 7,615,969, 10 November 2009. [Google Scholar]

- Kung, S.; Shen, Y. Method for Charging Portable Electronic Device. U.S. Patent 7,772,807, 10 August 2010. [Google Scholar]

- Wong, K.P.; Ng, S.O.A.; Yeo, C.W. Method and System for Determining the SOC of a Rechargeable Battery. U.S. Patent 7,888,911, 15 February 2011. [Google Scholar]

- Kaplan, J.; Furlan, J.L.W.; Schaefer, P.R.; Bacho, E.V.; Chu, J.Y.H.; Lin, R.; Inman, R.T.; Orner, W. System and Method for Charging Rechargeable Batteries in a Digital Camera. U.S. Patent 8,259,221, 4 September 2012. [Google Scholar]

- Hoff, C.M.; Nelson, J.E. Method and System for Charging a NiMH or NiCd Battery. U.S. Patent 7,405,538, 29 July 2008. [Google Scholar]

- Esnard-Domerego, D.; Walley, J.; Wang, L. Sink Current Adaptation Based on Power Supply Detection. U.S. Patent 8,729,867, 20 May 2014. [Google Scholar]

- Yuen, T.K. Battery Charger. U.S. Patent 6,225,789, 1 May 2001. [Google Scholar]

- Uchida, Z. Quick Charge Control Apparatus and Control Method Thereof. U.S. Patent 5,200,690, 6 April 1993. [Google Scholar]

- Yau, K.W.; Li, Y.C.; Bai, L. Intelligent Serial Battery Charger. U.S. Patent 7,557,538, 7 July 2009. [Google Scholar]

- Nicolai, J. Method for the Fast Charging of a Battery and Integrated Circuit for the Implementation of This Method. U.S. Patent 5,612,607, 18 March 1997. [Google Scholar]

- Fernandez, J.M.; Coapstick, R.S. Method for Ultra-Rapidly Charging a Rechargeable Battery Using Multi-Mode Regulation in a Vehicular Recharging System. U.S. Patent 5,986,430, 16 November 1999. [Google Scholar]

- Young, K.; Wang, C.; Wang, L.Y.; Strunz, K. Electric Vehicle Battery Technologies. In Electric Vehicle Integration into Modern Power Networks; Garcia-Valle, R., Lopes, J.A.P., Eds.; Springer Science, Business Media: New York, NY, USA, 2013; pp. 15–56. [Google Scholar]

- Johnson, T.W.; Rosenbecker, J.J.; Meyer, G.D.; Zeiler, J.M.; Glasgow, K.L.; Zick, J.A.; Brozek, J.M.; Scheucher, K.F. Method and System for Battery Protection. U.S. Patent 9,112,248, 18 August 2015. [Google Scholar]

- Carrier, D.A.; Seman, A.E., Jr.; Howard, G.S.; Brotto, D.C.; Trinh, D.T.; Watts, F.S.; Choksi, S.S.; Zhang, Q.J. Battery Pack for Cordless Power Tools. U.S. Patent 7,728,553, 1 June 2010. [Google Scholar]

- Kim, S.; Song, J. Battery Management System, Method of Controlling the Same, and Energy Storage System Including the Battery Management System. U.S. Patent 8,806,240, 12 August 2014. [Google Scholar]

- Duncan, W.D.; Hyde, R.A.; Kare, J.T. Management of a Remote Electric Vehicle Traction Battery System. U.S. Patent 20140351107 A1, 27 November 2014. [Google Scholar]

- Lin, X.; Stefanopoulou, A.; Anderson, R.D.; Li, Y. Detection of Imbalance across Multiple Battery Cells Measured by the Same Voltage Sensor. U.S. Patent 20140361743 A1, 11 December 2014. [Google Scholar]

- Duncan, W.D.; Hyde, R.A.; Kare, J.T. Managed Electric Vehicle Traction Battery System. U.S. Patent 9,002,537, 7 April 2015. [Google Scholar]

- Phouc, D.V.; Wieczorek, R.; Zeising, E.; Hruska, L.W.; Taylor, A.H.; Friel, D.D.; Hull, M.P. Battery Pack Having a Processor Controlled Battery Operating System. U.S. Patent 5,691,621 A, 25 November 1997. [Google Scholar]

- Townsley, D.B.; Blanc, J.J. Circuit Offering Sequential Discharge and Simultaneous Charge for a Multiple Battery System and Method for Charging Multiple Batteries. U.S. Patent 5,666,006, 9 September 1997. [Google Scholar]

- Kadouchi, E.; Watanabe, Y.; Kinoshita, M.; Ito, N.; Takata, K. Monitoring Apparatus for a Series Assembly of Battery Modules. U.S. Patent 6,020,717, 1 February 2000. [Google Scholar]

- Hess, R.L.; Cooper, P.R.; Interiano, A.; Freiman, J.F. Battery Charge Monitor and Fuel Gauge. U.S. Patent 5,315,228, 24 May 1994. [Google Scholar]

- Wood, S.J.; Maubert, E.; Veglio, O. Cell Diagnostic System and Method. U.S. Patent 8,788,225, 22 July 2014. [Google Scholar]

- Rathmann, R. Battery Pack and a Method for Monitoring Remaining Capacity of a Battery Pack. U.S. Patent 5,955,869, 21 September 1999. [Google Scholar]

- Ying, R.Y. State of Charge Algorithm for a Battery. U.S. Patent 6,356,083, 12 March 2002. [Google Scholar]

- Kikuchi, Y. Battery Control System. U.S. Patent 6,600,293, 29 July 2003. [Google Scholar]

- Bockelmann, T.R.; Hope, M.E.; Zou, Z.; Kang, X. Battery Control System for Hybrid Vehicle and Method for Controlling a Hybrid Vehicle Battery. U.S. Patent 7,489,101, 10 February 2009. [Google Scholar]

- Melichar, R.J. Battery State of Charge Voltage Hysteresis Estimator. U.S. Patent 7,570,024, 4 August 2009. [Google Scholar]

- Fassnacht, J. Method for Regulating the State of Charge of an Energy Accumulator in a Vehicle Having a Hybrid Drive Unit. U.S. Patent 7,934,573, 3 May 2011. [Google Scholar]

- Izumi, J. Upper-Limit of State-of-Charge Estimating Device and Upper-Limit of State-of-Charge Estimating Method. U.S. Patent 8,912,761, 16 December 2014. [Google Scholar]

- Takahashi, K.; Nishi, Y.; Tomura, S.; Takemoto, T.; Haga, N.; Fuchimoto, T.; Sugimoto, T. Control System of Vehicle. U.S. Patent 8,498,766, 30 July 2013. [Google Scholar]

- Galbraith, R.E.; Gisi, J.M.; Norgaard, S.P.; Reetz, D.D.; Ziebarth, D.J. Method and Apparatus for Estimating the Service Life of a Battery. U.S. Patent 6,191,556, 20 February 2001. [Google Scholar]

- Galbraith, R.E.; Gisi, J.M.; Norgaard, S.P.; Reetz, D.D.; Ziebarth, D.J. Method and Apparatus for Estimating the Service Life of a Battery. U.S. Patent 6,271,647, 7 August 2001. [Google Scholar]

- Juncker, C.; Christensen, F.K. Battery Life Estimation. U.S. Patent 6,538,449, 25 March 2003. [Google Scholar]

- Singh, P.; Fennie, C., Jr.; Reisner, D.E. Method and System for Determining State-of-Health of a Nickel-Metal Hydride Battery Using an Intelligent System. U.S. Patent 7,051,008, 23 May 2006. [Google Scholar]

- Staton, K.L. Detecting an End of Life for a Battery Using a Difference between an Unloaded Battery Voltage and a Loaded Battery Voltage. U.S. Patent 8,410,783, 2 April 2013. [Google Scholar]

- Center, M.B. Method for Estimating Battery Life in a Hybrid Powertrain. U.S. Patent 8,204,702, 19 June 2012. [Google Scholar]

- Tsenter, B.J.; James, J.E. State of Health Recognition of Secondary Batteries. U.S. Patent 7,605,591, 20 October 2009. [Google Scholar]

- Interiano, A.; Hess, R.L.; Cooper, P.R.; Freiman, J.F. Battery Charge Monitor to Determine Fast Charge Termination. U.S. Patent 5,200,689, 6 April 1993. [Google Scholar]

- Van Phuoc, D.; Wieczorek, R.; Zeising, E.; Hruska, L.W.; Taylor, A.H.; Friel, D.D.; Hull, M.P. Battery Pack Having a Processor Controlled Battery Operating System. U.S. Patent 5,652,502 A, 29 July 1997. [Google Scholar]

- Tate, E.D., Jr.; Verbrugge, M.W.; Sarbacker, S.D. State of Charge Prediction Method and Apparatus for a Battery. U.S. Patent 6,441,586, 27 August 2002. [Google Scholar]

- Yao, T.; Kasahara, H.; Suzuki, T.; Masui, M.; Konishi, H. Method for Managing Back-up Power Source. U.S. Patent 6,097,176, 1 August 2000. [Google Scholar]

- Vebrugge, M.W.; Tate, E.D., Jr.; Sarbacker, S.D.; Koch, B.J. Quasi-Adaptive Method for Determining a Battery’s State of Charge. U.S. Patent 6,359,419 B1, 19 March 2002. [Google Scholar]

- Furukawa, T. Method for Estimating State of Charge of a Rechargeable Battery. U.S. Patent 8,000,915, 16 August 2011. [Google Scholar]

- Lee, J.; Lee, H.; Lee, J.; Lee, H.; Kim, D. Method for a Measuring Residual Capacity of a Ni/MH Cell. U.S. Patent 5,701,078, 23 December 1997. [Google Scholar]

- Kinoshita, T.; Miyazaki, H.; Emori, A.; Okoshi, T.; Hirasawa, T. Battery System, Battery Monitoring Method and Apparatus. U.S. Patent 7,173,397, 6 February 2007. [Google Scholar]

- Shinohara, S.; Takano, N. Battery Charger. U.S. Patent 5,444,353, 22 August 1995. [Google Scholar]

- Garrett, S.M.; Fernandez, J.M.; Patino, J. Ultrafast Rechargeable Battery Pack and Method of Charging Same. U.S. Patent 5,576,612, 19 November 1996. [Google Scholar]

- Van Phuoc, D.; Wieczorek, R.; Zeising, E.; Hruska, L.W.; Hull, M.P.; Taylor, A.H.; Friel, D.D. Battery Pack Having a Processor Controlled Battery Operating System. U.S. Patent 5,633,573 A, 27 May 1997. [Google Scholar]

- Tibbs, B.L. Recharging Method and Temperature-Responsive Overcharge Protection Circuit for a Rechargeable Battery Pack Having Two Terminals. U.S. Patent 5,708,350, 13 January 1998. [Google Scholar]

- McGrath, F.D.; Kellogg, N.D. Rechargeable Battery Having Overcharge Protection Circuit and Method of Charging Rechargeable Battery. U.S. Patent 5,939,865, 17 August 1999. [Google Scholar]

- Saeki, M.; Ozawa, H.; Tsukuni, T.; Takeda, Y. Protection Circuit and Battery Unit. U.S. Patent 6,051,955, 18 April 2000. [Google Scholar]

- Narita, I. Over Discharge Protection Circuit for a Rechargeable Battery. U.S. Patent 5,729,061, 17 March 1998. [Google Scholar]

- Gamboa, P. Method and Apparatus for Charging and Discharging a Rechargeable Battery. U.S. Patent 7,541,781, 2 June 2009. [Google Scholar]

- Johnson, T.W.; Rosenbecker, J.J.; Meyer, G.D.; Zeiler, J.M.; Glasgow, K.L.; Zick, J.Z.; Brozek, J.M.; Scheucher, K.F. Method and System for Battery Protection. U.S. Patent 7,589,500, 15 September 2009. [Google Scholar]

- Van Phuoc, D.; Wieczorek, R.; Zeising, E.; Hruska, L.W.; Taylor, A.H.; Friel, D.D.; Hull, M.P. Battery Pack Having a Processor Controlled Battery Operating System. U.S. Patent 5,646,508 A, 8 July 1997. [Google Scholar]

- Glonner, H.; Strobl, W.; Rump, R.; Mallog, J. Energy Storage System. U.S. Patent 7,591,331, 22 September 2009. [Google Scholar]

- Reis, A.; Whitmer, D.K.; Muthu, M.E.J.; Korutla, S.K. Integrated Energy Storage Unit. U.S. Patent 8,481,203, 9 July 2013. [Google Scholar]

- Garascia, M.P.; Arena, A.P.; Wood, S.J. Battery System. U.S. Patent 8,235,732, 7 August 2012. [Google Scholar]

- Zhu, D.; Treharne, W.D. System and Method for Thermal Management of a Vehicle Power Source. U.S. Patent 7,683,582, 23 March 2010. [Google Scholar]

- Fuhr, J.D.; Obasih, K.; De Keuster, R.M.; Mack, R.; Houchin-Miller, G.P.; Patel, D. Battery Module Having a Cell Tray with Thermal Management Features. U.S. Patent 20140234687 A1, 21 August 2014. [Google Scholar]

- Hamada, S. Battery Pack. U.S. Patent 7,189,474, 13 March 2007. [Google Scholar]

- Wood, S.J.; Tiedemann, W.H. Battery System Including a Device Configured to Route Effluent Away from Battery Modules within the Battery System. U.S. Patent 7,846,572, 7 December 2010. [Google Scholar]

- Zolot, M.; Pesaran, A.A.; Mihalic, M. Thermal Evaluation of Toyota Prius Battery Pack; National Renewable Energy Laboratory: Golden, CO, USA, 2002.

- Murata, T. Power Source Apparatus. U.S. Patent 7,974,095, 5 July 2011. [Google Scholar]

- Thomas, G.; Moré, G. Hybrid Energy Storage System. U.S. Patent 5,587,250, 24 December 1996. [Google Scholar]

- Thomas, G.; Moré, G. Hybrid Energy Storage System. U.S. Patent 5,849,426, 15 December 1998. [Google Scholar]

- Kruger, D.D.; Young, G.; Moore, S.W. Method and Apparatus for Providing and Storing Power in a Vehicle. U.S. Patent 6,577,099, 10 June 2003. [Google Scholar]

- Ovshinsky, S.R.; Stempel, R.C. Very Low Emission Hybrid Electric Vehicle Incorporating an Integrated Propulsion System Including a Hydrogen Powered Internal Combustion Engine and a High Power Ni-MH Battery Pack. U.S. Patent 6,565,836, 20 May 2003. [Google Scholar]

- Lee, E. Energy Storage System and Method of Controlling the Same. U.S. Patent 9,041,354, 26 May 2015. [Google Scholar]

- Park, J.; Choi, J. Energy Storage System and Controlling Method of the Same. U.S. Patent 20130169064 A1, 4 July 2013. [Google Scholar]

- Yoo, H. Method of Measuring Voltage of Battery Pack and Energy Storage System Including the Battery Pack. U.S. Patent 2014/0035365 A1, 6 February 2014. [Google Scholar]

- Jung, Y. Battery Pack, Controlling Method of the Same, and Energy Storage System Including the Battery Pack. U.S. Patent 20140078632 A1, 20 March 2014. [Google Scholar]

- Pietrangelo, N.J.; Moran, T.J. Window Construction Combining NiMH Technology and Solar Power. U.S. Patent 20080236654 A1, 2 October 2008. [Google Scholar]

- Komori, K.; Fujioka, N.; Kimura, T.; Yamashita, H.; Takahashi, Y. Method for Recycling Battery Pack. U.S. Patent 6,936,371, 30 August 2005. [Google Scholar]

- Sloop, S.E. Recycling Batteries Having Basic Electrolytes. U.S. Patent 20130302223 A1, 14 November 2013. [Google Scholar]

- Smith, W.N.; Swoffer, S. Process for the Recovery of Metals from Used Nickel/metal Hydride Batteries. U.S. Patent 8,246,717 B1, 21 August 2012. [Google Scholar]

- Smith, W.N.; Swoffer, S. Process for the Recovery of AB5 Alloy from Used Nickel/metal Hydride Batteries. U.S. Patent 8,696,788, 15 April 2014. [Google Scholar]

- Prickett, O.G.; Czajkowski, R.; Citta, N.C.; Klein, M.R.; Huston, E.L.; Galbraith, P.W. Reclamation of Active Material From Metal Hydride Electrochemical Cells. U.S. Patent 6,180,278, 30 January 2001. [Google Scholar]

- Smith, W.N.; Swoffer, S. Process for the Recovery of Metals from Used Nickel/metal Hydride Batteries. U.S. Patent 8,252,085 B1, 28 August 2012. [Google Scholar]

- Jacobson, A.J.; Samarasekere, P. Methods and Systems for Recovering Rare Earth Elements. U.S. Patent 20140311294 A1, 23 October 2014. [Google Scholar]

- Burlingame, N.H.; Burlingame, S. Method for Recycling of Rare Earth and Zirconium Oxide Materials. U.S. Patent 8,940,256, 27 January 2015. [Google Scholar]

- Kleinsorgen, K.; KöHler, U.; Bouvier, A.; FöLzer, A. Process for the Recovery of Metals from Used Nickel/metal Hydride Storage Batteries. U.S. Patent 5,858,061, 12 January 1999. [Google Scholar]

- Kikuta, N.; Asano, S.; Takano, M. Method for Separating Nickel and Cobalt from Active Material Contained in Spent Nickel-Metal Hydride Battery. U.S. Patent 8,888,892, 18 November 2014. [Google Scholar]

- Kikuta, N.; Asano, S.; Takano, M. Method for Producing Nickel-Containing Acid Solution. U.S. Patent 8,974,754, 10 March 2015. [Google Scholar]

| Property | AB2 MH alloy | AB5 MH alloy |

|---|---|---|

| Basic crystal structure | Hexagonal C14 and FCC C15 | Hexagonal CaCu5 |

| Composition example | Ti12Zr21Ni38V10Cr5Mn12Co1.5Al0.5 | La10Ce5Pr0.5Nd1.5Ni60Co12Mn6Al5 |

| Discharge capacity | 340–440 mAh·g−1 | 300–330 mAh·g−1 |

| High-rate dischargeability | Acceptable | Excellent |

| Cycle life (1C/1C, 100% DOD) | 800 | 1200 |

| Self-discharge | Acceptable (V-free alloy) | Acceptable |

| High-temperature storage | Acceptable due to leach-out | Bad due to surface passivation |

| Activation | Modest | Easy |

| Low temperature | Good | Modest |

| Fabrication method | Casting, hydriding, and grinding | Casting and grinding |

| Raw material cost | V is expensive | Volatile due to rare earth price fluctuation |

| Low-cost version | V and Co-free alloy | Pr, Nd, and Co-free alloy |

| Methods | Pros | Cons |

|---|---|---|

| Dry compaction |

|

|

| Wet paste method |

|

|

| Dry paste method |

|

|

| Type | Description | Pros | Cons |

|---|---|---|---|

| Consumer |

|

|

|

| Stick |

|

|

|

| EV |

|

|

|

| HEV |

|

|

|

| Coin |

|

|

|

| Application | Examples | Main Competitor | Advantages over Competitor |

|---|---|---|---|

| Consumer | AA, AAA, cordless phone, shaver, power tool | Ni/Cd |

|

| Propulsion | EV, HEV | Li-ion |

|

| UPS | Cellphone communication hub, vending machine | Lead-acid |

|

| Grid | Solar and wind energy storage, voltage equalizer | Lead-acid |

|

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, S.; Young, K.-h.; Nei, J.; Fierro, C. Reviews on the U.S. Patents Regarding Nickel/Metal Hydride Batteries. Batteries 2016, 2, 10. https://doi.org/10.3390/batteries2020010

Chang S, Young K-h, Nei J, Fierro C. Reviews on the U.S. Patents Regarding Nickel/Metal Hydride Batteries. Batteries. 2016; 2(2):10. https://doi.org/10.3390/batteries2020010

Chicago/Turabian StyleChang, Shiuan, Kwo-hsiung Young, Jean Nei, and Cristian Fierro. 2016. "Reviews on the U.S. Patents Regarding Nickel/Metal Hydride Batteries" Batteries 2, no. 2: 10. https://doi.org/10.3390/batteries2020010